Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Boiler Energy Efficiency interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Boiler Energy Efficiency Interview

Q 1. Explain the different types of boiler efficiency calculations.

Boiler efficiency calculations quantify how effectively a boiler converts fuel energy into useful heat. Several methods exist, each with its own strengths and weaknesses:

- Thermal Efficiency: This is the most common method and represents the ratio of the heat output in the steam or hot water to the heat input from the fuel. It’s calculated as:

Thermal Efficiency = (Heat Output / Heat Input) x 100%. For example, if a boiler produces 1000 BTU of heat and consumes 1200 BTU of fuel, its thermal efficiency is 83.33%. - Boiler Efficiency by Direct Measurement: This involves directly measuring the heat input and output using instruments like flow meters, temperature sensors, and calorimeters. This offers high accuracy but requires specialized equipment and expertise.

- Indirect Measurement Methods: When direct measurement is impractical, indirect methods are used, such as using fuel consumption data and estimates of heat losses to determine efficiency. These methods are less precise but more accessible.

- Stack Loss Method: This method calculates efficiency by analyzing the flue gases exiting the boiler stack. By measuring the temperature and composition of these gases, we can determine the energy lost and thereby calculate the efficiency. This requires specialized gas analyzers.

The choice of method depends on factors such as the available resources, the required accuracy, and the boiler’s complexity.

Q 2. Describe the factors affecting boiler efficiency.

Boiler efficiency is influenced by a multitude of factors. Think of it like a finely tuned engine – even small issues can impact performance significantly. These factors can be broadly classified as:

- Combustion Factors: Excess air, insufficient air, improper fuel-air mixing, and incorrect burner adjustments all impact combustion efficiency and heat transfer.

- Heat Transfer Factors: Scaling or fouling on heat transfer surfaces (like tubes) reduces heat transfer and efficiency. Poor insulation of the boiler casing leads to heat loss to the surroundings.

- Fuel Quality: The type and quality of fuel (e.g., coal, natural gas, oil) impact combustion efficiency. Impurities in the fuel can cause fouling and reduce efficiency.

- Boiler Design and Maintenance: The boiler’s design, including the type of boiler (fire-tube or water-tube), and the condition of its components all affect efficiency. Regular maintenance is crucial for optimal performance.

- Operating Conditions: Load variations, steam pressure fluctuations, and water chemistry also play significant roles. Operating a boiler at its optimal load range maximizes efficiency.

For example, a boiler with heavily scaled tubes will have reduced heat transfer, lowering its overall efficiency. Similarly, using low-quality fuel can lead to incomplete combustion and increased emissions, further impacting efficiency.

Q 3. How do you identify and troubleshoot common boiler inefficiencies?

Identifying and troubleshooting boiler inefficiencies requires a systematic approach. Think of it as a detective solving a mystery, gathering clues to pinpoint the problem.

- Monitor Key Parameters: Regularly monitor fuel consumption, steam production, flue gas temperature and composition, and boiler water parameters.

- Visual Inspection: Check for leaks, damaged insulation, and signs of scaling or corrosion on the boiler’s exterior and interior surfaces.

- Analyze Flue Gases: Using a flue gas analyzer, measure O2, CO, CO2, and other components to assess combustion efficiency. High O2 suggests excess air, while high CO indicates incomplete combustion.

- Check Burner Adjustments: Ensure proper fuel-air mixing and adjust burner settings to optimize combustion.

- Inspect Heat Transfer Surfaces: If scaling or fouling is detected, undertake appropriate cleaning procedures.

- Assess Insulation: Repair or replace damaged insulation to reduce heat losses.

- Review Operating Procedures: Ensure the boiler is operated according to manufacturer’s recommendations and optimal load conditions are maintained.

For instance, if flue gas analysis reveals high CO, it points to insufficient air, requiring adjustment of the air-fuel ratio. Similarly, excessive O2 suggests excess air, leading to wasted fuel. Addressing these issues through proper maintenance and adjustments directly improves efficiency.

Q 4. What are the key performance indicators (KPIs) for boiler efficiency?

Key Performance Indicators (KPIs) for boiler efficiency are crucial for monitoring performance and identifying areas for improvement. They provide a quantitative measure of how well the boiler is performing.

- Thermal Efficiency (%): As discussed earlier, this is the most important KPI.

- Fuel Consumption (MMBTU/hr or similar): This tracks the amount of fuel consumed per unit of time.

- Steam Production (lbs/hr or similar): This indicates the amount of steam generated.

- Specific Steam Consumption (fuel/steam): This shows the amount of fuel required to produce a unit of steam.

- Flue Gas Temperature (°F or °C): High flue gas temperature suggests heat losses.

- O2 and CO concentrations in flue gas (%): These indicate combustion efficiency.

- Heat Loss to Surroundings (BTU/hr): This quantifies the heat lost to the environment.

Tracking these KPIs over time allows for the identification of trends and early detection of efficiency problems. For example, a gradual increase in fuel consumption while steam production remains constant points to a decline in efficiency and warrants investigation.

Q 5. Explain the importance of regular boiler maintenance in improving efficiency.

