Are you ready to stand out in your next interview? Understanding and preparing for Masonry Tool Handling interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Masonry Tool Handling Interview

Q 1. Describe your experience with various types of trowels and their applications.

Trowels are the mason’s most fundamental tools, each designed for specific tasks. My experience encompasses a wide range, from the common brick trowel to specialized pointing and finishing trowels. The standard brick trowel, with its flat, rectangular blade, is crucial for spreading and shaping mortar. I use it for most bricklaying and blockwork, employing different techniques depending on the material’s texture and the mortar’s consistency. For example, a stiffer mortar requires a more forceful application, while a softer mix allows for smoother spreading. The pointing trowel, with its narrower, curved blade, is perfect for precise work like filling joints. Its shape helps create neat, uniform lines. Margin trowels, similarly, possess a smaller blade, ideal for creating decorative borders and reaching tight corners. I’ve even utilized hawk trowels to hold mortar, making work faster and more efficient. The type of trowel chosen directly impacts the final look and structural integrity of the masonry. Choosing the right trowel is as critical as choosing the right mortar.

- Brick Trowel: General purpose, spreading and shaping mortar.

- Pointing Trowel: Precise work, joint filling.

- Margin Trowel: Decorative work, tight corners.

- Hawk Trowel: Holding mortar for efficient application.

Q 2. Explain the proper technique for using a brick hammer.

Using a brick hammer correctly is crucial for safety and efficiency. It’s not just about breaking bricks; it’s about controlled chipping and shaping. I always start by assessing the brick. A glancing blow, delivered with the claw end, is typically used to remove small chips, while a more direct strike with the hammer head might be necessary for larger pieces. The key is to maintain a firm grip and use a controlled swing. Avoid using excessive force, as this can lead to the brick shattering unpredictably. Before striking, I ensure my hand is placed in a secure position, well away from the point of impact. I also use the brick hammer’s claw end for extracting bricks carefully from a wall, preventing damage. Think of it like a surgeon’s scalpel: precise and controlled movements are key. Years of practice have honed my ability to gauge the necessary force needed for various tasks. Improper technique can lead to injury or damage, highlighting the importance of mastering this seemingly simple tool.

Q 3. How do you maintain and care for your masonry tools?

Maintaining masonry tools is essential for their longevity and performance. After each use, I thoroughly clean all my tools, removing any dried mortar with a wire brush or scraper. This prevents the mortar from hardening and damaging the tool’s surface. For metal tools, I regularly apply a light coating of oil to prevent rust. Wooden handles should be checked for cracks or splinters and oiled as needed. Sharpening is crucial for keeping tools efficient. I use a whetstone or sharpening steel to keep the edges of my trowels razor-sharp. Regular inspection and maintenance extend the lifespan of my tools, significantly reducing replacement costs and ensuring consistent, high-quality workmanship.

Q 4. What safety precautions do you take when using power masonry tools?

Safety is paramount when using power masonry tools. Before operating any power tool, I always ensure I have the correct personal protective equipment (PPE). This includes safety glasses or a face shield to protect my eyes from flying debris, hearing protection to mitigate the noise, and sturdy work gloves to prevent cuts and abrasions. I thoroughly inspect the tool before use, checking for any damage or loose parts. I only use tools in good working order. I make sure the work area is free from obstructions and that I have a secure footing. Never force a tool; if it binds or jams, switch it off and investigate the cause before resuming. I always disconnect the power supply before cleaning or performing any maintenance. Finally, I strictly adhere to the manufacturer’s instructions and any relevant safety regulations.

Q 5. Explain the difference between a pointing trowel and a margin trowel.

Both pointing and margin trowels are used for finishing work, but they have distinct applications. A pointing trowel has a relatively narrow, concave blade, specifically designed for neatly filling mortar joints. Its curved shape helps to create a smooth, even finish. In contrast, a margin trowel features an even narrower blade, often with a slightly more pointed tip, ideal for making precise lines and detailing such as creating decorative borders or intricate patterns in masonry work. The difference lies primarily in their size and the precision they offer. The pointing trowel is for filling, while the margin trowel is for creating lines and borders. Imagine the pointing trowel as a paintbrush for filling in cracks, and the margin trowel as a fine-tipped pen for adding detailed lines.

Q 6. How do you choose the right mortar for a specific masonry project?

Choosing the right mortar is critical for a successful masonry project. The selection depends on several factors: the type of masonry unit (brick, block, stone), the application (interior or exterior), and the expected environmental conditions (temperature fluctuations, moisture exposure). For example, a high-strength mortar is essential for load-bearing walls, while a more flexible mortar might be suitable for veneer applications. The type of cement, lime content, and aggregate size also play crucial roles. For exterior applications in a harsh climate, I often opt for a mortar with higher water resistance. Understanding the properties of different mortars – their compressive strength, water retention, and workability – is essential for making an informed decision. I often consult manufacturer specifications and industry standards to ensure I’m using the most appropriate mortar for the project’s specific demands.

Q 7. Describe your experience with different types of brick and stone.

My experience spans a variety of bricks and stones. I’ve worked with common clay bricks, ranging from standard red bricks to more decorative facing bricks with various textures and colors. I’m also familiar with different types of concrete blocks, including those designed for specific applications such as load-bearing or insulation. Working with natural stone presents unique challenges, requiring different techniques and tools. I’ve handled various types, including limestone, granite, and sandstone, each with its distinct properties – strength, porosity, and workability. Understanding the characteristics of each material – its strength, porosity, and potential for weathering – is crucial for selecting appropriate mortars and construction techniques. For example, porous stones might require a specialized mortar to ensure proper adhesion and water resistance.

