Unlock your full potential by mastering the most common Chemical Loading and Unloading interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Chemical Loading and Unloading Interview

Q 1. Explain the different types of chemical containers used in loading and unloading.

Chemical containers vary greatly depending on the properties of the substance being transported. The choice is critical for safety and regulatory compliance. Common types include:

- Drums (55-gallon): Steel or plastic drums are widely used for liquids and powders, offering good containment but requiring manual handling. They’re cost-effective but susceptible to damage.

- Intermediate Bulk Containers (IBCs): These large reusable containers, typically made of plastic, hold hundreds of gallons and are often used for bulk transport. They are easier to handle with forklifts than drums but need careful stacking and securing.

- Tank Trucks: For large-scale transport, tank trucks carry thousands of gallons, offering efficiency but demanding specialized handling and licensing. They are highly regulated due to potential environmental hazards.

- Tank Cars (Railcars): Similar to tank trucks but used for rail transport, these offer extremely high capacity for long-distance transport of large volumes of chemicals. They need specialized loading and unloading facilities.

- Cylinders (Gas Cylinders): High-pressure cylinders are used for gases and compressed materials. They require specialized handling equipment and rigorous safety protocols to prevent explosions or leaks. Examples include propane or chlorine gas.

- Flexitanks: These large, flexible containers are inserted into standard shipping containers. They are cost-effective and disposable for single use, but their susceptibility to damage needs careful handling.

The selection of the container is crucial and depends on factors such as the chemical’s properties (viscosity, reactivity, flammability), transport distance, and regulatory requirements.

Q 2. Describe the safety procedures for handling hazardous chemicals.

Safety when handling hazardous chemicals is paramount. A multi-layered approach is needed:

- Personal Protective Equipment (PPE): This is the first line of defense. Appropriate PPE, selected based on the specific chemical’s hazards, might include respirators, gloves (chemical-resistant), safety glasses, protective suits, and steel-toe boots.

- Proper Training and Education: All personnel involved in the loading and unloading process must receive comprehensive training on the hazards of the chemicals they handle, the proper use of PPE, emergency procedures, and spill response. Regular refresher training is crucial.

- Engineering Controls: These minimize exposure through design, such as enclosed loading bays with good ventilation, remote-controlled valves, and automated loading systems. These are often preferred over relying solely on PPE.

- Administrative Controls: This includes establishing clear procedures, permits, and work instructions. This ensures accountability and a consistent approach across different shifts and operators. Regular inspections of equipment are vital.

- Emergency Preparedness: Having well-rehearsed emergency response plans and access to readily available spill kits and emergency equipment, including showers, eyewash stations, and appropriate decontamination facilities, are essential.

Remember: Safety is not just a checklist; it’s a culture. A proactive, cautious attitude and a commitment to following procedures are vital to preventing accidents.

Q 3. What are the common hazards associated with chemical loading and unloading?

Chemical loading and unloading present several inherent hazards:

- Exposure to Hazardous Chemicals: Inhalation, skin contact, or ingestion can lead to severe health effects, ranging from minor irritation to serious injury or death. This depends heavily on the specific chemical’s toxicity and the level of exposure.

- Fires and Explosions: Many chemicals are flammable or reactive, posing a risk of fire or explosion, particularly if improperly handled or stored.

- Spills and Leaks: These can cause environmental damage and create hazardous conditions for workers and the public.

- Physical Hazards: Heavy lifting, working at heights, and using heavy machinery can lead to injuries.

- Equipment Malfunction: Failures in pumps, valves, or other equipment can lead to spills, leaks, or exposure.

Understanding these hazards is the first step towards implementing the appropriate preventive measures.

Q 4. How do you ensure the accurate weighing and measurement of chemicals during loading/unloading?

Accurate weighing and measurement are vital for efficient inventory management and safety. Several methods are employed:

- Electronic Scales and Load Cells: These are used to weigh chemicals directly during loading and unloading. These must be calibrated regularly for accuracy.

- Flow Meters: For liquids, flow meters measure the volume of chemical transferred. These require regular calibration and are often combined with electronic scales for redundancy.

- Level Sensors: These devices monitor the level of chemicals in tanks or containers, allowing for precise control of the loading process.

- Manual Measurement (Less Accurate): While less precise, manual measurements (e.g., using calibrated graduated cylinders for smaller volumes) are sometimes used for cross-checking or smaller quantities.

Data from these instruments are recorded in a log, often digitally, for traceability and verification. Regular equipment maintenance and calibration are crucial for maintaining accuracy.

Q 5. What are your methods for preventing chemical spills and leaks during transport?

Preventing spills and leaks during transport requires a combination of strategies:

- Proper Container Selection: Choosing containers appropriate for the chemical’s properties is fundamental. This includes considering its compatibility with the container material.

- Secure Container Closure: Ensuring containers are properly sealed prevents leaks. This includes using appropriate caps, seals, and other closure devices.

- Secure Transportation: Proper loading and securing of containers on vehicles or railcars prevents shifting and damage during transport.

- Regular Inspection: Checking containers for damage or leaks before, during, and after transport is crucial.

- Spill Containment: In case of a spill, readily available absorbent materials and spill containment systems are essential. A good response plan reduces the environmental impact of a spill.

- Weather Conditions: Inclement weather can compromise safety; transport may need to be delayed if conditions are too severe.

Think of it like building a sturdy, leak-proof box – careful planning and execution are key.

Q 6. Explain the process of verifying the chemical’s identity before loading or unloading.

Verifying chemical identity is critical for safety. This involves several steps:

- Visual Inspection: Checking labels, markings, and container condition for any inconsistencies.