Regular boiler maintenance is paramount for sustaining high efficiency and preventing costly breakdowns. Think of it as regular check-ups for your car – it keeps it running smoothly and prevents major problems down the line.

- Preventative Maintenance: Scheduled inspections and cleaning of heat transfer surfaces remove scale and deposits, improving heat transfer.

- Combustion Optimization: Regular checks and adjustments of burner settings ensure optimal air-fuel ratios for efficient combustion.

- Leak Detection and Repair: Promptly addressing leaks prevents energy loss and maintains system pressure.

- Water Treatment: Regular water treatment prevents scaling and corrosion, extending boiler lifespan and maintaining efficiency.

For example, neglecting to clean the tubes of a boiler allows scale buildup, significantly reducing heat transfer and efficiency. Regular cleaning prevents this issue and ensures the boiler operates at its peak performance for longer.

Q 6. Describe different boiler combustion optimization techniques.

Optimizing boiler combustion is crucial for maximizing efficiency and minimizing emissions. Several techniques can be employed:

- Air-Fuel Ratio Control: Precise control of the air-fuel ratio is critical. Advanced control systems can continuously monitor and adjust the ratio based on real-time data.

- Burner Adjustments: Proper burner alignment and adjustments ensure complete fuel combustion and minimize unburnt fuel losses.

- Oxygen Trim Control: Maintaining optimal oxygen levels in the flue gas minimizes excess air and improves combustion efficiency. Excess air leads to wasted energy heating unnecessary gases.

- Overfire Air Control: Overfire air is added above the burner to ensure complete combustion of volatiles. Careful control of this air improves combustion effectiveness.

- Low NOx Burners: These specialized burners are designed to minimize the formation of nitrogen oxides (NOx), a major pollutant, without compromising efficiency.

- Flue Gas Recirculation (FGR): In certain boiler designs, flue gas can be recirculated to improve combustion stability and reduce NOx formation.

For instance, using an oxygen trim control system that monitors oxygen levels in the flue gas and automatically adjusts the air-fuel ratio can significantly improve combustion efficiency and reduce fuel consumption.

Q 7. How does excess air affect boiler efficiency?

Excess air in boiler combustion reduces efficiency by wasting energy. Think of it like driving with your foot lightly on the gas pedal — you’re using more fuel than necessary to achieve the same result.

Excess air means more air than needed for complete combustion is being supplied to the boiler. This excess air must be heated to the flue gas temperature, representing wasted energy. The increased volume of flue gases also carries away more heat, further reducing efficiency. High oxygen levels in the flue gas indicate excess air. This can result in a significant drop in thermal efficiency.

Optimal combustion requires the correct air-fuel ratio. Minimizing excess air through proper burner adjustments and control systems is crucial for maximizing boiler efficiency and reducing fuel costs.

Q 8. What are the benefits of using economizers in boiler systems?

Economizers are heat recovery devices installed in boiler systems to significantly improve efficiency. They work by preheating the boiler feedwater using the waste heat from the flue gases exiting the boiler. Instead of letting this valuable heat escape up the stack, the economizer captures it, transferring it to the incoming water, thus reducing the amount of fuel needed to heat the water to the desired temperature.

Benefits:

- Reduced Fuel Consumption: This is the primary benefit. By preheating the feedwater, less fuel is required to bring it to the boiling point, leading to substantial cost savings.

- Lower Emissions: Less fuel burned translates to lower greenhouse gas emissions and a smaller carbon footprint.

- Improved Boiler Efficiency: Economizers directly boost the overall thermal efficiency of the boiler system, often resulting in a noticeable increase in the percentage of heat transferred to the water.

- Extended Boiler Lifespan: Reduced thermal stress on the boiler tubes due to lower temperature differences can extend the life of the boiler.

Example: Imagine a boiler system without an economizer. The hot flue gases exit the boiler at, say, 400°C. An economizer can reduce this temperature to 200°C, transferring that 200°C difference as heat to the feedwater. This significant heat recovery translates to a considerable reduction in fuel usage.

Q 9. Explain the function of a boiler air preheater.

A boiler air preheater is a heat exchanger that preheats the combustion air before it enters the boiler furnace. It achieves this by using the heat from the hot flue gases exiting the boiler. This preheated air improves combustion efficiency and reduces fuel consumption.

Function: The preheater transfers heat from the exhaust gases to the incoming combustion air. This is typically done through either a rotary regenerative type (a rotating wheel that absorbs heat from the flue gas and transfers it to the incoming air) or a tubular type (heat exchange between gases and air through tubes).

Benefits:

- Improved Combustion: Preheated air allows for more complete combustion of the fuel, leading to higher efficiency.

- Reduced Fuel Consumption: Because combustion is more efficient, less fuel is needed to achieve the same amount of heat output.

- Lower Emissions: More complete combustion results in reduced emissions of unburnt fuel and pollutants like carbon monoxide.

- Increased Boiler Output: In some cases, a preheater can allow the boiler to operate at a higher output without needing significant modifications.

Example: Imagine trying to start a fire with cold air versus warm air. The warm air helps ignite the fuel more easily and burns more completely. The air preheater essentially provides that ‘warm air’ advantage for the boiler combustion process.

