Unlock your full potential by mastering the most common Smoothness and Roughness Evaluation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Smoothness and Roughness Evaluation Interview

Q 1. Explain the difference between arithmetic mean roughness (Ra) and root mean square roughness (Rq).

Both arithmetic mean roughness (Ra) and root mean square roughness (Rq) are parameters used to quantify surface roughness, but they do so in different ways. Think of them as two different ways to describe the ‘bumpiness’ of a surface.

Ra (Arithmetic Mean Roughness): This is the average deviation of the surface profile from the mean line. Imagine taking the absolute value of all the peaks and valleys on a surface profile, then averaging them. That’s essentially Ra. It’s a simple and widely used parameter, but it doesn’t weigh larger deviations as heavily as smaller ones.

Rq (Root Mean Square Roughness): This represents the square root of the average of the squares of the deviations from the mean line. Unlike Ra, Rq gives more weight to larger peaks and valleys. It’s a more sensitive indicator of the overall surface roughness, particularly useful when dealing with surfaces containing significant peaks or deep valleys. Statistically, it’s more robust to outliers.

Analogy: Imagine two sets of exam scores. Ra is like calculating the average score, while Rq is like calculating the standard deviation. A high standard deviation (Rq) indicates a wider spread of scores, even if the average (Ra) is similar. Similarly, a high Rq indicates a rougher surface even if the average deviation (Ra) might be similar to another surface with smaller but more frequent variations.

Q 2. Describe the various methods used for measuring surface roughness.

Several methods exist for measuring surface roughness, each with its own strengths and weaknesses. The choice depends on the required precision, surface type, and budget.

- Profilometry: This involves tracing the surface profile with a stylus. A sharp stylus moves across the surface, and the vertical movements are measured, providing a detailed height profile. This method is relatively simple, versatile, and provides high resolution but can damage delicate surfaces. Different stylus types are available, each suited for specific surface types.

- Interferometry: This optical technique uses interference patterns from light waves reflected from the surface to create a 3D map of the surface. It offers non-contact measurement, high precision, and a larger measurement area than profilometry. Examples include white-light interferometry (WLI) and confocal microscopy.

- Optical microscopy: Techniques like confocal microscopy offer high resolution imaging of the surface’s microstructure, allowing for detailed analysis of roughness at the micro- and nano-scale. However, interpretation requires expertise and it’s less straightforward to obtain quantitative roughness parameters directly.

- Scanning Probe Microscopy (SPM): Techniques like Atomic Force Microscopy (AFM) offer nanometer-scale resolution allowing for measurement of extremely smooth surfaces. It’s also a non-contact method, avoiding potential damage, but it can be expensive and time-consuming.

- Focus Variation Microscopy (FVM): This technique uses a high-resolution camera to capture images of the surface at different focal planes. These images are then used to reconstruct a 3D model and determine roughness parameters. FVM is a non-contact, fast method but might struggle with steep surface features.

Q 3. What are the advantages and disadvantages of different surface roughness measurement techniques (e.g., profilometry, interferometry)?

The choice of surface roughness measurement technique involves weighing advantages and disadvantages:

- Profilometry:

- Advantages: Relatively inexpensive, versatile, high resolution, direct measurement of surface profile.

- Disadvantages: Can damage delicate surfaces, limited measurement area, stylus wear can affect accuracy.

- Interferometry:

- Advantages: Non-contact, high precision, large measurement area, fast measurements.

- Disadvantages: Can be affected by surface reflectivity and cleanliness, potentially expensive equipment.

- Optical Microscopy:

- Advantages: High resolution, visualization of microstructure.

- Disadvantages: Interpretation needs expertise, not always straightforward to obtain quantitative roughness data, limited depth of field.

- Scanning Probe Microscopy (SPM):

- Advantages: Nanometer scale resolution, non-contact, highly precise.

- Disadvantages: Expensive, time-consuming, sensitive to environmental conditions.

- Focus Variation Microscopy (FVM):

- Advantages: Non-contact, fast measurements, large measurement area.

- Disadvantages: Can be less accurate for steep surfaces, requires specialized software.

Q 4. How does surface roughness affect friction and wear?

Surface roughness significantly impacts friction and wear. A rougher surface generally leads to higher friction and increased wear.

