The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Boiler Troubleshooting and Repair interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Boiler Troubleshooting and Repair Interview

Q 1. Describe your experience troubleshooting boiler malfunctions.

Troubleshooting boiler malfunctions requires a systematic approach. My experience encompasses a wide range of issues, from simple control problems to complex component failures. I begin by carefully listening to the client’s description of the problem – is there a complete shutdown, reduced heating capacity, unusual noises, or leaking? This initial information helps me prioritize my diagnostic steps.

I then visually inspect the boiler, checking for obvious signs of leaks, corrosion, or damage. I’ll check gauges for pressure, temperature, and water level readings. I use specialized tools like multimeters to test electrical components, pressure gauges to verify system pressure and infrared thermometers to detect temperature anomalies. For example, I recently diagnosed a boiler failure where a seemingly minor electrical fault in the control circuit prevented the burner from igniting. Another case involved a significant leak traced back to a corroded section of piping identified through visual inspection and pressure testing. This systematic approach, combining observation, testing, and experience, allows me to quickly and accurately identify the root cause of the malfunction.

Q 2. Explain the process of boiler water treatment and its importance.

Boiler water treatment is crucial for preventing scale buildup, corrosion, and other problems that can severely impact efficiency and lifespan. It involves a multi-step process aimed at maintaining optimal water chemistry within the boiler system. The process typically begins with pre-treatment, often involving filtration to remove solids and suspended particles. This is followed by chemical treatment using chemicals such as oxygen scavengers (to prevent corrosion), scale inhibitors (to prevent mineral buildup), and pH adjusters (to maintain the ideal pH range). Regular water testing is vital to monitor the effectiveness of the treatment and adjust the chemical dosages as needed. The importance of proper water treatment cannot be overstated; neglecting it can lead to costly repairs, reduced efficiency, and even boiler failure.

For example, untreated water can lead to the formation of hard scale deposits on heat transfer surfaces. This scale acts as an insulator, significantly reducing heat transfer efficiency and increasing fuel consumption. In extreme cases, it can even lead to overheating and boiler tube failure.

Q 3. How do you diagnose a low water level in a boiler?

Diagnosing a low water level in a boiler involves several steps. First, visually check the water level gauge glass (if present). A low reading indicates a problem. If the gauge glass is faulty or missing, check the low-water cutoff switch or other low-level sensors. These are safety devices designed to shut down the boiler automatically if the water level gets dangerously low. Inspect for leaks around the boiler, feedwater lines, and other components. A consistent drop in water level points towards a leak. Check the feedwater pump to ensure it’s functioning correctly and supplying sufficient water. A malfunctioning feedwater pump would lead to a reduced water level. If the level is consistently low despite seemingly normal operation, consider the possibility of a leak within the boiler itself, possibly requiring a pressure test to identify its location.

For instance, I once dealt with a case where a seemingly low water level was actually due to a faulty gauge glass – the reading was incorrect. In another situation, a small leak in a valve was causing a slow but steady drop in water level over time.

Q 4. What are the common causes of boiler leaks?

Boiler leaks can stem from several causes. Corrosion is a major culprit, especially in older boilers or those exposed to corrosive water. Stress cracks can develop in areas of high pressure or temperature fluctuations. Poor maintenance, such as neglecting regular inspections, can accelerate wear and tear, leading to leaks. Improper installation or faulty components can also contribute to leaks. Specific locations include joints in the piping system, welds, pressure relief valves, and safety valves. The type of leak (dripping, spraying, etc.) can provide clues to its source.

For example, I’ve seen leaks develop at valve seals due to wear and tear, and I’ve dealt with leaks in the boiler shell due to long-term corrosion. In one case, an improperly installed gasket caused a significant leak. Thorough inspection and leak testing are vital to pinpoint the problem area.

Q 5. How would you identify and address a boiler burner malfunction?

Identifying and addressing a boiler burner malfunction starts with assessing the symptoms. Is the burner failing to ignite, is the flame unstable, or is there incomplete combustion? The first step is to check the gas or oil supply – ensure adequate fuel pressure and flow. Verify the operation of the ignition system (spark igniter or pilot light). Check the flame sensor to make sure it’s correctly detecting the flame. Inspect the air intake for obstructions that might be hindering proper combustion. Use a combustion analyzer to measure gas composition and ensure proper air-fuel mixture. Electrical components, such as relays, switches, and control boards, also need to be checked.

For example, a faulty flame sensor can prevent the burner from operating, even if there’s ample fuel supply. A dirty or clogged burner can lead to incomplete combustion, resulting in reduced efficiency and potentially dangerous gas emissions. I have regularly used a multimeter to test the continuity and voltage of various electrical components in the burner control circuit to isolate malfunctions.

Q 6. Explain the different types of boiler safety controls and their functions.

Boiler safety controls are paramount for preventing accidents and ensuring safe operation. These controls include:

- High-water cutoff: Shuts down the boiler if the water level becomes dangerously high.

- Low-water cutoff: Shuts down the boiler if the water level drops too low.

- Pressure relief valve: Releases excess pressure to prevent the boiler from exploding.

