Are you ready to stand out in your next interview? Understanding and preparing for Bridge Inspection Procedures interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Bridge Inspection Procedures Interview

Q 1. Describe the different levels of bridge inspection.

Bridge inspections are conducted at different levels of detail, depending on the bridge’s age, condition, and traffic volume. Generally, we see three main levels:

- Routine Inspections: These are typically visual inspections performed at least annually by trained inspectors. They cover readily accessible areas and focus on identifying obvious defects like significant cracking, spalling concrete, or loose components. Think of this as a quick check-up. I remember once during a routine inspection, we noticed some unusual staining on a bridge deck, which upon closer investigation, turned out to be a minor leak requiring immediate patching, preventing further damage.

- In-Depth Inspections: Conducted less frequently (e.g., every 2-5 years), these inspections involve a more thorough examination, possibly including some limited testing and access to less accessible areas. This level might incorporate the use of binoculars, close-up photography, and simple non-destructive testing methods like chain drag testing to assess deck conditions. During one such inspection, we discovered significant corrosion in a steel girder that wasn’t visible during routine checks, necessitating prompt maintenance.

- Special Inspections: These are triggered by specific events, such as after a significant incident (e.g., a heavy vehicle impact or extreme weather), or when a problem is identified during a routine or in-depth inspection. Special inspections often involve detailed investigation, advanced testing (including destructive methods if necessary), and the engagement of specialized engineers. I’ve been involved in several special inspections following flooding events, where we had to carefully assess scour damage to bridge foundations.

Q 2. Explain the role of non-destructive testing in bridge inspections.

Non-destructive testing (NDT) plays a crucial role in bridge inspections by allowing us to assess the internal condition of bridge components without causing damage. This is vital because it helps us identify potential problems early on, before they become major safety hazards and require costly repairs. Common NDT methods include:

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws like cracks and voids in concrete or steel. It’s like using sonar to image the inside of the bridge member. We used this successfully to pinpoint a hidden crack in a concrete pier during an inspection.

- Ground Penetrating Radar (GPR): Employs electromagnetic waves to image subsurface features, useful for identifying voids or deterioration under pavements and bridge decks.

- Chain Drag Testing: This involves dragging a chain across a bridge deck to identify areas with deteriorated concrete. It’s a simple yet effective method for quickly assessing the overall condition of a deck surface.

- Magnetic Particle Inspection (MPI): This method is used to detect surface and near-surface cracks in ferromagnetic materials (like steel). It’s especially helpful in identifying cracks that may have developed due to fatigue or corrosion.

The results from NDT inform decisions about necessary repairs, and often provide more cost effective solutions by helping avoid extensive, more disruptive repairs.

Q 3. What are the common types of bridge deck deterioration and their causes?

Bridge deck deterioration is a major concern in bridge maintenance. Several common types include:

- Spalling: This is the breaking away or chipping of concrete from the surface, often caused by freeze-thaw cycles (water seeps into cracks, freezes and expands, causing the concrete to break). I’ve witnessed significant spalling on bridges in colder climates, often necessitating surface repairs or overlays.

- Cracking: Cracks can be caused by various factors, such as shrinkage during curing, overloading, settlement of supports, and environmental effects (temperature changes). The location and pattern of cracking can help determine the underlying cause.

- Scaling: A surface deterioration where thin layers of concrete flake away, often due to exposure to de-icing salts or aggressive chemicals. This frequently happens on bridges in areas with harsh winters.

- Delamination: Separation of layers of concrete within the deck, often caused by poor construction techniques or environmental degradation. This is more challenging to detect and may require more sophisticated NDT methods.

- Corrosion of Reinforcing Steel: This is a serious concern, as rusting steel expands, causing further cracking and spalling of the concrete. Chloride ingress (from de-icing salts) is a major contributor.

Understanding the causes is critical, because addressing only the symptoms without treating the underlying causes will only lead to recurring problems.

Q 4. How do you assess the condition of bridge bearings?

Assessing the condition of bridge bearings is crucial because they’re vital for transferring loads from the superstructure to the substructure. We use a combination of visual inspection and sometimes specialized tools:

- Visual Inspection: We check for signs of damage like cracking, corrosion, displacement, excessive wear, or leakage of lubricant. Looking for signs of distress around the bearing area is also critical.

