The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Troubleshooting Water Treatment Problems interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Troubleshooting Water Treatment Problems Interview

Q 1. Explain the process of coagulation and flocculation in water treatment.

Coagulation and flocculation are crucial steps in water treatment designed to remove suspended solids. Think of it like cleaning a muddy pond – you can’t just filter out the mud directly; you need to clump it together first.

Coagulation involves adding a chemical coagulant, like alum (aluminum sulfate) or ferric chloride, to the water. These chemicals neutralize the charges on the tiny particles of dirt, clay, and other suspended solids, allowing them to come together. Imagine the particles as tiny magnets, all repelling each other. The coagulant neutralizes their magnetic charge, allowing them to clump together.

Flocculation is the gentle mixing process that follows coagulation. This slow stirring encourages the small coagulated particles to collide and grow into larger, heavier flocs (flocks of particles). These flocs are large enough to settle out of the water during sedimentation. It’s like gently stirring a pot of soup to help the ingredients combine.

For example, in a municipal water treatment plant, raw water enters a coagulation basin where the coagulant is added. Then, the water flows into a flocculation basin with gentle paddle mixers to encourage floc formation before sedimentation.

Q 2. Describe different types of filtration used in water treatment.

Water treatment utilizes various filtration methods to remove suspended solids and other impurities. The choice of filtration depends on the specific contaminants and desired water quality.

- Screen Filtration: This is the first line of defense, removing large debris like leaves and twigs using bar screens or mesh screens.

- Sedimentation: Gravity is used to settle out larger flocs formed during coagulation and flocculation. This is a passive process, reducing the load on subsequent filters.

- Sand Filtration: Water passes through a bed of sand, trapping finer particles. The sand needs to be regularly backwashed to remove accumulated solids.

- Gravel Filtration: Similar to sand filtration, but uses gravel as the filter medium. Often used in conjunction with sand filtration.

- Membrane Filtration (Microfiltration, Ultrafiltration, Nanofiltration): These use membranes with progressively smaller pore sizes to remove bacteria, viruses, and dissolved organic matter. Reverse osmosis is a type of membrane filtration.

- Activated Carbon Filtration: This removes dissolved organic compounds, chlorine, and other taste and odor-causing substances. Activated carbon has a high surface area that adsorbs these contaminants.

For instance, a typical municipal plant may use a combination of screen filtration, sedimentation, sand filtration, and then disinfection before distribution.

Q 3. What are the common causes of high turbidity in treated water?

High turbidity in treated water, meaning the water appears cloudy, can stem from several issues within the treatment process. It indicates that not all suspended solids have been effectively removed.

- Insufficient Coagulation/Flocculation: Inadequate coagulant dosage or insufficient mixing can lead to incomplete particle aggregation.

- Filter Media Failure: Clogged or damaged sand or other filter media can allow turbid water to pass through.

- Breakthrough: Sometimes, a sudden increase in turbidity in the raw water source overwhelms the treatment plant’s capacity.

- Sedimentation Problems: Inefficient sedimentation basins can result in incomplete solid settling.

- Backwash Problems: Improper backwashing of filters can leave behind residual solids, leading to higher turbidity.

For example, if a sudden rainstorm increases the turbidity of the raw water, the treatment plant might experience a temporary breakthrough unless the system has sufficient capacity and safeguards to handle such surges.

Q 4. How do you troubleshoot a malfunctioning reverse osmosis system?

Troubleshooting a malfunctioning reverse osmosis (RO) system requires a systematic approach. It’s like diagnosing a car problem – you need to check the various components.

- Check the Pressure: Low feed pressure is a common cause of RO failure. Ensure the pump is functioning correctly and that there are no leaks in the system.

- Examine the Membranes: Fouling (buildup of solids) or membrane damage can significantly reduce efficiency. Regular membrane cleaning or replacement is essential.

- Inspect the Pre-treatment: RO systems rely on pre-filtration to protect the membranes. If the pre-filters are clogged, the membranes will be overloaded.

- Check the Permeate (Product Water) Flow: Low permeate flow suggests a problem with the membranes or system pressure.

- Test the Water Quality: Analyze the feed water, concentrate, and permeate to identify potential contaminants and assess the RO system’s performance.

- Check for Leaks: Leaks in the system will reduce pressure and efficiency. Inspect all connections and fittings.

For example, if the permeate flow rate is low and the feed water pressure is normal, the most likely culprit is membrane fouling requiring cleaning or replacement.

Q 5. Explain the principles of disinfection using chlorine and UV light.

Disinfection is the final stage of water treatment, eliminating harmful microorganisms. Chlorine and UV light are two common methods.

Chlorine Disinfection: Chlorine (in various forms like hypochlorite) is a powerful oxidizing agent that kills bacteria and viruses by disrupting their cellular processes. It’s relatively inexpensive and provides residual disinfection in the distribution system – some chlorine remains in the water, preventing regrowth of bacteria. However, chlorine can react with organic matter, producing disinfection byproducts (DBPs) that can be harmful at high concentrations. Therefore, careful monitoring and control of chlorine levels are crucial.

UV Disinfection: Ultraviolet (UV) light uses short-wavelength UV-C radiation to damage the DNA of microorganisms, preventing their replication and effectively inactivating them. UV disinfection is effective, doesn’t produce DBPs, and requires no chemical addition. However, UV disinfection offers no residual disinfection, and the effectiveness depends on the UV lamp’s intensity and water clarity (turbidity can significantly reduce its effectiveness).

