The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Maintaining a clean and organized bar station interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Maintaining a clean and organized bar station Interview

Q 1. Describe your method for cleaning and sanitizing bar glasses.

Cleaning and sanitizing bar glasses is crucial for hygiene and preventing the spread of germs. My method involves a three-step process: washing, rinsing, and sanitizing.

Washing: I use a high-temperature dishwasher, ideally with a detergent designed for glassware, to remove all visible residue. If hand-washing, I use hot, soapy water and a clean washcloth or sponge, scrubbing thoroughly to remove lipstick, fingerprints, and any other debris. Think of it like giving each glass a spa treatment!

Rinsing: After washing, glasses are thoroughly rinsed with clean, hot water to remove all traces of soap. Residual soap can leave a film and affect the taste of drinks. This step ensures a sparkling clean glass.

Sanitizing: This is the most critical step. I use a food-grade sanitizer, following the manufacturer’s instructions precisely. This usually involves soaking the glasses in a diluted sanitizer solution for the recommended time – typically around 30 seconds to a minute. This kills harmful bacteria and viruses. I never skip this step; it’s vital for guest safety and regulatory compliance.

For example, during a particularly busy Friday night, a quick rinse and sanitize cycle is critical to keep up with demand without compromising hygiene. We aim for a rapid turnaround time, but never at the cost of cleanliness.

Q 2. How do you maintain the cleanliness of bar tools and equipment?

Maintaining clean bar tools and equipment is paramount. Regular cleaning and sanitizing prevent bacterial growth and ensure consistent drink quality. My approach is proactive and systematic:

Daily Cleaning: After each use, I rinse and wipe down tools like jiggers, strainers, and muddlers with hot, soapy water. This removes immediate residue. For example, a sticky muddler can easily spread unwanted flavors. I then sanitize them using a spray sanitizer or by soaking them in a solution.

Deep Cleaning: Once or twice a week, depending on usage, I perform a deeper clean. This involves disassembling tools where possible (e.g., cocktail shakers) for thorough cleaning and sanitizing in all crevices. This is when I address build-up of grime that may be harder to remove daily.

Equipment Maintenance: I regularly inspect equipment like ice machines, blenders, and coffee machines for cleanliness and proper functioning. I follow manufacturer’s cleaning instructions to avoid damage and ensure optimal performance. For instance, neglecting to clean an ice machine can lead to bacterial contamination and undesirable ice quality.

A clean and well-maintained tool kit is like a chef’s prized set of knives – essential for consistent, high-quality work.

Q 3. What steps do you take to prevent cross-contamination at a bar station?

Preventing cross-contamination is crucial for food safety. My approach focuses on dedicated tools and meticulous cleaning practices:

Designated Tools: I maintain separate tools for different types of drinks or ingredients (e.g., one jigger for spirits, another for juices). This minimizes the risk of transferring flavors or bacteria.

Thorough Cleaning: After each use, I immediately clean and sanitize all tools and surfaces to prevent the spread of bacteria. This is especially important when handling raw ingredients.

Ice Handling: I use separate ice bins for different purposes (e.g., one for cocktails, another for water). Contaminated ice can quickly spread problems across your entire bar.

Food Safety Practices: I strictly adhere to all food safety guidelines, including proper handwashing and the correct storage of ingredients.

Imagine mixing a margarita after handling raw fish – a disaster! Dedicated tools and rigorous cleaning eliminate such risks, guaranteeing safety and satisfying customer experiences.

Q 4. Explain your system for organizing liquor bottles and mixers.

Organizing liquor bottles and mixers is key to efficiency and a professional look. My system emphasizes visual appeal and easy access:

Categorization: I arrange bottles by type (spirits, liqueurs, mixers) and then alphabetically within each category. This makes locating specific items quick and effortless.

Visual Appeal: Bottles are arranged neatly, facing forward with labels visible. This creates an inviting and organized bar station.

Frequently Used Items: Frequently used items are placed at the front and center for easy access during peak hours. This minimizes downtime and keeps the bar flowing smoothly.

Height Considerations: Taller bottles are placed at the back to avoid obstructing shorter ones. It’s all about optimized spatial organization.

A well-organized bar is like a well-stocked pantry; everything is readily available when you need it. This system minimizes searching time and allows for smoother operation, even during busy service.

Q 5. How do you handle spills and messes efficiently during a busy shift?

Handling spills and messes swiftly and efficiently is critical, especially during peak hours. My approach combines speed and safety:

Immediate Action: I immediately address any spills, using absorbent materials like bar towels or spill mats to soak up liquids. Speed is crucial to prevent slips and falls.

Safety First: I prioritize safety by using caution when cleaning spills, especially on wet floors. I may cordon off affected areas to avoid accidents.

Thorough Cleaning: After cleaning up the immediate spill, I disinfect the affected area using a sanitizer solution to prevent contamination.

Teamwork: During very busy times, I work with my team to manage spills collectively, with everyone assisting in cleanup duties.

Picture a sticky mess on the floor during a rush – disastrous! Swift and safe spill management is crucial for maintaining order and ensuring a safe environment for both staff and patrons.

Q 6. What is your procedure for restocking bar supplies?

Restocking bar supplies requires a proactive and organized approach to avoid running out of essential items. My system involves:

Regular Inventory Checks: I conduct regular inventory checks (daily or weekly, depending on volume) to assess stock levels and identify items nearing depletion.