- Safety valves: Similar to pressure relief valves, providing additional safety redundancy.

- Flame safeguard controls: Prevent the burner from operating if the flame is not properly established or is extinguished.

- High-temperature limit control: Shuts off the boiler if the water temperature exceeds a safe limit.

These controls work in concert to ensure the boiler operates within safe parameters. Regular inspection and maintenance of these safety devices are essential for continued safe operation.

Q 7. What are the safety procedures you follow when working on a boiler?

Safety is my utmost priority when working on a boiler. I always follow a strict procedure, starting with a thorough risk assessment of the specific boiler and its surrounding environment. This includes checking for any potential hazards such as electrical shock, burns, or exposure to hazardous chemicals. Before commencing any work, I ensure the boiler is completely shut down, cooled down, and depressurized. I always use appropriate personal protective equipment (PPE), including safety glasses, gloves, and protective clothing. I thoroughly inspect all tools and equipment before use to ensure they are functioning correctly and safely. I never attempt to work on a boiler alone; I always have a colleague present for assistance and as a safety precaution. If a repair requires special skills or equipment that I do not possess, I consult a specialist or call for assistance.

Understanding the boiler’s operational characteristics and having a comprehensive understanding of the safety controls and procedures are key components to working safely.

Q 8. How do you interpret boiler pressure gauges and temperature indicators?

Boiler pressure gauges and temperature indicators are crucial for monitoring boiler operation and ensuring safe and efficient performance. The pressure gauge displays the steam pressure inside the boiler, typically in pounds per square inch (psi) or bar. A properly functioning gauge is essential for preventing boiler explosions. Temperature indicators, usually thermocouples or resistance temperature detectors (RTDs), display the temperature of the water or steam within the boiler. These readings are critical for maintaining optimal boiler efficiency and preventing overheating.

Interpreting these readings involves understanding normal operating parameters specific to the boiler system. For instance, a significant drop in pressure might indicate a leak, while a sudden rise could be a sign of overheating or a faulty safety valve. Similarly, unusually high or low temperatures can point to issues with fuel supply, burner efficiency, or water level. Regular monitoring and comparison against established baseline readings are essential for early detection of problems.

Example: If a boiler typically operates at 150 psi and 350°F, a sudden drop to 100 psi accompanied by a slightly lower temperature could point to a steam leak. Conversely, a rapid increase to 170 psi and 400°F suggests a potential control system malfunction or a problem with the safety valve. Always consult the boiler’s operating manual for specific acceptable ranges.

Q 9. Describe your experience with boiler combustion efficiency testing and optimization.

Combustion efficiency testing and optimization are vital for minimizing fuel consumption and reducing emissions. My experience involves using various techniques, including flue gas analysis using portable analyzers to measure oxygen (O2), carbon monoxide (CO), carbon dioxide (CO2), and nitrogen oxides (NOx) levels. These readings provide crucial data on the completeness of combustion. Low O2 indicates excess fuel, high CO suggests incomplete combustion, and elevated NOx points to high combustion temperatures.

Optimization involves adjusting fuel-air ratios, burner settings, and ensuring proper air distribution to achieve the optimal balance. This often involves a systematic approach of making small adjustments, recording the data, and repeating the process until the optimal efficiency is achieved. Furthermore, I utilize data loggers for continuous monitoring, providing a comprehensive understanding of the boiler’s performance over time. This aids in identifying trends and pinpointing areas for improvement.

Practical Example: In a recent project, a flue gas analysis revealed high CO levels. After adjusting the burner air register and performing a retest, we achieved a significant reduction in CO and a notable improvement in overall efficiency, leading to a decrease in fuel costs and environmentally friendly operation.

Q 10. Explain the importance of regular boiler maintenance and inspection.

Regular boiler maintenance and inspection are paramount for safety, efficiency, and longevity. Neglecting maintenance can lead to catastrophic failures, costly repairs, and even safety hazards. A comprehensive maintenance program includes regular visual inspections for leaks, corrosion, and other signs of wear and tear. It also involves checking and cleaning the burner, inspecting and cleaning heat exchanger surfaces to remove scale and deposits, testing safety devices like pressure relief valves and low-water fuel cut-off switches, and ensuring proper water chemistry.

Frequency: The frequency of inspection and maintenance depends on factors like boiler type, size, operating hours, and fuel type. However, a minimum of annual inspection and more frequent (e.g., quarterly or bi-annual) cleaning and maintenance are generally recommended. A well-documented maintenance log helps track these activities and enables proactive identification of potential problems before they escalate.

Importance: Regular maintenance reduces the risk of unexpected breakdowns, improves fuel efficiency, extends the boiler’s lifespan, and ensures compliance with safety regulations. Think of it like regular servicing of a car – preventative maintenance is far cheaper and less disruptive than emergency repairs.

Q 11. How do you identify and repair boiler scale buildup?

Boiler scale buildup is a common problem caused by mineral deposits accumulating on heat transfer surfaces. This reduces efficiency, increases fuel consumption, and can even lead to overheating and equipment damage. Identification usually involves visual inspection – looking for a hard, crusty deposit on the heat exchanger tubes or surfaces. Chemical testing of the boiler water can also indicate the presence and severity of scaling.