Friction: Rough surfaces have more points of contact, leading to greater resistance to motion. Think of trying to slide two pieces of sandpaper together versus two smooth glass plates. The sandpaper offers significantly more resistance due to its rough surface.

Wear: Higher friction, caused by increased surface contact, can lead to accelerated wear of the materials in contact. The high stress at the asperities (peaks) of a rough surface can cause material failure, abrasion, and adhesion. This is why lubricants are often used to minimize surface interaction and reduce wear.

Example: In machine components, a rough surface can result in increased energy consumption due to higher friction. It also leads to a shorter lifespan due to accelerated wear. This necessitates surface finishing techniques like polishing or honing to reduce roughness and improve performance.

Q 5. Explain the relationship between surface roughness and surface topography.

Surface topography and surface roughness are closely related but distinct concepts. Surface topography describes the overall three-dimensional shape and features of a surface, including its form, waviness, and roughness. Surface roughness is just one component of surface topography.

Analogy: Imagine a mountain range. Surface topography is the entire mountain range, including its valleys, peaks, slopes, and overall shape. Surface roughness, on the other hand, would focus only on the texture of a particular section of a mountain slope, neglecting the overall form of the entire mountain range. It’s a detailed, localized description of surface irregularities.

Roughness is typically characterized by short-wavelength variations while waviness and form refer to longer-wavelength components of the topography.

Q 6. How do you interpret a surface roughness profile?

Interpreting a surface roughness profile involves analyzing the measured height variations along a specific length. This provides information about the surface’s texture and helps determine appropriate roughness parameters.

Steps:

- Identify the mean line: The mean line represents the average height of the profile.

- Observe the peaks and valleys: Note the amplitude and frequency of the surface variations.

- Assess the overall texture: Determine whether the surface is predominantly rough or smooth.

- Calculate roughness parameters: Employ software or equations to calculate Ra, Rq, Rz (peak-to-valley height), etc. to quantify roughness.

- Consider the wavelength components: Differentiate between roughness, waviness, and form.

- Compare with specifications: Check if the measured roughness falls within the acceptable limits dictated by the application.

Example: A profile showing many sharp, high-amplitude peaks and deep valleys suggests a rough surface with high Ra and Rq values. A profile with small, evenly distributed variations would suggest a smooth surface with low roughness parameters.

Q 7. What are the key parameters used to characterize surface roughness?

Many parameters are used to characterize surface roughness, depending on the application and the desired level of detail. Some of the most common include:

- Ra (Arithmetic mean roughness): The average absolute deviation from the mean line.

- Rq (Root mean square roughness): The square root of the average of the squared deviations from the mean line.

- Rz (Peak-to-valley height): The difference between the highest peak and the lowest valley within the measurement length.

- Rt (Total height): The vertical distance between the highest peak and lowest valley within the measurement length.

- Rmax (Maximum height): The difference in height between the highest and lowest points across the entire profile.

- Rsk (Skewness): Describes the asymmetry of the profile; a positive value indicates more peaks than valleys.

- Rku (Kurtosis): Describes the peakedness of the profile. High kurtosis indicates sharp peaks and deep valleys.

- λa (Average wavelength): The average distance between peaks and valleys.

The selection of appropriate parameters depends on the specific application and the type of surface. Some applications may require a single parameter like Ra, while others may need a combination of parameters for a complete characterization.

Q 8. What are the common units used to express surface roughness?

Surface roughness is typically expressed in micrometers (µm) or microinches (µin). These units represent the average deviation of the surface from its mean line. Think of it like measuring the bumps and valleys on a surface; a smaller number indicates a smoother surface.

While µm and µin are the most common, you might also encounter other related units such as Ra (average roughness), Rz (maximum height of roughness profile), or Rq (root mean square roughness). Each of these provides slightly different insights into the surface texture, and the choice depends on the specific application and the standard being used.

Q 9. Describe different types of surface roughness measurement instruments.

Several instruments are used to measure surface roughness, each with its strengths and weaknesses. The most common types include:

- Contact Profilometers: These devices use a stylus to physically trace the surface profile. A highly accurate, but slow, method, ideal for detailed analysis. They are workhorses in many labs and provide data such as Ra, Rz, and other roughness parameters.

- Optical Profilers: These instruments use optical techniques, such as interferometry or confocal microscopy, to measure surface topography without physical contact. They are faster and can measure larger areas but might have limitations in terms of vertical resolution for very rough surfaces.

