Cracking a skill-specific interview, like one for Knowledge of Dyeing Principles, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Knowledge of Dyeing Principles Interview

Q 1. Explain the difference between direct and reactive dyes.

Direct dyes and reactive dyes are both used to color fabrics, but they differ significantly in how they bind to the fibers. Direct dyes, also known as substantive dyes, possess a high affinity for the fiber but only achieve a physical bond. Think of it like a magnet weakly attracting another magnet – the dye is attracted to the fiber, but the bond isn’t particularly strong. This means that the color is easily washed out, unless additional treatments are applied. Reactive dyes, on the other hand, form a covalent bond with the fiber, creating a much stronger and more permanent link. Imagine it as two puzzle pieces locking together – the dye chemically reacts with the fiber, making it extremely colorfast and resistant to washing.

In short: Direct dyes rely on physical attraction, leading to poor washfastness, while reactive dyes form strong chemical bonds resulting in excellent washfastness. Reactive dyes are commonly used for cotton, linen, and other cellulosic fibers, while direct dyes find applications in dyeing cellulosic fibers, as well as wool and silk, though they often require aftertreatments for better colorfastness.

Q 2. Describe the process of dyeing cotton fabric using vat dyes.

Vat dyeing is a fascinating process used primarily to dye cellulosic fibers like cotton with insoluble dyes. These dyes, in their original form, are not soluble in water, making direct application impossible. The process involves several key steps:

- Reduction: The insoluble dye is reduced in an alkaline solution, typically containing a reducing agent like sodium dithionite (also known as sodium hydrosulfite). This process converts the insoluble dye into its soluble, leuco form. Think of it as transforming a solid into a liquid that can then penetrate the fibers. This is usually performed in a large vat, giving the process its name.

- Dyeing: The reduced, soluble dye is then applied to the fabric. The fabric absorbs the soluble leuco form efficiently because it’s able to move through the spaces in the cotton fibers.

- Oxidation: After dyeing, the fabric is exposed to air or an oxidizing agent, which reverses the reduction process. This converts the soluble leuco form back into its original, insoluble form. The dye now becomes trapped inside the fibers, creating a permanent color that is resistant to washing and many other treatments. This step is crucial as it locks the dye within the fiber.

- Washing and soaping: Finally, the fabric is washed thoroughly to remove any residual dye or chemicals. Soaping may also be included to enhance color uniformity and improve the overall finish.

This multi-step process may seem complex, but it allows us to use vibrant and durable colors that would otherwise be impossible to apply directly.

Q 3. What are the key factors influencing dye uptake?

Dye uptake, the amount of dye absorbed by the fabric, is influenced by a multitude of factors. Key among these are:

- Fiber type and structure: Different fibers have different affinities for dyes. Cotton, for example, will interact with dyes differently than wool or silk due to their molecular structures.

- Dye properties: The chemical structure of the dye itself dictates its solubility, affinity for the fiber, and the resulting color. Some dyes have a greater attraction towards fibers than others.

- Dye concentration: Higher dye concentrations will lead to deeper shades, provided the fiber can absorb the dye.

- Temperature: Dyeing at elevated temperatures usually promotes faster diffusion of the dye into the fiber, increasing the uptake.

- pH of the dye bath: The acidity or alkalinity of the solution (pH) can significantly influence dye solubility and its ability to bind to the fiber.

- Electrolyte concentration: Salts, such as sodium chloride, can influence the uptake of anionic dyes. The presence of electrolytes shields the negatively charged dye molecules from mutual repulsion, allowing increased dye uptake into the negatively charged fibers.

- Time: Sufficient time must be allocated for the dye to fully penetrate and bond with the fibers.

Understanding and controlling these factors is essential for achieving consistent and reproducible dyeing results.

Q 4. How do you achieve colorfastness in dyed fabrics?

Colorfastness, the ability of a dyed fabric to resist color loss or change under various conditions, is crucial for ensuring the quality and durability of the final product. It is achieved through several methods:

- Choosing the right dye: Selecting a dye with high inherent washfastness, lightfastness, and other relevant properties is the first crucial step. Reactive dyes, for example, are known for their excellent washfastness.

- Proper dyeing techniques: Adhering to the correct dyeing parameters – temperature, time, pH, etc. – ensures optimal dye uptake and minimizes color bleeding.

- Aftertreatments: Applying aftertreatments such as fixing agents helps to bond the dye to the fiber more permanently. These agents can form cross-links with dye molecules, resulting in improved colorfastness.

- Washing and rinsing: Careful washing and rinsing after dyeing removes unbound dye, reducing the likelihood of color loss during subsequent washing.

- Finishing treatments: Applying a resin finish or other surface treatments helps protect the dyed color from abrasion and other external factors, enhancing the longevity of the fabric.