Par Stock Levels: I maintain predetermined par stock levels for each item, ensuring we always have enough on hand to meet demand.

Prioritization: I prioritize restocking frequently used items first, ensuring we never run out of essentials.

Ordering System: I utilize an efficient ordering system (whether it be digital or manual) to place timely orders with suppliers, avoiding shortages.

Running out of a key ingredient during a busy night can be catastrophic. Proactive restocking ensures smooth operations and avoids disappointing customers.

Q 7. How do you manage waste disposal at a bar station?

Proper waste disposal is crucial for hygiene and regulatory compliance. My system focuses on segregation and efficient removal:

Waste Segregation: I segregate waste into appropriate containers (e.g., recyclables, general waste, glass). This is crucial for environmental responsibility and efficient waste management.

Regular Disposal: I ensure waste containers are emptied regularly throughout the shift to prevent overflow and maintain a clean work environment.

Sharp Objects: I have a designated container for sharp objects (e.g., broken glass) to prevent injuries. Safety is always paramount.

Compliance: I adhere to all local regulations regarding waste disposal and recycling.

A cluttered bar station with overflowing trash is not only unsightly but also poses hygiene risks. Organized and responsible waste disposal ensures a safe and clean working space.

Q 8. What are your strategies for keeping a bar station organized throughout a busy service?

Maintaining a meticulously organized bar station during a busy service is paramount for efficiency and customer satisfaction. My strategy relies on a combination of proactive preparation and reactive adjustments. Before service begins, I ensure all tools and frequently used items are within easy reach, following a logical workflow. For example, garnishes are placed near the cutting board, mixers near the shakers, and glassware is organized by type and size. During service, I employ a ‘clean as you go’ philosophy. After each drink, I immediately wipe down the station, replace used items, and restock as needed. Think of it like a well-oiled machine – each part needs to be in its place and functioning smoothly. I regularly rotate stock to ensure freshness, moving older items to the front. This prevents waste and ensures consistently high-quality drinks. This organized approach reduces wasted time searching for items during rushes, allowing me to focus on crafting excellent drinks for my customers.

- Pre-shift Prep: Thorough stock check, glassware polishing, ice preparation.

- During Service: Continuous cleaning, immediate restocking, efficient waste disposal.

- Post-shift Cleanup: Deep cleaning of the station, restocking for the next service.

Q 9. How do you handle damaged or broken glassware or equipment?

Handling damaged glassware or equipment requires a swift and safe approach. Safety is my top priority. Immediately, I clear the area to prevent accidents and inform my supervisor or manager. Broken glassware is carefully swept up, using a brush and dustpan to avoid cuts. I then dispose of the shards according to safety guidelines – typically in a designated puncture-proof container. Damaged equipment is similarly handled with caution. I document the damage (type, extent, possible cause), often with a photo, to aid in the repair or replacement process. This process is crucial not only for safety but also for inventory management and insurance claims. Imagine a situation where a customer is injured; having a record of the incident minimizes liability risks. For less severe damage, like a chipped glass, I immediately remove it from service to prevent further breakage or injury. This demonstrates responsibility and dedication to the safety of both staff and patrons.

Q 10. Describe your approach to maintaining a safe and organized workspace.

Maintaining a safe and organized workspace isn’t just about aesthetics; it’s crucial for efficiency and preventing accidents. My approach incorporates several key elements. First, I adhere to strict hygiene standards, regularly wiping down surfaces with a sanitized cloth. Sharp objects like knives and bottle openers are stored securely and out of reach. Spills are cleaned immediately to prevent slips and falls. I also maintain a clear pathway around the bar, avoiding clutter that could cause obstacles. Furthermore, I always ensure that all electrical appliances are properly unplugged and stored when not in use. This prevents potential electrical hazards and extends the life of the equipment. A safe workspace promotes a calm and efficient workflow, minimizing stress and maximizing productivity, much like a well-organized kitchen ensures a smooth cooking process.

Q 11. What is your preferred method for polishing glassware?

My preferred method for polishing glassware involves a multi-step process that ensures sparkling clean and spotless glasses. First, I wash the glasses thoroughly using a commercial-grade detergent and hot water. I then rinse them completely under running water to eliminate any soap residue. Next, I use a lint-free cloth or a specialized bar towel, polishing each glass in a circular motion until it’s completely dry and streak-free. I inspect each glass closely before putting it back into service to ensure there are no smudges or water spots. A clean, polished glass elevates the drinking experience, creating a positive impression on customers. Think of it as presenting a carefully prepared dish – the presentation is just as important as the ingredients themselves.

Q 12. How do you ensure the proper temperature of refrigerated beverages?

Maintaining the proper temperature of refrigerated beverages is essential for both quality and safety. I regularly check the temperature of our refrigerators using a thermometer to ensure that they are consistently within the recommended range (typically between 35°F and 38°F). If the temperature fluctuates, I immediately report it to my supervisor. Proper rotation of stock is crucial; FIFO (First In, First Out) is the standard, making sure that older items are used before newer ones to prevent spoilage. Beverages are arranged logically within the refrigerator, based on frequency of use and storage requirements. This ensures that frequently accessed items are easily accessible, saving time during busy periods. Maintaining accurate temperature is a crucial part of food safety, preventing the growth of harmful bacteria.

Q 13. How do you quickly and efficiently identify missing or low stock items?