Q 10. How do you optimize boiler water treatment for efficiency?

Optimizing boiler water treatment is crucial for both efficiency and preventing costly damage. It involves managing the chemical composition of the boiler water to prevent scale formation, corrosion, and foaming.

Strategies for Optimization:

- Regular Water Analysis: Regular testing of boiler water allows for proactive adjustments to the treatment program based on the detected impurities (e.g., hardness, alkalinity, dissolved solids).

- Appropriate Chemical Treatment: Adding chemicals like oxygen scavengers (to prevent corrosion), scale inhibitors (to prevent calcium and magnesium buildup), and pH adjusters (to maintain optimal alkalinity) is essential. The type and quantity of chemicals must be tailored to the specific water quality and boiler operating conditions.

- Blowdown Management: Regular blowdown removes concentrated impurities from the boiler water, preventing the buildup of solids. Efficient blowdown management balances the need for impurity removal with the energy loss associated with water discharge.

- Feedwater Treatment: Pre-treating the feedwater before it enters the boiler is often vital. This could involve filtration, softening, or other processes to remove impurities before they reach the boiler.

- Monitoring and Control: Implementing a system for continuous monitoring of key water parameters (e.g., conductivity, pH) helps to identify and address problems early.

Example: If a boiler experiences excessive scale formation, it reduces heat transfer efficiency, necessitating increased fuel consumption. Regular water analysis and appropriate chemical treatment can effectively prevent this.

Q 11. What are the safety precautions associated with boiler operation and maintenance?

Boiler operation and maintenance demand stringent safety precautions to prevent accidents and injuries. This is paramount due to the high temperatures, pressures, and potential for hazardous materials involved.

Key Safety Precautions:

- Lockout/Tagout Procedures: Before any maintenance work, the boiler must be completely shut down and locked out to prevent accidental start-up. Appropriate tags should indicate the work being performed and who is responsible.

- Pressure Relief Valves: Regular inspection and testing of pressure relief valves are critical to ensure they function correctly and prevent overpressure situations.

- Regular Inspections: Routine inspections of boiler components (tubes, drums, valves, controls) help to identify potential problems before they escalate.

- Personal Protective Equipment (PPE): Appropriate PPE, including heat-resistant gloves, eye protection, and safety shoes, must always be used during operation and maintenance.

- Emergency Procedures: Clearly defined emergency procedures should be in place to handle situations like leaks, fires, or pressure surges.

- Trained Personnel: Only trained and qualified personnel should operate and maintain boilers. They need thorough understanding of the system and safety protocols.

- Proper Ventilation: Adequate ventilation is essential to prevent the buildup of harmful gases during combustion.

Example: Failure to properly inspect and maintain pressure relief valves could lead to a catastrophic boiler explosion.

Q 12. Describe various types of boiler fuel and their impact on efficiency.

Various fuels can power boilers, each with its own efficiency characteristics and environmental impact.

Types of Boiler Fuel and Efficiency:

- Natural Gas: A clean-burning fuel with high efficiency, typically around 80-90%. It produces relatively low emissions compared to other fuels.

- Fuel Oil: Offers good energy density but generally has lower efficiency (75-85%) and higher emissions than natural gas. Different grades of fuel oil exist, each with varying sulfur content and efficiency.

- Coal: A high-energy-density fuel but with significantly lower efficiency (60-75%) and substantial emissions, including sulfur dioxide and particulate matter. It requires more extensive pollution control equipment.

- Biomass: Renewable fuels derived from organic matter (wood, agricultural residues). Efficiency varies depending on the type and quality of biomass, typically ranging from 60-80%, and emissions profile can also vary significantly.

- Electricity: Electric boilers heat water directly using electricity. Their efficiency is usually very high (95-98%), but the overall efficiency depends on the source of electricity generation.

Example: Switching from coal to natural gas would lead to a significant increase in boiler efficiency and a reduction in emissions, although the initial investment costs may be high. The choice of fuel should consider both efficiency and environmental factors along with cost considerations.

Q 13. What is the role of insulation in improving boiler efficiency?

Insulation plays a vital role in improving boiler efficiency by minimizing heat loss to the surrounding environment. Heat loss represents wasted energy that increases fuel consumption.

Role of Insulation: Insulation materials act as a barrier, reducing the rate of heat transfer from the hot boiler surfaces to the cooler surroundings. This is achieved through low thermal conductivity, meaning the material resists the flow of heat.

Benefits:

- Reduced Heat Loss: The primary benefit is minimizing the amount of heat lost to the environment, which directly translates to less fuel needed to maintain operating temperature.

- Improved Efficiency: Reduced heat loss leads to a noticeable improvement in the overall thermal efficiency of the boiler.

- Enhanced Safety: Insulation reduces surface temperatures, making the boiler safer to operate and maintain.

- Reduced Operational Costs: By reducing fuel consumption, insulation contributes to significant cost savings over the boiler’s lifetime.

Example: Consider a boiler without proper insulation. A significant portion of the generated heat is lost to the surroundings, increasing fuel consumption. Adding appropriate insulation significantly reduces this heat loss, thereby increasing the efficiency of the boiler.