Repair: The method of removal depends on the severity of the buildup. For minor scale, chemical cleaning using acid-based descaling agents is often effective. This involves circulating the solution through the system for a specified time, followed by thorough rinsing to remove the dissolved scale. For heavy scale buildup, mechanical cleaning methods might be necessary, including using specialized tools to remove the scale manually. In extreme cases, sections of the boiler might require replacement.

Prevention: Regular water treatment, including water softening or the use of water treatment chemicals, is the most effective way to prevent scale formation. This involves controlling the hardness (calcium and magnesium content) and alkalinity of the boiler water.

Q 12. What are the common types of boiler feedwater pumps and their failure modes?

Boiler feedwater pumps are crucial for maintaining the water level within the boiler. Common types include centrifugal pumps and positive displacement pumps. Centrifugal pumps are widely used due to their simple design and relatively low cost. They use a rotating impeller to increase the water pressure and move it into the boiler. Positive displacement pumps, such as piston or diaphragm pumps, deliver a precise volume of water per stroke, making them suitable for applications requiring high-pressure and consistent flow.

Failure Modes: Common failure modes for centrifugal pumps include bearing failure, impeller wear, seal leaks, and cavitation (formation of vapor bubbles in the pump). Positive displacement pumps can suffer from similar bearing failures and seal leaks, but also from piston or diaphragm wear and tear. Improper lubrication, overloading, and inadequate priming can contribute to premature failure in both types. Regular monitoring of pump performance, including vibration analysis and pressure readings, helps identify potential problems early.

Q 13. How would you troubleshoot a problem with boiler steam pressure regulation?

Troubleshooting steam pressure regulation involves a systematic approach. First, I would check the pressure gauge to confirm the actual steam pressure is deviating from the set point. Then, I’d examine the pressure control valve (often a pressure reducing valve or PRV) to make sure it’s operating correctly. This might involve checking for leaks, mechanical obstructions, or sticking components. The control system’s settings, such as the set point and any safety interlocks, should also be reviewed.

Further Steps: If the problem persists, I would check the steam header pressure and ensure it’s within the normal operating range. I would then inspect the boiler’s steam supply and investigate potential issues with the boiler’s output, including problems with the burner, fuel supply, or the heat exchanger itself. Finally, I would consult the boiler’s schematics and operational manuals for detailed information on troubleshooting specific components. Modern boilers often incorporate advanced control systems. In such cases, diagnostic codes and data logs from the PLC or DCS system are crucial for accurate diagnosis.

Q 14. Describe your experience with boiler control systems (e.g., PLC, DCS).

My experience with boiler control systems encompasses both Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS). PLCs are widely used in smaller boiler systems, managing functions like burner control, feedwater regulation, and safety interlocks. I’m proficient in programming and troubleshooting PLCs using ladder logic and other programming languages. I have extensive experience with various brands and models of PLCs, understanding their specific functionalities and limitations.

DCS are more prevalent in larger, complex boiler systems, offering enhanced capabilities such as advanced process control, data logging, and remote monitoring. My work with DCS involves configuring and maintaining the control system’s hardware and software, interpreting process data for optimization, and troubleshooting complex control loops. This often involves working with various communication protocols like Modbus and Profibus.

Example: In one project, I successfully replaced an aging PLC in a small industrial boiler with a newer, more energy-efficient model. This involved migrating the existing control logic to the new PLC, testing the new system, and providing training to plant personnel. The upgrade resulted in improved fuel efficiency and reduced maintenance costs.

Q 15. How do you handle emergency situations related to boiler failures?

Boiler emergencies demand immediate, decisive action. My priority is always safety – securing the area, evacuating personnel if necessary, and shutting down the boiler according to established emergency procedures. This involves isolating fuel sources, stopping combustion, and venting steam safely. After securing the situation, I’d initiate a systematic diagnostic process, starting with a visual inspection to identify obvious problems (leaks, visible damage). I’d check pressure gauges, temperature indicators, and safety controls to pinpoint the source of the failure. Depending on the severity and my assessment, I would either initiate immediate repairs if feasible and safe, or contact specialized repair services and follow established protocols for emergency response. For example, in a case of a sudden pressure drop, I would immediately isolate the affected section, checking for leaks and assessing the extent of the problem to determine the repair strategy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of boiler startup and shutdown procedures.

Boiler startup and shutdown are crucial for operational safety and equipment longevity. Startup generally involves a series of checks: verifying fuel supply, inspecting water levels, examining safety devices and pressure gauges for correct operation. We then gradually increase the boiler’s heat input, monitoring pressure and temperature closely. We also check for leaks. This process is carefully monitored to ensure even heating and prevent thermal shock. Shutdown is a reverse process – slowly reducing heat input, allowing the boiler to cool down gradually. This prevents thermal stress on boiler components. We ensure all safety mechanisms are functional before concluding the shutdown process. Failure to follow proper procedures can lead to significant damage or even catastrophic failure. Imagine not allowing a boiler to cool down properly – the rapid temperature change could cause warping or cracking in the boiler tubes or shell.