Efficiently identifying missing or low-stock items requires a proactive inventory management system. I usually employ a combination of methods. First, a regular par stock system allows me to know exactly how much of each item should be on hand. I perform a visual check before, during and after each service, comparing what’s on hand with the par stock levels. Secondly, I use a bar inventory software (or a simple spreadsheet) to track consumption and automatically alerts me to items approaching low levels. This helps me anticipate needs and prevent shortages. This prevents running out of crucial ingredients at a peak time. The visual check combined with software is a very robust way to address the problem.

Q 14. What are your strategies for handling high-volume service at the bar?

Handling high-volume service demands efficient teamwork and preparation. My strategy focuses on anticipating demand and streamlining processes. This starts with pre-shift preparation. I ensure sufficient ice, garnishes, and frequently used ingredients are readily available. I coordinate with my fellow bartenders to divide tasks efficiently – one might focus on mixing, another on serving. Clear communication is key; we use concise terminology and established procedures to minimize confusion and maximize speed. During peak hours, I prioritize high-demand drinks, often employing techniques to quickly prepare common cocktails. Using pre-batched mixes for standard drinks can dramatically reduce prep time during high volume. This structured approach helps us provide excellent service even under pressure – it’s like a well-coordinated orchestra, where every musician plays their part in creating a harmonious performance.

Q 15. Describe your knowledge of health and safety regulations regarding food and beverage service.

My understanding of health and safety regulations in food and beverage service is comprehensive. It encompasses everything from proper handwashing techniques and the prevention of cross-contamination to the safe storage and handling of food and beverages. I am well-versed in regulations concerning temperature control, preventing foodborne illnesses, and adhering to allergen guidelines. For example, I know that all food items must be stored at the correct temperatures to prevent bacterial growth – cold items below 41°F and hot items above 135°F. I’m also familiar with the importance of proper cleaning and sanitizing procedures, using appropriate chemicals at the correct dilutions to eliminate harmful bacteria and viruses. My experience ensures we consistently maintain a safe and hygienic environment for both staff and patrons, conforming to all local and national health codes.

- Handwashing: Frequent and thorough handwashing, using soap and water for at least 20 seconds, is paramount.

- Cross-Contamination: Using separate cutting boards and utensils for raw and cooked foods is crucial. Regularly sanitizing work surfaces is also essential.

- Temperature Control: Using thermometers to monitor food temperatures and ensuring proper refrigeration and hot holding are critical.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks to maintain both efficiency and cleanliness?

Prioritizing tasks for efficiency and cleanliness involves a systematic approach. I utilize a combination of checklists and a ‘clean as you go’ philosophy. Imagine a busy Friday night – my priority is always guest service, so I’ll tackle tasks strategically. For example, I’ll quickly wipe down spills immediately, rather than letting them build up. After a rush, I prioritize washing and sanitizing glasses and preparing fresh ice before restocking garnishes and liquors. A well-stocked and organized bar makes everything faster. Essentially, I view organization as a time-saving tool. I can locate items quickly, reducing time spent searching and improving overall efficiency. My checklist ensures that less urgent, but equally important, tasks like deep cleaning are scheduled consistently.

- Immediate Cleaning: Addressing spills and messes immediately prevents them from becoming larger problems.

- Prioritized Cleaning: Focusing on high-touch areas and essential tools first ensures hygiene and operational flow.

- Scheduled Deep Cleaning: Regularly scheduled deep cleaning tasks ensure the bar remains in optimal condition.

Q 17. How do you ensure the correct storage and rotation of stock to minimize waste?

Correct stock rotation (FIFO – First In, First Out) is vital for minimizing waste and ensuring freshness. We use a combination of clear labeling with dates and strategic placement of items to achieve this. Liquor bottles are often rotated based on purchase date, and we always use the oldest bottles first. For perishable items like garnishes, we clearly label them with dates and keep them in designated, refrigerated areas. Regular stock checks allow us to identify approaching expiration dates and adjust our ordering accordingly. This prevents large-scale waste by ensuring that items don’t expire unused. Imagine a case of limes – clearly labeled with the date of purchase, they are used first, avoiding spoilage and unnecessary loss.

Q 18. What are some time-saving techniques for maintaining a clean and organized bar station?

Several time-saving techniques streamline bar station maintenance. One key strategy is ‘mise en place’ – French for ‘everything in its place.’ This involves prepping all ingredients and tools before service begins. Having pre-cut garnishes, measured ingredients, and tools readily accessible drastically reduces time spent during busy periods. Another is efficient cleaning methods – using a multi-purpose cleaner with microfibre cloths reduces the need for switching cleaning agents. Regularly decluttering the bar station eliminates unnecessary items and keeps everything within easy reach. Finally, using speed-cleaning techniques like using specialized tools, such as a glass rinsing machine and efficient ice scoop technique, significantly reduces time spent on cleaning tasks.

Q 19. Explain your understanding of different cleaning agents and their appropriate uses.

My understanding of cleaning agents covers a wide range of products and their appropriate applications. We use different cleaning agents based on the surface being cleaned and the type of soil. For instance, glass cleaner is best for glasses, while a sanitizer is crucial for eliminating bacteria from bar surfaces. A degreaser would be necessary to remove stubborn grease from equipment. It’s also crucial to understand dilutions – using too much can cause damage, while too little is ineffective. I always adhere to manufacturer guidelines for dilution ratios and safety precautions. For example, I know that bleach solutions need to be carefully mixed and used with appropriate safety measures (gloves, ventilation). Understanding these safety protocols is vital to ensure that cleaning procedures don’t risk staff health.