Many modern water treatment facilities use a combination of these methods for optimal disinfection.

Q 6. What are the indicators of microbial contamination in water?

Indicators of microbial contamination in water can be direct or indirect.

- Direct Indicators: These methods detect the presence of specific pathogens. Techniques include culturing water samples to isolate and identify bacteria, viruses, and parasites. This is precise but time-consuming.

- Indirect Indicators (Indicator Organisms): Since testing for every possible pathogen is impractical, indicator organisms are used. These are microorganisms whose presence suggests potential fecal contamination and, therefore, the possibility of harmful pathogens. The most common indicator is E. coli, a bacterium found in the intestines of warm-blooded animals. Total coliforms (a broader group of bacteria) are also used as indicators.

For instance, finding E. coli in a water sample strongly suggests fecal contamination and the potential presence of other harmful pathogens, prompting immediate action.

Q 7. How do you identify and resolve issues related to scaling in water treatment systems?

Scaling in water treatment systems is the buildup of mineral deposits (mostly calcium and magnesium carbonates) on pipes, equipment surfaces, and filters. This reduces efficiency and can lead to blockages.

- Identify the Cause: Water hardness (high concentrations of calcium and magnesium) is the primary cause. Analyze the water chemistry to determine the specific minerals causing scaling.

- Preventative Measures: The best approach is prevention. Techniques include:

- Softening: Ion exchange or lime softening to reduce water hardness.

- Chemical Treatment: Using antiscalants or corrosion inhibitors to prevent mineral precipitation.

- Regular Cleaning: Periodically cleaning pipes and equipment to remove accumulated scale.

- Corrective Measures: For existing scale, various methods can be used, such as:

- Acid Cleaning: Using weak acids (like citric acid) to dissolve the scale.

- Mechanical Cleaning: Physical removal using brushes or other tools. (This is labor intensive and may damage equipment)

- Chelating Agents: These agents bind to minerals, preventing further scaling and facilitating the removal of existing scale.

For example, if a reverse osmosis system shows reduced performance due to scaling on the membranes, acid cleaning or chelating agents can be used to restore efficiency. Preventative measures like pre-treatment with antiscalants would be implemented to avoid future problems.

Q 8. Describe the process of softening hard water.

Hard water softening primarily targets the reduction of calcium and magnesium ions, which cause scale buildup and reduce the effectiveness of soaps. The most common method is ion exchange. This involves passing the hard water through a resin bed containing negatively charged beads. These beads attract and bind the positively charged calcium and magnesium ions, releasing sodium ions in their place. Think of it like a trade – the hard water ions are exchanged for softer sodium ions.

The process is reversible. Once the resin is saturated with calcium and magnesium, it needs to be regenerated. This is typically done by flushing the resin bed with a concentrated solution of sodium chloride (common table salt). This high concentration of sodium ions reverses the exchange process, releasing the calcium and magnesium and reloading the resin with sodium, ready for another cycle of softening.

Example: Imagine a sponge soaking up water (hardness minerals). The salt solution washes the water out of the sponge, preparing it to absorb more.

Q 9. What are the common causes of iron and manganese in water and how are they removed?

Iron and manganese are naturally occurring elements often found in groundwater. Iron typically enters the water supply through the leaching of iron-bearing minerals from soil and rocks. Manganese behaves similarly. Both can cause staining, unpleasant taste and odor, and can support bacterial growth.

Several methods exist for iron and manganese removal. Oxidation is a common approach; we introduce oxygen into the water, converting the dissolved iron and manganese into insoluble forms that can be easily filtered out. This can be achieved through aeration (contact with air) or by using oxidizing chemicals like potassium permanganate. Following oxidation, filtration using media like greensand or manganese greensand effectively removes the precipitated iron and manganese. Alternatively, membrane filtration (reverse osmosis, ultrafiltration) can also be highly effective, removing both dissolved and particulate iron and manganese.

Example: Imagine rust (iron oxide) settling out of water after it’s been exposed to air. This is similar to the oxidation process. The filter then traps this settled rust.

Q 10. Explain the importance of pH control in water treatment.

pH control is crucial in water treatment for several reasons. The pH value indicates the acidity or alkalinity of water, expressed on a scale of 0 to 14 (7 being neutral). Maintaining the optimal pH is vital for:

- Chemical effectiveness: Many water treatment chemicals, such as coagulants and disinfectants, work best within a specific pH range. For example, chlorine disinfection is more effective at a slightly acidic pH.

- Corrosion control: Low pH (acidic) water can be corrosive to pipes and equipment. High pH (alkaline) water can also cause problems, such as scaling. Controlling pH minimizes these issues.

- Aesthetic quality: Water that is too acidic or alkaline can have an unpleasant taste.

- Environmental impact: Proper pH control is essential to prevent the discharge of corrosive or harmful water to the environment.

pH adjustment is typically achieved by adding acids (e.g., sulfuric acid, hydrochloric acid) to lower the pH or bases (e.g., sodium hydroxide, lime) to raise it.

Q 11. How do you interpret water quality test results?

Interpreting water quality test results requires a systematic approach. First, carefully review the specific parameters tested (pH, turbidity, total dissolved solids, bacteria levels, etc.). Then, compare the measured values to the relevant regulatory standards and guidelines (e.g., drinking water standards set by EPA). Any values outside of these limits indicate potential problems.

