Cracking a skill-specific interview, like one for Instrumentation and Control System Design for New Projects, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Instrumentation and Control System Design for New Projects Interview

Q 1. Explain the difference between a PID controller and a cascade control system.

A PID controller and a cascade control system are both used to regulate process variables, but they differ significantly in their structure and application. A PID (Proportional-Integral-Derivative) controller is a single feedback loop that uses proportional, integral, and derivative terms to adjust the manipulated variable based on the error between the setpoint and the measured process variable. Think of it like a thermostat – it continuously adjusts the heating/cooling to maintain a desired temperature.

In contrast, a cascade control system utilizes two or more nested control loops. The primary or outer loop controls a major process variable (e.g., reactor temperature), while a secondary or inner loop controls a variable that directly affects the primary loop (e.g., the flow rate of the cooling jacket). The inner loop acts as a ‘slave’ to the outer loop, ensuring precise control of the intermediary variable which in turn aids in better control of the main variable. This is like a car cruise control – the outer loop maintains speed, while an inner loop manages the engine’s throttle to achieve that speed precisely.

In essence: A PID controller is a single-loop system addressing one process variable, while a cascade control system employs multiple nested loops for more accurate and responsive control, especially when dealing with variables that have significant interaction.

Q 2. Describe your experience with PLC programming (specific brands preferred).

I have extensive experience in PLC programming, primarily with Siemens TIA Portal (S7-1200 and S7-1500) and Rockwell Automation’s Studio 5000 Logix Designer (ControlLogix and CompactLogix) platforms. My experience ranges from basic ladder logic programming to advanced functionalities such as motion control, data acquisition, and networking. For example, in a recent project involving a bottling line, I used Siemens TIA Portal to develop a PLC program that controlled the entire process, from bottle filling and capping to labeling and palletizing. This involved extensive use of timers, counters, and analog input/output modules to ensure precise coordination of different machines. In another project using Rockwell Automation’s Studio 5000, I implemented a complex safety system using the integrated safety features of the ControlLogix PLC to meet stringent safety standards in a food processing facility.

I’m proficient in using Structured Text (ST) and Function Block Diagram (FBD) programming languages along with Ladder Logic. I also have experience with HMI programming, designing user interfaces for easy operation and monitoring of the process. My approach always emphasizes code modularity, reusability, and clear documentation for maintainability and future scalability.

Q 3. What are the common types of industrial sensors and their applications?

Industrial sensors are the eyes and ears of a control system, providing critical data for process monitoring and control. There are many types, each with specific applications:

- Temperature Sensors: Thermocouples, RTDs (Resistance Temperature Detectors), and thermistors measure temperature in various ranges and applications, from ovens and furnaces to chemical reactors.

- Pressure Sensors: Strain gauge pressure transducers, piezoelectric sensors, and capacitive sensors are used to measure pressure in pipelines, vessels, and hydraulic systems.

- Flow Sensors: Coriolis flow meters, ultrasonic flow meters, and differential pressure flow meters measure flow rates of liquids and gases in various industrial processes.

- Level Sensors: Ultrasonic level sensors, radar level sensors, and float-type level sensors measure liquid levels in tanks, reservoirs, and process vessels.

- pH Sensors: These measure the acidity or alkalinity of solutions in chemical processes and wastewater treatment.

- Proximity Sensors: Inductive, capacitive, and photoelectric proximity sensors detect the presence or absence of objects without physical contact, often used in robotic systems and conveyor belt monitoring.

- Position Sensors: Encoders and potentiometers measure the position or angular displacement of mechanical components in robotics and motion control systems.

The choice of sensor depends on the specific application, the required accuracy, the environmental conditions, and the cost constraints. For example, a thermocouple might be suitable for high-temperature applications, while a capacitive sensor would be better for detecting non-metallic objects.

Q 4. How do you troubleshoot a malfunctioning control loop?

Troubleshooting a malfunctioning control loop is a systematic process. My approach involves the following steps:

- Identify the problem: Determine the specific symptoms – is the process variable oscillating, drifting, or simply not reaching the setpoint? Is there an alarm condition?

- Gather data: Examine the process data (trends, historical data) to identify patterns or anomalies. Review sensor readings, actuator outputs, and controller outputs.

- Check the sensor and actuator: Verify the sensor readings are accurate and the actuator is functioning correctly. This may involve calibration checks or replacement of faulty components.

