Cracking a skill-specific interview, like one for Knowledge of Painting Materials and Equipment, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Knowledge of Painting Materials and Equipment Interview

Q 1. What are the key differences between acrylic, latex, and oil-based paints?

The key differences between acrylic, latex, and oil-based paints lie primarily in their binder (the component that holds the pigment together), drying time, and cleaning solvents.

- Acrylic paints: These use acrylic polymers as their binder. They are water-based, dry quickly, are relatively low-odor, and clean up easily with soap and water. They are versatile and suitable for various surfaces. Think of them as the ‘everyday’ choice for many DIY and professional projects.

- Latex paints: Often used interchangeably with acrylics, latex paints also have a water-based formula, using synthetic polymers as a binder. They’re known for their durability and are common in interior and exterior house paints. They too clean up easily with water. The differences between acrylic and latex are often subtle in practical terms for the average user.

- Oil-based paints: These use drying oils like linseed oil or tung oil as their binder. They dry much slower than acrylic or latex paints, offering a longer working time, which artists often prefer. They have a richer, smoother finish and are known for their durability, particularly on exterior surfaces and trim. However, they require solvents like mineral spirits for cleanup, which are more hazardous.

In short: Acrylics are quick-drying and water-cleanable, making them user-friendly. Latex paints offer excellent durability. Oil paints offer longer working time and a richer finish, but require more caution in handling.

Q 2. Explain the importance of proper surface preparation before painting.

Proper surface preparation is paramount to a successful paint job. It ensures the paint adheres properly, preventing peeling, chipping, and providing a smooth, even finish. Think of it like preparing the ground before planting a garden – you wouldn’t just toss seeds onto rocky, un-tilled soil.

- Cleaning: The surface must be thoroughly cleaned to remove dirt, grease, mildew, or any loose material. A power washer might be appropriate for exterior surfaces while a simple wash with soap and water is adequate for interior walls.

- Repairing: Any cracks, holes, or imperfections need to be filled and sanded smooth using appropriate fillers and putties. This is crucial for a uniform finish.

- Priming: Priming acts as a bonding agent between the surface and the paint, improving adhesion and preventing bleed-through (where underlying colors or stains show through the new paint). Primer choice depends on the surface (wood, metal, etc.).

- Sanding: After filling and priming, sanding smooths out any imperfections, creating an even surface for painting. This prevents the final coat from showing irregularities.

Skipping these steps is a recipe for disaster. A poorly prepared surface will lead to a poorly executed paint job that might require repainting sooner than expected.

Q 3. Describe different methods of paint application (e.g., brush, roller, spray). What are the pros and cons of each?

Different paint application methods offer varied results and suit different projects. The choice depends on the surface area, desired finish, and skill level.

- Brushes: Offer excellent control and are ideal for detailed work, trim, or smaller areas. They can create textured finishes, but require more time and effort than other methods. Cleaning requires appropriate solvents (water for water-based paints, mineral spirits for oil-based paints).

- Rollers: Efficient for large, flat surfaces like walls. They provide a more even finish than brushes, and speed up the process significantly. Different nap thicknesses (the length of the fibers) are available for different surface textures.

- Sprayers: Ideal for large projects or surfaces needing a very even finish. Sprayers offer a fast application, but require careful preparation (masking, drop cloths) to prevent overspray. They can also be more expensive to purchase. Cleaning varies depending on the sprayer type and paint used.

For example, a brush would be perfect for painting intricate details on furniture, while a roller is efficient for painting a large room. A sprayer might be the best choice for a fence or car.

Q 4. How do you choose the appropriate paint type for a specific substrate (e.g., wood, metal, drywall)?

Choosing the right paint for a substrate is crucial for longevity and appearance. Different surfaces have unique properties that require specific paint formulations.

- Wood: Typically uses either oil-based or acrylic paints, sometimes requiring a wood primer to enhance adhesion and prevent the wood grain from showing through. Oil paints tend to offer better protection against moisture.

- Metal: Requires a rust-inhibiting primer, particularly for outdoor use, followed by an appropriate topcoat (oil-based or acrylic). The choice between oil-based or acrylic for the top coat depends on factors like the location and whether flexibility is needed for expansion/contraction.

- Drywall: Interior drywall usually uses latex or acrylic paints designed for interior walls. The type will depend on factors such as the level of sheen desired.

Ignoring these material requirements can lead to paint failure – peeling, blistering, or discoloration, necessitating costly repainting.

Q 5. What are the safety precautions associated with using different types of paint and solvents?

Safety is paramount when working with paints and solvents. Proper ventilation is critical in all cases to avoid inhaling fumes. Always read the manufacturer’s safety data sheet (SDS) for specific precautions.

- Ventilation: Work in well-ventilated areas or use respirators, especially when working with oil-based paints or solvents. Open windows and doors, and use fans to circulate air.

- Eye Protection: Wear safety glasses or goggles to prevent paint or solvent splashes from entering your eyes.

- Gloves: Wear appropriate gloves to protect your skin from irritation or chemical exposure. Nitrile gloves are generally a good choice.

- Clothing: Wear old clothes that you don’t mind getting paint on. Protective clothing is important when working with harsh chemicals.

- Disposal: Dispose of paint and solvents properly according to local regulations. Never pour paint down the drain.

Failing to follow these precautions can lead to serious health issues, including respiratory problems, skin irritation, and eye damage.

Q 6. Explain the concept of paint viscosity and its impact on application.

Paint viscosity refers to its thickness or flow. It significantly impacts the application process and the final finish.

High viscosity paint is thick and flows slowly, ideal for creating textured effects or for vertical surfaces where sagging is a concern. It requires more effort to apply, however.

