The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to MATLAB and Simulink Modeling interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in MATLAB and Simulink Modeling Interview

Q 1. Explain the difference between a script and a function in MATLAB.

In MATLAB, scripts and functions are both ways to organize code, but they differ significantly in how they are executed and how data is handled. Think of a script as a sequence of commands executed one after another, like a recipe. A function, on the other hand, is a self-contained block of code that performs a specific task and can accept inputs (arguments) and return outputs. This is more like a modular kitchen appliance—you feed it ingredients, and it produces a finished dish.

- Scripts: Scripts don’t accept inputs or return outputs. They operate directly on the workspace, modifying variables globally. This makes them simpler for quick tasks but less organized and potentially prone to errors in larger projects. For example, a script might directly plot data stored in a variable named ‘myData’.

- Functions: Functions are better for code reusability and maintainability. They encapsulate their operations, minimizing the risk of unintended side effects. The input and output data are explicitly defined, making it clear what the function does and how to use it. For instance, a function could take ‘myData’ as input, perform calculations on it, and return a processed result.

Example:

Script:

x = 1:10;y = x.^2;plot(x,y);Function:

function y = square_and_plot(x)y = x.^2;plot(x,y);endThe function is clearly defined, reusable, and avoids modifying the workspace variables outside its scope.

Q 2. Describe your experience with Simulink model building and verification.

I have extensive experience in Simulink model building and verification, primarily focused on control systems design and embedded systems development. My workflow typically involves using Simulink to create models representing the system’s dynamics, then verifying these models through simulations and analysis. I am proficient in creating various types of models, from simple linear systems to complex nonlinear systems with embedded software components.

My verification process includes:

- Unit Testing: I use Simulink’s testing framework to verify individual blocks and subsystems within the model, ensuring they function correctly in isolation.

- Integration Testing: This involves testing the interaction between different subsystems to ensure they work together seamlessly.

- System-Level Testing: I run extensive simulations under various operating conditions to evaluate the overall system performance and robustness.

- Code Generation and Hardware-in-the-Loop (HIL) testing: I generate C/C++ code from the Simulink model and deploy it to a target hardware platform or utilize HIL testing for realistic simulation environments.

For example, in a recent project involving the design of an autopilot system for an unmanned aerial vehicle (UAV), I used Simulink to model the UAV’s dynamics, sensors, and control algorithms. Through extensive simulations and HIL testing, I was able to verify the autopilot’s performance under various flight conditions, ensuring its stability and safety.

Q 3. How do you handle data types and memory management in MATLAB?

MATLAB provides a wide range of data types, enabling efficient memory management and facilitating various computations. Understanding these types and how MATLAB manages memory is crucial for optimizing performance and preventing unexpected errors.

- Data Types: MATLAB supports various data types like numeric (

double,single,int8, etc.), logical (logical), character (char), and cell arrays (cell) and structures (struct). Choosing the right data type is important for memory efficiency and computational speed. Usingint8instead ofdoublefor representing integer values, for example, will save memory. - Memory Management: MATLAB uses a sophisticated memory management system that automatically allocates and deallocates memory as needed. However, it is still essential to understand potential memory issues. Pre-allocating arrays with functions like

zerosoronescan significantly improve performance, especially in loops where the array size grows dynamically. Clearance of variables using theclearcommand or letting variables go out of scope can also aid memory management. Excessive use of temporary variables without explicit cleanup could lead to performance issues.

Example:

% Inefficient memory allocationA = [];for i = 1:1000A = [A, i];end% Efficient memory allocationB = zeros(1, 1000);for i = 1:1000B(i) = i;endThe second approach (using zeros) is significantly more efficient in terms of memory usage and execution speed because it pre-allocates the required memory.

Q 4. What are the different types of Simulink blocks and their applications?

Simulink offers a vast library of blocks categorized by their functionality. These blocks are the building blocks for creating models. Here are some key categories and examples:

- Sources: These blocks generate signals, such as constants (

Constant), ramps (Ramp), and sine waves (Sine Wave). They serve as the input to the system. - Sinks: These blocks display or log the simulation results, like scopes (

Scope), data displays (Display), and data loggers (To Workspace). - Continuous Time Blocks: These blocks represent continuous-time systems, like integrators (

Integrator), transfer functions (Transfer Fcn), and state-space blocks (State-Space). They are crucial for modeling dynamic systems. - Discrete Time Blocks: These blocks represent discrete-time systems, often used for digital control systems. Examples include unit delays (

Unit Delay) and discrete-time transfer functions (Discrete Transfer Fcn). - Logic and Comparison Blocks: These blocks implement logical operations and comparisons, like relational operators (

Relational Operator) and logical operators (Logical Operator). Useful for decision making within the model. - Math Blocks: These perform mathematical operations, such as adders (

Sum), multipliers (Product), and mathematical functions (Math Function).

Application Example: A model of a robotic arm might use source blocks to represent the desired trajectory, continuous-time blocks to model the arm’s dynamics, and control blocks to implement a feedback controller. Sinks would then display the arm’s position and other relevant data.