Q 17. What experience do you have with different types of boilers (e.g., firetube, watertube)?

My experience encompasses various boiler types, including firetube and watertube boilers. Firetube boilers, with hot gases passing through tubes surrounded by water, are commonly found in smaller applications. I’m proficient in troubleshooting their common issues, such as tube leaks or burner malfunctions. Watertube boilers, characterized by water circulating within tubes surrounded by hot gases, are prevalent in larger industrial settings. My expertise includes maintenance and repair for high-pressure watertube boilers, including the intricacies of water treatment and feedwater regulation in these more complex systems. I have hands-on experience with both types, which allows me to tailor my approach to the specific needs of different boiler systems. For instance, while a firetube boiler might require simpler maintenance and repairs, a watertube boiler needs more specialized knowledge and equipment.

Q 18. What are your troubleshooting techniques for boiler flue gas analysis?

Boiler flue gas analysis is crucial for optimizing combustion efficiency and identifying potential problems. My troubleshooting techniques involve systematically analyzing the flue gas composition—measuring oxygen (O2), carbon monoxide (CO), carbon dioxide (CO2), and nitrogen oxides (NOx) levels. High CO levels indicate incomplete combustion, potentially due to improper air-fuel mixture or burner malfunction. Low O2 levels might point towards insufficient combustion air. Elevated NOx levels suggest high combustion temperatures. Through the systematic analysis of these parameters, along with a review of boiler operating parameters, I can pinpoint the root cause of issues like poor combustion efficiency, excess fuel consumption, or environmental compliance concerns. For example, unexpectedly high CO2 would suggest potential problems in the fuel supply or air supply systems. I always rely on calibrated instruments and established standards to ensure accuracy and consistency.

Q 19. How would you diagnose and repair a problem with a boiler’s blowdown system?

A malfunctioning blowdown system can lead to scaling and corrosion within the boiler, negatively impacting efficiency and safety. My diagnostic approach starts with a visual inspection of the blowdown valve and piping for leaks or obstructions. I then check the blowdown valve operation, ensuring it opens and closes completely. Next, I’d test water quality for signs of scaling, using water samples from different parts of the system. Common problems include clogged valves, damaged piping, or faulty controls. Repair strategies vary depending on the identified problem – replacing faulty valves, repairing or replacing pipes, and calibrating or repairing the blowdown control system. A step-by-step approach and careful attention to detail are crucial in this process. For example, if a valve is stuck, careful lubrication and freeing may suffice. If the pipe is corroded, section replacement is typically required.

Q 20. Explain your understanding of boiler efficiency and energy conservation.

Boiler efficiency and energy conservation are paramount for operational cost-effectiveness and environmental responsibility. My understanding centers on optimizing combustion, minimizing heat loss, and improving overall system efficiency. This involves regular maintenance, proper water treatment, and the use of efficient combustion control systems. For example, installing advanced combustion controls, using air preheaters to increase combustion air temperature and improve efficiency, or implementing regular cleaning of heat exchanger surfaces to minimize heat loss, are all strategies I leverage. Beyond this, regular inspections and preventive maintenance are crucial for preventing failures that lead to significant energy waste. The goal is always to maximize the energy produced from the fuel consumed, thus minimizing operating costs and the environmental impact. I am also well versed in the application of energy-saving technologies like economizers and waste heat recovery systems.

Q 21. How familiar are you with relevant boiler codes and regulations?

I am familiar with relevant boiler codes and regulations, including ASME (American Society of Mechanical Engineers) standards, local and national safety regulations, and environmental protection guidelines. I understand the importance of adhering to these codes and regulations to ensure boiler safety, compliance, and operational efficiency. This familiarity allows me to ensure the work is performed in compliance with applicable regulations, including safety, emissions, and operational requirements. Regular updates on relevant codes and legislation are part of my professional development. These codes dictate the construction, inspection, maintenance, and operation of boilers, and are critical for safe and reliable operation. Ignoring these regulations can have serious legal and safety implications.

Q 22. Describe your experience with boiler automation and remote monitoring.

My experience with boiler automation and remote monitoring spans over ten years, encompassing various systems from simple programmable logic controllers (PLCs) to sophisticated Building Management Systems (BMS). I’ve worked extensively with systems that provide real-time data on boiler operation, including pressure, temperature, fuel consumption, and efficiency. This data allows for predictive maintenance and proactive adjustments, significantly minimizing downtime and optimizing performance. For example, I once implemented a remote monitoring system for a large industrial boiler that alerted us to a minor leak before it escalated into a major problem, saving the company thousands in repair costs and potential production losses. This involved integrating the boiler’s control system with a cloud-based platform enabling access to real-time data from any location with internet access. Furthermore, I am proficient in configuring and troubleshooting various communication protocols like Modbus and BACnet commonly used in boiler automation.

Q 23. How do you prioritize maintenance tasks for a boiler system?

