Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Hydraulic Tool Repair interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Hydraulic Tool Repair Interview

Q 1. Explain the principles of Pascal’s Law and its relevance to hydraulic systems.

Pascal’s Law is fundamental to hydraulics. It states that pressure applied to a confined fluid is transmitted equally and undiminished in all directions throughout the fluid. Imagine squeezing a balloon filled with water – the pressure you apply at one point is felt equally everywhere inside the balloon. In a hydraulic system, this means a small force applied to a small area can generate a much larger force on a larger area, providing mechanical advantage. This is the principle behind hydraulic jacks, presses, and countless other tools. For instance, a hydraulic brake system in a car utilizes Pascal’s Law. The relatively small force applied to the brake pedal is amplified by the hydraulic system to create the substantial force needed to stop the vehicle.

Q 2. Describe different types of hydraulic pumps (e.g., gear, vane, piston) and their applications.

Hydraulic pumps are the heart of a hydraulic system, providing the flow of fluid under pressure. There are several types:

- Gear Pumps: These are simple, relatively inexpensive, and use meshing gears to move fluid. They are suitable for low-pressure applications like lubrication systems or smaller hydraulic tools. Think of them as two cogs moving fluid between their teeth.

- Vane Pumps: These use a rotor with vanes sliding in and out of a casing, creating chambers that pump fluid. They offer a smoother flow than gear pumps and can handle higher pressures. They are often found in mobile equipment and industrial machinery.

- Piston Pumps: These are the workhorses of high-pressure hydraulic systems. They utilize reciprocating pistons to move fluid, offering high pressure and efficiency. You’ll find these in heavy-duty applications like construction equipment, large presses, and injection molding machines. There are axial piston pumps (pistons arranged in a circle) and radial piston pumps (pistons arranged radially).

The choice of pump depends heavily on the required pressure, flow rate, and application’s specific demands. For example, a small hydraulic press might use a gear pump, while a large excavator would rely on a high-pressure piston pump.

Q 3. How do you troubleshoot a hydraulic system with low pressure?

Low pressure in a hydraulic system is a common problem with several potential causes. Troubleshooting involves a systematic approach:

- Check the hydraulic fluid level: Low fluid levels are an obvious cause of low pressure. Top off the reservoir if needed.

- Inspect for leaks: Leaks anywhere in the system will reduce pressure. Check all hoses, fittings, seals, and cylinders for visible leaks.

- Examine the pump: A faulty pump, whether due to wear, damage, or a problem with the drive mechanism, is a major culprit. Listen for unusual noises or check for reduced output.

- Check the filter: A clogged filter restricts fluid flow, resulting in low pressure. Replace or clean the filter as needed.

- Inspect valves: Malfunctioning valves, such as a stuck relief valve or a partially closed directional control valve, can drastically reduce system pressure.

- Test pressure gauges: Use pressure gauges at various points in the system to pinpoint the exact location of the pressure drop.

Remember safety first! Always disconnect the power source before inspecting or repairing a hydraulic system.

Q 4. What are common causes of hydraulic leaks and how are they repaired?

Hydraulic leaks are a significant problem, leading to loss of pressure, fluid contamination, and potential safety hazards. Common causes include:

- Worn seals: Seals wear down over time, allowing fluid to escape. This is particularly common in cylinders and valves.

- Damaged hoses: Hoses can crack, burst, or develop abrasions, leading to leaks.

- Loose or damaged fittings: Loose or improperly tightened fittings can cause leaks at connection points.

- Damaged cylinders: Scratches or pits in the cylinder bore can allow fluid to leak past the piston seals.

Repair methods depend on the cause:

- Seal replacement: Worn seals are replaced with new ones, a common repair in hydraulic cylinder and valve maintenance.

- Hose replacement: Damaged hoses are replaced entirely. It’s critical to use the correct hose type and fittings.

- Tightening fittings: Loose fittings should be carefully tightened to the correct torque specification. Over-tightening can damage fittings.

- Cylinder repair or replacement: Severely damaged cylinders may require honing or even replacement.

Using the right tools and proper techniques is crucial for effective and safe repair. Always refer to the manufacturer’s recommendations for specific repair procedures.

Q 5. Explain the function of a hydraulic accumulator.

