Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Experience with Different Paint Systems interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Experience with Different Paint Systems Interview

Q 1. Explain the difference between solvent-based and water-based paints.

The primary difference between solvent-based and water-based paints lies in their solvents. Solvent-based paints, also known as oil-based paints, use organic solvents like mineral spirits or turpentine to dissolve the binder (the substance that holds the pigment together). These solvents evaporate, leaving behind a durable, hard-wearing film. Water-based paints, also known as latex paints, use water as the solvent. They are generally easier to clean up with soap and water, and often have lower VOC (Volatile Organic Compound) emissions, making them more environmentally friendly.

- Solvent-based paints: Offer excellent durability, water resistance, and are ideal for high-traffic areas or exterior applications. However, they have a strong odor, longer drying times, and require solvents for cleanup.

- Water-based paints: Easier to apply, clean up, and have a lower odor. They are a popular choice for interior applications but may not be as durable as solvent-based paints in all situations. Think of it like this: solvent-based paints are like tough, waterproof boots, while water-based paints are like comfortable sneakers – each suitable for different terrains.

Q 2. Describe the process of surface preparation before applying paint.

Surface preparation is crucial for a long-lasting, high-quality paint job. It ensures proper adhesion and prevents peeling or flaking. The process typically involves these steps:

- Cleaning: Remove loose dirt, dust, grease, or mildew using appropriate cleaners. A power washer can be helpful for exterior surfaces, but be cautious to avoid damaging delicate materials.

- Repairing: Fill any cracks, holes, or imperfections using suitable fillers or patching compounds. Allow ample drying time before proceeding.

- Sanding: Smooth out any rough surfaces using sandpaper. Start with coarser grit and gradually move to finer grit to achieve a smooth finish. This is essential for ensuring good paint adhesion.

- Priming: Applying a primer seals the surface, provides better adhesion for the topcoat, and can improve the overall finish. The type of primer should be selected based on the substrate and the type of paint being used.

- Masking: Protect areas that you don’t want to be painted using painter’s tape and drop cloths.

Imagine baking a cake: you wouldn’t just pour batter into a dirty, unprepared pan; similarly, you wouldn’t paint without adequately preparing the surface.

Q 3. What are the key factors to consider when selecting a paint system for a specific application?

Selecting the right paint system is vital for a successful project. Key factors to consider include:

- Substrate: The surface being painted (wood, metal, plaster, etc.) dictates the type of paint and primer needed for optimal adhesion. For example, a metal surface would require a rust-inhibiting primer.

- Environment: Interior or exterior applications require different paint properties. Exterior paints need to be weather-resistant and UV-resistant. Interior paints should be low-VOC for better indoor air quality.

- Durability: High-traffic areas require more durable paints, such as those with a higher gloss level and better scrub resistance. A child’s room might need a paint that is washable.

- Finish: The desired sheen – flat, eggshell, satin, semi-gloss, or gloss – affects the appearance and cleanability of the paint. Glossy finishes are more durable and easier to clean but show imperfections more readily.

- Color: Color choice affects the overall aesthetic appeal. Consider the light reflection and how it can alter the perceived color.

Q 4. What are the different types of paint spray equipment and their applications?

Various paint spray equipment caters to different needs and scales of projects:

- Airless sprayers: These are popular for larger projects due to their speed and efficiency. They atomize paint using high pressure, minimizing overspray and producing a smooth finish. Ideal for fences, houses, and large commercial projects.

- HVLP (High Volume Low Pressure) sprayers: These sprayers use a lower pressure and higher volume of air to atomize the paint, resulting in less overspray and a finer finish. Better for detailed work and smaller projects, offering more control.

- Air sprayers (conventional sprayers): They use compressed air to atomize the paint. These provide excellent control and finish but can be more time-consuming and prone to overspray. They are suited for delicate work and finishing touches.

- Spray guns (for automotive use): Provide precise control over paint application and are essential for automotive refinishing or specialized projects requiring a high-quality, uniform finish. They require significant skill and experience.

Q 5. How do you ensure proper adhesion between different paint layers?

Ensuring proper adhesion between paint layers involves several critical steps:

- Proper Surface Preparation: As discussed earlier, a clean, smooth, and primed surface is paramount for good adhesion. Any imperfections can prevent proper bonding.

- Correct Paint Selection: Choosing compatible paints and primers is crucial. For example, using an oil-based primer under a water-based topcoat can lead to adhesion problems. Always consult the manufacturer’s recommendations.

- Suitable Drying Time: Each coat needs sufficient time to dry before applying the next. Rushing the process can lead to lifting or peeling of the paint.

- Thinning (if necessary): Some paints may require thinning to achieve the correct viscosity for spraying or rolling. Over-thinning can compromise durability and adhesion.

