Preparation is the key to success in any interview. In this post, we’ll explore crucial Autoclave Data Analysis and Interpretation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Autoclave Data Analysis and Interpretation Interview

Q 1. Explain the principles of autoclave sterilization.

Autoclave sterilization relies on the principle of moist heat under pressure to eliminate microorganisms. High-pressure steam penetrates materials more effectively than dry heat, denaturing proteins and disrupting the cellular structure of bacteria, viruses, and spores. Think of it like this: Imagine trying to kill a bug with a blow dryer (dry heat) versus boiling water (moist heat). Boiling water is far more effective because the water penetrates the bug’s exoskeleton, leading to faster and more complete destruction. Similarly, the steam in an autoclave penetrates materials efficiently, ensuring sterilization.

The increased pressure within the autoclave raises the temperature of the steam well above the boiling point of water at normal atmospheric pressure (100°C). This higher temperature, combined with the penetrating power of the steam, effectively kills even the most resilient microbial life forms. A typical autoclave cycle reaches temperatures of 121°C (249°F) or 132°C (270°F) to ensure complete sterilization.

Q 2. Describe different types of autoclaves and their applications.

Autoclaves come in various types, each suited for specific applications:

- Gravity Displacement Autoclaves: These are the simplest type, relying on gravity to remove air and introduce steam. They are typically used in smaller labs and clinics for sterilizing smaller loads.

- Pre-vacuum Autoclaves: These are more sophisticated, using a vacuum pump to remove air before steam entry, ensuring quicker and more uniform sterilization of porous materials. This is ideal for sterilizing wrapped instruments or materials that may trap air.

- High-Speed/Flash Autoclaves: These are designed for rapid sterilization cycles, often used in situations demanding quick turnaround times like surgical settings. However, load size is usually limited.

- Steam Sterilizers: Often used in industrial settings, these large-scale steam sterilizers can handle significant volumes of materials requiring sterilization.

The choice of autoclave depends on the volume and type of materials to be sterilized, as well as the desired speed of the cycle. For example, a hospital operating room might use a pre-vacuum autoclave for rapid sterilization of surgical instruments, whereas a smaller medical clinic might use a gravity displacement autoclave for less time-sensitive sterilization needs.

Q 3. What are the critical parameters for effective autoclave sterilization?

Effective autoclave sterilization hinges on several critical parameters:

- Temperature: Achieving and maintaining the appropriate temperature (usually 121°C or 132°C) throughout the sterilization cycle is essential. Insufficient temperature will lead to incomplete sterilization.

- Pressure: Pressure is directly linked to temperature. The higher the pressure, the higher the temperature achievable. Monitoring pressure ensures the steam reaches the required temperature.

- Time: The duration of exposure to the temperature and pressure is crucial. A shorter time might not be enough to kill all microorganisms, while an excessively long time might damage certain materials.

- Steam Quality: The steam must be saturated (not superheated or wet) to ensure optimal heat transfer. Air in the chamber reduces the efficiency of heat transfer, preventing effective sterilization.

- Load Size and Placement: Overloading the autoclave or improperly placing items can hinder steam penetration, resulting in uneven sterilization. Items should be evenly spaced to allow for proper steam circulation.

Careful monitoring and control of these parameters are essential to guarantee the sterilization process’s effectiveness.

Q 4. How do you interpret autoclave cycle reports?

Autoclave cycle reports provide a detailed record of the sterilization process. They typically include information such as:

- Start and end times: Indicates the duration of the cycle.

- Temperature and pressure readings: Shows whether the required parameters were met throughout the cycle.

- Chamber pressure: Indicates the pressure inside the autoclave, reflecting the steam’s temperature.

- Steam quality: Ensures the steam was saturated for effective heat transfer.

- Drying time: Ensures materials are properly dried to avoid contamination.

- Any alarms or errors: Highlights potential issues during the cycle.

Interpreting these reports requires understanding the specific parameters required for the type of sterilization cycle used. Any deviation from the expected parameters warrants investigation and potential corrective action. A thorough review of these reports is crucial for quality control and ensuring the sterilization process’s efficacy. An example report might display a graph charting temperature and pressure over time, enabling quick visual assessment of cycle performance.

Q 5. What are the key indicators of a successful autoclave cycle?

Key indicators of a successful autoclave cycle include:

- Achieved target temperature and pressure: The cycle must reach and maintain the predefined temperature and pressure throughout the exposure phase.