- Documentation Review: Comparing the information on the shipping documents (bill of lading, certificates of analysis) against the container labels. Inconsistencies should immediately trigger investigation.

- Laboratory Analysis (If Necessary): In cases of doubt or high-risk chemicals, laboratory analysis can confirm the chemical’s identity. This may involve techniques such as spectroscopy or chromatography.

A robust system of checks and balances is vital to ensure the right chemical is being handled. Mistakes can have potentially devastating consequences.

Q 7. How do you handle discrepancies between the shipping documents and the actual chemical delivered?

Discrepancies between shipping documents and the actual chemical delivered are serious and require immediate action. The process includes:

- Stop the process immediately: Do not proceed with loading/unloading until the discrepancy is resolved. This prevents accidental use of the wrong chemical.

- Thorough investigation: Identify the source of the discrepancy (e.g., mislabeling, incorrect documentation, substitution). This involves a detailed examination of all documents and physical verification of the container.

- Contact relevant parties: Inform the shipper, receiver, and possibly regulatory authorities, depending on the nature and severity of the discrepancy. Documentation of communication is key.

- Segregation and containment: Isolate the misidentified chemical securely, ensuring it does not contaminate other materials or pose a risk. Appropriate storage is critical.

- Corrective action: Once the cause is identified, implement measures to prevent future discrepancies (e.g., improve labeling procedures, enhance documentation processes).

Transparency, thorough documentation, and a focus on corrective actions are crucial to prevent recurrence.

Q 8. What is your experience with different types of loading equipment (e.g., pumps, conveyors)?

My experience encompasses a wide range of loading and unloading equipment. I’m proficient with various pump types, including centrifugal pumps for high-volume transfers, positive displacement pumps for precise metering of viscous chemicals, and diaphragm pumps for handling corrosive or abrasive substances. My experience also includes working with different conveyor systems – belt conveyors for bulk materials, screw conveyors for powders and granular materials, and pneumatic conveyors for dust-sensitive materials. I understand the operational nuances of each, including safety protocols and maintenance requirements. For instance, I’ve managed the transition from a less efficient belt conveyor system to a more modern pneumatic system at a previous facility, resulting in a significant reduction in material loss and improved worker safety.

- Centrifugal Pumps: Ideal for high-volume, low-pressure applications.

- Positive Displacement Pumps: Ensure accurate and consistent flow rates, crucial for precise chemical mixing.

- Diaphragm Pumps: Suitable for handling chemicals that are corrosive or contain abrasive particles.

- Belt Conveyors: Efficient for bulk transportation of materials over long distances.

- Screw Conveyors: Used for handling powders and granular materials.

- Pneumatic Conveyors: Minimize dust generation during transportation of fine powders.

Q 9. Describe your experience with various chemical handling safety regulations (e.g., OSHA, DOT).

My experience with chemical handling safety regulations is extensive, encompassing OSHA (Occupational Safety and Health Administration) and DOT (Department of Transportation) standards. I’m well-versed in hazard communication, including the proper labeling, handling, and storage of hazardous chemicals (SDS review is a standard part of my workflow). I understand the importance of personal protective equipment (PPE), including respirators, gloves, and eye protection, and I’ve conducted numerous safety training sessions for colleagues. I’m familiar with emergency response protocols, including spill containment and cleanup procedures, and I’ve led emergency response drills to ensure preparedness. I’ve also consistently maintained compliance with all applicable regulations regarding the transportation of hazardous materials, including proper documentation and hazard classification.

For instance, during a recent audit, I identified and corrected a potential violation regarding the storage of incompatible chemicals, preventing a potential serious incident. This involved working with the safety committee and implementing new storage protocols, reinforcing my commitment to safety and compliance.

Q 10. How do you maintain accurate records of chemical loading and unloading activities?

Maintaining accurate records is paramount in chemical handling. We utilize a combination of digital and paper-based systems to track all loading and unloading activities. This includes detailed logs documenting the date, time, quantity, chemical identification (using CAS numbers), source, destination, and any relevant observations. Digital systems, like our facility’s chemical inventory management software, provide real-time tracking, which is easily accessed for audit trails and reporting. These systems integrate with our loading equipment, automatically recording quantities transferred. Paper logs are used for backup and in instances of temporary system outages and are always reconciled with the digital system. All records are maintained according to regulatory requirements and company policy for a minimum of three years.

Q 11. Explain the process for inspecting and maintaining chemical handling equipment.

Regular inspection and maintenance are critical to ensure the safe and efficient operation of chemical handling equipment. We follow a rigorous preventative maintenance schedule, including daily visual inspections for leaks, damage, or wear, and scheduled maintenance activities based on manufacturer recommendations and usage. These tasks include lubrication, cleaning, and component replacement as needed. Detailed records of all inspections and maintenance activities are meticulously maintained. We use a Computerized Maintenance Management System (CMMS) to schedule, track, and manage these activities. For example, pressure testing of pumps and thorough checks of conveyor belts and rollers prevent catastrophic failures and minimize downtime. If a problem is detected, we immediately take corrective actions, documenting the issue, the steps taken to rectify it, and confirming its resolution.

Q 12. What is your experience with emergency response procedures in case of chemical spills?