- Light Sanding (between coats): Lightly sanding between coats can improve adhesion by creating a slightly rough surface for the next coat to grip onto.

Think of it as building a brick wall: each brick (paint layer) needs a strong foundation (prepared surface) and proper mortar (primer and correct paint selection) for optimal strength and stability.

Q 6. Explain the importance of proper ventilation during paint application.

Proper ventilation during paint application is crucial for several reasons:

- Health and Safety: Many paints, particularly solvent-based paints, release volatile organic compounds (VOCs) that can be harmful if inhaled. Good ventilation removes these harmful fumes, protecting the painter’s health.

- Paint Drying: Adequate airflow facilitates the evaporation of solvents, ensuring proper drying and preventing the formation of wrinkles or bubbles in the paint film.

- Preventing Fire Hazards: Some paint solvents are flammable. Good ventilation reduces the risk of fire or explosion, especially when using spray equipment.

Always work in a well-ventilated area, or use respirators and appropriate safety measures. Never work in a confined space without proper ventilation.

Q 7. What are the common issues encountered during paint application and how are they resolved?

Common issues during paint application and their solutions:

- Uneven Finish: Caused by uneven application, improper thinning, or poor surface preparation. Solution: Use proper application techniques, thin paint correctly, and ensure adequate surface preparation.

- Runs and Drips: Often due to applying paint too thickly or using an unsuitable roller or brush. Solution: Apply thin, even coats, use appropriate tools, and let each coat dry completely before applying the next.

- Brush Marks: Visible brush strokes can result from using the wrong type of brush, poor brushing technique, or not using enough paint. Solution: Use a brush suited for the paint type, use smooth, even strokes, and apply enough paint to cover the surface without overloading the brush.

- Peeling or Flaking: Typically caused by poor surface preparation, moisture issues, or incompatible paints. Solution: Proper surface preparation, moisture control (addressing any leaks or water damage), and using compatible paint systems are essential.

- Poor Adhesion: Can be due to a dirty or greasy surface, wrong primer selection, or too much paint thinner. Solution: Thorough cleaning of the surface, selecting the right primer, and correct paint thinning are crucial.

Troubleshooting painting issues often involves a systematic approach: identifying the root cause (poor preparation, incorrect materials, etc.), then implementing the corrective measure.

Q 8. Describe the process of color matching.

Color matching is the process of replicating a specific color using paint. It’s crucial for achieving consistent aesthetics in various projects, from repainting a room to matching car parts. The process involves using tools like spectrophotometers or colorimeters to measure the color’s precise values (usually in terms of L*a*b* coordinates or other color spaces). These values guide the selection of base pigments and tints needed to create the desired shade. For example, if you need to match a faded piece of furniture, you’d use a colorimeter to scan the remaining color. The instrument will output numerical color data which is then inputted into a paint tinting system. The system will then automatically mix the correct proportions of base colors and tints to achieve the desired match. This ensures consistency and reduces guesswork. Advanced systems even account for variations in substrate, such as the type of wood or metal being painted, to further refine the match.

Manually, experienced painters might use color charts and their expertise to approximate the color. However, technology offers a much more precise and reliable way of achieving accurate color matches, especially for large projects where consistency is vital.

Q 9. What are the safety precautions to be followed when working with paint systems?

Safety is paramount when working with paint systems. Always start with proper ventilation – working in a well-ventilated area or using respirators is critical to avoid inhaling harmful fumes. Many paints contain volatile organic compounds (VOCs) that can cause respiratory issues, headaches, and even long-term health problems. Eye protection is also essential, as splashes can cause irritation or damage. Gloves are crucial to prevent skin contact, as some paints are skin irritants or allergens. Protective clothing should be worn to prevent spills from staining your clothes. When working with solvents or thinners, be extremely cautious, as they are highly flammable and can cause skin irritation or damage. Always follow the manufacturer’s safety data sheets (SDS) carefully. These sheets outline the specific hazards and precautions associated with that particular paint product. Proper disposal of waste paint and containers is also crucial. Never pour paint down the drain; instead, follow local regulations for proper disposal at designated hazardous waste facilities.

Q 10. How do you determine the appropriate paint thickness for a given application?

Paint thickness, or wet film thickness (WFT), directly impacts the final finish and durability. It’s measured using a wet film comb or gauge. The appropriate thickness depends on the paint type, substrate, application method, and desired finish. Thinner coats might require multiple applications to achieve adequate coverage, potentially leading to unevenness or poor adhesion. Conversely, excessive thickness can cause runs, sags, and longer drying times. Most paint manufacturers provide recommended WFT for their products. Following these guidelines is key. For example, a single coat of exterior house paint typically requires a wet film thickness between 3-5 mils (0.076mm-0.127mm), while automotive paints often need much thinner coats. Always ensure the surface is properly prepared (clean, dry, and possibly primed) before applying paint to achieve optimal adhesion and a consistent film thickness. Regular checks of WFT during application ensure uniformity and prevent defects.