Colorfastness testing is a common procedure in the textile industry to assess various performance parameters. These tests simulate real-world conditions, helping textile manufacturers to achieve the desired level of durability.

Q 5. Explain the concept of color matching and its importance.

Color matching is the process of replicating a specific color on a fabric using dyes. Its importance lies in ensuring consistency and meeting customer expectations, particularly in large-scale production. Imagine a clothing manufacturer aiming to produce thousands of shirts with a specific shade of blue. Without precise color matching, the resulting shirts might exhibit significant variations in color, making them unacceptable to the customer.

The process involves comparing the target color (sample or standard) with the dyed fabric using spectrophotometers or colorimeters. Dye recipes are carefully formulated and adjusted until the desired color match is achieved. Factors like the dye’s concentration, the substrate, and other dyeing parameters need precise control.

Accurate color matching is essential for maintaining brand image, meeting customer specifications, and avoiding costly production errors.

Q 6. What are the common methods for color measurement and assessment?

Color measurement and assessment involve quantifying and analyzing color properties objectively. Several common methods are employed:

- Spectrophotometry: Spectrophotometers measure the reflectance or transmittance of light across the visible spectrum. This data provides a detailed profile of the color’s composition, allowing precise color comparisons and matching. These provide objective and quantifiable color data, enabling accurate color management.

- Colorimetry: Colorimeters use standard color spaces (e.g., CIE L*a*b*) to quantify color differences between samples. The CIE L*a*b* system describes colors in terms of lightness (L*), redness/greenness (a*), and yellowness/blueness (b*), providing a numerical way to assess the difference between colors.

- Visual assessment: While subjective, visual assessment by trained personnel remains important, particularly for identifying subtle metameric matches (colors that look the same under one light source but differ under another).

These methods allow for accurate communication of color requirements, monitoring color consistency, and resolving color discrepancies in production.

Q 7. Describe different types of dyeing machines and their applications.

Various dyeing machines are used depending on the fabric type, dye class, and production scale. Here are some examples:

- Jet dyeing machines: These high-speed machines use a high-velocity flow of dye liquor to achieve rapid and uniform dyeing of fabrics. Ideal for large production volumes of lightweight fabrics like knitted garments.

- Beam dyeing machines: Fabric is wound onto a perforated beam, allowing the dye liquor to circulate through the fabric. Used for dyeing woven fabrics in continuous operation.

- Pad dyeing machines: The fabric is saturated with dye liquor using rollers, achieving high production speeds, typically used for low-cost and large-volume applications.

- Winch dyeing machines: This machine employs a winch mechanism that continuously moves the fabric through the dye liquor, ensuring thorough penetration. Well-suited for high-quality, even dyeing of woven and knitted fabrics, especially those that need a more controlled process.

- Jigger dyeing machines: These machines involve moving the fabric back and forth in a dye bath, commonly used for dyeing longer lengths of fabric. Used for dyeing delicate fabrics and producing high-quality dyeing results.

The choice of dyeing machine is crucial to achieving the optimal balance between efficiency, quality, and cost-effectiveness.

Q 8. How do you troubleshoot dye application problems such as uneven dyeing?

Uneven dyeing, often manifesting as streaks or blotches, is a common problem with various potential causes. Troubleshooting involves a systematic approach, eliminating possibilities one by one.

Fiber Preparation: Inconsistent wetting of the fabric can lead to uneven dye uptake. Check for proper scouring and bleaching to ensure the fabric is clean and receptive to dye. Insufficient wetting agents in the dye bath can also contribute to this.

Dyeing Process: Problems might stem from inadequate liquor ratio (the ratio of dye bath to fabric weight), insufficient agitation (leading to dye concentration differences), or temperature variations during the dyeing process. For example, a low liquor ratio can result in dye depletion in areas where the fabric is denser, causing uneven color.

Dye Bath Exhaustion: The dye’s exhaustion rate (how much dye is absorbed by the fabric) can affect uniformity. If the exhaustion is low, it could indicate issues with dye solubility, pH, or the presence of interfering substances.

Fabric Properties: The fabric itself may contribute. Differences in fiber maturity, yarn structure, or fabric construction can lead to variations in dye uptake. For example, a loosely woven fabric might exhibit uneven dyeing compared to a tightly woven one.

Equipment Issues: Malfunctioning dyeing equipment, such as uneven jet flow in a jet dyeing machine, can contribute to uneven dye distribution.

Troubleshooting Steps: Begin by examining the fabric’s preparation. Next, review the dyeing process parameters: liquor ratio, temperature profile, agitation speed, and dye concentration. Finally, consider the dyeing equipment’s condition. A controlled experiment by dyeing a sample with varied parameters can pinpoint the root cause.

Q 9. What are the environmental considerations in dyeing processes?