- Proper steam penetration: This ensures that the steam reaches all parts of the load.

- Complete drying cycle: Ensures materials are dry to prevent contamination.

- Absence of errors or alarms: The absence of alarms or error messages during the cycle indicates smooth operation.

- Verification with biological indicators: In high-risk situations, biological indicators (spores of highly resistant microorganisms) can be included in the load. Their successful inactivation confirms the effectiveness of the sterilization process.

- Chemical indicators: These indicators change color once exposed to the correct conditions of the sterilization cycle and indicate that the load has been subjected to a certain temperature and pressure, although not necessarily complete sterilization.

These indicators, taken together, provide strong evidence that the autoclave cycle has successfully eliminated microorganisms and rendered the sterilized materials safe.

Q 6. How do you identify and troubleshoot common autoclave malfunctions?

Troubleshooting autoclave malfunctions involves systematic investigation:

- Review the cycle report: Start by examining the autoclave’s cycle report. Errors or deviations from the expected parameters will often pinpoint the problem.

- Check for air leaks: Air leaks reduce the efficiency of sterilization. Inspect the door seals and chamber for any leaks.

- Inspect the steam supply: Ensure an adequate and uninterrupted supply of saturated steam. Issues with the steam generator could be the root cause.

- Verify the safety devices: Make sure safety devices like pressure relief valves are functioning correctly. Malfunctions here can halt the process or pose safety risks.

- Inspect the drainage system: Blockages in the drainage system can prevent air removal and proper steam circulation.

- Consult the manufacturer’s documentation: The manufacturer’s documentation provides troubleshooting guides and technical specifications that can help diagnose specific problems.

Remember to always follow safety protocols when troubleshooting any equipment and consult trained professionals when necessary. For example, a persistent failure to reach the target temperature could point to a malfunctioning heating element or a low steam pressure issue.

Q 7. Explain the concept of sterilization validation.

Sterilization validation is a critical process that demonstrates the autoclave consistently achieves sterilization according to its intended use. It’s not enough to assume the autoclave works; it must be proven. This involves comprehensive testing and documentation to ensure every cycle effectively eliminates microorganisms.

Validation typically includes:

- Installation Qualification (IQ): Verifying the autoclave’s proper installation and that it conforms to specifications.

- Operational Qualification (OQ): Testing the autoclave’s performance parameters – temperature, pressure, time – to ensure they are within acceptable ranges.

- Performance Qualification (PQ): Demonstrating the autoclave consistently achieves sterilization using both physical indicators (temperature/pressure monitoring) and biological indicators (spores of resistant microorganisms). This phase also considers load configurations representative of real-world applications.

Successfully completing sterilization validation provides documentation assuring regulatory compliance and patient safety, especially vital in healthcare and pharmaceutical settings where sterility is paramount. Regular revalidation ensures the autoclave continues to perform to the required standards over time.

Q 8. Describe the methods used to validate autoclave performance.

Autoclave validation ensures it consistently achieves sterilization. We use a multi-pronged approach involving physical, chemical, and biological methods. Physical validation focuses on parameters like temperature and pressure, ensuring they reach and maintain the required levels throughout the cycle. This often involves using temperature and pressure recorders that generate charts showing the cycle profile. Chemical indicators (CIs) change color when exposed to specific sterilization conditions, providing a visual confirmation that the process parameters were met at least at a specific point in the chamber. However, CIs don’t guarantee sterility. Finally, biological indicators (BIs) are the gold standard, employing live microorganisms highly resistant to the sterilization method. Their inactivation confirms the effectiveness of the sterilization process in killing even the most resistant spores.

For example, a typical physical validation might involve placing thermocouples at various points within the autoclave chamber to precisely map temperature distribution. Deviation from the targeted profile triggers an investigation and corrective action. Similarly, a thorough validation process will consider the effect of load size and type on sterilization efficacy.

Q 9. What are the regulatory requirements for autoclave sterilization documentation?

Regulatory requirements for autoclave sterilization documentation vary depending on the industry and geographical location. However, common threads include maintaining accurate and complete records. This typically includes the date, time, cycle parameters (temperature, pressure, duration), the load details (items sterilized, quantity), the BI and CI results (including lot numbers and expiry dates), and the operator’s signature. These records must be readily retrievable and stored according to regulations such as those outlined by the FDA (in the US), or the EU’s Medical Device Regulation (MDR), and relevant national standards. Failure to maintain proper records can lead to serious consequences, including regulatory action and product recalls.