- Analyze the control loop: Examine the PID controller settings (proportional gain, integral time, derivative time). Look for signs of instability (e.g., excessive oscillations) or poor performance (e.g., slow response). Are there any saturation issues (actuator at its limits)?

- Check for external factors: Determine if any external factors are affecting the process – for example, changes in raw material quality, environmental conditions, or other interacting control loops.

- Use simulation tools (if available): Simulation can help identify the root cause of the problem by isolating the effects of different components and tuning parameters.

- Implement corrective actions: Based on the analysis, adjust controller parameters, replace faulty components, or make changes to the process itself to resolve the issue.

Throughout this process, meticulous documentation is critical to ensure traceability and facilitate future troubleshooting.

Q 5. Explain the concept of loop tuning and its importance.

Loop tuning is the process of adjusting the PID controller parameters (proportional gain (Kp), integral time (Ti), and derivative time (Td)) to achieve optimal performance of the control loop. The goal is to minimize the error between the setpoint and the measured variable, while minimizing overshoot and oscillations. Think of it as fine-tuning a musical instrument – you adjust the various parameters until you achieve the desired sound.

The importance of loop tuning cannot be overstated. Poorly tuned loops can lead to:

- Excessive overshoot: The process variable surpasses the setpoint significantly before settling.

- Oscillations: The process variable continually fluctuates around the setpoint.

- Slow response: The process takes too long to reach the setpoint.

- Offset: The process variable settles at a value different from the setpoint.

Various methods exist for loop tuning, such as Ziegler-Nichols method and Cohen-Coon method. Modern DCS and PLC systems often provide automated tuning features that simplify the process. However, understanding the underlying principles and the impact of each parameter is essential for effective tuning. Properly tuned loops contribute to improved product quality, increased efficiency, and reduced energy consumption.

Q 6. Describe your experience with DCS systems (specific brands preferred).

My experience with Distributed Control Systems (DCS) includes working extensively with Emerson DeltaV and Honeywell Experion systems. I’ve been involved in the design, commissioning, and maintenance of DCS systems in various industrial settings, including chemical processing plants, oil refineries, and power generation facilities.

With Emerson DeltaV, I’ve worked on projects involving advanced process control (APC) strategies, integrating various field instruments, and developing customized control algorithms. For example, I was part of a team that implemented an APC strategy in a chemical plant to optimize the reactor yield, resulting in significant cost savings. With Honeywell Experion, I have experience with its highly reliable and scalable architecture for large-scale applications. This involved working with advanced operator interfaces and integrating third-party systems.

My experience extends to configuration of the DCS hardware, including I/O modules, communication networks, and operator workstations. I am comfortable working with various communication protocols like Profibus, Modbus, and Foundation Fieldbus.

Q 7. What is SCADA and how does it integrate with PLC and DCS systems?

SCADA (Supervisory Control and Data Acquisition) is a system used for monitoring and controlling industrial processes. It provides a centralized view of the entire process, allowing operators to monitor various parameters, control equipment remotely, and manage alarms. Think of it as a central dashboard displaying the status of multiple components and providing the ability to make adjustments from a central location.

SCADA systems integrate with PLCs and DCSs to collect data from field instruments and actuators. PLCs, being more focused on direct control of machinery and processes, serve as the lower-level controllers, whereas the DCS systems manage the larger-scale process control strategies. SCADA acts as the supervisory layer, gathering data from these lower-level systems and presenting it to the operators. The communication usually happens through industrial networks such as Ethernet/IP, Modbus TCP, or OPC UA.

For example, in a water treatment plant, PLCs might control individual pumps and valves, while a DCS might manage the overall treatment process. A SCADA system would integrate the data from these systems to provide a comprehensive overview of the plant’s performance, allowing operators to monitor water quality parameters, adjust chemical dosages, and respond to alarms.

Q 8. How do you handle instrument calibration and validation?

Instrument calibration and validation are critical for ensuring the accuracy and reliability of measurements in any control system. Calibration involves adjusting an instrument to match a known standard, while validation confirms that the instrument performs as expected within specified tolerances.

My approach involves a multi-step process. First, we establish a calibration schedule based on instrument type, criticality, and manufacturer recommendations. This schedule details the frequency of calibration and the specific procedures to be followed. We utilize traceable standards, ensuring our calibration procedures are themselves calibrated against national or international standards.