- Movement Measurement: Special instruments can measure the bearing’s movement and rotation under load to ensure it’s functioning within acceptable limits. This is particularly important for expansion joints.

- Lubricant Check: The condition and level of the lubricant in expansion bearings are vital, and their degradation or leakage can indicate a problem.

- Load Testing (in certain cases): For significant concerns, load testing might be performed to evaluate the bearing’s capacity.

For example, during an inspection of a bridge with elastomeric bearings, I noticed signs of excessive compression, indicating potential degradation and requiring further investigation and likely replacement.

Q 5. What are the key components of a bridge inspection report?

A comprehensive bridge inspection report should include:

- Bridge Identification: Location, name, and any relevant identifiers.

- Date and Time of Inspection: To establish context.

- Inspection Team Members: Names and qualifications of the inspectors.

- Methodology: Description of the inspection methods used.

- Detailed Findings: A thorough description of the condition of all major components (decks, beams, girders, piers, abutments, bearings, etc.), including photos and sketches. This should include quantification of damage such as the dimensions of cracks or areas of spalling.

- Rating System: Use of a standardized rating system (e.g., the commonly used AASHTO bridge rating system) to assess the overall condition.

- Recommendations: Clear and specific recommendations for repairs or maintenance, prioritized based on urgency and severity.

- Appendices: Supplementary information, such as detailed measurements, test results, and additional photographs.

The report should be clear, concise, and easy for engineers and decision-makers to understand. A good report is essential for prioritising repairs and ensuring the safety and longevity of the bridge.

Q 6. Describe your experience with different types of bridge structures (e.g., steel, concrete, timber).

Throughout my career, I’ve worked on a variety of bridge types, each presenting unique challenges and requiring specific inspection techniques:

- Steel Bridges: Inspections focus on detecting corrosion, fatigue cracking, and damage to connections. Methods include visual inspection, MPI, and UT. I recall one project involving a truss bridge where UT helped us detect fatigue cracking in critical members before it became a major issue.

- Concrete Bridges: Inspections concentrate on cracking, spalling, delamination, and corrosion of reinforcement. We employ visual inspection, chain drag testing, and GPR. A recent project included assessing concrete deterioration using GPR which led to the discovery of a significant void under a bridge deck.

- Timber Bridges: Inspections focus on decay, insect infestation, and damage from water exposure. Techniques include visual inspection and sometimes specialized tools for assessing wood moisture content. I’ve worked on several historic timber bridges where understanding the wood species and its susceptibility to decay was vital in determining the appropriate maintenance strategy.

My experience across these different materials ensures I can tailor my inspection approach to the specific needs of each bridge type. Understanding the different failure modes and the appropriate inspection methods for each is key to effective bridge management.

Q 7. How do you identify and document cracking in concrete bridge elements?

Documenting cracking in concrete is a critical aspect of bridge inspection. Here’s how I approach it:

- Location: Precisely locate and document the crack’s position using sketches, photographs, and measurements from a known reference point. For example, we might measure a crack’s distance from a bridge’s expansion joint.

- Orientation: Note the crack’s orientation (vertical, horizontal, inclined) relative to the bridge member.

- Dimensions: Measure the length, width, and depth of the crack as accurately as possible. This information is crucial for assessing the severity.

- Type: Describe the crack’s appearance: is it a hairline crack, a through-crack, or a map crack? Different crack types suggest different potential causes.

- Severity: Assess the severity based on its length, width, depth, and the potential for propagation or structural impact. AASHTO guidelines often provide a framework for this assessment.

- Photography: Include high-quality photographs of the crack, ideally with a scale to indicate its size. The photos should be clear, well-lit, and taken from multiple angles.

- Documentation Software: We often use dedicated bridge inspection software to record crack information along with other observations. This software assists in generating reports and tracking repairs over time.

Thorough documentation helps track crack progression over time, allowing us to determine if the crack is stable or growing and inform maintenance decisions.

Q 8. What are the common causes of scour at bridge foundations?

Scour at bridge foundations is the erosion of soil around the foundation piers, leading to instability and potential failure. It’s a significant concern for bridge safety. Several factors contribute to scour:

- High-velocity flow: Increased water velocity during floods or high-flow events significantly erodes the soil around bridge piers.

- Abrasive materials: The presence of sand, gravel, or other abrasive materials in the water accelerates the erosion process.

- Changes in river morphology: Alterations in the riverbed due to natural processes or human interventions (like dam construction or dredging) can increase scour potential.