A hydraulic accumulator is a pressure reservoir that stores energy in the form of pressurized fluid. Think of it as a shock absorber for the hydraulic system. It serves several vital functions:

- Pressure compensation: It compensates for pressure fluctuations, smoothing out pressure peaks and providing a more consistent pressure supply. This is particularly useful in systems with intermittent demands.

- Emergency power supply: In case of pump failure, the accumulator can provide a limited amount of hydraulic power to allow for controlled shutdown or completion of a critical operation.

- Shock absorption: It absorbs shock loads and pressure surges, protecting other components in the system from damage.

- Reduced pump cycling: By storing energy, the accumulator reduces the number of pump cycles needed, extending pump life and reducing energy consumption.

Accumulators come in different designs, such as bladder-type, diaphragm-type, and piston-type, each with its own advantages and disadvantages. The selection of an accumulator depends on the specific needs of the hydraulic system.

Q 6. Describe different types of hydraulic valves (e.g., directional control, pressure control, flow control) and their functions.

Hydraulic valves control the flow and pressure of hydraulic fluid. There are three main categories:

- Directional Control Valves: These valves control the direction of fluid flow, directing it to different parts of the system. Think of them as switches in the system. They can be manually operated, solenoid-operated (electrically controlled), or pilot-operated (controlled by another hydraulic signal). Examples include 2/2, 3/2, and 4/3 way valves.

- Pressure Control Valves: These valves regulate the pressure of the hydraulic fluid. Examples include relief valves (preventing excessive pressure), reducing valves (lowering pressure to a set value), and sequence valves (controlling the order of operations).

- Flow Control Valves: These valves regulate the flow rate of hydraulic fluid. They ensure a consistent flow to different parts of the system. Examples include flow control valves and pressure compensating flow control valves.

Understanding the function of each type is crucial for diagnosis and repair. For example, a malfunctioning directional control valve might cause the hydraulic tool to move in the wrong direction, while a faulty pressure control valve could lead to excessive pressure or insufficient force.

Q 7. How do you identify and repair a faulty hydraulic cylinder?

Identifying and repairing a faulty hydraulic cylinder involves several steps:

- Inspect visually: Check for external damage like dents, scratches, or leaks.

- Check for leaks: Carefully inspect the cylinder rod seals and piston seals for leaks.

- Test the cylinder: Operate the cylinder to check for smooth movement, unusual noises, or binding. If the cylinder extends or retracts unevenly, it suggests internal problems.

- Pressure testing: Use a pressure gauge to check the cylinder’s ability to hold pressure. A significant pressure drop indicates a leak in the seals or other internal damage.

- Disassemble the cylinder (if necessary): If inspection and pressure testing reveal internal problems, the cylinder might need to be disassembled. This requires careful attention to detail and specialized tools. Seals, piston rings, and other components can be replaced.

- Reassemble and test: After replacing damaged parts, reassemble the cylinder, and thoroughly test its operation before reinstalling it.

Repairing a hydraulic cylinder can be complex and requires specialized knowledge and tools. In some cases, especially with severe damage, replacement may be more cost-effective than repair.

Q 8. What are the safety precautions when working with hydraulic systems?

Safety is paramount when working with hydraulic systems, which operate under high pressure and can cause serious injury if not handled correctly. Think of it like handling a pressurized container of water – a small leak can become a powerful jet. Here’s a breakdown of crucial safety precautions:

- Always isolate the power source: Before performing any maintenance, ensure the hydraulic system is completely shut down and isolated from the power source (electric motor, internal combustion engine, etc.). This prevents unexpected activation.

- Use proper PPE (Personal Protective Equipment): This includes safety glasses, gloves (resistant to hydraulic fluid), and steel-toe boots. For high-pressure systems, consider a face shield and hearing protection.

- Release pressure gradually: Never attempt to quickly release pressure. Use the system’s pressure relief valve carefully and slowly, allowing pressure to dissipate gradually to prevent sudden bursts or component damage.

- Beware of high-pressure jets: Hydraulic fluid under pressure can be ejected with significant force, capable of piercing skin and causing severe injury. Never point a hydraulic fitting or hose towards yourself or others.