For example, high turbidity suggests the presence of suspended solids, requiring clarification treatment. High bacterial counts indicate potential contamination requiring disinfection. It is critical to identify the source of any problem, whether it’s from contamination, equipment malfunction or insufficient treatment. For complicated issues, consulting with water quality specialists is recommended.

Example: If a water sample shows high levels of coliform bacteria, it indicates fecal contamination, necessitating immediate investigation of the source and implementing corrective actions such as chlorination.

Q 12. What are the safety procedures you follow when working with chemicals in water treatment?

Safety is paramount when working with water treatment chemicals. My procedures always begin with a thorough risk assessment before handling any chemicals. This includes understanding the hazards associated with each chemical (corrosivity, toxicity, flammability) and selecting appropriate personal protective equipment (PPE). This PPE might include gloves, eye protection, respirators, and protective clothing depending on the specific chemical and task.

I strictly follow the manufacturer’s instructions for handling, storage, and disposal of chemicals. This includes proper labeling, storage in designated areas, and safe handling procedures to prevent spills or accidents. I also ensure adequate ventilation in work areas to prevent exposure to hazardous fumes. Emergency procedures, including spill response plans and access to safety showers and eyewash stations, are always in place and understood by everyone in the team.

Example: When handling chlorine, we always use appropriate respirators and protective gear to avoid inhalation of harmful gases.

Q 13. Describe your experience with troubleshooting membrane fouling.

Membrane fouling, a common problem in membrane filtration processes like reverse osmosis or ultrafiltration, occurs when contaminants accumulate on the membrane surface, reducing its permeability and efficiency. Troubleshooting involves a systematic approach:

- Identify the type of fouling: This could be organic (e.g., biological growth), inorganic (e.g., mineral scaling), or colloidal (e.g., suspended solids). Regular monitoring of membrane performance parameters, like flux and pressure drop, helps in early detection.

- Chemical Cleaning: Depending on the identified fouling type, I would select appropriate cleaning chemicals. For example, acidic or alkaline cleaning solutions are used to remove mineral scaling; while enzymatic cleaning solutions target organic fouling.

- Physical Cleaning: This might involve backwashing to remove loosely attached material, or air scouring to dislodge accumulated debris.

- Process Optimization: Adjusting operational parameters such as feed water pretreatment, operating pressure, and crossflow velocity can significantly reduce fouling potential.

- Membrane Replacement: In severe cases, especially when damage is irreversible, membrane replacement might be necessary.

Example: I once encountered severe organic fouling in a reverse osmosis system. After identifying the issue through water analysis, we implemented a regular cleaning schedule with an enzymatic cleaning solution and improved pretreatment, significantly extending the lifespan of the membranes.

Q 14. How do you maintain and troubleshoot water treatment equipment?

Maintaining and troubleshooting water treatment equipment requires a proactive approach. Regular maintenance schedules are crucial, encompassing tasks such as:

- Visual inspections: Regularly checking for leaks, corrosion, or damage to pipes, valves, and equipment.

- Performance monitoring: Tracking key parameters such as flow rates, pressures, and chemical dosages to ensure optimal operation.

- Cleaning and sanitization: Regular cleaning of filters, membranes, and other components to prevent fouling and bacterial growth.

- Calibration and testing: Ensuring accurate readings from instruments and sensors via regular calibration.

Troubleshooting involves a logical approach: pinpoint the problem by analyzing operational data and symptoms; check the equipment thoroughly; then implement the necessary repair or replacement. Documentation of all maintenance and troubleshooting activities is vital for tracking equipment performance and identifying recurring issues.

Example: If a pump fails to deliver sufficient water flow, I would first check the power supply, then examine the pump impeller for blockages, and finally check for leaks in the piping system.

Q 15. What are the different types of water meters and how do they work?

Water meters are crucial for monitoring water usage and ensuring efficient distribution. Several types exist, each with its own mechanism:

- Mechanical Meters: These are the most common type, using a rotating mechanism driven by the flow of water. A series of gears translates the rotation into a reading on a dial. They are relatively inexpensive and reliable but susceptible to wear and tear and less accurate at low flow rates. Think of it like an old-fashioned odometer in a car.

- Electronic Meters: These use sensors to measure the flow rate electronically and provide a digital readout. They are more accurate than mechanical meters, especially at low flows, and can provide more data, such as total consumption and even instantaneous flow rates. They’re like a smart meter in your home that tracks energy usage.

- Ultrasonic Meters: These meters use sound waves to measure the flow of water. They are non-invasive and don’t require any moving parts, making them highly durable and accurate. However, they tend to be more expensive than other types. Think of them like a sonar system measuring water movement.

- Positive Displacement Meters: These meters measure the exact volume of water passing through by trapping a known volume and counting the number of times this volume is filled. They offer high accuracy but can be more prone to clogging.

The choice of meter depends on factors like budget, required accuracy, flow rate, and the size of the water system. For example, a large municipal system might use electronic or ultrasonic meters for their accuracy and data capabilities, while a smaller residential system might use a more cost-effective mechanical meter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of activated carbon in water treatment.

Activated carbon plays a vital role in water treatment primarily by adsorbing impurities. Think of it like a sponge that attracts and holds onto unwanted substances. This process effectively removes various contaminants, including:

- Organic compounds: Activated carbon is highly effective at removing pesticides, herbicides, volatile organic compounds (VOCs), and other organic molecules that can impact taste, odor, and even health.