- Lack of adequate protection: Insufficient or damaged riprap (protective rock layer) around bridge foundations allows for direct erosion of the soil.

- Poor foundation design: Inadequate design considerations for scour potential, such as insufficient pier depth or unsuitable foundation materials, can exacerbate the problem.

For example, I once worked on a bridge inspection where significant scour had occurred due to an unexpected increase in river flow after a heavy rainfall. This highlighted the need for regular monitoring and assessment of scour potential, particularly in areas prone to flooding.

Q 9. How do you interpret visual inspection findings?

Interpreting visual inspection findings requires a systematic approach. It starts with documenting everything observed – cracks, corrosion, spalling (chipping of concrete), deformation, scour, and any other anomalies. We then classify these findings based on their severity and potential impact on the bridge’s structural integrity. This often involves referencing established standards and guidelines.

For instance, a small crack in the deck might be considered minor, requiring monitoring but not immediate repair. However, a large crack accompanied by significant deflection (bending) of the bridge structure is a critical finding requiring immediate action. Photographs and detailed sketches are crucial in documenting these findings. We compare current findings with past inspection reports to monitor deterioration rates and predict future needs. This allows us to develop a clear understanding of the bridge’s condition and prioritize necessary repairs.

Q 10. What software or tools do you use to aid bridge inspection?

Several software and tools enhance bridge inspection efficiency and accuracy. These include:

- Bridge inspection software: These programs allow for the digitization of inspection data, including photographs, videos, and detailed notes. They often incorporate mapping tools to easily locate and track deficiencies.

- Drones with high-resolution cameras: Drones offer a safe and efficient way to inspect hard-to-reach areas of the bridge, providing detailed imagery for assessment.

- 3D scanning technology: This advanced technology creates precise 3D models of the bridge structure, allowing for detailed analysis of geometry and identification of subtle anomalies.

- Structural analysis software: This is used to evaluate the structural integrity of the bridge based on inspection findings and to predict the bridge’s behavior under different loading conditions.

- Data management systems: These systems help manage large datasets from multiple inspections, allowing for easy retrieval and analysis of the information over time.

For example, we use drone imagery to assess the condition of bridge decks and substructures, significantly reducing the need for risky manual inspections on high structures. The data is then uploaded to the inspection software and reports are created automatically.

Q 11. How do you prioritize repair needs based on inspection findings?

Prioritizing repair needs involves a multi-faceted approach, considering factors like:

- Severity: Critical safety issues like significant structural damage or imminent collapse risk are always the top priority.

- Urgency: Immediate repairs are needed if a defect poses an immediate threat to safety or public inconvenience.

- Cost-benefit analysis: This weighs the cost of repairs against the potential consequences of delay, considering both financial and safety aspects.

- Risk assessment: The likelihood and potential consequences of failure must be assessed to understand the potential impact of delaying repairs.

- Life-cycle management: Prioritization should also consider the bridge’s overall lifespan and planned maintenance schedule.

We often use a scoring system to rank deficiencies based on these factors. This allows us to develop a prioritized list of repairs, ensuring that the most critical issues are addressed promptly.

Q 12. Describe your experience using bridge inspection software and data management systems.

I have extensive experience using various bridge inspection software and data management systems. My experience includes using software for data input, analysis, reporting, and visualization. We utilize these systems to manage inspection data from various bridges across multiple projects. This includes uploading images, videos, and creating detailed reports with clear identification of critical bridge components. Data management systems allow us to track repairs and maintenance activities over time, creating a comprehensive history for each bridge. The software’s reporting capabilities are crucial in communicating findings and recommendations to stakeholders. The use of these systems promotes efficiency and consistency in our inspection processes.

For example, using a particular software package, we were able to quickly identify a trend of corrosion in a specific type of bridge joint across multiple bridges. This allowed for proactive intervention and the development of a preventative maintenance strategy.

Q 13. Explain the process for reporting critical bridge deficiencies.

Reporting critical bridge deficiencies follows a well-defined procedure. The process typically involves:

- Immediate notification: If a critical deficiency is identified that poses an immediate risk to safety, immediate notification to the relevant authorities is paramount.

- Detailed report: A comprehensive report detailing the nature, location, severity, and potential consequences of the deficiency is prepared. This includes photographic and video evidence.

