Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Manufacturing Planning and Control interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Manufacturing Planning and Control Interview

Q 1. Explain the difference between MRP and ERP systems.

Material Requirements Planning (MRP) and Enterprise Resource Planning (ERP) are both crucial systems for managing manufacturing processes, but they differ significantly in scope and functionality. Think of MRP as a specialized tool focusing solely on production planning, while ERP is a much broader, integrated system encompassing all aspects of a business.

- MRP: Focuses specifically on managing inventory levels and scheduling production based on the bill of materials (BOM) and the master production schedule (MPS). It’s designed to answer the question: “What materials do I need, when do I need them, and how many?” It’s primarily concerned with the production planning process.

- ERP: Is a comprehensive system integrating all facets of a business, including planning, procurement, manufacturing, sales, finance, and human resources. MRP is often a *module* within a larger ERP system. An ERP system provides a holistic view of the entire organization, allowing for better collaboration and data sharing across departments.

For example, a small manufacturing firm might use a standalone MRP system to manage its production schedule. A larger multinational corporation, however, would likely employ a comprehensive ERP system with MRP as one integrated component to manage everything from raw material procurement to customer order fulfillment and financial reporting. The scale and complexity of operations dictate the system’s choice.

Q 2. Describe the process of creating a master production schedule (MPS).

Creating a Master Production Schedule (MPS) is a critical step in manufacturing planning. It’s essentially a detailed plan outlining what products will be produced, in what quantities, and when. Think of it as the roadmap for your entire production facility. A well-structured MPS is crucial for efficient resource allocation and meeting customer demand.

The process typically involves these steps:

- Sales Forecasting: Begin by analyzing sales data, market trends, and customer orders to forecast future demand for your products.

- Capacity Planning: Assess your production capacity to determine if you have the resources (equipment, labor, materials) to meet the forecasted demand.

- Production Capacity Adjustments: If the forecasted demand exceeds your capacity, you’ll need to adjust the forecast or increase production capacity (e.g., by adding shifts, investing in new equipment, or outsourcing).

- Developing the MPS: Based on the forecasted demand and available capacity, create the MPS, which should include specific product details, quantities, and production dates.

- Review and Iteration: The MPS is not a static document. It needs to be regularly reviewed and updated to account for changes in demand, supply chain issues, or other unexpected disruptions.

For example, imagine a furniture manufacturer. Their MPS might show they need to produce 100 dining tables in week 1, 150 chairs in week 2, and 50 sofas in week 3, considering anticipated customer orders and available resources. Effective MPS creation requires collaboration between sales, marketing, production, and procurement teams.

Q 3. How do you handle unexpected disruptions to the production schedule?

Unexpected disruptions are inevitable in manufacturing. A robust planning process anticipates potential problems and builds resilience. My approach to handling disruptions involves a multi-pronged strategy:

- Immediate Response: Quickly assess the impact of the disruption on the production schedule. Identify bottlenecks and critical paths affected.

- Problem Solving: Collaborate with the relevant teams (production, procurement, engineering) to identify solutions. This might involve rescheduling production, finding alternative suppliers, or adjusting the production process.

- Communication: Keep all stakeholders (customers, suppliers, internal teams) informed about the situation and the mitigation plan. Transparency is critical in maintaining trust.

- Root Cause Analysis: After the immediate crisis is over, conduct a thorough root cause analysis to understand why the disruption occurred and implement preventative measures to reduce the likelihood of similar events in the future.

- Contingency Planning: Develop and maintain contingency plans for various types of disruptions (e.g., supplier delays, equipment failures, natural disasters). This proactive approach minimizes the impact of future disruptions.

For instance, if a key supplier experiences a delay, we’d immediately explore alternative sources, potentially paying a premium for faster delivery. We’d also communicate the delay to customers and adjust the MPS accordingly, prioritizing orders based on urgency and impact. We would then analyze the supplier’s issue to prevent similar problems in the future, possibly diversifying our supply chain.

Q 4. What are the key performance indicators (KPIs) you use to measure the effectiveness of manufacturing planning and control?

Key Performance Indicators (KPIs) are essential for evaluating the effectiveness of manufacturing planning and control. I use a range of KPIs, categorized for clarity:

- On-Time Delivery (OTD): Percentage of orders delivered on or before the promised due date. High OTD reflects excellent planning and execution.

- Production Efficiency: Output compared to planned capacity. This indicates how effectively resources are being utilized.