Q 5. Explain your experience with Stateflow and its use in modeling.

Stateflow is a powerful tool within Simulink used for modeling the logic and control flow of complex systems. It’s particularly useful when dealing with discrete events, hierarchical states, and decision-making processes. Think of it as a visual programming language integrated directly into Simulink, allowing you to define state machines, statecharts, and flow charts.

My experience with Stateflow includes building state machines to model hybrid systems, where both continuous and discrete dynamics are present. For example, in modeling an automotive powertrain control system, Stateflow can represent the different operating modes (idle, acceleration, braking) and the transitions between these modes based on sensor inputs and control signals. This is far more efficient and readable than managing such logic purely in Simulink using only blocks.

Key features of Stateflow I leverage include:

- State Machines: Representing different system modes and transitions between them.

- Hierarchical States: Organizing complex logic into smaller, more manageable states.

- Data and Events: Passing information between different parts of the state machine through data signals and events.

- Actions and Transitions: Defining actions performed within a state and transitions triggered by specific conditions.

Using Stateflow makes the model much more understandable and maintainable, especially for large, complex systems. Its visual nature makes it intuitive to develop, debug and analyze state-based logic.

Q 6. How do you debug and troubleshoot complex Simulink models?

Debugging and troubleshooting complex Simulink models requires a systematic approach. My strategy typically involves a combination of techniques:

- Simulink’s Debugging Tools: I leverage the integrated debugger to step through the model, inspect signals, and identify the source of errors. Setting breakpoints and stepping through code allows for line-by-line examination of variables and signals. Data logging (using scopes, data displays, and To Workspace blocks) helps visualize the model’s behavior.

- Signal Inspection: I use scopes and data logging to visualize signals throughout the model. Examining signal waveforms helps identify unexpected values or behavior.

- Model Verification Tools: Simulink offers various verification tools, such as model checking, that can help identify potential issues like deadlocks or unreachable states. Formal verification helps check against specific design properties.

- Subsystem Isolation: When dealing with large models, I often isolate subsystems to debug them individually. This makes the debugging process more manageable.

- Code Generation and Debugging (if applicable): If code generation is involved, I debug the generated code using standard debugging tools for the target platform, allowing me to examine the code’s runtime behavior.

A systematic approach, starting with the most obvious error sources and working outwards, is key to effectively troubleshooting Simulink models.

Q 7. Describe your experience with Model-Based Design (MBD).

Model-Based Design (MBD) is a powerful methodology that uses models as the central artifact throughout the system development lifecycle. I have significant experience implementing MBD in various projects, from requirements capture to code generation and testing. My experience shows that it enhances the development process by providing a standardized process.

Key aspects of my MBD experience include:

- Requirements Management: Linking model elements to requirements helps ensure traceability and verifies that the design meets the specified needs.

- Model Development: Building accurate and robust models using Simulink and Stateflow, adhering to coding standards and best practices.

- Verification and Validation: Rigorous testing using various methods (simulation, HIL, etc.) to validate the model’s accuracy and ensure the system meets its requirements.

- Code Generation: Generating production-quality code (C/C++, etc.) from the Simulink model for deployment to target hardware.

- Continuous Integration and Continuous Deployment (CI/CD): Integrating MBD into CI/CD pipelines to streamline the development process and ensure quick iterative model development and verification.

MBD offers numerous advantages, such as improved communication, reduced development time, increased efficiency, and better quality software. In a recent project, utilizing MBD resulted in a 20% reduction in development time and a 15% improvement in the quality of the generated code compared to traditional methods. It was instrumental in quickly identifying and resolving issues before they impacted the hardware implementation.

Q 8. How do you ensure the accuracy and reliability of your Simulink models?

Ensuring accuracy and reliability in Simulink models is paramount. It’s not just about getting a result; it’s about trusting that result. My approach is multifaceted and involves a combination of techniques throughout the entire model development lifecycle.

- Model Verification: This involves checking if the model correctly implements the intended design. I use techniques like code review, model checking tools (like Simulink Design Verifier), and unit testing. For instance, I might create test harnesses to verify individual blocks or subsystems function as expected under various conditions. A common approach is to compare the model’s output against a known analytical solution or data from a physical experiment.

- Model Validation: This step confirms that the model accurately represents the real-world system it’s meant to simulate. This often involves comparing simulation results against real-world experimental data. Techniques like parameter estimation and sensitivity analysis help identify discrepancies and refine the model. For example, I’ve worked on projects where we used experimental data from a wind turbine to validate our Simulink model of its aerodynamic performance.

- Rigorous Testing: Comprehensive testing is critical. I employ various testing methods, including:

- Unit Testing: Testing individual components in isolation.

- Integration Testing: Testing the interaction between different components.

- System Testing: Testing the entire model as a complete system.

- Regression Testing: Retesting after any modifications to ensure that previous functionality is not broken.

- Documentation: Thorough documentation of the model, assumptions, and validation process is essential for traceability and future maintenance. This allows others (and my future self) to understand the model’s purpose and limitations.