Q 8. How do you handle different types of masonry projects (e.g., restoration, new construction)?

Handling masonry projects, whether restoration or new construction, requires a nuanced approach. Restoration demands meticulous attention to detail and often involves working with aged, potentially fragile materials. My approach starts with a thorough assessment of the existing structure, identifying any weaknesses or damage. This informs my selection of tools and techniques. For example, I might use gentler methods like hand chisels for delicate repairs, avoiding power tools that could cause further damage. New construction, conversely, allows for more streamlined processes, though precision remains paramount. This often involves working with pre-fabricated units and coordinating with other trades. For both, I prioritize safety, using proper personal protective equipment (PPE) such as safety glasses, gloves, and dust masks.

A recent restoration project involved repairing a historic brick wall. The bricks were soft and crumbling in places. I carefully removed the damaged bricks, cleaned the area, and rebuilt the section using compatible materials, employing a lime mortar to match the original. In a new construction project, I recently built a retaining wall using concrete blocks. Here, speed and efficiency were more important, while maintaining structural integrity. The process involved precise leveling and accurate placement of blocks, ensuring proper bonding and reinforcement.

Q 9. What are the common problems encountered during masonry work, and how do you solve them?

Common problems in masonry work often stem from poor planning, material issues, or improper technique. One frequent issue is efflorescence – the white, powdery deposits that appear on brick surfaces due to salts migrating from within. This is usually addressed by cleaning the surface and applying a sealant to prevent further migration. Another challenge is mortar cracking. This can result from poor mixing, improper curing, or insufficient support. Solving this might involve repairing the cracks with compatible mortar, reinforcing the structure, and ensuring proper curing by protecting the wall from extreme weather conditions. Lastly, uneven settling of the foundation can cause cracks and misalignment. This requires a more significant intervention, potentially requiring foundation repairs before masonry work can be addressed.

I remember one project where a retaining wall developed significant cracks due to inadequate drainage behind the wall. We solved this by improving the drainage system, which prevented water pressure from building up against the wall. This is a great example of how addressing underlying issues is crucial to long-term success.

Q 10. Describe your experience with different types of masonry bonds.

My experience encompasses various masonry bonds, each with its structural and aesthetic implications. Common bonds include running bond (simple alternating pattern), common bond (headers every 5-7 courses), English bond (alternating headers and stretchers), and Flemish bond (alternating headers and stretchers in each course). Each bond presents unique challenges and requires specific tools and techniques. The running bond is the simplest, and the English bond is more visually appealing but can be more challenging to execute correctly. Flemish bond, while aesthetically pleasing, requires precise bricklaying skills.

For example, the English bond requires careful alignment to ensure proper header-stretcher placement and a strong, visually consistent wall. I’ve often found that meticulous planning and consistent checking with a level and plumb bob are key to successfully constructing a wall using this bond. Understanding the interplay of strength and aesthetics within a chosen bond is paramount.

Q 11. What is your experience with leveling and aligning masonry units?

Leveling and aligning masonry units is fundamental to quality masonry work. I use a combination of tools and techniques, starting with establishing a level baseline. I employ a spirit level and plumb bob extensively to ensure each unit is accurately placed. For larger projects, laser levels provide enhanced accuracy and speed. Accurate alignment requires carefully checking each unit against the preceding one and adjusting as necessary. This involves using tools like a mason’s line, a square, and a level to maintain precise vertical and horizontal alignment.

A key to accurate leveling is to start from a solid foundation. If the foundation is uneven, it will lead to problems regardless of skill in placement. We use shims to correct minor unevenness in the foundation, ensuring a level starting point before placing the first row of masonry units.

Q 12. How do you ensure the structural integrity of your work?

Ensuring structural integrity requires a multifaceted approach. It starts with proper design and planning, selecting appropriate materials, and following correct construction practices. This includes employing adequate reinforcement, such as steel reinforcing bars (rebar) in concrete block walls, and using proper bonding patterns to distribute loads evenly. I always check for and address any weaknesses or irregularities as I work, correcting them immediately. Regular inspections throughout the project are also vital, making sure the wall is plumb, level, and free from cracks or other defects.

A crucial aspect is proper mortar selection and application. I make sure the mortar is mixed correctly and applied consistently, creating a strong bond between the units. Over-wetting the bricks and insufficient curing are common causes of weakening that I diligently avoid.

Q 13. What are your experience with cutting bricks or stones accurately?

Accurate cutting of bricks or stones requires precision and the right tools. For bricks, I use a brick saw, ensuring it’s properly lubricated to prevent chipping. For more intricate cuts or shaping, I might use a hand chisel and mallet. When working with stone, I might use a variety of tools depending on the type of stone and the required cut: diamond blades for harder stones, specialized saws for softer stones, and hand tools for shaping and finishing. Accuracy is paramount; I measure twice and cut once, using templates when necessary to ensure consistent and precise cuts.

One project required cutting many bricks at a precise angle to match an existing curve in a wall. Using a combination of a brick saw and careful hand-chiselling, I was able to create an almost seamless integration of the new section.