Low viscosity paint is thin and flows easily, covering large areas quickly, but may be prone to sagging on vertical surfaces or dripping. It might require multiple coats.

The appropriate viscosity can be adjusted by adding thinners or extenders (specific to the paint type). For example, adding water to water-based paint reduces viscosity, while mineral spirits thin oil-based paints. Incorrect viscosity can result in an uneven finish, brush strokes showing, or dripping.

Q 7. How do you determine the correct amount of paint needed for a project?

Determining the correct paint quantity prevents waste and ensures you have enough for the job. Several factors must be considered.

- Surface area: Calculate the total area to be painted (length x width x height for walls, etc.).

- Number of coats: Most projects require at least two coats. Factor this into the calculation.

- Paint coverage: Check the paint can for coverage per gallon or liter – usually expressed as square footage per gallon. This is a manufacturer’s estimate, and conditions may vary slightly.

- Material absorption: Highly porous surfaces (like untreated wood) may absorb more paint than smooth surfaces (like primed drywall).

A simple calculation: Total surface area (in square feet) x number of coats / paint coverage (square feet per gallon) = gallons needed. It’s always better to slightly overestimate to avoid running short. Consider purchasing a small sample size for testing or a smaller area before purchasing full quantities.

Q 8. Describe different types of primers and their uses.

Primers are essential coatings applied before painting to prepare the surface and enhance paint adhesion, durability, and appearance. Different primers cater to specific needs.

- Oil-based primers: These offer excellent adhesion to various surfaces, including wood and metal, and are often used for surfaces that require a strong barrier against moisture. They are durable but require longer drying times and may require mineral spirits for cleanup.

- Acrylic primers: Water-based acrylic primers are user-friendly, low-odor, and easier to clean up with soap and water. They’re suitable for interior and exterior applications on various surfaces, such as drywall and wood. They are generally less durable than oil-based primers.

- Sheen primers: Primers come in various sheens (e.g., matte, satin, gloss). Matte primers are ideal for hiding imperfections, while glossy primers provide a smoother surface for the top coat.

- Specialty primers: These are designed for specific substrates or problem areas. For example, stain-blocking primer prevents bleed-through of stains from wood, and alkyd primers offer exceptional adhesion to metallic surfaces.

- Universal primers: These are designed to work on a wide variety of surfaces. While convenient, they may not be as effective as a specialized primer for a particular surface.

Choosing the right primer depends entirely on the surface being painted and the type of paint being used. For instance, an oil-based primer might be ideal for a metal gate that will be exposed to harsh weather conditions, while an acrylic primer would suffice for an interior wall.

Q 9. What are common paint defects and how are they prevented?

Paint defects can ruin a project’s aesthetic appeal and even compromise its durability. Knowing how to prevent them is key.

- Lap marks: Uneven paint application, often caused by applying too much paint in one area or failing to blend wet edges. Prevention: Use thin, even coats and maintain a wet edge.

- Brush strokes: Visible brush marks in the final paint finish. Prevention: Use appropriate brushes, thin the paint slightly (if needed), and use smooth, even strokes, blending thoroughly.

- Roller marks: Similar to brush strokes, but caused by the roller. Prevention: Use a high-quality roller with an appropriate nap for the surface texture.

- Sagging: Paint dripping or sagging from the surface. Prevention: Apply thin coats and avoid overloading the brush or roller.

- Orange peel: A textured finish caused by incorrect application or spray equipment issues. Prevention: Maintain a consistent distance from the surface when spraying, and ensure the paint has the correct viscosity.

- Color variations: Differences in color tones within a single coat or between coats. Prevention: Thoroughly mix the paint before application and use the same paint batch for the entire project.

Proper surface preparation, such as cleaning, sanding, and priming, significantly reduces the chances of paint defects.

Q 10. Explain the process of color matching.

Color matching involves replicating a specific color using available paint pigments. This can be done manually or with a color matching system.

Manual color matching: Requires experience and relies on the painter’s ability to mix pigments to achieve the desired shade. It’s often done by visually comparing the mixed color to the target color.

Computerized color matching systems: These systems use spectrophotometers to measure the color of the target and then calculate the appropriate pigment mixture. They are more accurate and efficient, especially for complex colors. A sample of the target color is scanned, and the system provides the exact formula for creating that color using the available paints.

In both methods, careful and precise measurement and mixing are crucial. Even minor variations in pigment amounts can affect the final color.

For example, if you’re matching a specific shade of blue from a fabric swatch, a computerized system could analyze the swatch and provide the precise amounts of cyan, blue, and possibly other pigments needed to achieve the closest possible match in your chosen paint base.

Q 11. How do you deal with paint spills and cleanup?

Dealing with paint spills effectively requires prompt action and the right materials.

- Immediate action: Absorb the spill immediately using absorbent materials like kitty litter, sawdust, or absorbent cloths. Avoid spreading the spill.

- Safe disposal: Dispose of the absorbed paint and materials according to local regulations. Never pour paint down the drain.

- Cleaning tools: Clean brushes, rollers, and other equipment immediately. Use appropriate solvents (e.g., mineral spirits for oil-based paints, water for water-based paints).

- Hard surfaces: For spills on hard surfaces, scrape off excess paint and clean the area thoroughly with soap and water or an appropriate solvent.

- Carpet and fabrics: Spills on carpet or fabrics should be treated as soon as possible, ideally with a specialized carpet cleaner or by blotting with clean cloths to prevent staining.

Always wear gloves and protective eyewear during cleanup to prevent skin and eye irritation. Proper ventilation is also important, especially when working with solvents.

Q 12. What are the different types of paint finishes (e.g., gloss, satin, matte)?

Paint finishes determine the sheen and overall look of the painted surface. The level of gloss influences light reflection and the appearance of imperfections.

