The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to OTDR (Optical Time Domain Reflectometer) Testing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in OTDR (Optical Time Domain Reflectometer) Testing Interview

Q 1. Explain the principle of operation of an OTDR.

An OTDR, or Optical Time Domain Reflectometer, works by sending a short pulse of light into an optical fiber. This light travels down the fiber, and a portion of it is reflected back towards the OTDR at various points due to imperfections and changes in the fiber’s refractive index. The OTDR measures the time it takes for this reflected light to return, along with its intensity. This information is then used to create a trace, a visual representation of the fiber’s characteristics along its length.

Think of it like sending a sound wave into a long pipe. If there are obstructions or changes in the pipe’s diameter, the sound wave will reflect back at those points, revealing their location and nature. The OTDR does the same, but with light instead of sound, and it measures the intensity of the returning signal to determine the severity of any issues.

Q 2. What are the different types of OTDR scattering?

OTDR scattering primarily involves two types: Rayleigh scattering and Fresnel reflection.

- Rayleigh scattering is caused by microscopic variations in the fiber’s refractive index. These variations scatter light in all directions, with a portion returning to the OTDR. This creates a background signal that gradually decreases with distance, representing fiber attenuation. It’s like a hazy mist – scattering light in all directions.

- Fresnel reflection occurs at interfaces where there is a significant change in the refractive index, such as at fiber connectors, splices, or the end of the fiber. This reflection is much stronger than Rayleigh scattering and appears as sharp peaks on the OTDR trace. Think of this as a mirror, reflecting a strong, concentrated beam of light back to the source.

Q 3. Describe the various OTDR parameters and their significance (e.g., pulse width, averaging, wavelength).

Several key OTDR parameters influence the quality and accuracy of the trace:

- Pulse Width: This determines the resolution of the trace. A shorter pulse offers better resolution, allowing for the identification of closely spaced events, but reduces the range and signal-to-noise ratio. A longer pulse provides a longer reach but lower resolution. It’s a trade-off between detail and distance.

- Averaging: Multiple traces are averaged to improve the signal-to-noise ratio and reduce the impact of random noise, resulting in a smoother and more reliable trace. More averaging means a cleaner trace but a longer test time.

- Wavelength: The wavelength of the light source affects attenuation and scattering characteristics. Different wavelengths may be used to optimize for specific fiber types or applications. For instance, 1310nm and 1550nm are common wavelengths for single-mode fibers.

Proper selection of these parameters is crucial for obtaining accurate results and depends heavily on the fiber length, type, and the expected locations of events.

Q 4. How do you interpret an OTDR trace?

Interpreting an OTDR trace involves analyzing both the signal level (power) and distance. The trace displays signal loss (attenuation) as a downward sloping line, and events such as connectors, splices, and faults appear as sharp drops or reflections in the signal.

A typical trace shows:

- Attenuation Slope: A gradual decrease in signal level due to Rayleigh scattering. The slope indicates the attenuation coefficient of the fiber.

- Events: Sharp changes in signal level, indicating connectors, splices, or faults in the fiber.

- Reflections: Peaks indicating strong reflections from events like fiber breaks or poorly connected connectors.

By measuring the distance to these events and their associated signal loss, one can identify and characterize the issues in the fiber optic link. Experienced technicians utilize specialized OTDR software that allows accurate measurements and analysis, often including automated reporting features.

Q 5. Explain the difference between Fresnel reflection and Rayleigh scattering in OTDR traces.

While both Fresnel reflection and Rayleigh scattering are important in OTDR traces, they differ significantly:

- Fresnel Reflection: Produces sharp, distinct peaks on the trace representing a significant change in refractive index. It is a strong, localized reflection and is easily identifiable as a clear peak. These peaks occur at abrupt changes like connector terminations or breaks in the fiber.

- Rayleigh Scattering: Creates a continuous, gradual decline in the signal level. This is a diffuse scattering caused by microscopic variations in the fiber’s composition. It provides information about the overall fiber attenuation and is more of a background signal.

Think of it like a flashlight beam shining down a hallway. A mirror at the end would cause a strong Fresnel reflection. Dust and particles in the air would create Rayleigh scattering, reducing the intensity of the beam as it travels down the hallway.