By combining these methods, I build confidence in the accuracy and reliability of my Simulink models, reducing the risk of errors and ensuring the models effectively support decision-making processes.

Q 9. Explain your familiarity with different solvers in Simulink.

Simulink offers a variety of solvers, each with its strengths and weaknesses. Choosing the right solver is crucial for simulation accuracy, efficiency, and stability. My experience spans several solvers, and I select them based on the specific characteristics of the system being modeled.

- Variable-step solvers (e.g., ode45, ode23s): These solvers adjust the time step dynamically, adapting to the model’s dynamics.

ode45is a good general-purpose solver, whileode23sis suitable for stiff systems (systems with vastly different time constants). I often use these for their accuracy, especially in complex models with nonlinear behavior. - Fixed-step solvers (e.g., ode1, ode5): These solvers use a constant time step, making them simpler and potentially faster but less accurate for systems with rapid changes. They are often used in real-time applications where consistent step sizes are necessary.

- Discrete solvers: These solvers are used for discrete-time systems, where the system’s state only changes at specific points in time. They are essential when modeling systems controlled by digital logic or embedded systems.

For example, in simulating a control system for a robotic arm, I might use a variable-step solver like ode45 for its accuracy in capturing the complex dynamics. However, if the same model were deployed on a microcontroller with fixed sampling rate, I’d switch to a fixed-step solver like ode5 for real-time performance.

Beyond the solver type, I also consider factors like solver tolerances (RelTol and AbsTol) and the model’s properties to optimize simulation performance while maintaining accuracy.

Q 10. How do you handle real-time data acquisition and integration with Simulink?

Real-time data acquisition and integration with Simulink are crucial for model validation and hardware-in-the-loop (HIL) simulations. I have extensive experience using various tools and techniques to achieve this.

- Data Acquisition Toolboxes: MATLAB provides toolboxes like the Data Acquisition Toolbox, which allows direct interaction with data acquisition hardware. I’ve used this to interface with various sensors (e.g., accelerometers, temperature sensors) and actuators.

- Real-Time Workshop (RTW): This is a core component of Simulink that allows code generation for real-time execution. It enables the deployment of Simulink models to embedded systems or real-time targets for hardware-in-the-loop testing.

- External Mode: This feature allows running a Simulink model in real time while interacting with external hardware and software. Data can be exchanged seamlessly between the model and external devices.

- Custom Interfaces: For specialized hardware or protocols, I develop custom interfaces using MATLAB’s capabilities. For example, I have integrated custom protocols for communication with industrial robots, using TCP/IP or other network communication interfaces.

In a recent project involving a wind turbine simulator, we used the Data Acquisition Toolbox to acquire real-time wind speed data from an anemometer, fed this into our Simulink model, and then compared the model’s predicted power output to the actual power generated by the turbine.

Q 11. What is your experience with Simulink code generation?

Simulink code generation is a powerful tool for deploying models to embedded systems or generating production-quality code. I’m proficient in using RTW to generate C code from Simulink models. This allows the efficient implementation of complex algorithms on embedded systems and microcontrollers.

- Code Generation Configuration: I understand the importance of configuring code generation parameters carefully. This includes optimizing for speed, size, and code readability. I’ve worked on projects requiring stringent memory constraints, and I know how to fine-tune the code generation process to meet these requirements.

- Target Selection: I’ve worked with various target hardware, and understand the process of selecting the appropriate target hardware configuration, including processor type and memory. For example, we’ve used RTW to generate code for a variety of microcontrollers, such as Texas Instruments TMS320F28335 and ARM Cortex-M processors, which are often used in real-time control applications.

- Code Verification: After code generation, rigorous testing is critical. I employ techniques like unit testing, integration testing, and in-circuit emulation (ICE) to verify that the generated code accurately reflects the Simulink model.

A notable example involves the generation of code for a motor controller. We used RTW to generate optimized C code, which was then deployed onto the motor control unit. This code provided precise control over the motor, meeting the strict timing constraints of the real-time application.

Q 12. Describe your experience with testing and validation of Simulink models.

Testing and validation are crucial for ensuring the quality and reliability of Simulink models. My approach involves a comprehensive strategy across multiple levels.

- Unit Testing: Testing individual blocks and subsystems in isolation to verify their functionality. I use Simulink Test to automate this process.

- Integration Testing: Testing the interaction between different components of the model to ensure proper communication and data flow. This is often done using test harnesses that simulate inputs and verify outputs.

- System Testing: Evaluating the entire system’s behavior under various scenarios to determine whether it meets overall specifications. I use Simulink Verification and Validation (SVV) to manage and automate these test cases.

- Requirement Traceability: Linking test cases to specific requirements to ensure that all requirements are adequately covered during testing. I document this extensively to demonstrate traceability and compliance.

- Coverage Analysis: Measuring the extent to which the model has been tested to identify untested areas. This helps pinpoint potential weaknesses and ensure thorough testing.

In one project involving a flight control system, we conducted rigorous testing, including hardware-in-the-loop simulations, using Simulink Real-Time and a flight simulator. This rigorous testing helped identify and fix critical errors in the control algorithms, improving the overall robustness and safety of the flight control system.