Environmental considerations in dyeing are paramount due to the significant water and energy consumption, and the potential release of harmful chemicals. Minimizing environmental impact requires a multi-pronged approach.

Water Conservation: Implementing techniques like low liquor ratio dyeing, improved water recycling systems, and efficient water treatment processes are crucial. The use of closed-loop systems helps reduce the discharge volume.

Energy Efficiency: Utilizing energy-efficient dyeing equipment, optimizing dyeing parameters to reduce processing time, and recovering waste heat from the process can significantly decrease energy consumption.

Wastewater Treatment: Effective wastewater treatment is essential to remove or neutralize harmful chemicals such as dyes, salts, and auxiliaries before discharge. This often involves biological, chemical, or physical treatments.

Dye Selection: Opting for environmentally friendly dyes, such as low-impact reactive dyes or natural dyes, can reduce the environmental burden. These options often require less harsh treatment conditions and produce less wastewater.

Auxiliary Chemicals: Utilizing environmentally friendly auxiliaries with low toxicity and biodegradability is key. Selecting auxiliaries with minimal environmental impact is critical.

Regulations are becoming increasingly stringent globally. Compliance with these regulations and proactive environmental management are essential for sustainability in the dyeing industry.

Q 10. Explain the role of different auxiliaries in dyeing (e.g., wetting agents, dispersing agents).

Auxiliaries play a crucial role in optimizing dyeing processes. They don’t impart color themselves but significantly influence dye uptake, leveling, and overall dye bath performance.

Wetting Agents: These reduce the surface tension of water, enabling faster and more uniform wetting of the fabric. This prevents uneven dye penetration, a common cause of dyeing defects. Think of it like adding dish soap to water – it allows the water to spread more easily.

Dispersing Agents: These keep insoluble dyes (like disperse dyes used for polyester) finely dispersed in the dye bath, preventing aggregation and ensuring uniform dye distribution on the fiber. They essentially keep the dye particles from clumping together.

Leveling Agents: These assist in achieving even dye distribution by slowing down the dye absorption rate in the initial stages of dyeing. They help prevent the dye from quickly attaching itself to the more accessible fiber regions, allowing for better penetration.

pH Control Agents: Maintaining the correct pH of the dye bath is critical for many dye classes. Acids or alkalis (buffers) can be used to adjust pH to the optimum level required for dye absorption.

Penetration Agents: These chemicals enhance the penetration of the dye into the fiber, particularly useful for dense fabrics. They assist the dye molecules in reaching the interior portions of the fibers.

The selection of auxiliaries depends on the fiber type, dye class, and desired dyeing outcome. Incorrect selection or dosage can lead to poor dye uptake, uneven dyeing, or reduced wash fastness.

Q 11. How do you determine the appropriate dye concentration for a specific fabric?

Determining the appropriate dye concentration involves a combination of lab tests and experience. The goal is to achieve the desired shade with optimal dye exhaustion while minimizing dye costs and environmental impact.

Lab Dyeing Trials: Small-scale dyeing trials are conducted using varying dye concentrations. These trials use standardized conditions (temperature, time, liquor ratio) to assess the resulting shade and dye exhaustion.

Colorimetric Measurement: Instruments like spectrophotometers measure the color of the dyed fabric, allowing precise quantification and comparison across different dye concentrations. This allows for quantitative assessment of shade and reproducibility.

Dye Exhaustion Measurement: Measuring the amount of dye remaining in the bath after dyeing provides a quantitative measure of how effectively the dye was absorbed by the fabric.

Experience and Data: Experienced dyers rely on their knowledge of specific dyes, fibers, and dyeing equipment. Databases of past dyeing recipes can also assist in determining suitable dye concentrations for similar fabrics.

The process often involves iterative adjustments. Initial trials help establish a range of appropriate concentrations, further refined based on colorimetric and exhaustion data to obtain the desired shade and optimized exhaustion.

Q 12. Describe the wash fastness and light fastness testing procedures.

Wash fastness and light fastness are crucial indicators of dye quality and fabric durability. Testing procedures are standardized to ensure consistent evaluation.

Wash Fastness: This assesses the color’s resistance to washing. Standard test methods involve washing dyed fabric samples under controlled conditions (temperature, detergent concentration, time) and comparing their color change (ΔE) against a control sample that wasn’t washed. A higher ΔE indicates poorer wash fastness.

Light Fastness: This assesses the color’s resistance to fading caused by exposure to light. Samples are exposed to controlled light sources (xenon arc lamps are common) for specific durations, and their color change is compared to a control. The results are often expressed using a grading scale (e.g., 1-8, where 8 represents excellent light fastness).

These tests are performed using standardized equipment and procedures. The results are essential for meeting quality standards and informing consumers about the fabric’s durability. ISO and AATCC standards offer detailed guidelines on these testing procedures.