- Follow lockout/tagout procedures: Implement a rigorous lockout/tagout system to prevent accidental start-up during maintenance or repair. This involves physically locking out and tagging the power source to confirm it’s inactive.

- Handle hydraulic fluid carefully: Hydraulic fluids can be harmful to skin and eyes. Use proper handling techniques and avoid direct skin contact. If exposure occurs, wash the affected area thoroughly with soap and water and seek medical attention if necessary.

- Proper ventilation: In enclosed spaces, ensure adequate ventilation to prevent the build-up of potentially hazardous fumes from hydraulic fluids.

Remember, a moment of carelessness can have severe consequences. Always prioritize safety and follow established procedures.

Q 9. Explain the process of bleeding a hydraulic system.

Bleeding a hydraulic system involves removing trapped air that can impede its proper functioning. Air bubbles create compressibility, leading to inconsistent performance and damage to components. Think of it like trying to drink a milkshake with air bubbles—it doesn’t flow smoothly. The process typically involves:

- Identify bleed points: Consult the system’s schematic to locate all the bleed points—usually valves or fittings designed for air expulsion.

- Prepare equipment: You’ll need a wrench to access bleed valves and possibly a container to catch the fluid expelled during bleeding. If the system requires a specific fluid type or level, make sure you have the right materials on hand.

- Start the pump (if applicable): Some systems may require the pump to be operating during bleeding to circulate the fluid.

- Open the bleed valves: Slowly open the bleed valves one at a time, starting at the highest point in the system. This allows air to escape.

- Monitor for air bubbles: Observe the fluid as it exits the bleed valve. Continue to open the valve until a consistent stream of fluid free from air bubbles emerges.

- Close the bleed valves: Once a continuous, bubble-free flow is observed, close the bleed valve securely. Repeat the process for all bleed points.

- Check system operation: Once bleeding is complete, check the system for proper operation. Look for leaks and verify that all components function correctly.

Always refer to the system’s specific instructions, as different systems may have unique bleeding procedures. Incorrect bleeding can lead to system failure, so paying close attention to detail is vital.

Q 10. How do you interpret hydraulic schematics and diagrams?

Hydraulic schematics and diagrams are essential for understanding the system’s layout, component interactions, and fluid flow paths. They act like a blueprint for the hydraulic system. Interpreting them involves:

- Identifying symbols: Familiarize yourself with standard hydraulic symbols, such as pumps, valves, actuators, and reservoirs. Each symbol represents a specific component and its function within the system.

- Tracing fluid flow: Follow the lines and arrows representing fluid flow paths to understand how the fluid moves through the system from the reservoir, through the pump, actuators, and back to the reservoir.

- Understanding component functions: Analyze the position and connections of components to understand their roles within the system. A valve’s placement dictates its control over fluid flow, for example.

- Identifying control loops: Recognize feedback loops and control elements that regulate the system’s pressure, flow, or position. These loops are crucial in understanding how the system maintains a desired operational state.

- Reading pressure and flow information: Many schematics include pressure and flow ratings for components or sections of the system. This helps determine the system’s capacity and operational parameters.

For example, a symbol of a directional control valve indicates the direction of fluid flow based on the valve’s position. Understanding the directional control valve’s function is key to troubleshooting or maintaining the system.

Q 11. What are the different types of hydraulic fluids and their properties?

Hydraulic fluids are the lifeblood of a hydraulic system, transmitting power and lubricating components. Several types exist, each with its own properties. Key examples include:

- Mineral oil-based fluids: These are common, cost-effective fluids offering good lubrication and performance across a wide range of temperatures. However, they have limitations in extreme temperatures or applications requiring enhanced performance.

- Synthetic fluids: These provide superior performance compared to mineral oils, particularly in extreme temperatures or high-pressure applications. They offer improved oxidation resistance and longer lifespan, but are generally more expensive.

- Water-glycol fluids: These are environmentally friendly and often used in applications requiring fire resistance. However, they are more prone to corrosion and require specific system designs to prevent issues.

- Fire-resistant fluids: Specifically designed for applications requiring high fire resistance, such as mining or aircraft systems. These fluids offer enhanced safety but often require specialized seals and components.

The properties of hydraulic fluids include viscosity (resistance to flow), pour point (temperature at which it solidifies), oxidation resistance (resistance to degradation), and compatibility with system seals and materials.