Emergency response to chemical spills is a critical aspect of my expertise. I’ve participated in numerous training programs and drills simulating various spill scenarios, involving different chemicals and response procedures. My training includes the use of spill kits and appropriate containment techniques. I’m proficient in activating emergency response plans, contacting relevant authorities (e.g., emergency services, environmental agencies), and coordinating evacuation procedures if necessary. I understand the importance of personal safety and the use of proper protective equipment during a spill response. Furthermore, I ensure post-spill cleanup adheres to environmental regulations and includes proper disposal of contaminated materials. For instance, I once led the response team in a minor sulfuric acid spill, implementing containment procedures and safely neutralizing the spill, minimizing environmental impact and preventing injury.

Q 13. How do you ensure the proper segregation of incompatible chemicals during storage and transport?

Proper segregation of incompatible chemicals is essential to prevent hazardous reactions. We maintain a detailed chemical compatibility matrix that guides the storage and transportation of chemicals, keeping incompatible substances physically separated. This includes using designated storage areas, labeled containers, and implementing strict protocols for handling and movement of chemicals. Incompatible materials are never stored adjacent to each other. Our warehouse layout is specifically designed to maximize separation, with clear visual indicators denoting incompatible chemical zones. We also use color-coded labels and storage racks to further improve segregation, making identification and handling of incompatible chemicals straightforward and mistake-proof.

Q 14. How do you manage inventory control for chemicals to prevent stockouts or overstocking?

Inventory control is crucial for efficient chemical management. We use a sophisticated inventory management system which tracks chemical quantities, usage rates, and ordering thresholds, preventing stockouts and minimizing overstocking. This system provides real-time insights into inventory levels, allowing for proactive ordering and preventing production delays due to material shortages. The system integrates with our loading and unloading processes, updating inventory levels automatically. Regular stock audits are conducted to verify accuracy. We also implement a just-in-time inventory strategy to minimize storage space and reduce waste, optimizing our stock levels and ensuring a sufficient supply while limiting unnecessary costs associated with excessive storage.

Q 15. Describe your understanding of the various labeling and identification systems for chemicals.

Chemical labeling and identification are critical for safety. Various systems exist, each aiming to clearly communicate the inherent hazards of a chemical substance. These systems are designed to prevent accidents and ensure proper handling.

- Globally Harmonized System of Classification and Labelling of Chemicals (GHS): This internationally recognized system uses pictograms, signal words (danger/warning), hazard statements, and precautionary statements to provide a standardized approach. For instance, a flammable liquid will display a flame pictogram with corresponding hazard and precautionary statements indicating flammability hazards and safe handling instructions.

- Safety Data Sheets (SDS): These comprehensive documents provide detailed information about a chemical’s properties, hazards, safe handling procedures, emergency response measures, and disposal information. Think of them as a chemical’s detailed instruction manual.

- Manufacturer-Specific Labels: Manufacturers often add their own specific labels containing additional information pertinent to their product, often including concentration, lot number, and expiry dates, enhancing traceability and accountability.

- Color-Coding Systems: In some industries, color-coding systems are used on containers to quickly identify the type or hazard class of a chemical. This is often used for quick identification in a warehouse or lab. For example, red might signify flammability, while yellow might signify corrosivity.

Understanding these systems is paramount to prevent accidents. A mislabeled or unidentified chemical can lead to serious consequences, ranging from minor skin irritation to severe health problems or even explosions. In my experience, consistently verifying labels and SDS information before handling any chemical is an absolute priority.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with chemical waste disposal and recycling procedures.

Chemical waste disposal and recycling are crucial for environmental protection and worker safety. My experience encompasses various procedures, each tailored to the specific chemical waste’s properties. Ignoring proper procedures can lead to environmental contamination and health hazards.

- Waste Characterization: The first step involves identifying the chemical waste and its hazards. This includes determining its physical state (solid, liquid, gas), flammability, corrosivity, toxicity, and reactivity.

- Segregation: Incompatible wastes must be segregated to prevent dangerous reactions. For example, acids and bases should never be mixed.

- Containerization: Appropriate containers – often specialized, leak-proof containers – are used for storing the waste, with clear labeling indicating the chemical’s identity and hazards.

- Disposal/Recycling Methods: This involves choosing the appropriate disposal method based on local regulations and the nature of the waste. Options may include incineration, landfilling, specialized waste treatment facilities, or recycling programs for certain chemicals.

- Documentation: Meticulous record-keeping is essential, documenting the waste generated, its disposal method, and the disposal facility used. This ensures compliance with environmental regulations and facilitates tracing the waste stream.

In a past role, I was involved in implementing a new chemical waste management system that reduced waste generation by 20% through improved recycling and process optimization. This demonstrated a significant cost savings and reduced our environmental footprint.

Q 17. How do you identify potential hazards during the loading and unloading process?

Identifying potential hazards during loading and unloading is a proactive measure to prevent accidents. This requires a methodical approach combining pre-planning and on-site observation.

- Pre-Loading Checklist: This includes verifying the compatibility of the chemicals being transported, ensuring containers are in good condition, and checking the vehicle’s suitability for the specific chemicals being loaded. It also requires reviewing the SDS for each chemical to understand its specific hazards.

- On-site Inspection: Before the loading or unloading process begins, I conduct a thorough visual inspection of the area, checking for potential trip hazards, spills, damaged containers, and proper ventilation. I also examine the equipment to ensure it’s in good working order and suitable for handling the chemical.

- Monitoring During Loading/Unloading: During the process itself, I actively monitor for leaks, spills, or any unusual occurrences. I ensure that the workers follow all safety protocols and that the equipment is operated correctly. A key part of this is communicating effectively with the team to promptly address any issue.

- Emergency Preparedness: Having an emergency plan in place and readily available is crucial. This includes knowing where safety equipment is located and understanding emergency procedures in case of a spill or other incident.

