Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Electrical Engineering Design Principles and Standards (IEC, NEC) interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Electrical Engineering Design Principles and Standards (IEC, NEC) Interview

Q 1. Explain the difference between IEC and NEC standards.

The IEC (International Electrotechnical Commission) and NEC (National Electrical Code) are both crucial sets of standards for electrical safety and design, but they serve different geographical areas and have some differences in their approach.

The IEC is an international standard, developed by a global organization, and its standards are adopted worldwide. They tend to be more general and performance-based, focusing on the outcomes and allowing for flexibility in implementation. This approach encourages innovation and adaptation to local conditions.

The NEC, on the other hand, is a national standard specifically for the United States and is legally enforced. It’s more prescriptive, providing detailed rules and regulations that must be followed. While striving for safety, this can sometimes limit flexibility in design choices compared to the IEC’s more performance-oriented approach. Imagine it like this: IEC provides the guiding principles, while NEC offers a detailed blueprint.

For example, both might address grounding, but the IEC might specify minimum resistance levels, allowing for various methods to achieve that, while the NEC might dictate specific grounding electrode materials and connection methods.

Q 2. Describe your experience with grounding and bonding techniques according to NEC.

Grounding and bonding are paramount for safety. My experience involves applying NEC guidelines to ensure equipment grounding, electrical system grounding, and bonding for various projects, including industrial facilities and commercial buildings.

According to the NEC, I ensure proper grounding electrode conductor sizing, using the appropriate materials (like copper) and ensuring low-impedance paths to earth. This involves regular inspections to confirm the integrity of connections and check for corrosion. I also implement equipment grounding conductors and bonding jumpers to interconnect metallic enclosures and ensure a low-impedance path for fault currents, preventing dangerous voltage buildup on exposed metal surfaces.

One project involved a large industrial plant where we had to carefully coordinate grounding grids for different equipment and systems to prevent ground potential differences that could cause problems or even hazards. We meticulously documented all connections and resistance measurements to maintain compliance and ensure safety.

I am proficient in using testing equipment like earth ground testers to verify ground resistance meets NEC requirements. I also understand the importance of surge protection and grounding systems to mitigate damage from lightning strikes and other transient events.

Q 3. How do you ensure compliance with IEC 61439-1 for low-voltage switchgear and controlgear assemblies?

IEC 61439-1 governs the safety of low-voltage switchgear and controlgear assemblies. Ensuring compliance involves a multi-faceted approach. First, we select components that bear the appropriate IEC 61439-1 certification. This verifies that individual components meet the required safety and performance standards. This is like building with pre-approved LEGO bricks; you know they meet the quality standards.

Next, we carefully design the assembly itself, adhering to the standard’s requirements for clearances, creepage distances, and internal wiring. This prevents electrical shorts and ensures safety. We also carefully consider environmental factors like temperature and humidity that might affect the performance and lifespan of the assembly. This step is like carefully following the LEGO instructions to assemble the creation correctly.

Finally, the complete assembly undergoes rigorous testing to verify that it meets the specifications outlined in IEC 61439-1. This includes electrical testing, mechanical testing, and thermal testing. Think of this as quality control; ensuring the assembled LEGO model is sturdy and functional.

Thorough documentation of the design, component selection, and testing results is essential to demonstrate compliance and traceability, allowing for easy audits and future maintenance.

Q 4. Explain the importance of arc flash hazard analysis and mitigation.

Arc flash hazards are a serious concern in electrical systems, caused by short circuits or other electrical faults that can produce intense light, heat, and pressure. An arc flash can result in severe burns, blindness, and even death.

Arc flash hazard analysis is crucial for identifying potential hazards. This involves calculating the incident energy levels at various points within the electrical system. Specialized software and calculations based on system parameters determine the level of risk. The outcome guides the selection of appropriate Personal Protective Equipment (PPE) and safe work practices.

Mitigation involves implementing several strategies: reducing available fault current using protective devices like circuit breakers and fuses; installing arc flash reduction equipment; implementing lockout/tagout procedures; and providing employee training on safety protocols. Using engineering controls and administrative controls in tandem provides a layered approach, which is critical for safety.

For instance, a recent project required us to perform arc flash studies and update the electrical panels with arc flash labels. This not only informed the workers about the level of risk but also ensured that they had the correct PPE available when working on the panels. This minimized the risk considerably.

Q 5. What are the key considerations for designing electrical systems in hazardous locations (Class I, II, III)?

Designing electrical systems for hazardous locations requires specialized knowledge and adherence to relevant standards, such as NEC Article 500 and its associated classifications (Class I, II, III). These locations present unique challenges due to the presence of flammable or combustible materials.

Class I locations contain flammable gases or vapors. Here, equipment must be intrinsically safe, explosion-proof, or purged. This means they are designed to prevent ignition or to contain any potential explosion.

Class II locations contain combustible dusts. Similar to Class I, equipment needs to be suitable for dust-ignition prevention or contain any potential explosions.

Class III locations contain easily ignitable fibers or flyings. These require equipment suitable for preventing the ignition of fibers. This involves using specific enclosure types and careful consideration of ventilation.

