Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Electrical Design Software Proficiency (e.g., AutoCAD Electrical, EPLAN) interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Electrical Design Software Proficiency (e.g., AutoCAD Electrical, EPLAN) Interview

Q 1. Explain your experience with AutoCAD Electrical’s schematic capture tools.

AutoCAD Electrical’s schematic capture tools are the heart of efficient electrical design. My experience spans several years, encompassing everything from simple circuit diagrams to complex industrial control systems. I’m proficient in using the tools to create and manage symbols, wires, components, and annotations. I understand the importance of establishing a structured workflow to ensure accuracy and maintainability.

For instance, when designing a motor control circuit, I’d meticulously place components using intelligent object snapping, ensuring proper alignment and spacing for readability. I utilize AutoCAD Electrical’s built-in component libraries extensively, customizing them as needed to reflect our company’s specific standards. I’m also comfortable leveraging features like automatic wire numbering and terminal connection verification to minimize errors and save time. Using project templates significantly speeds up the initial setup and ensures design consistency across multiple projects.

One project involved designing the electrical schematics for a large automated manufacturing facility. The sheer number of components and interconnections initially seemed daunting. However, by effectively using AutoCAD Electrical’s tools like project manager, I successfully created well-organized, manageable, and error-free schematics, leading to a smooth manufacturing rollout.

Q 2. Describe your proficiency in creating and managing EPLAN projects.

My EPLAN proficiency includes project setup, schematic design, PLC I/O management, and report generation. I find EPLAN’s structured approach crucial for creating well-organized and easily maintainable projects. I’m adept at managing multiple pages, cross-referencing components, and creating comprehensive documentation. EPLAN’s macro functionality allows me to automate repetitive tasks, improving efficiency and consistency.

A key feature I utilize is EPLAN’s device navigator and its ability to seamlessly integrate with the project’s bill of materials (BOM). This ensures that all components in the schematic are accurately listed, and it facilitates easy tracking of component specifications and availability. I’ve also worked extensively with EPLAN’s routing capabilities, creating panel layouts and wiring diagrams, minimizing errors and ensuring a clean design. This streamlined process from schematic to panel layout contributes significantly to improved overall efficiency.

Recently, I used EPLAN to manage a complex project involving several sub-systems, each requiring meticulous documentation. The project’s success heavily relied on maintaining a clear and well-structured database. By leveraging EPLAN’s structured workflow, we easily ensured consistency and eliminated the risk of design errors.

Q 3. How do you handle version control and collaboration in electrical design software?

Version control and collaboration are paramount in electrical design. My typical approach involves using a combination of version control software (like Git) and the built-in revision management features within AutoCAD Electrical and EPLAN. For smaller projects, the in-built revision control might suffice. But larger projects necessitate external version control systems.

I prefer a structured process where each revision is clearly documented with change logs explaining the modifications. This provides a clear audit trail, enabling us to track changes and revert to previous versions if needed. Collaborative workflows often involve employing cloud-based storage services to facilitate real-time access and concurrent work by multiple engineers. We use a defined check-in/check-out process to avoid conflicts and ensure the integrity of the design. Tools like markup and annotation features within the software facilitate communication about design changes and clarifications.

For example, on a recent large-scale project, we utilized Git to manage the project files, which ensured that everyone had access to the most recent version and that changes could be tracked effectively. This collaborative approach allowed us to resolve issues rapidly and deliver the project on time and within budget.

Q 4. What are your preferred methods for generating reports and documentation from electrical design software?

Generating reports and documentation is crucial for efficient project management and communication. AutoCAD Electrical and EPLAN offer various tools for this purpose. I commonly use their built-in reporting functions to create BOMs, wire lists, terminal schedules, and other essential documents. These reports are vital for procurement, assembly, and testing phases.

Beyond the built-in features, I’ve integrated the software with other tools to customize reports further. This includes using Excel or other spreadsheet applications to analyze and present design data more effectively. For sophisticated documentation, I’ve leveraged external tools for generating professional-looking PDFs with automated numbering, cross-referencing, and indexes to enhance clarity and accessibility. This ensures that all stakeholders—from engineers to clients—can easily understand and use the documentation.

For instance, when working on a project involving extensive PLC programming, I utilized the EPLAN reporting features to create a detailed I/O list, cross-referenced with the PLC’s hardware configuration. This report significantly reduced the time needed for commissioning.

Q 5. Describe your experience with creating and managing component libraries in AutoCAD Electrical or EPLAN.