Q 12. How do you select the appropriate hydraulic fluid for a specific application?

Selecting the right hydraulic fluid is critical for optimal system performance and longevity. The choice depends on several factors:

- Operating temperature range: The fluid must remain fluid enough to flow properly at the lowest operating temperature and viscous enough to lubricate adequately at the highest temperature.

- System pressure: High-pressure systems require fluids with sufficient viscosity to prevent leakage and wear.

- Environmental considerations: Fire safety and environmental regulations may necessitate the use of specific fire-resistant or biodegradable fluids.

- Compatibility with system materials: The fluid must be compatible with all seals, gaskets, and other components in the system to avoid swelling, degradation, or leakage.

- Performance requirements: The required performance characteristics, such as load-carrying capacity, cleanliness, and wear protection, influence the selection.

For example, a high-temperature hydraulic press will necessitate a synthetic fluid designed to resist high-temperature breakdown. Similarly, a system operating in a cold climate requires a fluid with a low pour point. Consult the equipment manufacturer’s recommendations for the most appropriate fluid.

Q 13. Describe the process of replacing a hydraulic hose.

Replacing a hydraulic hose requires careful attention to detail and safety precautions. The steps typically involve:

- Isolate the system: Ensure the system is depressurized and the power source is isolated before starting the replacement.

- Drain fluid: Drain the fluid from the affected section of the hydraulic line to prevent spillage during hose replacement.

- Disconnect fittings: Carefully disconnect the old hose from the fittings at both ends. Use appropriate wrenches and be cautious to avoid damaging the fittings. If any fittings are damaged, they should be replaced.

- Measure and select replacement hose: Accurately measure the length, diameter, and fittings of the old hose to select a precise replacement. Make sure the new hose is rated for the system’s working pressure and fluid type.

- Assemble the new hose: Carefully attach the new hose to the fittings at both ends. Ensure that the hose is correctly seated and tightened to the manufacturer’s specifications.

- Check for leaks: After installation, thoroughly inspect all connections for leaks. The system should then be pressurized gradually to check for leaks and proper functioning.

- Bleed the system (if necessary): If air is introduced during the hose replacement, the system may require bleeding to remove trapped air bubbles.

Using the wrong type of hose or improper installation can lead to leaks, system failure, and safety hazards. Always follow the manufacturer’s instructions and prioritize safety.

Q 14. How do you test a hydraulic pump for efficiency?

Testing a hydraulic pump’s efficiency involves measuring its actual output against its theoretical output. This provides insights into its mechanical health and overall effectiveness. Several methods exist, including:

- Flow measurement: Using a flow meter, measure the volume of fluid the pump delivers at a given speed and pressure. Compare this measurement with the pump’s rated flow capacity.

- Pressure measurement: Using a pressure gauge, measure the pressure the pump generates at a given speed and flow. Compare this measurement with the pump’s rated pressure capacity.

- Power measurement: Measure the power input to the pump (electric power or engine power) and the hydraulic power output. Efficiency is calculated by dividing hydraulic power output by input power. A lower efficiency indicates losses due to friction or internal leakage.

- Leakage test: Inspect the pump for external leaks. Internal leakage can also be assessed indirectly by comparing measured flow and pressure to the rated capacity, indicating a lower efficiency than expected.

A significant deviation from the rated specifications indicates potential issues like worn bearings, internal leakage, or valve problems. Regular testing is recommended for preventive maintenance and early detection of potential failures.

Q 15. What are common causes of hydraulic system overheating?

Hydraulic system overheating is a serious issue that can lead to component failure and safety hazards. It’s usually caused by a combination of factors, rather than a single culprit. Think of it like a car engine; if you don’t have proper cooling, it will overheat.

- Insufficient Cooling: This is the most common cause. A clogged or malfunctioning cooling system (radiator, fan, oil cooler) prevents heat dissipation. Imagine trying to cool a pot of boiling water without enough water in the sink.

- High Operating Pressure: Excessive pressure generates friction within the system, converting energy into heat. This is like rubbing your hands together – the faster and harder you rub, the hotter they get.

- Internal Leakage: Internal leaks within hydraulic components create friction and heat. It’s like having a tiny hole in your water hose – the water leaks and creates extra friction.

