Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Dye House Machine Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Dye House Machine Operation Interview

Q 1. What are the different types of dyeing machines used in a dye house?

Dye houses utilize a variety of machines, each suited to different fabric types and dyeing processes. The choice depends on factors like fabric weight, dye type, production volume, and desired quality. Common types include:

- Jet dyeing machines: High-speed, efficient machines ideal for large-scale production. They use high-pressure jets to circulate dye liquor around the fabric.

- Winch dyeing machines: Suitable for medium-to-large batches, these machines utilize a winch to continuously move fabric through the dye liquor. They offer good control over dye penetration.

- Beam dyeing machines: Primarily used for dyeing woven fabrics on large beams, they’re known for even dye distribution and are suitable for delicate fabrics.

- Jigger dyeing machines: Used for continuous dyeing of fabrics, typically in open-width, they’re effective for lighter-weight fabrics and offer good control over dye application.

- Padding mangle dyeing machines: Primarily for continuous dyeing, these machines apply dye liquor to fabric via rollers, followed by a drying process. They are very efficient for high volume production.

Each machine type has its strengths and weaknesses; selecting the right one is crucial for optimal results.

Q 2. Explain the process of dyeing fabric using a jet dyeing machine.

Jet dyeing is a highly efficient process. Imagine a powerful whirlpool, that’s essentially what happens inside a jet dyeing machine. The process involves several key steps:

- Preparation: Fabric is loaded into the machine’s dyeing chamber. The chamber is then filled with water to pre-wet the fabric ensuring even dye absorption.

- Dyeing: The dye solution is introduced, and high-pressure jets create a powerful circulation. This ensures even distribution of the dye throughout the fabric, minimizing variations in color.

- Temperature and time control: Temperature is precisely controlled and carefully monitored throughout the dyeing process according to the specific dye and fabric type to optimize the dyeing process. The dyeing time is also crucial, and depends on the dye, the fabric, and desired color depth. The precise temperature and time are critical for achieving the desired color and shade.

- Rinsing: After dyeing, the fabric is rinsed to remove excess dye and any chemicals. This step is crucial to ensure color fastness and prevent dye bleeding.

- Finishing: The final step may involve additional processes like soaping (for reactive dyes), softening, or drying, depending on the fabric type and desired finish.

Monitoring and control parameters like temperature, pH, dye concentration, and liquor ratio are all constantly monitored to ensure quality and consistency. This is a complex process that requires skilled operators to ensure proper execution.

Q 3. Describe your experience with different dyeing techniques (e.g., reactive, disperse, acid).

My experience encompasses a wide range of dyeing techniques. Each technique requires a different approach and careful consideration of the fabric and dye chemistry involved.

- Reactive dyeing: I’ve extensively worked with reactive dyes, which form a strong covalent bond with cellulose fibers (like cotton and linen). This results in excellent wash fastness. A key challenge is controlling the reaction to prevent dye exhaustion and ensuring uniform color. I’ve found that precise control of pH, temperature, and salt concentration is paramount.

- Disperse dyeing: This technique is used for synthetic fibers such as polyester and nylon. Disperse dyes are insoluble in water and require high temperatures and carriers to facilitate dye absorption. I’ve encountered challenges in achieving level dyeing, particularly with fabrics containing blends of fibers, requiring careful selection of carriers and process parameters.

- Acid dyeing: Acid dyes work best on protein fibers like wool and silk. They have a wide range of shades and good color fastness. Precise pH control is crucial in acid dyeing, and careful attention must be paid to fiber damage. I’ve worked with this dye type and fine-tuned the pH to ensure optimum color yield and prevent fiber degradation.

Understanding the chemistry of each dye and its interaction with the fiber is essential for achieving consistent and high-quality results.

Q 4. How do you ensure consistent color throughout a batch of fabric?

Ensuring consistent color throughout a batch is critical. It’s achieved through a combination of meticulous preparation and precise control during the dyeing process. Key factors include:

- Careful pre-treatment: Thorough cleaning and scouring of the fabric to remove impurities that could affect dye uptake is essential.

