Are you ready to stand out in your next interview? Understanding and preparing for Electrical Arc Flash and Blast Hazard Training interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Electrical Arc Flash and Blast Hazard Training Interview

Q 1. What are the primary hazards associated with electrical arc flash?

Electrical arc flash is a serious workplace hazard involving a sudden, high-temperature release of electrical energy. The primary hazards stem from the intense heat and pressure generated. These include:

- Severe burns: Arc flash burns are often deep and extensive, requiring significant medical treatment. The intense heat can cause third-degree burns in a fraction of a second.

- Eye injuries: The bright flash of light can cause blindness or severe eye damage, even through protective eyewear if it’s not appropriate for the hazard level.

- Blast injuries: The rapid expansion of heated air creates a pressure wave that can cause hearing loss, lung damage, and other injuries from the force of the blast.

- Electrical shock: While not always the primary concern in an arc flash, the possibility of simultaneous electrical shock exists, further increasing the severity of the incident.

- Fire hazards: The extreme heat can ignite nearby flammable materials, leading to a secondary fire that compounds the dangers.

Imagine a short circuit in a high-voltage panel – the resulting arc flash can be like a miniature explosion, instantly releasing devastating energy.

Q 2. Explain the concept of incident energy and its calculation.

Incident energy is the amount of thermal energy released during an arc flash incident, measured in calories per square centimeter (cal/cm²). It determines the severity of the potential burn injury. A higher incident energy level indicates a greater risk of serious burns. Calculating incident energy requires a detailed arc flash study, typically performed by a qualified electrical engineer. This study involves several factors:

- Fault current: The amount of current flowing during the fault.

- System voltage: The voltage level of the electrical system.

- Arc duration: The length of time the arc persists.

- Working distance: The distance between the worker and the arc flash source.

- Protective device characteristics: How quickly the protective device clears the fault.

The calculation is complex and usually involves specialized software. The result is presented as an incident energy value, which is then used to select appropriate PPE. For example, an incident energy level of 1.2 cal/cm² would require a different level of PPE than 4.0 cal/cm².

Q 3. Describe the different levels of personal protective equipment (PPE) used in arc flash protection.

The level of PPE required depends on the calculated incident energy. Arc flash PPE is designed to protect against thermal burns, eye injuries, and other hazards associated with arc flash events. Several categories exist, offering various levels of protection:

- Category 1: Provides limited protection, suitable for low incident energy levels. Might include flame-resistant clothing and safety glasses.

- Category 2: Offers increased protection suitable for moderate incident energy levels. Includes arc-rated clothing with higher heat resistance.

- Category 3: Provides the highest level of protection, necessary for high incident energy levels. Involves specialized arc-rated suits, face shields, and high-protection gloves, often tested to withstand significantly higher incident energies.

The selection of PPE is crucial, and a proper arc flash risk assessment is mandatory to determine the appropriate category. It’s important to remember that even with PPE, some exposure is possible; the aim is mitigation, not elimination of risk.

Q 4. How do you determine the arc flash boundary?

The arc flash boundary is the distance from an energized electrical equipment where the incident energy reaches 1.2 cal/cm². Beyond this boundary, the risk of serious burns is significantly reduced. Determining this boundary requires the same arc flash study used to calculate incident energy. The results of the study will indicate specific distances from different equipment within a facility. These boundaries are typically marked using visual warnings, such as lines or signs, to help workers understand safe working distances.

For example, a study might reveal an arc flash boundary of 3 feet from a specific panel. Workers should maintain a safe distance exceeding this boundary unless performing specific, controlled tasks with appropriate safety precautions and permitted-to-work systems. Failure to adhere to these guidelines could lead to a catastrophic incident.

Q 5. What is the role of an arc flash risk assessment?

An arc flash risk assessment is crucial for protecting workers from arc flash hazards. It’s a systematic process that identifies potential arc flash incidents, evaluates the associated risks, and determines the necessary control measures. This assessment helps to:

- Identify hazardous equipment: Pinpointing which electrical equipment poses the greatest risk.