Prioritizing boiler maintenance tasks requires a systematic approach. I typically use a combination of factors, including manufacturer recommendations, operational history, criticality of the system, and regulatory requirements. I start by identifying critical components, such as safety valves, burner controls, and the combustion chamber, which require more frequent inspections and preventative maintenance. I then utilize a CMMS (Computerized Maintenance Management System) to schedule tasks, track completed work, and monitor the overall health of the boiler system. For example, a high-priority task might be a yearly inspection of the safety valve, while a lower priority task might be a bi-annual cleaning of the boiler’s external surfaces. This approach ensures that vital components are maintained regularly, reducing the risk of failures and extending the boiler’s lifespan. The prioritization also considers the potential impact of a failure on operations, prioritizing components crucial for continuous operations.

Q 24. How would you troubleshoot a boiler that is overheating?

Troubleshooting an overheating boiler requires a methodical approach, starting with ensuring personnel safety. First, I’d isolate the boiler and shut it down safely. Then, I’d systematically investigate possible causes. This includes checking the following:

- Low water level: This is a major cause of overheating and can lead to serious damage. I’d check the water level gauge and inspect for leaks.

- Scale buildup: Scale on heat transfer surfaces reduces efficiency and can lead to overheating. A visual inspection and possibly a chemical analysis would be conducted.

- Malfunctioning pump: An inefficient or failed circulation pump can result in uneven heating and overheating in certain areas. I’d check pump operation, pressure, and flow rate.

- Faulty burner controls: Problems with the burner’s flame sensor or control system can cause it to run excessively, leading to overheating. I’d inspect these components and check for proper operation and calibration.

- Blocked flue gas pathway: Restricted gas flow can cause excessive heat buildup. I’d inspect the flue gas passages for blockages.

Once the root cause is identified, appropriate repairs or adjustments would be implemented. I’d always document the issue, the troubleshooting steps taken, and the final resolution.

Q 25. What are the common causes of boiler pump failures?

Boiler pump failures can stem from several issues. Common causes include:

- Wear and tear: Mechanical components like seals, bearings, and impellers wear out over time due to constant operation. Regular lubrication and preventative maintenance can mitigate this.

- Cavitation: This occurs when the pump’s suction pressure is too low, causing vapor bubbles to form and collapse, leading to damage. It’s often related to insufficient water supply or incorrect piping.

- Corrosion: Exposure to water and other chemicals can cause corrosion of internal pump components, reducing efficiency and eventually leading to failure. Regular inspections and water treatment can prevent this.

- Overheating: Excessive heat can damage the pump’s seals and bearings. This is linked to problems within the boiler system itself.

- Sealing Issues: Leakage around seals can lead to reduced pump performance and eventual failure. This needs regular monitoring and prompt replacement when required.

Proper maintenance, including regular inspections and timely replacement of worn parts, is crucial in preventing boiler pump failures.

Q 26. Explain your experience working with different types of boiler fuels (e.g., natural gas, oil).

I have extensive experience working with boilers fueled by natural gas and oil. Natural gas systems require careful monitoring of gas pressure, flow, and combustion efficiency. I’m familiar with various gas burner types and their maintenance requirements. Oil-fired boilers, on the other hand, demand attention to fuel quality, atomization, and nozzle maintenance. I understand the importance of regular cleaning of fuel lines and filters to prevent clogging and ensure efficient combustion. The safety protocols for handling these fuels are significantly different, requiring strict adherence to safety guidelines to prevent accidents. I have experience working on boilers that use both low and high-pressure burners with adjustments to air and fuel mixture.

For example, I once worked on a project that converted an oil-fired boiler to natural gas. This involved a thorough evaluation of the existing system, design modifications, and installation of new gas burners and safety controls. The project required a deep understanding of both fuel types, and meticulous attention to detail for a safe and successful conversion.

Q 27. How do you ensure the safety of personnel during boiler maintenance or repair?

Ensuring personnel safety during boiler maintenance and repair is paramount. I always follow a strict safety protocol that includes:

- Lockout/Tagout (LOTO) procedures: This crucial step ensures that the boiler is completely isolated from power and fuel sources before any work begins, preventing accidental activation.

- Personal Protective Equipment (PPE): Appropriate PPE, such as heat-resistant gloves, safety glasses, and respirators, is always worn to protect against burns, injuries, and exposure to hazardous materials.

- Confined space entry procedures: If work requires entry into confined spaces, such as the boiler’s firebox, I strictly adhere to procedures that include atmospheric testing for oxygen levels and hazardous gases.

- Proper ventilation: Ensuring adequate ventilation is essential, especially when working with fuels or cleaning agents, which may produce hazardous fumes.

- Hot work permits: For any activity involving open flames or heat sources near the boiler, a hot work permit is required, ensuring proper safety precautions.

Safety briefings are conducted before each task, and all personnel are required to understand and follow established procedures. I always prioritize safety above all else.

Q 28. Describe your experience documenting boiler maintenance and repair activities.