Q 11. Explain the concept of film build and its significance in paint performance.

Film build refers to the final thickness of the dried paint layer after application and curing. It’s a critical factor influencing paint performance. A sufficient film build ensures proper protection against environmental factors such as moisture, UV radiation, and abrasion. Insufficient film build can lead to premature failure, such as cracking, peeling, or fading. Conversely, an excessively thick film build can also be problematic, causing cracking or uneven curing. The desired film build depends on the specific application and paint type. For example, a marine paint needs a thicker film build for enhanced corrosion resistance compared to interior wall paint. The film build is influenced by several factors, including the number of coats applied, the paint’s viscosity, and the application method. A smooth, even film build provides optimal performance, whereas an uneven build can lead to weaknesses in the paint system.

Q 12. What are the different types of primers and their uses?

Primers are crucial preparation coats applied before the topcoat to improve adhesion, enhance the topcoat’s performance, and often provide a more uniform surface. Different primers serve different functions.

- Adhesion primers: These improve bonding between the paint and substrate, especially important for surfaces like metal, plastic, or previously painted surfaces that might have low adhesion properties. They create a better key for the subsequent coats.

- Sealing primers: These seal porous surfaces like wood or plaster, preventing moisture absorption and promoting a more uniform paint finish. This prevents uneven paint absorption, which could lead to blotchiness or uneven color.

- Stain-blocking primers: These are designed to prevent stains like watermarks, rust, or grease from bleeding through the topcoat. They are essential for surfaces with significant staining or discoloration.

- Specialty primers: These address specific surface issues, such as rust inhibitors for metal or alkyl primers for plastics.

Q 13. How do you identify and address defects in a paint finish?

Identifying and addressing paint finish defects requires careful observation and understanding of their causes. Common defects include

- Runs and sags: Caused by applying too thick a coat or poor leveling properties of the paint. They can be minimized by proper application techniques and using appropriate paint viscosity.

- Orange peel: A textured finish resembling an orange peel, often caused by excessive spraying pressure or improper spraying distance. It can be minimized by adjusting spraying parameters and using a suitable reducer.

- Blotchiness: Uneven color distribution, often due to inconsistent surface preparation or uneven paint absorption. It often necessitates better surface prep or multiple thin coats.

- Cracking: Caused by insufficient film build, poor substrate preparation, or exposure to extreme temperature fluctuations. It indicates a failure of the paint system and often requires complete repainting.

- Peeling: Poor adhesion between the paint and substrate, often due to inadequate surface preparation or use of the incorrect primer. It requires removing the peeling paint and starting again.

Q 14. What are the common methods of paint curing?

Paint curing is the process by which the paint film solidifies and achieves its final properties. This involves a chemical reaction, often oxidation or polymerization, that converts the liquid paint into a solid film. Several methods influence curing:

- Oxidation curing: This involves the reaction of the paint with oxygen in the air. It’s common in oil-based paints and is influenced by factors such as temperature and humidity.

- Polymerization curing: This involves chemical reactions between molecules in the paint, forming long chains that create a solid structure. Many water-based and acrylic paints use this method.

- Baking or forced curing: This method speeds up the curing process by using elevated temperatures, often in ovens or specialized curing chambers. It’s common in industrial applications and automotive repainting.

- UV curing: This involves using ultraviolet light to initiate and accelerate the curing process. It’s often used in specialized coatings and inks.

Q 15. Describe the different types of paint testing and their purpose.

Paint testing is crucial for ensuring quality and performance. Several types exist, each serving a specific purpose. These include:

- Adhesion testing: Determines how well the paint bonds to the substrate. This might involve cross-hatch adhesion testing, where a grid is cut into the dried paint and tape is used to assess how much paint is removed. Poor adhesion leads to peeling and premature failure.

- Durability testing: Evaluates the paint’s resistance to weathering, abrasion, and chemicals. This could involve accelerated weathering tests using UV light and humidity cycles to simulate years of exposure in a short time. Understanding durability is vital for choosing the right paint for a given application—exterior house paint needs far greater durability than interior wall paint.

- Colorimetric testing: Measures the color accuracy and consistency of the paint. Spectrophotometers are used to quantify color, ensuring batches match and meet specified standards. This is essential for large projects where consistent color is vital.

- Gloss and sheen testing: Quantifies the surface reflectivity of the paint. This is measured using a glossmeter and is important for aesthetics and function; high-gloss paints are more resistant to staining but show imperfections more readily.