Q 13. How do you manage version control for your MATLAB and Simulink projects?

Version control is paramount for collaborative projects and maintaining a history of changes. I primarily use Git for version control of my MATLAB and Simulink projects. This allows me to track changes, collaborate effectively with others, and easily revert to previous versions if needed.

- Git Integration: I’m familiar with integrating Git with MATLAB and Simulink using either the command line or a GUI-based client like Sourcetree or GitHub Desktop. This ensures all model files, scripts, and data are under version control.

- Branching Strategy: I utilize branching strategies like Gitflow to manage different versions and features concurrently. This helps maintain stability in the main branch while allowing development of new features in separate branches.

- Regular Commits: I make regular commits with clear and descriptive messages to track the evolution of the project and facilitate code review. This makes it easy to understand changes over time.

- Collaboration: Using platforms like GitHub or GitLab allows seamless collaboration with team members, facilitating code sharing and peer review.

This systematic approach to version control ensures that all changes are tracked, enabling efficient collaboration, easy rollback capabilities and minimizing the risk of losing crucial work.

Q 14. Explain your understanding of different simulation techniques in Simulink.

Simulink offers various simulation techniques tailored to different modeling needs. My understanding encompasses the following:

- Continuous-time simulation: This is the standard simulation method for systems modeled by differential equations, where the system’s state changes continuously over time. This is commonly used for simulating physical systems with continuous dynamics like mechanical or electrical systems.

- Discrete-time simulation: This method is used for systems where the system’s state changes only at discrete points in time. This is common for digital control systems, where state changes are determined by a clock or sampling rate.

- Hybrid simulation: This approach combines continuous-time and discrete-time simulations, often used for systems that incorporate both continuous and discrete elements. For example, a control system with a continuous-time plant and a digital controller would require a hybrid simulation approach.

- Co-simulation: This technique links different simulation environments or models together to simulate a larger, more complex system. This is very useful for integrating simulations of different subsystems developed using distinct tools or techniques.

- Hardware-in-the-loop (HIL) simulation: This is an advanced simulation approach where the model interacts with real-world hardware components in real-time. This allows for testing control systems or embedded systems under realistic conditions.

The choice of simulation technique depends heavily on the specific characteristics of the system being modeled. For instance, a purely mechanical system might be simulated using continuous-time simulation, while a robotic arm controlled by a microcontroller would necessitate a hybrid or co-simulation approach, potentially involving HIL testing for final validation.

Q 15. How do you optimize Simulink models for performance?

Optimizing Simulink models for performance is crucial for handling complex systems and achieving real-time capabilities. It involves a multi-pronged approach focusing on model structure, solver configuration, and code generation options.

Firstly, we need to analyze the model’s structure. Identifying and eliminating unnecessary blocks, using efficient block types (e.g., preferring built-in functions over custom-coded ones where appropriate), and optimizing data types to minimize memory usage are key steps. For example, if a signal only needs integer values, using an ‘int8’ instead of a ‘double’ significantly reduces memory footprint.

Secondly, the solver configuration plays a vital role. While variable-step solvers offer accuracy, fixed-step solvers often provide better performance for real-time applications. Careful selection of the solver and its parameters (like step size) is critical. Experimentation is usually needed to find the right balance between accuracy and speed. For instance, the ‘ode4’ solver is generally good for accuracy but ‘ode3’ or even a fixed-step solver like ‘ode5 fixed’ can be faster depending on the model.

Finally, code generation offers significant performance gains. Generating C code from Simulink, using tools like Real-Time Workshop (RTW), allows for highly optimized execution on target hardware. The generated code’s performance can be further enhanced by leveraging compiler optimization flags and carefully configuring the code generation options within RTW. We can specify memory allocation strategies, enable vectorization, and perform other optimizations to get best results on a specific processor.

In a project involving a complex aircraft control system, I once significantly improved simulation speed by switching from a variable-step solver to a fixed-step solver and optimizing data types. This reduced simulation time by over 60%, allowing for faster design iterations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your experiences with different Simulink toolboxes?

My experience spans various Simulink toolboxes, each catering to specific engineering domains. I’ve extensively used the Control System Toolbox for designing and analyzing control systems, utilizing tools like PID Tuner and Linear Analysis tools. This includes designing controllers for everything from simple servo motors to complex multi-variable processes.

The Stateflow toolbox has been essential for modeling complex logic and state machines, particularly in projects involving hybrid systems. I used it in a robotics project, where it facilitated modelling the robot’s various operational modes (e.g., idle, moving, grasping) and their associated transitions.

The Simulink Coder has been crucial for generating C code for deployment on embedded systems. I’ve used this extensively for generating real-time code for applications in automotive and aerospace domains where deterministic behaviour is vital.

Furthermore, I have experience with toolboxes like Simscape for modeling physical systems (mechanical, electrical, hydraulic, etc.) and Simulink Real-Time for hardware-in-the-loop (HIL) simulations. Each toolbox has its strengths, and effective model development necessitates choosing the right tools for the specific task.