- Chlorine and chloramines: These disinfectants are often necessary to kill bacteria and viruses, but they can leave an unpleasant taste and odor. Activated carbon effectively removes these residual chemicals.

- Taste and odor compounds: Many natural substances in water can contribute to unpleasant taste and odor. Activated carbon effectively reduces these compounds, leading to improved water quality.

- Color: Activated carbon can help remove organic matter that causes discoloration in water.

The effectiveness of activated carbon depends on factors like the type of carbon used, the size of the particles, the contact time with the water, and the concentration of contaminants. For example, granular activated carbon (GAC) is commonly used in filters, while powdered activated carbon (PAC) is added directly to the water.

Q 17. How do you address issues related to taste and odor in treated water?

Addressing taste and odor issues in treated water requires a multi-pronged approach, beginning with identifying the source of the problem. This could involve laboratory analysis to pinpoint specific compounds causing the issue.

- Enhanced Filtration: Often, additional filtration stages, such as granular activated carbon (GAC) filtration, are added to remove the offending substances. The GAC acts like a filter absorbing the compounds causing taste and odor.

- Oxidation: Chemical oxidation, using compounds like ozone or chlorine dioxide, can break down some taste and odor-causing substances, making them easier to remove through filtration. This is like pre-treating the water to make the contaminants more manageable.

- Aeration: Stripping volatile organic compounds (VOCs) from the water by exposing it to air can be very effective. It’s like letting the water breathe to remove some gases.

- Biological Treatment: In some cases, biological processes can be used to break down the organic matter responsible for taste and odor. This is a more natural approach, using microorganisms to remove contaminants.

The specific solution depends on the nature of the contaminants. A thorough investigation and targeted treatment are key to successfully resolving taste and odor problems.

Q 18. What are the regulatory requirements for potable water in your region?

(Note: Regulatory requirements for potable water vary significantly by region. This answer provides a general overview. Specific regulations must be researched based on your location.)

Potable water regulations typically focus on ensuring the water is safe for human consumption. These regulations often cover:

- Microbiological Contaminants: Limits are set on the number of bacteria, viruses, and other microorganisms allowed in the water. This is done to prevent waterborne illnesses.

- Chemical Contaminants: Regulations specify maximum contaminant levels (MCLs) for various chemicals, including heavy metals (lead, arsenic), pesticides, and industrial byproducts.

- Physical Characteristics: Standards are set for turbidity (cloudiness), color, taste, and odor to ensure the water is aesthetically pleasing.

- Treatment Processes: Regulations often dictate the minimum treatment processes required to meet the water quality standards.

Agencies responsible for enforcing these regulations regularly inspect water treatment facilities and sample water to ensure compliance. Non-compliance can result in fines, penalties, and even legal action.

Q 19. Describe your experience with SCADA systems in water treatment.

SCADA (Supervisory Control and Data Acquisition) systems are integral to modern water treatment plants. My experience includes designing, implementing, and troubleshooting SCADA systems for multiple facilities. This includes:

- Data Acquisition: SCADA systems collect real-time data from various sensors throughout the plant, including flow meters, pressure gauges, chemical feed controllers, and water quality analyzers. This provides a comprehensive overview of the plant’s operation.

- Process Control: SCADA systems automate many aspects of the treatment process, such as adjusting chemical feed rates, controlling valve positions, and managing pumps. This allows for efficient and consistent operation.

- Alarm Management: SCADA systems generate alarms based on predefined thresholds, alerting operators to potential problems before they escalate into major incidents. This helps prevent failures and ensures timely intervention.

- Data Logging and Reporting: SCADA systems record vast amounts of data, which is essential for compliance, troubleshooting, and process optimization. Regular reports generated provide insights into plant performance.

I’ve used various SCADA platforms and have a strong understanding of networking, communication protocols (like Modbus and DNP3), and database management systems used in SCADA. My experience extends to integrating SCADA with other systems, such as Geographic Information Systems (GIS), which are crucial for asset management and network oversight.

Q 20. How do you handle emergency situations related to water treatment failures?

Handling emergency situations requires a structured and decisive approach. My experience involves:

- Rapid Assessment: The first step is to quickly assess the nature and extent of the problem. This may involve reviewing SCADA data, checking physical parameters, and communicating with plant personnel.

- Emergency Response Plan: Activating the pre-defined emergency response plan is crucial. This plan outlines specific steps to take based on the type of emergency, including isolating affected areas, initiating backup systems, and contacting relevant authorities.

- Communication: Maintaining clear and effective communication with all stakeholders is essential. This includes informing customers, regulatory agencies, and emergency services as appropriate.

- Containment and Remediation: The focus shifts to containing the problem, minimizing its impact, and restoring normal operations. This may involve implementing temporary solutions or repairs until the underlying cause can be identified and addressed.

- Root Cause Analysis: Once the emergency is under control, a thorough root cause analysis is performed to identify the underlying factors that contributed to the failure. This prevents similar incidents from occurring in the future.

For example, a major power failure could trigger the emergency generator, while a chemical spill would initiate procedures for containment and cleanup. Each situation necessitates a tailored response, guided by established protocols and best practices.

Q 21. Explain your understanding of water treatment plant automation.