- Inventory Turnover Rate: How quickly inventory is sold or used. Optimal levels ensure efficient cash flow without risking stockouts.

- Lead Time: Time from order placement to delivery. Short lead times indicate efficient processes.

- Production Costs: Total cost of production, broken down into various components. Monitoring costs helps identify areas for improvement.

- Defect Rate: Percentage of defective products produced. Low defect rate reflects quality control efficiency.

- Schedule Adherence: How closely actual production adheres to the planned schedule. High adherence shows accurate planning and execution.

Regularly tracking and analyzing these KPIs provides insights into the strengths and weaknesses of the planning and control system, enabling data-driven improvements. For instance, a low inventory turnover rate might suggest overstocking or poor demand forecasting, while a high defect rate points to issues in quality control or training.

Q 5. Explain the concept of capacity planning and its importance.

Capacity planning is the process of determining the production capacity needed to meet anticipated demand. It’s a critical function because insufficient capacity leads to missed deadlines and lost revenue, while excessive capacity leads to wasted resources. Think of it as sizing your engine to match the weight and power needs of your vehicle—too small, and you won’t get there; too big, and it’s inefficient.

The process typically involves:

- Demand Forecasting: Accurately predicting future product demand.

- Capacity Assessment: Evaluating existing production capacity in terms of equipment, labor, and space.

- Gap Analysis: Identifying the difference between forecasted demand and available capacity.

- Capacity Improvement Strategies: Developing strategies to bridge the gap, which may include investing in new equipment, optimizing production processes, hiring additional staff, or outsourcing.

For example, a clothing manufacturer facing increased demand might need to invest in additional sewing machines or hire more seamstresses to ensure they can meet customer orders without delays. Proper capacity planning ensures the business can grow sustainably and profitably.

Q 6. How do you determine the optimal inventory levels for raw materials and finished goods?

Determining optimal inventory levels requires a delicate balance. Too much inventory ties up capital and increases storage costs, while too little leads to stockouts and lost sales. This is where inventory management techniques like the Economic Order Quantity (EOQ) model come in handy. However, it’s crucial to consider additional factors beyond the purely mathematical model.

Factors influencing optimal inventory levels:

- Demand Variability: The more volatile the demand, the higher the safety stock needs to be to buffer against uncertainty.

- Lead Time: Longer lead times require higher inventory levels to ensure continuous production.

- Storage Costs: High storage costs push for lower inventory levels.

- Ordering Costs: Frequent orders increase ordering costs, encouraging larger order quantities.

- Product Perishability: Perishable goods need shorter inventory cycles.

I use a combination of quantitative models (like EOQ) and qualitative assessments to determine inventory levels, taking into account factors like seasonal demand, potential supply chain disruptions, and the cost of stockouts. For example, a grocery store needs to maintain higher inventory levels for highly perishable items like milk compared to shelf-stable goods like canned food.

Q 7. Describe your experience with different scheduling techniques (e.g., FIFO, LIFO, Kanban).

I have extensive experience with various scheduling techniques, each with its strengths and weaknesses. My choice depends heavily on the specific context and production environment.

- FIFO (First-In, First-Out): This simple method processes items in the order they arrive. It’s effective for minimizing spoilage in perishable goods and avoiding inventory obsolescence. However, it might not be optimal for prioritizing urgent orders.

- LIFO (Last-In, First-Out): This method processes the most recently received items first. It can be useful for tracking the cost of goods sold accurately. However, it’s less suitable for perishable goods and may lead to higher inventory holding costs.

- Kanban: A lean manufacturing scheduling technique that uses visual signals to trigger production. It’s excellent for minimizing waste and improving workflow efficiency. Kanban requires disciplined implementation and close coordination between production stages.

- Priority Scheduling: This method prioritizes specific jobs based on various criteria (due date, importance, customer priority). It is efficient for meeting critical deadlines but might neglect less urgent orders. A common algorithm is Shortest Processing Time (SPT) that prioritizes the tasks with shortest duration.

In my previous role, we implemented a Kanban system for a high-volume production line, significantly reducing lead times and inventory levels. In another project, we used priority scheduling with a sophisticated algorithm that optimized for on-time delivery and minimized total tardiness.

Q 8. How do you manage lead times and ensure timely delivery of products?

Managing lead times and ensuring timely delivery is crucial for customer satisfaction and operational efficiency. It involves a multi-pronged approach focusing on accurate forecasting, efficient scheduling, and proactive risk management.