Next, a detailed calibration procedure document is created, outlining steps to be taken, acceptance criteria, and responsibilities. After calibration, a certificate is issued documenting the results and indicating whether the instrument passed or failed. This certificate is essential for auditing and regulatory compliance. Validation goes beyond calibration; it focuses on demonstrating that the entire measurement system—including the instrument, its installation, and its interaction with the process—provides accurate and reliable data. This often involves testing under realistic operating conditions.

For example, in a pharmaceutical manufacturing plant, highly accurate temperature sensors are crucial. We’d calibrate these regularly, using certified thermometers as standards, and validate their performance by comparing readings against multiple independent sensors and confirming they fall within predefined acceptance criteria.

Q 9. Explain your understanding of safety instrumented systems (SIS).

Safety Instrumented Systems (SIS) are independent systems designed to protect personnel, equipment, and the environment from hazardous situations. They’re crucial in industries like oil and gas, chemicals, and pharmaceuticals where process failures can lead to catastrophic consequences. An SIS typically includes sensors, logic solvers (like Programmable Logic Controllers – PLCs), and final elements (e.g., emergency shutdown valves).

My understanding encompasses the entire lifecycle of an SIS, from hazard identification and risk assessment to design, implementation, testing, and maintenance. We use techniques like HAZOP (Hazard and Operability Study) and SIL (Safety Integrity Level) determination to define the necessary safety functions and the required performance levels. SIL defines the probability of failure on demand for the SIS; higher SIL levels demand higher reliability.

During design, we ensure functional safety by selecting appropriate hardware and software components, implementing redundancy and fail-safe mechanisms, and rigorously testing the system. Testing involves proof testing (periodically verifying the system’s ability to perform its safety function) and functional safety testing to check the logic and response times of the system. Documentation is paramount; we meticulously maintain safety manuals, drawings, and test reports throughout the SIS lifecycle.

For instance, in an offshore oil platform, an SIS might be designed to automatically shut down a well in case of high pressure. The system’s reliability is critical, as failure could lead to a significant environmental hazard or loss of life.

Q 10. What is your experience with control system design software?

I have extensive experience with various control system design software packages, including Rockwell Automation’s RSLogix 5000, Siemens TIA Portal, and Emerson DeltaV. I’m proficient in using these tools to design, simulate, and commission control systems for diverse applications. My expertise extends to configuring PLCs, designing Human-Machine Interfaces (HMIs), developing control algorithms, and performing simulations to verify the system’s performance.

For example, using RSLogix 5000, I’ve designed complex control logic for a large-scale chemical processing plant, including PID controllers for temperature regulation, sequential control for batch processes, and safety interlocks to prevent hazardous conditions. I leverage simulation capabilities within these platforms to test different scenarios and optimize the system’s performance before deployment. This approach significantly reduces the risk of errors and minimizes commissioning time.

Beyond the core functionality, I also have experience with advanced features like scripting, data logging, and network configuration. Understanding these nuances allows for efficient development, streamlined troubleshooting, and improved overall system performance.

Q 11. Describe a challenging control system design project you worked on and how you overcame the challenges.

One challenging project involved designing the control system for a new wastewater treatment plant. The primary challenge was integrating legacy equipment with modern control technology. The plant had existing pumps, blowers, and other equipment, all with varying communication protocols and control systems. The project required careful planning and a phased approach to ensure minimal disruption during the upgrade.

We started by conducting a thorough assessment of the existing equipment, identifying its capabilities and limitations. Then, we developed a migration strategy, prioritizing the most critical systems for initial integration. We used gateway devices to bridge the communication gaps between the old and new systems, enabling seamless data transfer. We also implemented a robust data acquisition system to monitor the overall performance of the plant, providing real-time data for optimization and troubleshooting.

Another critical aspect was operator training. We developed customized training modules that covered the new control system, its operation, and troubleshooting techniques. This was vital for ensuring a smooth transition and minimizing potential operator errors. Throughout the project, we adhered strictly to industry best practices and regulatory standards. The result was a modernized wastewater treatment plant with improved efficiency, reliability, and reduced operational costs.

Q 12. How do you ensure the safety and reliability of control systems?

Ensuring the safety and reliability of control systems is paramount. My approach integrates several key strategies throughout the entire lifecycle of the system, from design to decommissioning.

Firstly, we use robust design methodologies. This includes adhering to industry standards like IEC 61508 (functional safety) and ISA 84.1 (automated systems), employing redundancy where necessary, and selecting components with high reliability ratings. We perform rigorous testing at each stage, including unit testing, integration testing, and factory acceptance testing (FAT) before installation.