For instance, in a pharmaceutical setting, these records are subject to rigorous audits by regulatory bodies. Incomplete or inaccurate documentation is a major cause of audit failures.

Q 10. How do you ensure data integrity in autoclave records?

Data integrity in autoclave records is paramount. It involves implementing measures to ensure accuracy, completeness, consistency, and reliability of the data. This starts with using calibrated instruments, employing validated software, and establishing clear standard operating procedures (SOPs). Regular instrument calibration and preventative maintenance are critical. Electronic data logging systems offer enhanced traceability and minimize human error but require validation to ensure they consistently and accurately record data. A robust audit trail should also be maintained to track any changes or modifications made to the records. Furthermore, access control measures prevent unauthorized alteration of data.

Imagine a scenario where a crucial parameter is incorrectly recorded. This could lead to a false sense of security and potentially compromise patient or consumer safety. Robust data integrity measures prevent such occurrences.

Q 11. Explain the importance of biological indicators (BIs) in autoclave validation.

Biological indicators (BIs) are crucial for autoclave validation because they provide the most direct evidence of sterilization efficacy. Unlike physical and chemical indicators, BIs use living microorganisms, usually highly resistant bacterial spores (like Geobacillus stearothermophilus for steam sterilization), which are designed to withstand harsh conditions. If the autoclave process successfully inactivates these spores, it provides strong evidence that the process is capable of killing less resistant organisms. The presence of viable spores after the cycle indicates a failure of the sterilization process. BIs are the only way to definitively prove the lethality of the cycle, confirming that the conditions were sufficient to eliminate all microorganisms, even those most resistant to the process.

Think of BIs as the ultimate test of the autoclave’s sterilization capabilities—a ‘canary in the coal mine’ for sterilization effectiveness.

Q 12. How do you interpret BI results?

BI results are interpreted by comparing the post-sterilization growth to the pre-sterilization growth. BIs typically consist of a carrier (e.g., a paper strip) containing a known population of spores. After the autoclave cycle, the BI is incubated under specific conditions, allowing for the growth of any surviving spores. The absence of growth indicates successful sterilization; the presence of growth indicates a failure. This is often assessed visually, by checking for turbidity or a color change in the growth medium, or quantitatively using plate counting techniques. The results are documented and compared to predetermined acceptance criteria; failure to meet these criteria triggers an investigation and corrective actions.

For example, if a BI shows growth after incubation, a thorough investigation is warranted, including checking the autoclave’s cycle parameters, the BI’s integrity, and potential issues with the load configuration or the autoclave itself.

Q 13. What are the different types of BIs and their applications?

Several types of BIs exist, each tailored to different sterilization methods and applications. For steam sterilization, Geobacillus stearothermophilus spores are commonly used due to their high resistance to moist heat. For ethylene oxide (EO) sterilization, Bacillus atrophaeus spores are often employed. BIs can be self-contained (containing the growth medium within a vial), or they can be inoculated on a carrier that is then placed in the growth medium after the sterilization cycle. Self-contained BIs are convenient but more expensive. The choice of BI depends on factors such as the sterilization method, the type of load being sterilized, and regulatory requirements.

For instance, a manufacturer of surgical instruments might use self-contained BIs for steam sterilization to simplify the testing process.

Q 14. Describe the process of conducting a sterility test.

A sterility test, also known as a sterility assurance level (SAL) test, is a rigorous microbiological examination designed to confirm the absence of viable microorganisms in a sample after a sterilization process. The method involves aseptically transferring a sample from the sterilized item into a suitable growth medium (broth). The medium is then incubated under optimal conditions for the growth of microorganisms. The absence of turbidity or color change after incubation indicates that the sample is sterile. The test duration depends on the type of organism expected and the conditions used in incubation. Positive controls (samples known to contain microorganisms) and negative controls (sterile media) are always included to ensure the validity of the test. These tests are typically conducted in accredited laboratories to ensure high standards of sterility and quality control.

The process mimics the ‘worst-case scenario’ to determine the effectiveness of the sterilization cycle and the likelihood of product contamination. It’s a crucial step, especially in medical device manufacturing or pharmaceutical applications, to ensure patient safety and product quality.

Q 15. How do you investigate and resolve out-of-specification (OOS) results from autoclave cycles?