For example, during the unloading of a corrosive chemical, I discovered a crack in the container. Promptly stopping the unloading and reporting the damage prevented a potential spill and associated injuries.

Q 18. What are the best practices for securing chemicals during transportation?

Securing chemicals during transport is paramount to prevent spills, leaks, and potential hazards. This involves a multi-faceted approach:

- Proper Packaging: Chemicals must be packaged in appropriate containers designed to withstand the rigors of transportation, including vibrations and potential impacts. This includes using secondary containment, such as placing containers inside larger, leak-proof containers.

- Securement: Containers need to be securely fastened within the transport vehicle to prevent movement during transit. This often involves using straps, chains, or other restraints to anchor them firmly. Properly secured cargo prevents shifting and potential damage to containers.

- Placarding: Transport vehicles carrying hazardous chemicals must be clearly marked with appropriate placards to indicate the type and hazard class of the chemicals being transported. This alerts other drivers and emergency responders to potential hazards.

- Route Planning: The chosen route should minimize the risk of accidents. Avoiding areas with high traffic or potential hazards reduces the likelihood of incidents during transport. Weather conditions should also be considered, with alternatives planned for potential hazardous weather.

- Driver Training: Drivers responsible for transporting hazardous chemicals must receive proper training on safe handling, emergency response, and securement procedures.

Imagine a scenario where improperly secured drums of corrosive chemicals shifted during transit causing a leak. This would be dangerous for both the driver and the environment. Proper securement is non-negotiable.

Q 19. How do you ensure the proper ventilation in areas where chemicals are handled?

Ensuring proper ventilation in areas where chemicals are handled is critical to prevent exposure to harmful fumes and vapors. The approach depends on the type and quantity of chemicals involved.

- Local Exhaust Ventilation (LEV): For localized sources of chemical fumes, LEV systems are commonly employed. These systems use hoods or enclosures to capture fumes at the source and exhaust them safely outside the building.

- General Ventilation: For larger areas or less concentrated fumes, general ventilation, such as fans or HVAC systems, might be sufficient. These systems dilute the concentration of airborne chemicals to safe levels.

- Monitoring: Regularly monitoring air quality with appropriate sensors is crucial to ensure the effectiveness of the ventilation system. This involves detecting the presence and concentration of harmful chemicals in the air.

- Emergency Ventilation: Emergency ventilation systems should be in place to address unexpected releases or spills of chemicals. This might involve additional fans or a dedicated ventilation system for emergency situations.

- Engineering Controls: Incorporating engineering controls, such as sealed containers and enclosed processes, minimize the release of fumes into the air in the first place.

Poor ventilation can lead to serious health problems for workers, from headaches and nausea to more serious respiratory issues. In my experience, continuous air quality monitoring and prompt maintenance of ventilation systems are essential.

Q 20. Describe your experience with using personal protective equipment (PPE) while handling chemicals.

Personal Protective Equipment (PPE) is indispensable when handling chemicals. My experience emphasizes the importance of selecting and using the right PPE for the specific hazard. PPE alone won’t prevent every accident but reduces risks significantly.

- Respirators: For airborne hazards, respirators are critical, and the type chosen depends on the specific chemical and its hazard. For example, a full-face respirator with an appropriate cartridge is required for handling highly toxic chemicals.

- Gloves: Appropriate gloves must be chosen based on the chemical’s corrosivity, reactivity, and permeability. Different gloves are used for acids, bases, solvents, and other chemicals.

- Eye Protection: Safety glasses or goggles are essential to protect the eyes from splashes or airborne particles. Face shields offer additional protection when working with large quantities of chemicals.

- Protective Clothing: Depending on the hazard, this may range from lab coats to full body suits, designed to protect the skin from chemical contact. The material of the clothing should be resistant to the specific chemical.

- Footwear: Safety boots provide protection from chemical spills and potential puncture hazards.

I once observed a colleague fail to wear the correct gloves when handling a corrosive solvent, resulting in a minor burn. This reinforced the need for strict adherence to PPE protocols, and it underscores the importance of proper training and supervision.

Q 21. Explain your experience with using different types of pumps for chemical transfer.

Chemical transfer often involves various types of pumps, each suited for different chemicals and applications. Selecting the right pump is crucial for safe and efficient transfer.

- Centrifugal Pumps: These are commonly used for low-viscosity liquids and are relatively simple to operate and maintain. They are widely applicable but may not be suitable for highly viscous or abrasive chemicals.

- Positive Displacement Pumps: These pumps are better suited for highly viscous liquids or those containing solids. Examples include gear pumps, lobe pumps, and peristaltic pumps. Peristaltic pumps are particularly useful when preventing contamination is crucial, as the chemical doesn’t come into contact with the pump’s internal components.

- Diaphragm Pumps: These are versatile pumps capable of handling corrosive, abrasive, and viscous chemicals. They use a diaphragm to move the liquid, minimizing the risk of pump damage.

- Air-Operated Double Diaphragm (AODD) Pumps: These pumps are often preferred for hazardous chemicals because they provide a positive shutoff and can handle liquids with suspended solids. They’re also useful in situations where electricity might be unavailable or poses a risk.

In a previous role, we had to transfer a highly corrosive chemical. We used a specialized AODD pump with chemically resistant components to ensure safe and efficient transfer, while minimizing the risk of pump failure and chemical exposure.

Q 22. How do you ensure the integrity of chemical containers during loading and unloading?

Ensuring the integrity of chemical containers during loading and unloading is paramount to prevent leaks, spills, and contamination. This involves a multi-pronged approach starting with a thorough pre-loading inspection.