- Non-contact Sensors: These include various sensor technologies like laser scanners and structured light scanners. These are excellent for fast, large-area measurements and are often used in automated manufacturing processes. However, they can sometimes be affected by surface reflectivity and other optical characteristics.

The choice of instrument depends on factors like the required accuracy, the surface material, the size of the area to be measured, and the speed of measurement. For example, a contact profilometer would be ideal for inspecting a critical part in aerospace, while a non-contact sensor would be more suitable for quality control of a large batch of manufactured parts.

Q 10. Explain the concept of surface texture and its importance in manufacturing.

Surface texture encompasses all aspects of a surface’s appearance, including roughness, waviness, and lay (the directionality of the surface features). It’s more than just roughness; it encompasses the overall topography of the surface. Think of it as the complete fingerprint of the surface.

In manufacturing, surface texture is crucial because it significantly impacts:

- Functional Performance: Surface texture affects friction, wear, lubrication, and sealing properties. A smooth surface might be desired for low friction in a bearing, whereas a rougher surface could be better for gripping applications.

- Aesthetics: Surface texture contributes significantly to the visual appeal of products. Think of the difference between a polished metal surface and a brushed metal surface.

- Fatigue Life: Surface features can act as stress concentrators, impacting the fatigue strength of a component. Smoother surfaces generally enhance fatigue resistance.

- Corrosion Resistance: Surface roughness influences the adhesion of protective coatings and the formation of corrosion products.

Understanding and controlling surface texture is, therefore, essential for ensuring product quality and reliability.

Q 11. How does surface roughness affect the performance of bearings?

Surface roughness significantly affects the performance of bearings. Excessive roughness can lead to increased friction, wear, and noise. Imagine trying to roll a ball bearing across a bumpy surface versus a smooth one – the bumpy surface will cause more resistance and potentially damage the ball bearing.

Specifically:

- Increased Friction: Rougher surfaces increase the contact area between bearing components, leading to higher friction and increased energy loss.

- Accelerated Wear: The peaks and valleys on a rough surface cause increased stress concentrations, leading to faster wear and tear of the bearing components.

- Higher Noise Levels: The irregularities on a rough surface cause vibrations, leading to increased noise generated during operation.

- Reduced Load Capacity: Roughness can reduce the effective contact area and hence lower the bearing’s load-carrying capacity.

Therefore, achieving appropriate surface roughness is critical to ensuring the longevity, efficiency, and quiet operation of bearings.

Q 12. How do you determine the appropriate surface roughness for a given application?

Determining the appropriate surface roughness involves a careful consideration of the application’s requirements. There isn’t a one-size-fits-all answer; it is a detailed process considering several factors. This often involves collaboration between design engineers, manufacturing engineers, and material scientists.

Here’s a step-by-step approach:

- Understand the application: What is the function of the component? What are the expected loads, speeds, and operating conditions?

- Identify relevant performance criteria: What are the critical performance characteristics? For example, friction, wear, corrosion resistance, or fatigue life?

- Consult relevant standards and specifications: Industry standards often provide guidelines on acceptable surface roughness values for specific applications.

- Consider material properties: The material’s hardness, machinability, and susceptibility to corrosion will influence the achievable and desirable surface roughness.

- Conduct experiments or simulations: To verify performance, testing is crucial. This might involve tribological testing (friction and wear) or fatigue testing.

- Balance cost and performance: Achieving extremely smooth surfaces can be expensive. It’s important to find an optimal balance between performance requirements and manufacturing costs.

For example, a high-precision bearing will require a much smoother surface than a simple bolt. The process involves selecting the appropriate manufacturing method and process parameters to control the surface texture and achieve the desired result.

Q 13. Describe the impact of surface roughness on corrosion resistance.

Surface roughness significantly impacts corrosion resistance. Rougher surfaces generally exhibit poorer corrosion resistance than smoother surfaces. Think of it as providing more surface area for corrosive agents to attack. More surface area means more potential sites for corrosion initiation.

Specifically:

- Increased Surface Area: Rougher surfaces have a larger surface area compared to smoother surfaces, leading to increased exposure to corrosive environments.

- Stress Concentration: Surface irregularities can act as stress concentrators, accelerating the initiation and propagation of corrosion.