- Flat/Matte: A non-reflective, low-sheen finish that minimizes the appearance of imperfections; however, it is more prone to staining and scuffs. Ideal for ceilings and low-traffic areas.

- Eggshell: A slightly more reflective finish than matte, offering a bit more durability and washability. Good for walls in low-traffic areas.

- Satin: A semi-gloss finish that provides increased durability and washability, while still maintaining a soft, elegant look. Suitable for trim, doors, and areas requiring more frequent cleaning.

- Semi-gloss: More durable and washable than satin, reflecting more light and highlighting imperfections. Commonly used for trim, doors, and areas prone to moisture.

- Gloss: The highest sheen finish, providing maximum durability and washability, but also highlighting surface flaws. Best suited for areas needing high durability and easy cleaning, such as kitchen cabinets or trim.

Choosing the right finish depends on the area being painted, the desired aesthetic, and the level of durability and washability needed.

Q 13. What is the difference between enamel and lacquer?

Both enamel and lacquer are hard, durable finishes, but they differ in their composition, drying time, and application.

- Enamel paints: Typically oil-based, they dry slowly (often hours or even days), creating a tough, durable finish. They are more resistant to scratches and wear than lacquer. Cleanup requires mineral spirits or other solvents.

- Lacquer paints: Usually fast-drying (minutes to hours), lacquer paints are either nitrocellulose or acrylic lacquer. They provide a hard, smooth finish but are generally less durable than enamels. Lacquer is often preferred for quick drying applications and is easily cleaned with lacquer thinner.

Enamels offer superior durability, while lacquer is often chosen for its fast drying time and ease of application, making it suitable for projects where a quick turnaround is needed.

Q 14. Explain the importance of proper ventilation when working with paints.

Proper ventilation when working with paints is crucial for both health and safety reasons. Paints, especially oil-based paints and primers, release volatile organic compounds (VOCs), which can cause a range of health problems, including headaches, nausea, dizziness, and respiratory issues. These VOCs can be very harmful over prolonged exposure. Inhaling high concentrations of VOCs can lead to serious medical complications.

Always work in a well-ventilated area. Open windows and doors to allow fresh air circulation. For enclosed spaces, using exhaust fans or respirators with appropriate cartridges might be necessary. If working indoors, consider using low or zero-VOC paints to minimize health risks. Never work in poorly ventilated areas. This applies to both small confined spaces like closets and large spaces like garages.

Protecting yourself and others from paint fumes is of paramount importance. Always follow the safety precautions outlined on the paint product’s label.

Q 15. How do you handle different sheen levels in a painting project?

Sheen levels in paint refer to the amount of light reflected from the painted surface. They range from flat (matte) to high-gloss, each offering a different aesthetic and practical effect. Choosing the right sheen is crucial for the overall look and durability of the project.

- Flat/Matte: Reflects very little light, ideal for hiding imperfections on walls but less durable and harder to clean. Think of a softly textured wall in a bedroom.

- Eggshell: Slightly more sheen than matte, offering better washability while still hiding minor imperfections. Good for living rooms or hallways.

- Satin: A moderate sheen, providing good washability and durability. A popular choice for kitchens and bathrooms.

- Semi-gloss: More sheen than satin, very durable and easy to clean. Often used on trim, doors, and window frames.

- High-gloss: Reflects the most light, very durable and easy to clean, but shows imperfections easily. Best for areas needing high washability, like kitchen cabinets.

In a project, I’d select sheen based on the surface, the desired aesthetic, and the level of durability needed. For instance, I’d use a semi-gloss paint on bathroom trim for its durability and ease of cleaning, while opting for an eggshell on living room walls for a softer look and better imperfection hiding.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the role of a paint thinner or solvent?

A paint thinner, or solvent, is a liquid that dissolves or dilutes paint, making it easier to apply and clean up. The choice of thinner depends entirely on the type of paint used.

- Oil-based paints: Require mineral spirits or turpentine to thin and clean brushes and equipment.

- Water-based (latex) paints: Use water as their thinner and cleaner. This makes them significantly more environmentally friendly.

Using the correct thinner is crucial. Using the wrong thinner can damage the paint film, resulting in uneven application or poor adhesion. For example, using water to thin oil-based paint will result in a clumpy, unusable mess. Safety is paramount when handling thinners; always work in a well-ventilated area and wear appropriate personal protective equipment (PPE).

Q 17. Describe the different types of brushes and rollers and their applications.

Different brushes and rollers are designed for specific applications, impacting the final finish. The choice depends on the surface, paint type, and desired texture.

- Brushes:

- China bristle (natural): Holds more paint, ideal for oil-based paints, provides a smooth finish.

- Synthetic bristle (nylon or polyester): Suitable for water-based paints, various stiffness levels for different applications.

- Angle sash brushes: Excellent for cutting in around edges and details.

- Wall brushes: Designed for covering large areas efficiently.

- Rollers:

- Short-nap rollers: For smooth surfaces, producing a smooth finish. Think drywall.

- Medium-nap rollers: Suitable for slightly textured surfaces. Think stucco.

- Long-nap rollers: For heavily textured surfaces, allowing good paint penetration. Think rough brick.

- Foam rollers: Good for smooth surfaces and even coats of varnish or sealer.

For instance, I’d use a high-quality china bristle brush for detailed oil-based trim work, while a large roller with a medium nap would be efficient for painting textured walls with latex paint.

Q 18. How do you maintain and clean painting equipment?

Proper maintenance and cleaning are crucial to extend the lifespan of painting equipment. This also helps prevent cross-contamination and ensures consistent results in future projects.

- Brushes: Immediately after use, clean brushes thoroughly with the appropriate thinner (water for latex, mineral spirits for oil-based). Shape the bristles and store brushes bristle-side up to prevent damage.