- Contaminated Fluid: Contaminants in the hydraulic fluid increase friction and impede heat transfer. Think of trying to lubricate your car engine with dirty oil – it won’t run smoothly and will heat up quickly.

- Overloading the System: Demanding too much from the system beyond its design capacity generates excessive heat. This is like trying to lift a weight far beyond your capacity – you’ll quickly overheat and fatigue.

Diagnosing overheating requires a systematic approach, checking each of these potential causes, from visual inspection to pressure and temperature readings. Repair depends on identifying the root cause. It might involve cleaning filters, replacing a faulty radiator, or repairing a leaking component.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you diagnose and repair a hydraulic motor?

Diagnosing and repairing a hydraulic motor is a complex process requiring both theoretical knowledge and practical skills. Think of it as a sophisticated engine needing careful attention.

Diagnosis:

- Visual Inspection: Check for leaks, damage, or unusual wear. Look for obvious signs of trouble like cracks or loose fittings.

- Pressure Testing: Measure the input and output pressure. Significant pressure drops indicate internal problems like worn components or blockages. Think of it as checking your car’s tire pressure – low pressure suggests a leak.

- Flow Rate Measurement: Check the flow rate of the hydraulic fluid. Low flow may indicate internal restrictions or pump issues.

- Disassembly and Inspection: If the above tests reveal problems, the motor may need to be disassembled. Carefully inspect gears, bearings, seals, and other components for wear or damage. This is like performing a thorough engine checkup on your car.

Repair: Repairing a hydraulic motor involves replacing or repairing the faulty components. This could involve replacing seals, bearings, gears, or even the motor casing itself. It requires precision and the right tools. You wouldn’t try to fix a complex engine using just a screwdriver; you need specialized tools.

This process demands precision and a deep understanding of hydraulic systems. Improper repair can lead to further damage or safety risks.

Q 17. Explain the importance of preventative maintenance in hydraulic systems.

Preventative maintenance is crucial for hydraulic systems, just like regular checkups are essential for maintaining your health. It significantly extends the lifespan of the system, minimizes downtime, prevents costly repairs, and enhances safety.

- Extended Lifespan: Regular maintenance prevents premature wear and tear on components.

- Reduced Downtime: Addressing minor issues before they become major problems minimizes production interruptions.

- Cost Savings: Preventing catastrophic failures saves significant amounts of money compared to emergency repairs.

- Improved Safety: A well-maintained system is a safer system, reducing the risk of accidents caused by malfunctioning equipment.

A preventative maintenance program typically includes regular fluid analysis, filter changes, leak checks, and thorough inspections of all components. The frequency of these checks depends on the system’s usage and operating environment. Think of it as regular servicing of your car – it may seem costly in the short term, but it pays off in the long run.

Q 18. What are the common tools and equipment used in hydraulic tool repair?

Hydraulic tool repair requires a specialized set of tools. It’s not a job for a standard toolbox.

- Hydraulic Presses: Used for installing and removing seals and bearings.

- Torque Wrenches: Essential for tightening fittings to the correct specifications.

- Specialized Wrenches: Various sizes and types are needed for accessing different components.

- Micrometers and Calipers: Used for precise measurements during component inspection and repair.

- Hydraulic Pumps and Gauges: For testing and troubleshooting systems.

- Seal Installation Tools: Prevent damage to seals during installation.

- Fluid Filtration Equipment: Keeps hydraulic fluid clean and free from contaminants.

- Safety Equipment: Eye protection, gloves, and appropriate clothing are paramount.

Choosing the correct tools is critical. Improper tools can lead to damage during repairs, increasing repair time and costs. The quality of the tools also matters. Cheap, inferior tools may break or damage components.

Q 19. Describe your experience with hydraulic system diagnostics using various tools.

My experience with hydraulic system diagnostics using various tools is extensive. I’ve used a wide range of tools throughout my career to efficiently and accurately diagnose problems. Here are a few examples:

- Pressure gauges: To pinpoint pressure drops indicating leaks or blockages in different parts of the system.

- Flow meters: To measure fluid flow rates and identify restrictions or pump deficiencies.

- Particle counters: To analyze the cleanliness of the hydraulic fluid and identify potential contamination issues.