Q 20. How do you prevent the buildup of grime and residue on bar surfaces?

Preventing grime and residue buildup requires a proactive approach involving regular cleaning and proper maintenance. This includes frequent wiping of surfaces, particularly high-touch areas like the bar top, speed rail, and POS system. We use appropriate cleaning agents and regularly sanitize surfaces to eliminate bacteria. Regular deep cleaning procedures, perhaps once a week, including thorough scrubbing and sanitizing of the entire bar area, ensure the removal of embedded grime. Also, addressing spills and sticky residues immediately prevents them from hardening and becoming more difficult to remove. This consistent care maintains a clean and hygienic work environment.

Q 21. Describe your experience with various bar equipment and their maintenance needs.

My experience encompasses a variety of bar equipment, including espresso machines, ice machines, blenders, and various glassware. I’m familiar with the maintenance needs of each. For example, espresso machines require regular descaling to remove mineral buildup that can affect taste and machine performance. Ice machines require periodic cleaning to prevent bacterial growth and maintain optimal ice production. Blenders require careful cleaning to avoid damage from trapped liquids or ingredients. Regular cleaning and minor maintenance tasks prolong the lifespan of equipment and prevent costly repairs or replacements. Proactive maintenance is key to prevent major breakdowns during busy service periods. For instance, regular inspection of ice machines will prevent potential issues and reduce downtime.

Q 22. How do you handle customer complaints related to cleanliness or service?

Addressing customer complaints about cleanliness or service is paramount. My approach is always to apologize sincerely, acknowledge their concern, and immediately address the issue. I would first listen attentively without interruption, ensuring I understand their complaint fully. For example, if a customer complains about sticky glassware, I would immediately replace the glasses with clean ones, and depending on the situation, potentially conduct a thorough cleaning of the area. If the complaint relates to slow service, I’d explain the situation (perhaps it’s an unusually busy period), apologize for the delay, and prioritize their order. I always strive to turn a negative experience into a positive one by offering a complimentary drink or discount, depending on the severity of the complaint. Ultimately, my goal is to maintain a positive customer experience and demonstrate the establishment’s commitment to quality.

Q 23. What is your understanding of proper garnish preparation and storage?

Proper garnish preparation and storage are crucial for maintaining food safety and visual appeal. Garnishes should be sourced from reputable suppliers and stored correctly to prevent spoilage. For example, citrus slices are best stored in airtight containers in the refrigerator, while herbs are often best kept in a damp paper towel wrapped container. Preparation involves careful washing and thorough drying of all garnishes. I’d always ensure that everything is meticulously chopped or cut to the appropriate size and kept in clearly labelled containers to prevent cross-contamination and facilitate quick access during service. Regularly discarding old garnishes is vital to preventing bacterial growth. Think of it like a chef’s mise en place – having everything prepared, organized, and readily available ensures smooth and efficient service.

Q 24. How would you deal with a malfunctioning bar appliance during peak hours?

Dealing with a malfunctioning appliance during peak hours requires swift action and problem-solving skills. My first step would be to assess the severity of the malfunction. Is it something minor that can be quickly fixed, or does it require a more significant intervention? For example, if the ice machine breaks down, I’d immediately inform my manager and begin rationing the remaining ice, focusing on the most essential drinks first. If a blender malfunctions, I would try to resolve minor issues myself (e.g., resetting it), but if this fails, I would find a replacement method such as using a manual shaker or temporarily removing blended drinks from the menu. Open communication with my team and customers is crucial; letting them know about potential delays and offering alternative options prevents frustration.

Q 25. How do you ensure compliance with alcohol service regulations?

Compliance with alcohol service regulations is non-negotiable. This includes checking IDs diligently to ensure all patrons are of legal drinking age, understanding and adhering to responsible service of alcohol (RSA) policies, and recognizing signs of intoxication. I would never serve visibly intoxicated individuals, and if I suspect someone is underage, I would politely refuse service and, if necessary, seek assistance from my supervisor or security personnel. I regularly update my knowledge of local alcohol laws and RSA best practices to maintain compliance and ensure a safe and responsible environment. Think of it as a duty of care – protecting both the patrons and the establishment’s legal standing.

Q 26. Explain your strategies for training new bar staff on cleanliness and organization.

Training new bar staff on cleanliness and organization begins with a thorough orientation. This involves a detailed tour of the bar station, explaining the location of all equipment and supplies. I’d then provide hands-on training, showing them the proper procedures for cleaning and sanitizing glasses, equipment, and the workspace. I implement a clear checklist to ensure consistent hygiene standards. I would also emphasize the importance of proper storage techniques to prevent spillage or cross-contamination. For example, storing alcohol bottles in designated order and cleaning spills immediately. Role-playing scenarios, like handling a busy period or dealing with customer complaints, further enhances their understanding and confidence. Regular feedback and reinforcement of best practices ensure consistent adherence to high standards.

Q 27. How do you effectively communicate with co-workers regarding bar station maintenance?

Effective communication with co-workers regarding bar station maintenance is crucial for efficiency and consistency. I use a combination of verbal communication and visual aids (such as checklists or whiteboards) to ensure everyone is informed about tasks, cleanliness schedules, and any issues that need addressing. For example, if a bottle needs refilling or an area requires cleaning, I’d communicate this clearly and promptly to my colleagues. I always create a positive work atmosphere to encourage open communication and mutual support, because efficient teamwork ensures a clean, organized and smoothly functioning bar environment.