- Precise dye measurement and mixing: Accurate weighing and mixing of dyes are crucial to maintain the same concentration throughout the batch. Using calibrated equipment minimizes errors.

- Optimized dyeing parameters: Temperature, pH, time, and liquor ratio must be consistently maintained throughout the process. Automation and process control systems are very useful here.

- Even liquor circulation: Adequate liquor circulation within the dyeing machine (especially in jet dyeing) is crucial for even dye distribution.

- Regular monitoring and adjustments: Color checks at different stages of the process help detect any deviation from the target shade and allow for corrective actions. Colorimetric measurements help quantify these deviations.

Maintaining a consistent process using standardized operating procedures, well-maintained equipment, and properly trained personnel are all critical in ensuring batch-to-batch consistency.

Q 5. What are the safety precautions you take while operating dyeing machines?

Safety is paramount in dye house operations. I always follow strict safety protocols to mitigate risks:

- Personal Protective Equipment (PPE): This includes gloves, safety goggles, aprons, and respirators to protect against chemical spills and inhalation of dye dust or fumes.

- Chemical handling: Safe handling and storage of dyes and chemicals are essential. I follow proper procedures for transferring, mixing, and disposing of chemicals. Proper labeling and understanding of the Safety Data Sheets (SDS) for each chemical is critical.

- Machine safety: I always ensure that all machine guards are in place and functioning correctly before operating any equipment. Regular maintenance checks prevent mechanical failures that can lead to injury.

- Emergency procedures: I’m familiar with the emergency shut-off procedures for each machine and the location of safety showers and eyewash stations. I participate in regular safety training to stay updated on emergency response.

- Housekeeping: A clean and organized workspace is crucial to prevent accidents. I always clean up spills promptly and dispose of waste according to the company’s environmental guidelines.

A proactive and cautious approach to safety is integral to dye house operations.

Q 6. How do you troubleshoot common dyeing machine malfunctions?

Troubleshooting dyeing machine malfunctions requires a systematic approach. My strategy involves:

- Identify the problem: Precisely define the nature of the malfunction. Is it a color issue, a mechanical problem, or a process control issue? Observe the symptoms carefully.

- Check the obvious: Start with simple checks. Are there any power supply issues, pump failures, or leaks? Are the sensors functioning correctly?

- Consult manuals and documentation: Refer to the machine’s operational manual and maintenance logs for troubleshooting guides and potential solutions.

- Systematic elimination: Work through the potential causes systematically, checking each component to isolate the problem. Use your understanding of the machine’s operational principles to pinpoint potential faults.

- Seek expert assistance: If the problem cannot be resolved using standard troubleshooting methods, consult experienced technicians or engineers.

Example: If a jet dyeing machine fails to circulate dye liquor effectively, I’d check the pump, filter, and piping system for blockages or malfunctions. I’d also inspect the control panel for any error messages. Experience and a systematic approach greatly enhance troubleshooting efficiency.

Q 7. Explain your understanding of colorimetric measurements and their importance in dyeing.

Colorimetric measurements are essential for objective assessment of color in dyeing. These measurements use instruments like spectrophotometers to quantify color properties such as:

- L*a*b* values: These represent lightness (L*), redness/greenness (a*), and yellowness/blueness (b*). They provide a numerical representation of color, enabling precise color matching and quality control.

- Delta E (ΔE): This measures the difference between two colors. A smaller ΔE value indicates a closer match. It’s crucial for ensuring consistency between batches and meeting customer specifications.

The importance of colorimetric measurements lies in its ability to eliminate subjective color assessment. Instead of relying on visual inspection, which can be prone to human error, we use precise numerical data to ensure consistent color throughout production runs. By carefully monitoring the L*a*b* values and ΔE of each batch, we can maintain strict quality control and minimize waste caused by color variations. This is particularly crucial for large-scale production where precise color matching is critical for achieving quality and customer satisfaction.

Q 8. Describe your experience with different types of dyes and their applications.