Managing component libraries is critical for ensuring design consistency and efficiency. In both AutoCAD Electrical and EPLAN, I prioritize creating well-organized and standardized libraries. This involves meticulously documenting each component, including its properties, symbols, and 3D models (when available). Careful organization enhances search capabilities, preventing duplication of effort and ensuring accuracy across projects.

My approach is to categorize components logically, using a hierarchical structure that makes them easy to find. I use descriptive naming conventions that follow company standards to maintain consistency. Regular updates to the library are crucial, ensuring that it always reflects the most current versions of components. I also make sure to maintain backups of the libraries to prevent accidental data loss. This structured and organized approach streamlines the design process, ensuring that my projects remain efficient and consistent.

In a recent instance, a standardized component library, maintained meticulously with regularly updated parts information, expedited the design of a new line of control panels, significantly reducing design time and errors by allowing us to rapidly add components from our pre-approved library.

Q 6. How do you ensure accuracy and consistency in your electrical designs?

Accuracy and consistency are vital for successful electrical designs. My approach involves adhering strictly to company standards, using design templates, and utilizing the software’s built-in error-checking tools. Regular reviews and cross-checking of the designs with colleagues are essential to catch potential errors before they become significant issues.

I follow a methodical design process, employing techniques like design reviews and peer checks. This ensures that multiple sets of eyes examine the design for potential discrepancies or overlooked aspects. A rigorous testing phase, which includes simulated runs and testing under real-world conditions, is fundamental in validating the designs. Employing software features like design rule checks and automated validation greatly assist in identifying potential problems early on.

For example, while designing the control system for a complex robotic arm, adherence to industry standards and a thorough design review process identified potential interference issues, preventing costly rework later on.

Q 7. Explain your process for troubleshooting errors and resolving conflicts in your designs.

Troubleshooting and conflict resolution are integral to my design process. When errors arise, I systematically investigate the problem, starting with a careful review of the schematics and error messages provided by the software. I use tools like the software’s built-in diagnostics to pinpoint the location and nature of the errors.

My approach involves utilizing the software’s tracing functions and cross-referencing capabilities to understand the relationships between different components and identify the root cause of the problem. Communication with colleagues is critical, particularly when resolving conflicts that might arise during collaborative design efforts. Version control allows me to revert to previous revisions if necessary, facilitating the restoration of a stable design.

In one instance, a conflict arose between different design revisions during a collaborative project. Utilizing the version control system, I was able to quickly pinpoint the source of the conflict, resolve the discrepancies, and merge the changes without impacting the overall project timeline or the quality of the design.

Q 8. How familiar are you with electrical symbols and standards (e.g., IEC, ANSI)?

I possess extensive familiarity with electrical symbols and standards, primarily IEC and ANSI. Understanding these standards is fundamental to creating clear, unambiguous, and internationally recognized electrical designs. IEC standards (International Electrotechnical Commission) are widely used globally, while ANSI (American National Standards Institute) standards are prevalent in North America. Knowing the nuances between these – for instance, the slight variations in symbol representation for components like contactors or circuit breakers – is crucial for effective communication and collaboration with engineers from different regions.

For example, the symbol for a normally open (NO) contact in IEC is a different shape compared to the ANSI representation. Recognizing this subtle difference prevents misinterpretations during design review and project execution. My experience encompasses working directly with these standards in various projects, ensuring compliance and avoiding potential safety hazards.

- IEC 60617: This standard defines symbols for electrical diagrams.

- ANSI/IEEE Std 315: This standard specifies graphic symbols for electrical and electronics diagrams.

I’ve personally used both standards extensively in software like EPLAN and AutoCAD Electrical, and I can quickly adapt my design practices to whichever standard is mandated by the project requirements.

Q 9. Describe your experience with generating bills of materials (BOMs) from electrical design software.

Generating accurate and comprehensive Bills of Materials (BOMs) is a critical aspect of electrical design, and I’ve developed considerable expertise in this area using both EPLAN and AutoCAD Electrical. These software packages automate much of the BOM creation process, but proficiency lies in configuring them correctly and understanding how to manage complex scenarios.

My typical workflow involves setting up the project’s BOM structure at the outset, defining the required data fields (part number, description, manufacturer, quantity, etc.). The software then automatically extracts this data as components are placed within the schematic and panel layouts. I regularly cross-reference the generated BOM with the project specifications to ensure accuracy. This avoids costly mistakes later in procurement and assembly.