Key considerations include using appropriate explosion-proof equipment, specialized wiring methods, proper sealing and grounding techniques, and the selection of materials with high ignition resistance. A crucial aspect is the implementation of proper ventilation systems to prevent the accumulation of flammable materials.

In practice, this requires careful selection of components certified for hazardous locations and thorough documentation to ensure compliance with regulations. Any deviation necessitates detailed justification and documented risk assessment.

Q 6. How do you select appropriate cable sizing based on NEC requirements?

Cable sizing is critical for ensuring efficient and safe operation of electrical systems. The NEC provides detailed guidance, primarily in Chapter 9, Table 310.16. We use this table to determine the appropriate ampacity (current-carrying capacity) of a cable based on its insulation type, installation method, and ambient temperature.

The process involves: first, determining the expected load current for the circuit; next, selecting a cable with an ampacity that exceeds the load current to provide an acceptable safety margin; finally, considering factors like derating for multiple cables in a conduit, installation in ambient temperatures above 30°C, and other environmental conditions.

For example, a 100-amp load might require a 125-amp cable to account for the margin. However, if the cable is installed in a conduit with other cables, we would need to derate the ampacity based on NEC Table 310.15(B)(2) and select a larger cable to meet the requirements.

Voltage drop is another critical factor. Oversized cables minimize voltage drop, ensuring sufficient voltage reaches the loads and preventing inefficient operation or damage to equipment. Tools and software simplify these calculations, but understanding the underlying principles is essential for accurate sizing.

Q 7. Describe your experience with voltage drop calculations and their impact on system design.

Voltage drop calculations are fundamental in electrical system design. They determine the voltage loss along a conductor due to its resistance and current flow. Excessive voltage drop can lead to equipment malfunction, reduced efficiency, and even safety hazards. My experience includes calculating voltage drops using various methods, including manual calculations and specialized software.

The basic formula for voltage drop is: Voltage Drop = (2 * Length * Current * Resistance) / 1000 where length is in feet, current in amps, and resistance in ohms per 1000 feet.

I routinely use software tools that incorporate more complex factors, such as cable type, temperature, and power factor. This ensures greater accuracy in predicting voltage drop. For instance, I’ve encountered scenarios where seemingly adequate cable sizing resulted in unacceptable voltage drops due to long conductor lengths. Utilizing calculation tools allowed me to identify and rectify these issues before construction.

The impact on system design is significant. High voltage drops necessitate larger cable sizes, increasing material and installation costs. This involves a trade-off between minimizing voltage drop and controlling project costs. My approach prioritizes optimizing the design to balance both cost and performance while adhering to all NEC and IEC guidelines.

Q 8. Explain the concept of power factor correction and its benefits.

Power factor correction (PFC) addresses the issue of reactive power in AC circuits. Ideally, we want all the power supplied to a load to be used for actual work (real power, measured in watts). However, inductive loads like motors and transformers also draw reactive power (measured in Volt-Ampere Reactive or VAR), which doesn’t contribute to useful work but increases the current flowing through the system. This leads to higher energy costs and increased stress on equipment.

Imagine a water pump: Real power is like the water actually being pumped to your house for use. Reactive power is like water sloshing back and forth in the pipes, not contributing to your household water supply but still requiring a larger pump and creating more wear and tear.

PFC involves adding devices like capacitors to compensate for the inductive reactance. These capacitors supply the reactive power, reducing the overall current draw from the supply. This results in several benefits:

- Reduced electricity costs: Lower current means lower energy bills.

- Improved system efficiency: Less current flowing means less power loss in cables and transformers.

- Increased system capacity: Existing infrastructure can handle higher real power loads.

- Reduced voltage drops: Lower current minimizes voltage drops along transmission lines.

- Improved power factor closer to unity (1): A power factor closer to 1 indicates higher efficiency.

For instance, a factory with numerous induction motors might experience a low power factor, leading to high electricity bills. Implementing PFC by installing capacitor banks improves the power factor, resulting in significant cost savings.

Q 9. How do you perform short-circuit current calculations?

Short-circuit current calculations are crucial for proper protection device sizing and system safety. The objective is to determine the maximum current that could flow during a short circuit. This calculation depends on several factors, and different methods exist depending on the complexity of the system.

One common approach involves using the impedance method. We start by creating a single-line diagram of the power system, representing all components (generators, transformers, cables, etc.) with their respective impedances (resistance and reactance). These impedances are often obtained from manufacturer’s data or using established calculation methods.

Then, we simplify the equivalent impedance of the entire system ‘seen’ from the fault location. The short-circuit current is then calculated using Ohm’s law (Isc = Vs/Zeq), where:

- Isc is the short-circuit current

- Vs is the pre-fault voltage

- Zeq is the equivalent impedance of the system

Software tools are commonly used for complex systems, incorporating detailed models of transformers, generators, and transmission lines. They allow for a more accurate analysis, considering factors such as X/R ratios and various fault types (e.g., three-phase, line-to-ground). For example, software like ETAP or SKM PowerTools allows for detailed short-circuit calculations and coordination studies. It’s essential to follow relevant standards like IEC 60909 for accurate and reliable results.