Investigating and resolving out-of-specification (OOS) autoclave results requires a systematic approach. Think of it like a detective solving a crime – you need to gather evidence and follow a trail to pinpoint the root cause. First, we verify the OOS result itself. Is there a possible instrument error? Was the data logger functioning correctly? We’ll review the cycle’s parameters – temperature, pressure, and time – against the validated cycle. Any deviation here is a clue. Then, we meticulously check the load configuration. Was the load properly prepared? Were items evenly distributed, allowing for proper steam penetration? Poor load placement is a frequent culprit. We examine the autoclave itself – were there any maintenance issues recently? Was the door properly sealed? Any physical issues need documenting. Next, we interview operators – were there any procedural deviations? Was the cycle started and stopped correctly? Documentation is crucial here. Finally, we analyze the data, possibly using statistical process control (SPC) charts to determine if this is a random event or indicative of a larger problem. The investigation should culminate in a comprehensive report outlining the findings and corrective actions, including process improvements or equipment repairs to prevent recurrence. A key example: An OOS result might stem from a faulty temperature sensor; replacing it and revalidating the cycle resolves the issue.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the potential causes of autoclave cycle failures?

Autoclave cycle failures can arise from various sources. Think of it as a complex machine with multiple interdependent parts. A malfunctioning component anywhere in the process can result in failure. We can categorize these into several groups: Equipment malfunctions: Faulty sensors (temperature, pressure), malfunctioning steam generators, problems with door seals, or issues with the vacuum system are common mechanical culprits. Operational errors: Incorrect loading procedures (overloading, improper placement), incorrect cycle selection, and human errors in operating the equipment all contribute to failure. Process deviations: Insufficient steam penetration due to blocked vents, air entrapment, or improper load preparation, leading to insufficient sterilization. Environmental factors: Unusually low steam quality from the building’s system or unexpected power failures can also disrupt a cycle. Each potential cause necessitates a thorough investigation to determine the root cause and prevent future failures. For instance, a consistently low temperature in several cycles might point towards a failing heating element; a recurring failure to reach vacuum might highlight a leak in the system.

Q 17. Explain the role of statistical process control (SPC) in autoclave monitoring.

Statistical Process Control (SPC) is invaluable in autoclave monitoring. It provides a visual representation of process performance over time, allowing for early detection of trends indicating potential problems. Imagine it as a dashboard that shows you the ‘health’ of your autoclave operation. We use control charts, like Shewhart charts or CUSUM charts, to track key parameters like temperature and pressure during sterilization cycles. By plotting data points on these charts, we can establish control limits. Data points consistently falling within the limits demonstrate a stable process; points outside these limits signal potential deviations that require investigation. For instance, an upward trend in temperature might suggest a gradual heating element degradation, while unusually high variability might imply issues with the steam generation process. SPC allows for proactive intervention, preventing major failures and maintaining consistent sterilization quality. It’s a powerful tool that shifts autoclave monitoring from reactive troubleshooting to proactive risk management.

Q 18. How do you develop and implement an effective autoclave preventative maintenance program?

A preventative maintenance (PM) program for an autoclave is crucial for ensuring its reliable operation and preventing unexpected downtime. It’s like regularly servicing your car – it prevents major repairs later. The program should be based on the manufacturer’s recommendations and should encompass regular inspections, lubrication, cleaning, and testing of critical components. A comprehensive PM program includes: Visual inspections: Regular checks for leaks, corrosion, damage, and proper functioning of safety devices. Functional testing: Periodic verification of temperature, pressure, and vacuum sensors, as well as the steam generator. Cleaning and sanitization: Regular cleaning of the chamber, door seals, and other components to prevent contamination and buildup. Calibration and validation: Periodic calibration of sensors and revalidation of sterilization cycles according to established protocols. Documentation: Meticulous record-keeping of all PM activities, including dates, performed tasks, and any identified issues. The frequency of these tasks varies depending on usage and manufacturer guidelines; a higher usage frequency warrants more frequent checks. Regular, thorough PM drastically reduces the likelihood of failures and ensures the autoclave consistently performs at its best.

Q 19. Describe your experience with different autoclave software and data management systems.