Comprehensive documentation of boiler maintenance and repair activities is crucial for tracking performance, identifying recurring issues, and ensuring compliance with regulations. I meticulously record all activities in a CMMS, including the date, time, performed work, any parts replaced, and any observations made. This documentation includes detailed descriptions of problems encountered, troubleshooting steps taken, repairs performed, and preventative maintenance activities. Digital images and videos are often included to support the written record. This allows us to analyze trends, plan future maintenance, and justify repairs. For example, we recently identified a pattern of leaks in a specific type of valve after reviewing several years’ worth of maintenance records, leading to a proactive change of suppliers which reduced the number of replacements and therefore downtime. This thorough record keeping enables efficient tracking of our work, improves decision-making, and demonstrates accountability and compliance.

Key Topics to Learn for Boiler Troubleshooting and Repair Interview

- Boiler System Fundamentals: Understanding boiler types (fire-tube, water-tube), combustion processes, safety systems, and control systems. Practical application: Explain how different boiler types operate and their respective advantages and disadvantages.

- Troubleshooting Techniques: Systematic approaches to diagnosing boiler malfunctions, including using diagnostic tools and interpreting error codes. Practical application: Describe your methodology for isolating a problem in a complex boiler system.

- Combustion Efficiency and Optimization: Understanding factors affecting combustion efficiency (air-fuel ratio, excess air), and methods for optimizing boiler performance. Practical application: Explain how to adjust combustion parameters to improve efficiency and reduce fuel consumption.

- Safety Procedures and Regulations: Knowledge of relevant safety standards, lockout/tagout procedures, and emergency response protocols. Practical application: Describe your experience with maintaining a safe working environment while performing boiler maintenance and repair.

- Boiler Maintenance and Repair: Practical experience in performing routine maintenance tasks (e.g., cleaning, inspection, repairs) and troubleshooting common boiler problems. Practical application: Describe a challenging boiler repair you successfully completed, highlighting your problem-solving skills.

- Hydraulics and Piping Systems: Understanding boiler water chemistry, pump operation, and piping systems. Practical application: Explain the importance of maintaining proper water chemistry and how it relates to boiler efficiency and longevity.

- Control Systems and Instrumentation: Familiarity with different types of boiler control systems (e.g., PLC, DCS) and instrumentation (e.g., pressure gauges, temperature sensors). Practical application: Describe your experience working with different types of boiler control systems and troubleshooting related issues.