Q 14. What is your experience with using a spirit level and plumb bob?

The spirit level and plumb bob are indispensable tools for ensuring vertical and horizontal accuracy. The spirit level checks for horizontal alignment, while the plumb bob checks for vertical alignment. I use them constantly throughout a project, frequently checking the alignment of each course of masonry units. A slight deviation early on can quickly accumulate to significant misalignment, leading to structural problems. The plumb bob, especially, is essential for maintaining vertical alignment, particularly for tall walls or structures. Using both tools together, ensuring the walls are both level and plumb, allows for structural strength and a visually pleasing finished product.

Imagine building a tower without constantly checking for verticality. Even a small error at the base will magnify as you build higher! These tools are my constant companions, preventing such build-up of errors and ensuring a stable structure.

Q 15. What is your understanding of building codes and regulations relevant to masonry work?

Building codes and regulations are crucial for ensuring the safety and structural integrity of masonry structures. My understanding encompasses a broad range of standards, including those related to material specifications, construction techniques, and safety protocols. For example, I’m familiar with codes dictating the minimum compressive strength requirements for different types of masonry units (bricks, blocks, etc.), the proper methods for laying units to ensure stability and prevent cracking, and the necessary safety measures to protect workers from falling objects or collapsing structures. I regularly consult local and national building codes, such as the International Building Code (IBC) and relevant regional amendments, to ensure all my work complies with the latest standards. This includes understanding requirements for things like fireproofing, seismic resistance, and accessibility.

A practical example is when working on a project requiring a high-strength wall. The local building code might specify a minimum compressive strength for the mortar and the masonry units. I would then source materials and adjust the mix design to ensure we exceed these minimum requirements to provide a safety margin and prevent failure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with scaffolding and other safety equipment.

Safety is paramount in masonry work. My experience with scaffolding and other safety equipment is extensive. I’m proficient in erecting, dismantling, and inspecting scaffolding according to OSHA regulations, ensuring proper stability and load-bearing capacity. This includes understanding the different types of scaffolding – tube and clamp, system scaffold, etc. – and choosing the appropriate type for the job. I’m also adept at using fall protection systems such as harnesses, lifelines, and safety nets, and I ensure that all workers on my team are properly trained and equipped. Beyond scaffolding, I’m experienced with using other safety equipment, including hard hats, safety glasses, gloves, steel-toed boots, and respirators to protect against dust and harmful fumes. Regular safety checks are integral to my process – before starting any task, I check the stability of all equipment, and I immediately halt work if any unsafe condition is identified.

In one project, we were working on a high-rise building. Before erecting the scaffolding, I personally inspected the ground conditions, ensuring it could support the weight. We also conducted daily inspections of the scaffolding throughout the project to prevent accidents.

Q 17. What is your experience with reading and interpreting blueprints?

Reading and interpreting blueprints is fundamental to my work. I’m proficient in understanding architectural drawings, structural details, and specifications related to masonry work. This includes deciphering symbols, dimensions, and notations to accurately determine the required materials, quantities, and construction methods. I’m able to identify critical details like wall types, footing dimensions, bond patterns, and reinforcement requirements directly from the blueprints. I often cross-reference the blueprints with other project documents, such as specifications and material schedules, to ensure a complete understanding of the project’s requirements.

For example, I can interpret a blueprint showing a cavity wall and accurately determine the required thickness of the inner and outer wythes, the insulation type and thickness, and the location of any ties or reinforcement. This allows me to procure the correct materials and proceed with construction in a precise and efficient manner.

Q 18. How do you calculate the amount of materials needed for a project?

Calculating material quantities requires meticulous planning. My approach involves a multi-step process. First, I carefully review the blueprints to determine the dimensions and types of masonry units needed. Then, I calculate the total volume of masonry work based on those dimensions, accounting for openings (windows, doors, etc.). Next, I factor in waste, typically 5-10%, depending on the complexity of the project and the skill of the masons. I use this adjusted volume to calculate the number of masonry units required. For mortar, I estimate the required quantity based on the type of masonry unit, the joint thickness, and the total area. Again, I add a waste factor. Finally, I double-check my calculations and often consult with suppliers to confirm my estimates and account for any potential variations.

For instance, if a wall is 10ft x 10ft and uses standard bricks, I would calculate the area, add the waste factor, and then convert that to the number of bricks needed by referencing the brick’s dimensions and accounting for mortar joints. I always prefer to slightly overestimate material quantities to prevent delays during the project.

Q 19. Describe a time you had to troubleshoot a problem during a masonry project.

During a recent project, we encountered an unexpected issue with the foundation alignment. While laying the first course of bricks, we noticed a slight deviation from the plumb line, which would have resulted in an uneven wall. Instead of ignoring the problem, I immediately stopped the work and investigated the cause. After careful measurement and inspection, we discovered a minor error in the initial foundation work. Rather than proceeding and risking structural problems, we collaborated with the foundation crew to correct the alignment. This involved carefully removing the already-laid bricks, adjusting the foundation, and then resuming the masonry work with the corrected alignment. This proactive approach saved us significant time and effort later in the project by avoiding major structural problems.

This illustrates my problem-solving approach. I prioritize identifying the root cause of problems before implementing a solution. This thorough approach ensures that the problem is properly addressed, and that any implemented solution is effective and lasting.

Q 20. How do you deal with challenging weather conditions during masonry work?