My experience encompasses a wide range of dyes, each with unique properties and applications. We use reactive dyes extensively for cellulosic fibers like cotton and linen, known for their vibrant colors and excellent wash fastness. For polyester fabrics, we rely on disperse dyes, which penetrate the hydrophobic fibers effectively. Acid dyes are our go-to for wool and silk, providing rich and deep shades. Direct dyes, while less colorfast, are useful for simpler applications and offer a cost-effective solution. I’ve also worked with pigment dyes, which are essentially insoluble color particles applied to the fabric’s surface, offering a good level of opacity. The selection of dye type hinges on the fiber composition, desired colorfastness, and the overall cost-benefit analysis for the project.

For example, a high-end silk scarf might utilize acid dyes for the luxurious color depth and excellent lightfastness, while a basic cotton t-shirt might use reactive dyes for cost-effectiveness and good color retention after numerous washes. Understanding the interaction between dye chemistry and fiber structure is crucial for selecting the right dye for each job.

Q 9. How do you maintain the quality of dyed fabrics?

Maintaining consistent dye quality is paramount. It begins with rigorous incoming inspection of raw materials, ensuring consistent dye lots and accurate chemical concentrations. Precise control over the dyeing process is key. We meticulously monitor and adjust parameters like temperature, pH, and liquor ratio throughout each cycle. Regular calibration and maintenance of our dyeing machines, including the pumps, jets and sensors, prevents variations in dye uptake and distribution. Furthermore, we conduct regular lab tests on dyed samples to measure color strength, colorfastness to washing, light, and rubbing. Any deviation from our quality standards triggers immediate investigation and corrective action, ensuring every batch meets our specifications. This is essentially quality control throughout the process, from raw materials to the finished product.

Q 10. What is your experience with batching and processing large quantities of fabric?

I’m highly experienced in handling large fabric batches. We routinely process thousands of meters of fabric in a single dyeing run, using jiggers, jet dyeing machines, and continuous dyeing ranges depending on the fabric type and desired production volume. Batching involves careful organization, ensuring consistency in fabric weight, type, and pretreatment. Precise weighing and thorough mixing of dyes and chemicals are paramount to prevent inconsistencies in shade. Efficient loading and unloading of the machines are critical to maintaining high throughput, and we utilize automated systems where possible to optimize these processes. For continuous dyeing, we have a sophisticated system for accurately controlling dye feed and fabric speed, and for batch dyeing, the precise timing of the entire cycle is fundamental. I am accustomed to managing all aspects of large scale fabric dyeing from planning and execution to quality control.

Q 11. How do you monitor and control the temperature and pressure during the dyeing process?

Precise temperature and pressure control are critical for optimal dye uptake and color consistency. We utilize sophisticated automated control systems that monitor and regulate these parameters in real-time. These systems are integrated with sensors within the dyeing machines that provide constant feedback to adjust heating and pressure as needed, maintaining optimal conditions for the specific dyeing process. For example, jet dyeing requires precise temperature profiles to achieve the desired color depth and uniformity, while jigger dyeing necessitates careful pressure control to prevent fabric damage. Regular maintenance and calibration of these control systems are crucial to maintaining the accuracy and reliability of our dyeing operations. Deviating from the set parameters can lead to uneven dyeing, color variations, and even fabric damage.

Q 12. How do you handle chemical waste generated during the dyeing process?

Responsible chemical waste handling is crucial. We adhere strictly to all environmental regulations. Our dye house uses a closed-loop system where possible, minimizing water usage and waste generation. Spent dye baths are treated on-site using chemical precipitation and filtration systems to remove residual dyes and chemicals. The treated wastewater then undergoes further treatment before discharge, ensuring it meets all regulatory standards. Hazardous waste, such as spent dye chemicals and cleaning solvents, are collected and properly disposed of by licensed waste disposal companies in compliance with relevant regulations. Comprehensive record-keeping documents all aspects of our waste management practices, allowing for continuous improvement and compliance audits.

Q 13. What is your experience with different types of fabric pre-treatment?