Q 14. How do you perform a boiler heat loss analysis?

A boiler heat loss analysis determines the various ways heat is being lost from the boiler system, allowing for targeted improvements to enhance efficiency. This involves a systematic assessment of potential heat loss sources.

Steps in Performing a Heat Loss Analysis:

- Data Collection: Gather data on boiler operating parameters such as fuel consumption, steam production, flue gas temperature, feedwater temperature, ambient temperature, and boiler surface temperatures. This might involve using instruments like thermocouples, flow meters, and gas analyzers.

- Identifying Loss Sources: Based on collected data, identify potential heat loss sources, which include:

- Stack Losses: Heat carried away by flue gases.

- Radiation Losses: Heat radiated from boiler surfaces.

- Conduction Losses: Heat conducted through boiler walls and components.

- Convection Losses: Heat transferred by air movement around the boiler.

- Blowdown Losses: Heat lost with boiler water blowdown.

- Calculating Losses: Use appropriate engineering equations and correlations to calculate the magnitude of each identified heat loss. These calculations often rely on thermodynamic principles and heat transfer mechanisms.

- Analysis and Prioritization: Analyze the results to identify the major heat loss sources. This prioritization helps in focusing improvement efforts on the areas with the largest impact on efficiency.

- Recommendations for Improvement: Based on the analysis, provide recommendations for reducing heat losses. This might involve implementing economizers, air preheaters, improved insulation, optimizing combustion, or addressing leaks.

Example: A heat loss analysis might reveal that stack losses account for 20% of the total heat input. This indicates that optimizing the combustion process or installing an economizer could significantly improve the boiler’s efficiency.

Q 15. Explain the concept of boiler blowdown and its impact on efficiency.

Boiler blowdown is the process of periodically removing a small amount of water from a boiler to prevent the buildup of impurities like dissolved solids and suspended particles. These impurities, if left unchecked, can lead to scaling, corrosion, and reduced efficiency. Think of it like regularly cleaning your coffee maker – you need to remove the built-up residue to maintain optimal performance.

Its impact on efficiency is significant. Scaling, caused by the concentration of these impurities, reduces heat transfer within the boiler tubes, forcing the boiler to consume more fuel to achieve the same steam production. Furthermore, excessive buildup can lead to premature boiler failure, resulting in costly repairs and downtime. Blowdown helps maintain clean boiler tubes, improving heat transfer and thus, enhancing efficiency. The amount of blowdown required depends on factors such as the water quality and boiler operation. Too little blowdown leads to scaling, while excessive blowdown wastes energy and water.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different types of boiler control systems and their advantages.

Boiler control systems maintain optimal boiler operation, ensuring safety and efficiency. Several types exist:

- On-Off Control: This is the simplest type, where the burner is either fully on or fully off. It’s inexpensive but less efficient, leading to temperature fluctuations.

- Proportional Control: This system adjusts the fuel input proportionally to the deviation from the setpoint. It’s more efficient than on-off control, providing smoother operation and reducing temperature swings.

- PID (Proportional-Integral-Derivative) Control: This advanced system incorporates proportional, integral, and derivative actions to minimize errors and maintain precise temperature control. PID control offers superior stability and efficiency, minimizing fuel waste and improving steam quality.

- Cascade Control: This involves a master controller regulating a primary variable (e.g., steam pressure) and a slave controller managing a secondary variable (e.g., fuel flow) to maintain the primary variable within the desired range. This is especially useful in complex systems.

The choice of control system depends on factors like budget, boiler size, and desired level of precision. For large industrial boilers, advanced systems like PID or cascade control are favored for their superior efficiency and precise control. Smaller boilers might utilize simpler systems like proportional control.

Q 17. How do you interpret boiler performance data and identify areas for improvement?

Interpreting boiler performance data is crucial for optimizing efficiency. Key parameters include:

- Steam Production: This reflects the boiler’s output, which should be compared to the designed capacity.

- Fuel Consumption: This indicates the amount of fuel used for steam generation. An increase in fuel consumption without a corresponding increase in steam production suggests inefficiencies.

- Stack Temperature: High stack temperatures indicate significant heat loss. This needs investigation to identify potential issues.

- Boiler Water Chemistry: Monitoring parameters like pH, dissolved solids, and oxygen levels helps detect scaling, corrosion, and other problems that impact efficiency.

- Efficiency: This is calculated based on fuel consumption and steam produced. A decrease in efficiency points to potential problems.

By analyzing these data points, you can identify areas for improvement. For instance, a high stack temperature might indicate inadequate heat transfer due to scaling, requiring cleaning or chemical treatment. High fuel consumption with low steam production suggests potential issues with combustion, air-fuel ratio, or boiler controls. Trends in the data over time are crucial in recognizing developing problems.

Q 18. What is the significance of stack temperature in determining boiler efficiency?

Stack temperature is a critical indicator of boiler efficiency. It represents the heat energy lost in the flue gases exiting the boiler. A lower stack temperature implies more efficient heat transfer, meaning a larger portion of the fuel’s energy is used to generate steam, resulting in higher efficiency. A high stack temperature, on the other hand, indicates that a significant portion of the heat is being wasted, leading to lower efficiency.