My experience encompasses a range of autoclave software and data management systems. I’ve worked with systems ranging from basic paper-based records to sophisticated electronic data acquisition (EDA) systems integrated with enterprise resource planning (ERP) software. I’m familiar with different types of software, including those that monitor and record autoclave parameters (temperature, pressure, time), generate reports, and manage maintenance logs. Some systems allow for real-time monitoring, while others provide historical trend analysis. For example, I’ve used Sysmac Studio and other similar industrial automation software for advanced autoclave monitoring and data logging, in addition to various custom-developed systems and commercially available packages for data management and regulatory compliance. My experience extends to integrating these systems with laboratory information management systems (LIMS) for complete data traceability. Proper data management is critical for ensuring data integrity, traceability, and regulatory compliance. This expertise allows me to effectively troubleshoot, validate and interpret data from various systems to ensure accurate and reliable information for sterilization processes.

Q 20. Explain how you ensure compliance with Good Manufacturing Practices (GMP) in autoclave operations.

Ensuring GMP compliance in autoclave operations is paramount. It’s about ensuring the quality and safety of the products being sterilized. GMPs mandate rigorous documentation, validation, and standardized operating procedures. This involves: Standardized Operating Procedures (SOPs): Detailed, validated SOPs for all aspects of autoclave operation, including loading, cycle selection, monitoring, and maintenance. Validation: Thorough validation of the sterilization cycles to demonstrate that they consistently achieve the desired level of sterility. This usually includes biological indicators (BIs) and physical monitoring. Calibration and Maintenance: Regular calibration of instruments and preventative maintenance as per a scheduled program. Data Management: A robust system for recording, retaining, and managing all autoclave data, including cycle parameters, maintenance records, and any deviations. Personnel Training: Thorough training of personnel on SOPs and GMP requirements. Deviation Management: A system for documenting, investigating, and resolving any deviations from established procedures. A robust system in place ensures regulatory compliance and helps maintain a high standard of quality and safety. Failure to comply can lead to serious consequences, including product recalls or regulatory sanctions.

Q 21. How do you handle deviations from established autoclave procedures?

Handling deviations from established autoclave procedures requires a methodical approach, emphasizing documentation and root cause analysis. Think of it as a quality control process that ensures the integrity of the sterilization process. Whenever a deviation occurs, it must be immediately documented, detailing the specific deviation, the time of occurrence, and the personnel involved. Then, a thorough investigation is launched to identify the root cause of the deviation. This might involve reviewing the autoclave logs, interviewing operators, inspecting the equipment, and evaluating the sterilization process. Once the root cause is identified, corrective actions are implemented to prevent recurrence. This includes changes to SOPs, equipment repairs, or staff retraining. Finally, a comprehensive report is generated, documenting the deviation, the investigation, the corrective actions, and the effectiveness of those actions. A deviation management system, often integrated within a LIMS or similar system, is crucial for tracking, analyzing, and reporting deviations. For example, a deviation might be caused by a power fluctuation; corrective action might involve installing a backup power system. Detailed documentation of each step in this process is critical for demonstrating regulatory compliance and minimizing risk.

Q 22. Describe your experience with different types of sterilization methods (e.g., dry heat, ethylene oxide).

My experience encompasses a broad range of sterilization methods, primarily focusing on steam sterilization (autoclaving) but also including experience with dry heat and ethylene oxide (EtO) sterilization. Steam sterilization, the most common method, uses pressurized steam to achieve high temperatures, effectively killing microorganisms. Dry heat sterilization uses high temperatures in the absence of moisture, suitable for materials that cannot withstand steam. This method takes longer to achieve sterilization than steam. Ethylene oxide is a gaseous sterilant used for heat-sensitive medical devices and equipment, but it’s crucial to note its toxicity and the need for specialized handling and ventilation. I’ve worked extensively with validating and troubleshooting each of these methods, focusing on ensuring efficacy and safety in diverse applications. For example, I once assisted a medical device manufacturer in switching from EtO to gamma irradiation to meet regulatory changes and improve environmental friendliness.

- Steam Sterilization (Autoclaving): I’m proficient in various autoclave types and cycle parameters, understanding how factors like temperature, pressure, and exposure time influence sterilization efficacy.

- Dry Heat Sterilization: My experience involves validating dry heat ovens for glass and metal instruments, ensuring thorough sterilization while preventing damage.

- Ethylene Oxide Sterilization: My work with EtO included monitoring the process parameters, managing residual EtO levels, and ensuring compliance with strict environmental regulations.

Q 23. How do you assess the effectiveness of different sterilization cycles?