For instance, in a recent project using EPLAN, I had to manage a BOM with over 500 items, including various cable types, connectors, and terminal blocks. The software’s built-in filtering and sorting features were invaluable in managing this complexity. I used conditional formatting to highlight items with potential conflicts or requiring special attention.

Beyond the automated aspects, I understand the importance of manually verifying the BOM for completeness and accuracy. I regularly review for any missing items or discrepancies between the design and the generated BOM. This meticulous approach minimizes errors and facilitates a smooth transition to the procurement and construction phases of the project.

Q 10. How do you handle design changes and revisions in your projects?

Handling design changes and revisions is an integral part of any large-scale electrical engineering project. I employ a structured approach leveraging the revision control features within EPLAN and AutoCAD Electrical. These features allow tracking and managing changes effectively. This prevents conflicting versions and ensures everyone works with the most up-to-date information.

Specifically, I utilize version control systems to track modifications, creating new revisions with clear documentation of each change. This includes using change logs within the software that detail who made the modifications, the date, and a description of the change. The software helps visualize the changes through comparison features, pinpointing the modifications visually.

Moreover, I strictly adhere to a formal change management process that involves reviewing changes with colleagues, documenting the impact assessment, and obtaining necessary approvals. This rigorous process prevents errors and ensures that all stakeholders are aligned on the modifications. Clear communication and meticulous documentation prevent confusion and ensure the integrity of the design throughout the project lifecycle.

Imagine a scenario where a client requests a change in the location of a motor starter. I would generate a new revision, document the change clearly, update the schematic, panel layout, and the BOM, and then notify the relevant stakeholders.

Q 11. What strategies do you use to optimize electrical designs for efficiency and cost-effectiveness?

Optimizing electrical designs for efficiency and cost-effectiveness is a continuous process requiring a holistic approach. My strategies include using standardized components, optimizing cable routing for reduced material usage, and implementing energy-efficient components and systems.

For example, selecting a standardized range of circuit breakers and contactors minimizes costs associated with purchasing and stocking multiple different parts. Careful cable routing, using software features for automated cable path calculation, reduces the length of cables and minimizes material costs. Incorporating energy-efficient components like high-efficiency motors reduces the overall power consumption of the system, lowering operational costs over the product’s life cycle.

Furthermore, I employ simulation tools within the software to analyze power consumption and voltage drop. This predictive analysis helps to identify potential problems early on and allows for adjustments to optimize the design, preventing costly issues during commissioning. For instance, by adjusting cable sizes to minimize voltage drop, I can reduce energy losses and ensure the equipment functions correctly.

I always explore various design options, comparing their pros and cons before settling on a final solution. This involves considering different component choices, cable types, and panel arrangements to determine the most efficient and cost-effective approach. A holistic view of the project—from component selection to overall system architecture—is crucial for optimizing both efficiency and cost.

Q 12. Describe your experience with electrical design software’s PLC programming capabilities (if applicable).

While not all electrical design software directly handles PLC programming, some, like EPLAN, offer integration with PLC programming software. My experience is focused on the integration aspect rather than directly writing PLC code within the electrical design software. I can seamlessly integrate the electrical schematic designs created in EPLAN with PLC programs developed in a separate environment, such as TIA Portal (for Siemens PLCs).

This integration typically involves exporting data from the electrical design software, such as I/O assignments and wiring information, to the PLC programming software. This ensures consistency and avoids errors that could occur from manual data entry. The accuracy and completeness of this data transfer is crucial for the PLC program to accurately control the electrical system. I am adept at configuring the software to facilitate a smooth transfer of data and thoroughly verify the consistency between the design and the PLC program.

For example, if I design a control system for a conveyor belt in EPLAN, I’ll ensure the I/O points allocated to the motor starter and other sensors are correctly transferred to the PLC programming environment. This ensures the PLC program can accurately control the conveyor belt according to the intended functionality.

Q 13. How do you incorporate safety standards and regulations into your electrical designs?

Safety standards and regulations are paramount in electrical design. I meticulously incorporate these into my designs by adhering to relevant codes and standards like NEC (National Electrical Code) in the US, or equivalent standards in other regions. This isn’t just a compliance exercise; it’s a fundamental aspect of designing a safe and reliable system.

My process includes selecting components with appropriate safety certifications (e.g., UL, CE), ensuring proper grounding and bonding practices, and employing arc flash analysis techniques to mitigate risks. I also pay particular attention to the proper sizing of protective devices like circuit breakers and fuses to ensure safety and equipment protection. The software often provides tools to help in these calculations and to identify potential hazards.