- Rollers: Remove excess paint by rolling the roller back and forth on a piece of cardboard or plastic. Rinse thoroughly with water (for latex) or thinner (for oil-based) and allow to dry completely before storage.

- Trays and other equipment: Wash thoroughly with soap and water, or thinner if necessary. Allow to dry completely.

Proper cleaning prevents paint from hardening in the bristles or roller cover, ruining the equipment. I always make sure to follow manufacturer’s cleaning recommendations for specific products.

Q 19. What are the environmental concerns related to paint disposal?

Environmental concerns surrounding paint disposal are significant due to the presence of volatile organic compounds (VOCs) and heavy metals in some paints. Improper disposal can contaminate soil and water sources, harming both the environment and human health.

- VOCs: Contribute to air pollution and can have adverse health effects. Low-VOC or zero-VOC paints are environmentally preferable.

- Heavy metals: Some paints contain heavy metals like lead, which are toxic and persist in the environment. Proper disposal is crucial to prevent contamination.

- Disposal methods: Check with your local waste management authority for regulations on paint disposal. Many areas offer hazardous waste collection centers where paints can be disposed of safely.

Always try to minimize waste by accurately estimating paint needs and using appropriate techniques to prevent spills and drips. Proper disposal is not only environmentally responsible but is also legally mandated in many areas.

Q 20. Describe your experience with different types of spray equipment.

My experience encompasses various spray equipment, each suited for different applications and project scales.

- Airless sprayers: Ideal for large-scale projects like exterior house painting. They apply paint efficiently but require careful technique to avoid overspray.

- HVLP (High Volume Low Pressure) sprayers: Provide finer atomization, leading to less overspray and a smoother finish. They are excellent for detailed work and interior projects.

- Aerosol cans: Convenient for small touch-up jobs or hard-to-reach areas but less efficient for large surfaces. Cleanup is minimal.

The choice depends on factors like project size, desired finish, and budget. For example, I would use an airless sprayer for a large exterior painting job, opting for an HVLP sprayer for a finer finish on interior trim. Safety precautions such as wearing a respirator are essential when using any spray equipment.

Q 21. Explain the concept of VOCs in paints.

VOCs, or Volatile Organic Compounds, are organic chemical compounds that easily evaporate at room temperature. Many paints contain VOCs as solvents or binders. These compounds contribute to smog formation and can have negative health effects, including respiratory problems and eye irritation. The level of VOCs is usually indicated on the paint can.

Regulations regarding VOCs in paints are increasingly stringent to protect both the environment and public health. Choosing low-VOC or zero-VOC paints is an environmentally responsible choice and often a healthier option for both the painter and occupants of the painted space.

For example, many modern water-based paints have significantly lower VOCs than traditional oil-based paints. Always check the label for VOC content before purchasing paint.

Q 22. How do you address challenges with adhesion in painting?

Adhesion problems in painting are a common frustration, often resulting in peeling or flaking paint. Successfully addressing this hinges on proper surface preparation and choosing the right paint for the substrate. Think of it like trying to stick a sticker to a greasy surface – it won’t hold!

- Surface Cleaning: Thorough cleaning is paramount. This involves removing dirt, grease, mildew, old paint (if flaking), and any other contaminants. Power washing, degreasing agents, and scraping may be necessary depending on the surface.

- Surface Repair: Any cracks, holes, or imperfections in the surface must be repaired and smoothed before painting. This often involves filling with spackle or patching compounds, sanding, and priming.

- Primer Selection: A primer acts as a bonding agent between the surface and the topcoat. Choosing the right primer is crucial. For instance, an oil-based primer is often better for glossy surfaces than a water-based one. Always check the primer’s compatibility with both the substrate and the topcoat paint.

- Paint Selection: The type of paint needs to be suitable for the surface and environmental conditions. Exterior paints are formulated for UV resistance and weatherability, which are crucial for good adhesion.

- Application Technique: Applying thin, even coats allows for better penetration and adhesion. Over-application can lead to cracking and peeling.

For example, I once worked on a project where previous paint was poorly adhered due to insufficient surface preparation. We had to completely scrape off the old paint, power wash the surface, and apply a high-quality bonding primer before applying the final coat. The result was a perfectly adhered finish that lasted for years.

Q 23. What is the importance of using quality painting materials?

Using quality painting materials is not just about aesthetics; it directly impacts the longevity, durability, and overall success of a project. Think of it as building a house – you wouldn’t use substandard materials, would you?

- Better Coverage: High-quality paints generally require fewer coats, saving time and money.

- Increased Durability: Superior paints offer better resistance to fading, chipping, cracking, and peeling, leading to a longer-lasting finish.

- Improved Finish: Premium paints produce smoother, more even surfaces with better flow and leveling properties.

- Reduced VOCs: Many high-quality paints have lower volatile organic compound (VOC) content, making them safer for both the painter and the environment.

- Warranty and Support: Reputable paint manufacturers often provide warranties, ensuring a level of quality and recourse if problems arise.

In my experience, using inferior paints often leads to costly rework. For example, I once encountered a project where the client had used a very cheap exterior paint; it faded dramatically within a year, requiring a complete repaint.

Q 24. Describe your experience with different types of protective coatings.

My experience encompasses a broad range of protective coatings, each with unique properties and applications.

- Epoxies: Excellent for floors, offering durability and chemical resistance. I’ve used them in industrial settings and garages where heavy-duty protection is needed.

- Polyurethanes: Versatile coatings providing exceptional wear resistance and UV protection. They’re ideal for furniture, wood decks, and other applications requiring durability and a beautiful finish.

- Acrylics: Water-based and environmentally friendly, acrylics are widely used for interior and exterior applications. They offer good adhesion, flexibility, and a wide range of colors.