- Calculate incident energy: Determining the severity of potential arc flash events.

- Define arc flash boundaries: Establishing safe working distances.

- Specify PPE requirements: Dictating the appropriate level of personal protective equipment.

- Develop safe work procedures: Creating guidelines for working safely around electrical equipment.

- Provide training: Educating workers on the risks and control measures.

Imagine a large industrial facility – an arc flash risk assessment will systematically evaluate every piece of electrical equipment to ensure worker safety and compliance with regulations.

Q 6. Explain the importance of lockout/tagout procedures in electrical safety.

Lockout/tagout (LOTO) procedures are essential for electrical safety. They are a critical process designed to prevent the unexpected energization or startup of equipment during maintenance or repair. This process involves:

- Lockout: Physically securing the energy-isolating device (e.g., circuit breaker) using a lock to prevent it from being re-energized.

- Tagout: Attaching a tag to the energy-isolating device, clearly indicating that the equipment is locked out and who is responsible.

LOTO procedures are vital because even seemingly de-energized equipment can unexpectedly become energized, resulting in severe injury or death. It creates a highly visible reminder that equipment is undergoing maintenance and should not be operated. Imagine a technician working on a panel – if someone accidentally turns the circuit breaker back on, LOTO procedures are the ultimate safeguard to prevent this.

Q 7. Describe the steps involved in performing an arc flash study.

Performing an arc flash study is a multifaceted process involving several steps:

- Data gathering: Collecting information about the electrical system, including one-line diagrams, equipment specifications, and protective device characteristics.

- Software selection: Choosing appropriate arc flash calculation software.

- Model creation: Building a detailed model of the electrical system in the software.

- Fault current calculations: Calculating the fault current at various points in the system.

- Incident energy calculations: Determining the incident energy levels at various distances from the equipment.

- Arc flash boundary determination: Identifying the distances where incident energy reaches 1.2 cal/cm².

- Report generation: Creating a comprehensive report that summarizes the findings, including arc flash boundaries, incident energy levels, and recommended PPE.

- Labeling and signage: Applying arc flash labels and warning signs to equipment indicating the hazards and safety precautions.

The process requires expertise in electrical engineering and the use of specialized software. The results are crucial for creating a safe working environment and preventing serious injuries. This thorough process aims to minimize risks and protect workers.

Q 8. What are the key elements of an effective arc flash safety program?

An effective arc flash safety program is the cornerstone of preventing injuries and fatalities in electrical environments. It’s not just about having the right PPE; it’s a holistic approach encompassing several key elements.

- Hazard Identification and Risk Assessment: This is the first and most critical step. A thorough assessment identifies all potential arc flash hazards, including electrical equipment, wiring, and working conditions. This often involves using software to calculate arc flash incident energy levels.

- Engineering Controls: These are the preferred method of hazard mitigation. Examples include installing arc flash relays, using properly sized fuses and circuit breakers, implementing lockout/tagout procedures, and employing equipment with built-in arc flash protection features.

- Administrative Controls: These controls establish safe work practices, such as training programs, permit-required work systems, and clear communication protocols among workers.

- Personal Protective Equipment (PPE): Appropriate PPE is crucial for mitigating the risks when engineering and administrative controls aren’t sufficient. This includes arc flash suits, face shields, gloves, and footwear, each selected based on the calculated incident energy levels.

- Training and Competency: Regular and comprehensive training is paramount. Workers must understand arc flash hazards, how to identify them, the proper use of PPE, and emergency procedures. Training should be specific to their roles and the equipment they handle.

- Program Evaluation and Improvement: A safety program isn’t static. Regular audits and reviews are needed to identify weaknesses, update procedures based on new technologies, and ensure the program remains effective.

Imagine a scenario where a maintenance electrician needs to work on a live panel. A robust program would ensure a detailed risk assessment is done, appropriate PPE is selected and used correctly, and the electrician is fully trained on the procedures. This approach minimizes the risk significantly.