Imagine a car engine – if a significant amount of heat is escaping through the exhaust, it means the engine isn’t converting all the fuel energy into useful motion. Similarly, a high stack temperature in a boiler shows significant heat loss, and thus poor efficiency. Optimizing combustion and minimizing excess air can help reduce the stack temperature and improve overall boiler efficiency.

Q 19. How do you address boiler scaling and its effect on efficiency?

Boiler scaling is the formation of hard mineral deposits on heat transfer surfaces. These deposits act as an insulator, reducing heat transfer from the boiler tubes to the water, leading to decreased efficiency. It also increases the risk of tube failure due to overheating. Think of it like a layer of grime on a cooking pan – it prevents efficient heat transfer and can damage the pan.

Addressing boiler scaling involves several strategies:

- Chemical Treatment: Regular addition of water treatment chemicals prevents scale formation and removes existing deposits. The specific chemicals used depend on the type of scale and water chemistry.

- Mechanical Cleaning: This involves physically removing scale using specialized tools. It’s typically more disruptive and costly than chemical treatment.

- Regular Blowdown: This helps control the concentration of dissolved solids, reducing the likelihood of scaling.

- Water Softening: Pre-treating boiler feedwater to remove hardness minerals helps prevent scaling.

The best approach to managing scaling involves a combination of these methods tailored to the specific boiler and water conditions. Regular monitoring of water chemistry is vital for proactive scale management.

Q 20. Describe the process of boiler commissioning and testing.

Boiler commissioning and testing is a critical process to ensure the boiler is installed correctly, operates safely, and meets performance expectations. This involves several stages:

- Pre-commissioning Inspection: This involves checking the boiler and all associated equipment for proper installation and integrity before the system is energized.

- Start-up and Performance Testing: This stage involves gradually bringing the boiler online and conducting performance tests to verify that it meets design specifications. Key parameters like steam production, fuel consumption, efficiency, and emissions are measured and documented.

- Safety Testing: This includes pressure tests to verify the boiler’s structural integrity and safety relief valve testing to ensure they function correctly.

- Operational Training: Operators are trained on the safe and efficient operation and maintenance of the boiler system.

- Documentation: All tests and inspections are meticulously documented to provide a record of the commissioning process.

Proper commissioning is essential for ensuring safe and efficient boiler operation and complying with relevant regulations. It involves a multidisciplinary team including engineers, technicians, and operators.

Q 21. Explain the regulations and codes related to boiler safety and efficiency.

Regulations and codes related to boiler safety and efficiency vary by region but generally focus on preventing accidents and minimizing environmental impact. Key aspects include:

- Pressure Vessel Codes: These codes, like ASME Section I in the US, specify design, fabrication, inspection, and testing requirements for boilers to ensure structural integrity and prevent explosions.

- Emission Standards: These regulations limit the amount of pollutants, such as NOx and CO, that can be emitted from the boiler stack. They drive the use of low-emission burners and combustion controls.

- Safety Regulations: These regulations address aspects such as safe operation, emergency shutdown systems, and operator training to prevent accidents.

- Energy Efficiency Standards: These standards promote the use of energy-efficient boilers and encourage regular maintenance to optimize performance.

Compliance with these regulations is crucial for safe and legal boiler operation. Failure to comply can result in fines, legal action, and potentially serious accidents. Regular inspections and maintenance are essential for maintaining compliance.

Q 22. How do you perform a boiler efficiency test using the direct method?

The direct method of boiler efficiency testing involves measuring the fuel input and the heat output directly. It’s a straightforward approach, offering a clear picture of how efficiently your boiler converts fuel energy into usable heat. Think of it like calculating your car’s fuel efficiency – you measure how much fuel you use (gallons) and how far you travel (miles). Similarly, with boilers, we measure the fuel consumed and the heat produced.

Here’s a step-by-step process:

- Measure fuel consumption: Accurately record the amount of fuel (gas, oil, or coal) used over a specific time period. This might involve using flow meters, weight scales, or analyzing gas meter readings.

- Measure the boiler’s heat output: This is done by measuring the temperature and flow rate of the water entering and leaving the boiler. The heat output (in BTU/hr or kW) is calculated using the specific heat capacity of water and the temperature difference. Specialized instruments like thermocouples and flow meters are crucial here.

- Calculate efficiency: The efficiency is determined by dividing the heat output by the heat input (fuel’s calorific value multiplied by the amount of fuel consumed). The result is usually expressed as a percentage. For example:

Efficiency (%) = (Heat Output / Heat Input) * 100 - Consider losses: Remember that some heat is always lost through radiation, convection, and other factors. A well-conducted test accounts for these losses to obtain a more accurate efficiency figure. Insulation quality and proper maintenance significantly impact these losses.

Example: If a boiler consumes 100,000 BTU of natural gas and produces 80,000 BTU of heat, its efficiency is 80% (80,000 BTU / 100,000 BTU * 100). Discrepancies from ideal efficiency (100%) highlight areas for improvement.

Q 23. Describe the concept of boiler load optimization.