Q 13. What are the different methods for preparing fabrics for dyeing?

Fabric preparation is a critical step before dyeing. Its goal is to ensure the fabric is clean, free of impurities, and optimally receptive to the dye.

Scouring: This process removes natural impurities such as waxes, pectins, and oils from fibers like cotton, wool, and silk. It often involves treatment with alkali (like sodium hydroxide) and detergents.

Bleaching: This removes discoloration from the fabric, ensuring a consistent base color before dyeing. Hydrogen peroxide is a commonly used bleaching agent for various fibers.

Singeing: This process burns off protruding fiber ends, resulting in a smoother fabric surface and improved dye penetration. It is frequently applied to cotton and other natural fibers.

Desizing: For fabrics that have been sized (treated with starch or other substances to improve weaving properties), desizing removes these substances before dyeing to prevent uneven dye uptake.

Mercerization: Used for cotton, this treatment with strong alkali enhances the fabric’s luster, strength, and dye affinity, leading to improved color yield and evenness.

The specific preparation methods vary depending on the fabric type and the subsequent dyeing process. Proper preparation is crucial for achieving high-quality dyeing results.

Q 14. Explain the concept of exhaustion in dyeing.

Exhaustion in dyeing refers to the percentage of dye from the bath that is absorbed by the fabric. A high exhaustion rate is generally desirable, indicating efficient dye utilization and minimized dye loss in wastewater.

It’s expressed as a percentage:

Exhaustion (%) = [(Initial dye concentration - Final dye concentration) / Initial dye concentration] * 100

For instance, if the initial dye concentration is 10g/L and the final dye concentration after dyeing is 2g/L, the exhaustion is 80%. This means 80% of the dye from the bath was absorbed by the fabric.

Factors that influence exhaustion include dye type, fiber type, dyeing temperature, pH, liquor ratio, and the presence of auxiliaries. Optimizing these factors is key to achieving high exhaustion and minimizing environmental impact.

Q 15. How do you manage dye inventory and control costs?

Dye inventory management and cost control are crucial for profitability in dyeing. It’s a multi-faceted approach combining careful forecasting, efficient storage, and rigorous waste reduction strategies.

Forecasting Demand: Accurate prediction of dye requirements based on production schedules and upcoming orders is paramount. This minimizes overstocking, which leads to dye degradation and obsolescence, while preventing stockouts that halt production.

Efficient Storage: Proper storage conditions are vital for preserving dye quality. Dyes should be stored in a cool, dry, dark place, away from direct sunlight and humidity, following manufacturer recommendations. Implementing a FIFO (First-In, First-Out) system ensures that older dyes are used first, reducing the risk of spoilage.

Waste Reduction: Minimizing dye waste is critical both environmentally and economically. This involves precise dye recipe formulation, efficient dye application techniques (like using precise metering pumps), and effective dye bath recycling/recovery systems. Regular training for dye house personnel on best practices is key.

Negotiating with Suppliers: Building strong relationships with reliable dye suppliers can yield significant cost advantages through bulk purchasing, negotiated pricing, and access to preferred payment terms.

Regular Inventory Audits: Conducting regular physical inventory checks against the inventory management system ensures accuracy and helps to identify discrepancies or potential issues early on.

For example, in one project, we implemented a new dye management software which improved our forecasting accuracy by 15%, leading to a direct reduction in dye waste and a 10% decrease in overall dye costs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different fiber types and their dyeing characteristics.

My experience encompasses a wide range of fiber types, each presenting unique dyeing challenges and opportunities. Understanding these characteristics is crucial for achieving consistent and high-quality results.

Cotton: Cotton, a cellulosic fiber, readily accepts direct, reactive, and vat dyes. Its affinity for dye is high, requiring careful control of dye concentration and application time to avoid uneven dyeing.

Wool: Wool, a protein fiber, is more sensitive to high temperatures and requires milder dyeing conditions. Acid dyes are commonly used, and achieving level dyeing requires precise pH control and careful monitoring of the dyeing process.

Polyester: Polyester, a synthetic fiber, requires high temperatures (often above boiling point) and the use of disperse dyes. Carrier dyes can be used to enhance dye uptake. Careful temperature control is crucial to achieve even coloration and avoid fiber damage.

Silk: Silk, another protein fiber, is delicate and requires gentle dyeing techniques. Acid dyes are frequently used, and special care needs to be taken to avoid damaging the delicate fiber structure.

Nylon: Nylon is a synthetic fiber that can be dyed with acid, disperse, and reactive dyes depending on the desired shade and fastness properties. The choice of dye and dyeing method significantly impacts the final result.

I’ve worked extensively with blends, such as cotton/polyester, which often involve multi-stage dyeing processes using different dyes compatible with each fiber type. The order of dyeing is essential and depends upon the specific dye types and the desired final color.