Q 9. How do you interpret an arc flash label?

Arc flash labels, often found on electrical equipment, are vital safety warnings. They provide critical information to inform workers of the potential arc flash hazards and the necessary precautions. Understanding these labels is crucial for safety.

A typical label will include:

- Arc Flash Boundary: A defined area around the equipment where the risk of arc flash is present.

- Incident Energy: This value (typically in cal/cm²) represents the amount of thermal energy released during an arc flash. It’s the most crucial piece of information, determining the required PPE.

- Arc Flash Boundary: This is a designated area around the equipment where the risk of arc flash is present.

- Required PPE Category: This indicates the level of protection needed based on the incident energy, specifying the appropriate PPE category (e.g., Category 2, Category 4).

- Voltage Rating: The voltage of the equipment.

- Date of Calculation: Indicates when the arc flash risk assessment was performed.

For example, a label might state “Incident Energy: 40 cal/cm², PPE Category 2.” This signifies that the incident energy is 40 calories per square centimeter, requiring at least Category 2 arc flash PPE for protection within the designated arc flash boundary.

Q 10. What are the different types of arc flash protection devices?

Several devices are designed to mitigate or prevent arc flash hazards. These are often used in conjunction with other safety measures such as proper PPE and training.

- Arc Flash Relays: These devices detect the occurrence of an arc flash and quickly interrupt the power supply to limit the duration and severity of the event. This is a primary method of engineering control.

- Ground Fault Relays: While not specifically for arc flashes, they detect ground faults that can lead to arc flash incidents. They promptly isolate the faulted circuit, minimizing the risk.

- Current Limiting Fuses: These fuses break the circuit incredibly fast in case of a fault, reducing the energy available to sustain the arc flash.

- Circuit Breakers with Arc Flash Protection: Some circuit breakers incorporate arc flash mitigation features, such as faster trip times, to limit the energy release during an arc flash.

- Overcurrent Relays: These detect excessive current flow, which can be a precursor to an arc flash. They help trip the circuit breaker quickly, preventing the fault from escalating.

The selection of the appropriate device depends on the specific application and the level of risk. It’s often a combined approach to achieve the best safety outcome.

Q 11. Explain the concept of arc flash relay protection.

Arc flash relay protection is a crucial safety mechanism used to mitigate the effects of an arc flash. These specialized relays continuously monitor electrical circuits for abnormal conditions like high currents or voltage imbalances that may indicate an impending arc flash.

Upon detection of a fault, the arc flash relay acts swiftly, tripping the circuit breaker to disconnect the power source within milliseconds. This rapid response significantly reduces the duration and severity of the arc flash, minimizing the incident energy and thus the potential for harm to personnel and equipment.

Modern arc flash relays often include sophisticated algorithms to differentiate between harmless transients and actual arc faults, thus preventing nuisance tripping. Their effectiveness is directly tied to proper installation, configuration, and regular maintenance. A properly functioning arc flash relay is a critical part of a comprehensive arc flash mitigation strategy.

Q 12. Describe the difference between an arc flash and a blast hazard.

While both arc flash and blast hazards are associated with electrical faults, they differ significantly in their nature and effects.

- Arc Flash: An arc flash is a sudden, high-temperature electrical arc that occurs when an unintended electrical path is created. The primary hazard is the intense thermal energy released, which can cause severe burns, blindness, and other injuries.

- Blast Hazard: A blast hazard involves a rapid expansion of gases due to the high temperatures generated by an arc flash. This expansion creates a pressure wave, similar to a small explosion, that can cause further injuries by propelling debris or even throwing individuals. This is an additional hazard layered on top of the arc flash.

Imagine a scenario where an arc flash occurs inside a switchgear. The arc flash itself delivers intense heat and light, but the blast hazard is the sudden pressure wave caused by the rapid expansion of heated air and vaporized metal. This pressure wave can violently propel nearby objects causing further damage.

Q 13. What are the potential consequences of neglecting arc flash safety precautions?