Water treatment plant automation enhances efficiency, reliability, and safety through the integrated use of advanced technologies, including SCADA systems, Programmable Logic Controllers (PLCs), and advanced sensors. This automation provides several key benefits:

- Improved Efficiency: Automated systems optimize the treatment process by precisely controlling chemical feed rates, adjusting flow rates, and managing energy consumption. This leads to cost savings and reduced environmental impact.

- Enhanced Reliability: Automation ensures consistent water quality and reduces the risk of human error. Redundant systems and automated fault detection prevent failures and ensure continuous operation.

- Increased Safety: Automation minimizes the need for manual handling of hazardous chemicals and reduces the risk of occupational injuries.

- Data-Driven Decision Making: Real-time data collected by automated systems allows operators to make informed decisions, optimize plant performance, and proactively address potential problems.

- Remote Monitoring and Control: Automation enables remote monitoring and control of the plant, enhancing situational awareness and allowing for timely intervention even when personnel are not physically present.

The degree of automation can vary widely, ranging from basic automated control of individual processes to fully automated plants with advanced artificial intelligence (AI) capabilities. The level of automation chosen depends on various factors, including budget, plant size, and the complexity of the treatment process.

Q 22. Describe your experience with different types of pumps used in water treatment.

My experience encompasses a wide range of pumps crucial in water treatment, each selected based on the specific application and its demands. For example, centrifugal pumps are workhorses for moving large volumes of water at moderate pressures – think transferring water from a reservoir to a treatment plant. They’re reliable and relatively inexpensive, but their efficiency drops off at very low or very high flow rates. I’ve extensively used these in pre-treatment stages.

Conversely, positive displacement pumps, like diaphragm pumps, are excellent for handling slurries and viscous materials often encountered in sludge handling and chemical dosing. Their consistent flow rate, regardless of pressure changes, makes them invaluable in these situations. I’ve successfully troubleshooted issues with diaphragm pump seals in several wastewater treatment facilities, optimizing their performance and reducing downtime.

Submersible pumps are a must in well water intake and groundwater extraction. Their compact design and direct immersion in the water source simplifies installation and minimizes space requirements. However, they are vulnerable to damage if the water level drops too low. I’ve worked on projects involving the integration and maintenance of submersible pumps, carefully considering factors like motor cooling and preventative maintenance to extend their lifespan.

Finally, I have experience with progressive cavity pumps, ideal for handling highly viscous or shear-sensitive fluids, used often in advanced treatment processes and chemical injection systems. This requires precise control of pumping parameters and understanding of potential cavitation issues.

Q 23. How do you conduct a root cause analysis for water treatment problems?

Conducting a root cause analysis for water treatment problems follows a structured approach. Think of it like detective work – we need to systematically eliminate possibilities until we find the culprit. I typically employ the ‘5 Whys’ technique, repeatedly asking ‘why’ to drill down to the fundamental cause. For example, if a filter is failing frequently, the first ‘why’ might be ‘because the filter media is clogging.’ Then, ‘Why is the filter media clogging?’ ‘Because there’s too much suspended solids in the influent.’ ‘Why are there too many suspended solids?’ ‘Because the pre-treatment process is inadequate.’ ‘Why is the pre-treatment inadequate?’ ‘Because the flocculation process is not optimized.’ This final ‘why’ points to the root cause needing attention, allowing us to address the underlying problem rather than just treating the symptom.

Beyond the ‘5 Whys’, I use data analysis. Reviewing historical operational data, flow rates, chemical dosages, and effluent quality parameters reveals trends and anomalies. For instance, a sudden increase in turbidity might indicate a problem with the coagulation/flocculation process or a failure in the filtration system. Visual inspections, equipment checks, and laboratory analyses are equally important to confirm our findings.

Finally, I always involve a collaborative approach. This may include gathering input from operators, technicians, and engineers to gain a comprehensive understanding of the problem and the possible solutions. The combination of the ‘5 Whys’, data analysis, and team collaboration ensures a thorough and effective root cause analysis, preventing future occurrences.

Q 24. What are the key performance indicators (KPIs) used to monitor water treatment plant efficiency?

Key Performance Indicators (KPIs) for water treatment plant efficiency are carefully chosen to reflect different aspects of the process. Imagine these as vital signs for the plant’s health. Some essential KPIs include:

- Effluent Quality: This covers parameters like turbidity, suspended solids, total organic carbon (TOC), and various chemical constituents (e.g., chlorine, nitrogen, phosphorus), ensuring compliance with discharge permits and protecting receiving waters. Low turbidity and suspended solids indicate effective filtration.

- Production Rate/Capacity: The volume of treated water produced per unit time is crucial for meeting demand. A lower production rate may signal operational issues or equipment malfunctions.

- Chemical Consumption: Monitoring chemical usage (coagulants, disinfectants, etc.) helps optimize treatment costs and efficiency. Unexpected spikes might hint at problems in the treatment processes.

- Energy Consumption: Reducing energy usage is important for cost savings and environmental responsibility. High energy consumption might suggest inefficiencies in pump operation or aeration systems.

- Equipment Downtime: Minimizing equipment downtime is essential for continuous plant operation. Tracking downtime helps identify recurring issues or equipment needing maintenance.

- Sludge Production: In wastewater treatment, monitoring the quantity and characteristics of sludge generated is crucial for proper disposal or further processing.

By continuously monitoring these KPIs and analyzing trends, we can identify potential problems early on, optimize treatment strategies, and improve overall plant efficiency.