Q 10. Describe your experience with motor control circuits and protection devices.

I have extensive experience designing and implementing motor control circuits, encompassing various types of motors (AC induction, DC, servo) and protection devices. My work has involved different control strategies such as direct-on-line starters, star-delta starters, soft starters, variable frequency drives (VFDs), and programmable logic controllers (PLCs).

For instance, I designed a motor control system for a large conveyor belt in a manufacturing plant. This involved selecting a suitable VFD to control the AC induction motor, ensuring precise speed control and smooth operation. The design incorporated overcurrent, overload, and thermal protection using relays and the VFD’s internal protection features, complying with NEC and IEC standards.

Protection devices are critical, and my experience includes selecting and applying various devices like:

- Overcurrent relays: To protect against excessive current.

- Thermal relays: To prevent motor overheating.

- Ground fault relays: To detect and trip on ground faults.

- Fuses: For overcurrent protection, particularly as backup protection.

I’ve always prioritized safety and reliability in my designs, ensuring appropriate grounding, short-circuit protection, and proper coordination between protection devices to prevent cascading failures.

Q 11. What is your experience with the selection and application of circuit breakers and fuses?

The selection and application of circuit breakers and fuses are fundamental aspects of electrical system design. The choice depends on several factors, including the fault current level, voltage rating, interrupting capacity, and the type of load being protected. The key is ensuring proper coordination to selectively isolate faults without unnecessarily interrupting the entire system.

Circuit breakers offer advantages like the ability to be reset after a trip, making them suitable for frequent operations. They’re often used for larger loads and systems where frequent tripping isn’t expected to severely impact operations. Fuses, on the other hand, are one-time devices that melt and require replacement after a fault. They are often cost-effective for smaller loads and applications where replacement is easier and more economical than breaker repair or replacement.

For example, in a low-voltage distribution panel, I might use molded-case circuit breakers for branch circuits and a larger frame breaker for the main feed. In the same panel, fuses might be used for specific equipment requiring specific protection characteristics that are better handled by a fuse than a breaker. Proper coordination is crucial; a smaller breaker or fuse should trip before a larger one upstream to isolate the fault quickly and effectively. My approach always includes referring to the manufacturer’s data sheets and complying with relevant standards (NEC, IEC) to ensure proper selection and coordination.

Q 12. Explain the importance of proper documentation in electrical design projects.

Proper documentation is essential in electrical design projects for several reasons. It serves as a record of the design process, facilitates communication between stakeholders, ensures consistency and traceability, and aids in future maintenance and modifications. Poor documentation leads to confusion, errors, delays, and increased costs.

My approach to documentation includes creating clear and concise drawings, specifications, calculations, and reports. This usually involves:

- Single-line diagrams: To illustrate the overall power system.

- Wiring diagrams: To show the interconnection of components.

- Panel schedules: To list components within electrical panels.

- Calculations: To demonstrate design compliance with standards.

- Bill of materials (BOM): To list all required materials.

- Test and inspection reports: To document verification and compliance.

I utilize revision control systems to track changes and ensure everyone works with the most current version of the documentation. Clear and organized documentation ensures safety, compliance, and simplifies future work on the project, be it maintenance, upgrades, or expansion.

Q 13. How do you approach troubleshooting electrical problems in existing systems?

Troubleshooting electrical problems in existing systems requires a systematic approach. Safety is paramount; I always start by de-energizing the affected area before performing any work. Then, I follow these steps:

- Gather information: Understand the symptoms of the problem (e.g., complete power outage, intermittent flickering, blown fuse). Interview those involved to get all the relevant information.

- Inspect visually: Look for obvious problems like loose connections, damaged wires, or burnt components.

- Use appropriate test equipment: Employ multimeters, clamp meters, insulation testers to measure voltages, currents, and resistances. Check continuity and isolation.

- Follow the circuit: Trace the circuit from the source to the point of failure, systematically eliminating potential causes. Diagrams and documentation are invaluable here.

- Isolating the fault: Once the area is narrowed down, focus on that section, checking components one by one.

- Document findings and solutions: Keep a record of every test performed and the conclusions reached. This will be helpful for future troubleshooting or improvements.

For example, if a circuit breaker keeps tripping, I would first check the load for overcurrent conditions. If everything seems correct, I would then inspect the wiring for shorts or other faults. A systematic approach and the use of appropriate tools are key to resolving problems efficiently and safely.

Q 14. Describe your experience with using electrical CAD software (AutoCAD, Eplan, etc.).

I am proficient in several electrical CAD software packages, including AutoCAD Electrical, EPLAN Electric P8, and similar software. These tools are indispensable for efficient and accurate electrical design.

My experience spans from creating simple schematic diagrams to designing complex electrical systems for large-scale projects. This includes creating single-line diagrams, wiring diagrams, panel layouts, and generating reports. The use of these software packages improves efficiency through automation of tasks like generating bills of materials (BOMs), generating reports, and ensuring design consistency.

For example, I utilized EPLAN Electric P8 to design the electrical system for a new manufacturing facility. The software’s capabilities for managing large projects, ensuring consistency across multiple drawings, and generating detailed reports were invaluable. AutoCAD Electrical was used to create detailed panel layouts and accurately position components, reducing errors and improving the overall quality of the design. My expertise in these software tools allows me to create high-quality, error-free designs, thereby optimizing time and resources.