Q 17. How do you create custom blocks in Simulink?

Creating custom blocks in Simulink allows for modularity and code reusability. There are several ways to achieve this.

The simplest approach involves using MATLAB functions. A MATLAB function can be packaged as a Simulink block by using the MATLAB Function block. This is ideal for simple algorithms. For instance, if you need a block to implement a custom non-linear transfer function, you can write a MATLAB function describing that function and wrap it within a MATLAB Function block.

For more complex blocks with user interfaces, S-functions are powerful. S-functions can be written in MATLAB, C, C++, or other languages, providing flexibility and high performance. This enables the creation of highly customized blocks that can interact directly with the Simulink environment. For example, a complex block simulating a motor controller might benefit from an S-function written in C to optimize its speed and efficiency.

Finally, Level-2 MATLAB S-functions provide the most control, allowing direct interaction with the Simulink solver and the entire simulation environment. However, they require a deep understanding of Simulink’s internal workings.

In one project involving a complex signal processing algorithm, I created a custom S-function in C to significantly improve the speed of the simulation compared to a MATLAB Function block approach.

Q 18. Explain your experience with continuous and discrete-time systems modeling in Simulink.

Simulink seamlessly handles both continuous and discrete-time systems. Continuous systems are those where the variables change continuously over time, while discrete systems only change at specific instances.

Continuous-time systems are often represented using differential equations, and Simulink uses numerical integration methods (defined by the solver) to solve these equations. For example, a simple mass-spring-damper system is modeled using integrators and gain blocks to represent the equations of motion.

Discrete-time systems are represented using difference equations. Simulink’s discrete blocks, such as Unit Delay, Discrete-Time Integrator, and other specialized blocks, manage the discrete-time dynamics. For instance, a digital filter would be effectively implemented using these discrete-time blocks.

Many real-world systems are hybrid, combining continuous and discrete elements. For example, a flight control system involves continuous dynamics (aircraft motion) controlled by a discrete-time digital computer. Simulink elegantly manages such systems using a mix of continuous and discrete blocks, often with the help of Stateflow for managing the discrete control logic.

Q 19. How do you handle model partitioning and code generation in large projects?

Handling model partitioning and code generation in large Simulink projects requires a structured approach. Model partitioning involves breaking down a large model into smaller, more manageable subsystems. This improves readability, simplifies debugging, and enables parallel processing during simulation.

Simulink’s model referencing capabilities are crucial here. You can create independent subsystems (referenced models) and link them together. This approach facilitates collaboration among team members working on different parts of the model.

Code generation for large projects requires careful planning. We need to use appropriate build configurations to manage dependencies and target multiple hardware components. Consider using the Simulink Project feature to set up configurations for compiling each subsystem separately and linking them together effectively. The use of Makefiles or other build systems might be necessary for large-scale compilation.

In a recent project developing a complex power grid simulator, we used model partitioning to divide the model into sub-systems representing different sections of the grid. Each subsystem was handled by a separate team, and the final model was assembled using model references. This approach allowed for efficient development and testing, drastically reducing the overall project completion time.

Q 20. Explain your understanding of the different scopes of variables in MATLAB.

MATLAB uses a hierarchical scope system for variables. This means the visibility and lifetime of a variable are determined by where it’s defined.

The innermost scope is the local scope—variables declared within a function are only accessible within that function. The next level is the function scope, which includes all variables declared within the function, including any nested functions.

The base workspace is the outermost scope. Variables declared directly in the MATLAB command window or at the top level of a script are accessible from any function unless explicitly shadowed by a local variable of the same name.

Global variables can be declared using the global keyword. These variables are accessible from any function or script within the current MATLAB session. While convenient, using global variables should be done carefully as they can lead to hard-to-debug issues in larger projects. It is generally better to pass variables as arguments to functions or use persistent variables (using the persistent keyword within a function) for retaining state between function calls.

For example:

% Base workspace variable x = 10; function myFunction(y) global z; % Global variable persistent p; % Persistent variable if isempty(p) p = 0; end p = p + 1; disp(x); % Accessing base workspace variable disp(y); % Function input argument disp(z); % Accessing global variable disp(p); % Accessing persistent variable end z = 20; % Assigning global variable myFunction(5);

Q 21. How do you implement control algorithms using Simulink?

Implementing control algorithms in Simulink is straightforward due to its extensive library of blocks specifically designed for control systems. You can implement virtually any control algorithm, from simple Proportional-Integral-Derivative (PID) controllers to advanced model predictive controllers (MPC).

PID controllers are easily implemented using the built-in PID Controller block. You simply specify the proportional, integral, and derivative gains, and connect the block to your plant model. The PID Tuner app provides valuable tools for tuning the controller parameters.

More complex algorithms, such as MPC, often involve state-space representations. Simulink’s State-Space block and other linear systems blocks are well-suited for this. You can define the system matrices (A, B, C, D) and use these blocks within your control system design.