For instance, when designing a panel layout, I ensure that components are positioned to prevent accidental contact, that proper clearances are maintained, and that lockout/tagout procedures are considered. The design process includes thorough review and checks to ensure compliance with all applicable safety regulations and best practices. By considering safety from the initial stages of design, I minimize the risk of accidents and ensure the long-term reliability of the electrical system.

Q 14. What is your experience with generating wiring diagrams and panel layouts?

Generating wiring diagrams and panel layouts is a core part of my daily work. I am proficient in using the capabilities of EPLAN and AutoCAD Electrical to create detailed and accurate diagrams and layouts. These software packages offer tools to automate many aspects of this process, such as automatic wire numbering, cable sizing calculations, and generating reports.

For wiring diagrams, I utilize the software’s schematic capture capabilities to create clear, concise diagrams showing the connections between various components. The software automatically generates wire lists, bill of materials for components used in the panel, and other relevant documentation that saves time and enhances accuracy. I also utilize the software’s features to manage multiple sheets and cross-referencing between sheets, which is crucial for complex systems.

In panel layout design, I use the software’s libraries of components to place devices within the panel ensuring compliance with standards for spacing and clearances. The software assists with verifying that components fit within the designated physical space and checks for potential clashes. I strive to optimize the panel layout for ease of assembly, maintenance, and access, ensuring that all components are readily accessible. The final panel layout includes detailed annotations, labels, and wiring information. This meticulous process ensures that the final product is functional and safe.

Q 15. Describe your experience using libraries and templates within your chosen software.

Libraries and templates are crucial for efficient electrical design. Think of them as pre-built components and blueprints – they save time and ensure consistency. In EPLAN, for instance, I extensively utilize project templates that define the page layout, symbol libraries, and even macros for commonly used components like motors and contactors. This ensures a standardized approach across projects. My experience includes creating custom libraries for specific client requirements, like specialized connectors or in-house designed circuit boards. This involves not only drawing the components but also defining their properties, such as pin assignments and connection points. For example, I created a library of custom PLC modules for a recent automation project, significantly reducing design time and improving consistency.

AutoCAD Electrical also provides robust library management capabilities. I often leverage pre-made components from the extensive library, but also customize them or add new ones to reflect specific project needs. Imagine needing a unique sensor – I would model it accurately, specifying its parameters and connections within the library for future use.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage large and complex electrical designs effectively?

Managing large and complex electrical designs requires a structured approach. I use a combination of techniques. Firstly, proper project organization is paramount. This involves breaking down the project into smaller, manageable subsystems, each with its own dedicated folder structure within the software. In EPLAN, I utilize the cross-referencing features extensively to track connections between different parts of the schematic. This is like having a detailed map of the entire electrical system.

Secondly, version control is vital. I use the software’s revision control to track changes and revert to previous versions if needed, ensuring that multiple team members can work concurrently without conflicts. Imagine a team working on different sections of a large power plant design; version control avoids accidental overwrites. Thirdly, employing automation features (like generating reports and BOMs automatically) reduces errors and saves considerable time. This is like having a robotic assistant that handles the repetitive tasks.

Q 17. Explain your process for creating and reviewing design specifications.

Creating design specifications is a collaborative process that begins with a thorough understanding of the client’s requirements. I actively participate in initial meetings, gathering all necessary information. This includes understanding the intended function of the system, power requirements, safety standards (like IEC 61131-3), and environmental considerations. These details are documented in a formal specification document, outlining the scope of work, technical specifications (e.g., voltage levels, current ratings), and acceptance criteria.

Reviewing the specifications involves internal and client feedback. We hold design reviews with the team to discuss potential issues and ensure everyone’s understanding is aligned. Client sign-off is essential before proceeding to the detailed design phase. Think of it like architectural blueprints – it is a critical checkpoint before construction commences.

Q 18. How do you ensure the accuracy of your designs through quality control measures?

Accuracy is paramount in electrical design. My quality control process involves multiple checks at each stage. First, I use the software’s built-in functions for design rule checking (DRC) to identify potential errors like incorrect wire connections or component mismatches. This is like an automated spell-checker for electrical schematics.

Then, I perform manual checks, visually inspecting the schematics for clarity and consistency. This includes verifying component ratings and ensuring that all connections are correctly labeled and documented. Finally, before project completion, a thorough cross-checking with the bill of materials (BOM) is performed to prevent discrepancies. Peer reviews are also included, where another experienced engineer checks the design for any potential problems. This multi-layered approach significantly reduces errors and ensures a safe and reliable design.