Q 25. How do you ensure compliance with environmental regulations related to wastewater discharge?

Ensuring compliance with environmental regulations regarding wastewater discharge is paramount. It’s not just about following the rules; it’s about protecting our environment. My approach is proactive and multi-faceted. First, I ensure that the plant operates strictly within the limits set by the discharge permit, monitoring effluent quality parameters continuously using online sensors and regular laboratory testing. This includes parameters like pH, BOD (Biochemical Oxygen Demand), COD (Chemical Oxygen Demand), nutrients (nitrogen and phosphorus), and heavy metals.

Second, I maintain meticulous records of all plant operations, chemical usage, and effluent data. This documentation is crucial for demonstrating compliance during audits and inspections. We use a computerized maintenance management system (CMMS) to track all aspects of plant operation and maintenance, providing an auditable trail of our activities.

Third, regular calibration and maintenance of monitoring equipment is essential to ensure the accuracy and reliability of the data we collect. We adhere to strict quality control procedures in our laboratory to guarantee the integrity of our effluent quality analyses.

Finally, I stay abreast of all changes and updates to environmental regulations. This involves regular review of relevant legislation and participation in industry training and workshops to maintain best practices and implement new technologies. Proactive compliance not only minimizes environmental impact but also prevents costly penalties and protects the facility’s reputation.

Q 26. Describe your experience with water treatment modeling and simulation.

My experience with water treatment modeling and simulation is extensive. I’ve used various software packages, such as EPANET for water distribution system modeling and specialized programs for simulating treatment processes like activated sludge or membrane filtration. These models allow us to virtually test different scenarios before implementing them in the real world, avoiding costly mistakes.

For instance, we can use models to optimize the design of a new treatment plant, predicting its performance under various conditions and identifying potential bottlenecks. Similarly, we can simulate the impact of proposed upgrades or changes to an existing plant, assessing their effectiveness and identifying potential side effects before committing to costly modifications. We can even use models to predict the response of the treatment system to extreme weather events or unexpected influent quality changes, helping us develop contingency plans to mitigate potential problems.

Calibration of these models using real-world data is crucial for their accuracy. Regular model updates and validation ensure that simulations remain relevant and reliable as plant conditions evolve. The ability to use these modeling tools significantly enhances our troubleshooting and optimization capabilities.

Q 27. What are the advantages and disadvantages of different water treatment technologies?

Different water treatment technologies each have strengths and weaknesses; the ideal choice depends heavily on factors like water quality, budget, available space, and regulatory requirements.

Conventional Treatment (Coagulation, Flocculation, Sedimentation, Filtration, Disinfection): This is a tried-and-true method, relatively inexpensive and effective for many contaminants. However, it’s less efficient for removing certain micro-pollutants or emerging contaminants.

Membrane Filtration (Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis): Membrane filtration offers excellent removal of a broad range of contaminants, including bacteria, viruses, and dissolved solids. But, it can be energy-intensive and expensive, requiring skilled operation and maintenance.

Advanced Oxidation Processes (AOPs): AOPs, such as ozonation or UV disinfection, are powerful tools for removing recalcitrant organic compounds and disinfection byproducts. They are generally more expensive and require specialized expertise.

Biological Treatment (Activated Sludge, Trickling Filters): Biological treatment effectively removes organic matter in wastewater through microbial action, a cost-effective solution for many applications. However, it can be sensitive to influent variations and may require large land areas.

The best approach often involves a combination of technologies to achieve optimal water quality. A good understanding of each technology’s capabilities and limitations is crucial for selecting the most appropriate and cost-effective treatment train.

Q 28. Explain your understanding of water distribution system maintenance and troubleshooting.

Water distribution system maintenance and troubleshooting are critical for ensuring reliable and safe water delivery to consumers. Think of it as maintaining the veins and arteries of a city. My approach focuses on both preventative and corrective actions. Preventative maintenance involves regular inspections of pipes, valves, pumps, storage tanks, and other components, identifying and addressing potential issues before they lead to failures. This includes hydraulic flushing to remove sediment buildup, leak detection using acoustic methods, and pressure testing to identify weak points in the system.

When problems arise, I use a systematic approach to troubleshooting. First, I isolate the affected area, determining the extent of the disruption. Then, I systematically check various components (pumps, valves, pipes) to identify the root cause. Specialized equipment might be utilized, such as pressure gauges, flow meters, and leak detection tools. This may also involve analyzing water samples to rule out quality issues causing pipe damage (e.g., corrosive water). Data logging systems on the pumps and other equipment can be critical in identifying when a failure occurred, the sequence of events leading up to it, and the conditions at that point in time. This detailed information is essential for effective troubleshooting and repair.

Effective communication with the operators and maintenance crews is also crucial. This ensures that maintenance procedures are consistently followed and that any unusual events are reported promptly, thereby minimizing service disruptions and safeguarding public health.

Key Topics to Learn for Troubleshooting Water Treatment Problems Interview

- Water Chemistry Fundamentals: Understanding pH, alkalinity, hardness, and their impact on treatment processes. Practical application: Diagnosing issues based on water quality test results.

- Membrane Technologies: Reverse Osmosis (RO), Ultrafiltration (UF), Microfiltration (MF) principles, troubleshooting common malfunctions (e.g., fouling, pressure drops). Practical application: Identifying the root cause of membrane failure and recommending solutions.