- Trapped Contaminants: Rough surfaces can trap moisture, salts, and other contaminants, creating localized corrosive environments.

- Reduced Coating Adhesion: Rough surfaces can hinder the proper adhesion of protective coatings, reducing their effectiveness in preventing corrosion.

Therefore, for applications requiring high corrosion resistance, achieving a smooth surface finish is crucial. This is often achieved through processes like polishing or electropolishing.

Q 14. What are the common standards used for surface roughness measurements?

Several international standards govern surface roughness measurement and specification. The most prominent include:

- ISO 4287: This is a widely recognized international standard that defines surface texture parameters and their measurement methods.

- ANSI B46.1: The American National Standard for surface texture is often referenced in US-based applications.

- DIN 4768: This is a German standard that addresses surface roughness measurement and specification, often used in European contexts.

- JIS B 0601: This Japanese standard covers similar aspects of surface roughness to the ISO standard.

These standards specify methods for measuring various surface texture parameters, providing consistency and comparability across different measurements and manufacturing processes. Understanding the applicable standard is important to ensure proper communication and quality control.

Q 15. How can you improve the surface roughness of a component?

Improving surface roughness involves controlling the manufacturing process to minimize irregularities. Think of it like smoothing out a bumpy road – the smoother the road, the lower the roughness.

- Machining Techniques: Using finer cutting tools, slower feed rates, and optimized cutting parameters in processes like milling and turning significantly reduces roughness. For example, switching from a roughing cut to a finishing cut with a sharper tool drastically improves surface quality.

- Polishing and Grinding: These techniques use abrasive materials to progressively remove material and create a smoother surface. Imagine sanding wood – each finer grit sandpaper yields a smoother finish. Diamond polishing, for example, can achieve extremely low roughness values.

- Electrochemical Processes: Techniques like electropolishing use electrochemical reactions to remove material, leaving a very smooth surface, often employed in creating highly reflective surfaces or minimizing friction.

- Chemical Treatments: Chemical etching or polishing can selectively remove material to create a desired surface finish. This is useful for creating specific textures or improving surface properties beyond just roughness.

- Coating Applications: Applying thin coatings can effectively mask underlying roughness. Think of painting a rough-textured wall to make it appear smoother.

The choice of method depends on the material, desired roughness level, and the application’s requirements. Often a combination of these techniques is necessary to achieve optimal results.

Career Expert Tips:

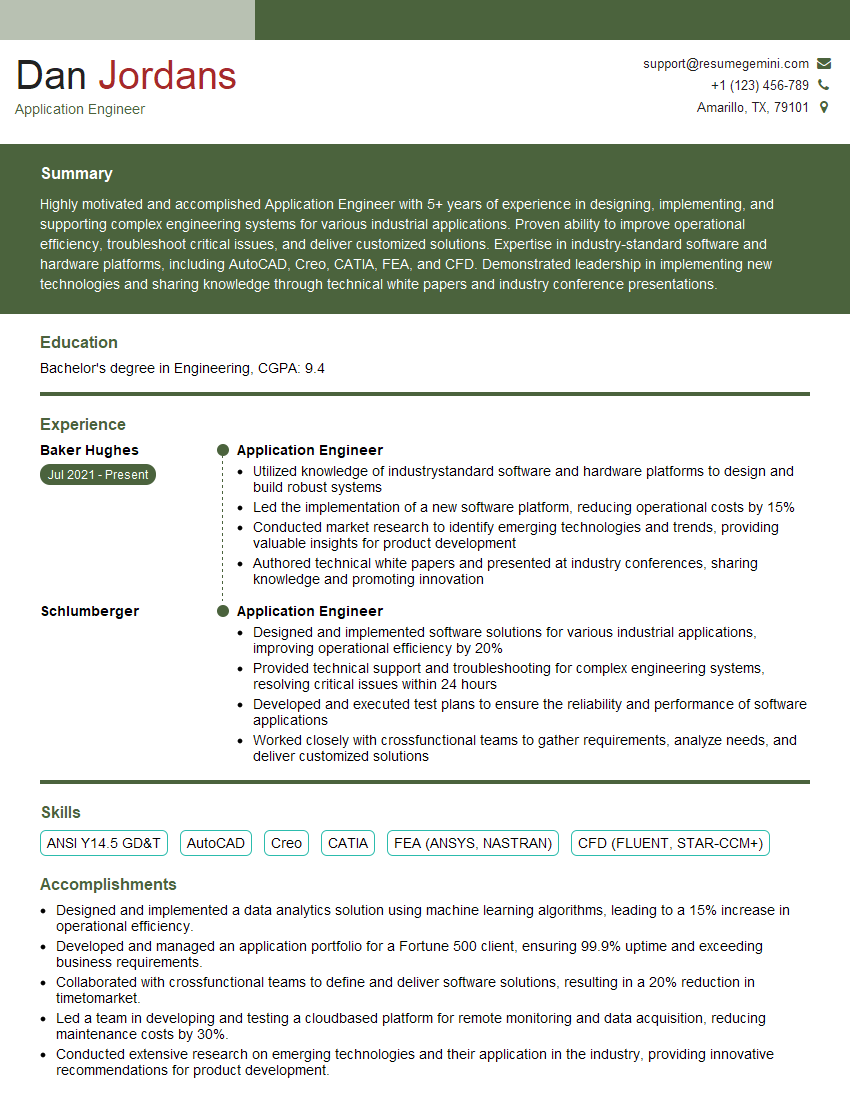

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of surface roughness in the adhesion of coatings.

Surface roughness plays a crucial role in coating adhesion. A rough surface provides more mechanical interlocking for the coating, like a climbing plant gripping a rough wall. This increases the surface area for contact, strengthening the bond. Conversely, a smooth surface offers less mechanical interlocking, leading to weaker adhesion.

Imagine trying to glue two smooth pieces of glass together versus gluing two rough pieces of wood. The wood, with its rough surface, will provide far superior adhesion because the glue can penetrate into the crevices and form a stronger bond.

The optimal roughness is not simply ‘more is better’. Excessive roughness can create stress concentrations within the coating, leading to cracking and delamination (separation of the coating from the substrate). There’s a ‘Goldilocks’ zone of optimal roughness where the mechanical interlocking is maximized without introducing excessive stress. This optimal roughness will vary depending on the coating material and the substrate material.

Q 17. How does surface roughness affect the optical properties of a material?

Surface roughness significantly impacts a material’s optical properties, particularly its reflectivity, scattering, and absorption of light. A smooth surface reflects light specularly (like a mirror), while a rough surface scatters light diffusely (like a matte surface).

- Reflectivity: Smooth surfaces exhibit higher specular reflectivity, meaning they reflect light in a concentrated beam. Rough surfaces, in contrast, scatter light in many directions, reducing specular reflectivity and increasing diffuse reflection.

- Scattering: Rough surfaces scatter light more, affecting the material’s transparency and color appearance. This is why frosted glass appears opaque – the roughness scatters light, preventing it from passing through.

- Absorption: While less directly related, roughness can indirectly affect absorption by influencing how light interacts with the material’s surface. For instance, a rough surface may trap light within its irregularities, leading to increased absorption.

In optical applications, controlling surface roughness is critical. For example, mirrors require extremely smooth surfaces for high reflectivity, while diffusers need a controlled roughness to achieve the desired light scattering properties.

Q 18. What are the challenges associated with measuring surface roughness on complex geometries?

Measuring surface roughness on complex geometries presents significant challenges. Traditional stylus profilometers, which use a stylus to trace the surface, struggle to access crevices, deep recesses, and overhanging features. This leads to incomplete measurements and inaccurate roughness values.

Additionally, the orientation of the measurement relative to the surface can heavily influence the results. A seemingly small change in angle can drastically alter the apparent roughness. For example, measuring a threaded screw with a stylus would provide very different results depending on the orientation of the stylus relative to the thread profile.

Optical techniques, like confocal microscopy or white-light interferometry, offer advantages by providing non-contact measurement and capable of measuring complex geometries, yet can still have limitations in extremely steep or deep features.

Solutions involve utilizing multiple measurement techniques, choosing appropriate probe sizes and geometries for the stylus method, and implementing advanced data analysis and stitching techniques for optical measurements to produce a more complete picture of the surface topography.

Q 19. How do you ensure the accuracy and repeatability of surface roughness measurements?

Ensuring accurate and repeatable surface roughness measurements requires careful attention to detail and standardized procedures.