- Film thickness testing: Measures the thickness of the dried paint film. This is critical for ensuring adequate protection and performance; too thin, and the coating may be inadequate; too thick, and it may crack or peel. We use wet and dry film thickness gauges for this.

The results of these tests inform material selection, application techniques, and quality control throughout a project.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the importance of maintaining accurate records of paint application?

Maintaining accurate paint application records is paramount for several reasons:

- Warranty and liability: Detailed records, including paint type, manufacturer, lot number, application date, and surface preparation methods, are crucial for resolving disputes and honoring warranties. If problems arise later, these records prove the correct materials and procedures were followed.

- Quality control: Tracking paint usage and application details allows for identification of trends and potential issues. Consistent record-keeping helps pinpoint where problems occurred and prevent their recurrence.

- Future maintenance: Knowing the type and history of paint applied is essential for future repainting or maintenance. This prevents incompatibility issues and ensures long-term protection.

- Regulatory compliance: Some industries and jurisdictions require detailed records of paint usage and disposal, especially for hazardous materials. Accurate records ensure adherence to environmental regulations and prevent penalties.

- Cost tracking: Detailed records help in accurately calculating the costs associated with paint projects, enabling better budgeting and cost control for future projects.

I always utilize a standardized record-keeping system, including digital photography and spreadsheets, to track all project-related paint information.

Q 17. Explain the concept of pot life in paint.

Pot life refers to the time period after mixing a paint (especially multi-component paints like epoxies) during which it remains usable. After this time, the paint begins to thicken, cure, or otherwise become unusable. Think of it like baking a cake – once you combine all the ingredients, you have a limited time to bake it before it becomes inedible.

Pot life is affected by factors such as temperature, humidity, and the specific paint chemistry. Manufacturers specify the pot life for their products, usually in hours or minutes. Exceeding the pot life leads to poor application properties, uneven curing, and reduced performance of the final coating.

In practice, we always carefully monitor the pot life of mixed paints, ensuring that we only use the paint within the recommended time frame. We often mix smaller batches to avoid waste and ensure that the paint remains workable throughout the application process.

Q 18. How do you handle paint spills and waste disposal in accordance with regulations?

Handling paint spills and waste disposal requires strict adherence to regulations and safety protocols. The first step is always prevention – careful pouring, containment areas, and proper protective gear.

For spills, immediate containment is crucial. We use absorbent materials like spill pads or kitty litter to soak up the spilled paint. The absorbed material is then placed in a sealed container for proper disposal. Larger spills may require more specialized equipment and procedures.

Waste disposal varies based on paint type and local regulations. Some paints can be disposed of in regular trash, others require special hazardous waste disposal methods. We always refer to the paint’s Safety Data Sheet (SDS) and local guidelines before disposing of any paint waste. Often, we partner with licensed hazardous waste disposal companies for proper and safe disposal of regulated materials.

It’s essential to document all spill incidents and waste disposal actions for compliance purposes.

Q 19. What experience do you have with different types of paint rollers and brushes?

My experience with paint rollers and brushes is extensive. I’m proficient in using various types, selecting the appropriate tool for each job and surface.

- Rollers: I’ve used short-nap, medium-nap, and long-nap rollers for different paint types and surface textures. Short-nap rollers are ideal for smooth surfaces, while long-nap rollers are better for textured surfaces. I understand the importance of using the correct roller cover material (e.g., woven polyester, synthetic sheepskin) for optimal paint application and finish.

- Brushes: My brush experience covers natural bristle brushes (for oil-based paints) and synthetic bristle brushes (for water-based paints). I’m skilled in using various brush sizes and shapes for detailed work, such as cutting in edges, and for broader applications. The selection depends on the paint type, surface, and desired finish. Proper brush cleaning and maintenance are crucial for extending their lifespan.

I also have experience with specialized rollers and brushes like mini-rollers for tight spaces and specialty brushes for decorative techniques. The choice always depends on the project requirements and the desired outcome.

Q 20. Describe your experience with epoxy coatings.

Epoxy coatings are high-performance coatings known for their exceptional durability, chemical resistance, and adhesion. My experience includes working with both two-part (resin and hardener) and single-part epoxy systems. I’ve applied epoxy coatings to various substrates, including concrete floors, metal structures, and fiberglass components.

I understand the critical importance of surface preparation when applying epoxy coatings. Proper cleaning, etching, and priming are essential for achieving optimal adhesion and long-term performance. I’m familiar with different application methods, including brushing, rolling, and spraying, and I select the most appropriate method depending on the project scope and surface area.

One memorable project involved applying an epoxy coating to a heavily corroded steel bridge support. Precise surface preparation and careful application were critical to ensure the long-term protection of the structure. The project demonstrated the importance of meticulous attention to detail when working with epoxy systems.