- Alkyds (Oil-based): Known for their durability and water resistance, alkyds are often used on trim and doors, offering a classic, high-gloss finish. However, they have higher VOCs.

- Specialty Coatings: This includes things like rust-inhibiting primers, anti-graffiti coatings, and fire-retardant paints. I’ve used these in specialized projects requiring unique protection.

Choosing the right coating depends entirely on the project’s requirements. For example, selecting a polyurethane coating for a wood deck ensures its protection from harsh weather conditions and prevents premature deterioration.

Q 25. How do you ensure a smooth and even paint finish?

Achieving a smooth and even paint finish requires meticulous preparation and application.

- Surface Preparation: As emphasized before, proper surface preparation is key. This includes cleaning, sanding, priming, and filling any imperfections.

- Proper Mixing: Thoroughly mix the paint according to the manufacturer’s instructions to ensure even pigment distribution.

- Thin Coats: Apply thin, even coats, allowing each coat to dry completely before applying the next. This minimizes runs, sags, and brush marks.

- Appropriate Tools: Use high-quality brushes, rollers, and spray equipment appropriate for the surface and paint type. Proper tool maintenance also plays a significant role.

- Technique: Employ consistent strokes with even pressure. For rollers, use a wet-edge technique, overlapping each stroke to avoid visible seams.

- Sanding (if needed): Between coats, lightly sanding can help smooth out imperfections and create a better surface for the subsequent coat.

Imagine painting a canvas – you wouldn’t just slap on the paint haphazardly; you’d use delicate strokes to create a smooth, flawless image. The same principle applies to painting walls or any surface.

Q 26. Explain the process of estimating material costs for a painting project.

Estimating material costs accurately is critical for project success. It involves carefully calculating the quantity of each material needed and multiplying by its cost.

- Surface Area Calculation: Begin by precisely measuring the area to be painted. This includes walls, ceilings, trim, and any other surfaces. Remember to account for doors and windows, subtracting those areas.

- Paint Coverage: Check the paint manufacturer’s specifications for coverage per gallon or liter. This will give you an estimate of how many gallons you need per coat.

- Number of Coats: Determine the number of coats required based on the surface condition, paint type, and desired finish. Primers always count as one coat, and sometimes a second coat of primer is necessary.

- Material List: Compile a comprehensive list of all materials: paint, primer, brushes, rollers, drop cloths, painter’s tape, sandpaper, etc.

- Pricing: Obtain price quotes from various suppliers to compare costs and ensure you’re getting the best value. Don’t forget to factor in sales taxes.

- Contingency: Always add a contingency factor (typically 10-15%) to account for unexpected needs or overages.

I always create a detailed spreadsheet to track all material costs, allowing for easy revision and transparency with the client.

Q 27. What are some common problems encountered during the painting process and their solutions?

Many issues can arise during painting. Proactive planning and problem-solving skills are essential.

- Problem: Runs and Sags – Solution: Apply thinner coats, use a suitable paint consistency, and avoid overloading the brush or roller.

- Problem: Brush Marks – Solution: Use a high-quality brush, apply smooth, even strokes, and ensure proper drying time between coats.

- Problem: Uneven Coverage – Solution: Thoroughly mix the paint, apply multiple thin coats, and use a proper application technique.

- Problem: Peeling or Flaking Paint – Solution: Address adhesion problems by proper surface preparation (cleaning, repair, priming) and choosing an appropriate paint for the surface.

- Problem: Color Variations – Solution: Purchase enough paint from the same batch to avoid color discrepancies. Always mix thoroughly.

For instance, I once encountered a project where lap marks (visible streaks where coats overlapped) were a problem. We corrected this by using a better quality roller with a longer nap, which helped produce a smoother finish.

Q 28. Describe your experience working with specialized paint systems (e.g., powder coating, automotive paints).

My experience extends to specialized paint systems, requiring specific knowledge and techniques.

- Powder Coating: I’ve worked with powder coating extensively, particularly on metal furniture and automotive parts. This electrostatically applied coating provides excellent durability, scratch resistance, and a wide range of color options. Proper surface preparation is critical to ensure adhesion. It involves a multi-step process including cleaning, degreasing, and pre-treatments.

- Automotive Paints: I have experience with automotive refinishing, which requires precision and attention to detail. This includes color matching, meticulous application, and careful curing to achieve a factory-like finish. Different types of clear coats provide varying levels of gloss and protection. Using a spray gun is essential for an even and professional finish.

Working with these systems requires specialized equipment and safety precautions. For example, powder coating requires an oven for curing, while automotive painting often involves using respirators due to the VOCs in the paints and clear coats.

Key Topics to Learn for Knowledge of Painting Materials and Equipment Interview

- Paint Types and Properties: Understanding the characteristics of various paint types (e.g., acrylic, oil, water-based, etc.), their suitability for different surfaces and applications, and their drying times. Consider the impact of pigment concentration and binder type on the final result.

- Surface Preparation: Explore techniques for preparing surfaces for painting, including cleaning, priming, and the selection of appropriate primers based on the substrate and paint type. This includes understanding the importance of adhesion and preventing future problems.

- Application Techniques: Mastering various painting techniques such as brushing, rolling, spraying, and specialized methods. Analyze the impact of each technique on the final finish and efficiency.

- Equipment Selection and Maintenance: Familiarize yourself with different brushes, rollers, sprayers, and other tools. Understand their appropriate uses, cleaning procedures, and proper storage to ensure longevity.

- Health and Safety: Understand and apply relevant safety precautions when handling painting materials and equipment, including proper ventilation, personal protective equipment (PPE), and disposal of hazardous waste.