- Calibration: Regular calibration of the measuring instrument (stylus profilometer, optical profiler, etc.) using certified standards is crucial. This verifies that the instrument is providing accurate readings.

- Sample Preparation: Proper sample preparation is essential. Cleaning the surface to remove debris and ensuring a representative sampling area are critical steps. A poorly prepared sample can lead to inaccurate and non-repeatable results.

- Measurement Parameters: Consistent measurement parameters such as cutoff length, sampling length, and evaluation parameters must be maintained. Variations in these parameters can significantly affect the roughness values.

- Multiple Measurements: Taking multiple measurements at different locations on the sample and averaging the results improves the accuracy and minimizes the effect of localized variations.

- Environmental Control: Maintaining a stable environment minimizes the impact of temperature and humidity variations, which can affect both the sample and the measurement instrument.

- Operator Training: Well-trained operators are essential to ensure consistent procedures and minimize operator-induced errors.

By adhering to these practices, you can significantly enhance the accuracy and repeatability of your surface roughness measurements, ensuring consistent and reliable data for analysis and decision-making.

Q 20. Describe different types of surface defects and their impact on roughness.

Surface defects beyond simple roughness variations significantly impact the overall surface quality. These defects can dramatically influence the functional performance of a component. Examples include:

- Scratches: Linear imperfections caused by abrasive contact. They increase roughness and can compromise a component’s structural integrity or optical properties, for example, reducing the reflectivity of a mirror.

- Pits and Pores: Small depressions or holes in the surface. These decrease surface area, decrease adhesion of coatings and also act as stress concentration sites, potentially leading to fatigue failure.

- Cracks: Fractures in the surface, often arising from stress or material defects. Cracks significantly weaken the material and can lead to catastrophic failure.

- Inclusions: Foreign particles embedded in the surface, affecting both the roughness and the material’s homogeneity. These inclusions can act as nucleation sites for cracks or corrosion.

- Voids: Empty spaces within the material that extend to the surface. These impact the material’s strength and can contribute to surface irregularity and degradation.

The impact of these defects on roughness is usually assessed using a combination of profilometry and other techniques like microscopy to characterize both roughness and the presence and nature of specific defects. The severity of the impact of these defects will depend greatly on the application. For instance, tiny pits on a bearing surface may cause significant wear, while similar defects on a decorative item may be imperceptible.

Q 21. Explain the concept of fractal dimension in relation to surface roughness.

Fractal dimension is a mathematical concept used to quantify the complexity and roughness of surfaces. Unlike traditional roughness parameters that rely on simple statistical measures, fractal dimension captures the self-similarity of a surface at different scales. Imagine zooming in on a very rough surface – at each magnification level, you may still observe similar patterns of roughness.

A higher fractal dimension indicates a more complex and rougher surface. A smooth surface has a fractal dimension close to 2 (a flat plane), while highly irregular surfaces have dimensions approaching 3. Fractal analysis can characterize surfaces with complex, non-repeating patterns which are difficult to describe using conventional roughness parameters.

Practical applications include characterizing the roughness of natural surfaces like rocks and fractured materials, analyzing the texture of porous media, and modeling surface growth processes. It is used in fields such as materials science, geology, and image processing to quantify and compare surface complexity in greater detail than traditional methods alone can achieve.

Q 22. How do you analyze surface roughness data using statistical methods?

Analyzing surface roughness data using statistical methods involves extracting meaningful parameters from the profile obtained through techniques like profilometry. We typically use parameters derived from the height distribution and spatial characteristics of the surface.

Height parameters describe the vertical variations. Common ones include:

- Ra (average roughness): The arithmetic average of the absolute values of the profile deviations from the mean line. It’s a widely used overall indicator of roughness.

- Rz (maximum height): The difference between the highest and lowest peaks within the assessment length. Provides information about the largest asperities.

- Rq (root mean square roughness): The square root of the mean of the squares of the profile deviations from the mean line. It’s more sensitive to large peaks than Ra.

Spatial parameters describe the horizontal variations. These include:

- Sm (mean spacing of roughness): The average distance between peaks or valleys.

- Sk (skewness): Indicates the asymmetry of the height distribution. A positive value suggests more high peaks than deep valleys and vice versa.

- Ku (kurtosis): Describes the sharpness of the peaks. A high kurtosis suggests sharp peaks and deep valleys.