Q 21. What is your experience with polyurethane paints?

Polyurethane paints are another high-performance coating option known for their excellent durability, UV resistance, and weatherability. My experience with polyurethane paints covers both oil-based and water-based varieties. I’ve utilized them in various applications, from automotive finishes to marine applications and high-end furniture projects.

The key to successful polyurethane paint application lies in careful surface preparation and the proper application techniques. I’m experienced in applying multiple thin coats for optimal build and finish, allowing sufficient drying time between coats. Different techniques such as spray application (for even finishes), brushing (for detailed work), or rolling (for large areas) are applied based on the context and desired outcome.

Working with polyurethane paints, especially the oil-based varieties, often requires appropriate respiratory protection due to the solvents involved. I always adhere to safety regulations and wear appropriate personal protective equipment (PPE).

Q 22. Discuss your familiarity with powder coating techniques.

Powder coating is a dry finishing process where a finely ground powder is applied to a surface and then cured under heat. Unlike liquid paints, it doesn’t require solvents, resulting in a more environmentally friendly process. My experience encompasses the entire process, from surface preparation – crucial for optimal adhesion – to the selection of powder type based on desired finish and application (e.g., polyester for outdoor durability, epoxy for chemical resistance). I’m proficient in various application methods, including electrostatic spraying and fluidized bed coating, and understand the nuances of curing parameters like temperature and dwell time to achieve the desired film thickness and properties. I’ve worked extensively with different powder types, including those with metallic finishes, textured effects, and specialized properties for various applications, for example, a project involving coating high-voltage electrical components required a specific powder with exceptional dielectric strength.

For example, in a recent project involving the powder coating of outdoor furniture, I selected a polyester powder with UV inhibitors to ensure long-term color and gloss retention. The critical step here was to meticulously prepare the metal substrates to ensure a smooth, defect-free finish. Through precise control of the spraying process and curing cycle, we achieved a durable and aesthetically pleasing finish.

Q 23. What are the characteristics of high-performance coatings?

High-performance coatings are designed to exceed the capabilities of standard paints, offering superior durability, corrosion resistance, and other specialized properties. Key characteristics include:

- Enhanced Durability: They resist abrasion, chipping, and weathering far better than conventional paints, extending the lifespan of the coated surface.

- Superior Corrosion Protection: They often contain specialized pigments and polymers that create a robust barrier against rust and degradation. This is particularly crucial in harsh environments.

- Chemical Resistance: Some high-performance coatings are designed to withstand exposure to acids, alkalis, or other corrosive chemicals.

- Specialized Properties: This can include things like high-temperature resistance (e.g., for engine components), UV resistance (for outdoor applications), or anti-fouling properties (for marine applications).

- Enhanced Aesthetics: They can offer a wider range of colors, finishes (gloss, matte, textured), and special effects.

For instance, a high-performance coating used on a bridge would need exceptional durability to withstand years of exposure to the elements and traffic vibrations. In aerospace applications, coatings are required to withstand extreme temperatures and pressures.

Q 24. Explain your experience with different types of substrate materials.

My experience spans a variety of substrate materials, including metals (steel, aluminum, galvanized steel), plastics (polypropylene, ABS), wood, and composites. Each material requires a different surface preparation and potentially a different paint system for optimal adhesion and performance. For example, steel requires thorough cleaning and potentially a pretreatment such as phosphating to enhance adhesion and corrosion resistance, while plastics often need a primer to improve paint bonding. Working with wood necessitates careful consideration of the wood type, grain, and moisture content to prevent problems such as blistering or peeling. Composites require specialized adhesion promoters to ensure proper bonding. Understanding the unique characteristics of each substrate and choosing the appropriate surface treatment and paint system is crucial for long-lasting, high-quality results.

Q 25. How do you ensure quality control throughout the painting process?

Quality control is paramount throughout the entire painting process. This involves a multi-faceted approach starting with:

- Substrate Inspection: Thoroughly inspecting the substrate for defects, ensuring proper cleaning and preparation.

- Paint Mixing and Application: Adhering to precise mixing ratios and application techniques to ensure uniform film thickness and finish.

- In-process Monitoring: Regularly checking the application process, including spray gun settings and film thickness, to identify and correct issues early on.

- Curing Control: Maintaining precise temperature and time settings in the curing process for optimal film formation and durability.

- Post-Cure Inspection: A final visual and potentially instrumental inspection to verify the finish quality, film thickness, and the absence of defects.

Implementing statistical process control techniques and regularly calibrating equipment helps to ensure consistency and identify potential problems before they escalate.

Documentation is a vital aspect of quality control, ensuring traceability and accountability at each stage of the process.