- Risk assessment: The report includes a thorough risk assessment outlining the potential impact of the deficiency.

- Recommended actions: The report specifies recommended repair or mitigation measures, including the urgency of the actions needed.

- Follow-up: Progress on implementing the recommended actions should be carefully monitored and reported.

These reports are typically submitted through established channels, often following specific agency guidelines and regulations. Clear and concise communication with all stakeholders is crucial during this process to ensure timely response and effective resolution.

Q 14. How do you ensure the safety of yourself and your team during bridge inspections?

Safety is paramount during bridge inspections. We utilize various measures to ensure the safety of ourselves and our team:

- Proper training: All team members undergo thorough training in safety procedures, including the use of safety equipment and fall protection.

- Safety equipment: We always use appropriate safety equipment, including hard hats, safety vests, harnesses, and fall arrest systems, especially when working at heights.

- Traffic control: When working on bridges carrying traffic, we implement traffic control measures to minimize risks to both the inspection team and the public.

- Risk assessments: A thorough risk assessment is conducted before each inspection to identify and mitigate potential hazards.

- Emergency plans: We have clearly defined emergency procedures in place to handle unforeseen circumstances.

- Communication: Clear communication among team members is crucial to ensure coordination and safety throughout the inspection process.

For example, before starting an inspection on a high-level bridge, we establish a detailed safety plan, ensuring that all team members have received proper training in using the specialized harnesses and fall protection systems. We also maintain constant communication via radio to ensure our safety.

Q 15. Describe your experience with various types of bridge inspection equipment.

My experience with bridge inspection equipment spans a wide range, from basic tools to sophisticated technologies. I’m proficient in using visual inspection tools like binoculars, cameras (including drones for hard-to-reach areas), and high-powered magnifying glasses for detailed examinations of concrete and steel. I’m also experienced with more advanced equipment such as:

- Ground Penetrating Radar (GPR): Used to detect internal flaws in concrete decks and substructures, helping identify delamination or voids that aren’t visible on the surface. For instance, I used GPR to successfully identify a significant void beneath the surface of a bridge deck, preventing a potential catastrophic failure.

- Ultrasonic testing equipment: This helps assess the thickness and integrity of concrete elements and detect internal cracks. I’ve used this to measure the remaining thickness of a bridge deck, determining the extent of deterioration and informing repair decisions.

- Chain-suspended climbing equipment: Essential for safe and efficient inspection of bridge piers and substructures, particularly tall ones where working from a scaffold is impractical or impossible. I’ve used this method countless times to thoroughly inspect bridge supports in challenging locations.

- Digital data collection devices: These devices enable recording inspection findings efficiently and systematically. They generally allow integration of photos, GPS coordinates, and other relevant data directly into inspection reports.

My familiarity with this diverse range of equipment allows me to tailor my inspection approach to the specific characteristics of each bridge and ensure a comprehensive and accurate assessment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different inspection standards and codes (e.g., AASHTO)?

I’m thoroughly familiar with various inspection standards and codes, primarily AASHTO (American Association of State Highway and Transportation Officials) standards. My understanding extends to their application in diverse bridge types, materials, and environmental contexts. This includes:

- AASHTO LRFD (Load and Resistance Factor Design) Bridge Design Specifications: These guide the structural design and load-carrying capacity of bridges, which is crucial for determining the appropriate inspection frequency and intensity.

- AASHTO Manual for Bridge Evaluation: This provides a structured approach to bridge evaluation, including rating procedures for structural elements and determining the overall bridge condition rating. I regularly use this manual to classify the structural condition of bridges and recommend necessary maintenance or repairs.

- State-Specific Codes and Guidelines: While AASHTO provides a baseline, many states have supplementary codes and guidelines that I’m well-versed in applying. This ensures compliance with all relevant regulations. For example, I’ve worked on projects that required adherence to both AASHTO standards and specific requirements from the California Department of Transportation (Caltrans).

My experience extends beyond simply knowing these standards; I can interpret their implications, adapting the inspection process to the specific needs of each project while always ensuring compliance.

Q 17. How do you handle unexpected findings during a bridge inspection?

Unexpected findings during a bridge inspection are routine occurrences. My response is always systematic and prioritizes safety:

- Immediate Documentation: Thoroughly document the unexpected finding, including location, type, severity, and any immediate safety concerns. I use high-resolution photos and detailed written descriptions.