On-site, we conduct site acceptance testing (SAT) and commissioning procedures to verify that the system works as designed in the actual operating environment. We implement comprehensive safety interlocks and alarm systems to protect against hazardous events. Regular maintenance and preventative measures are also crucial. This includes scheduled calibrations, inspections, and software updates to ensure the system remains reliable and safe. Finally, we utilize cybersecurity measures to protect the system from unauthorized access and cyber threats. This is critical to maintaining both safety and operational integrity.

Imagine a nuclear power plant; the consequences of a control system failure are catastrophic. The layers of safety and redundancy we build into these systems are essential for preventing accidents and protecting people and the environment.

Q 13. Explain your familiarity with different communication protocols (e.g., Profibus, Modbus).

I am familiar with a wide range of industrial communication protocols, including Profibus, Modbus, Ethernet/IP, Profinet, and others. These protocols govern how different devices and systems communicate within a control system.

Profibus (Process Fieldbus) is a widely used fieldbus for process automation, offering high speed and reliable data transmission. Modbus, a simpler and more widely adopted protocol, is frequently used for connecting PLCs and other devices. Ethernet/IP is a popular industrial Ethernet protocol offering high bandwidth and advanced features. Profinet, another prominent industrial Ethernet protocol, is favored for its deterministic nature in real-time applications.

My experience includes selecting the appropriate protocol based on the specific application requirements, considering factors like bandwidth, distance, real-time requirements, and cost. I can configure devices to communicate using these protocols, troubleshoot communication issues, and design communication networks that are efficient and reliable. I understand the differences between master-slave and peer-to-peer communication models and can implement them effectively. For example, I might choose Profibus for high-speed, deterministic control of critical process variables in a chemical plant, while Modbus might be sufficient for simple data acquisition from less critical sensors.

Q 14. What are the key considerations for designing a control system for a hazardous environment?

Designing a control system for a hazardous environment requires a much more rigorous approach than for a standard industrial application. Key considerations include intrinsic safety, explosion protection, environmental protection, and enhanced safety features.

Intrinsic safety involves designing the system so that it can’t generate enough energy to ignite flammable materials. This often involves using special intrinsically safe instruments and communication networks with limited energy levels. Explosion protection might involve the use of explosion-proof enclosures, flameproof designs, or other techniques to prevent the ignition of flammable gases or vapors.

Environmental considerations are crucial, especially in harsh environments. We need to consider factors such as temperature extremes, humidity, corrosion, and vibration when selecting components. The system needs to be robust and reliable enough to withstand these conditions. Enhanced safety features, such as emergency shutdown systems, redundant sensors, and robust fail-safe mechanisms, are critical to minimize risks. Rigorous testing and validation are vital to ensure the system’s safety and reliability in these challenging conditions.

For instance, when designing a control system for an offshore oil rig, we’d prioritize intrinsically safe instruments and communication protocols to prevent explosions, use explosion-proof enclosures for all critical components, and implement a sophisticated emergency shutdown system. Every aspect of the design needs to account for the potential dangers and the consequences of failure. Thorough risk assessment and rigorous testing are essential.

Q 15. Explain the concept of redundancy and its importance in control systems.

Redundancy in control systems refers to the incorporation of backup components or systems to ensure continued operation even if a primary component fails. Think of it like having a spare tire in your car – you don’t need it until you have a flat, but when you do, it’s invaluable. In industrial control systems, this is crucial for safety, reliability, and preventing costly downtime.

Redundancy can be implemented at various levels, including:

- Hardware Redundancy: Using duplicate sensors, actuators, controllers, or even entire control systems. For instance, a critical valve might have two independent actuators, each receiving its control signal from a separate controller. If one fails, the other takes over seamlessly.

- Software Redundancy: Employing redundant software routines or algorithms. For example, a critical calculation might be performed by two independent processors, and their results compared. Any discrepancy triggers an alert.

- Communication Redundancy: Utilizing multiple communication pathways (e.g., Ethernet and Profibus) to transmit data between devices. If one path fails, the other takes over, ensuring continuous communication.

The importance of redundancy is paramount in safety-critical applications like nuclear power plants, oil refineries, and chemical processing facilities where a single point of failure could lead to catastrophic consequences. It’s also crucial in maximizing operational efficiency by minimizing unplanned downtime.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage and mitigate risks in control system projects?

Risk management in control system projects is a proactive and systematic process that starts from the initial design phase and continues throughout the entire lifecycle. I employ a structured approach, typically using a combination of techniques like HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis).