Firstly, accurate forecasting of demand is paramount. We utilize various forecasting methods, including exponential smoothing and ARIMA models, to predict future demand and adjust production accordingly. This allows us to better estimate the time required for each stage of production.

Secondly, efficient scheduling plays a vital role. Tools like capacity planning software help to optimize the production schedule, considering machine availability, workforce capacity, and material availability. This ensures that tasks are sequenced effectively to minimize lead times. For instance, in a previous role, implementing a lean scheduling system reduced our average lead time by 15%.

Thirdly, proactive risk management is essential. We identify potential bottlenecks and disruptions (e.g., supplier delays, equipment failures) and develop contingency plans. This might involve holding safety stock of critical components or having backup suppliers. Regular monitoring of the production process, using real-time dashboards, allows for early detection and mitigation of potential delays.

Q 9. Explain your understanding of Material Requirements Planning (MRP).

Material Requirements Planning (MRP) is a production planning and inventory control system that uses bill-of-materials (BOM) and master production schedules (MPS) to determine the materials and components needed to produce a finished product. Think of it as a recipe book for manufacturing.

The MPS outlines the quantities of finished goods to be produced over a specific period. The BOM details the raw materials and sub-assemblies required for each finished product. MRP uses this information to calculate the net requirements for each item, considering existing inventory levels and lead times. This ensures that materials are available when needed, minimizing stockouts and excessive inventory.

For example, if we’re manufacturing 100 bicycles and each bicycle needs two tires (lead time 2 days) and a frame (lead time 5 days), MRP would automatically calculate when to order tires and frames to meet the production schedule. This prevents us from having too many tires and not enough frames.

Q 10. How do you utilize forecasting methods in manufacturing planning?

Forecasting is the cornerstone of effective manufacturing planning. We employ a variety of methods depending on the product’s characteristics and the available data. Simple methods like moving averages are useful for stable demand patterns, while more sophisticated techniques like exponential smoothing or ARIMA models are suitable for more volatile demand.

For new products, we often use qualitative forecasting methods like market research or expert opinions. We then combine these methods, using statistical models to refine the initial forecasts and ensure they align with business objectives. Regularly reviewing and updating our forecasts based on actual sales data is crucial to maintain accuracy.

For example, when launching a new product, we started with market research to estimate initial demand. We then used a combination of exponential smoothing and regression analysis to create a refined forecast, which was adjusted based on sales data during the first few months. This iterative approach minimizes forecasting errors.

Q 11. How do you address capacity constraints in your manufacturing operations?

Capacity constraints are a common challenge in manufacturing. Addressing them requires a strategic approach encompassing capacity planning, process improvement, and resource allocation.

- Capacity Planning: We regularly analyze our production capacity, considering machine utilization, workforce availability, and production space. This helps identify potential bottlenecks before they impact production.

- Process Improvement: Lean manufacturing principles, such as eliminating waste and streamlining workflows, can significantly enhance capacity. Techniques like value stream mapping help us identify non-value-added activities and improve efficiency.

- Resource Allocation: Optimizing resource allocation ensures that resources are used effectively. This could involve rescheduling production, outsourcing certain tasks, or investing in additional equipment.

In a past project, we faced a capacity constraint in our assembly line. By implementing a Kaizen event (focused improvement project), we identified and eliminated several bottlenecks, resulting in a 20% increase in assembly line capacity.

Q 12. Describe your experience with different inventory management systems.

My experience encompasses various inventory management systems, from simple systems like First-In, First-Out (FIFO) and Last-In, First-Out (LIFO) to sophisticated Enterprise Resource Planning (ERP) systems.

FIFO and LIFO are basic methods that dictate the order in which inventory is used. FIFO minimizes waste by using the oldest inventory first, while LIFO can be advantageous for tax purposes in certain situations. However, these methods are often insufficient for complex manufacturing environments.

ERP systems offer a comprehensive solution, integrating inventory management with other aspects of the business. They provide real-time visibility into inventory levels, automate ordering processes, and support advanced forecasting techniques. In a previous role, we implemented an ERP system, which significantly improved our inventory accuracy and reduced stockouts.

Just-in-Time (JIT) inventory systems are also relevant. JIT aims to minimize inventory by receiving materials only when needed. While effective in reducing holding costs, it requires close coordination with suppliers and a highly efficient production process.