- Thermal imaging cameras: To detect overheating components that might not be immediately obvious.

- Ultrasonic leak detectors: To locate hidden leaks that are not visible to the naked eye.

I’ve worked on systems ranging from small hand-held tools to large industrial presses and have used these diagnostic techniques to effectively isolate problems. This combination of experience and tool usage enhances troubleshooting precision and saves time and resources. For example, I once used a thermal imaging camera to locate a faulty solenoid that was causing significant overheating in a large hydraulic press. This quick identification prevented major system damage.

Q 20. What is your experience with different types of hydraulic seals?

I have extensive experience with various types of hydraulic seals, each with its own properties and applications. Choosing the correct seal is crucial for system performance and longevity. Think of them as the gaskets in your plumbing – the wrong ones will lead to leaks.

- O-rings: These are the most common type, offering a simple and effective sealing solution. They are widely available and relatively inexpensive.

- U-cups: These provide a better seal than O-rings under higher pressures and offer better resistance to extrusion.

- V-packings: Designed for reciprocating applications, offering excellent sealing capabilities with minimal friction.

- Lip seals: Used to prevent leakage in rotating applications such as hydraulic cylinders and pumps. These are often found in automotive applications.

- Hydraulic seal materials: The choice of material is critical. Common materials include nitrile (NBR), polyurethane (PU), Viton (FKM) and others each offering different properties and resistance to specific fluids and temperature ranges.

Selecting the appropriate seal material is crucial and depends on the hydraulic fluid used, the operating temperature, and the system’s pressure. An incorrect seal can quickly lead to leaks, fluid loss, and system malfunction, underlining the need for deep knowledge in selecting the appropriate seal.

Q 21. How do you handle a hydraulic system emergency?

Handling a hydraulic system emergency requires a calm and methodical approach prioritizing safety. Think of it like responding to a fire – swift, decisive action is vital.

- Safety First: Immediately shut down the system to prevent further damage or injury. Isolate the power source to the hydraulic system to stop any further fluid movement.

- Assess the Situation: Determine the nature and extent of the emergency. Is there a leak? Is there a fire? Is someone injured?

- Contain the Problem: If there’s a leak, try to contain the spilled fluid. If there is a fire, evacuate the area and call emergency services.

- Call for Help: If needed, contact a qualified hydraulic technician or emergency services. Don’t attempt repairs beyond your expertise.

- Document Everything: After the emergency is resolved, document the incident, including the cause, damage, and any repairs performed. This is useful for insurance claims, future preventative maintenance, and potential system improvements.

Remember, safety should always come first. Never attempt repairs on a damaged system unless you are appropriately trained and qualified to do so.

Q 22. What is your experience with hydraulic power units?

My experience with hydraulic power units (HPUs) spans over ten years, encompassing design, maintenance, and troubleshooting. HPUs are the heart of many hydraulic systems, providing the power and flow needed to operate hydraulic actuators. My work has involved everything from routine maintenance tasks like oil changes and filter replacements to diagnosing complex issues like pump failures and pressure fluctuations. I’m proficient in identifying the root cause of failures by analyzing system pressure, flow, and temperature data. For example, I once diagnosed a recurring HPU failure in a large industrial press to a faulty relief valve, which was causing excessive heat and eventual valve seizure. Replacing the valve with a higher quality, correctly sized unit resolved the problem permanently. I’m also familiar with various HPU components including reservoirs, pumps (gear, vane, piston), motors, and control systems, and understand the interplay between them.

Q 23. Explain your experience with hydraulic press maintenance and repair.

My hydraulic press maintenance and repair experience is extensive. I’ve worked on presses ranging from small benchtop units to massive industrial presses used in forging and stamping. Maintenance tasks I routinely perform include lubrication, leak detection and repair (often involving seal replacement), cylinder inspections, and safety checks. Repair work includes troubleshooting malfunctioning control systems, rectifying hydraulic leaks using various techniques such as brazing or replacing damaged hydraulic lines, and repairing or replacing worn or damaged components like cylinders, valves, and pumps. One challenging repair involved a press with a fractured cylinder. Instead of a complete cylinder replacement (a costly option), I successfully welded the fracture, meticulously machined the surface to precise tolerances and tested the repaired cylinder under full load before returning the press to service. This saved the company significant downtime and expense.