Boiler load optimization is the process of ensuring your boiler operates at its most efficient output level for the prevailing demand. Boilers aren’t equally efficient across all operating loads; they often have a ‘sweet spot’ where they perform best. Think of a car; it’s less fuel-efficient when idling or accelerating aggressively. Similarly, a boiler running far below or above its optimal load consumes more fuel per unit of heat produced.

Strategies for load optimization include:

- Right-sizing the boiler: Selecting a boiler appropriately sized for typical demand prevents prolonged operation at low or high loads.

- Load shedding: Temporarily reducing the load on the boiler during periods of low demand, perhaps by prioritizing less critical heating zones.

- Multiple smaller boilers: Using several smaller boilers that can be independently controlled allows for efficient operation across varying demand levels.

- Advanced control systems: Implementing sophisticated control systems (like those incorporating predictive algorithms) ensures the boiler operates at the optimal load based on real-time and predicted demand.

Real-world example: A hospital with varying heating demands throughout the day could benefit from load optimization. By employing a sophisticated control system, the boiler could adjust its output to match the patient areas’ fluctuating heating needs, minimizing energy waste during low-demand periods.

Q 24. What is the role of predictive maintenance in preventing boiler failures and maintaining efficiency?

Predictive maintenance utilizes data analysis and machine learning to anticipate potential boiler failures and schedule maintenance proactively. Instead of reactive maintenance (fixing problems after they occur), it shifts to a preventative approach, maximizing uptime and efficiency. Imagine predicting a car’s tire blowout based on wear patterns – that’s the essence of predictive maintenance for boilers.

Key aspects include:

- Data collection: Sensors monitor various parameters like temperature, pressure, vibration, and fuel consumption.

- Data analysis: Algorithms analyze this data to identify patterns and anomalies that might indicate impending failures.

- Predictive modelling: Sophisticated models forecast the likelihood of failures and their potential impact.

- Scheduled maintenance: Maintenance is performed before failures occur, minimizing downtime and preventing costly repairs.

Benefits: Predictive maintenance extends the boiler’s lifespan, reduces energy consumption, improves safety, and lowers overall operational costs. By preventing unexpected breakdowns, it avoids costly production downtime and keeps the heating system functioning efficiently.

Q 25. Explain the principles of heat transfer relevant to boiler operation.

Heat transfer in boilers is fundamental to their operation. It’s the process of moving heat from the combustion chamber (where fuel burns) to the water being heated. Three primary modes are involved:

- Conduction: Heat transfer through direct contact. Think of heat flowing through the boiler’s metal walls from the hot gases to the water.

- Convection: Heat transfer through the movement of fluids. The hot combustion gases circulate within the boiler, transferring heat to the surrounding surfaces. The heated water itself also circulates, ensuring uniform heating.

- Radiation: Heat transfer through electromagnetic waves. Hot surfaces in the combustion chamber radiate heat towards the water tubes, contributing significantly to the overall heat transfer process.

Understanding these principles is crucial for boiler design and operation. For example, efficient heat transfer requires proper gas flow, sufficient surface area for heat exchange, and optimal water circulation. Poor design or fouling (buildup of deposits) can hinder heat transfer, reducing boiler efficiency and increasing fuel consumption.

Q 26. Describe the various types of boiler feedwater pumps and their selection criteria.

Boiler feedwater pumps are crucial for delivering water to the boiler at the required pressure and flow rate. Several types exist, each with its own characteristics and suitability for different applications:

- Centrifugal pumps: These are the most common type, using a rotating impeller to increase water pressure. They are suitable for most boiler applications due to their relatively simple design, reliability, and efficient operation at higher flow rates.

- Reciprocating pumps: These pumps use a piston or diaphragm to move water in a pulsating motion. They can deliver high pressure but are less efficient than centrifugal pumps and often require more maintenance.

- Positive displacement pumps: These pumps move a fixed volume of water with each stroke, regardless of pressure changes. They are suitable for high-pressure applications but can be noisy and require specialized maintenance.

Selection criteria include:

- Boiler pressure: The pump must provide sufficient pressure to overcome the boiler’s operating pressure.

- Flow rate: The pump needs to deliver the required water flow rate to match the boiler’s steam demand.

- Water temperature: The pump’s materials and design must withstand the feedwater temperature.

- Maintenance requirements: Consider the maintenance frequency and cost for each pump type.

- Initial cost and efficiency: Balance the initial investment against the long-term operating costs and efficiency.

Example: A large industrial boiler might utilize a centrifugal pump due to its high flow rate capability and relatively low maintenance needs, whereas a smaller boiler system might opt for a more compact and less expensive positive displacement pump.

Q 27. How do you calculate the return on investment (ROI) for boiler efficiency upgrades?

Calculating the ROI for boiler efficiency upgrades involves comparing the cost of the upgrade with the savings it generates. It’s a financial assessment that determines the profitability of an investment.

Here’s a step-by-step process:

- Determine the initial investment: This includes the cost of the upgrade (new equipment, installation, etc.).

- Calculate annual fuel savings: Estimate the reduction in fuel consumption based on the improved efficiency. Use the existing fuel consumption data and the projected efficiency improvement percentage to calculate this.