Neglecting arc flash safety precautions can have catastrophic consequences, leading to severe injuries or even fatalities. The potential ramifications extend beyond the immediate impact to encompass significant financial losses and legal liabilities.

- Severe Burns: Arc flashes cause extremely serious burns, often requiring extensive medical treatment and long-term rehabilitation.

- Eye Injuries: The intense light and heat emitted during an arc flash can cause permanent blindness or vision impairment.

- Hearing Loss: The loud noise associated with an arc flash can lead to temporary or permanent hearing damage.

- Death: In severe cases, arc flash incidents can be fatal.

- Equipment Damage: Arc flashes can severely damage electrical equipment, leading to costly repairs or replacements.

- Production Downtime: Incidents necessitate investigations, repairs, and potentially legal proceedings, causing significant disruptions to operations and productivity.

- Legal and Regulatory Penalties: Failure to comply with safety regulations can result in substantial fines and legal action.

A single arc flash incident can devastate a workplace, impacting employees, the company’s financial stability, and its reputation. The cost of neglecting safety far outweighs the investment in a comprehensive arc flash safety program.

Q 14. How do you identify potential arc flash hazards in a workplace?

Identifying potential arc flash hazards requires a systematic approach. It’s not just a matter of visual inspection; it involves a thorough understanding of the electrical system and associated risks.

- Visual Inspection: Examine all electrical equipment for signs of wear and tear, loose connections, and damaged insulation. Look for areas where exposed conductors might exist.

- Electrical System Analysis: Analyze the electrical system’s design, including voltage levels, short-circuit currents, and equipment ratings. This provides a comprehensive understanding of the potential severity of any arc flash.

- Arc Flash Risk Assessment Software: Using specialized software is crucial for accurately calculating arc flash incident energy levels and identifying potential hazards based on equipment specifications and system characteristics. This involves inputting various parameters to obtain results which can then inform safety planning.

- Lockout/Tagout Procedures Review: Verify that effective lockout/tagout procedures are in place and properly implemented to ensure that electrical power is safely disconnected before any work is performed.

- Worker Input and Experience: Solicit feedback from workers directly involved with electrical equipment. They often possess valuable insights into potential hazards that might not be apparent through formal assessments.

For instance, imagine a facility with older switchgear. A visual inspection might reveal corroded connections and damaged insulation. Using arc flash software and analyzing the system’s short-circuit currents would determine the incident energy levels, guiding the selection of appropriate PPE and safety procedures.

Q 15. What are the regulatory requirements for arc flash safety?

Regulatory requirements for arc flash safety vary depending on location, but they generally stem from a combination of national and international standards, as well as company-specific policies. Key regulations often reference or directly incorporate standards like NFPA 70E (Standard for Electrical Safety in the Workplace) in the United States, or equivalent standards in other countries. These regulations mandate risk assessments, implementation of appropriate safety measures, and employee training to minimize arc flash hazards. Failure to comply can result in significant fines and legal ramifications.

For example, in many jurisdictions, employers are legally obligated to conduct regular arc flash risk assessments and provide personal protective equipment (PPE) appropriate to the calculated incident energy levels. These regulations also often dictate the frequency of safety training and the qualifications of personnel performing electrical work.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of NFPA 70E.

NFPA 70E is the widely recognized standard for electrical safety in the workplace in the United States. It provides detailed guidelines for minimizing the risk of electrical hazards, including arc flash. The standard outlines a comprehensive risk assessment process, emphasizing the importance of understanding incident energy, arc flash boundary, and the selection of appropriate PPE. It also addresses safe work practices, lockout/tagout procedures, and the training requirements for electrical workers. Think of NFPA 70E as a comprehensive instruction manual for electrical safety, aiming to prevent injuries and fatalities.

Key aspects of NFPA 70E include the requirement for arc flash hazard analysis studies to determine incident energy levels at various locations. This analysis, often performed by qualified electrical engineers, directly informs the selection of appropriate PPE, such as arc-rated clothing, gloves, and face shields. The standard also stresses the importance of using proper tools and techniques to minimize the risk of accidental contact with energized equipment.