Statistical analysis often involves generating histograms of height distributions, calculating the aforementioned parameters, and potentially using techniques like autocorrelation analysis to understand the spatial correlation of roughness features. Software packages dedicated to surface metrology provide automated calculations and visualizations of these parameters.

Example: Imagine analyzing the roughness of a machined part. A high Ra value might indicate a need for adjustments to the machining process to achieve a smoother surface. A high Rz value might point to specific imperfections that need to be addressed.

Q 23. What are the limitations of using a single roughness parameter to describe a surface?

Relying on a single roughness parameter to fully characterize a surface is inherently limiting, akin to trying to describe a person solely by their height. A surface’s texture is complex and multifaceted.

Using only one parameter ignores the rich information contained in the height distribution and spatial characteristics. For instance, two surfaces might have the same Ra value but drastically different peak distributions or spatial frequencies. One might have many small peaks while the other has a few large ones. These differences would be missed by focusing on Ra alone. This can lead to misinterpretations and inappropriate material selection or process decisions.

Limitations include:

- Lack of comprehensive description: Single parameters ignore spatial frequency content and peak distribution details.

- Potential for misinterpretation: Similar single parameter values can represent very different surface textures.

- Limited suitability for specific applications: Different applications may require consideration of different aspects of surface roughness.

Therefore, a comprehensive surface roughness analysis always requires multiple parameters, considering both height and spatial aspects, to fully understand the surface texture and its implications for the intended application.

Q 24. Describe the influence of machining parameters on surface roughness.

Machining parameters significantly impact surface roughness. Think of it like sculpting – the tools and techniques directly influence the final surface finish. Key parameters include:

- Cutting speed: Higher speeds often lead to smoother surfaces, as the tool spends less time in contact with the material at any given point. However, excessively high speeds can induce unwanted effects such as vibration and built-up edge formation, degrading surface quality.

- Feed rate: This determines the material removal rate per revolution or pass. Higher feed rates generally produce rougher surfaces due to the larger amount of material removed with each cut. Conversely, slow feed rates lead to smoother surfaces but may increase machining time.

- Depth of cut: Deeper cuts remove more material, increasing the likelihood of producing a rougher surface due to the greater impact and potential for chip formation. Smaller depth of cuts result in smoother surfaces but require multiple passes to achieve the desired material removal.

- Tool geometry: The shape and sharpness of the cutting tool are crucial. A sharp tool produces a smoother surface than a dull tool that causes tearing and material deformation. The rake angle and nose radius of the tool also influence surface finish.

- Coolant: The use of coolants helps control temperature during machining, reducing thermal deformation and improving the surface quality.

Example: In turning operations, increasing the cutting speed and decreasing the feed rate typically reduces surface roughness. Choosing a tool with a sharper tip and a larger nose radius will also lead to improvements in the surface finish.

Q 25. How does surface roughness affect the fatigue life of a component?

Surface roughness plays a crucial role in influencing the fatigue life of a component. Rough surfaces act as stress concentrators, initiating crack propagation and ultimately leading to fatigue failure at a lower number of cycles compared to smooth surfaces.

The mechanism is as follows: microscopic surface irregularities create stress concentrations which act as starting points for fatigue cracks. These cracks propagate under cyclic loading, leading to failure. The higher the roughness, the more pronounced these stress concentrations, and the shorter the fatigue life. The severity depends on the type of loading (e.g. bending, tension), the material’s properties, and the environment.

Examples: Consider a connecting rod in an engine or the shaft in a turbine. For these parts operating under cyclic stress, even a small increase in surface roughness can significantly reduce the fatigue life and cause premature failure. Therefore, careful control of surface roughness during manufacturing is essential to ensure that components meet the required service life.

Q 26. Discuss the role of surface roughness in biocompatibility.

Surface roughness significantly influences biocompatibility, which is how well a material interacts with living tissue. The interaction between a biomedical implant and the surrounding tissue is strongly affected by the implant’s surface texture.

Smooth surfaces generally reduce the risk of blood clot formation and inflammation. They minimise the area for protein adsorption, which is crucial for cell adhesion and tissue integration. However, excessive smoothness might hinder cell attachment and tissue growth, delaying osseointegration (bone integration).

Rough surfaces can promote cell adhesion and proliferation. A certain level of roughness facilitates the attachment of proteins that trigger cell growth, improving osseointegration and overall biocompatibility. However, excessive roughness can lead to increased inflammation, infection, and even wear particle generation, negatively impacting biocompatibility.