- Calculate annual savings in other operating costs: Account for any additional savings such as reduced maintenance costs due to improved performance.

- Determine the payback period: Divide the initial investment by the annual savings to find the number of years it will take to recover the investment cost.

- Calculate the ROI: ROI is typically expressed as a percentage and is calculated as follows:

ROI (%) = [(Annual Savings - Annual Costs) / Initial Investment] * 100

Example: Let’s say an upgrade costs $10,000, resulting in annual fuel savings of $3,000 and reduced maintenance costs of $500. The annual savings are $3,500. The payback period is approximately 2.9 years ($10,000 / $3,500). The ROI after 5 years would be: ROI = [($3,500 * 5) / $10,000] * 100 = 175%

This analysis helps decision-makers assess whether the upgrade is a worthwhile investment, considering factors like the lifespan of the equipment and potential future fuel price increases.

Q 28. What are some emerging technologies used to improve boiler energy efficiency?

Several emerging technologies are enhancing boiler energy efficiency:

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms optimize boiler operation in real-time, predicting and preventing faults, and fine-tuning parameters to improve efficiency.

- Advanced control systems: Predictive control systems adjust boiler operation based on predicted energy demand, preventing over- or under-firing, leading to substantial fuel savings.

- Smart sensors and IoT integration: Real-time monitoring of various parameters using interconnected sensors provides comprehensive insights into boiler performance, enabling timely maintenance and optimized operation.

- Waste heat recovery systems: Capturing and utilizing heat normally lost from the boiler’s exhaust gases or other components can significantly improve overall energy efficiency.

- High-efficiency burners and combustion technologies: Innovations in burner design and combustion control enhance fuel-air mixing, leading to improved combustion efficiency and reduced emissions.

These technologies offer substantial improvements in efficiency and reduction in operational costs. The use of AI, for example, can allow for autonomous operation, significantly decreasing human intervention and energy waste. These technologies represent a move towards smarter, more efficient, and sustainable boiler systems.

Key Topics to Learn for Boiler Energy Efficiency Interview

- Boiler Types and Operation: Understanding different boiler types (fire-tube, water-tube, etc.), their operational principles, and efficiency characteristics.

- Combustion Optimization: Analyzing combustion efficiency, air-fuel ratio control, and minimizing pollutant emissions. Practical application: troubleshooting combustion issues and implementing optimization strategies for improved efficiency.

- Heat Transfer and Loss Analysis: Identifying and quantifying heat losses through various mechanisms (radiation, convection, conduction) and applying strategies for minimization. Practical application: Performing energy audits and proposing insulation upgrades.

- Instrumentation and Control Systems: Familiarity with boiler instrumentation (pressure gauges, temperature sensors, flow meters) and control systems (PID controllers, safety interlocks). Practical application: interpreting data from boiler control systems to diagnose operational issues.

- Energy Efficiency Technologies: Understanding and evaluating the application of energy-saving technologies like economizers, air preheaters, and condensate recovery systems. Practical application: Cost-benefit analysis of implementing energy-efficiency upgrades.

- Boiler Maintenance and Troubleshooting: Proficiency in preventative maintenance procedures, fault diagnosis, and repair techniques. Practical application: Developing and implementing a comprehensive boiler maintenance plan.

- Regulations and Standards: Knowledge of relevant environmental regulations and industry standards related to boiler operation and efficiency. Practical application: Ensuring compliance with all applicable regulations.

- Data Analysis and Reporting: Analyzing boiler performance data, identifying trends, and generating reports to track efficiency improvements. Practical application: using data to justify investments in energy efficiency upgrades.