Q 13. How do you improve production efficiency and reduce waste?

Improving production efficiency and reducing waste is a continuous improvement process. We use a combination of lean manufacturing principles, Six Sigma methodologies, and technological advancements.

Lean principles focus on eliminating waste (muda) in all aspects of production. This includes reducing excess inventory, improving workflow, and minimizing defects. Tools like 5S (sort, set in order, shine, standardize, sustain) and value stream mapping help identify and eliminate waste.

Six Sigma focuses on reducing variation and improving process capability. Using statistical methods, we identify and eliminate sources of variation that lead to defects and inefficiency. DMAIC (Define, Measure, Analyze, Improve, Control) is a commonly used framework.

Technological advancements, such as automation and advanced analytics, can significantly improve efficiency. Implementing automated systems reduces manual labor, increases consistency, and improves accuracy. Data analytics helps us identify trends, predict potential problems, and optimize resource allocation. For instance, implementing automated quality control systems reduced our defect rate by 10%.

Q 14. What are the common challenges in manufacturing planning and control, and how do you address them?

Common challenges in manufacturing planning and control include demand variability, supply chain disruptions, capacity constraints (as discussed earlier), and inaccurate forecasting. Addressing these requires a proactive and adaptable approach.

Demand variability can be mitigated through robust forecasting techniques and agile manufacturing processes that allow for quick adjustments to changing demand. Supply chain disruptions necessitate strong supplier relationships, diversified sourcing strategies, and contingency planning.

Inaccurate forecasting can be addressed through improved data collection, advanced forecasting methods, and continuous monitoring of actual vs. forecasted data. By utilizing various techniques and maintaining open communication, we can effectively minimize the impact of these challenges and ensure smooth manufacturing operations. Regularly reviewing key performance indicators (KPIs) and adapting our strategies based on data-driven insights is vital for continued success.

Q 15. Explain your experience with Lean Manufacturing principles.

Lean Manufacturing focuses on eliminating waste and maximizing value for the customer. My experience involves implementing various Lean tools and techniques across multiple manufacturing settings. This includes:

- Value Stream Mapping: I’ve led several value stream mapping exercises, identifying bottlenecks and non-value-added activities in production processes. For instance, in one project, we mapped the entire assembly line for a specific product, uncovering a significant delay caused by inefficient material handling. By implementing Kanban and optimizing the layout, we reduced lead time by 30%.

- 5S Methodology: I’ve implemented 5S (Sort, Set in Order, Shine, Standardize, Sustain) to create a more organized and efficient workspace. This resulted in improved safety, reduced search times for tools and parts, and a more streamlined workflow.

- Kaizen Events: I’ve facilitated numerous Kaizen events, engaging cross-functional teams to identify and eliminate waste in real-time. One successful Kaizen event focused on reducing downtime on a critical machine. Through collaborative problem-solving, we identified a minor lubrication issue causing frequent breakdowns, resulting in a 15% increase in uptime.

- Poka-Yoke (Mistake-Proofing): I’ve implemented poka-yoke techniques to prevent defects from occurring. For example, designing fixtures to ensure parts are assembled correctly, minimizing human error and improving product quality.

These Lean initiatives consistently improved efficiency, reduced costs, and enhanced overall product quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with Six Sigma methodologies in a manufacturing environment.

Six Sigma methodologies focus on reducing variation and improving process capability. My experience spans various Six Sigma projects, using DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify) methodologies.

- DMAIC: I successfully used DMAIC to reduce defects in a critical component manufacturing process. We defined the problem (high defect rate), measured the current process capability, analyzed the root causes using statistical tools like control charts and Pareto analysis, improved the process through design changes and operator training, and implemented controls to maintain the improvements. This resulted in a 75% reduction in defects.

- DMADV: I employed DMADV to design a new manufacturing process for a newly launched product. We defined the product requirements, measured customer needs, analyzed various design options using simulation, designed the optimal process, and verified its performance before full-scale implementation. This ensured a smooth product launch with minimal issues.

My proficiency includes using statistical software like Minitab to analyze data and identify significant factors impacting process performance. The structured approach of Six Sigma ensured data-driven decision making and sustainable improvements.

Q 17. How do you ensure accurate demand forecasting?