Weather significantly impacts masonry work. Extreme temperatures, rain, and wind can all affect the setting time of mortar, the strength of the masonry, and the safety of the workers. My approach involves planning and adapting. I meticulously review weather forecasts before and during the project. On extremely hot days, I might adjust the working schedule to avoid the peak heat and ensure sufficient hydration for the team. We also might use techniques to help prevent the mortar from drying too quickly, like shading the work area. In rainy conditions, we implement proper water protection methods such as tarps and waterproof covers, or postpone the work until suitable conditions return. Wind can cause materials to shift or fall, and we would take precautions such as securing materials and potentially stopping work during high winds. Safety is the top priority in such situations. I always prioritize the safety of my team and make decisions to ensure their well-being.

For example, if it’s a particularly cold day, I would use a different type of mortar mix designed to withstand freezing temperatures, and would avoid work during periods of freezing rain or snow.

Q 21. What is your experience working with different types of mortar mixes?

My experience with different mortar mixes is comprehensive. I understand the properties of various types, including their compressive strength, workability, water retention, and setting time. I’m proficient in selecting the appropriate mix depending on the specific project requirements and environmental conditions. For example, I know that Type N mortar is generally suitable for most interior and exterior applications, while Type S mortar is required for higher-strength applications such as load-bearing walls. I’m also familiar with specialized mixes designed for specific conditions, such as those that are resistant to freezing or have enhanced water repellency. I understand the importance of proper mixing techniques to ensure the consistency and workability of the mortar. This includes using the correct water-to-cement ratio, avoiding overmixing, and ensuring that the mix is uniform throughout.

The choice of mortar mix significantly impacts the final quality of the masonry work. Using an incorrect mix can lead to poor bonding, reduced strength, and increased susceptibility to damage. My experience allows me to choose and utilize the right mix for the right job every time.

Q 22. Explain your experience with different types of masonry adhesives.

My experience with masonry adhesives spans a wide range of products, each suited for specific applications. Think of choosing the right adhesive like choosing the right glue for a particular project – you wouldn’t use superglue to attach a large piece of wood, right? Similarly, selecting the wrong adhesive can lead to failure in a masonry project.

- Portland cement-based mortars: These are the workhorses of the industry, offering excellent strength and durability, especially for structural work. I’ve used them extensively in bricklaying and blockwork, carefully adjusting the water-cement ratio for optimal workability and strength. For example, in a recent project restoring a historic building, we used a specially formulated, low-shrinkage mortar to minimize cracking.

- Polymer-modified mortars: These enhanced mortars offer improved adhesion, flexibility, and water resistance. They’re ideal for situations where movement is expected, such as fixing facing bricks to a substrate or working in areas prone to vibration. I’ve relied on these in situations requiring higher bond strength and weather resistance.

- Epoxy-based adhesives: These are incredibly strong and are perfect for critical repairs or bonding materials with low porosity. I’ve utilized them for repairing severely damaged sections of stonework, where the high strength and long-term durability are paramount. For instance, I used epoxy to consolidate loose stone pieces on a historic chimney.

- Specialty adhesives: This category includes adhesives designed for specific masonry materials, like natural stone or concrete. Each has unique properties I take into account to ensure a successful bond. Choosing the right one is vital – a wrong choice can lead to premature failure and costly repairs.

Q 23. What is your experience with cleaning and sealing masonry work?

Cleaning and sealing masonry is crucial for maintaining its appearance and longevity. Think of it as providing the structure with a protective ‘skin’. Neglecting this step can lead to premature deterioration and expensive repairs down the line.

Cleaning methods vary depending on the type of masonry and the soiling. I typically start with a gentle cleaning, using water and a soft brush for light dirt. For heavier soiling, I may use a pressure washer – but always carefully, to avoid damaging the surface. For stubborn stains, specialized cleaners can be employed. I’ve dealt with everything from efflorescence (salt deposits) to graffiti removal.

Sealing protects the masonry from water damage, freeze-thaw cycles, and air pollution. The choice of sealer depends on the material and the desired effect. Some sealers enhance the color of the brick, others provide a matte finish. I’ve worked with penetrating sealers for enhanced protection, and surface sealers for cosmetic purposes. Careful consideration is given to the breathability of the sealer to avoid trapping moisture within the masonry.

Q 24. Describe your experience with using a grinder and masonry saw.

Using a grinder and masonry saw requires skill and caution. These tools are powerful and can be dangerous if mishandled. Safety is always my top priority.

I’m proficient in using both angle grinders with diamond blades for cutting and shaping various masonry materials, from bricks and blocks to stone. I regularly use them for tasks like creating precise cuts, removing excess material, and preparing surfaces for repairs. For instance, I used a grinder to carefully shape irregular stones to fit into a complex mosaic pattern on a recent project.

Masonry saws, both wet and dry, are essential for making straight cuts, particularly for large pieces or intricate designs. I select the appropriate blade depending on the material I’m cutting – softer materials might require a diamond blade for smoother cuts. I always ensure the correct safety measures are in place – including wearing appropriate PPE (personal protective equipment) such as safety glasses, hearing protection, and a dust mask.

Q 25. What is your experience working with different types of masonry anchors?

My experience with masonry anchors encompasses a variety of types, each chosen based on the application, the load requirements, and the material being anchored into. Choosing the wrong anchor can lead to failure and safety issues.