Q 24. Describe your experience with hydraulic component testing and calibration.

Hydraulic component testing and calibration are critical aspects of maintaining reliable hydraulic systems. My experience includes using various testing equipment to evaluate the performance of pumps, valves, cylinders, and other components. This involves measuring flow rates, pressures, and response times, comparing them against manufacturer specifications, and identifying deviations. Calibration involves adjusting components to meet these specifications, ensuring accurate and efficient system operation. For instance, I use flow benches to test pump performance, pressure gauges for evaluating valve function, and specialized equipment to assess cylinder leakage. Proper calibration and testing prevents premature failures and improves the efficiency and safety of the entire hydraulic system. A recent project involved calibrating proportional valves on a complex robotics system, requiring precision adjustments to ensure accurate and responsive movements.

Q 25. How familiar are you with different hydraulic system architectures (open-center, closed-center)?

I’m very familiar with different hydraulic system architectures. Open-center systems are simpler, using a continuous flow of hydraulic fluid through the system even when actuators are not actively working. This reduces wear and tear on the pump, but isn’t ideal for precision applications. Closed-center systems, on the other hand, are more energy efficient, only supplying fluid when needed. They are more complex and commonly found in applications requiring precise control. I have experience working with both types and understand their advantages and disadvantages. Choosing the correct architecture depends heavily on the specific requirements of the application. For example, a simple lifting system might use an open-center system, while a complex robotic arm would benefit from a closed-center system’s precision control capabilities.

Q 26. What is your experience with troubleshooting hydraulic servo systems?

Troubleshooting hydraulic servo systems requires a systematic approach and in-depth understanding of control theory. Servo systems utilize feedback mechanisms to achieve precise control of position, velocity, or force. I’ve worked extensively with these systems, diagnosing problems related to incorrect feedback signals, faulty sensors (e.g., position sensors), problems within the servo valve itself (such as leakage or stiction), or issues with the control algorithm. My troubleshooting strategy often involves systematically checking sensor outputs, examining valve response times, and analyzing system response to various inputs. One challenging case involved a servo-controlled machine tool whose movements were erratic. After thorough diagnostics, I traced the problem to a faulty position sensor providing inaccurate feedback to the servo controller, leading to inconsistent movement.

Q 27. What is your experience with proportional hydraulic valves?

Proportional hydraulic valves are essential components in many modern hydraulic systems, providing smooth and precise control of fluid flow. My experience encompasses various types of proportional valves, including solenoid-controlled, servo-controlled, and electro-hydraulic proportional valves. I’m skilled in diagnosing and repairing malfunctions in these valves, which can range from electrical issues to mechanical wear. Troubleshooting frequently involves checking electrical signals, testing valve spool movement, and assessing internal leakage. For example, I recently repaired a proportional valve in a material handling system exhibiting inconsistent flow. After systematically ruling out electrical problems, I discovered internal leakage due to wear on the valve’s seals. Replacing these seals restored the valve’s proper functionality.

Q 28. Describe your experience working with hydraulic systems in different industries.

My experience with hydraulic systems spans various industries including manufacturing (presses, machine tools), construction (heavy equipment), and agriculture (tractors, harvesting machinery). Each industry presents unique challenges and requirements. In manufacturing, precision and repeatability are paramount. In construction, durability and robustness are key considerations. Agricultural applications demand a balance of both. This broad experience has given me a versatile skill set, allowing me to adapt to different system designs and troubleshooting approaches.

Key Topics to Learn for Hydraulic Tool Repair Interview

- Hydraulic System Fundamentals: Understanding Pascal’s Law, pressure, flow, and force relationships within hydraulic systems. Practical application includes diagnosing pressure loss in a hydraulic jack.

- Hydraulic Components: Detailed knowledge of pumps, valves (directional control, pressure relief, check valves), cylinders, actuators, and filters. Practical application includes troubleshooting a malfunctioning hydraulic cylinder.

- Fluid Power: Understanding different types of hydraulic fluids, their properties, and the importance of proper fluid selection and maintenance. Practical application includes identifying the correct fluid for a specific application and recognizing signs of fluid contamination.