HAZOP involves systematically identifying potential hazards and operability problems by reviewing the process and control system design. This method uses guide words (e.g., ‘no,’ ‘more,’ ‘less’) to explore deviations from the intended design.

FMEA identifies potential failure modes of individual components and assesses their impact on the overall system. This helps in prioritizing mitigation efforts based on risk severity. For each identified failure mode, we determine the likelihood of occurrence, the severity of its consequences, and the detectability of the failure. This leads to a Risk Priority Number (RPN) which guides our mitigation strategies.

Mitigation strategies can include using redundant components (as discussed earlier), implementing safety instrumented systems (SIS), installing alarm systems, developing detailed emergency procedures, and providing comprehensive operator training.

Regular audits, inspections, and simulations are essential to continuously monitor and manage risks throughout the system’s operational life.

Q 17. Describe your experience with control system documentation and standards.

Throughout my career, I’ve adhered to and contributed to comprehensive control system documentation, prioritizing clarity, consistency, and compliance with relevant industry standards (like ISA-88, IEC 61131-3, and ISA-95). My experience encompasses various documentation types, including:

- System Architecture Diagrams: Detailed representations of the control system’s structure, showing how different components interact.

- Process and Instrumentation Diagrams (P&IDs): Schematic drawings illustrating the process flow and the location of instruments and equipment.

- Functional Specifications: Precise descriptions of the system’s functionalities and performance requirements.

- Control Logic Diagrams: Representations of the control logic, often using ladder logic (

LD,OR,AND, etc.) or function block diagrams. - Operation and Maintenance Manuals: Comprehensive guides for operators and maintenance personnel.

I ensure that all documentation is version-controlled, readily accessible, and easily understandable by all stakeholders – from engineers to operators. A well-maintained documentation system is key for efficient troubleshooting, system upgrades, and regulatory compliance.

Q 18. What are your preferred methods for control system testing and commissioning?

My preferred methods for control system testing and commissioning involve a phased approach, ensuring thorough verification and validation at each stage. This includes:

- Factory Acceptance Testing (FAT): Testing individual components and subsystems at the vendor’s facility to verify their conformance to specifications.

- Site Acceptance Testing (SAT): Testing the integrated system on-site to ensure proper functionality and interoperability within the plant environment.

- Commissioning: The process of configuring and testing the system in its operational environment, including loop tuning, operator training, and safety verification.

- Performance Testing: Evaluating the system’s performance against predetermined criteria under various operating conditions.

I utilize advanced tools and techniques such as simulation software to create realistic test scenarios and predict system behavior before actual deployment. Automated testing scripts are used to streamline the testing process, minimizing human error and ensuring repeatability. Throughout commissioning, rigorous documentation ensures a complete audit trail of testing procedures, results, and deviations.

Q 19. Explain your understanding of control system architecture.

Control system architecture defines the overall structure and organization of the system. It encompasses various levels, typically including:

- Field Level: This includes sensors, actuators, and other field devices that directly interact with the process. This level often involves various fieldbuses like Profibus or Foundation Fieldbus.

- Control Level: This level consists of Programmable Logic Controllers (PLCs) and other controllers that implement the control algorithms. This is the ‘brains’ of the operation.

- Supervisory Level: This level involves supervisory control and data acquisition (SCADA) systems that monitor and control multiple PLCs, providing a higher-level overview and operator interface. Often includes HMI (Human-Machine Interface) screens for operators.

- Enterprise Level: This level connects the control system to the plant’s enterprise resource planning (ERP) system, enabling data integration and broader business management.

The choice of architecture depends on factors like the complexity of the process, safety requirements, scalability needs, and budget constraints. I have experience designing various architectures, from simple single-loop controllers to complex distributed control systems (DCS) across multiple plants.

Q 20. What is your experience with industrial network design?

My experience in industrial network design encompasses various aspects, from selecting appropriate network protocols to configuring and troubleshooting network devices. I’m proficient in designing networks using protocols such as:

- Ethernet/IP: A widely used industrial Ethernet protocol offering high bandwidth and robust communication capabilities.

- Profibus: A fieldbus system commonly used in process automation for connecting sensors and actuators to PLCs.

- Profinet: Another industrial Ethernet protocol built upon standard Ethernet.

- Modbus: A simple and widely supported serial communication protocol.