- Disinfection Methods: Chlorination, UV disinfection, ozonation – mechanisms, effectiveness, and limitations. Practical application: Selecting appropriate disinfection strategies based on water quality and regulatory requirements.

- Filtration Systems: Sand filters, multimedia filters, activated carbon filters – operation, maintenance, and troubleshooting common problems (e.g., backwashing, filter media replacement). Practical application: Determining the optimal filtration strategy for a given water source and contaminant profile.

- Instrumentation and Control Systems: Understanding the role of sensors, controllers, and data loggers in monitoring and controlling water treatment processes. Practical application: Interpreting sensor readings to identify operational issues and deviations from setpoints.

- Troubleshooting Methodologies: Systematic approaches to problem-solving, including data analysis, root cause analysis, and corrective actions. Practical application: Developing and implementing effective troubleshooting plans for complex water treatment challenges.

- Safety and Regulatory Compliance: Understanding relevant safety protocols and regulatory requirements related to water treatment operations. Practical application: Ensuring safe and compliant operation of water treatment facilities.

Next Steps

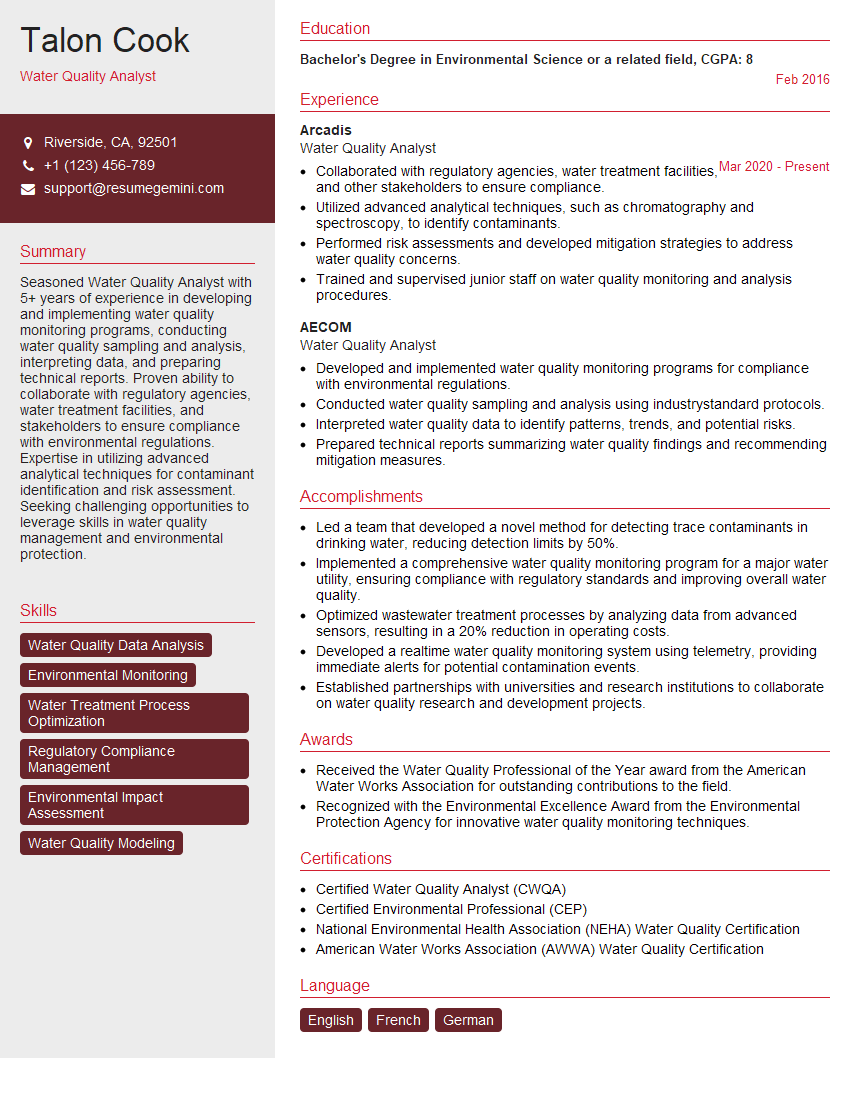

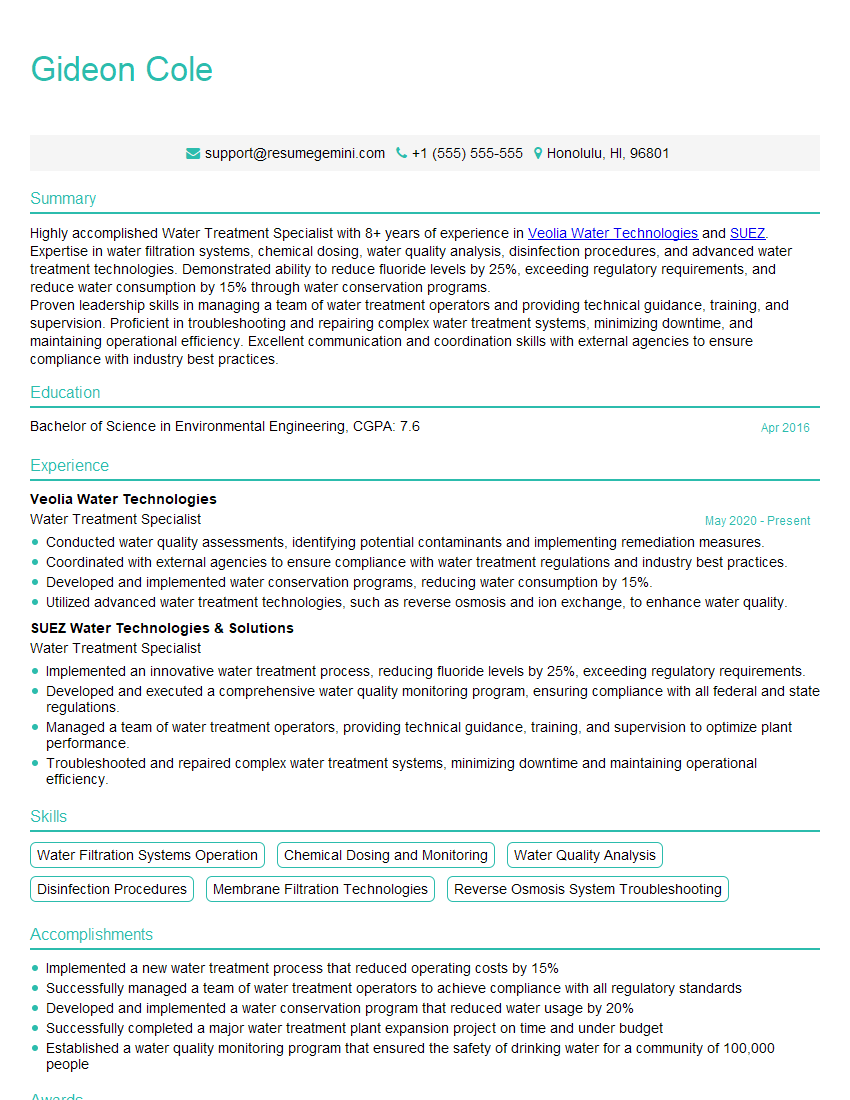

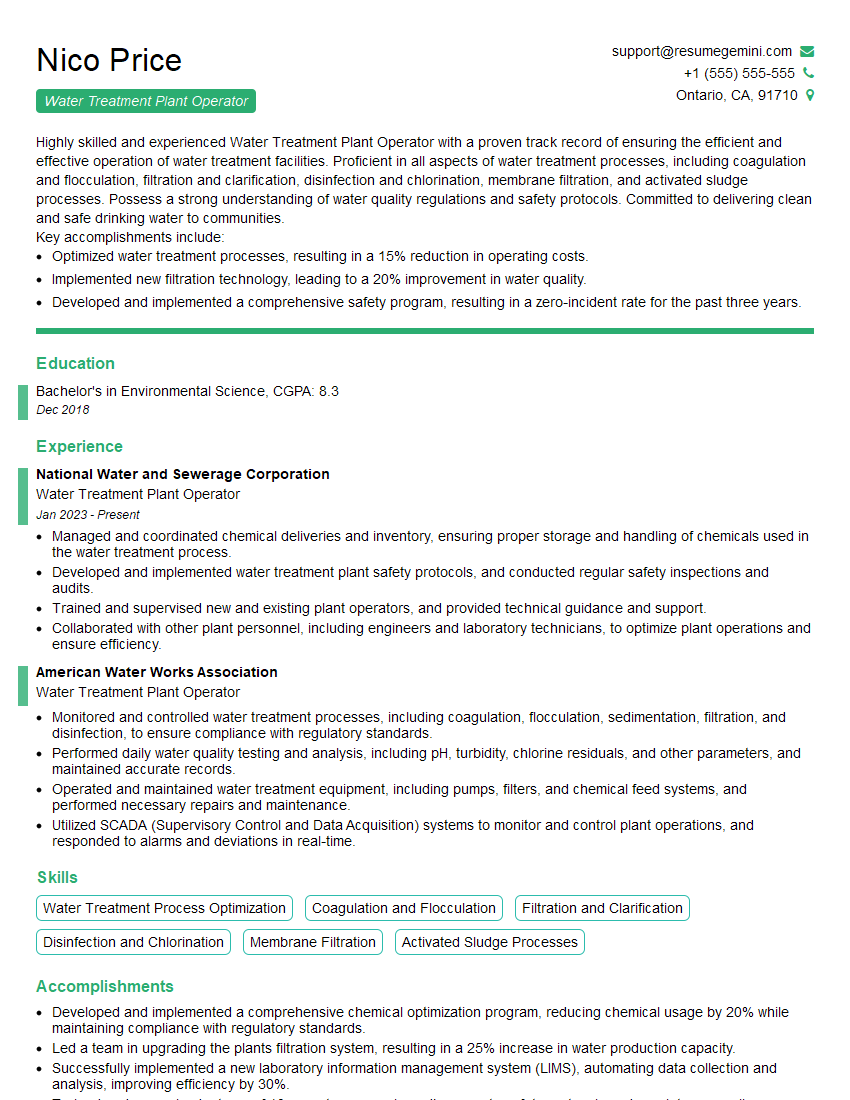

Mastering Troubleshooting Water Treatment Problems is crucial for career advancement in this field. A strong understanding of these concepts significantly improves your problem-solving skills and demonstrates your value to potential employers. To maximize your job prospects, invest time in creating an ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They offer examples of resumes tailored specifically to Troubleshooting Water Treatment Problems, ensuring your qualifications shine through to recruiters.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?