- Troubleshooting and Diagnostics: Developing systematic approaches to identify and resolve hydraulic system malfunctions using diagnostic tools and techniques. Practical application includes using pressure gauges and flow meters to pinpoint leaks or blockages.

- Safety Procedures: Understanding and adhering to safety protocols when working with high-pressure hydraulic systems. This includes proper lockout/tagout procedures and personal protective equipment (PPE) usage. Practical application includes describing the correct procedure for servicing a hydraulic press.

- Hydraulic Seals and Packings: Identifying different types of seals, their functions, and how to select and install them correctly. Practical application includes replacing a worn seal in a hydraulic pump.

- Preventive Maintenance: Understanding the importance of regular inspections, lubrication, and filter changes to prevent hydraulic system failures. Practical application includes creating and implementing a preventive maintenance schedule for a fleet of hydraulic tools.

Next Steps

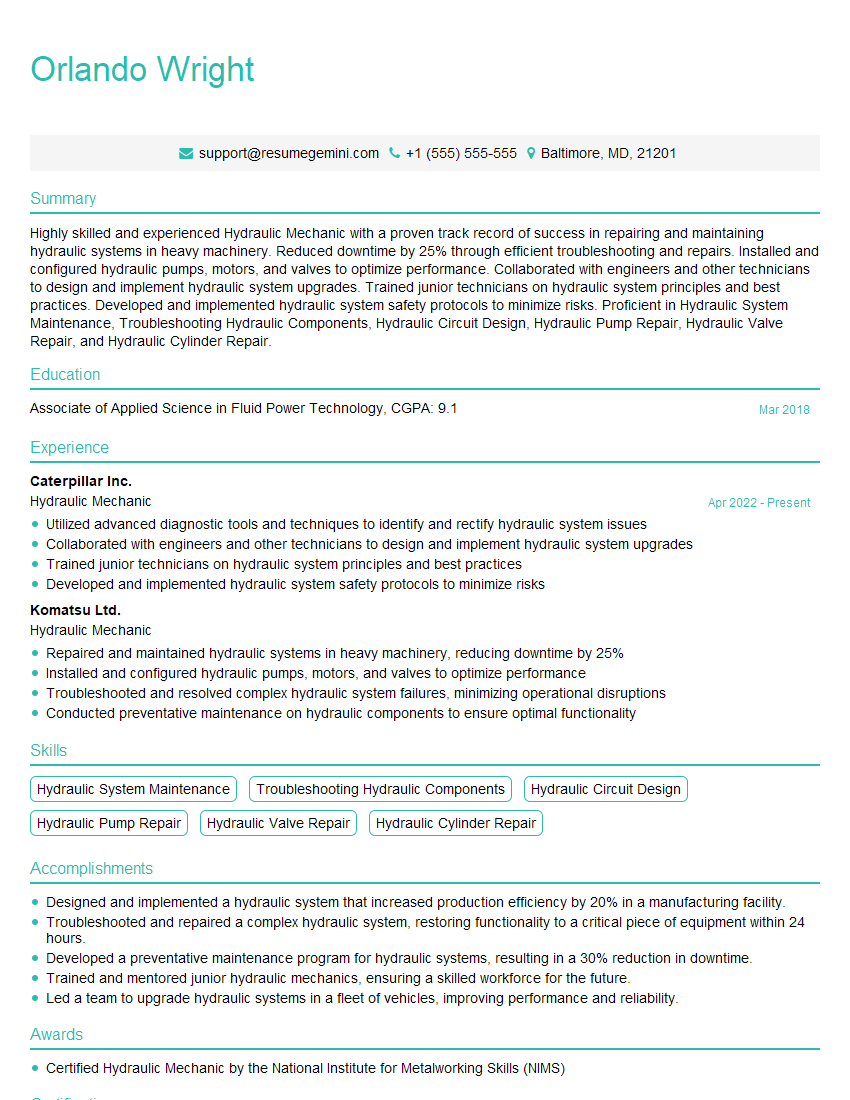

Mastering Hydraulic Tool Repair opens doors to rewarding and stable careers in various industries. Your expertise in maintaining and repairing critical equipment will be highly valued. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Hydraulic Tool Repair are available, providing you with valuable templates to help you showcase your qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?