Therefore, finding the optimal surface roughness is critical in biomedical applications. The optimal value varies widely depending on the specific application (e.g., hip implants, dental implants, stents) and the type of tissue interaction desired. Extensive research is conducted to optimize surface roughness for specific applications to enhance the biocompatibility and longevity of biomedical implants.

Q 27. Explain the difference between surface roughness and waviness.

Surface roughness and waviness both describe deviations from an ideal surface but operate at different length scales. Think of it like the difference between the fine wrinkles on your skin (roughness) and the overall shape of your face (waviness).

Surface roughness refers to the fine-scale irregularities, typically with wavelengths less than 0.8 mm. It encompasses the peaks and valleys that contribute to the overall texture of the surface. Parameters like Ra, Rz, and Rq characterize roughness.

Waviness represents the larger-scale deviations, typically with wavelengths greater than 0.8 mm. It describes the overall form or shape of the surface. Waviness can be caused by factors such as machine vibrations, deflections, or imperfections in the workpiece during manufacturing.

In metrology, the separation between roughness and waviness is usually performed using a filtering process. A low-pass filter separates the high-frequency components representing roughness from the low-frequency components representing waviness. The cutoff wavelength for the filter typically lies between 0.25 mm and 0.8 mm.

Example: A machined part might exhibit both roughness due to tool marks and waviness due to machine vibrations during the machining process. Separately analyzing roughness and waviness provides a more complete understanding of the surface’s overall texture and quality.

Q 28. How does surface roughness affect the performance of seals?

Surface roughness significantly impacts the performance of seals. The contact between the sealing surfaces determines leakage and wear, and roughness plays a major role in this contact behavior.

Excessive roughness can lead to increased leakage, as the peaks and valleys prevent complete sealing. Increased friction and wear can also result, reducing seal life and requiring more frequent replacements. This is particularly relevant in high-pressure applications where even small leaks can have serious consequences.

Moderate roughness, on the other hand, can actually enhance seal performance in some cases. Microscopic asperities can interlock, creating a better seal against leakage. However, excessive roughness will still lead to premature wear.

Therefore, the optimal surface roughness for sealing applications requires careful consideration of the specific application, pressure conditions, materials, and sealing mechanism. Proper surface finishing techniques are employed to achieve the required roughness for optimal sealing performance and longevity.

Example: In the automotive industry, engine seals require extremely precise surface finishes to prevent leaks of high-pressure lubricating oils and coolants. Similarly, in the aerospace industry, seals in aircraft hydraulic systems require similar levels of precision to ensure safety and prevent catastrophic failures.

Key Topics to Learn for Smoothness and Roughness Evaluation Interview

- Surface Texture Characterization: Understanding various methods for quantifying surface roughness (e.g., Ra, Rz, Rq) and their implications for different applications.

- Profilometry Techniques: Familiarize yourself with different profilometry techniques (optical, contact stylus, confocal microscopy) and their strengths and limitations in measuring surface roughness.

- Statistical Analysis of Surface Roughness Data: Learn to interpret roughness parameters, understand their distributions, and perform statistical comparisons between different surfaces.

- Influence of Manufacturing Processes: Explore how different manufacturing processes (machining, polishing, additive manufacturing) affect surface roughness and how to control it.

- Material Properties and Roughness: Understand the correlation between surface roughness and material properties like friction, wear, corrosion resistance, and adhesion.

- Applications of Smoothness and Roughness Evaluation: Explore diverse applications across various industries, such as manufacturing, tribology, biomedical engineering, and microelectronics.

- Advanced Techniques: Consider exploring advanced techniques like fractal analysis or wavelet analysis for complex surface characterization (depending on the job requirements).

- Problem-Solving Approaches: Practice identifying and troubleshooting issues related to surface roughness measurement and interpretation of results.

Next Steps

Mastering Smoothness and Roughness Evaluation opens doors to exciting opportunities in various high-tech fields. A strong understanding of these concepts is highly sought after and significantly enhances your career prospects. To stand out, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your specific experience. We offer examples of resumes specifically designed for candidates in Smoothness and Roughness Evaluation to help guide your process. Invest in your future – build a resume that reflects your expertise and helps you land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?