Q 19. Describe your experience with creating and interpreting electrical schematics.

Creating and interpreting electrical schematics is fundamental to my work. I’m proficient in using both AutoCAD Electrical and EPLAN to develop clear and concise schematics that follow industry standards. This involves understanding and adhering to standard symbols, creating clear wiring diagrams, and using proper annotation techniques. For instance, I recently created a schematic for a complex control system, meticulously documenting each component, its connections, and signal flow. I pay close attention to details such as wire numbering, busbar arrangements and terminal markings for easy traceability.

Interpreting schematics involves understanding the functionality of each component and how they interact. I often use these schematics to troubleshoot issues or provide maintenance documentation for the end-user. Think of a schematic as a map, guiding you through the electrical system. My expertise lies in being able to ‘read’ these maps accurately and make informed decisions based on that information.

Q 20. What is your experience with different types of electrical drawings (e.g., single-line diagrams, three-line diagrams)?

My experience includes creating various types of electrical drawings. Single-line diagrams provide a high-level overview, showing the main power flow and components, perfect for initial planning and presentations. They are like a bird’s-eye view of the electrical system. Three-line diagrams are more detailed, showing all three phases of a power system. These are essential for detailed analysis and design of power distribution systems.

I’m also proficient in creating other drawing types such as wiring diagrams (showing detailed wiring connections), panel layouts (showing component placement in control panels), and cable schedules (listing cable types, lengths, and routing). Each drawing type serves a specific purpose, and I understand which type is most appropriate for each situation. Selecting the right drawing is crucial for effective communication and efficient project execution.

Q 21. How do you integrate electrical designs with other disciplines (e.g., mechanical, civil)?

Integrating electrical designs with other disciplines like mechanical and civil engineering is crucial for successful project delivery. This often involves using data exchange formats like DXF or DWG to share models and coordinate designs. I’m experienced in collaborating with mechanical engineers to ensure that electrical components fit properly within the physical constraints of the equipment. This includes coordinating cable routing and ensuring sufficient space for electrical equipment.

With civil engineers, I coordinate cable tray routing and conduit placement within the building structure. This requires careful consideration of building plans and other infrastructure elements. Effective communication and a collaborative approach are key to successful integration across disciplines, ensuring a seamless and functional final product. Software like EPLAN’s integration features and the use of cloud-based collaboration tools facilitate this process significantly, minimizing conflicts and improving coordination.

Q 22. What software tools do you use for collaboration and project management?

Effective collaboration and project management are crucial in electrical design. My preferred tools include a combination of software solutions depending on project needs and team preferences. For instance, we utilize SharePoint for central document storage and version control, ensuring everyone accesses the most up-to-date drawings and specifications. Microsoft Teams facilitates seamless communication, allowing for instant messaging, video conferencing, and file sharing directly within our design teams. For more complex projects, we often employ project management software such as Microsoft Project or Asana, creating task assignments, setting deadlines, and tracking progress. This integrated approach ensures transparency, facilitates efficient workflow, and minimizes potential conflicts.

For instance, on a recent data center project, using SharePoint to manage revisions of the AutoCAD Electrical drawings saved us significant time and eliminated confusion caused by working from outdated files. Each team member could see the latest versions, leaving an auditable trail of changes.

Q 23. How do you stay up-to-date with the latest advancements in electrical design software?

Staying current in the rapidly evolving field of electrical design software is a continuous process. I actively participate in online webinars and workshops offered by software vendors like Autodesk (for AutoCAD Electrical) and EPLAN. These sessions provide insights into new features, improved workflows, and best practices. I also subscribe to industry publications and technical journals, such as IEEE publications, which publish articles on advancements in design methodologies and software applications. Furthermore, I actively participate in professional networking groups, attending conferences and engaging in online forums to learn from other engineers’ experiences and challenges. Finally, I dedicate time to self-directed learning, experimenting with new features and techniques within the software to improve my proficiency.

For example, I recently participated in an Autodesk webinar showcasing the new automation capabilities within AutoCAD Electrical, which significantly streamlined my schematic design process for a subsequent project.

Q 24. Describe a time you had to solve a challenging problem in an electrical design project.

During the design phase of a large-scale industrial automation project, we encountered a significant challenge with integrating a new PLC system. The vendor provided incomplete documentation, and the communication protocol was unusual. The initial design, based on incomplete data, resulted in several conflicts.