- Visual Inspection: We check for any visible damage like dents, cracks, rust, or corrosion on the containers. For example, a bulging drum could indicate internal pressure buildup and imminent failure.

- Seal Integrity: We verify that all seals and closures are intact and properly secured. Loose caps or damaged seals are immediate red flags.

- Container Type Verification: We confirm that the container material is compatible with the chemical being transported. For instance, using an unsuitable material can lead to chemical reactions and container degradation.

- Proper Handling Equipment: Using appropriate lifting equipment like forklifts or specialized pumps ensures the containers aren’t damaged during movement. Incorrect lifting can cause punctures or structural damage.

- Documentation: We maintain detailed records of inspections, noting any defects or issues found. This documentation is crucial for traceability and for identifying potential patterns or problems.

Think of it like this: just as you wouldn’t use a cracked glass to hold water, we don’t use damaged containers to hold hazardous chemicals. Each step in our process contributes to a safe and efficient operation.

Q 23. How do you manage the potential risks associated with temperature-sensitive chemicals?

Managing temperature-sensitive chemicals demands meticulous planning and execution. The key is to maintain the product’s required temperature range throughout the entire loading, transportation, and unloading process. This often involves:

- Temperature Monitoring: We use calibrated temperature sensors and data loggers to continuously monitor the temperature of the chemicals inside the containers, both during transit and storage. This provides a verifiable record of temperature fluctuations.

- Insulated Containers: We use insulated containers, refrigerated trucks, or specialized temperature-controlled containers to prevent excessive heating or cooling. The choice depends on the chemical’s specific temperature requirements.

- Pre-cooling/Heating: Before loading, we might pre-cool or pre-heat the containers to match the product’s temperature to minimize temperature shock during transit.

- Emergency Protocols: We have established procedures to handle temperature deviations, including immediate notification of relevant personnel and implementation of corrective actions.

- Proper Documentation: Meticulous record-keeping documenting temperature readings throughout the process is crucial for regulatory compliance and quality control.

For example, a pharmaceutical product might require constant refrigeration, while certain reactive chemicals need to be kept below a specific temperature to avoid degradation or hazardous reactions.

Q 24. What is your experience with using computer systems to track and manage chemical inventory?

I have extensive experience using computer systems for chemical inventory tracking and management. We’ve utilized various software solutions, including ERP (Enterprise Resource Planning) systems and specialized chemical management software.

- Inventory Tracking: These systems allow real-time monitoring of chemical inventory levels, including location, quantity, and batch numbers.

- Automated Ordering: Many systems are capable of automatically generating purchase orders when inventory levels fall below a predetermined threshold, ensuring timely replenishment.

- Safety Data Sheet (SDS) Management: They often incorporate SDS management, enabling easy access to relevant safety information for each chemical. This significantly improves safety procedures.

- Reporting and Analytics: The data collected provides valuable insights into usage patterns, helping optimize inventory levels and identify potential areas for improvement.

- Integration with other systems: Some systems integrate with warehouse management systems and transportation logistics platforms, streamlining the entire supply chain.

For example, I’ve worked with systems that provide alerts when incompatible chemicals are stored together, enhancing safety in the warehouse. The use of such systems reduces human error, speeds up processes, and improves overall efficiency.

Q 25. How do you conduct a pre-shift inspection of chemical handling equipment and work areas?

A pre-shift inspection of chemical handling equipment and work areas is a non-negotiable safety procedure. It involves a methodical check of all equipment and the work environment to identify and rectify potential hazards before operations begin.

- Equipment Check: This includes verifying the functionality of pumps, valves, hoses, forklift trucks, and other handling equipment. We look for leaks, damage, or malfunctions that could lead to spills or equipment failure.

- Work Area Inspection: We check for any spills, obstructions, or unsafe conditions in the work area, such as damaged flooring or inadequate lighting.

- Personal Protective Equipment (PPE) Check: We ensure that adequate and correctly functioning PPE, such as gloves, respirators, safety glasses, and protective clothing, is readily available and in good condition.

- Emergency Equipment: We verify that safety showers, eyewash stations, and spill kits are in place and functional, ready to be used in case of an incident.

- Documentation: We meticulously document all findings, including any defects or deficiencies. The documentation serves as a record of the inspection and ensures accountability.

Think of it as a pre-flight check for an airplane. A thorough inspection minimizes risk and ensures a safe and productive work environment.

Q 26. Describe your experience with different types of chemical storage tanks and their safe handling.

My experience encompasses various types of chemical storage tanks, including:

- Horizontal Cylindrical Tanks: These are commonly used for storing large volumes of liquids. Safe handling involves ensuring proper grounding to prevent static electricity buildup and using appropriate valves and fittings to control fluid flow.

- Vertical Cylindrical Tanks: These offer efficient storage, especially for larger volumes. Safety considerations include proper inspection of tank walls for corrosion and ensuring that pressure relief valves are correctly functioning.

- Spherical Tanks: These are often used for storing high-pressure gases. Safe handling requires adherence to strict pressure and temperature limits, as well as regular inspections for structural integrity.

- Bulk Bags (Flexible Intermediate Bulk Containers or FIBCs): These are used for storing and transporting powders and granular materials. Safe handling includes ensuring the bags are properly secured and not overloaded, to prevent tears or spills.

Each tank type has specific safety protocols. For instance, entering a confined space like a large tank requires a permit-to-work system, atmospheric monitoring, and appropriate respiratory protection. The overarching principle is understanding the specific hazards associated with each tank type and applying the necessary safety measures.