I consider factors like network topology, bandwidth requirements, security, and redundancy when designing industrial networks. Security is paramount, so I employ strategies like firewalls, VLANs, and secure authentication to protect the network from unauthorized access and cyber threats. I also incorporate redundancy to ensure continuous operation even if part of the network fails. My experience includes designing both wired and wireless industrial networks tailored to specific application needs.

Q 21. How familiar are you with different types of actuators?

My familiarity with actuators is extensive, encompassing a broad range of types used in various industrial applications. These include:

- Pneumatic Actuators: These use compressed air to provide linear or rotary motion, offering simplicity, low cost, and intrinsically safe operation in hazardous environments. They are often used for large valves in process industries.

- Hydraulic Actuators: Using hydraulic fluid, these actuators provide high force and torque, making them suitable for heavy-duty applications. They are commonly found in heavy machinery and some process control applications.

- Electric Actuators: These use electric motors to generate linear or rotary motion, offering precise control and easy integration with digital control systems. They are often preferred for precise and repeatable movements in automated processes.

- Electro-pneumatic Actuators: A combination of electric and pneumatic actuators. An electric signal controls a pneumatic actuator.

- Electro-hydraulic Actuators: Similarly a combination of electrical and hydraulic systems.

Selecting the appropriate actuator requires careful consideration of factors like required force/torque, speed, accuracy, environmental conditions (temperature, humidity, hazardous atmospheres), and cost. My experience involves not only selecting the right actuator but also ensuring proper sizing, mounting, and integration with the control system.

Q 22. Explain your experience with HMI design and development.

HMI (Human-Machine Interface) design is crucial for effective control system operation. It’s about creating a user-friendly interface that allows operators to monitor and control processes efficiently and safely. My experience encompasses the entire lifecycle, from initial concept and requirements gathering to testing and deployment.

I’ve worked extensively with various HMI software packages, including Wonderware InTouch, Rockwell FactoryTalk View, and Siemens WinCC. For example, in a recent project for a water treatment plant, I designed an HMI that presented real-time data on water quality parameters (pH, turbidity, chlorine levels) using intuitive dashboards and alarm management systems. This involved careful consideration of screen layout, color-coding, and alarm prioritization to minimize operator confusion during critical situations. I also incorporated trend graphs and historical data access to facilitate effective process analysis and troubleshooting.

Furthermore, my experience extends to integrating HMIs with various control systems, including PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems. I understand the importance of secure communication protocols (e.g., OPC UA) and data integrity when connecting the HMI to the underlying automation infrastructure.

Q 23. How do you ensure the maintainability of a control system?

Maintainability of a control system is paramount for long-term reliability and cost-effectiveness. It’s about designing a system that’s easy to understand, troubleshoot, modify, and upgrade. This involves several key strategies:

- Modular Design: Breaking down the system into independent modules simplifies troubleshooting and allows for easier upgrades. If one module fails, the rest of the system can continue to operate.

- Standardized Components: Utilizing standardized hardware and software components reduces complexity, simplifies procurement, and enables easier replacements.

- Comprehensive Documentation: Detailed documentation, including system architecture diagrams, I/O lists, and configuration files, is essential for understanding the system’s operation and facilitating future maintenance.

- Well-commented Code: For programmable controllers, clean, well-commented code is crucial for understanding logic and making future modifications easier. For example, using meaningful variable names and adding comments to explain complex logic helps future engineers.

- Remote Access and Diagnostics: Incorporating remote access capabilities allows technicians to diagnose and address issues without physically visiting the site, reducing downtime. This might involve using VPNs or cloud-based monitoring tools.

Imagine a large industrial oven control system. A modular design would allow technicians to isolate and replace a faulty temperature sensor module without shutting down the entire system. Comprehensive documentation would quickly guide them to the specific sensor’s location and wiring.

Q 24. Describe your experience with control system upgrades and modifications.

Control system upgrades and modifications are a common part of industrial life, driven by process improvements, technological advancements, or regulatory changes. My experience involves a structured approach:

- Requirements Analysis: Clearly defining the scope and objectives of the upgrade is paramount. What are we trying to achieve? What are the limitations?

- Risk Assessment: Identifying potential risks associated with the upgrade, including downtime and potential safety hazards. A thorough risk assessment helps mitigate potential problems.

- Testing and Validation: Rigorous testing is crucial to verify the functionality and performance of the upgraded system. This may involve simulation, factory acceptance testing, and site acceptance testing.