You can also use custom blocks (as discussed earlier) to encapsulate complex algorithms. Furthermore, integrating Simulink with MATLAB enables utilizing more sophisticated control design algorithms. You can design the controller in MATLAB using the Control System Toolbox and then integrate it into your Simulink model. For example, you could design a Kalman filter in MATLAB and then use the generated filter coefficients within a custom Simulink block.

In a project designing an autonomous vehicle’s lane-keeping system, we employed a combination of a PID controller for basic steering and a more advanced Model Predictive Control (MPC) algorithm for smoother handling of curves and obstacles. Simulink’s flexibility allowed a seamless integration of both methods to create a robust and effective control system.

Q 22. Describe your experience using MATLAB for data analysis and visualization.

MATLAB’s data analysis and visualization capabilities are unparalleled. I’ve extensively used it to import, clean, and analyze datasets from various sources, ranging from CSV files to specialized instrument data logs. My approach typically involves several steps: first, I import the data using functions like csvread or xlsread. Then, I perform exploratory data analysis (EDA) using tools like histograms, scatter plots, and box plots to understand data distributions and identify outliers. For more complex analysis, I leverage MATLAB’s statistical toolbox, employing functions like corrcoef for correlation analysis or regress for regression modeling.

Visualization is crucial for communicating insights. I frequently use functions such as plot, surf, and imagesc to create visually appealing and informative graphs. For more advanced visualizations, I utilize the plotting toolbox to create custom legends, labels, and annotations. For instance, while working on a project involving sensor data, I used MATLAB to visualize sensor readings over time, clearly highlighting anomalies and trends through interactive plots that allowed for zooming and data point examination. This visual representation was instrumental in identifying a recurring sensor malfunction that was previously undetectable through raw data inspection.

Furthermore, I’m proficient in creating custom visualizations tailored to specific needs. I can generate reports and presentations using MATLAB’s publishing capabilities, exporting figures in various formats for seamless integration into reports and documents.

Q 23. How would you approach model linearization and analysis?

Model linearization is crucial for control system design and analysis, simplifying nonlinear systems around an operating point. I typically use two main approaches: numerical linearization and analytical linearization.

Numerical Linearization: This involves using numerical methods to approximate the system’s Jacobian matrix. In MATLAB, I’d use functions like linmod or its Simulink counterpart. linmod takes a Simulink model and an operating point as inputs, then numerically calculates the linearized state-space representation. For example: [A,B,C,D] = linmod('mySimulinkModel',opPoint); This gives you the A, B, C, and D matrices of the linearized model. This method is great for complex systems where an analytical approach is difficult or impossible.

Analytical Linearization: This involves deriving the linearized model mathematically from the system’s nonlinear equations. This requires a good understanding of calculus and linear algebra. Once the linearized equations are derived, I would then express them in state-space form (or transfer function form) and implement this in MATLAB using the appropriate matrices. This approach gives deeper insights into the system’s behavior and is often preferred for simpler systems where accuracy is paramount.

After linearization, analysis involves determining stability, performance characteristics (e.g., rise time, settling time), and robustness using techniques like eigenvalue analysis (eig function in MATLAB), Bode plots (bode), and Nyquist plots (nyquist). This allows for the design and tuning of controllers.

Q 24. Explain your experience with signal processing techniques in MATLAB.

I possess extensive experience in using MATLAB for signal processing, applying various techniques such as filtering, Fourier transforms, and wavelet analysis. For instance, while working on a project that involved analyzing audio signals to identify specific sounds within noisy environments, I used MATLAB’s Signal Processing Toolbox. I started by importing the audio signal using audioread, then applied a bandpass filter to isolate the frequency range containing the target sound, using functions like fir1 or butter to design the filter.

To isolate the specific sound events, I utilized short-time Fourier transforms (STFT) to obtain a time-frequency representation of the signal using spectrogram. I then used thresholding techniques to detect peaks in the spectrogram corresponding to the target sound. Furthermore, I employed wavelet transforms using functions from the Wavelet Toolbox for signal denoising and feature extraction, improving the accuracy of sound event identification. The results were then visualized to showcase the effectiveness of signal processing techniques used for sound detection and classification. This project successfully demonstrated my ability to apply a combination of signal processing techniques for solving real-world problems.

Beyond this project, I’ve also worked with other signal processing techniques including correlation, convolution, and various filtering algorithms to analyze and process signals from different domains. My experience covers both time-domain and frequency-domain analysis, enabling me to tackle a wide array of signal processing challenges.

Q 25. How do you implement different control strategies (PID, etc.) in Simulink?

Simulink provides a powerful environment for implementing various control strategies. PID control is a common example, easily implemented using Simulink blocks. I typically start by creating a closed-loop control system architecture:

- Plant Model: This represents the system to be controlled; it might be a transfer function, a state-space model, or a more complex Simulink subsystem.

- PID Controller: This block is readily available in Simulink’s library. You can configure the proportional (Kp), integral (Ki), and derivative (Kd) gains. I often use the ‘PID Controller’ block and adjust its parameters iteratively to obtain desired performance. The auto-tuning feature in Simulink can significantly assist in initial gain selection.

- Sensors: This block represents the feedback mechanism, measuring the output of the plant.