Fabric pretreatment significantly impacts dyeing results. Common methods include scouring (removing impurities), bleaching (whitening the fabric), and singeing (burning off loose fibers). The choice of pretreatment depends on the fabric type and desired outcome. For example, cotton fabric requires scouring to remove natural waxes and impurities before dyeing, whereas synthetic fabrics may need different pretreatments. Bleaching ensures a consistent base color for uniform dyeing, particularly important for light shades. Singeing improves fabric appearance and reduces pilling. I’m proficient in applying these methods using various machinery, including scouring ranges, bleaching kiers, and singeing machines, ensuring the fabric is properly prepared for optimal dye uptake and color consistency.

Q 14. How do you ensure the efficiency and productivity of the dyeing process?

Dyeing process efficiency is enhanced through several strategies. We optimize dye recipes to minimize chemical usage and maximize dye exhaustion (amount of dye absorbed by the fabric). Regular machine maintenance prevents downtime and ensures consistent performance. Continuous process improvement initiatives aim at streamlining operations and reducing waste. Data-driven approaches, such as monitoring key performance indicators (KPIs) like production rate, dye consumption, and energy usage, allow us to identify bottlenecks and optimize the processes. Effective workforce training ensures that all operators understand and adhere to standard operating procedures, leading to increased productivity and consistent quality.

Q 15. What is your experience with maintaining and cleaning dyeing equipment?

Maintaining and cleaning dyeing equipment is crucial for consistent color, fabric quality, and operational efficiency. My experience encompasses preventative maintenance, such as regularly checking and lubricating pumps, jets, and rollers to prevent wear and tear. I’m also proficient in scheduled cleaning procedures, involving the complete dismantling and cleaning of dye vats, pipes, and filters to remove dye build-up and prevent clogging. This includes using appropriate cleaning agents based on the type of dye used, and meticulously rinsing to ensure no residual chemicals remain. For example, after a reactive dye run, a thorough cleaning with a strong alkaline solution followed by an acid rinse is necessary. I meticulously document all maintenance activities and cleaning procedures, ensuring traceability and compliance with safety regulations.

I understand the importance of keeping detailed records. This helps with predictive maintenance – anticipating potential issues before they become major problems. For instance, tracking the frequency of pump repairs allowed me to identify a recurring issue with a specific pump model and recommend its replacement, thus preventing costly downtime.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting problems related to dye uptake and color consistency.

Troubleshooting dye uptake and color consistency issues requires a systematic approach. I start by analyzing the entire dyeing process, from fabric preparation to the final rinse. Factors such as dyeing temperature, dye concentration, pH levels, and the type and amount of dyeing auxiliaries are carefully examined. For instance, inconsistent dye uptake might indicate issues with fabric pretreatment (like uneven scouring or bleaching), while uneven color could stem from faulty jet circulation leading to non-uniform dye distribution.

To solve these problems, I use a combination of visual inspection, data analysis (from process control systems), and lab testing. If dye uptake is low, adjusting the pH or adding a dispersing agent can improve dye solubility and penetration. If color consistency is off, adjustments to the dyeing time, temperature profile or dye concentration may be necessary. For example, a batch exhibiting mottled coloration might require re-dyeing with a more thorough agitation system or adjustments to the dye liquor ratio. I always meticulously document my findings and corrective actions to prevent similar issues in the future.

Q 17. What is your experience with different types of dye fixation methods?

Dye fixation is the process of making the dye permanently bond to the fabric. My experience covers various methods, including heat setting (for disperse dyes on polyester), steaming (for reactive dyes on cellulose), and after-treatment with fixing agents (for acid dyes on wool or nylon). The choice of method depends on the fiber type and dye class. Each method requires precise control of parameters like temperature, time, and pressure to achieve optimal fixation and colorfastness.

For instance, with reactive dyes, the steaming process needs careful monitoring of the temperature and steam pressure to ensure complete dye fixation without damaging the fabric. I’ve worked with various types of steaming equipment including jiggers and continuous steamers, each requiring different levels of operational expertise to ensure proper fixation and achieve the desired level of colorfastness. For acid dyeing processes, the careful selection and control of the after-treatment agent and the pH are critical to ensure proper dye-fiber bond and color stability.

Q 18. How do you manage and resolve conflicts with fellow team members?

Conflict resolution is an essential skill in a team environment. My approach focuses on open communication and collaborative problem-solving. I always strive to understand the perspectives of all involved parties before suggesting solutions. Rather than focusing on blame, I prioritize finding common ground and working together to resolve the issue effectively.