Q 17. Explain the differences between dyeing natural and synthetic fibers.

The primary differences in dyeing natural and synthetic fibers stem from their chemical structures and how they interact with dyes.

Natural Fibers (Cellulosic & Protein): These fibers contain numerous reactive sites that readily bind with dyes. Cellulosic fibers (cotton, linen) primarily use direct, reactive, and vat dyes. Protein fibers (wool, silk) utilize acid dyes. Dyeing processes often involve lower temperatures and pressures.

Synthetic Fibers (Polyester, Nylon, Acrylic): Synthetic fibers have fewer reactive sites and require different dye classes. Disperse dyes are commonly used for polyester; their smaller molecules can penetrate the fiber’s structure. Higher temperatures and pressures are often necessary to achieve sufficient dye uptake.

For example, dyeing cotton with a reactive dye forms a strong covalent bond between the dye and the fiber, leading to high wash fastness. In contrast, dyeing polyester with disperse dyes involves physical absorption, and the fastness properties depend heavily on the dyeing temperature and the type of disperse dye used. This difference significantly impacts the cost, time, and environmental impact of the dyeing process.

Q 18. What are the common defects encountered in dyeing and how are they addressed?

Common dyeing defects can significantly impact the quality of the final product. Addressing these promptly and effectively is vital.

Uneven Dyeing (Crocking): This manifests as streaks or blotches of color. Causes include inadequate dye penetration, inconsistent dye application, or insufficient fiber preparation. Solutions include improved dye mixing, better control of dyeing parameters (temperature, pH, time), and pre-treatment of the fabric to enhance dye uptake.

Poor Color Fastness: This is the inability of the dyed fabric to resist fading, crocking (rubbing), or washing. Improper dye selection, incorrect dyeing parameters, or inadequate after-treatment (e.g., washing or fixing) are potential causes. Solutions involve selecting appropriate dyes with good fastness properties, optimizing dyeing conditions, and performing thorough after-treatments.

Color Shade Variation (Metamerism): This occurs when the dyed fabric appears to be a different shade under various light sources. Selecting dyes that are spectrally similar and implementing strict color control procedures are crucial to minimize this. Using spectrophotometers for precise color matching helps alleviate this issue.

Fiber Damage: Harsh dyeing conditions can damage fibers, leading to weakened fabric. Careful control of temperature, pH, and chemicals are essential. Using appropriate dyeing auxiliaries and protective agents can mitigate fiber damage.

Troubleshooting dyeing defects often requires a systematic approach, involving analyzing the defect, identifying the potential causes, and implementing corrective measures. Careful record-keeping throughout the dyeing process aids in this diagnosis.

Q 19. Describe your experience with quality control procedures in dyeing.

Quality control (QC) in dyeing is paramount to ensure consistent color, fastness, and overall fabric quality. My experience involves a multi-stage QC approach.

Incoming Raw Material Inspection: Checking the quality of incoming dyes, chemicals, and fibers before use is vital. This involves verifying their properties against specifications and conducting any necessary testing.

In-Process Monitoring: Continuously monitoring dyeing parameters (temperature, pH, time, dye concentration) during the dyeing process is critical. This often involves using automated monitoring systems to ensure consistent conditions. We utilize spectral analysis during the dyeing process to monitor the dye uptake rate. This allows us to make timely adjustments to maintain consistency.

Final Product Inspection: Thorough inspection of the dyed fabric after the dyeing process is complete is crucial. This involves assessing aspects such as color uniformity, fastness to washing, rubbing, and light, and adhering to pre-established quality standards.

Color Measurement and Matching: Using spectrophotometers to accurately measure and match colors is an integral part of QC. This ensures consistent color reproduction across different batches and minimizes shade variations.

Documentation and Record Keeping: Maintaining detailed records of all dyeing processes, including parameters, dye batches used, and test results, allows for traceability and helps identify the root cause of any quality issues.

A well-defined QC system, combined with regular training and updates for the dyeing personnel, is critical for ensuring high quality and consistency in our dyed products. We use statistical process control (SPC) techniques to identify potential issues before they affect the final product.

Q 20. Explain the importance of pH control in dyeing.

pH control is crucial in dyeing because it significantly impacts dye solubility, dye uptake, and the overall dyeing process. The optimal pH varies depending on the type of dye and fiber being used.

Dye Solubility: Many dyes are pH-sensitive, meaning their solubility and ability to diffuse into the fiber depend on the pH of the dye bath. An incorrect pH can lead to precipitation of the dye, resulting in uneven dyeing.

Dye Uptake: The pH affects the ionization of both the dye and the fiber, influencing the interaction between them and therefore affecting dye uptake. A controlled pH ensures that the dye molecules bind effectively to the fiber.