Assessing the effectiveness of sterilization cycles relies on a multi-pronged approach combining physical monitoring, chemical indicators, and biological indicators. Physical monitoring involves recording temperature, pressure, and time parameters during each cycle. This data ensures that the autoclave reached and maintained the required conditions for a sufficient duration. Chemical indicators are labels that change color when exposed to the sterilization process, confirming the cycle’s completion. Biological indicators (BIs) are spore strips containing highly resistant microorganisms (like Geobacillus stearothermophilus for steam). These BIs provide definitive proof of sterilization—if no growth is detected after incubation, sterilization is successful. To analyze the effectiveness, I compare the recorded data against pre-defined parameters specified in the validation protocols. Any deviations trigger an investigation. Consider a scenario where the temperature consistently falls short during several cycles. This alerts us to a possible problem with the autoclave’s heating element or a faulty sensor needing immediate attention.

Q 24. How do you interpret the results of physical and chemical indicators?

Interpretation of physical and chemical indicators is essential in ensuring sterilization efficacy. Physical indicators like temperature and pressure charts show whether the autoclave reached and maintained the target parameters throughout the cycle. Significant deviations, like sustained low temperature, suggest incomplete sterilization. Chemical indicators (CIs) are a visual confirmation, demonstrating exposure to sterilization conditions. For instance, a color change on a CI tape indicates the steam has penetrated the package. However, CIs alone don’t confirm sterilization. A lack of color change means the sterilization process didn’t reach the package, while a color change assures only that the package was exposed to the conditions, not necessarily that it was sterilized. Biological indicators are the ultimate test. Incubation of BIs following a sterilization cycle confirms or refutes the presence of viable spores. Positive results indicate a failure of the sterilization process, and investigation is imperative. This three-step process is critical to ensure complete and accurate sterilization.

Q 25. What is your experience with using statistical software for autoclave data analysis?

I have extensive experience using statistical software like Minitab and JMP for autoclave data analysis. This involves analyzing large datasets of temperature, pressure, and time readings to identify trends, assess cycle-to-cycle variability, and determine whether the autoclave consistently meets the predetermined parameters. Statistical methods, such as control charts (e.g., Shewhart charts, CUSUM charts) and process capability analysis, are crucial for establishing and maintaining consistent sterilization performance. For example, I’ve used these tools to demonstrate that an autoclave consistently achieves a sterilization process capability (Cpk) greater than 1.33, indicating a robust and reliable process, greatly reducing the risk of sterilization failures. I’m also proficient in using statistical software to analyze biological indicator results, determining the sterility assurance level (SAL).

Q 26. Describe your experience in writing validation reports and SOPs related to autoclaves.

I’ve been extensively involved in writing validation reports and standard operating procedures (SOPs) for autoclaves. Validation reports meticulously document the process of validating an autoclave’s performance, showing evidence that it consistently meets predefined sterilization parameters. These reports include detailed information on equipment qualification, process validation, and results of performance qualification tests. SOPs provide detailed instructions on how to operate, maintain, and troubleshoot autoclaves, ensuring consistent performance and operator safety. I’ve developed SOPs covering aspects like loading techniques, cycle selection, and record-keeping practices, always aiming for clear, concise documentation tailored to the specific autoclave model and application. A well-structured SOP minimizes human error and ensures consistent sterilization across multiple operators. For example, I once developed an SOP for a new autoclave installation that streamlined the entire process, resulting in a 15% reduction in cycle time.

Q 27. How do you stay updated with the latest regulations and best practices in autoclave sterilization?

Staying updated with the latest regulations and best practices in autoclave sterilization is crucial. I actively participate in professional organizations like the Association for the Advancement of Medical Instrumentation (AAMI) and follow their publications and guidelines. I also regularly review relevant regulatory documents, including those from the FDA and other governing bodies. Attending workshops and conferences and participating in professional development activities are other ways I stay abreast of current advancements and regulatory changes. The field is continually evolving, with technological improvements in autoclave design and sterilization techniques continually emerging. Staying current with these changes ensures that the sterilization processes remain effective, safe, and compliant.

Key Topics to Learn for Autoclave Data Analysis and Interpretation Interview

- Understanding Autoclave Cycles: Mastering the parameters (temperature, pressure, time) and their impact on sterilization efficacy. This includes recognizing deviations and their potential causes.

- Data Acquisition and Validation: Familiarize yourself with different data logging systems and methods for ensuring data accuracy and reliability. Understanding data cleaning and preprocessing techniques is crucial.