Q 28. Describe your experience working in a fast-paced bar environment.

I thrive in fast-paced bar environments. My previous experience involved managing high-volume service during peak hours, requiring quick thinking, multi-tasking abilities, and excellent organizational skills. I’m adept at prioritizing tasks, maintaining composure under pressure, and efficiently managing multiple orders simultaneously. During busy periods, my focus is on maintaining a streamlined workflow, delegating tasks where appropriate, and ensuring that both service speed and quality remain consistently high. I am confident that my skills and experience make me an ideal candidate for this role. It is exhilarating to be part of a highly functioning team delivering excellent customer service in a challenging environment.

Key Topics to Learn for Maintaining a Clean and Organized Bar Station Interview

- Inventory Management: Understanding stock rotation (FIFO), proper storage techniques for different beverage types (spirits, beers, wines), and recognizing when re-stocking is needed. Practical application: Describe a system you’d use to prevent stockouts and spoilage.

- Hygiene and Sanitation: Implementing proper cleaning procedures for glassware, bar surfaces, equipment (e.g., ice machines, taps), and adhering to health and safety regulations. Practical application: Explain your approach to maintaining a consistently clean and sanitary work environment during a busy service period.

- Organization and Efficiency: Setting up a bar station for optimal workflow, utilizing efficient garnishing and preparation techniques, and maintaining a visually appealing and clutter-free workspace. Practical application: Describe how you would organize a bar station to minimize movement and maximize speed during peak hours.

- Troubleshooting and Problem-Solving: Identifying and addressing common equipment malfunctions (e.g., faulty ice machine, leaky tap), dealing with spills and breakages efficiently, and maintaining composure under pressure. Practical application: Describe a time you had to quickly resolve a problem at a bar station to maintain service.

- Teamwork and Communication: Collaborating effectively with bartenders, servers, and other staff, communicating clearly about inventory needs and potential issues, and contributing to a positive team environment. Practical application: Explain how you contribute to a smooth and efficient teamwork dynamic within a busy bar setting.