Dye Fastness: pH can affect the fastness properties of the dye, such as its resistance to washing and light. A carefully controlled pH helps enhance the fastness characteristics of the dyed fabric.

Fiber Damage: Extreme pH levels (highly acidic or alkaline) can damage the fiber structure, leading to degradation and weakening of the fabric. Careful pH control safeguards the fabric.

For instance, dyeing wool with acid dyes requires a slightly acidic pH (typically around 5-6) to ensure proper dye uptake and prevent fiber damage. Conversely, dyeing cotton with reactive dyes may involve adjusting the pH to optimize the reaction between the dye and the cellulose fiber. pH meters and automated control systems are widely employed to maintain the desired pH throughout the dyeing process.

Q 21. How do you handle dyeing emergencies or process disruptions?

Dyeing emergencies and process disruptions require a swift, methodical response to minimize production downtime and prevent further damage. My approach involves:

Immediate Assessment: Quickly assess the nature and extent of the disruption, determining the root cause if possible.

Safety First: Prioritize the safety of personnel. If there is a chemical spill or equipment malfunction, follow established safety protocols and emergency procedures.

Problem Isolation: Isolate the affected area to prevent the problem from spreading. If a dye bath is contaminated, for example, it needs to be isolated immediately to prevent further issues.

Corrective Actions: Implement corrective actions based on the identified cause. This may involve adjusting dyeing parameters, replacing faulty equipment, or correcting chemical imbalances.

Documentation: Thoroughly document the incident, including the cause, corrective actions taken, and any lessons learned. This informs future preventative measures.

Communication: Maintain clear communication with all relevant personnel, keeping them informed of the situation and the steps being taken to resolve it.

In one instance, a sudden power outage disrupted the dyeing process. We immediately switched to our backup generator, minimizing downtime and successfully completing the dyeing cycle without compromising product quality. This highlights the importance of having contingency plans in place.

Q 22. What are the safety precautions you would take when working with dyes and chemicals?

Safety is paramount in dyeing. Working with dyes and chemicals requires a multi-layered approach. This begins with thorough understanding of the Safety Data Sheets (SDS) for each substance used. These sheets provide crucial information on hazards, safe handling, and emergency procedures.

- Personal Protective Equipment (PPE): This is non-negotiable. This includes gloves (nitrile is often preferred), eye protection (goggles or face shields), and appropriate respiratory protection (depending on the dye and process, this might range from a simple dust mask to a respirator). Lab coats or protective clothing are also essential to prevent skin contact and clothing contamination.

- Ventilation: Many dyes and chemicals release volatile organic compounds (VOCs) which are harmful when inhaled. Adequate ventilation, either through exhaust systems or working in well-ventilated areas, is vital.

- Spill Response: Having a pre-planned spill response procedure is crucial. This includes knowing the appropriate absorbent materials for different spills, the neutralization methods for specific chemicals, and the proper disposal procedures.

- Hygiene: Regular handwashing is crucial before and after handling dyes and chemicals. Eating, drinking, and smoking should be strictly prohibited in dyeing areas.

- Emergency Procedures: Knowing the location of safety showers, eyewash stations, and emergency exits is critical. All personnel should be trained in emergency procedures.

For example, when working with reactive dyes, which are known to be skin irritants, I always ensure I’m wearing nitrile gloves, a lab coat, and eye protection. I also work under a well-ventilated fume hood whenever possible to minimize exposure to the dust.

Q 23. Explain your understanding of different dyeing techniques (e.g., padding, jet dyeing, etc.).

Dyeing techniques vary significantly depending on the fiber type, dye class, and desired outcome. Here are a few common methods:

- Padding: This is a continuous process where fabric is passed through a bath containing the dye and then squeezed to remove excess liquid. It’s efficient for large-scale production and works well with fiber reactive dyes. Imagine soaking a sponge in dye, then squeezing it gently—the fabric acts like the sponge, absorbing the dye.

- Jet Dyeing: This high-pressure, high-temperature process circulates dye liquor rapidly through the fabric. It ensures excellent dye penetration and levelness, particularly effective with delicate fibers like silk and wool. Think of it as a powerful, controlled ‘dye shower’ for the fabric.

- Exhaust Dyeing: This is a batch process where fabric is immersed in a dye bath at controlled temperature and pH. Dye is gradually exhausted from the solution onto the fiber. This method is versatile and often used for natural fibers.

- Piece Dyeing: In this method, the whole piece of fabric is dyed, ideal for achieving a solid or even colour across the fabric.

- Garment Dyeing: The finished garment is dyed, allowing for a more precise application of colour, particularly useful for specialized items.

The choice of technique depends on many factors. For example, delicate silk might benefit from the gentle exhaust dyeing method, while cotton might be efficiently dyed using padding. Jet dyeing is often preferred for its speed and evenness, especially in large-scale production.