Q 15. Explain the different types of grounding systems and their applications.

Grounding systems are crucial for electrical safety, protecting people and equipment from dangerous voltages. They provide a low-impedance path for fault currents to flow to the earth, preventing hazardous voltage buildup. Several types exist, each suited to different applications:

- Grounding Electrode System (GES): This is the foundation of any grounding system. It consists of electrodes (rods, plates, pipes) driven into the earth, providing a connection point for the grounding conductor. The effectiveness depends heavily on soil resistivity; higher resistivity requires more extensive electrode systems.

- Plate Grounding: Uses large, flat conductive plates buried in the earth. These are particularly effective in areas with high soil resistivity, offering a larger surface area for current dissipation. They are often used in high-power applications or where space is less of a constraint.

- Rod Grounding: The most common type, using multiple ground rods driven into the ground. The rods are typically copper-clad steel. Their effectiveness increases with the number of rods and their depth. They’re commonly seen in residential and smaller commercial installations.

- Pipe Grounding: Utilizes metallic pipes, such as water pipes (if metallic and bonded correctly, according to code), to provide a grounding path. However, reliance on water pipes alone is generally discouraged due to corrosion and potential disconnections. It’s often used as a supplementary grounding electrode.

- Grounding Grid: Used for large installations, such as substations or industrial plants. It’s a network of interconnected conductors buried in the ground, providing a wide area for current dissipation. It ensures low ground impedance across the entire site, improving safety and protecting against potential ground faults.

The choice of grounding system depends on factors like soil resistivity, installation size, and the level of fault current expected. For example, a large industrial plant would need a robust grounding grid, while a small residential building might suffice with a rod grounding system.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the safety of electrical workers during construction and maintenance?

Ensuring electrical worker safety during construction and maintenance is paramount. A multi-layered approach is essential, encompassing procedural, technological, and personal protective measures. Here’s a breakdown:

- Lockout/Tagout (LOTO) Procedures: Before any work begins on energized equipment, a strict LOTO procedure must be followed, ensuring the equipment is de-energized and locked out, preventing accidental re-energization.

- Permit-to-Work Systems: Formal systems documenting the work to be performed, the hazards involved, the safety precautions necessary, and authorization for the work to commence. This system provides accountability and traceability.

- Grounding and Bonding: Thorough grounding and bonding of equipment and circuits to ensure that any fault currents are safely directed to the earth, eliminating shock hazards. This includes using proper grounding clamps and conductors, verified by testing.

- Personal Protective Equipment (PPE): Electrical workers must wear appropriate PPE, including insulated gloves, safety glasses, arc flash protective clothing, and safety shoes. The PPE requirements are determined by the potential arc flash hazard based on incident energy calculations.

- Training and Competency: Workers must receive adequate training on safe work practices, electrical safety regulations, and the proper use of PPE. Competency assessments should be regularly conducted.

- Regular Inspections and Maintenance: Regular inspections of equipment and wiring are vital to identify and rectify potential hazards before they cause accidents. Proper maintenance practices help prevent equipment failures.

- Arc Flash Hazard Analysis: For work on energized systems, a thorough arc flash hazard analysis must be conducted to determine the incident energy level and select appropriate PPE.

In my experience, a strong safety culture, built on communication and strict adherence to protocols, is the most effective way to minimize electrical hazards in the workplace. A near-miss reporting system allows for continuous improvement and learning from incidents without injury.

Q 17. Describe your understanding of electrical safety regulations and codes.

Electrical safety regulations and codes are crucial for public safety and the safe operation of electrical systems. My understanding encompasses several key aspects:

- National Electrical Code (NEC) in the US: The NEC is a widely adopted standard that outlines safe installation practices for electrical systems. It’s regularly updated to reflect technological advances and address emerging safety concerns.

- International Electrotechnical Commission (IEC) Standards: IEC standards provide a global framework for electrical safety. Many national codes, including the NEC, incorporate or reference IEC standards.

- Occupational Safety and Health Administration (OSHA) Regulations: OSHA regulations in the US establish workplace safety standards, including those related to electrical safety, covering things like lockout/tagout procedures and worker training. These regulations are enforced through inspections and penalties for non-compliance.

- Local and Regional Codes: In addition to national and international standards, local authorities may have specific codes that need to be considered during design and installation, reflecting regional conditions or unique circumstances.

Understanding these codes requires constant learning and staying updated on revisions and amendments. It’s crucial for designing and installing safe and compliant electrical systems.

Q 18. How familiar are you with the National Electrical Code (NEC) article 250 (Grounding)?

NEC Article 250, Grounding, is a comprehensive section detailing the requirements for grounding and bonding of electrical systems. My familiarity with it extends to:

- Grounding Electrode System (GES): Understanding the requirements for different types of grounding electrodes, their installation, and testing. This includes calculating the required number and size of ground rods based on soil resistivity.

- Grounding Conductor Sizing: Knowing how to size grounding conductors based on the fault current levels and the impedance of the grounding path.