Accurate demand forecasting is crucial for effective manufacturing planning. I utilize a combination of quantitative and qualitative methods to achieve this:

- Quantitative Methods: These include time series analysis (e.g., moving averages, exponential smoothing, ARIMA models), regression analysis, and causal modeling. I select the most appropriate method based on data characteristics and forecasting horizon. For example, exponential smoothing is effective for relatively stable demand, while ARIMA models can handle more complex patterns.

- Qualitative Methods: These involve incorporating expert opinions, market research, and sales forecasts. Techniques like Delphi method can help gather and synthesize expert judgments to improve forecast accuracy. I also consider external factors like economic trends and seasonality.

- Collaborative Forecasting: I actively engage sales, marketing, and product development teams to gather insights and ensure alignment between the forecast and business objectives. This collaborative approach ensures that the forecast reflects real-world market dynamics.

Regularly reviewing and updating the forecast based on actual sales data and market changes is crucial for maintaining accuracy. I also employ techniques like error analysis to identify biases and improve future forecasting performance.

Q 18. How do you use data analytics to improve manufacturing planning and control?

Data analytics plays a vital role in enhancing manufacturing planning and control. I leverage data analytics to:

- Optimize Production Schedules: By analyzing historical production data, machine utilization rates, and order lead times, I optimize production schedules to minimize lead times, reduce inventory costs, and maximize throughput. This might involve using linear programming or simulation techniques.

- Improve Inventory Management: Analyzing inventory levels, demand patterns, and lead times helps optimize inventory levels, minimizing carrying costs while preventing stockouts. Techniques like ABC analysis and safety stock calculations are used.

- Predict Equipment Failures: Analyzing sensor data from machines allows for predictive maintenance, minimizing downtime and reducing maintenance costs. Machine learning algorithms can be applied to identify patterns indicating potential failures.

- Identify Bottlenecks: Data analysis can pinpoint bottlenecks in the production process, allowing for targeted improvement initiatives. This often involves analyzing cycle times, throughput rates, and resource utilization.

I utilize various tools, including SQL, statistical software, and data visualization platforms, to analyze data, identify trends, and support decision-making.

Q 19. Describe your experience with different software applications used in manufacturing planning and control (e.g., SAP, Oracle).

My experience encompasses several manufacturing planning and control software applications.

- SAP ERP: I’ve extensively used SAP PP (Production Planning) module for master data management, production planning (MRP, capacity planning), shop floor control, and material requirements planning. I’ve configured and maintained the system to ensure it aligns with our manufacturing processes.

- Oracle ERP: I’ve worked with Oracle’s manufacturing modules for similar functionalities as SAP. This includes experience with order management, production scheduling, and inventory control. I’ve leveraged Oracle’s reporting and analytics capabilities to gain insights into production performance.

- Other specialized software: I have experience with various MES (Manufacturing Execution Systems) and specialized scheduling software which provide granular control over shop floor operations, enabling real-time monitoring and control.

My expertise extends beyond simple data entry to include system configuration, process optimization, and report development, ensuring that these systems are effectively utilized to support manufacturing goals.

Q 20. How do you collaborate with other departments to ensure smooth manufacturing operations?

Collaboration is key to smooth manufacturing operations. I foster strong relationships with various departments, including:

- Sales & Marketing: Close collaboration ensures that production plans align with sales forecasts and customer demands. This involves regular communication and joint forecasting meetings to anticipate market changes.

- Engineering: Working with engineering ensures that designs are manufacturable, minimizing production challenges. This includes participating in design reviews and providing feedback on manufacturability.

- Purchasing/Procurement: Close collaboration with purchasing guarantees timely delivery of materials, preventing production disruptions. This involves sharing production plans and collaborating on supplier selection and risk mitigation.

- Quality Control: Collaboration with quality control ensures that products meet quality standards, minimizing rework and scrap. This includes regular communication and collaboration on quality improvement initiatives.

Effective communication, regular meetings, and shared goals are instrumental in fostering successful inter-departmental collaboration.

Q 21. Explain your experience with supply chain risk management.

Supply chain risk management is critical for ensuring business continuity. My experience includes:

- Risk Identification & Assessment: I conduct regular risk assessments, identifying potential disruptions such as supplier failures, natural disasters, geopolitical events, and demand fluctuations. This involves using various risk assessment methodologies and considering the likelihood and impact of each risk.

- Mitigation Strategies: I develop and implement mitigation strategies to reduce the impact of identified risks. This might involve diversifying suppliers, holding safety stock, developing contingency plans, or implementing robust supply chain monitoring systems.