- Expansion anchors: These are common for heavier loads in concrete or solid masonry. The anchor expands within the hole, providing a secure grip. I’ve used these extensively for hanging heavy fixtures or securing structural elements.

- Sleeve anchors: These are suitable for hollow materials like concrete block or brick. They work by expanding within a sleeve, creating a firm hold. I often use these for lighter-duty fixings.

- Chemical anchors: These use epoxy or resin to create a strong bond within a drilled hole. They are ideal for extremely heavy loads or cracked masonry. I’ve relied on these for critical applications demanding exceptionally high load capacity.

- Drop-in anchors: These are quick and easy to install and are suitable for applications where speed and simplicity are important. They are commonly used for mounting shelves and other lightweight items.

Proper anchor selection is crucial for ensuring a safe and structurally sound installation. I always consult load tables and choose anchors with ample safety margins.

Q 26. What are the signs of damaged or deteriorated masonry, and how do you handle it?

Recognizing signs of damaged or deteriorated masonry is essential for preventative maintenance and timely repairs. Ignoring these signs can lead to structural compromise and costly repairs down the line. It’s like noticing a small crack in a car’s windshield – if left unchecked, it can spread and become a much bigger problem.

- Cracks: Vertical cracks can indicate foundation settling, while horizontal cracks might suggest structural issues. The width and direction of cracks provide vital clues.

- Spalling: This refers to the chipping or flaking of the masonry surface, often caused by freeze-thaw cycles or chemical attack. Spalling is a significant indicator of material deterioration.

- Efflorescence: White, powdery deposits on the surface indicate salt migration, often due to moisture intrusion. This needs addressing to prevent further damage.

- Missing mortar: Deterioration of mortar joints weakens the structure, leading to instability and water ingress. I always check for and address missing or deteriorated mortar.

Handling damaged masonry depends on the extent and cause of the damage. Minor repairs might involve cleaning, repointing, and sealing. More extensive damage could necessitate more complex interventions, potentially involving structural engineers. I always assess the situation carefully before deciding on a course of action, and I always prioritize safety.

Q 27. Describe your experience with waterproofing masonry structures.

Waterproofing masonry structures is vital to prevent damage from moisture, which can lead to frost damage, efflorescence, and structural weakening. Think of it as providing a robust shield against the elements.

Methods vary depending on the structure and the severity of the water ingress. I’ve used several techniques:

- Surface treatments: Applying water-repellent sealers to the exterior is often a sufficient measure for minor issues. I select sealers based on the type of masonry and the level of protection needed.

- Injection waterproofing: For more serious issues, injecting waterproof membranes into cracks and joints can effectively stop water penetration. This is a more complex technique that requires careful planning and execution.

- Membrane systems: These systems involve applying a waterproof membrane to the exterior, either directly or over a protective layer. This is effective against significant water ingress.

- Drainage solutions: Sometimes, water problems stem from poor drainage around the structure. I always assess and address drainage issues to prevent excess moisture from reaching the masonry.

The most effective waterproofing strategy requires a careful evaluation of the structure and its existing problems. My approach is always to understand the root cause of the water problem before selecting and implementing a solution.

Q 28. What is your experience with repairing cracks and other masonry defects?

Repairing cracks and other masonry defects requires a careful and systematic approach. A simple crack might seem minor, but it can be a symptom of a larger underlying issue. I always treat repairs as a chance to enhance both the aesthetics and the structural integrity.

My approach generally involves these steps:

- Assessment: Carefully determine the cause and extent of the damage. Is it just cosmetic, or does it indicate a structural problem? I often use tools like a crack meter to get precise measurements.

- Preparation: Clean the area thoroughly, removing loose material and debris. I may use a wire brush and/or pressure washing (carefully).

- Repair: Use appropriate materials and techniques to fill the cracks. For small cracks, I might use a suitable mortar. Larger cracks may require more advanced techniques, like epoxy injection. Matching the repair mortar to the existing masonry is crucial for aesthetics.

- Finishing: Ensure a smooth and even finish to the repair, blending seamlessly with the surrounding masonry. Tools such as pointing trowels are essential for this.

- Sealing (if necessary): Apply a sealant to protect the repaired area from moisture and further damage.

Thoroughness is key in masonry repair. A well-executed repair will not only restore the structure’s integrity but will also improve its appearance, often extending its lifespan significantly.

Key Topics to Learn for Masonry Tool Handling Interview

- Tool Identification and Selection: Understanding the purpose and proper application of various masonry tools (e.g., trowels, levels, plumb bobs, chisels, hammers, etc.). Knowing when to choose the right tool for a specific task is crucial.

- Safe Tool Handling and Maintenance: Mastering safe operating procedures for each tool, including proper grip, posture, and preventative maintenance to ensure longevity and safety.

- Practical Application of Tools in Common Masonry Tasks: Demonstrating a clear understanding of how to use tools for tasks such as bricklaying, blocklaying, mortar mixing, and pointing. This includes understanding different mortar types and their applications.

- Troubleshooting Common Issues: Identifying and resolving problems related to tool malfunction, material inconsistencies, and unexpected on-site challenges. This shows problem-solving skills highly valued in the field.

- Understanding Material Properties and Their Impact on Tool Usage: Knowing how different masonry materials (brick, block, stone) affect tool selection and techniques, showcasing a comprehensive understanding of the craft.