- Bonding Requirements: Understanding the requirements for bonding metallic water pipes, gas pipes, and other metallic structures to the grounding electrode system. This helps prevent voltage gradients and potential hazards.

- Ground Fault Protection: Awareness of the different types of ground fault protection equipment, like ground fault circuit interrupters (GFCIs) and arc fault circuit interrupters (AFCIs).

- Testing and Inspection: Familiarity with the procedures for testing grounding systems to ensure their effectiveness. This includes ground resistance measurements using specialized equipment.

Article 250 is a critical part of electrical safety, and I regularly refer to it when designing and analyzing grounding systems for various projects. It guides me to ensure the safety and reliability of the electrical installations I work on.

Q 19. Explain your experience with lighting design calculations and standards.

Lighting design calculations involve determining the appropriate number, type, and placement of light fixtures to achieve the desired illumination levels. This requires a sound understanding of illumination principles, lighting standards, and relevant software. My experience involves:

- Illuminance Calculations: Using the inverse square law and other relevant formulas to calculate the illuminance levels at various points in a space.

- Luminance Calculations: Calculating luminance values to account for glare and visual comfort.

- IES Files and Software: Using industry-standard lighting design software and IES (Illuminating Engineering Society) files to model lighting systems and predict their performance.

- Lighting Standards: Adherence to relevant lighting standards, such as those published by the IES, to ensure that the design meets the required illumination levels and complies with relevant safety and energy efficiency regulations.

- Energy Efficiency Considerations: Optimizing lighting designs to minimize energy consumption, using energy-efficient light sources and control systems.

For instance, I recently designed the lighting for a large office space, using DIALux software to model the lighting layout and ensure uniform illuminance levels throughout the space, while minimizing glare and energy consumption. This involved selecting energy-efficient LED luminaires and incorporating daylight harvesting strategies.

Q 20. Describe your knowledge of different types of transformers and their applications.

Transformers are essential components in electrical power systems, used to step-up or step-down voltage levels. Several types exist, each serving a unique purpose:

- Step-up Transformers: Increase voltage for efficient long-distance power transmission. These are typically found at power generation stations and substations.

- Step-down Transformers: Reduce voltage to safer and usable levels for distribution to homes and businesses. These are commonly seen on utility poles and in buildings.

- Power Transformers: Used in high-power applications, such as substations and industrial facilities. They handle large amounts of power and often require sophisticated cooling systems.

- Distribution Transformers: Used to distribute power to smaller areas, such as residential neighborhoods or individual buildings.

- Isolation Transformers: Used to isolate circuits electrically, providing a barrier between different parts of a system. This improves safety by preventing ground faults from affecting other parts of the system.

- Autotransformers: Have a single winding that is tapped at various points to provide different voltage levels. They are often used for voltage regulation or to provide a variable voltage output.

- Instrument Transformers: Used to measure current and voltage in high-voltage systems without directly connecting measuring instruments to these high voltages. Current transformers (CTs) and potential transformers (PTs) are the most common types.

The selection of the appropriate transformer depends on the application, voltage levels, power requirements, and other factors. For instance, in a residential setting, a step-down distribution transformer is used to reduce the high-voltage transmission lines to the lower voltages needed for home appliances.

Q 21. How do you calculate the ampacity of conductors?

Calculating the ampacity of conductors is crucial for ensuring that they can safely carry the intended current without overheating. The ampacity is the maximum current that a conductor can carry continuously under specified conditions. The calculation involves several factors:

- Conductor Material: Copper and aluminum are common conductor materials, each having different ampacity ratings.

- Conductor Size: Larger conductors have higher ampacity ratings.

- Insulation Type: Different insulation materials have different temperature ratings, affecting the conductor’s ampacity.

- Ambient Temperature: Higher ambient temperatures reduce the ampacity of conductors.

- Number of Conductors in a Conduit: The ampacity is derated when multiple conductors are installed in a conduit due to increased heat buildup.

- Installation Method: The method of installation (e.g., in free air, in conduit, buried) impacts the ampacity.

The calculation often involves consulting tables in the NEC or other relevant standards. For example, NEC Table 310.15(B)(16) provides ampacity ratings for copper conductors with various insulation types. These tables consider many of the factors mentioned above. To calculate the actual ampacity for a specific installation, you would need to consider all these factors and apply any necessary derating factors. This ensures the selected conductor size can safely carry the intended current under the given conditions and prevents overheating.

Q 22. What is your experience with harmonic analysis and mitigation techniques?

Harmonic analysis is crucial for understanding and mitigating power quality issues stemming from non-linear loads. These loads, like rectifiers in variable-speed drives or switching power supplies, draw current in a non-sinusoidal waveform, creating harmonic currents that distort the sinusoidal voltage waveform. These harmonics can lead to overheating in equipment, malfunctioning of sensitive electronics, and increased energy losses.

My experience includes performing harmonic analysis using software like ETAP or PSCAD. This involves simulating the system, identifying harmonic sources, and calculating the harmonic distortion levels (THD). For example, in a recent project involving a large industrial facility, I used harmonic analysis to determine that significant 5th and 7th harmonics were present, primarily originating from a newly installed set of variable frequency drives. This analysis was critical for selecting appropriate mitigation techniques.