Q 26. What is your experience with different paint mixing ratios and formulations?

My experience includes working with a wide range of paint formulations, from simple solvent-based systems to complex waterborne and high-performance coatings. Accurate mixing ratios are crucial; even a slight deviation can significantly affect the final properties of the paint, such as its color, gloss, durability, and viscosity. I have experience reading and interpreting paint manufacturer’s specifications, using precision scales and measuring devices to accurately measure pigments, binders, solvents, and additives. I’m proficient in different mixing techniques including mechanical stirring, and I understand the importance of controlled mixing time and temperature to prevent settling and ensure uniformity.

Working with specialized formulations, such as those for marine or aerospace applications, demands meticulous attention to detail because the mixing and application processes need to be very precise to satisfy the strict quality requirements in those fields.

Q 27. What is your understanding of VOC regulations concerning paint?

Volatile Organic Compounds (VOCs) are organic chemicals that easily evaporate at room temperature and contribute to air pollution. Paint typically contains VOCs in the solvents and some binders. Regulations, such as those set by the EPA (Environmental Protection Agency) in the US, aim to limit VOC emissions from paints to reduce air pollution. This necessitates the use of low-VOC or VOC-free paints, which often rely on water-based systems or alternative solvents. My experience includes working with these low-VOC paints, understanding their properties, application techniques, and the environmental considerations associated with their use. Understanding and complying with VOC regulations is critical for environmental protection and regulatory compliance. We often need to select paints based not only on their performance characteristics but also on their VOC content, ensuring we meet all applicable regulations for the location and type of project.

Q 28. Describe your experience with specialized paint systems, such as marine or aerospace coatings.

I have experience with specialized paint systems beyond standard applications. In the marine industry, I’ve worked with anti-fouling paints designed to prevent marine growth on hulls, requiring specific application methods and curing processes. These paints often contain biocides that need careful handling. In aerospace applications, I’ve worked with high-temperature resistant coatings for engine components and specialized primers to protect against corrosion and abrasion in extreme conditions. These paints require precise application and curing parameters to ensure they meet stringent performance and safety standards. For instance, a project involving the coating of an aircraft component demanded the use of a paint system that could withstand high temperatures and maintain its integrity during flight. The understanding of the properties and application requirements of these specialized coatings is key to ensuring the durability and functionality of the final product.

Key Topics to Learn for Experience with Different Paint Systems Interview

- Types of Paint Systems: Understanding the differences between water-based, oil-based, solvent-based, and powder coating systems; their respective properties, applications, and limitations.

- Surface Preparation: Mastering techniques for proper surface cleaning, priming, and sanding to ensure optimal paint adhesion and durability. Discuss various methods and their suitability for different substrates.

- Application Techniques: Familiarize yourself with various application methods including spraying (airless, HVLP, electrostatic), brushing, rolling, and dipping. Explain the advantages and disadvantages of each, and their suitability for different paint types and projects.

- Paint Chemistry Basics: Develop a foundational understanding of paint components (binders, pigments, solvents, additives) and how they affect film properties like gloss, durability, and adhesion.

- Troubleshooting and Problem Solving: Prepare to discuss common painting problems such as sagging, orange peel, pinholes, and fisheyes. Explain the likely causes and potential solutions for each.

- Safety Procedures and Regulations: Demonstrate knowledge of relevant safety regulations and procedures for handling paints, solvents, and equipment; including proper ventilation, personal protective equipment (PPE), and waste disposal.

- Quality Control and Inspection: Describe methods for inspecting painted surfaces for defects and ensuring adherence to quality standards. Discuss the use of appropriate tools and techniques for quality assurance.

- Cost Estimation and Project Management: Discuss your experience in estimating material costs, labor hours, and overall project budgets related to paint projects.