Q 27. How would you address a situation where a chemical spill occurs during loading/unloading?

Responding to a chemical spill during loading/unloading requires immediate and decisive action. Our response protocol is based on a well-defined emergency plan that prioritizes personnel safety and environmental protection:

- Immediate Evacuation: The first step is to evacuate personnel from the immediate vicinity of the spill to prevent exposure. The extent of the evacuation depends on the nature and quantity of the spilled chemical.

- Containment: We use absorbent materials like spill pads or diatomaceous earth to contain the spill, preventing further spread. Dams or barriers may also be used depending on the circumstances.

- Notification: We immediately notify emergency response teams, including fire department and hazmat (hazardous materials) specialists. This notification includes the type and quantity of spilled chemical, the location, and the extent of the spill.

- Decontamination: We ensure that any affected personnel are decontaminated using appropriate methods, including showering and changing clothing.

- Clean-up: Specialized cleanup crews trained in hazardous materials handling remove the spilled chemical using appropriate techniques and equipment.

- Investigation: After the immediate response, a thorough investigation is conducted to determine the cause of the spill and to implement preventative measures to avoid similar incidents in the future.

Regular training exercises simulating spill scenarios are conducted to enhance our response capabilities and ensure that our team can react swiftly and effectively in real situations.

Q 28. What are your strategies for preventing and mitigating the risks of chemical exposure?

Preventing and mitigating the risks of chemical exposure is central to our operations. Our strategy relies on a combination of engineering controls, administrative controls, and personal protective equipment (PPE):

- Engineering Controls: These aim to eliminate or reduce exposure at the source. Examples include enclosed systems for chemical transfer, local exhaust ventilation to remove airborne contaminants, and automated systems to minimize manual handling.

- Administrative Controls: These address work practices and procedures. Examples are implementing strict standard operating procedures (SOPs), providing comprehensive safety training to all personnel, and enforcing regular health monitoring programs.

- Personal Protective Equipment (PPE): Appropriate PPE, such as gloves, respirators, eye protection, and protective clothing, is provided and regularly inspected to ensure effectiveness. Employee training on the correct use and limitations of PPE is mandatory.

- Emergency Preparedness: Having a detailed emergency response plan, including procedures for spill response and decontamination, is critical. Regular drills and training ensure that the team is adequately prepared.

- Monitoring and Evaluation: Regular monitoring of workplace air quality and personnel exposure levels helps assess the effectiveness of control measures and identify areas for improvement.

A robust safety culture, where everyone understands and embraces safety procedures, is essential to minimizing chemical exposure risks. We foster this culture through open communication, regular safety meetings, and a commitment to continuous improvement.

Key Topics to Learn for Chemical Loading and Unloading Interview

- Safety Regulations and Procedures: Understanding and adhering to OSHA regulations, MSDS interpretation, and emergency response protocols. This includes practical application in recognizing and handling hazardous materials.

- Chemical Properties and Handling: Knowledge of different chemical classifications (acids, bases, flammables, etc.), their reactivity, and appropriate handling techniques. Practical application includes understanding compatibility charts and safe transfer methods.

- Equipment Operation and Maintenance: Familiarity with pumps, valves, hoses, and other equipment used in loading and unloading. This includes troubleshooting common issues and performing basic maintenance.

- Loading and Unloading Procedures: Understanding the entire process from pre-loading checks to post-loading verification, including documentation and record-keeping. Practical application includes planning efficient loading sequences and minimizing risks.

- Inventory Management and Tracking: Accurately tracking chemical quantities, ensuring proper labeling, and managing inventory levels. This includes understanding inventory control software and best practices.

- Waste Management and Disposal: Proper handling, storage, and disposal of chemical waste in accordance with environmental regulations. Practical application involves understanding different waste streams and appropriate disposal methods.

- Documentation and Reporting: Maintaining accurate records, completing necessary paperwork, and reporting any incidents or near misses. This includes understanding the importance of clear and concise communication.