Q 17. Describe your experience with arc flash hazard mitigation strategies.

My experience with arc flash hazard mitigation strategies is extensive. I’ve been involved in numerous projects, ranging from small-scale modifications to large-scale facility upgrades. My approach always begins with a thorough risk assessment, utilizing industry-standard software and calculations to determine incident energy levels. This informs the subsequent mitigation strategies.

Examples of mitigation strategies I’ve implemented include:

- Engineering controls: These include measures such as installing arc flash reduction devices like arc flash relays, improving equipment grounding, and using inherently safer equipment designs. For example, replacing older switchgear with modern designs that incorporate arc flash mitigation technology.

- Administrative controls: These encompass safe work practices, detailed procedures, lockout/tagout programs, and robust training programs for electrical workers. Implementing a permit-required work system for high-risk tasks is also critical.

- Personal protective equipment (PPE): Selecting and providing appropriate arc-rated PPE based on the calculated incident energy is paramount. This ensures workers have the necessary protection against arc flash and blast injuries. Proper training on the correct use and maintenance of PPE is also crucial.

I’ve successfully integrated these strategies into various projects, resulting in significant reductions in arc flash hazards and improved worker safety.

Q 18. How do you ensure compliance with OSHA standards related to electrical safety?

Ensuring compliance with OSHA standards related to electrical safety is a critical aspect of my work. I approach this by staying abreast of current regulations and integrating them into every project. This starts with understanding OSHA’s General Industry standards (29 CFR 1910) and any relevant subpart specific to the industry (like Subpart S for electrical). Key areas of focus include:

- Lockout/Tagout (LOTO): Implementing and enforcing strict LOTO procedures to ensure equipment is de-energized before any work is performed. Regular audits and training are vital to maintain compliance.

- Hazard Communication: Clearly communicating electrical hazards to all workers through labeling, training, and safety data sheets (SDS). This includes properly labeling energized equipment with arc flash hazard warnings.

- Personal Protective Equipment (PPE): Ensuring workers have and use appropriate PPE, including arc-rated clothing, gloves, and eye protection, based on the risk assessment. Regular inspection and maintenance of PPE are also crucial.

- Training: Providing comprehensive and documented training to all employees who work with or near energized equipment. Training should cover safe work practices, hazard recognition, and the proper use of PPE.

Regular safety audits and inspections help identify potential non-compliance issues proactively, allowing for timely corrective actions.

Q 19. What is your experience with different types of arc flash testing equipment?

My experience encompasses a range of arc flash testing equipment. This includes:

- Incident energy meters: These instruments are used to measure the incident energy levels at various points near electrical equipment. They are essential for accurate arc flash risk assessments.

- Arc flash calculators: Software programs that utilize input data, such as equipment characteristics and fault currents, to calculate the incident energy and arc flash boundaries.

- Thermal imagers: These tools allow for the detection of heat signatures, which can help identify potential hotspots and areas of increased risk. They are valuable for preventative maintenance and troubleshooting.

- High-voltage test equipment: While not directly used for arc flash testing, equipment like dielectric strength testers and insulation resistance testers are critical in assessing the overall electrical condition of equipment and preventing potential failures that could lead to arc flashes.

I am proficient in using these tools to accurately assess arc flash hazards and ensure that the results are used to inform effective mitigation strategies. Proficiency with these tools also ensures that the risk assessment process is robust and reliable.

Q 20. Explain the process of developing and delivering arc flash safety training.

Developing and delivering arc flash safety training involves a multi-faceted approach. I begin by assessing the specific needs of the audience, considering their existing knowledge and the specific hazards they face. The training should always be tailored to the specific tasks and environment. The training program typically includes:

- Theoretical instruction: Covering the fundamentals of arc flash, including the causes, consequences, and mitigation strategies. This includes explaining concepts like incident energy, arc flash boundary, and the importance of PPE.