- Safety Assessment: Determine whether the finding poses an immediate safety hazard, such as significant cracking or deterioration that could lead to immediate failure. If necessary, I initiate immediate traffic control or closure measures.

- Preliminary Assessment: Perform a preliminary assessment to determine the potential extent and severity of the problem. This may involve additional testing or further visual inspection.

- Communication: Immediately report the finding to the appropriate stakeholders, including the project engineers, bridge owners, and relevant authorities. This is a critical step, ensuring prompt and appropriate action.

- Follow-up Actions: Based on the assessment, develop a plan for further investigation and remediation. This could range from additional inspections to more extensive investigations involving structural analysis and potential repair recommendations.

For example, during one inspection, I discovered a previously undocumented crack in a critical support member. Following the steps above, I immediately notified the relevant parties, temporarily reduced the load capacity of the bridge, and arranged for further investigations leading to timely and effective repair.

Q 18. Explain your familiarity with bridge load rating methodologies.

I have extensive experience with bridge load rating methodologies. This involves determining the load-carrying capacity of a bridge based on its current structural condition. My understanding encompasses various methods, including:

- Inventory Rating: This method uses the initial design specifications and considers the bridge’s age and deterioration. It’s a relatively simpler assessment focusing on whether the bridge can carry its current loads.

- Operating Rating: A more detailed evaluation considering the current condition of the bridge members and the effects of deterioration. It determines the bridge’s capacity for the present operating loads.

- Analytical Rating: This involves performing detailed structural analysis using software to determine the bridge’s load-carrying capacity. It’s more complex and computationally intensive but provides a more accurate assessment.

I am proficient in using specialized software packages to perform analytical load rating, accounting for factors like material degradation, geometry changes, and the presence of any damage. I understand the various load combinations and factors of safety required by codes such as AASHTO to ensure the reliability and safety of the bridge.

Q 19. How do you communicate inspection findings to non-technical stakeholders?

Communicating complex technical information to non-technical stakeholders requires clear and concise language, avoiding jargon. I use several strategies:

- Visual Aids: I utilize photos, diagrams, and charts to illustrate key findings and their locations on the bridge. A picture of a crack, for example, is far more effective than a technical description.

- Analogies: I often use analogies to relate technical concepts to everyday experiences. For instance, I might compare the deterioration of concrete to rusting in a car.

- Simplified Language: I avoid technical terms whenever possible, replacing them with straightforward explanations. Instead of saying ‘deck delamination,’ I might say ‘separation of layers in the bridge deck’.

- Prioritization: I focus on conveying the most critical information first, highlighting the safety implications and the urgency of any necessary actions.

- Summary Reports: I prepare concise summary reports containing the key findings and recommendations, with appendices for those who want detailed technical information.

The goal is to empower stakeholders with the information they need to make informed decisions without being overwhelmed by technical details.

Q 20. Describe your experience in developing bridge inspection plans.

Developing a bridge inspection plan is a crucial initial step. My approach ensures a systematic and comprehensive evaluation. This involves:

- Bridge-Specific Information Gathering: I begin by collecting all available information on the bridge, including its design specifications, construction history, past inspection reports, and any known issues.

- Risk Assessment: I conduct a thorough risk assessment, identifying potential hazards and areas requiring special attention, such as areas with known previous problems or those susceptible to environmental degradation.

- Inspection Scope Definition: Based on the risk assessment and relevant standards (like AASHTO), I define the scope of the inspection, specifying which elements need detailed examination and the frequency of inspection for each component.

- Inspection Methodology Selection: I select appropriate inspection methods and equipment based on the bridge’s type, materials, and accessibility. This might involve visual inspection, non-destructive testing, or a combination of both.

- Resource Allocation: I estimate the time, personnel, and equipment required for the inspection. This includes considerations for safety measures and potential access challenges.

- Documentation Procedures: I outline procedures for data collection, documentation, and report generation to ensure consistency and compliance with standards.

The resulting plan acts as a roadmap, ensuring a thorough and efficient inspection process that addresses specific risks and complies with all relevant regulations.

Q 21. How do you ensure consistency in inspection data collection?

Ensuring consistency in inspection data collection is paramount for accurate assessment and effective long-term monitoring. My approach focuses on:

- Standardized Forms and Procedures: I use standardized data collection forms and checklists, ensuring all inspectors follow the same procedures and collect consistent data. This ensures that data collected across multiple inspections can be compared meaningfully.