Q 24. Describe your experience with digital printing technology in relation to dyeing.

Digital printing has revolutionized textile dyeing, offering unparalleled design flexibility and precision. Unlike traditional dyeing methods, which involve dyeing the entire fabric before cutting and sewing, digital printing allows for direct application of dyes onto fabric in intricate designs.

My experience includes working with inkjet printers that use reactive, disperse, or pigment inks depending on the fabric. The process involves designing the pattern using specialized software, which is then transferred to the printer. The printer jets tiny droplets of dye onto the fabric, creating high-resolution images and gradients. This technology allows for on-demand printing, reducing inventory and waste, and permits the creation of highly detailed and personalized designs.

One particular project involved digitally printing custom designs on silk scarves. The precision of digital printing allowed us to achieve sharp details and vibrant colors that would be impossible with conventional techniques. We used a reactive ink system, ensuring excellent colour fastness and wash durability.

Q 25. How do you stay updated on the latest trends and innovations in dyeing technology?

Staying abreast of the latest innovations is crucial in this rapidly evolving field. I utilize several strategies:

- Industry Publications and Journals: I regularly read publications like Textile World, American Dyestuff Reporter, and other specialized journals to keep updated on new dye chemistries, technologies, and industry trends.

- Conferences and Trade Shows: Attending industry events such as ITMA and other relevant conferences provides exposure to new technologies and networking opportunities with other professionals.

- Online Resources and Webinars: I regularly access online platforms and participate in webinars offered by dye manufacturers and textile technology companies.

- Professional Networks: Participating in professional organizations such as AATCC (American Association of Textile Chemists and Colorists) provides access to a wealth of information and expertise.

- Manufacturer’s Data Sheets and Training: Staying updated on the latest information directly from dye manufacturers through their training and literature is essential.

Continuous learning is essential in this dynamic industry. By combining these methods, I can effectively stay informed about the latest advances in dyeing technology and their practical applications.

Q 26. What are your strengths and weaknesses in relation to dyeing knowledge and skills?

Strengths: My strengths lie in my deep understanding of dye chemistry, color theory, and a broad knowledge of various dyeing techniques. I have proven expertise in troubleshooting dyeing processes and achieving consistent high-quality results. My experience with both traditional and digital printing methods is a significant asset.

Weaknesses: While I am proficient in many areas, my experience with specific niche dyeing techniques, such as high-pressure dyeing of certain specialized fibers, is limited. I am always eager to expand my knowledge and learn new techniques. I actively seek opportunities to address this area and broaden my skillset.

Q 27. Describe a time you solved a complex problem related to dyeing.

During a large-scale production run, we encountered a significant problem with uneven dyeing on a batch of cotton fabric using a reactive dye. The resulting color was blotchy and unacceptable.

My approach involved a systematic investigation. We first ruled out problems with the dye itself by testing a small sample with a known good batch of fabric and dye. We then examined the dyeing process parameters, including temperature, pH, time, and the efficiency of the padding mangle. We discovered the mangle wasn’t distributing the dye liquor evenly across the fabric. The rollers were slightly misaligned, leading to inconsistent dye uptake.

The solution involved a careful realignment of the mangle rollers. We then ran a small test batch to verify the correction. Once the issue was resolved, we continued the production run, achieving consistent color and eliminating the blotchy appearance.

Q 28. How would you approach a new dyeing project or challenge?

Approaching a new dyeing project requires a structured approach. I would start with a thorough understanding of the project requirements. This includes the type of fiber, the desired color, the wash fastness requirements, and the production scale.

- Fiber Analysis: Initial testing is necessary to determine the fiber composition and its suitability for different dye classes.

- Dye Selection: The choice of dye depends on the fiber type, desired color, and wash fastness requirements. We would consider factors such as lightfastness, wash fastness, and the potential for environmental impact.

- Pilot Runs: Small-scale trials (pilot runs) are essential to optimize dyeing parameters such as temperature, time, pH, and the concentration of dye and auxiliaries.

- Color Matching: Accurate color matching is crucial. Instrumental color measurement tools are used to ensure consistency and meet the client’s specifications.

- Scale-Up: Once the optimal parameters are determined, the process is scaled up to the required production volume, while maintaining careful monitoring.

Throughout the process, detailed records are maintained, including all parameters and observations. This documentation ensures consistency and enables effective troubleshooting if any issues arise.

Key Topics to Learn for Your Knowledge of Dyeing Principles Interview

Ace your upcoming interview by mastering these crucial areas of dyeing principles. Remember, a strong understanding of both theory and practice is key!

- Fiber Chemistry and Dye Affinity: Understand the chemical structures of different fibers (cotton, wool, polyester, etc.) and how they interact with various dyes. Explore the concepts of dye uptake, exhaustion, and migration.