- Actuators: This block represents the mechanism through which the controller’s output is applied to the plant.

For more advanced control strategies like LQR (Linear Quadratic Regulator) or Model Predictive Control (MPC), I often utilize Simulink’s Stateflow for state machine logic or incorporate custom MATLAB functions to implement the control algorithms. In these cases, I leverage MATLAB’s control system toolbox, which provides functions for designing and analyzing controllers. For example, I could use lqr for LQR controller design and simulate its performance within the Simulink model.

I always thoroughly test the implemented controller through simulations, varying initial conditions and disturbances to evaluate robustness and performance. Scope blocks and other visualization tools in Simulink are essential for monitoring and interpreting simulation results.

Q 26. Describe your experience with using Simulink for hardware-in-the-loop (HIL) testing.

My experience with HIL testing in Simulink involves using real-time hardware to simulate the plant’s environment. This enables testing control systems in a realistic setting before deploying them in the actual hardware. The process typically involves:

- Real-Time Target: Selecting a suitable real-time target (e.g., dSPACE, NI VeriStand) that aligns with the hardware requirements of the project.

- Model Configuration: Configuring the Simulink model for real-time execution. This includes setting appropriate sample rates, ensuring data type compatibility, and implementing any necessary hardware interfaces.

- Hardware Interface: Setting up the connection between the Simulink model running on the real-time target and the physical hardware. This often necessitates using I/O boards, sensors, and actuators. Appropriate driver setup and data acquisition are key elements in HIL testing.

- Test Execution: Executing tests and collecting data. This stage involves running various scenarios, injecting faults, and analyzing the controller’s response under realistic conditions. This also involves developing and executing test scripts for automated testing.

- Result Analysis: Analyzing the data collected during the test and validating controller performance. The recorded data provides insights into system behavior under stress, ultimately leading to a more robust and efficient control system.

I’ve personally used HIL testing for several projects involving automotive applications. For example, I tested a traction control system using a dSPACE real-time target, simulating vehicle dynamics and interacting with actual motor controllers. This allowed us to thoroughly validate the system’s response to various driving conditions before deployment, avoiding potential issues and cost overruns.

Q 27. What are the advantages and disadvantages of using MATLAB and Simulink for model-based design?

MATLAB and Simulink offer significant advantages for model-based design, but also present some disadvantages.

Advantages:

- Early Problem Detection: Simulating the system early in the design process helps identify and resolve potential issues before physical prototyping, saving time and reducing costs.

- Rapid Prototyping: Simulink allows for rapid prototyping and iteration, enabling quick testing of different design options.

- Comprehensive Toolset: The combination of MATLAB and Simulink provides a wide array of tools for modeling, simulation, analysis, and code generation.

- Improved Collaboration: The visual nature of Simulink enhances team collaboration, making it easier to understand and discuss complex systems.

- Automated Code Generation: Simulink can automatically generate code for various target platforms, reducing development time and effort.

Disadvantages:

- Complexity: For large and complex systems, developing and managing Simulink models can become challenging.

- Cost: MATLAB and Simulink licenses can be expensive.

- Learning Curve: Mastering the toolset requires significant training and experience.

- Model Fidelity: The accuracy of the simulation results depends heavily on the accuracy of the model itself. A poorly developed model can lead to misleading results.

- Real-Time Limitations: Achieving true real-time performance in Simulink can be demanding, especially for complex systems.

Despite the disadvantages, the overall advantages of using MATLAB and Simulink for model-based design outweigh the drawbacks, particularly for complex systems where rigorous simulation and testing are essential.

Q 28. How would you troubleshoot a Simulink model that is not producing the expected results?

Troubleshooting a malfunctioning Simulink model requires a systematic approach. My strategy usually involves the following steps:

- Verify Model Structure: Carefully examine the model’s structure for any inconsistencies, such as incorrect signal connections or missing blocks. Double-check the data types and units used throughout the model for compatibility issues.

- Check for Errors: Look for any errors or warnings generated by Simulink during the simulation. These messages often provide valuable clues about the problem’s source.

- Use Debugging Tools: Simulink’s debugging tools, such as breakpoints, data inspection points, and probes, are invaluable. I would strategically place these tools to examine the values of signals at various points in the model, tracking variable changes and values at different timesteps to pinpoint the problem area.

- Simplify the Model: To isolate the problem, try simplifying the model by removing unnecessary components. This can help identify the faulty part and simplify debugging.

- Test Individual Blocks: Test individual blocks independently to ensure their functionality. Simulate sections of the model to narrow down which part is behaving unexpectedly.

- Check Initial Conditions: Ensure that the initial conditions of the model are correctly set.

- Review Simulation Parameters: Confirm that the simulation parameters, such as solver type, step size, and stop time, are appropriate for the model.

- Consult Documentation and Online Resources: Utilize Simulink documentation and online forums for assistance if needed. Many issues have common solutions which are often easily searchable online.

For example, if a control system model isn’t responding as expected, I would systematically check for issues like incorrect feedback paths, faulty PID controller gains, inconsistencies in data types, or problems within individual blocks. A step-by-step approach, using the debugging tools mentioned, will effectively resolve most Simulink model issues.