Next Steps

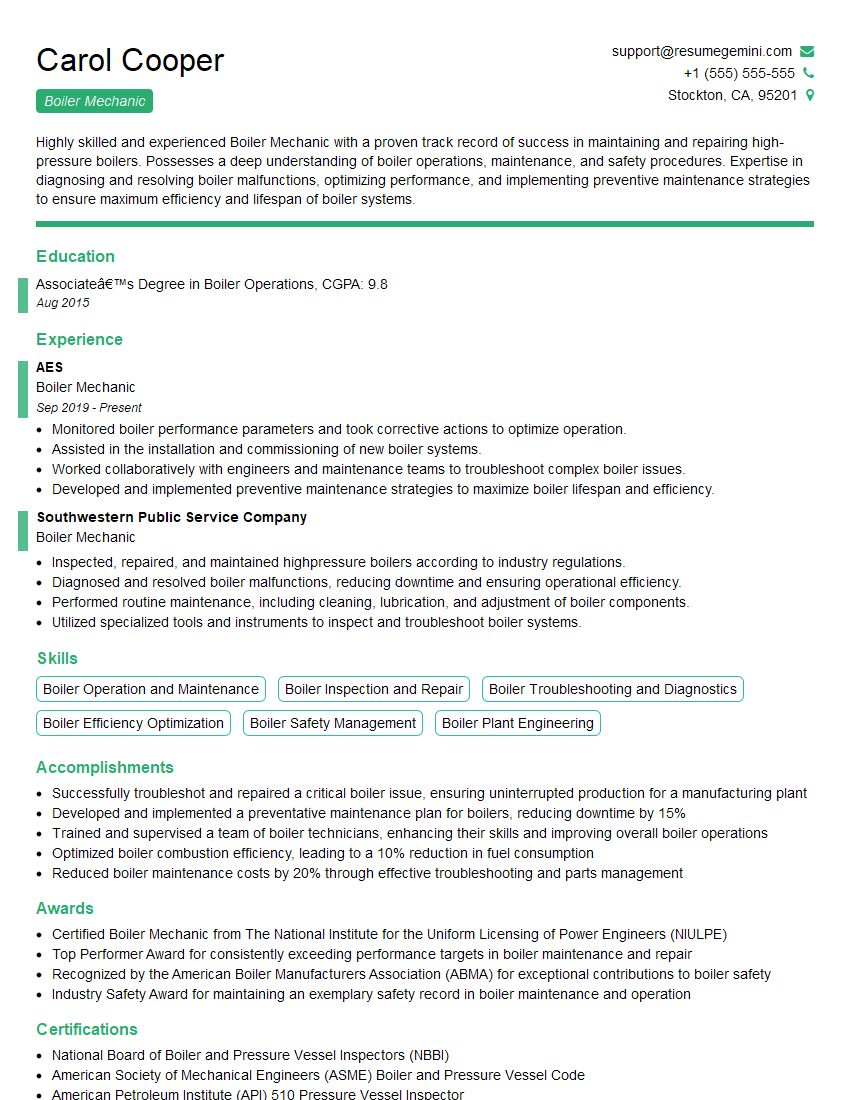

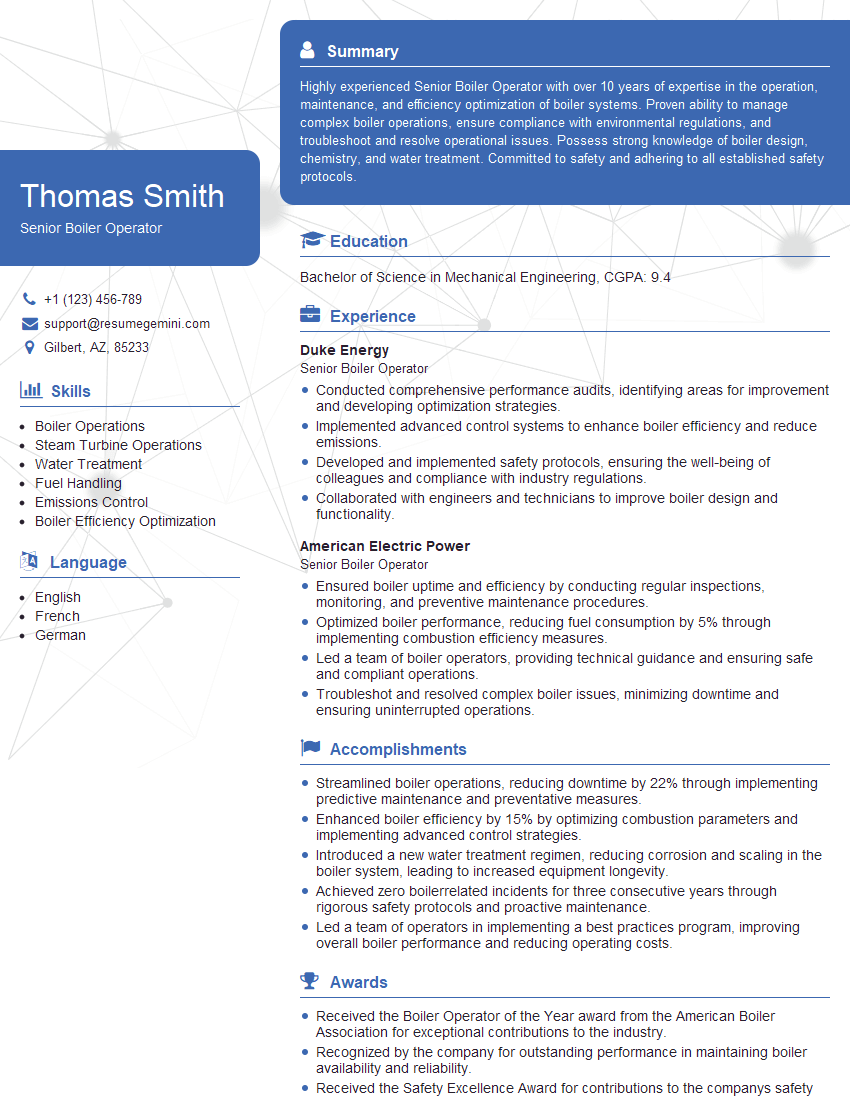

Mastering boiler energy efficiency is crucial for a successful and rewarding career in this vital sector. Demand for skilled professionals who can optimize energy consumption and reduce environmental impact is consistently high. To significantly improve your job prospects, focus on creating an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and compelling resume tailored to the demands of the energy efficiency industry. Examples of resumes tailored specifically to Boiler Energy Efficiency roles are available for your review, providing valuable guidance and inspiration as you craft your application materials.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?