In one instance, a conflict arose between two team members regarding the scheduling of dyeing runs. Instead of taking sides, I facilitated a discussion where both members could express their concerns. We collaboratively created a revised schedule that accommodated both their needs while optimizing overall production efficiency. I believe a respectful and proactive approach, emphasizing teamwork and mutual understanding, is key to effectively resolving conflicts in a professional setting.

Q 19. What is your experience with using computer systems to monitor and control the dyeing process?

I have extensive experience using computer systems for monitoring and controlling the dyeing process. This includes programming and operating Programmable Logic Controllers (PLCs) to manage dyeing parameters such as temperature, pH, and liquor ratio. I am also proficient in using Supervisory Control and Data Acquisition (SCADA) systems to monitor and record dyeing parameters in real-time, generating reports and facilitating data analysis for continuous improvement.

For example, our SCADA system allows for remote monitoring of multiple dyeing machines simultaneously, providing real-time data on each run. This allows for early detection of anomalies (like a sudden temperature drop) and proactive intervention, minimizing potential issues. The ability to analyze historical data helps identify trends and optimize the dyeing process for improved efficiency and consistency. This reduces waste and ensures consistent product quality.

Q 20. Describe your experience with different types of dyeing auxiliaries.

Dyeing auxiliaries are essential chemicals added to the dye bath to enhance the dyeing process. My experience includes working with a wide range of auxiliaries, including wetting agents (to improve dye penetration), dispersing agents (to prevent dye aggregation), leveling agents (to ensure even dye distribution), and fixing agents (to improve colorfastness).

The selection of auxiliaries depends on the fiber type, dye class, and desired outcome. For instance, using an appropriate dispersing agent for disperse dyes is crucial to prevent particle agglomeration that results in uneven dyeing. Selecting a suitable leveling agent during dyeing ensures that the dye penetrates the fabric evenly and prevents the formation of streaks or blotches. The correct choice of auxiliaries is critical for optimal results and cost efficiency. I’m familiar with the properties and applications of various types of auxiliaries, and I understand how their interactions affect the overall dyeing process.

Q 21. How do you ensure compliance with environmental regulations related to dyeing operations?

Ensuring compliance with environmental regulations is paramount in dyeing operations. My experience includes implementing and maintaining procedures to minimize wastewater discharge, manage hazardous waste, and adhere to air emission standards. This involves monitoring and controlling the discharge of dyes and chemicals, implementing water treatment systems, and regularly calibrating monitoring equipment.

For example, I’m experienced in handling and disposing of spent dye baths and other chemical waste according to local regulations, using proper labeling and documentation. We meticulously track water usage and implement water recycling strategies where feasible, significantly reducing our environmental footprint. I regularly update my knowledge on new regulations and best practices to maintain compliance and contribute to a sustainable dyeing operation.

Q 22. How do you handle situations requiring urgent repairs or maintenance?

Urgent repairs in a dye house are a critical situation demanding swift action to minimize downtime and prevent larger problems. My approach follows a structured process:

- Assessment: I first quickly assess the severity of the issue. Is it a complete machine shutdown, or a minor malfunction? Safety is paramount; if there’s a risk, I immediately shut down the machine and secure the area.

- Troubleshooting: Based on my experience, I attempt to identify the root cause. This often involves checking pressure gauges, examining pumps and pipes for leaks, and verifying electrical connections. I rely on my detailed knowledge of the machine’s schematics and operational manuals.

- Prioritization: I prioritize repairs based on urgency and impact on production. If a component failure significantly affects the overall process, I’ll focus on that first. Minor issues might be addressed after the critical ones.

- Repair or Call for Support: I attempt minor repairs myself, like replacing a faulty valve or fixing a minor electrical fault. For major repairs that require specialized tools or expertise, I immediately contact the maintenance team or the equipment supplier. I clearly document the problem and any troubleshooting steps already taken.

- Documentation & Preventative Measures: Once the issue is resolved, I meticulously document the repair process, including the cause, the solution, and the time taken. This helps prevent similar issues in the future. I also suggest preventative maintenance steps to prevent recurring problems.