- Color Theory and Mixing: Gain a fundamental understanding of color theory and how to mix colors accurately to achieve desired shades and tints. Practice color matching techniques.

- Troubleshooting Common Issues: Develop the ability to identify and resolve common painting problems such as uneven application, brushstrokes, drips, and poor adhesion. This involves understanding the root causes and appropriate solutions.

- Cost Estimation and Material Selection: Learn how to estimate material costs based on project requirements and select appropriate materials considering budget constraints and project specifications.

Next Steps

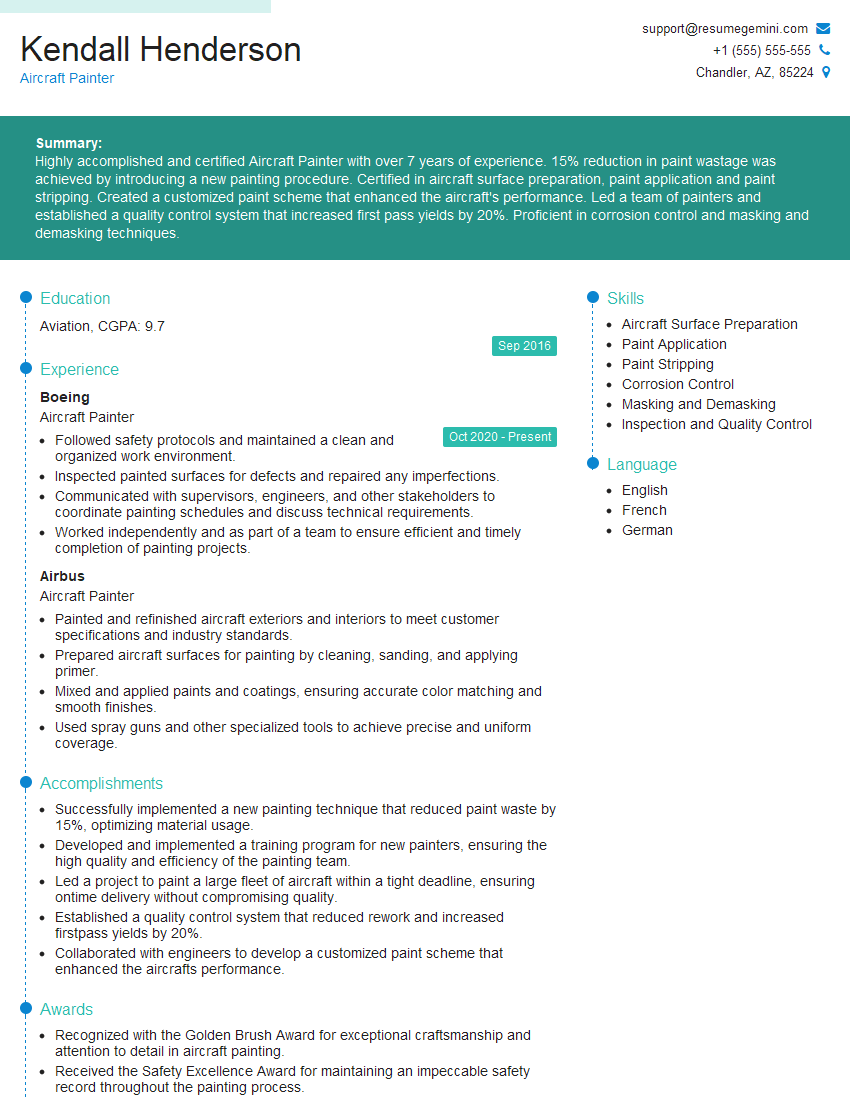

Mastering knowledge of painting materials and equipment is crucial for career advancement in the painting and decorating industry, opening doors to higher-paying roles and more challenging projects. A strong understanding of these topics showcases your professionalism and expertise to potential employers.