- Supplier Relationship Management: Building strong relationships with key suppliers is vital. This involves regular communication, performance monitoring, and collaborative problem-solving. This reduces the risk of supplier-related disruptions.

- Supply Chain Visibility: Utilizing technology to enhance supply chain visibility, such as real-time tracking systems and advanced analytics, enables proactive identification and management of potential risks.

A proactive and data-driven approach to supply chain risk management is crucial for ensuring the resilience and sustainability of manufacturing operations.

Q 22. How do you handle supplier relationship management?

Supplier Relationship Management (SRM) is crucial for a successful manufacturing operation. It’s about building strong, collaborative relationships with your suppliers to ensure a consistent flow of high-quality materials and services. This goes beyond simply placing orders; it involves strategic planning, risk mitigation, and ongoing communication.

- Strategic Partnering: I focus on selecting suppliers not just based on price, but also on their reliability, quality control processes, and overall capabilities. This might involve thorough due diligence, including site visits and performance audits.

- Collaboration & Communication: Open and transparent communication is key. I utilize regular meetings, shared dashboards, and collaborative platforms to track performance, address issues proactively, and anticipate potential problems. For example, if a supplier faces a raw material shortage, early communication allows us to explore alternative sourcing or adjust our production schedule accordingly.

- Performance Measurement: Key Performance Indicators (KPIs) are essential for tracking supplier performance. These might include on-time delivery, quality metrics (defect rates, etc.), and responsiveness. We establish clear expectations and conduct regular performance reviews, offering constructive feedback and support.

- Risk Management: We identify and mitigate potential risks, such as supplier dependency, geopolitical instability, or natural disasters. This might involve diversifying our supplier base, building inventory buffers, or establishing contingency plans.

For example, in a previous role, I successfully negotiated a long-term contract with a key supplier, which resulted in a 15% reduction in material costs and a significant improvement in delivery times. This involved building a strong relationship with their management team and implementing a collaborative planning process.

Q 23. How do you ensure quality control throughout the manufacturing process?

Quality control is not a single event, but a continuous process integrated throughout the entire manufacturing lifecycle. It starts with the selection of raw materials and continues through production, packaging, and delivery. My approach is multifaceted:

- Incoming Inspection: All incoming materials are rigorously inspected to ensure they meet our specifications. This might involve visual inspections, testing, and verification against certificates of analysis.

- In-Process Control: Regular checks are conducted at various stages of the production process to identify and correct defects early. This is often achieved through Statistical Process Control (SPC) techniques, using control charts to monitor process variables and detect any deviations from the norm.

- Final Inspection: Before products are shipped, a final inspection ensures that they meet all quality standards. This might include functional testing, dimensional checks, and visual inspection.

- Corrective and Preventive Actions (CAPA): When defects are found, we implement a systematic CAPA process to identify the root cause, implement corrective actions, and prevent similar issues from occurring in the future. This often involves root cause analysis techniques, such as the 5 Whys.

- Continuous Improvement: We employ tools like Lean Manufacturing and Six Sigma to continuously improve our quality control processes. This includes regularly reviewing our quality metrics, identifying areas for improvement, and implementing changes to reduce defects and improve efficiency.

Think of it like baking a cake. You wouldn’t just check the finished product; you’d ensure the ingredients are fresh, the oven temperature is correct, and you’d monitor the baking process to ensure the cake rises evenly. Quality control in manufacturing follows a similar principle, involving constant vigilance and attention to detail.

Q 24. What is your experience with production simulation tools?

I have extensive experience with various production simulation tools, including Arena, AnyLogic, and Plant Simulation. These tools are invaluable for optimizing manufacturing processes, identifying bottlenecks, and evaluating different scenarios before implementation.

For instance, in a previous project, we used Arena to simulate the impact of a new automated assembly line. The simulation allowed us to identify potential bottlenecks, optimize the layout of the line, and determine the required staffing levels. This resulted in a 20% increase in production efficiency and a 10% reduction in production costs. // Example simulation code (pseudocode): // Define resources (machines, workers) // Define processes (assembly steps, transportation) // Define input parameters (production rate, defect rate) // Run simulation and analyze results (throughput, bottleneck analysis)

My expertise extends beyond simply running simulations; I am proficient in designing experiments, analyzing results, and communicating findings to stakeholders. I understand the limitations of simulation and use it as a tool to support informed decision-making, not as a replacement for real-world testing.