- Safety Regulations and Best Practices: Demonstrating familiarity with relevant safety regulations and best practices for handling masonry tools and materials to ensure a safe working environment for yourself and others.

Next Steps

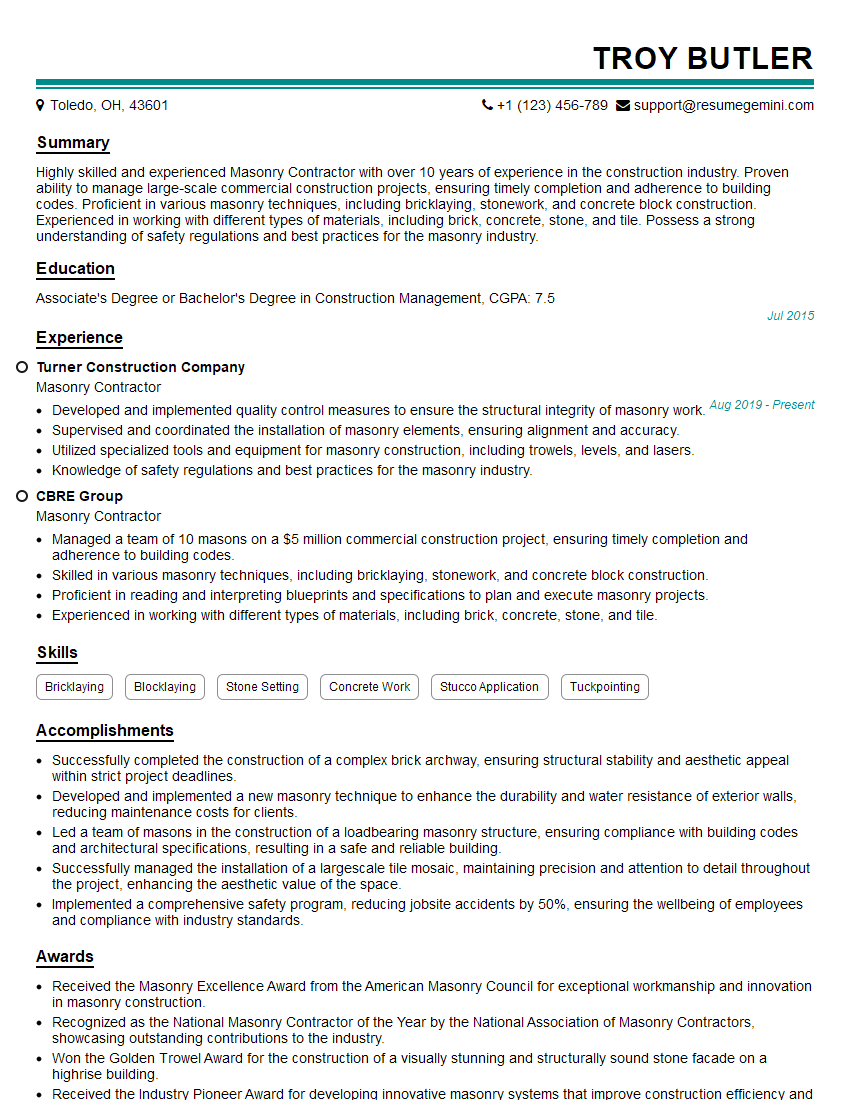

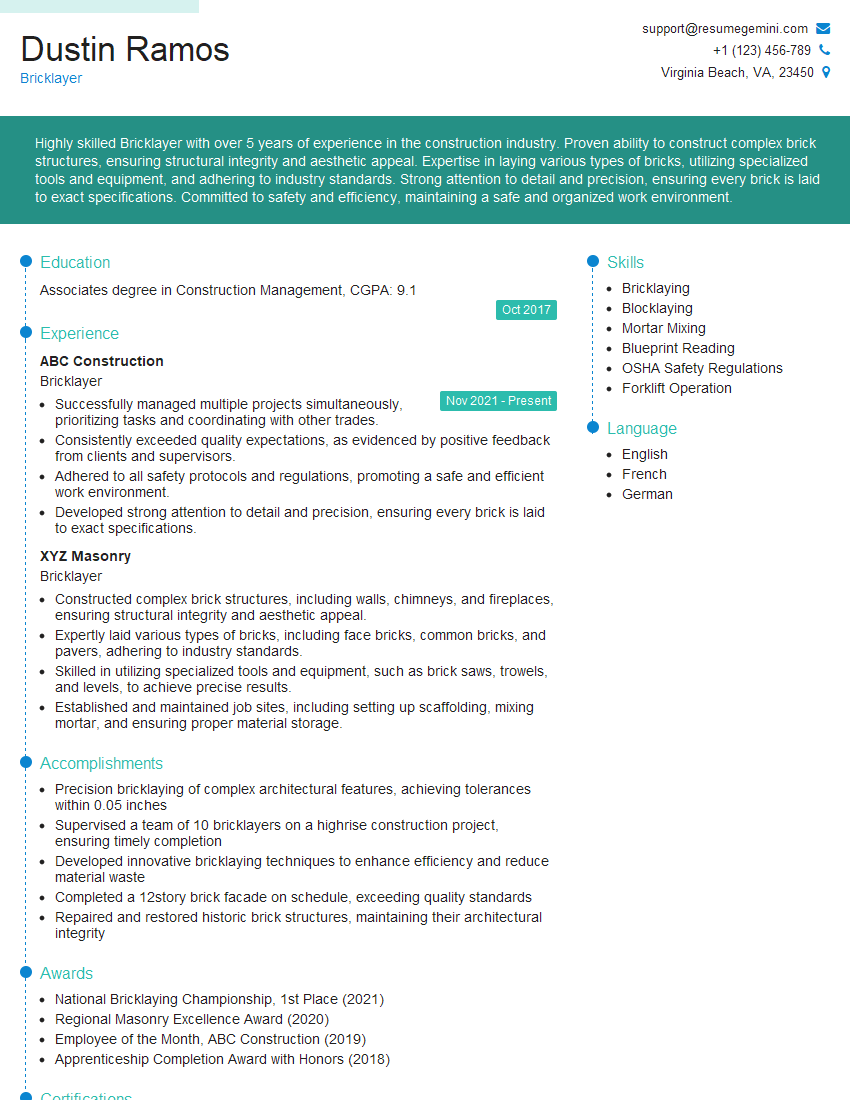

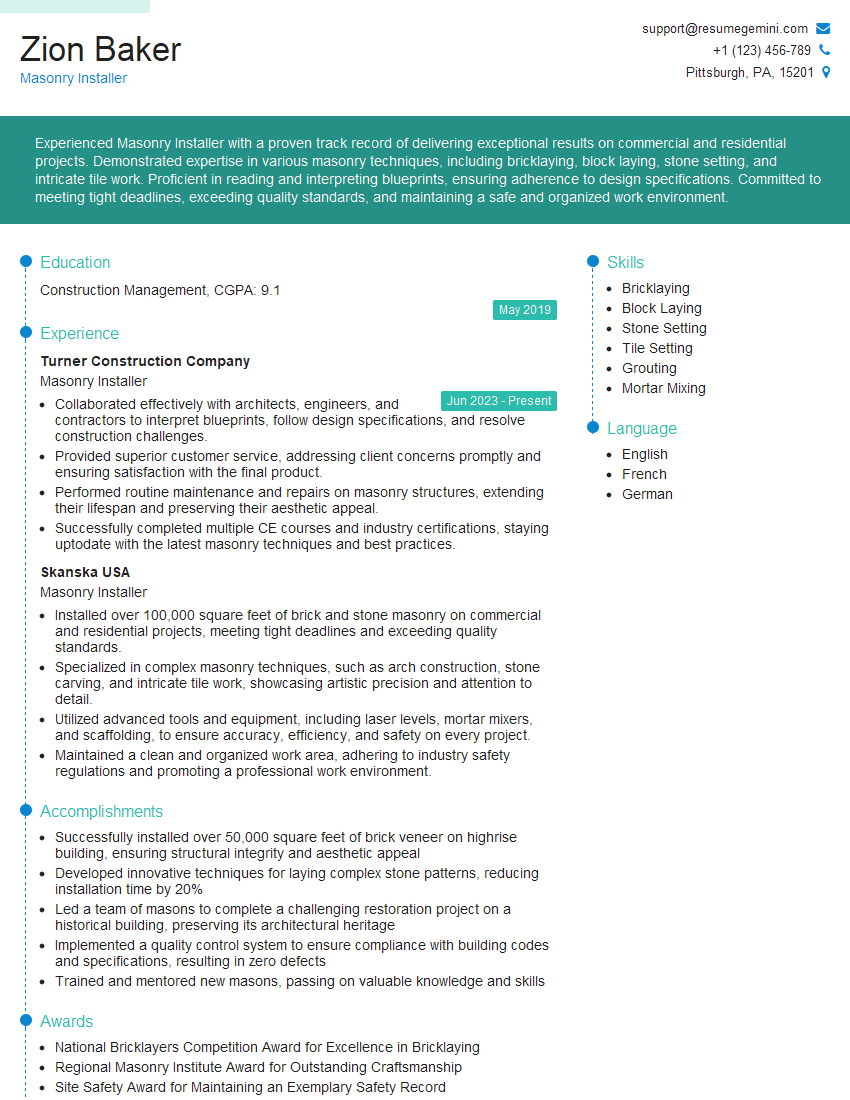