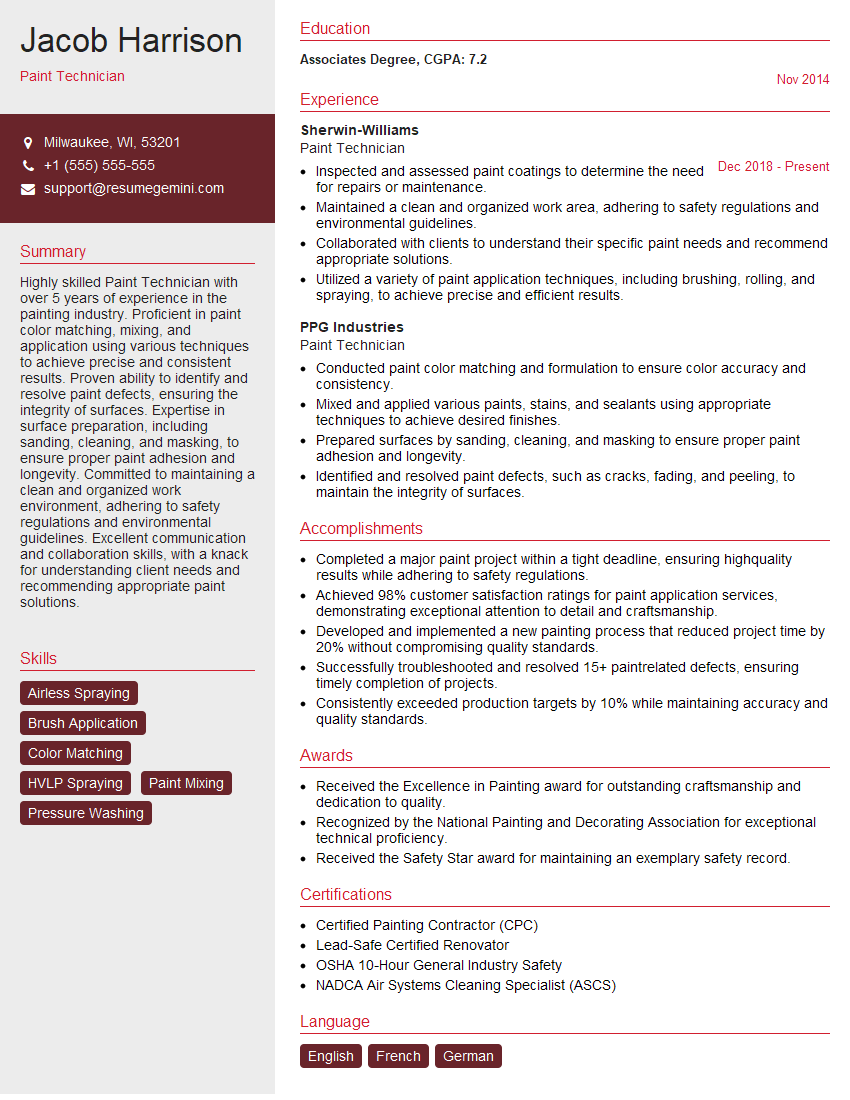

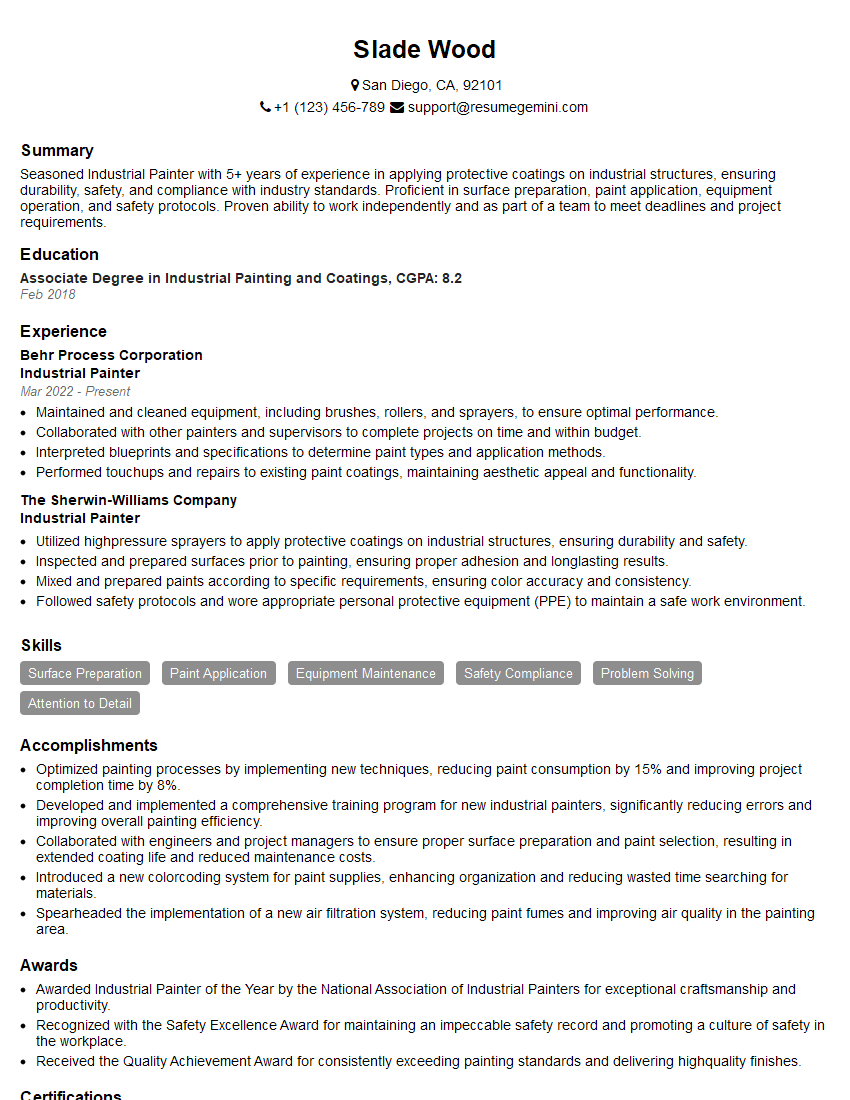

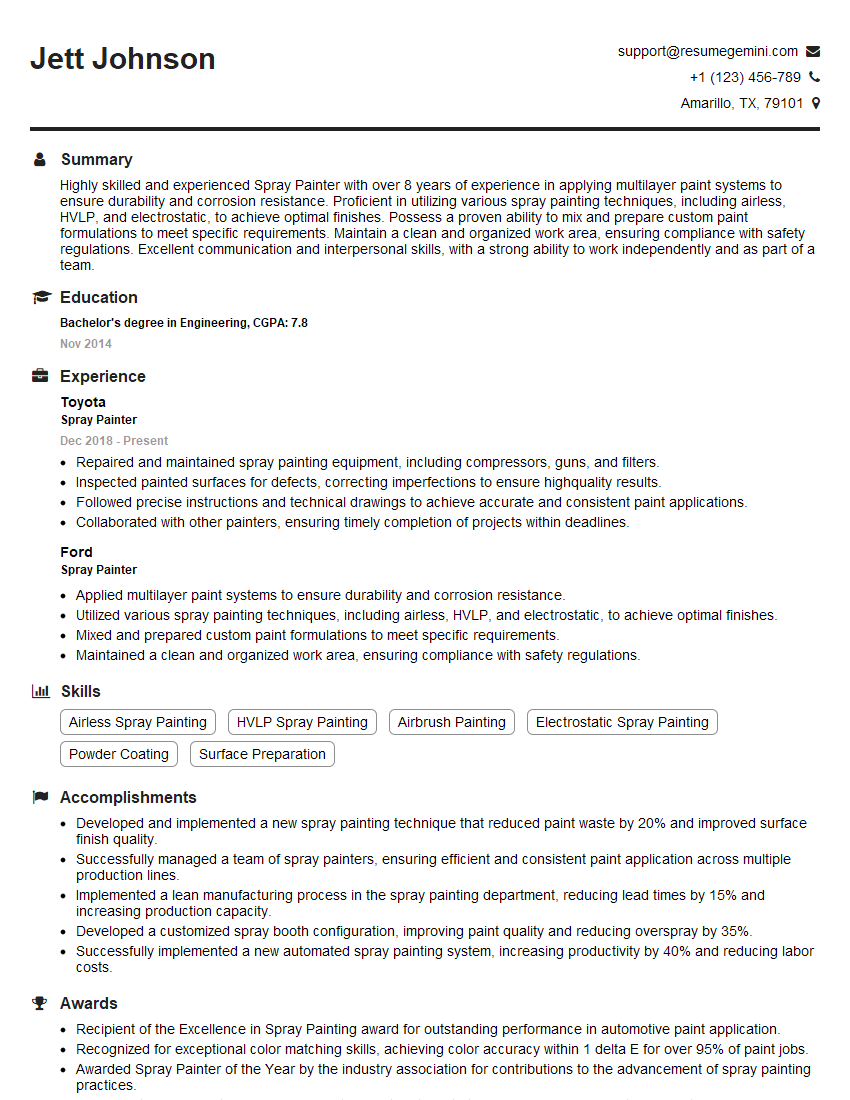

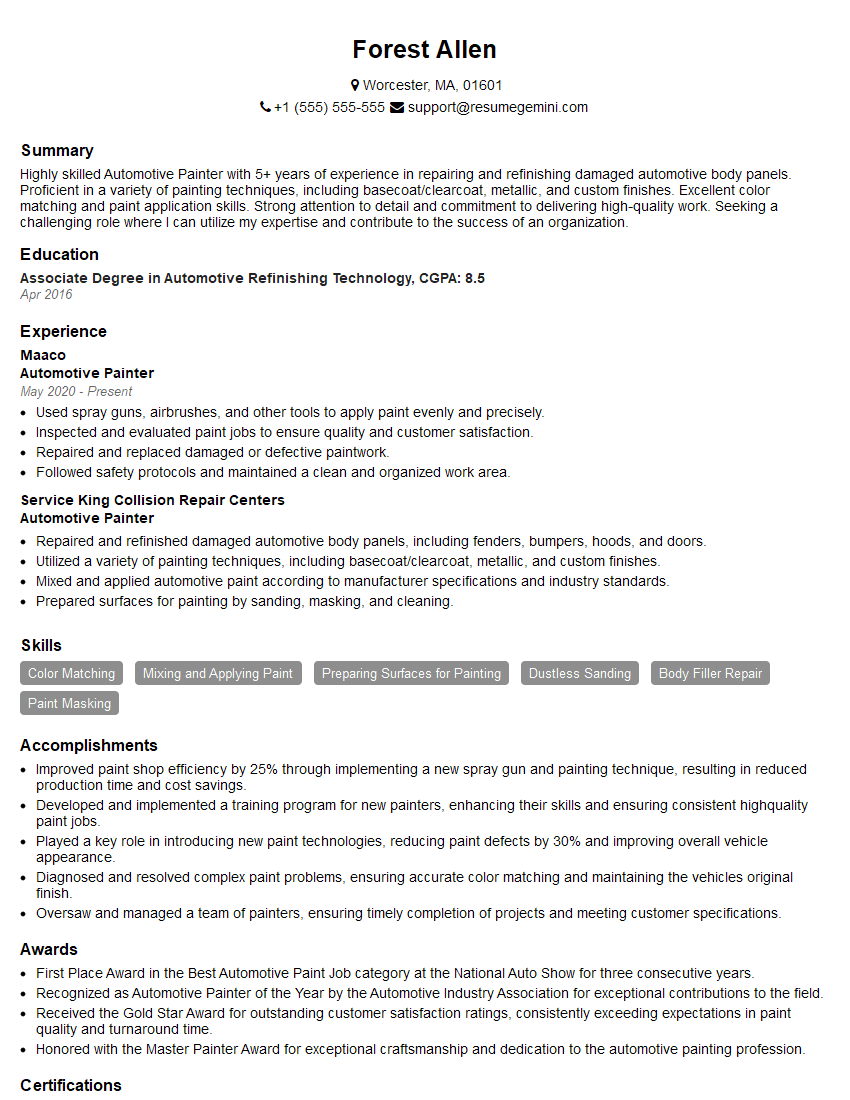

To maximize your job prospects, it’s vital to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini can help you build a professional and impactful resume tailored to the specific requirements of painting and decorating jobs. Leverage ResumeGemini’s resources to craft a resume that showcases your expertise in Knowledge of Painting Materials and Equipment. Examples of resumes tailored to this field are available to further guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Dear Sir/Madam,

Do you want to become a vendor/supplier/service provider of Delta Air Lines, Inc.? We are looking for a reliable, innovative and fair partner for 2025/2026 series tender projects, tasks and contracts. Kindly indicate your interest by requesting a pre-qualification questionnaire. With this information, we will analyze whether you meet the minimum requirements to collaborate with us.

Best regards,

Carey Richardson

V.P. – Corporate Audit and Enterprise Risk Management

Delta Air Lines Inc

Group Procurement & Contracts Center

1030 Delta Boulevard,

Atlanta, GA 30354-1989

United States

+1(470) 982-2456