- Practical demonstrations: Showing examples of proper PPE usage, safe work practices, and lockout/tagout procedures. Hands-on activities can significantly improve knowledge retention.

- Case studies: Analyzing real-world incidents to highlight the consequences of neglecting safety procedures and illustrate the importance of adherence to standards.

- Interactive exercises: Engaging the learners through quizzes, scenarios, and discussions to assess understanding and reinforce key concepts.

- Documentation: Maintaining detailed records of training, including attendance sheets, test scores, and competency assessments.

The training must be engaging, practical, and tailored to the specific needs of the trainees. A post-training assessment is crucial to ensure that the knowledge has been successfully imparted.

Q 21. Describe your experience with incident investigation related to electrical accidents.

My experience with incident investigation related to electrical accidents involves a systematic approach, aiming to identify root causes and prevent future occurrences. The investigative process usually includes:

- Securing the scene: Prioritizing safety by isolating the affected area and preventing further hazards.

- Gathering evidence: Documenting the scene with photographs, videos, and witness statements. Examining damaged equipment to understand the failure mechanism.

- Analyzing data: Reviewing relevant safety records, permits, and training documents. Analyzing the electrical system design and operational procedures.

- Identifying root causes: Using techniques like fault tree analysis (FTA) or root cause analysis (RCA) to pinpoint the underlying reasons for the accident.

- Developing corrective actions: Implementing changes to procedures, equipment, or training to prevent similar incidents from occurring. This may include updates to safety procedures, improved risk assessment methodologies, or enhanced training programs.

A thorough investigation is crucial, not only for legal and regulatory compliance, but also to learn from mistakes and improve overall safety practices.

Q 22. How do you communicate effectively about electrical safety hazards to non-technical personnel?

Communicating electrical safety hazards to non-technical personnel requires simplifying complex concepts without sacrificing accuracy. I use a multi-pronged approach, focusing on visual aids and relatable analogies. For instance, instead of discussing incident energy, I might explain arc flash as a massive, super-heated explosion of electricity that can cause severe burns and even death. I use pictures and videos of arc flash incidents (carefully selected to avoid being overly graphic), demonstrating the severity of the potential consequences. I also leverage storytelling; sharing real-life examples of accidents helps drive home the importance of safety protocols. Furthermore, I keep the language straightforward, avoiding jargon like ‘impedance’ or ‘symmetrical fault current’. Instead, I focus on the ‘what’ and ‘why’ of safe practices, emphasizing the potential for serious injury and the simple steps individuals can take to protect themselves. Finally, I always ensure there’s ample opportunity for questions and encourage active participation to ensure comprehension.

Q 23. What is your approach to improving an existing arc flash safety program?

Improving an existing arc flash safety program begins with a thorough assessment of its current state. This involves reviewing existing documentation, including risk assessments, procedures, training materials, and incident reports. I’d then identify gaps and deficiencies in the program. For example, are arc flash studies up-to-date? Is PPE appropriate and properly maintained? Are employees adequately trained and retrained? After the assessment, I develop a strategic improvement plan, prioritizing critical areas for remediation. This plan typically includes updates to arc flash studies, ensuring the proper selection and use of personal protective equipment (PPE), implementing a robust training program with regular refreshers, and establishing a clear reporting and investigation process for near misses and incidents. Finally, I’d implement a monitoring system to track the effectiveness of the improvements and make further adjustments as needed. This iterative approach ensures continual improvement and sustained safety. One example of a significant improvement I’ve implemented was introducing a ‘lockout/tagout’ program combined with improved training, significantly reducing the risk of accidental energization.

Q 24. Explain the importance of regular electrical safety inspections.