Key Topics to Learn for MATLAB and Simulink Modeling Interview

- MATLAB Fundamentals: Mastering basic syntax, data structures (arrays, matrices, structures), and control flow (loops, conditional statements). Understand how to efficiently manipulate and analyze data within the MATLAB environment.

- Simulink Modeling Basics: Gain proficiency in creating, simulating, and analyzing Simulink models. Practice building models with various blocks, including sources, sinks, and mathematical operations. Understand the concept of continuous and discrete-time systems.

- Signal Processing in MATLAB/Simulink: Explore techniques for filtering, transforming, and analyzing signals. Familiarize yourself with common signal processing tools and their applications in various engineering disciplines.

- Control Systems Design using Simulink: Learn how to design and simulate control systems using Simulink’s control system toolbox. Understand concepts like PID control, state-space representation, and system stability analysis.

- Model-Based Design Workflow: Understand the process of developing, testing, and deploying models within a Model-Based Design (MBD) framework. Practice using Simulink’s features for model verification and validation.

- Code Generation from Simulink: Explore the capabilities of generating C/C++ code from Simulink models and the implications for real-time implementation.

- Debugging and Troubleshooting: Develop strong debugging skills for identifying and resolving errors in both MATLAB code and Simulink models. Learn to effectively utilize MATLAB’s debugging tools.

- Practical Applications: Think about how you’ve used MATLAB and Simulink to solve real-world problems. Be prepared to discuss projects or coursework that highlight your skills and problem-solving abilities in detail.

Next Steps

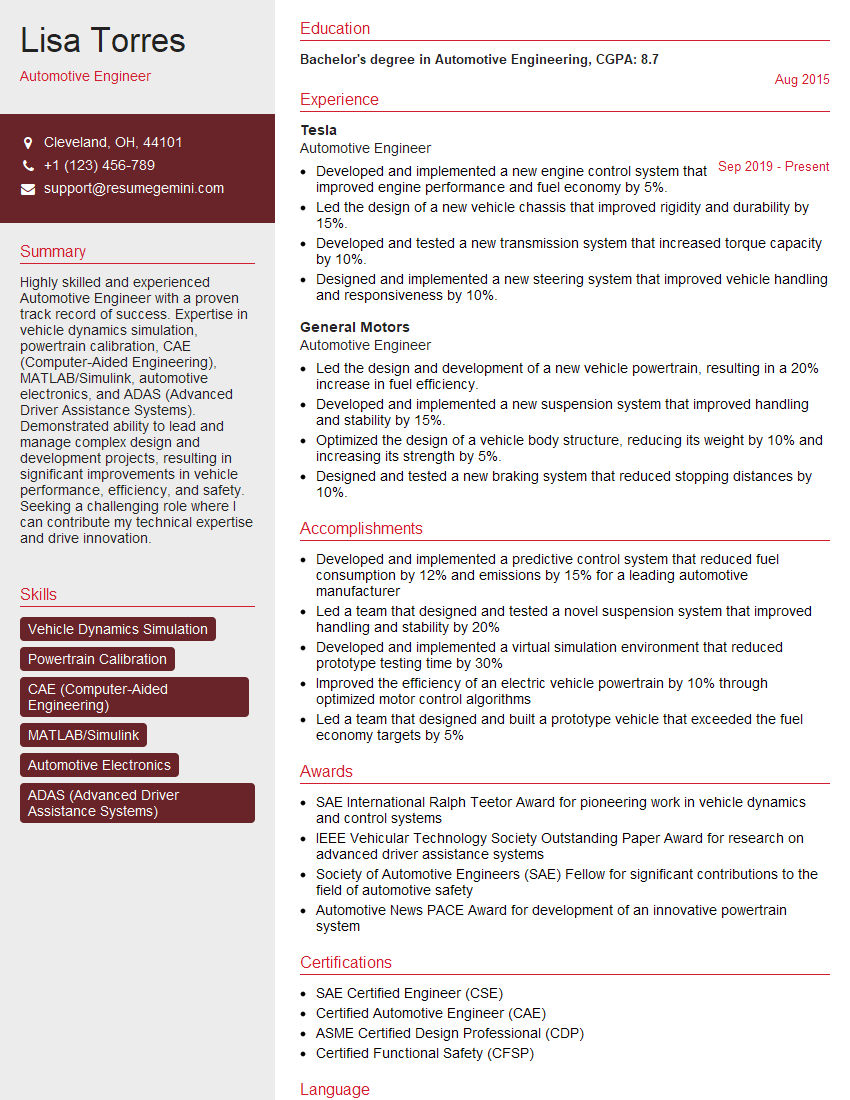

Mastering MATLAB and Simulink Modeling opens doors to exciting careers in various engineering fields, offering opportunities for innovation and problem-solving. A strong grasp of these tools significantly enhances your employability and allows you to contribute meaningfully to complex projects. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your experience. Examples of resumes specifically designed for candidates with MATLAB and Simulink Modeling expertise are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?