Q 25. Explain your understanding of different types of production processes (e.g., batch, continuous, job shop).

Different production processes are best suited for different types of manufacturing. Understanding these differences is crucial for efficient planning and control.

- Job Shop: This is characterized by low-volume, high-variety production. Each product or job may have unique processing requirements and routings. Think of a custom furniture maker; each piece is unique, requiring different materials, tools, and time.

- Batch Production: This involves producing goods in batches or lots of similar items. The production process is repeated for each batch. Think of a bakery producing batches of cookies; the recipe and process are the same for each batch, but the volume is finite.

- Mass Production: This focuses on high-volume production of standardized products using specialized equipment and assembly lines. Think of an automobile manufacturer; millions of cars are produced using highly automated systems and standardized components.

- Continuous Production: This involves a continuous flow of materials and processing, often operating 24/7. Think of oil refineries or chemical plants; the production never stops, and products are continuously produced.

The choice of production process depends on factors like product volume, variety, customization level, and market demand. An effective manufacturing strategy leverages the strengths of each process type and adapts to the specific needs of the products being produced.

Q 26. How do you prioritize different production orders?

Prioritizing production orders is a critical aspect of manufacturing planning and control. The method used depends on various factors, including customer demand, delivery deadlines, material availability, and production capacity.

- Due Date Scheduling: This method prioritizes orders with the earliest due dates, ensuring timely delivery to customers. It’s effective when on-time delivery is paramount.

- Priority Scheduling: This assigns priorities to orders based on factors such as customer importance, contract terms, or product profitability. High-priority orders are processed first, regardless of their due dates.

- Shortest Processing Time (SPT) Scheduling: This prioritizes orders with the shortest processing times to minimize work-in-process inventory and improve throughput.

- Critical Ratio (CR) Scheduling: This calculates a ratio for each order based on the remaining time and the total processing time. Orders with the lowest critical ratio are prioritized, balancing due dates and processing times.

I often use a combination of these methods, considering the specific context and priorities of the manufacturing environment. For example, critical orders from key customers might receive higher priority than others, even if their due dates are later. Sophisticated scheduling software and algorithms can also assist in automating this process.

Q 27. How do you manage change requests to the production schedule?

Managing change requests to the production schedule requires a structured approach to minimize disruption and ensure timely execution. My strategy involves the following steps:

- Impact Assessment: When a change request is received, I assess its potential impact on the existing schedule, considering factors such as resource availability, lead times, and customer commitments. This might involve running simulations or using scheduling software to evaluate different scenarios.

- Negotiation and Prioritization: If the change request is significant, negotiation with the relevant stakeholders (e.g., sales, engineering, customers) may be necessary to find a mutually acceptable solution. This might involve prioritizing certain orders over others or adjusting delivery dates.

- Replanning and Communication: Once a decision is made, the production schedule is updated accordingly, and all relevant parties are informed of the changes. This ensures everyone is aware of the updated plan and their roles in executing it.

- Monitoring and Adjustment: The revised schedule is closely monitored, and any further adjustments are made as needed. This might involve tracking progress, addressing bottlenecks, and proactively communicating with stakeholders about any potential delays or issues.

Transparency and communication are vital throughout this process. Keeping stakeholders informed minimizes confusion and helps to manage expectations. In my experience, proactive communication and a structured approach to change management are key to minimizing the disruption caused by schedule adjustments.

Key Topics to Learn for Manufacturing Planning and Control Interview

- Demand Planning & Forecasting: Understanding different forecasting methods (e.g., moving average, exponential smoothing), their applications, and limitations. Practical application: Analyzing historical sales data to predict future demand and optimize inventory levels.

- Master Production Scheduling (MPS): Developing and managing a master production schedule, considering capacity constraints, material availability, and customer orders. Practical application: Creating and adjusting an MPS to meet fluctuating demand while minimizing production costs and lead times.

- Material Requirements Planning (MRP): Understanding the MRP process, bill of materials (BOM), and its role in ensuring timely procurement of raw materials. Practical application: Using MRP software to generate purchase orders and manage inventory levels efficiently.

- Capacity Planning & Resource Allocation: Analyzing production capacity, identifying bottlenecks, and optimizing resource allocation to meet production goals. Practical application: Using capacity planning tools to determine the optimal number of machines and personnel required for production.