- Phased Rollout: A phased rollout minimizes disruption. For example, you might upgrade one section of a system at a time, allowing for validation before upgrading the rest.

In one project, we upgraded an aging SCADA system for a manufacturing plant. The upgrade involved migrating from an obsolete platform to a modern one, improving data visualization and enhancing the system’s security. We implemented a phased rollout, upgrading each production line sequentially, minimizing any production downtime.

Q 25. What is your experience with predictive maintenance strategies in control systems?

Predictive maintenance leverages data analytics to anticipate equipment failures and schedule maintenance proactively, reducing downtime and operational costs. My experience includes implementing predictive maintenance strategies using data from control systems.

This typically involves:

- Data Acquisition: Collecting real-time data from sensors and actuators within the control system. This could include vibration data, temperature readings, and operational parameters.

- Data Analysis: Using machine learning algorithms or statistical methods to analyze the collected data and identify patterns indicative of impending failures.

- Maintenance Scheduling: Based on the analysis, proactively scheduling maintenance tasks to prevent equipment failures.

For example, in a power generation plant, we used vibration data from turbine sensors to predict potential bearing failures. By analyzing the vibration data, we could anticipate failures weeks in advance, allowing for scheduled maintenance to avoid unplanned outages.

Q 26. How do you handle changes and modifications to control system specifications?

Handling changes and modifications to control system specifications requires a disciplined approach to ensure the integrity and functionality of the system. This involves:

- Formal Change Management Process: Establishing a clear process for evaluating, approving, and implementing changes. This often involves documentation and sign-off from relevant stakeholders.

- Impact Assessment: Assessing the impact of proposed changes on the overall system and identifying potential conflicts or unintended consequences.

- Version Control: Using version control systems to track changes to software and configuration files. This allows for easy rollback to previous versions if necessary.

- Thorough Testing: Testing the changes thoroughly to verify their functionality and ensure they do not introduce new problems. This may involve unit testing, integration testing, and system testing.

In a recent project, a client requested a modification to the control logic of a process control system. We followed a formal change management process, documenting the change, assessing its impact, and performing rigorous testing before deploying the modification to the live system.

Q 27. What are your preferred methods for control system performance monitoring?

Effective control system performance monitoring is crucial for identifying potential issues and ensuring optimal operation. My preferred methods include:

- Real-time Data Monitoring: Using SCADA systems or HMIs to monitor key process variables and identify deviations from setpoints or expected behavior.

- Historical Data Analysis: Analyzing historical data to identify trends, patterns, and potential areas for improvement. This often involves using data historians and analytics tools.

- Key Performance Indicators (KPIs): Defining and monitoring KPIs to track the performance of the control system and identify areas needing attention.

- Alarm Management: Implementing an effective alarm management system to alert operators to critical events and prevent potential problems from escalating.

For instance, in a chemical plant, we monitored key process variables like temperature and pressure using real-time data monitoring. We also analyzed historical data to identify recurring issues and optimize the control system for better performance.

Key Topics to Learn for Instrumentation and Control System Design for New Projects Interview

- Process Instrumentation: Understanding various sensors, transmitters, and actuators used in industrial processes. This includes selecting appropriate instrumentation based on process parameters and accuracy requirements.

- Control System Architectures: Familiarity with different control system architectures (e.g., distributed control systems (DCS), programmable logic controllers (PLCs), supervisory control and data acquisition (SCADA) systems) and their applications in new project designs. Consider the advantages and disadvantages of each in various contexts.

- Control Loop Design and Tuning: Mastering the principles of feedback control, PID control, and advanced control strategies. Be prepared to discuss practical tuning methods and the impact of different tuning parameters on system stability and performance. Consider case studies where tuning was crucial.

- Safety Instrumented Systems (SIS): Understanding safety instrumented systems (SIS) design principles, including hazard identification, risk assessment, and safety integrity levels (SIL). Discuss the importance of safety in process control.

- Process Simulation and Modeling: Experience with process simulation software and techniques for modeling dynamic systems. This includes understanding how models are used for design, optimization, and troubleshooting.

- Data Acquisition and Analysis: Understanding how data is acquired from the field instruments and processed to provide meaningful insights into the process. Familiarize yourself with data analysis techniques for process optimization and troubleshooting.

- Project Management Aspects: Discuss your understanding of project planning, execution, and commissioning within the context of instrumentation and control system design. Consider aspects such as budgeting, scheduling, and teamwork.