Mitigation techniques vary depending on the severity and sources of the harmonics. Common approaches include:

- Passive Filters: These are tuned circuits designed to resonate at specific harmonic frequencies, absorbing the unwanted harmonics. They are cost-effective for specific harmonic issues, but less flexible for changing load conditions.

- Active Filters: These use power electronics to actively inject currents that cancel out the harmonic currents. They are more adaptable to changing loads but are generally more expensive.

- Harmonic Sources Mitigation: Addressing the root cause by using equipment with low harmonic generation (e.g., employing 12-pulse rectifiers instead of 6-pulse) is the most effective long-term solution.

- Oversizing Equipment: This approach allows equipment to handle the increased current due to harmonics without significant overheating.

The choice of mitigation technique is based on a cost-benefit analysis considering the severity of harmonic distortion, the cost of mitigation equipment, and potential long-term operational savings.

Q 23. Explain your knowledge of different types of protective relays and their functions.

Protective relays are the brain of a power system’s protection scheme, instantly detecting faults and initiating appropriate actions to isolate the faulty section while keeping the rest of the system operational. My experience encompasses a wide range of relay types, including:

- Overcurrent Relays: These are the most common and respond to excessive current flow, indicating a short circuit or overload. They are often categorized as instantaneous, time-delayed, or inverse-time overcurrent relays, each with specific characteristics and settings.

- Differential Relays: These compare the current entering and leaving a protected zone (like a transformer or busbar). Any significant difference indicates an internal fault.

- Distance Relays: These measure the impedance to a fault along a transmission line and trip the circuit breaker if the impedance falls within a pre-defined zone. This allows for faster protection of long transmission lines.

- Ground Fault Relays: These detect ground faults, which are particularly dangerous, and can be configured to operate on various ground fault detection principles such as phase-to-ground, ground-overcurrent, or residual current.

- Pilot Wire Relays: Used for long transmission lines, these utilize communication links between substations to detect and isolate faults.

Proper relay selection and coordination are vital for maintaining system reliability and safety. I’ve worked on projects involving the design, specification, and testing of these relays, ensuring they meet the specific requirements of each application. For example, in one project, we had to carefully coordinate multiple overcurrent relays to ensure selective tripping, avoiding unnecessary outages during a fault.

Q 24. Describe your understanding of power quality issues and their solutions.

Power quality issues affect the reliability and performance of electrical equipment and can manifest in various forms. Understanding these issues and their solutions is critical for efficient and safe system operation. Common power quality problems include:

- Voltage Sags and Swells: Temporary reductions (sags) or increases (swells) in voltage amplitude. These can be caused by equipment switching, lightning strikes, or utility system disturbances.

- Voltage Transients (Spikes and Surges): Very short-duration, high-amplitude voltage variations. These are often caused by switching operations or lightning.

- Harmonics: As discussed earlier, these are non-sinusoidal current waveforms that distort the voltage waveform.

- Interruptions: Complete loss of voltage for a period of time.

- Flicker: Perceptible variations in light intensity, usually due to fluctuating loads.

Solutions depend on the specific issue and its severity. They range from simple solutions like surge protection devices (SPDs) to more complex approaches such as active power filters or uninterruptible power supplies (UPS). For instance, to mitigate voltage sags affecting a critical server room, I recommended and implemented an online UPS system to provide a continuous, clean power supply.

I often employ power quality monitoring equipment to identify the nature and frequency of power quality issues, allowing for data-driven decision-making in selecting and implementing appropriate mitigation measures.

Q 25. How do you ensure the proper coordination of protective devices in an electrical system?

Proper coordination of protective devices ensures that the correct protective device trips during a fault, isolating the fault while minimizing the impact on the rest of the system. This is achieved through careful selection and setting of protective devices considering their characteristics and the system’s configuration.

The coordination process involves several steps:

- Fault Current Calculations: Determining the magnitude of fault currents at various points in the system is fundamental. Software tools are often used for these calculations.

- Relay Setting Selection: Each relay’s operating characteristics (time-current curves) must be selected so that the closest relay to the fault operates first and isolates the fault. This is often done using coordination software to ensure proper selectivity and minimize the impact on other parts of the system.

- Protective Device Selection: Choosing the appropriate type and rating of circuit breakers, fuses, and other protective devices is crucial for ensuring the system operates safely and efficiently. The coordination of different types of protective devices, for example, fuses and circuit breakers, also needs special care.

- Testing and Verification: Once the settings are determined, the protection system must be thoroughly tested using various methods such as relay testing equipment to ensure it functions as intended.

Imagine a scenario where two circuit breakers protect the same feeder. If not properly coordinated, both could trip simultaneously, resulting in a larger outage. Through careful coordination, we ensure that only the circuit breaker closest to the fault will trip, minimizing the impact of the outage.

Q 26. Explain your experience with the design of electrical distribution systems.

My experience in electrical distribution system design encompasses all aspects, from initial concept and design through to commissioning and testing. This includes:

- Load Forecasting and Analysis: Accurately predicting future load demands to ensure adequate system capacity.