- Inventory Management: Understanding different inventory control techniques (e.g., EOQ, JIT), their advantages and disadvantages, and their impact on production efficiency. Practical application: Implementing an inventory management system to minimize holding costs while ensuring sufficient inventory to meet demand.

- Production Scheduling & Control: Developing and implementing effective production schedules, monitoring progress, and taking corrective actions when necessary. Practical application: Using scheduling software to track production progress, identify delays, and make adjustments to meet deadlines.

- Lean Manufacturing Principles: Understanding and applying lean principles to eliminate waste and improve efficiency in the manufacturing process. Practical application: Implementing Kaizen events to identify and eliminate sources of waste in the production process.

- Metrics and KPIs: Understanding key performance indicators (KPIs) used in manufacturing planning and control, such as lead time, on-time delivery, inventory turnover, and production efficiency. Practical application: Analyzing KPIs to identify areas for improvement and track progress toward goals.

Next Steps

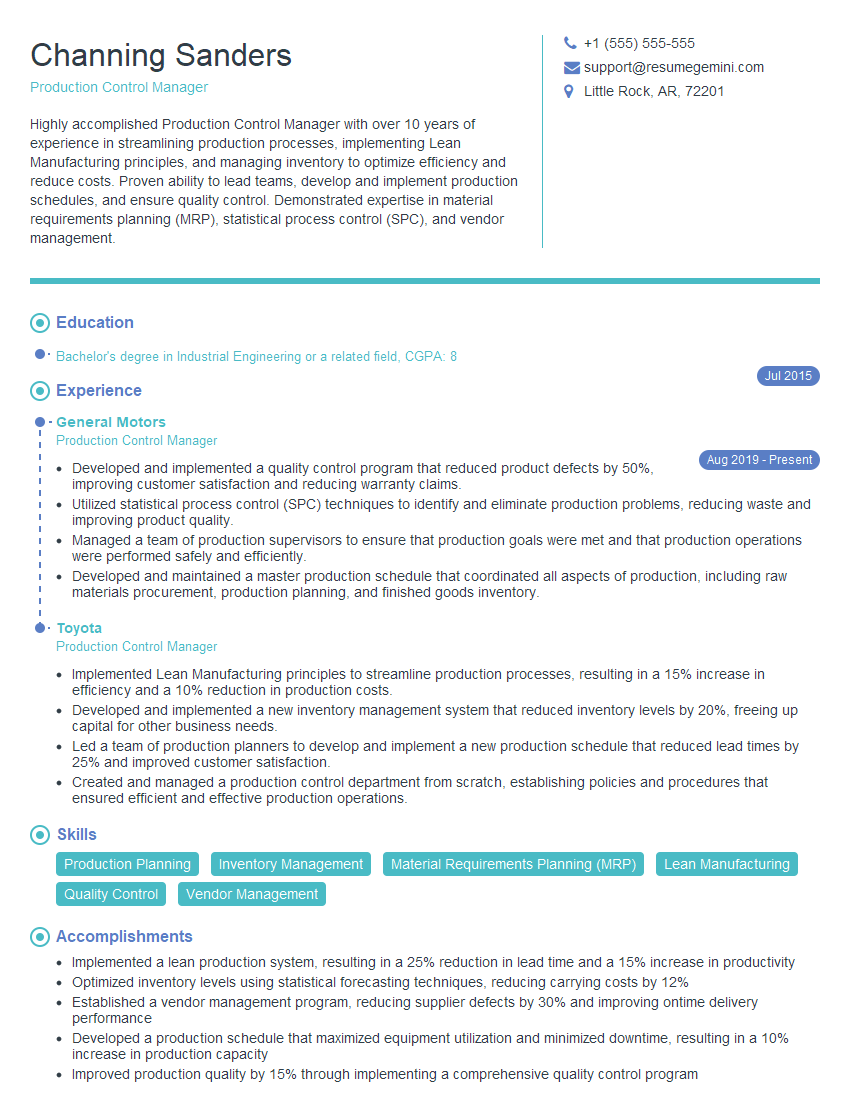

Mastering Manufacturing Planning and Control is crucial for career advancement, opening doors to leadership roles and higher earning potential. A strong, ATS-friendly resume is your key to unlocking these opportunities. To ensure your resume showcases your skills and experience effectively, we highly recommend using ResumeGemini. ResumeGemini offers a streamlined process for building professional, impactful resumes, and we provide examples tailored specifically to Manufacturing Planning and Control to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?