For instance, once I had to handle a sudden pressure drop in a jet dyeing machine during a crucial production run. Quick assessment revealed a leak in a high-pressure pipe. I quickly isolated the section, minimizing the dye loss and preventing further damage. After temporary repair, I immediately called for the maintenance team to conduct a permanent fix, ensuring minimal production downtime.

Q 23. What is your experience with different types of fabric finishes?

My experience encompasses a wide range of fabric finishes, categorized by their function and application:

- Softening Finishes: These enhance the hand feel of the fabric, making it softer and more comfortable. Examples include silicone finishes and enzyme treatments.

- Water-Repellent Finishes: Used to create water-resistant or waterproof fabrics, often achieved through fluorocarbon-based or silicone-based treatments.

- Anti-Wrinkle Finishes: These reduce creasing and wrinkling, often achieved through resin treatments that provide dimensional stability.

- Flame-Retardant Finishes: These impart fire-resistant properties to fabrics, critical for certain applications like safety garments. They involve the application of specialized chemicals that inhibit combustion.

- Anti-Microbial Finishes: Provide protection against bacteria and fungi, commonly used in medical textiles and sportswear. These often utilize silver-based or other biocidal agents.

I am familiar with both conventional and environmentally friendly finishing techniques, emphasizing sustainable practices wherever possible. I understand the limitations and advantages of each finish, including their impact on the fabric’s colorfastness, durability, and feel. For example, I’ve successfully implemented a new silicone-based softening finish that reduces environmental impact compared to traditional methods, resulting in a softer hand feel and improved cost-effectiveness.

Q 24. How do you interpret and follow dyeing recipes and procedures?

Dyeing recipes and procedures are the blueprints for consistent color reproduction. Interpreting them requires careful attention to detail and a thorough understanding of dyeing principles. I follow a methodical approach:

- Understanding the Recipe: The recipe outlines the dye type, concentration, temperature profile, and bath ratio (the ratio of fabric weight to dye bath volume). I carefully review these parameters, understanding their impact on the final shade.

- Preparing the Dye Bath: I accurately weigh and measure the dyes and chemicals based on the recipe’s specifications. I use calibrated measuring instruments to ensure precision.

- Following the Procedure: The procedure outlines the dyeing steps, such as pre-treatment, dyeing, and after-treatment. I meticulously follow these steps, carefully monitoring the temperature, pH, and time.

- Monitoring & Adjustment: Throughout the process, I continuously monitor the dye bath parameters. Depending on the situation, minor adjustments may be necessary to achieve the desired shade and evenness. This could involve adjusting the pH or temperature.

- Quality Control: After dyeing, I perform quality control checks to ensure the batch meets the color specifications and quality standards. This involves visual inspection and instrumental color measurement.

For example, a recipe might specify a 2% dye concentration for a specific shade of blue. I’ll meticulously calculate the required amount of dye based on the weight of the fabric batch and the dye bath ratio. Any deviation from the recipe is documented.

Q 25. What is your experience with quality control testing in the dyeing process?

Quality control (QC) is vital in ensuring consistent color and fabric quality. My experience includes various QC testing methods:

- Visual Inspection: This involves a thorough visual examination of the dyed fabric for any imperfections, such as uneven dyeing, staining, or damage.

- Instrumental Color Measurement: Using spectrophotometers, I measure the color values (L*, a*, b*) of the dyed fabric to compare it against the target color specified in the recipe. This provides objective color data for consistent quality.

- Rub Test: This determines the colorfastness of the dyed fabric to rubbing, ensuring the color doesn’t transfer easily.

- Wash Test: This assesses the colorfastness to washing, evaluating the color’s resistance to fading or bleeding after washing cycles.

- Lightfastness Test: This measures the resistance of the dye to fading caused by light exposure.

In one instance, I detected a slight color variation between two batches through instrumental color measurement. This early detection prevented a large batch of substandard fabric from being shipped. It highlighted the importance of regular QC testing.

Q 26. How do you calculate the required amount of dye for a given batch of fabric?