To solve this, I employed a multi-pronged approach. First, I established direct communication with the PLC vendor’s engineering team, obtaining clarified specifications and updated documentation. Then, I utilized the software’s simulation capabilities (within EPLAN in this case) to test various integration scenarios, identifying and resolving potential compatibility issues. Through rigorous testing, we identified and corrected wiring errors, ensuring a smooth integration. This involved careful analysis of the PLC’s I/O configuration, meticulous I/O point mapping within the EPLAN software, and thorough verification using PLC simulation software. Finally, I documented all changes, updates, and solutions thoroughly for future reference. The successful resolution of this challenge significantly enhanced the project’s efficiency and prevented costly delays later in the installation phase.

Q 25. What are some best practices for creating efficient and maintainable electrical designs?

Efficient and maintainable electrical designs hinge on adhering to best practices. These include, but are not limited to:

- Consistent Naming Conventions: Establishing clear and consistent naming conventions for components, wires, and other elements ensures easy identification and traceability. This simplifies troubleshooting and future modifications.

- Modular Design: Breaking down complex designs into smaller, manageable modules simplifies design, testing, and future modifications. Changes within a module have minimal impact on other parts of the system.

- Utilizing Software Features: Leveraging the built-in features of your electrical design software, like automated wire numbering, bill of materials generation, and cross-referencing, streamlines processes and reduces errors.

- Proper Documentation: Comprehensive documentation including schematics, wiring diagrams, panel layouts, and component specifications is essential for maintenance and future updates. This documentation should follow established standards such as IEC or ANSI.

- Version Control: Employing version control systems, either within the software or using external tools, allows for tracking changes, reverting to previous versions, and ensuring collaboration without overwriting each other’s work.

For example, imagine creating a large motor control center; modular design allows easier troubleshooting by isolating problems to specific sections rather than combing through a large, monolithic drawing. Similarly, consistent naming conventions avoid confusion when tracing wires during maintenance.

Q 26. Explain your understanding of different cable sizing and selection methods.

Cable sizing and selection is critical for ensuring the safety and reliable operation of electrical systems. Several methods are employed, depending on the application and relevant standards. The most common methods include:

- Ampacity-based sizing: This method determines the minimum cable size based on the current-carrying capacity (ampacity) of the conductor, taking into account factors such as ambient temperature, installation method, and cable grouping. We refer to tables and standards like NEC (National Electrical Code) or IEC 60364 to find appropriate ampacity values.

- Voltage drop calculations: This method calculates the voltage drop along the cable length, ensuring that the voltage at the load remains within acceptable limits. Excessive voltage drop can impact equipment performance and efficiency. The calculation considers cable length, resistance, and current.

- Short-circuit current calculations: This method determines the cable’s ability to withstand short-circuit currents without damage. It involves calculating the short-circuit current and selecting a cable with an appropriate short-circuit rating.

Software tools often incorporate these calculations. In AutoCAD Electrical or EPLAN, after defining cable type and length, the software automatically calculates voltage drop and flags potential issues based on chosen standards and ampacity ratings.

For instance, selecting a cable for a long distance motor control circuit requires careful voltage drop calculation to avoid performance degradation. Ignoring this can lead to issues like motor overheating or slow response times.

Q 27. How do you handle conflicts between design requirements and budget constraints?

Balancing design requirements and budget constraints often requires creative problem-solving. My approach involves a structured process:

- Prioritize Requirements: First, I carefully analyze all design requirements and prioritize them based on their criticality to the project’s overall success and safety. Essential safety requirements always take precedence.

- Explore Cost-Effective Alternatives: Once priorities are defined, I explore cost-effective alternatives without compromising safety or essential functionality. This might involve researching different components, materials, or construction methods.

- Value Engineering: I participate actively in value engineering exercises with the project team, identifying areas where cost savings can be achieved without sacrificing performance. This could include optimizing cable routing, using standard components, or simplifying the design.

- Phased Implementation: In some cases, a phased implementation might be considered, where less critical features are implemented later to fit within the budget. This approach allows for a functional system now with future upgrades.

For example, on a recent project, we had to reduce costs. Instead of using expensive custom-designed enclosures, we opted for readily available, standardized units, saving considerable money without affecting functionality. It’s essential to document and communicate all these trade-offs clearly.

Q 28. What are your preferred methods for documenting and communicating design changes?