Next Steps

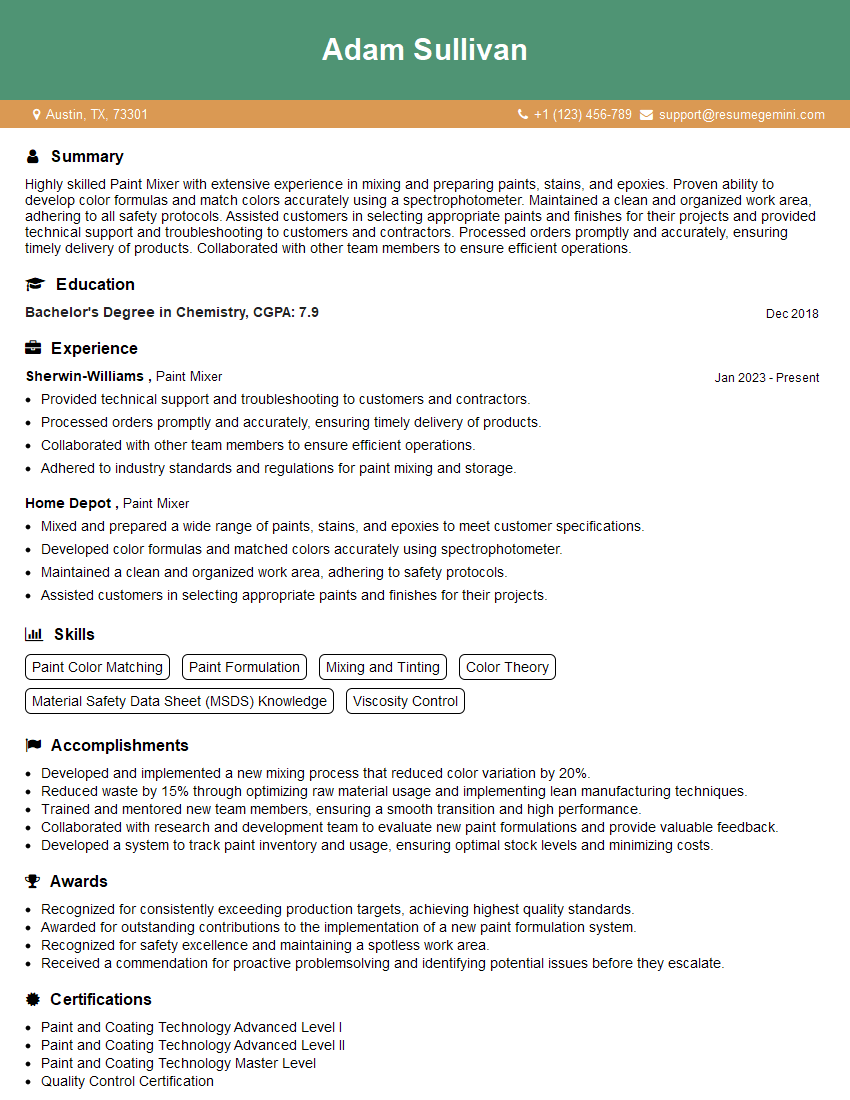

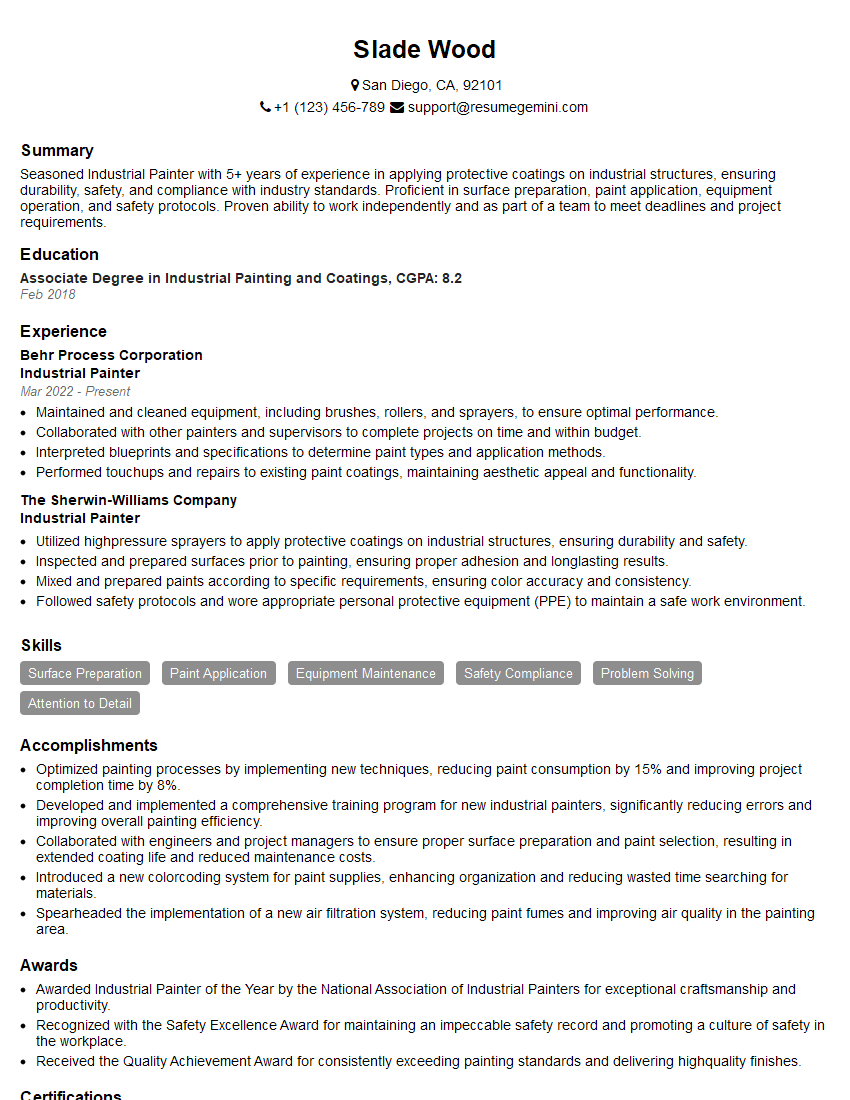

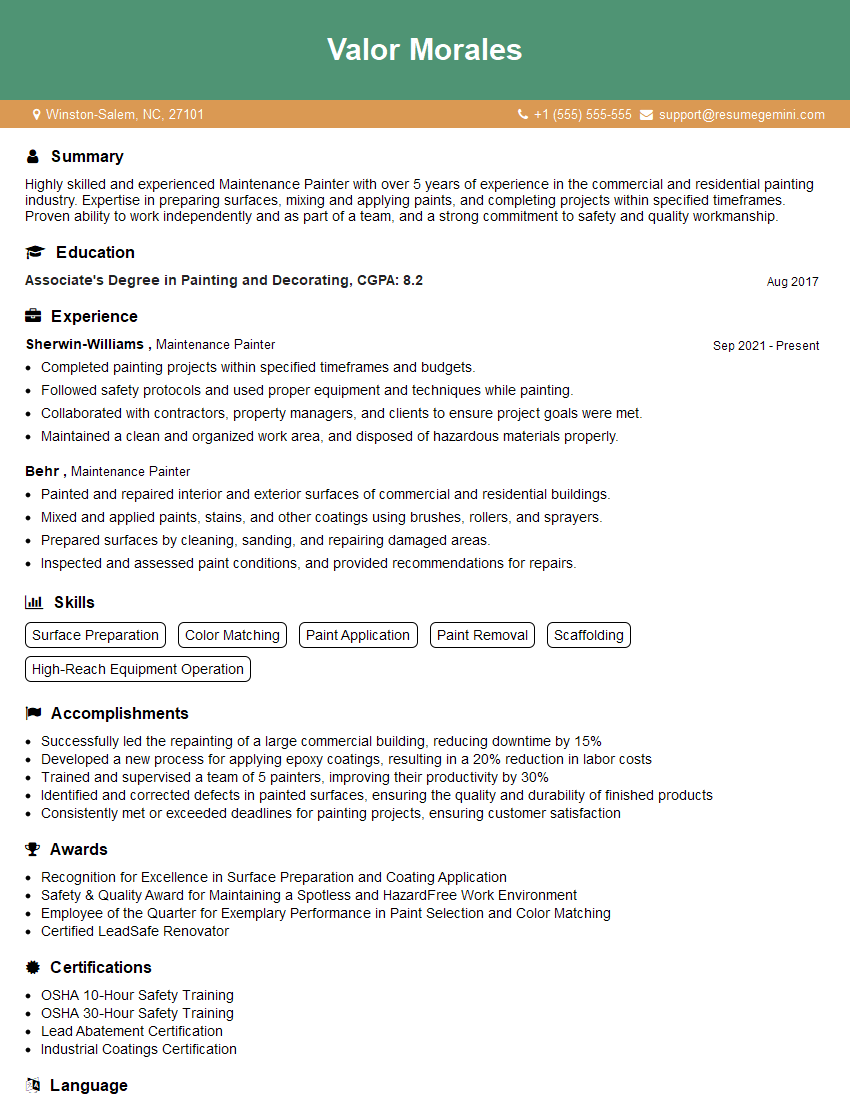

Mastering experience with different paint systems is crucial for career advancement in many industries, demonstrating your practical skills and problem-solving abilities. A strong resume is your key to unlocking opportunities. Crafting an ATS-friendly resume is essential to get noticed by potential employers. ResumeGemini can help you build a professional and impactful resume that highlights your expertise. We provide examples of resumes tailored to showcasing experience with different paint systems to help you present your skills effectively. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Dear Sir/Madam,

Do you want to become a vendor/supplier/service provider of Delta Air Lines, Inc.? We are looking for a reliable, innovative and fair partner for 2025/2026 series tender projects, tasks and contracts. Kindly indicate your interest by requesting a pre-qualification questionnaire. With this information, we will analyze whether you meet the minimum requirements to collaborate with us.

Best regards,

Carey Richardson

V.P. – Corporate Audit and Enterprise Risk Management

Delta Air Lines Inc

Group Procurement & Contracts Center

1030 Delta Boulevard,

Atlanta, GA 30354-1989

United States

+1(470) 982-2456