- Training and Calibration: Inspectors receive thorough training on the use of inspection equipment, data collection procedures, and relevant standards. Regular calibration ensures all equipment performs as expected.

- Quality Control Checks: I implement quality control checks and peer reviews to ensure the accuracy and consistency of collected data. This may involve comparing data from multiple inspectors or cross-referencing findings with previous inspections.

- Digital Data Management: Using digital data collection devices and software allows for efficient organization and storage of inspection data, facilitating comparison over time and enabling efficient analysis. This helps highlight trends in deterioration over time, allowing for predictive maintenance planning.

- Clear Definitions and Ratings Scales: Utilizing well-defined criteria and standardized rating scales helps ensure that inspectors provide consistent assessments of the condition of bridge components. This avoids subjective interpretations and leads to more reliable conclusions.

By meticulously implementing these practices, I ensure that the collected data is reliable, repeatable, and serves as a reliable basis for decision-making regarding bridge maintenance and repair.

Q 22. How familiar are you with using drones or other advanced technologies for bridge inspections?

Drone technology has revolutionized bridge inspection. I’m highly proficient in utilizing unmanned aerial vehicles (UAVs) or drones equipped with high-resolution cameras, LiDAR, and thermal imaging for detailed bridge assessments. This allows for safer and more efficient inspections, particularly in hard-to-reach areas. For example, a drone can easily capture high-quality images of the underside of a bridge deck, revealing cracks or corrosion that might be missed during a traditional inspection. We can also use photogrammetry software to create 3D models of the bridge, allowing for precise measurements and detailed analysis of structural components. Beyond drones, I’m also familiar with other advanced technologies like ground-penetrating radar (GPR) to detect subsurface anomalies and fiber optic sensors embedded within the bridge structure for real-time monitoring of stress and strain.

Q 23. Explain your understanding of bridge rehabilitation methods.

Bridge rehabilitation methods aim to restore structural integrity and extend the service life of a bridge. These methods vary depending on the type of damage and the bridge’s material. Common methods include:

- Crack Repair: This involves cleaning the crack, filling it with epoxy or other suitable material, and sometimes adding reinforcement to prevent further propagation. This is a common fix for minor cracking in concrete decks.

- Strengthening: This can involve adding steel plates or carbon fiber reinforced polymers (CFRP) to strengthen weakened members. This is particularly useful for strengthening existing steel girders or concrete beams.

- Deck Replacement: If the deck is severely deteriorated, a complete or partial replacement might be necessary. This often involves removing the old deck and pouring a new one, sometimes incorporating pre-stressed concrete panels for enhanced durability.

- Substructure Repair: This involves addressing issues with the bridge’s foundations, abutments, and piers. This could range from minor repairs to complete reconstruction, depending on the severity of the damage. Methods include grouting, underpinning, and even replacing damaged foundation elements.

The selection of the most appropriate method often involves a detailed engineering assessment and cost-benefit analysis.

Q 24. What are some common signs of fatigue in bridge steel members?

Fatigue in bridge steel members is a critical concern, leading to premature failure if left unaddressed. Common signs include:

- Fatigue Cracks: These are typically small cracks that initiate at stress concentration points, such as weld toes, holes, or changes in cross-section. They often appear as fine, hairline cracks, and their progression is often unpredictable.

- Crack Propagation: As fatigue progresses, cracks grow longer and wider, potentially leading to failure. The presence of multiple cracks or cracks that are increasing in length is a significant red flag.

- Surface Deformation: Fatigue can cause slight bulging or distortion of the steel member near the crack. This is subtle but detectable during close visual inspection.

- Loss of Stiffness: Although difficult to detect without specialized testing, advanced fatigue can lead to a reduction in the overall stiffness of the member.

Identifying these signs early is crucial, and often requires a combination of visual inspection, non-destructive testing (NDT) techniques such as ultrasonic testing (UT), and advanced fatigue analysis.

Q 25. Describe your understanding of corrosion mechanisms affecting bridges.

Corrosion is a major threat to bridge longevity, particularly in steel structures. The most common corrosion mechanisms affecting bridges include:

- Atmospheric Corrosion: This is caused by exposure to oxygen, moisture, and pollutants in the air. Rust formation is the most visible manifestation of atmospheric corrosion.