Calculating the required dye amount involves a precise calculation based on several factors:

- Fabric Weight: The weight of the fabric batch in kilograms or pounds is the fundamental starting point.

- % on Weight of Goods (owg): The dyeing recipe specifies the percentage of dye (owg) relative to the fabric weight. For example, a 2% owg means 2 grams of dye per 100 grams of fabric.

- Dye Concentration: The recipe often indicates the concentration of the dye in the form of a paste or powder.

- Bath Ratio: The ratio of fabric weight to the total weight of the dye bath, often expressed as a ratio (e.g., 1:10, 1:20) or in liters of water per kilogram of fabric.

Calculation Example: Let’s say we have 10 kg of fabric, a 2% owg dye recipe, and a 1:20 bath ratio.

1. Dye required: 10,000 g (fabric) * 0.02 (2% owg) = 200 g dye.

2. Water required: 10,000 g (fabric) * 20 (bath ratio) = 200,000 g or 200 liters of water (approximately).

Precise measurement and accounting for dye concentration (if it’s not 100% pure dye) are essential for accurate calculation. Any errors in calculation can result in incorrect shade and waste of materials.

Q 27. Describe your experience with different types of fabric inspection techniques.

Fabric inspection involves a variety of techniques to ensure quality and identify defects:

- Visual Inspection: A primary method involving careful examination of the fabric for any visible flaws, such as holes, stains, creases, or uneven dyeing. This can be done under different lighting conditions to detect subtle imperfections.

- Microscopic Inspection: Using microscopes, this method allows for closer examination of the fabric’s structure and fiber properties to identify hidden defects.

- Instrumental Testing: Utilizing instruments like tensile strength testers, we can evaluate the fabric’s mechanical properties, including strength, elongation, and tear resistance. This helps ensure the fabric meets specified quality standards.

- Dimensional Stability Testing: Measuring the fabric’s shrinkage after washing and drying to ensure that it maintains its shape and size.

- Fabric Defect Analysis: Identifying the root cause of the defects to determine preventative measures for future production runs.

I’m experienced in using various inspection tools and techniques to identify and categorize defects efficiently. For instance, during a recent inspection, I used a microscope to identify tiny yarn breaks that were not visible to the naked eye, preventing them from affecting the final product.

Q 28. How do you stay up-to-date with the latest advancements in dyeing technology?

Staying up-to-date in the dyeing industry requires continuous learning. My approach involves:

- Industry Publications & Journals: I regularly read industry publications and journals focused on dyeing technologies, including new dyes, equipment, and sustainable practices.

- Trade Shows & Conferences: Attending industry trade shows and conferences allows me to see the latest equipment and technologies firsthand and interact with leading experts.

- Online Resources & Webinars: I use online resources, including webinars and manufacturer websites, to learn about new developments and best practices.

- Professional Networks: I actively participate in professional networks and online forums to engage with other professionals, share knowledge, and learn from their experiences.

- Manufacturer Training: I seek out training opportunities offered by equipment manufacturers and chemical suppliers to deepen my understanding of their products and technologies.

For example, I recently attended a webinar on new environmentally friendly dyes and their applications, improving my knowledge of sustainable dyeing practices and allowing me to explore ways to reduce our environmental impact.

Key Topics to Learn for Dye House Machine Operation Interview

- Dyeing Processes: Understanding various dyeing methods (e.g., jet dyeing, winch dyeing, pad dyeing) and their applications for different fabrics and colors.

- Machine Operation & Maintenance: Practical knowledge of operating and maintaining specific dye house machinery (specify relevant machines based on job description, e.g., jet dyeing machines, pad steamers). This includes troubleshooting common issues and performing routine maintenance tasks.

- Chemical Handling & Safety: Safe handling, storage, and disposal of dyes, chemicals, and other materials used in the dyeing process. Understanding relevant safety regulations and procedures.

- Quality Control & Testing: Knowledge of color matching techniques, shade assessment, and quality control procedures to ensure consistent and high-quality dyed fabrics.

- Fabric Preparation: Understanding pre-treatment processes such as scouring, bleaching, and mercerizing, and their impact on the dyeing process.