Documenting and communicating design changes effectively is paramount for maintaining project integrity. My preferred methods include:

- Formal Change Requests: All design changes are documented formally via change requests, clearly outlining the reason for the change, its impact, and the proposed solution. This ensures traceability and auditable changes.

- Version Control Within Software: Utilizing version control features within AutoCAD Electrical or EPLAN allows for tracking each revision, enabling easy rollback if necessary. This also provides a clear record of who made the changes and when.

- Redlining and Markup Tools: For smaller changes, redlining tools within the software or PDF markup tools help to clearly show alterations on drawings. These marked-up drawings should be accompanied with descriptions.

- Regular Team Meetings: Holding regular team meetings ensures that all design changes are communicated promptly and that any questions or concerns are addressed proactively.

For instance, if I need to change the routing of a cable, I create a formal change request, update the drawing using the software’s version control, and highlight the change using redlining. This assures everyone is aware and has the latest version.

Key Topics to Learn for Electrical Design Software Proficiency (e.g., AutoCAD Electrical, EPLAN) Interview

- Schematic Design & Capture: Mastering the creation of accurate and efficient electrical schematics, including component placement, wiring, and annotation. Understand industry standards and best practices for design documentation.

- Component Libraries & Management: Learn how to effectively utilize and manage component libraries, including creating custom components and updating existing ones. This includes understanding symbol attributes and properties for efficient design.

- Panel Layout & Design: Develop proficiency in designing control panels and other electrical enclosures, considering factors like component placement, wiring routing, and safety regulations. Practice using tools for automated wire numbering and reporting.

- Wire Routing & Numbering: Understand the principles of efficient wire routing and automated wire numbering systems. Practice creating clean and organized wiring diagrams that adhere to industry standards.

- Report Generation & Documentation: Learn to generate comprehensive reports from your designs, including bills of materials (BOMs), wire lists, and other essential documentation. This includes understanding different report formats and customization options.

- Project Management & Collaboration: Familiarize yourself with project management features within the software, such as version control, collaboration tools, and data management techniques for efficient teamwork.

- Troubleshooting & Problem Solving: Develop your ability to identify and resolve design errors, including electrical rule checking and other diagnostic features. Practice troubleshooting common issues that arise during the design process.

- Software Specific Features: Deepen your understanding of advanced features specific to your chosen software (AutoCAD Electrical or EPLAN), such as PLC integration, automated design checks, and customization options. Explore the software’s full potential.