- Troubleshooting and Maintenance: Be prepared to discuss your approaches to troubleshooting malfunctions in control systems and your understanding of preventative maintenance strategies.

- Industry Standards and Codes: Familiarity with relevant industry standards and codes of practice for instrumentation and control system design. This showcases your understanding of regulatory compliance.

- Communication Protocols: Understanding various communication protocols (e.g., Profibus, Modbus, Ethernet/IP) used in industrial automation and their applications in system integration.

Next Steps

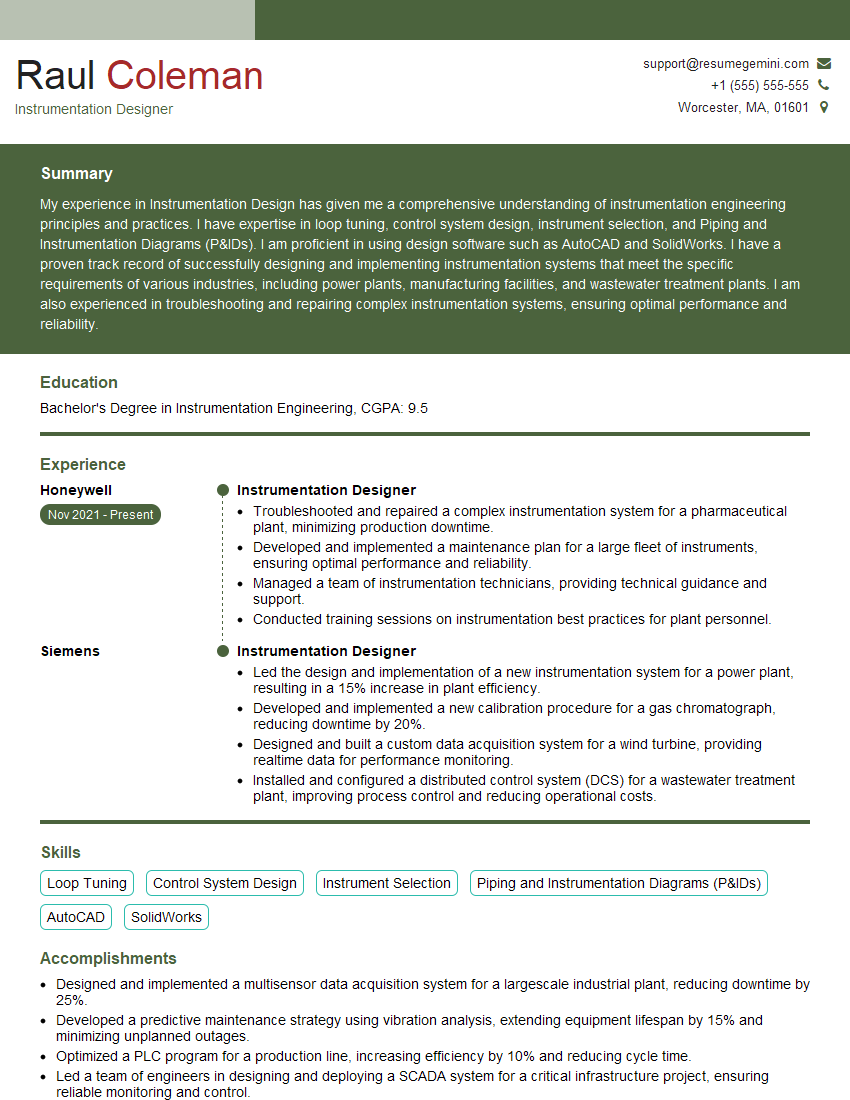

Mastering Instrumentation and Control System Design for New Projects is crucial for career advancement in this dynamic field, opening doors to challenging and rewarding roles with significant responsibility and growth potential. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Instrumentation and Control System Design for New Projects are available to guide you. Invest the time to build a strong resume; it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Dear Sir/Madam,

Do you want to become a vendor/supplier/service provider of Delta Air Lines, Inc.? We are looking for a reliable, innovative and fair partner for 2025/2026 series tender projects, tasks and contracts. Kindly indicate your interest by requesting a pre-qualification questionnaire. With this information, we will analyze whether you meet the minimum requirements to collaborate with us.

Best regards,

Carey Richardson

V.P. – Corporate Audit and Enterprise Risk Management

Delta Air Lines Inc

Group Procurement & Contracts Center

1030 Delta Boulevard,

Atlanta, GA 30354-1989

United States

+1(470) 982-2456