- Statistical Analysis of Autoclave Data: Learn to apply statistical methods (e.g., mean, standard deviation, control charts) to analyze trends, identify outliers, and assess process capability. Understanding the principles of statistical process control (SPC) is essential.

- Interpreting Results and Reporting: Practice effectively communicating your findings through clear and concise reports, including visualizations (graphs and charts) to highlight key insights and conclusions.

- Troubleshooting and Problem Solving: Develop your skills in identifying and resolving issues related to autoclave performance, including interpreting error messages and suggesting corrective actions. Understanding root cause analysis techniques will be valuable.

- Regulatory Compliance and Documentation: Understand relevant regulations and guidelines pertaining to sterilization processes and documentation requirements. This includes knowledge of Good Documentation Practices (GDP).

- Different Autoclave Types and Applications: Become familiar with various autoclave types (e.g., gravity displacement, prevacuum) and their specific applications in different industries (e.g., pharmaceutical, medical device).

Next Steps

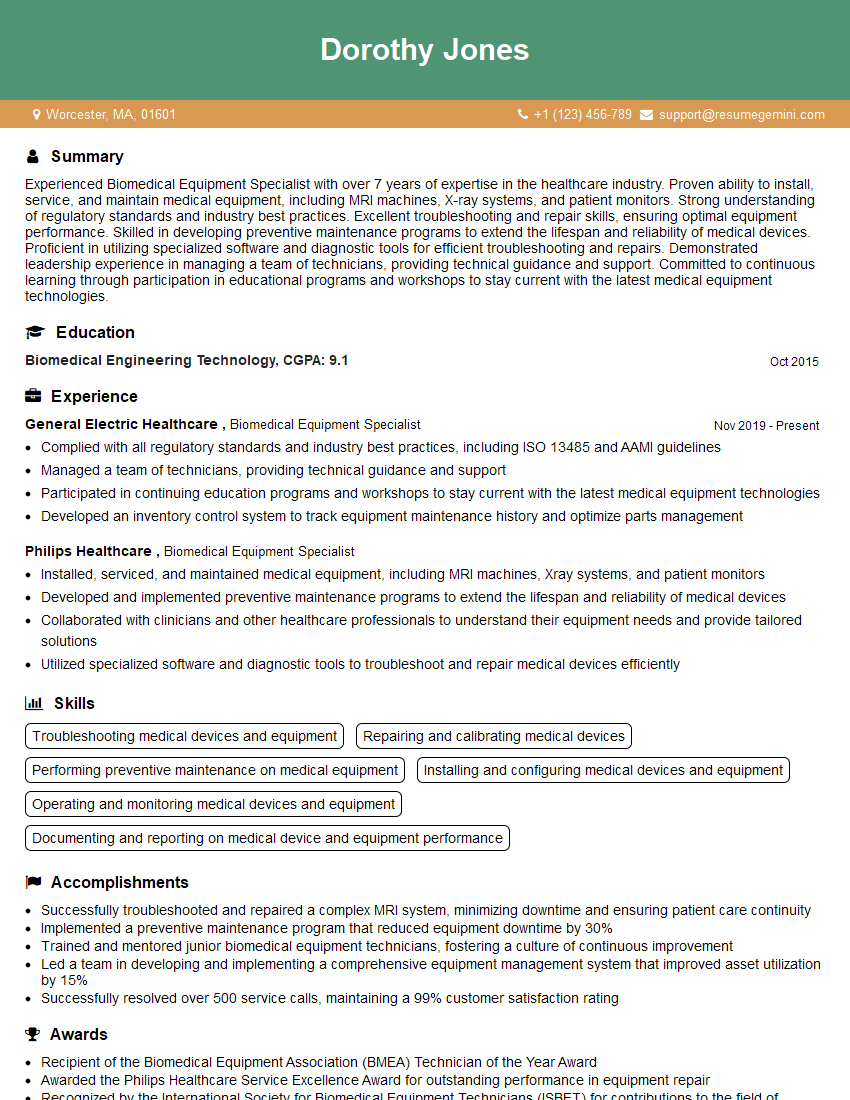

Mastering Autoclave Data Analysis and Interpretation is vital for advancing your career in quality control, manufacturing, or research environments that rely on sterilization processes. A strong understanding of these techniques demonstrates valuable problem-solving and analytical skills highly sought after by employers. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Autoclave Data Analysis and Interpretation are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?