- Process Optimization: Identifying areas for improvement in the dyeing process to enhance efficiency, reduce waste, and improve the quality of the dyed fabric. This might include understanding energy consumption and water usage.

- Troubleshooting & Problem Solving: Developing analytical skills to identify and resolve issues that may arise during the dyeing process, such as color variations, fabric damage, or machine malfunctions.

- Record Keeping & Documentation: Maintaining accurate records of dyeing processes, chemical usage, and quality control results. Understanding the importance of precise documentation for traceability and compliance.

Next Steps

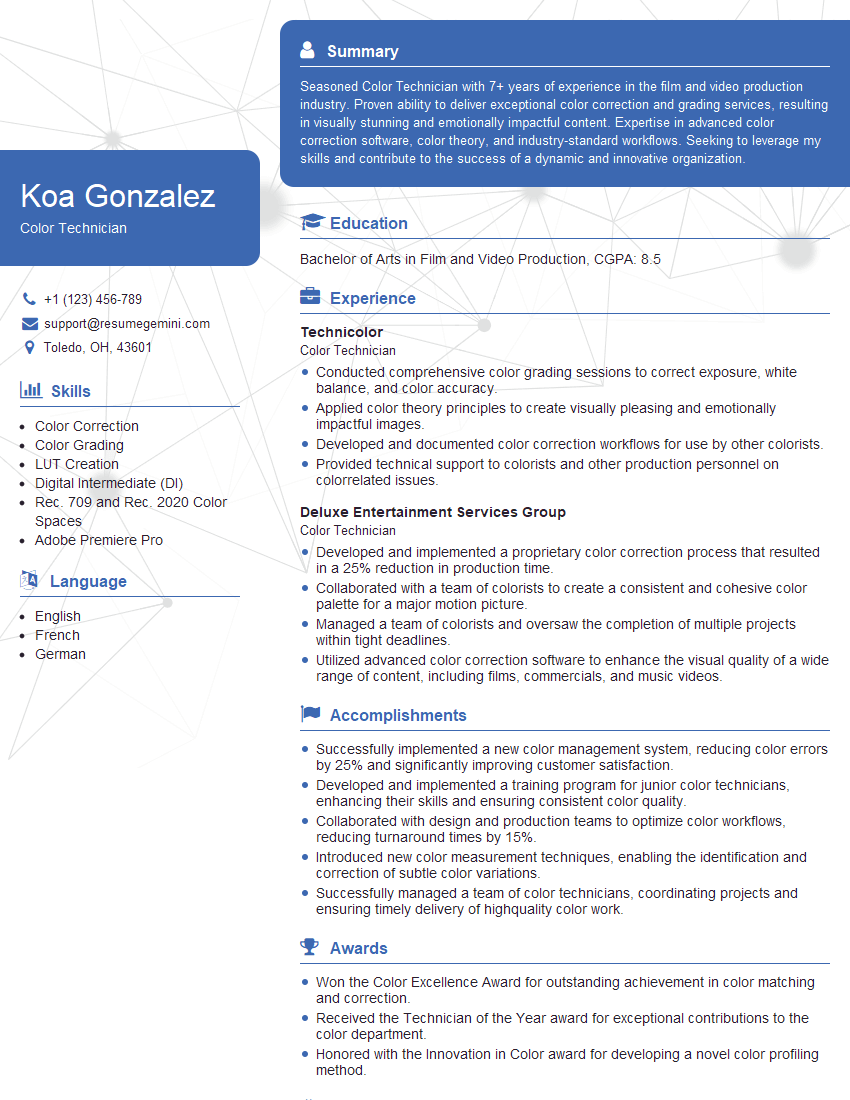

Mastering Dye House Machine Operation opens doors to a rewarding career with excellent growth potential, offering opportunities for specialization, increased responsibility, and higher earning potential. A strong resume is crucial for showcasing your skills and experience to potential employers. Create an ATS-friendly resume to ensure your application gets noticed by Applicant Tracking Systems. We recommend using ResumeGemini, a trusted resource, to build a professional and impactful resume that highlights your expertise. Examples of resumes tailored to Dye House Machine Operation are available to help you create your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?