Next Steps

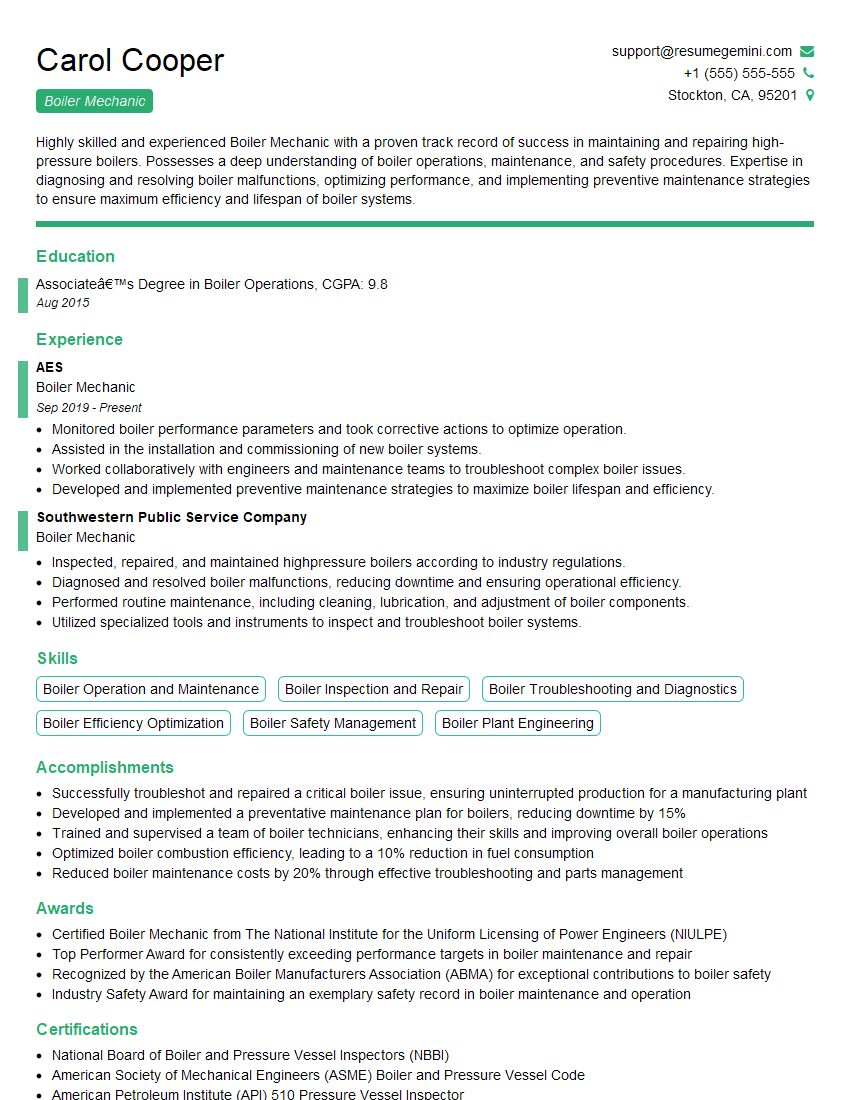

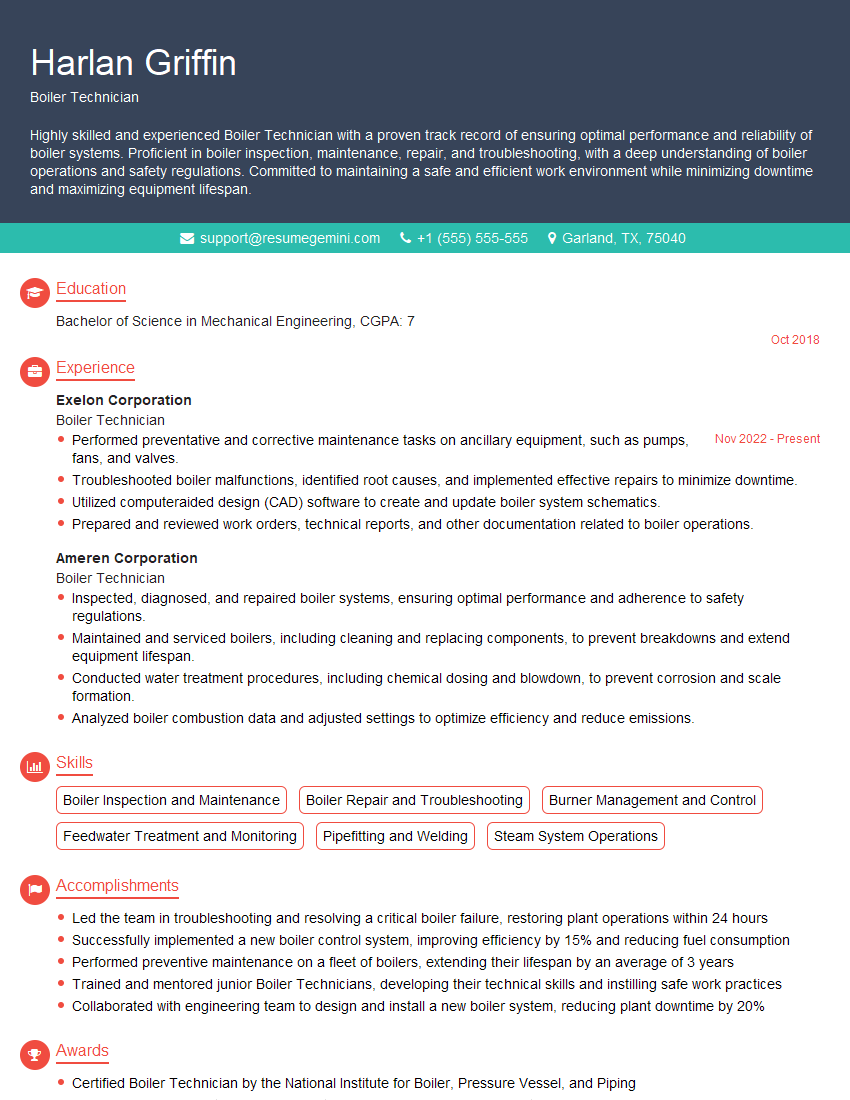

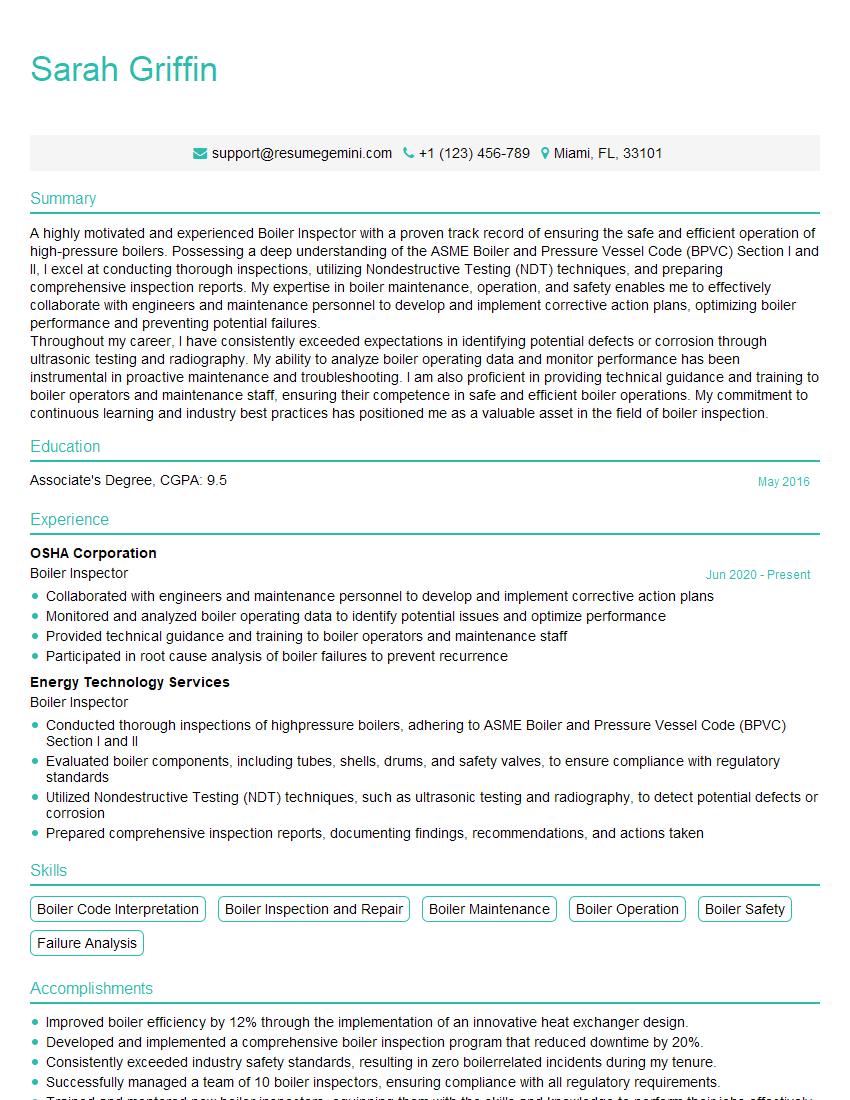

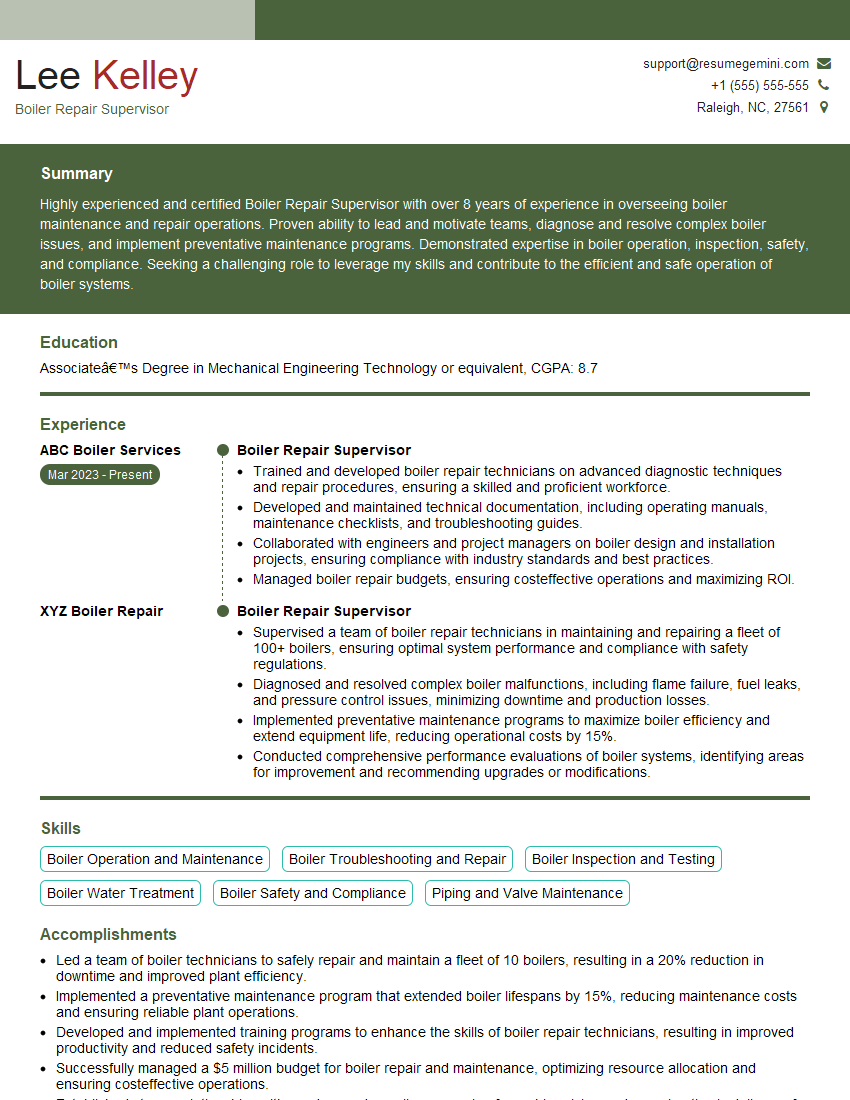

Mastering Boiler Troubleshooting and Repair opens doors to rewarding and high-demand careers in industrial maintenance, power generation, and building operations. To maximize your job prospects, it’s crucial to present your skills effectively. An ATS-friendly resume is essential for getting your application noticed by recruiters and hiring managers. We strongly encourage you to utilize ResumeGemini to create a powerful resume that highlights your expertise in Boiler Troubleshooting and Repair. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored specifically to this field, ensuring your application stands out from the competition. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?