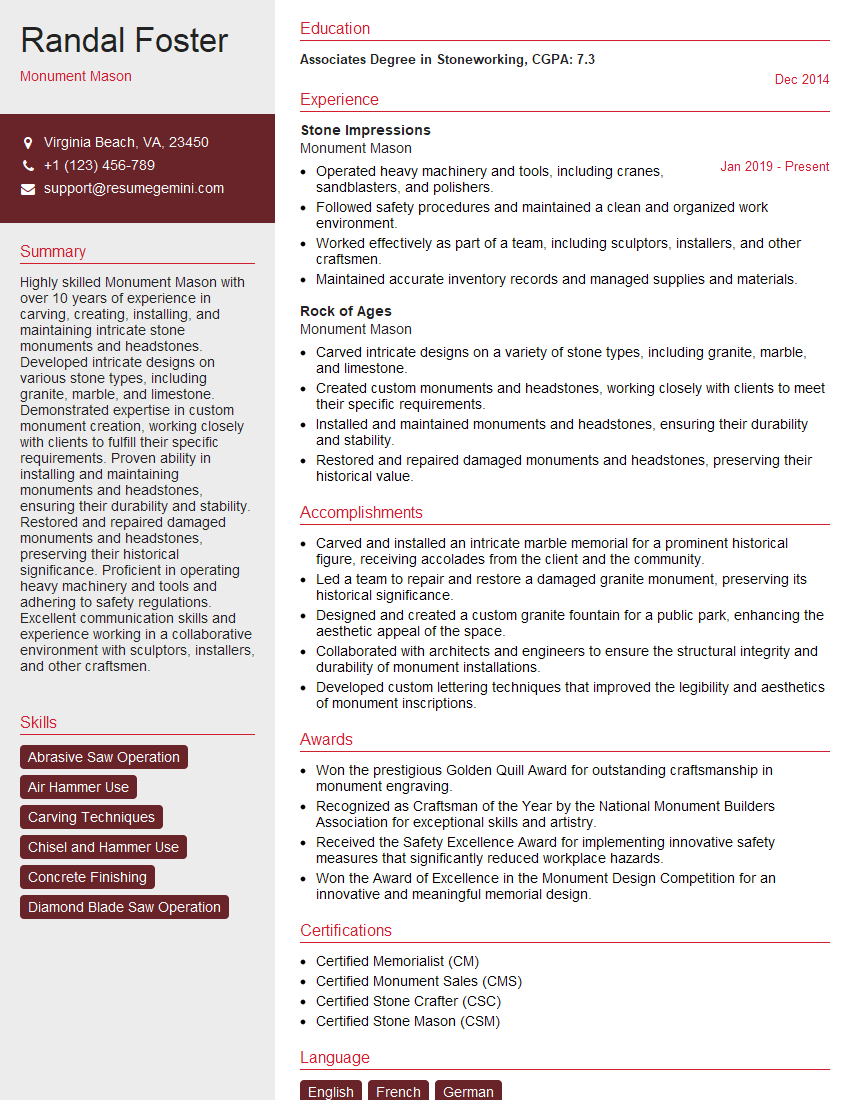

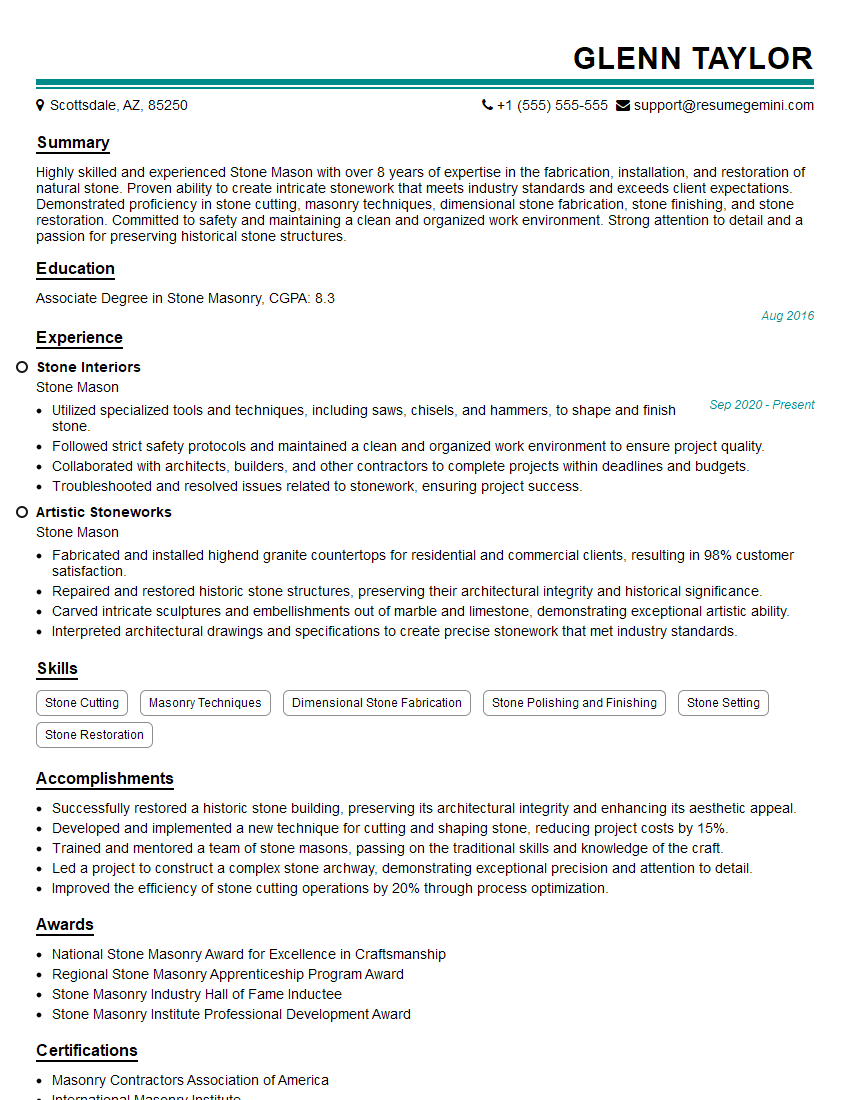

Mastering masonry tool handling is essential for career advancement in this skilled trade. Proficiency in these techniques directly translates to increased efficiency, safety, and higher-quality work, making you a more valuable asset to any construction team. To maximize your job prospects, it’s crucial to create a resume that effectively highlights your abilities. Building an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you craft a compelling and effective resume. Examples of resumes tailored specifically to Masonry Tool Handling are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?