- System Sizing and Design: Determining the appropriate sizes of conductors, transformers, switchgear, and other components based on load calculations and applicable standards (NEC, IEC).

- Protection Scheme Design: Developing a robust protection scheme using protective relays and other devices to ensure fault detection, isolation, and system stability.

- Short Circuit and Coordination Studies: Conducting studies to determine fault current levels and to coordinate the operation of protective devices.

- Power Quality Analysis: Assessing potential power quality issues and implementing solutions to mitigate their effects.

- Grounding and Lightning Protection: Designing effective grounding systems to protect equipment and personnel from electrical hazards and implementing suitable lightning protection measures.

A recent project involved designing the electrical distribution system for a new hospital. This required careful consideration of critical load requirements, redundancy, and safety regulations. The design process involved detailed load calculations, short-circuit studies, coordination of protective devices, and meticulous adherence to the NEC.

Q 27. How do you stay current with changes in electrical codes and standards?

Staying current with changes in electrical codes and standards is paramount for providing safe and compliant designs. I employ several strategies to remain up-to-date:

- Professional Organizations: Active membership in organizations like IEEE and participation in their conferences and workshops.

- Code Subscription Services: Subscribing to services that provide updates on code changes and interpretations, ensuring access to the most current versions of relevant codes.

- Continuing Education Courses: Regular participation in continuing education courses and training programs to stay abreast of the latest technologies and best practices.

- Industry Publications: Reading industry publications, journals, and online resources to stay informed about new developments and changes in codes and standards.

- Networking and Collaboration: Engaging with colleagues, experts, and regulatory authorities to discuss and learn about current issues and best practices.

For example, I recently completed a training course on the latest updates to the NEC, focusing on changes in arc flash hazard calculations and mitigation techniques. This ensures that all my future designs meet the most current safety standards.

Key Topics to Learn for Electrical Engineering Design Principles and Standards (IEC, NEC) Interview

- Circuit Protection: Understanding overcurrent protection devices (fuses, circuit breakers), coordination, and arc flash hazard analysis. Practical application: Designing a safe and compliant electrical system for a commercial building.

- Wiring Methods and Cable Selection: Knowledge of different wiring methods (conduit, cable tray, etc.), cable sizing calculations based on NEC ampacity tables, and voltage drop calculations. Practical application: Selecting appropriate cables for a specific application considering environmental factors and safety regulations.

- Grounding and Bonding: Understanding the principles of grounding and bonding, equipment grounding conductor sizing, and the importance of safety. Practical application: Designing a grounding system for a substation to protect against electrical shocks and equipment damage.

- Power Systems Analysis: Familiarity with per-unit systems, power flow analysis, fault calculations (symmetrical and unsymmetrical), and load flow studies. Practical application: Analyzing the stability and reliability of a power distribution system.

- Lighting Design: Understanding lighting calculations (illuminance, luminance), energy efficiency considerations, and relevant codes. Practical application: Designing a lighting system for an industrial facility that meets both safety and productivity requirements.

- Motor Control and Protection: Understanding different motor starter types, motor protection relays, and safety considerations. Practical application: Designing a motor control center for a manufacturing plant.

- IEC and NEC Code Compliance: Thorough understanding of relevant articles and sections within the IEC and NEC standards. Practical application: Ensuring designs meet all applicable safety and regulatory requirements.

- Renewable Energy Integration: Understanding the integration of renewable energy sources (solar, wind) into existing electrical systems, including grid-tied inverters and protection schemes. Practical application: Designing a microgrid system for a remote location.

- Electrical Safety: A comprehensive understanding of electrical hazards, lockout/tagout procedures, and personal protective equipment (PPE). Practical application: Conducting a risk assessment for an electrical installation.