Next Steps

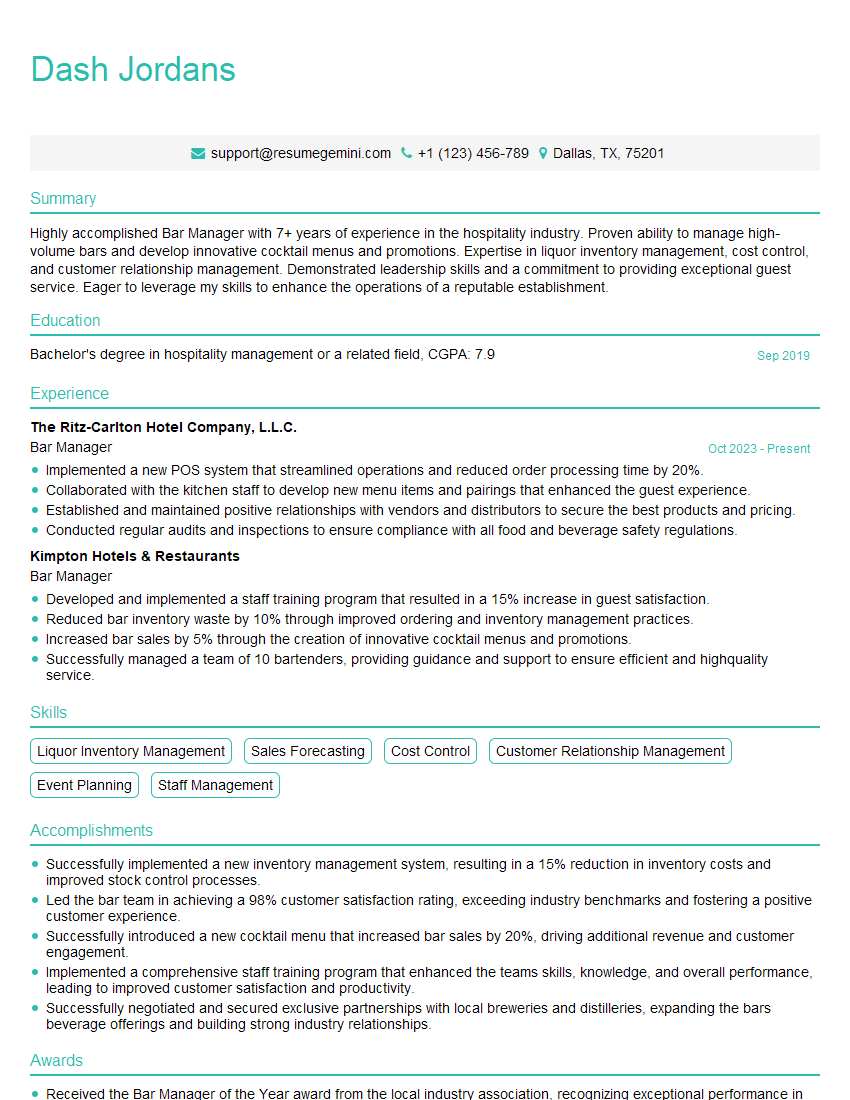

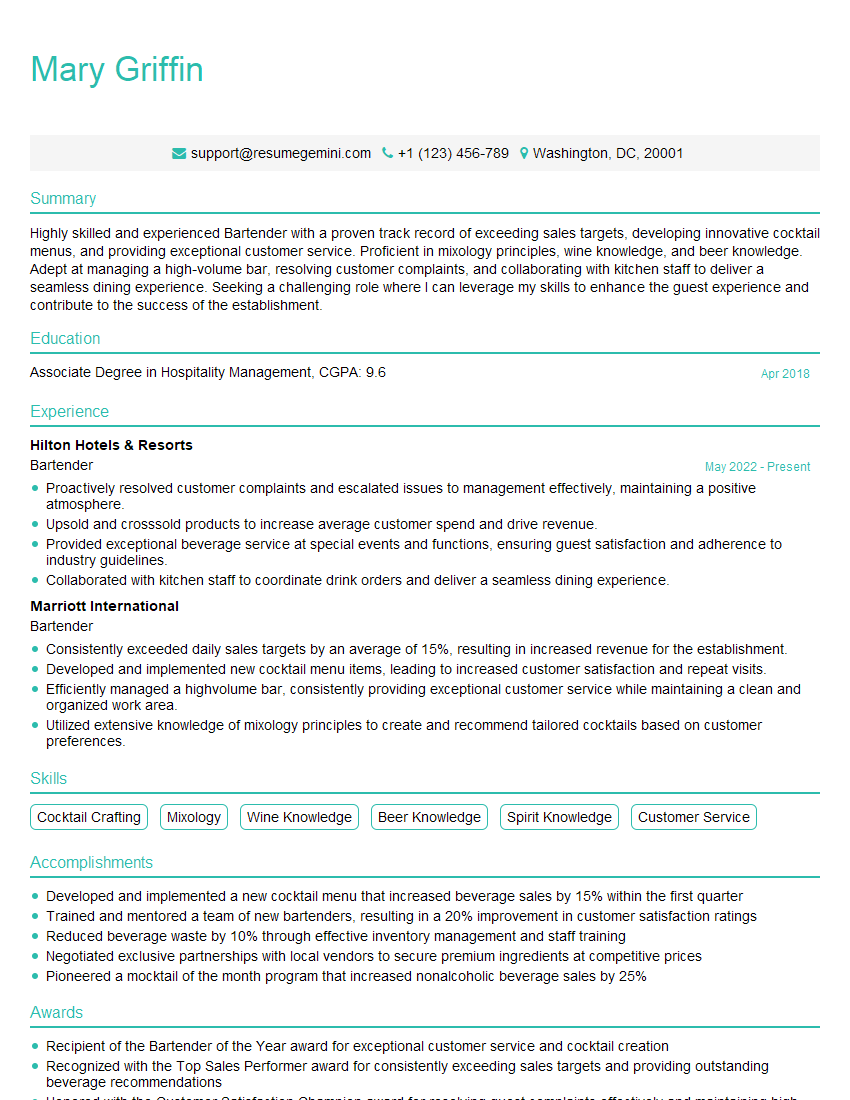

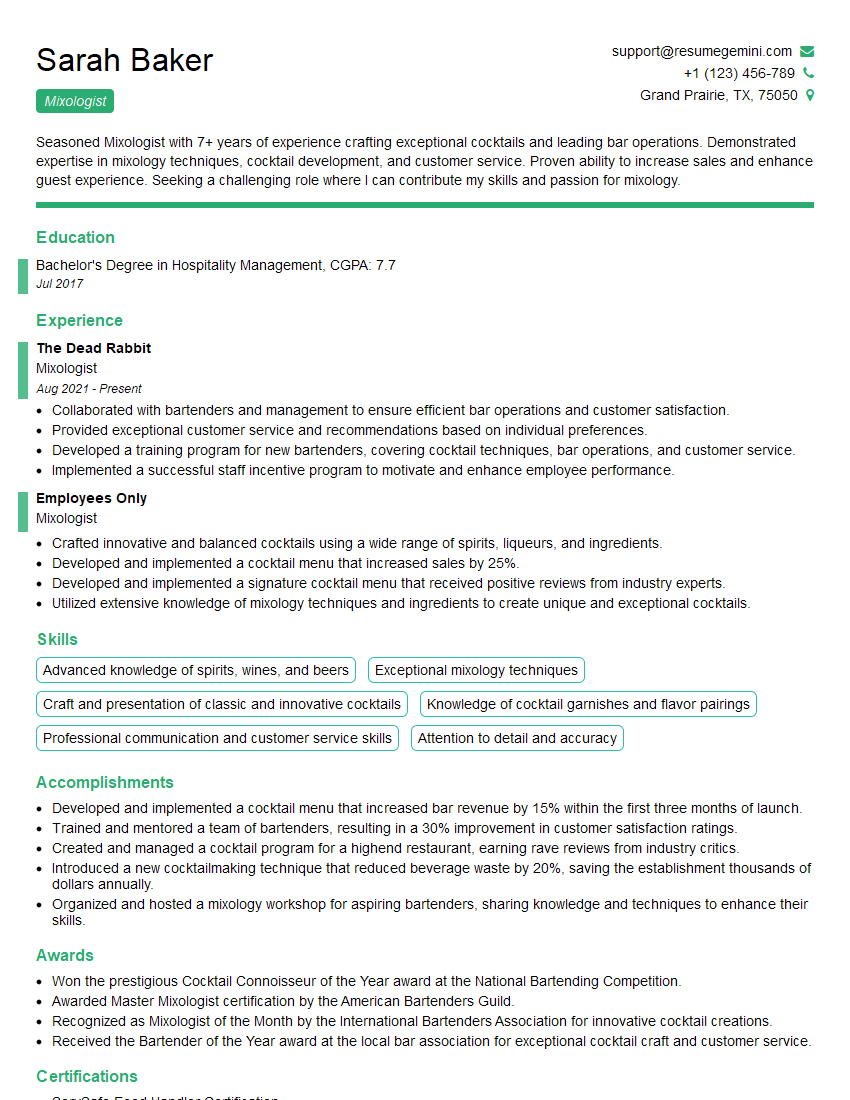

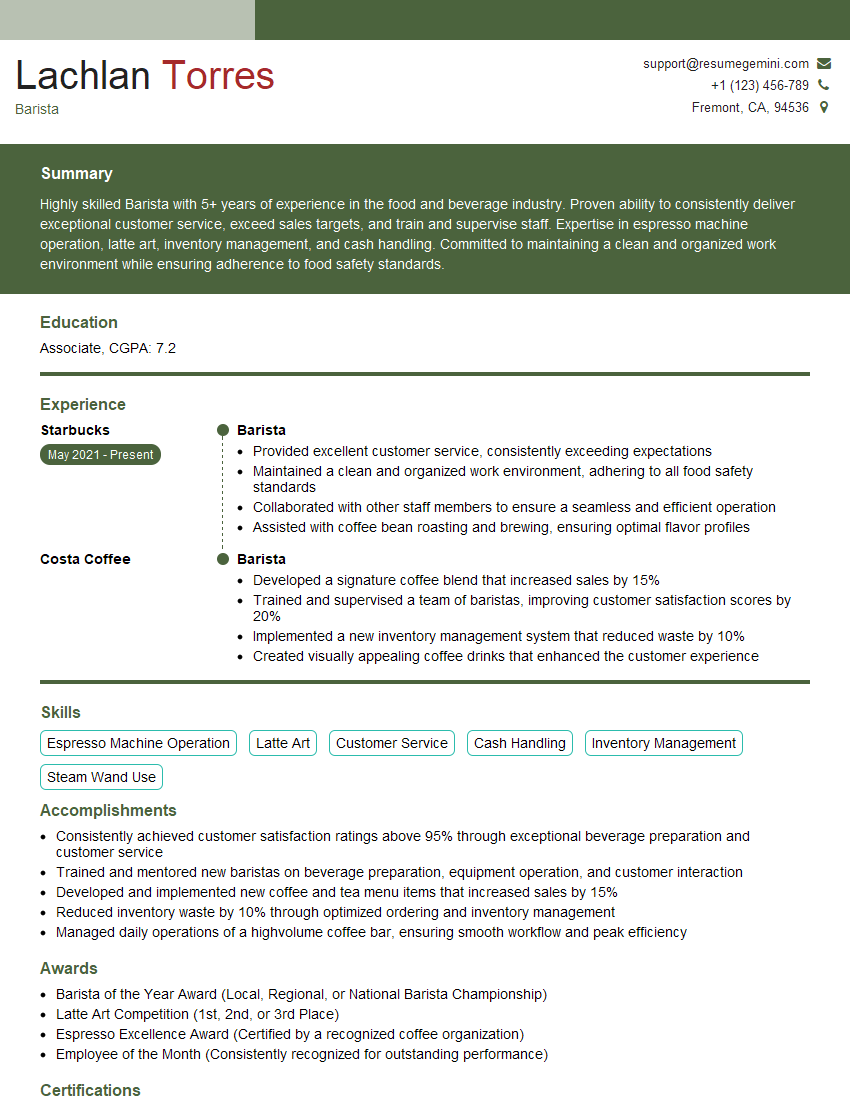

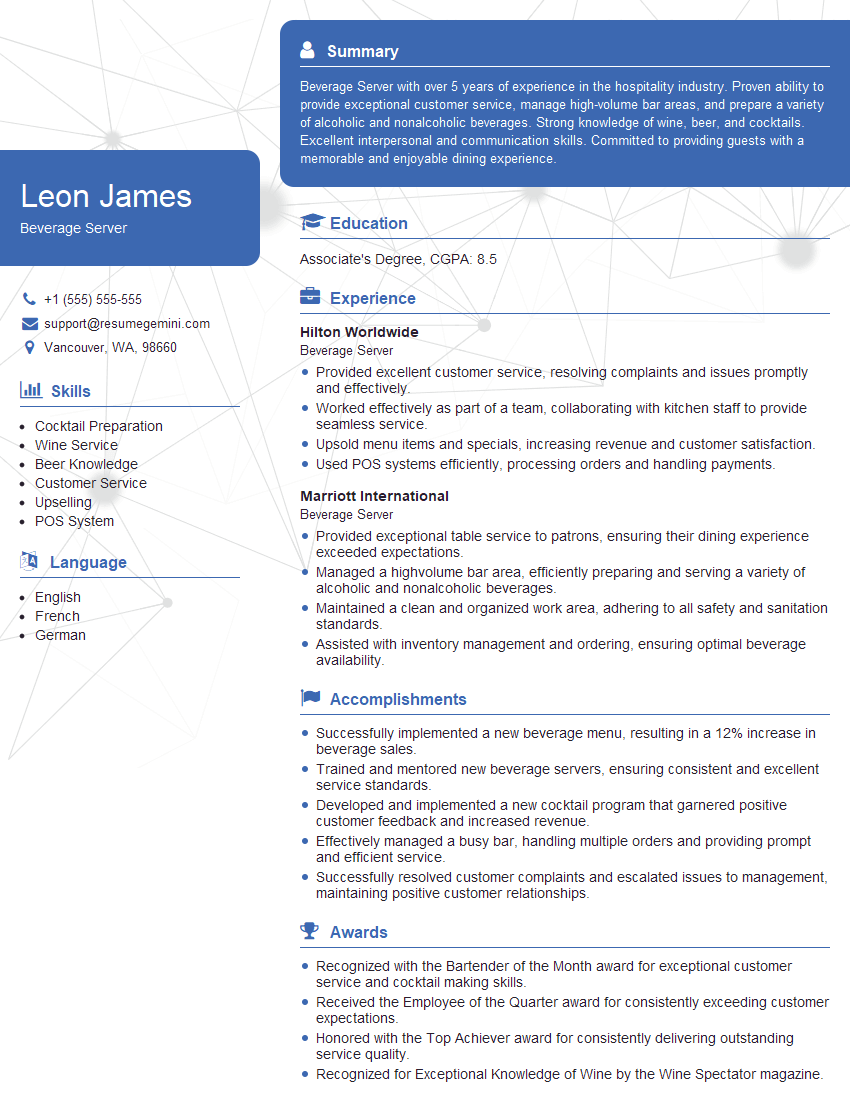

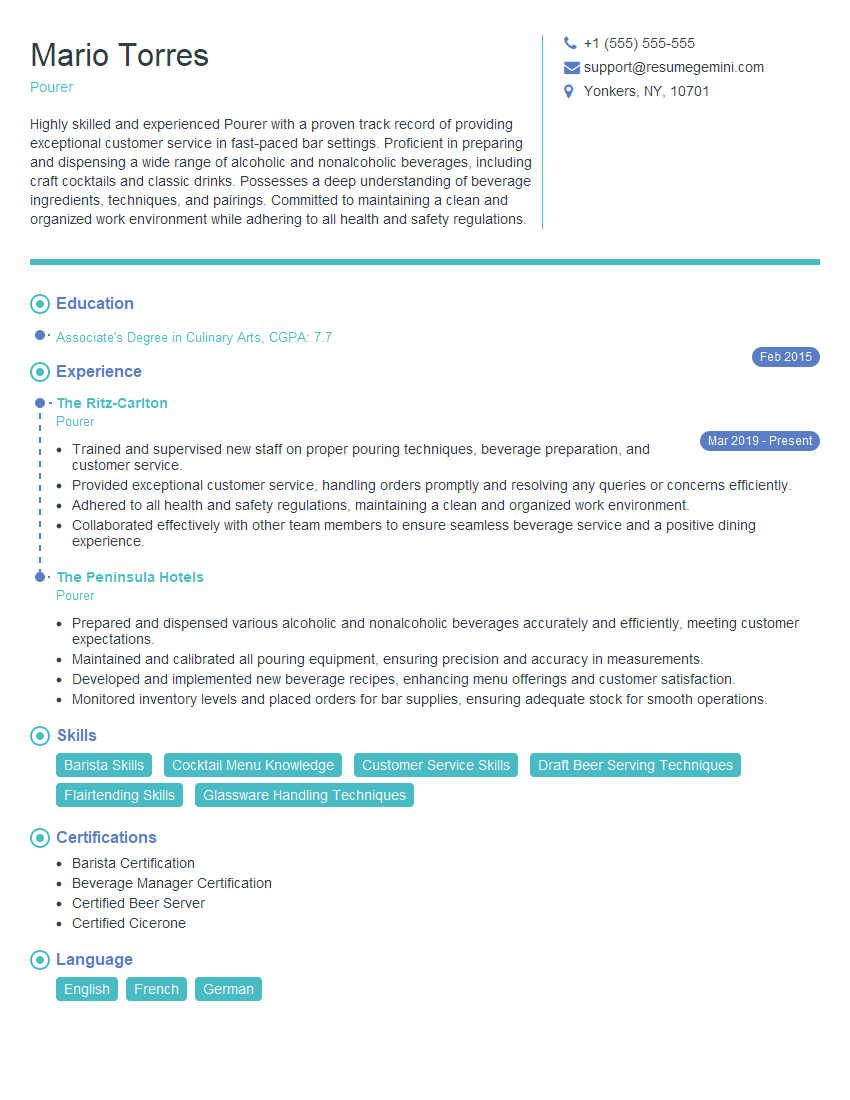

Mastering the art of maintaining a clean and organized bar station demonstrates crucial skills highly valued in the hospitality industry – efficiency, attention to detail, and a commitment to hygiene and safety. These skills translate to increased productivity, improved customer satisfaction, and ultimately, greater career opportunities. To highlight these skills effectively, invest time in crafting an ATS-friendly resume that showcases your accomplishments. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to showcasing expertise in maintaining a clean and organized bar station are available, helping you present your skills in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Dear Sir/Madam,

Do you want to become a vendor/supplier/service provider of Delta Air Lines, Inc.? We are looking for a reliable, innovative and fair partner for 2025/2026 series tender projects, tasks and contracts. Kindly indicate your interest by requesting a pre-qualification questionnaire. With this information, we will analyze whether you meet the minimum requirements to collaborate with us.

Best regards,

Carey Richardson

V.P. – Corporate Audit and Enterprise Risk Management

Delta Air Lines Inc

Group Procurement & Contracts Center

1030 Delta Boulevard,

Atlanta, GA 30354-1989

United States

+1(470) 982-2456