Regular electrical safety inspections are crucial for preventing accidents and ensuring compliance with safety standards. They act as a proactive measure to identify potential hazards before they lead to incidents. Inspections uncover issues like worn insulation, loose connections, overloaded circuits, and damaged equipment. These problems, if left unaddressed, can increase the risk of arc flash events and electrical shocks. Regular inspections also help ensure that existing safety measures, such as grounding, bonding, and lockout/tagout procedures, are effectively implemented and maintained. For instance, a visual inspection might reveal corrosion on a grounding wire, which could compromise its effectiveness and increase the risk of an arc flash. Documentation of findings is vital; it provides a record of the inspection’s scope, identifies necessary repairs or improvements, and aids in tracking the overall electrical safety performance of the facility. A comprehensive inspection schedule, incorporating both visual inspections and more thorough testing, is fundamental to minimizing electrical hazards and maintaining a safe working environment.

Q 25. Describe your experience in using arc flash software or calculation tools.

I have extensive experience using various arc flash software and calculation tools, including ETAP, SKM PowerTools, and EasyPower. My experience goes beyond simply inputting data; I understand the underlying principles and limitations of these tools. For example, I know how to accurately model complex electrical systems to determine short-circuit currents, arc flash boundary distances, and incident energy levels. I can interpret the results of these calculations to define appropriate PPE categories and develop safe work procedures. I’ve also used these tools to optimize existing electrical systems, reducing the risk of arc flash hazards. For instance, in one project, we used arc flash software to identify a section of the electrical system with unusually high incident energy levels. This analysis led to modifications in the system design, significantly reducing the risk. The software output—reports detailing incident energy levels and arc flash boundaries—was then used to update safety procedures and ensure the appropriate PPE was employed.

Q 26. How do you stay current with the latest updates and best practices in arc flash safety?

Staying current with the latest updates and best practices in arc flash safety requires continuous professional development. I actively participate in industry conferences and workshops, such as those hosted by IEEE and NFPA, which offer the latest insights and research on arc flash hazards and mitigation strategies. I’m also a member of relevant professional organizations, receiving regular updates on code changes and best practices. I subscribe to industry publications and online resources, keeping abreast of new technologies and regulatory changes. Furthermore, I participate in online training courses and webinars to refresh my knowledge and learn about new software and techniques. I also regularly review the latest editions of relevant safety standards, like NFPA 70E, ensuring that my understanding aligns with the current requirements. This holistic approach ensures I maintain a high level of expertise and competence in this field.

Q 27. How do you handle disagreements or conflicts regarding electrical safety protocols?

Handling disagreements regarding electrical safety protocols requires a collaborative and respectful approach. My first step is to understand the perspectives of all parties involved, encouraging open communication and actively listening to their concerns. I then focus on using data and objective evidence, such as relevant standards and industry best practices, to support my recommendations. If the disagreement involves interpretations of safety standards, I leverage my knowledge of NFPA 70E and other relevant codes to clarify the requirements. I ensure everyone involved understands the potential consequences of non-compliance with safety protocols, emphasizing the importance of prioritizing safety above all else. In cases where a consensus can’t be reached, I advocate for escalation to a higher authority within the organization, such as a safety committee or management, to make a final determination based on all available information. Throughout the process, I maintain professionalism and objectivity, ensuring that the decisions are made in the best interest of safety for all.

Key Topics to Learn for Electrical Arc Flash and Blast Hazard Training Interview

- Arc Flash Hazard Analysis: Understanding incident energy calculations, arc flash boundary determination, and the use of software tools for risk assessment.

- Personal Protective Equipment (PPE): Selecting and properly using appropriate PPE, including arc flash suits, face shields, and hearing protection. Knowing the limitations and maintenance requirements of PPE.

- Lockout/Tagout (LOTO) Procedures: Mastering safe LOTO procedures to prevent accidental energization during maintenance and repairs. Understanding the importance of proper documentation and verification.

- Electrical Safety Regulations and Standards: Familiarity with relevant codes and standards (e.g., NFPA 70E) and their practical application in the workplace.

- Incident Investigation and Reporting: Understanding the importance of thorough incident investigation, root cause analysis, and accurate reporting to prevent future occurrences.