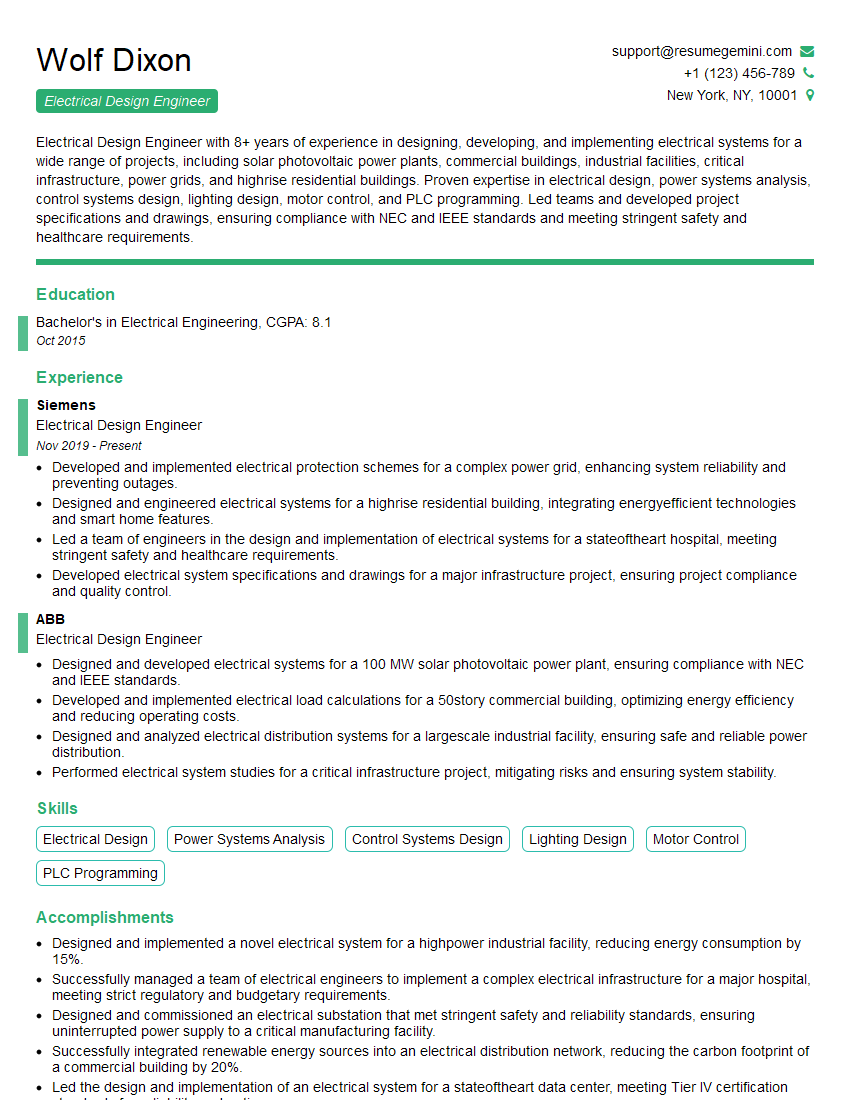

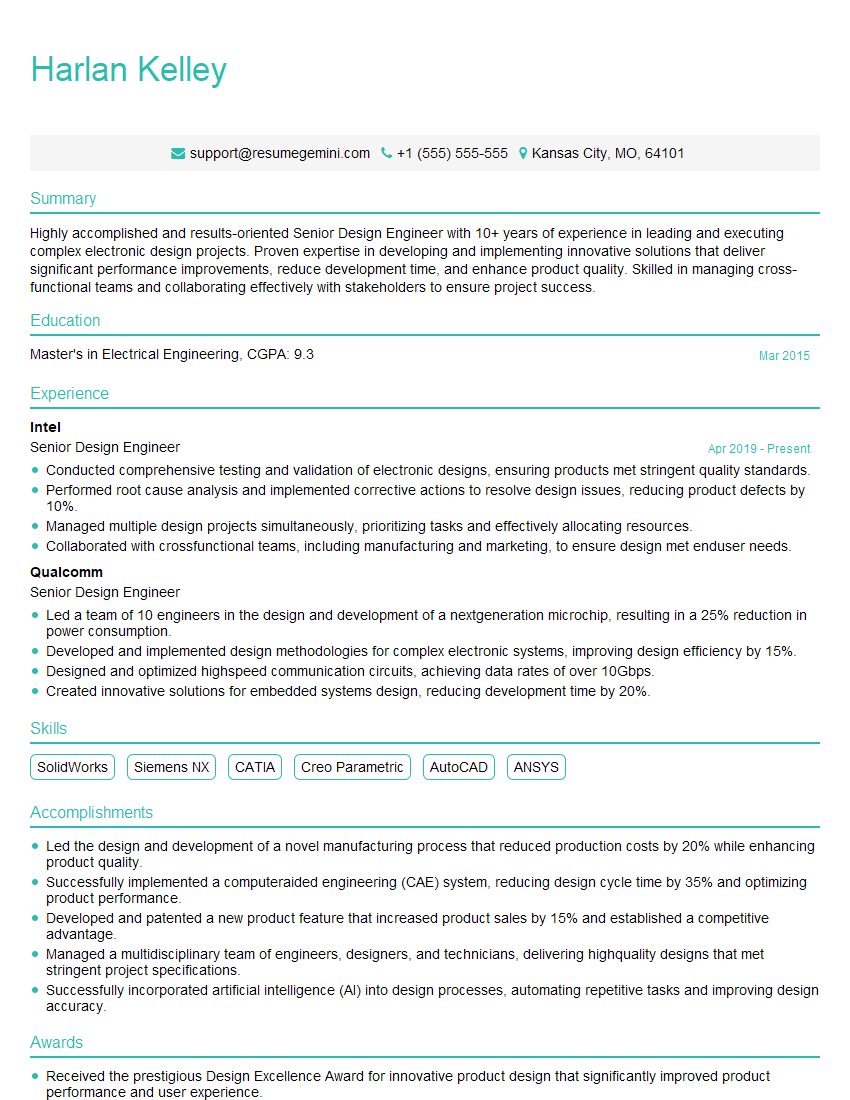

Next Steps

Mastering Electrical Engineering Design Principles and Standards (IEC, NEC) is crucial for career advancement, opening doors to specialized roles and leadership opportunities. A strong understanding of these standards demonstrates competence and commitment to safety. To enhance your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Electrical Engineering Design Principles and Standards (IEC, NEC) are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?