- Chloride-Induced Corrosion: Chlorides from de-icing salts penetrate concrete and reach reinforcing steel, accelerating corrosion. This is a significant problem in cold-climate regions.

- Carbonation: Carbon dioxide in the air reacts with concrete’s calcium hydroxide, reducing its pH and making it less protective of embedded steel. This leads to corrosion initiation.

- Stray Current Corrosion: This occurs when stray electrical currents from nearby sources, like electric railway systems, flow through the bridge structure, accelerating corrosion in specific areas.

Understanding these mechanisms is critical for implementing appropriate preventative measures and effective corrosion mitigation strategies, such as cathodic protection or proper coating applications.

Q 26. How would you identify and assess the condition of bridge abutments?

Assessing the condition of bridge abutments requires a thorough inspection, focusing on both the substructure and superstructure elements. My approach involves:

- Visual Inspection: Checking for cracks, spalling, erosion, settlement, scour (erosion of soil around the abutment), and signs of distress in the abutment’s structural elements.

- Non-Destructive Testing (NDT): Employing techniques like ground-penetrating radar (GPR) to assess the foundation’s integrity, ultrasonic testing to check for internal defects in concrete, and chain dragging to locate potential voids behind the abutment.

- Documentation: Detailed photographic and video documentation is essential for recording the observed damage and supporting any subsequent repair recommendations. Measurements of cracks and settlement are also critical.

- Load Testing (if necessary): In cases where significant damage is suspected or load capacity is in question, load testing may be conducted to quantitatively assess the abutment’s performance.

For instance, significant settlement might indicate foundation issues, whereas cracks in the abutment wall could signify structural weakness. Careful evaluation of these observations guides corrective actions, from minor repairs to major reconstruction.

Q 27. Explain your approach to managing a complex bridge inspection project.

Managing a complex bridge inspection project necessitates a systematic and well-organized approach. My strategy involves:

- Planning & Scoping: Defining the project objectives, scope of work, and timeline. This includes identifying the bridge’s specific characteristics and potential challenges.

- Team Assembly: Gathering a skilled team with expertise in various disciplines like structural engineering, inspection techniques, and documentation.

- Resource Allocation: Securing necessary equipment, including drones, scaffolding, NDT devices, and software for data analysis.

- Inspection Execution: Following a structured inspection protocol, adhering to safety regulations, and meticulously documenting findings.

- Data Analysis & Reporting: Analyzing the collected data to assess the bridge’s condition and prepare a comprehensive report detailing findings, including recommendations for repair or maintenance.

- Communication & Collaboration: Maintaining open communication with clients, stakeholders, and team members throughout the project lifecycle.

A crucial aspect is risk management. This involves identifying potential hazards during the inspection process and developing mitigation strategies to ensure the safety of the inspection team and the public.

Q 28. How do you stay current with advancements in bridge inspection technologies and techniques?

Staying current in this dynamic field requires continuous professional development. I actively participate in:

- Professional Conferences and Workshops: Attending industry conferences and workshops to learn about the latest technologies and best practices.

- Continuing Education Courses: Engaging in continuing education courses focusing on advanced inspection techniques, NDT methods, and software applications.

- Professional Organizations: Being a member of relevant professional organizations (e.g., ASCE, PCI) provides access to technical publications, updates, and networking opportunities.

- Literature Reviews: Regularly reviewing technical journals and research papers to stay abreast of advancements in bridge engineering and inspection technologies.

- Software Training: Keeping up-to-date with advancements in software for data analysis, 3D modeling, and report generation.

By consistently pursuing professional development, I ensure my expertise remains relevant and effective in tackling the complexities of modern bridge inspection.

Key Topics to Learn for Bridge Inspection Procedures Interview

- Visual Inspection Techniques: Understanding different inspection methods, including close-range visual inspection, remote sensing techniques (e.g., drones), and the use of specialized equipment.

- Structural Assessment: Analyzing bridge components (decks, girders, piers, abutments) for signs of distress like cracking, corrosion, spalling, and deflection. Practical application: Knowing how to interpret inspection data and identify potential safety hazards.

- Load Rating and Capacity Analysis: Understanding how to assess a bridge’s ability to safely carry its intended loads. This includes familiarity with load rating methodologies and relevant standards.

- Documentation and Reporting: Mastering the proper procedures for documenting inspection findings, including detailed reports, photographs, and sketches. Knowing how to effectively communicate findings to engineers and decision-makers.