- Practical Application of Safety Procedures: Demonstrating a clear understanding of how theoretical knowledge translates into safe work practices in real-world scenarios.

- Emergency Response and First Aid: Knowing the appropriate emergency procedures in case of an arc flash incident and basic first aid response techniques.

- Different types of Arc Flash Protection Devices: Understanding the functionality and limitations of various arc flash protective devices.

- Risk Mitigation Strategies: Developing and implementing strategies to minimize arc flash hazards, such as engineering controls and administrative controls.

Next Steps

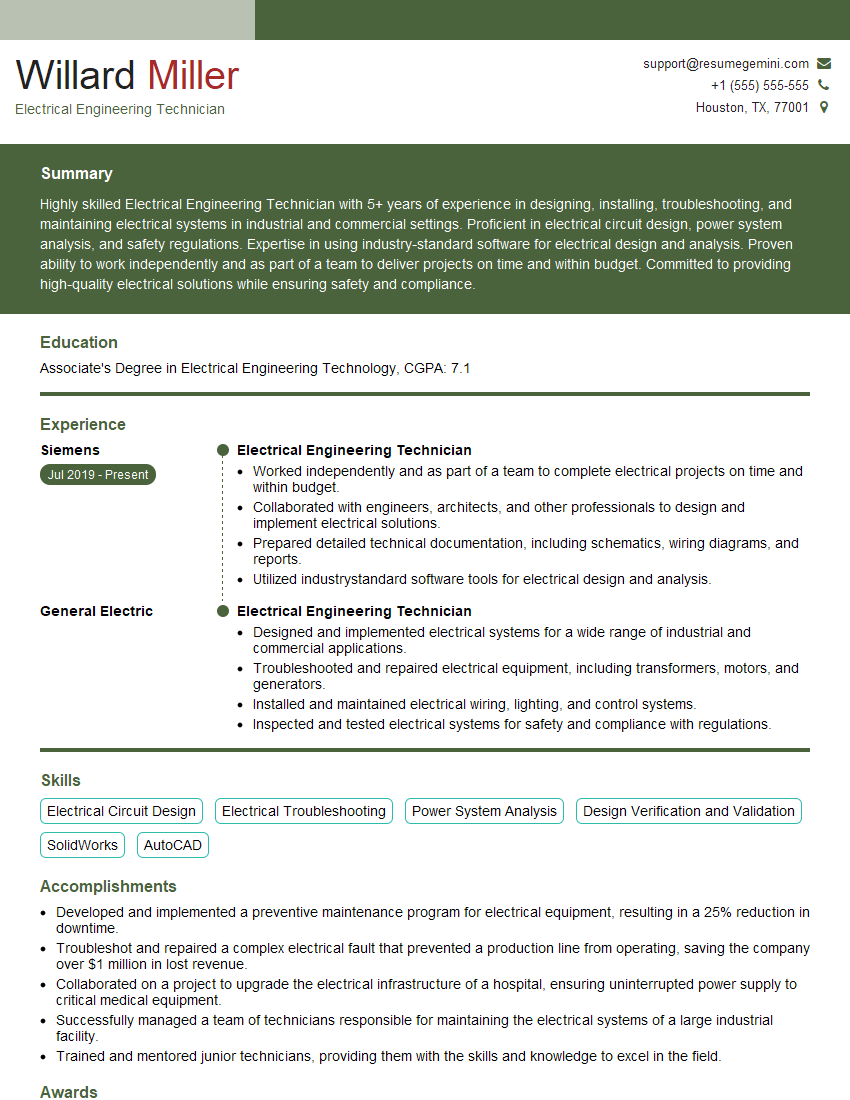

Mastering Electrical Arc Flash and Blast Hazard Training is crucial for career advancement in the electrical industry, demonstrating your commitment to safety and expertise in a high-demand field. To significantly boost your job prospects, focus on crafting a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that showcases your qualifications effectively. Examples of resumes tailored to Electrical Arc Flash and Blast Hazard Training professionals are available to help you get started. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?