Next Steps

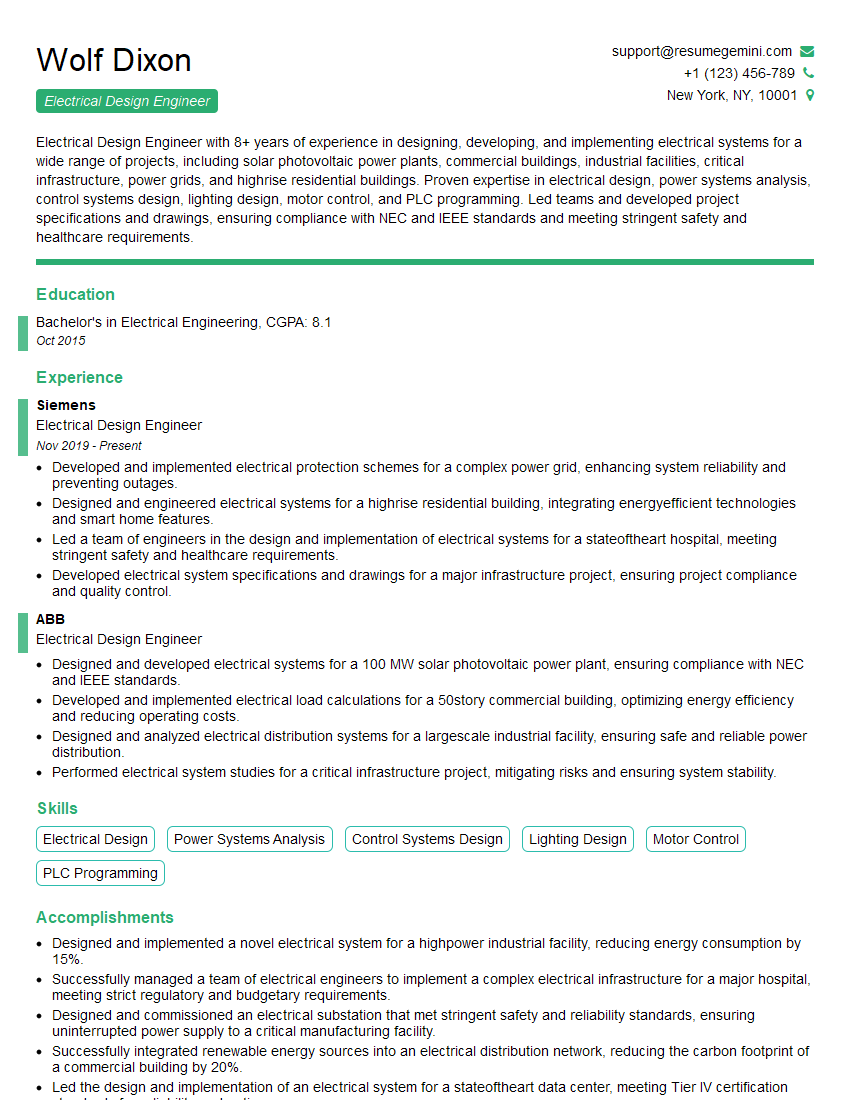

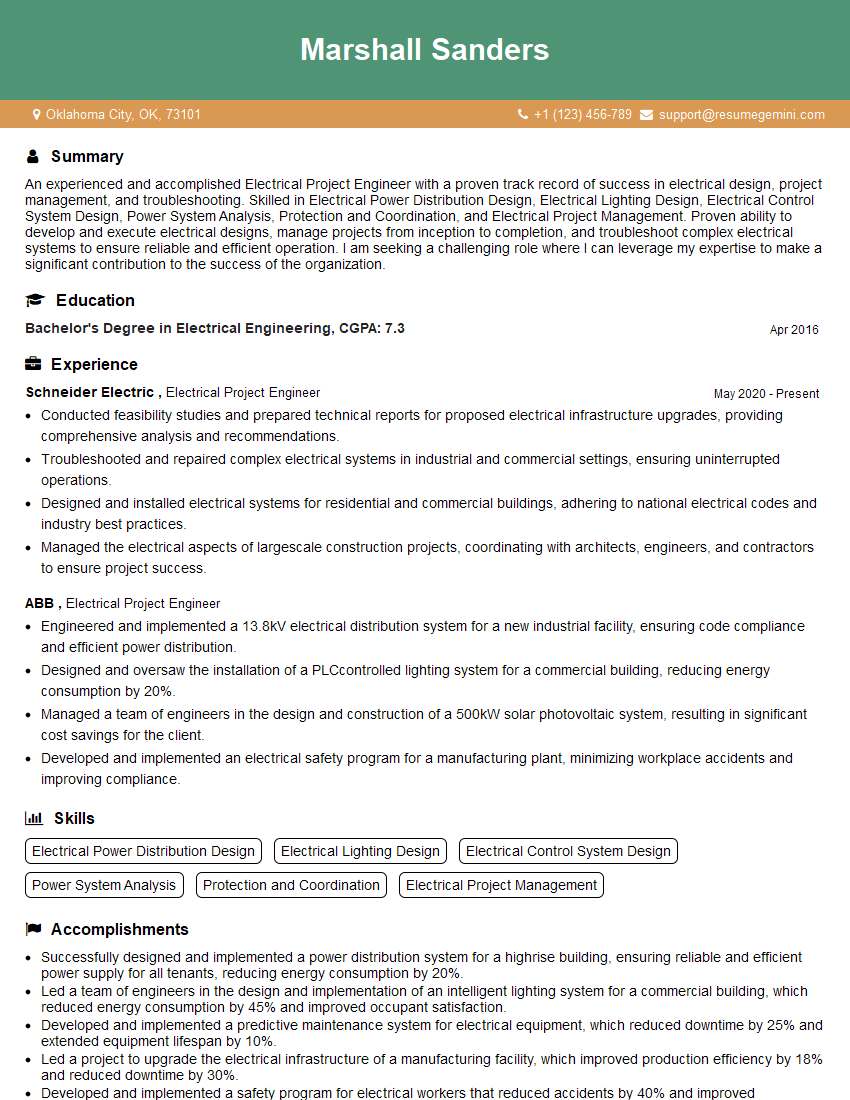

Mastering Electrical Design Software like AutoCAD Electrical or EPLAN is crucial for career advancement in the electrical engineering field. It demonstrates a high level of technical skill and efficiency, making you a highly valuable asset to any team. To maximize your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your proficiency. Examples of resumes tailored to Electrical Design Software Proficiency, specifically AutoCAD Electrical and EPLAN, are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?