- Safety Procedures and Regulations: Thorough understanding of safety protocols for bridge inspectors, including personal protective equipment (PPE), work zone safety, and compliance with relevant regulations.

- Common Bridge Defects and Repair Methods: Familiarity with common bridge defects and appropriate repair techniques. This includes understanding the causes, consequences, and potential solutions for various types of damage.

- Software and Technology for Bridge Inspection: Proficiency with relevant software and technologies used in bridge inspection, such as data management systems, bridge modeling software, and potentially drone operation software.

- Legal and Regulatory Compliance: Understanding the legal and regulatory framework surrounding bridge inspections, including reporting requirements and liability considerations.

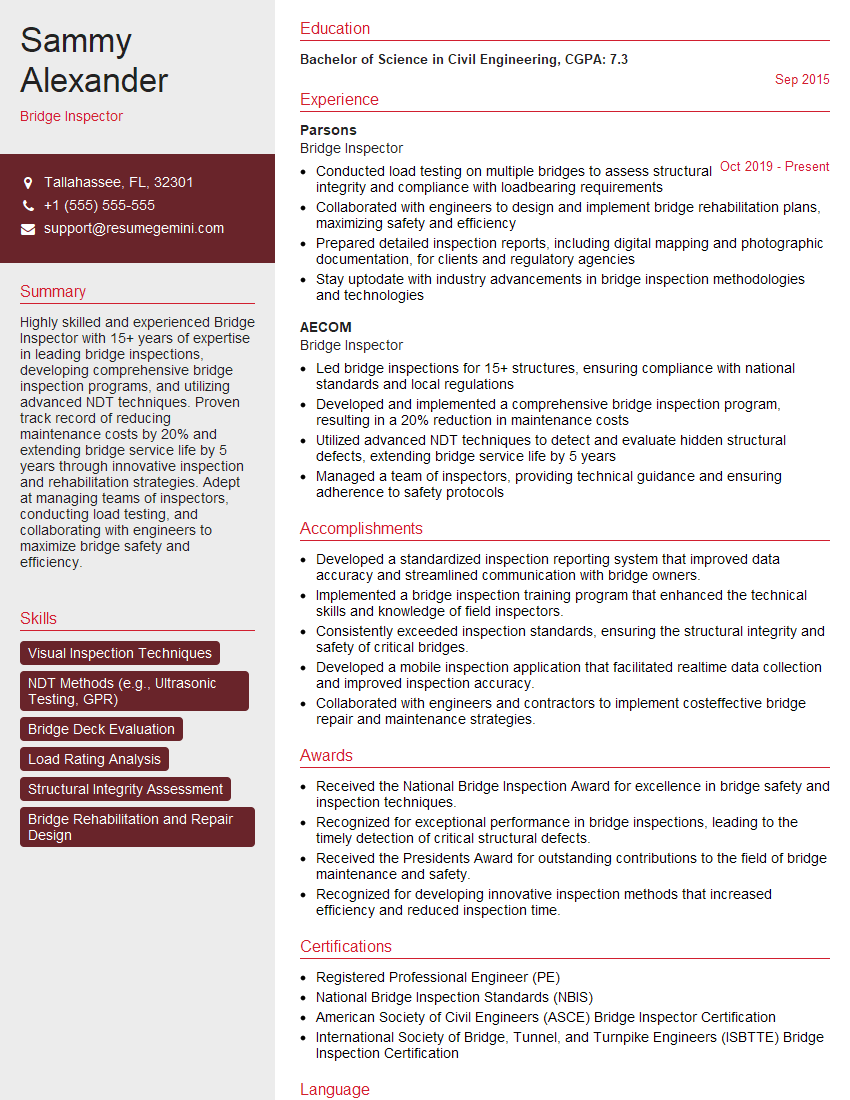

Next Steps

Mastering Bridge Inspection Procedures is crucial for career advancement in the civil engineering and infrastructure management fields. It demonstrates a commitment to safety, technical expertise, and a dedication to maintaining critical infrastructure. To significantly boost your job prospects, it’s essential to craft a resume that Applicant Tracking Systems (ATS) can easily read and understand. ResumeGemini can help you build a professional and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes specifically tailored to the Bridge Inspection Procedures field, ensuring your application stands out. Take the next step in your career journey – invest in creating a winning resume today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?