- Dye Classes and Properties: Become familiar with the major dye classes (e.g., azo dyes, reactive dyes, disperse dyes) and their respective characteristics, applications, and limitations. Be prepared to discuss the advantages and disadvantages of each.

- Dyeing Processes and Equipment: Gain a solid understanding of different dyeing methods (e.g., batch dyeing, continuous dyeing, jet dyeing) and the associated machinery. Know the principles behind each process and their suitability for various fabrics and dyes.

- Color Measurement and Quality Control: Learn about colorimetric systems (e.g., CIE Lab), spectrophotometers, and the importance of color matching and quality control in the dyeing process. Be ready to discuss different methods for assessing color fastness.

- Environmental Considerations in Dyeing: Discuss environmentally friendly dyeing practices, waste treatment, and the impact of dyeing processes on the environment. Familiarity with sustainable dyeing technologies is a significant plus.

- Troubleshooting Dyeing Problems: Develop your problem-solving skills by considering common dyeing defects (e.g., uneven dyeing, crocking, bleeding) and their causes. Practice explaining how you would approach diagnosing and resolving such issues.

Next Steps: Level Up Your Career

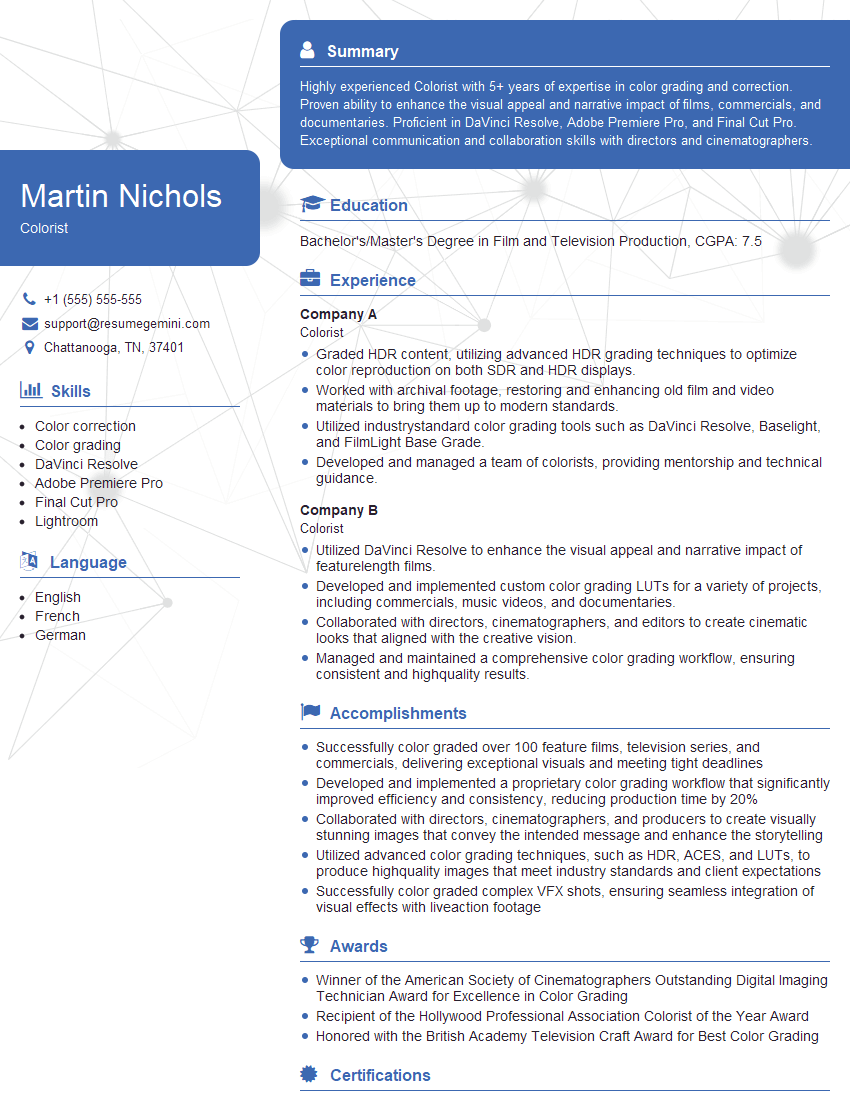

A strong understanding of dyeing principles is essential for career advancement in the textile industry. It demonstrates your technical expertise and opens doors to exciting opportunities. To maximize your chances, invest time in creating a professional, ATS-friendly resume that highlights your skills and experience effectively.

ResumeGemini can help you build a powerful resume that showcases your expertise in Knowledge of Dyeing Principles. Their user-friendly platform and tailored templates will help you present your qualifications in the best possible light. They even provide examples of resumes specifically designed for professionals in this field.

Take the next step towards your dream job – build a compelling resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?