Next Steps

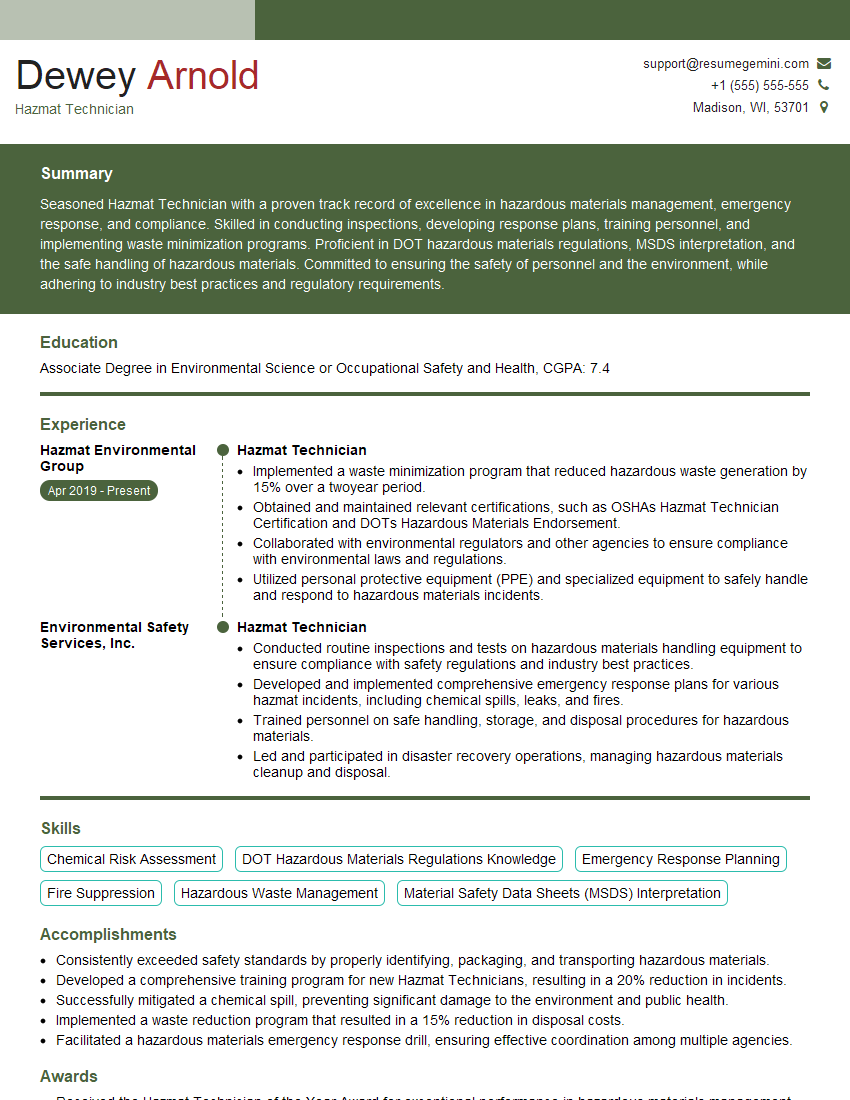

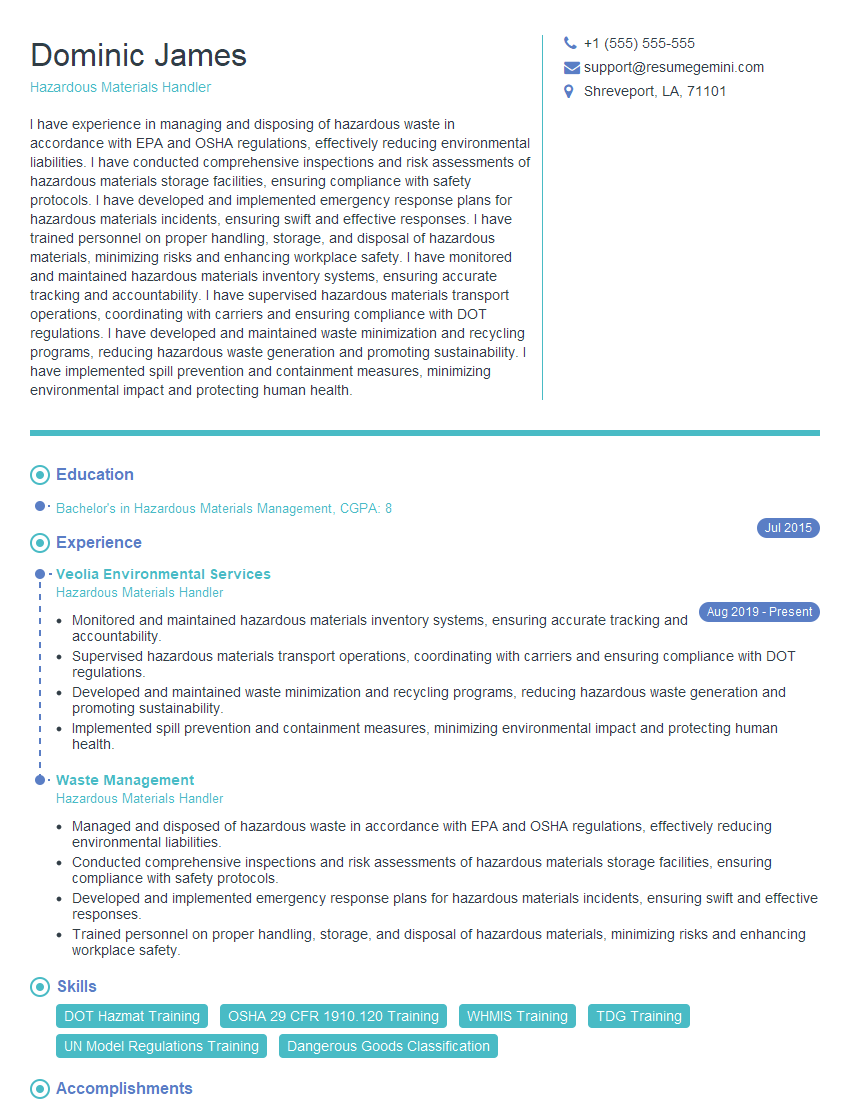

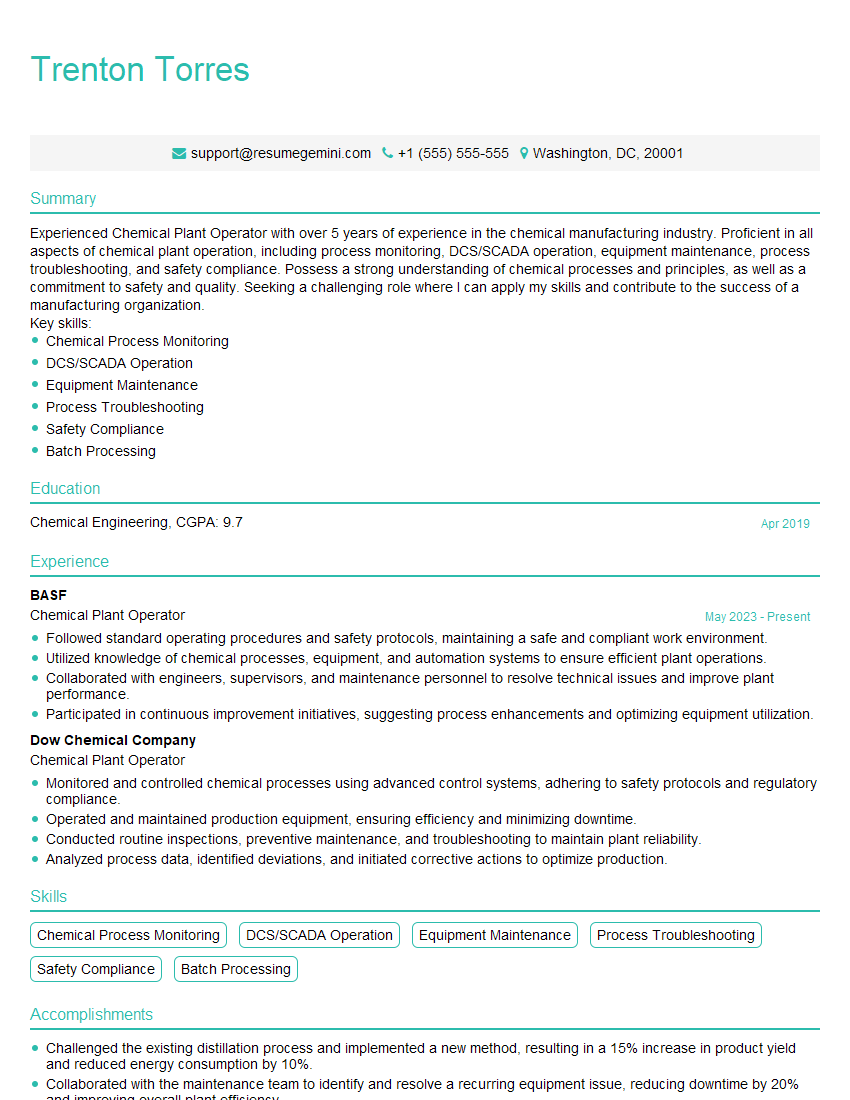

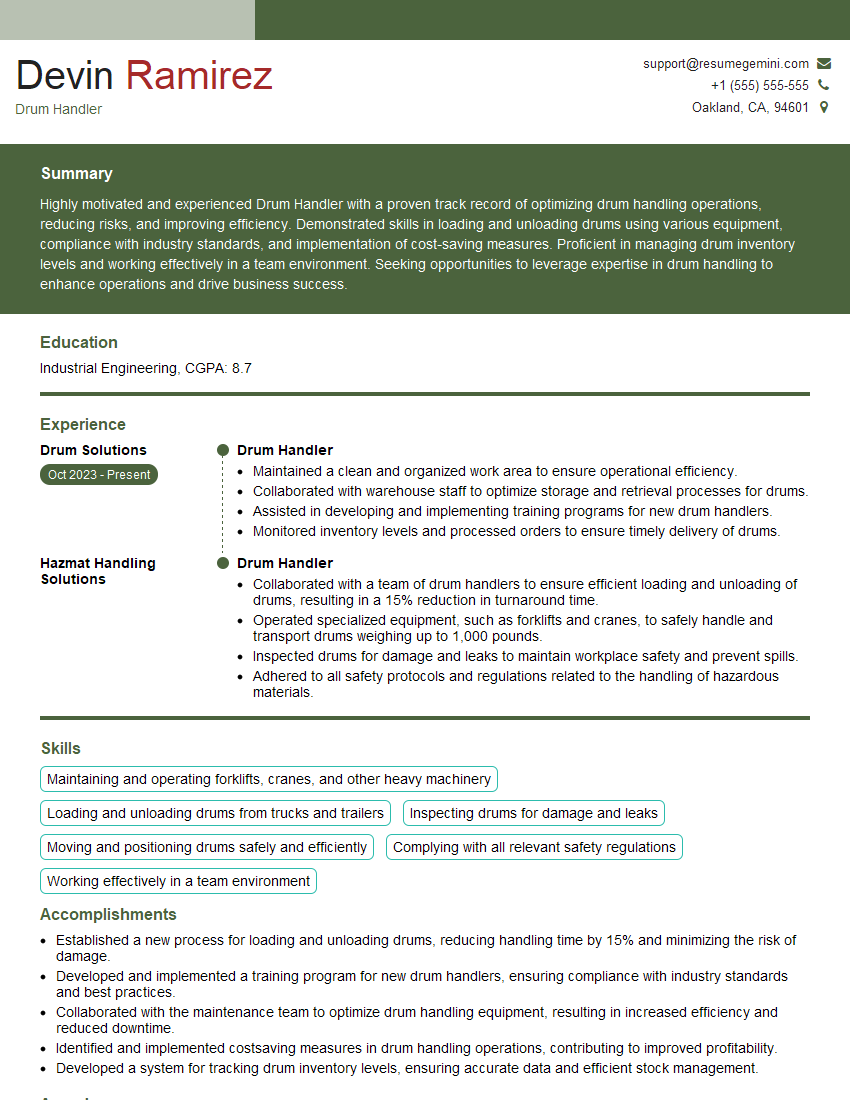

Mastering chemical loading and unloading opens doors to a rewarding career with excellent growth potential in various industries. A strong understanding of safety protocols and efficient handling techniques is highly sought after. To maximize your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you craft a professional resume showcasing your skills and experience effectively. We provide examples of resumes tailored to Chemical Loading and Unloading to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?