Q 6. What are the common causes of attenuation in fiber optic cables, and how are they identified using an OTDR?

Several factors contribute to attenuation in fiber optic cables. An OTDR helps identify these by analyzing the attenuation slope and specific events on the trace:

- Macrobends: Sharp bends in the fiber cause increased attenuation and can be identified as localized loss regions on the trace.

- Microbends: Tiny bends in the fiber, often caused by improper cabling, similarly increase attenuation and create a somewhat diffuse loss along a fiber section.

- Connectors and Splices: These introduce insertion loss due to imperfect alignment or contamination. They manifest as clear dips in the OTDR trace, with the magnitude of the dip indicating the severity of the loss.

- Fiber Degradation: Aging or environmental factors can degrade fiber quality, leading to higher attenuation and visible change in the attenuation slope.

- Improper Splices: Poorly fused fiber splices increase attenuation significantly, resulting in a larger loss in the signal in that specific location.

By carefully examining the trace, comparing the attenuation with specifications, and analyzing the location of loss events, an OTDR user can pinpoint the causes of attenuation.

Q 7. How do you identify fiber breaks, macrobends, and connector losses on an OTDR trace?

An OTDR trace reveals these issues in distinct ways:

- Fiber Breaks: A complete break in the fiber results in a sharp, high-amplitude reflection at the break point. Beyond this point, there is no signal. This is a clear and easily identifiable event.

- Macrobends: Appear as localized increases in attenuation, creating a visible dip or a region of higher than expected signal loss on the trace. The location helps pinpoint the physical bend.

- Connector Losses: Show up as distinct, sharp dips in the signal level at the connector location. The magnitude of the dip directly corresponds to the loss introduced by that connector. Poorly made connections will have larger dips.

By understanding the characteristic signatures of these events on the OTDR trace, technicians can effectively troubleshoot fiber optic cables and identify the specific location and nature of the problems, allowing for targeted repairs or replacements.

Q 8. What is the significance of the dead zone in OTDR measurements?

The dead zone in OTDR measurements is a critical concept to understand. It’s essentially a region immediately following a significant event, such as a connector or splice, where the OTDR cannot accurately measure reflections. This is because the backscattered light from the event overwhelms the sensor’s ability to detect weaker reflections further down the fiber. Think of it like trying to hear a whisper immediately after a loud explosion – the quieter sound is masked.

The length of the dead zone depends on several factors: the OTDR’s pulse width (shorter pulses result in smaller dead zones), the event’s reflectivity (highly reflective events create larger dead zones), and the OTDR’s dynamic range (a wider dynamic range allows for better resolution near the event). It’s crucial because it prevents accurate assessment of fiber problems close to connectors or splices, potentially leading to missed faults.

For instance, if a fiber break occurs right after a connector within the dead zone, the OTDR might not detect it. Careful planning and the use of shorter pulse widths are vital to minimize this issue.

Q 9. Explain different OTDR measurement methods (e.g., bidirectional, single-ended).

OTDR measurements can be performed using different methods, each with its own advantages and disadvantages.

- Bidirectional OTDR Testing: This involves testing the fiber in both directions. One end of the fiber is connected to the OTDR and tested. Then, the OTDR is moved to the other end, and the measurement is repeated in the reverse direction. This method provides a more complete picture of the fiber link, allowing the identification of faults from both ends, and it helps to compensate for any directional variations in the fiber’s performance.

- Single-ended OTDR Testing: Here, the OTDR is connected at only one end of the fiber and the signal reflects back to the sensor. This is simpler and faster, but it may not reveal problems that exist near the far end of the fiber, as the backscattered signal from the far end may be significantly attenuated.

The choice of method depends on the specific application and the available access points to the fiber optic cable. For instance, in a point-to-point link where both ends are easily accessible, a bidirectional test is preferred for complete characterization. If access is restricted to one end, a single-ended test might be the only viable option.

Q 10. How do you determine the length of a fiber optic cable using an OTDR?

Determining the fiber length using an OTDR is straightforward once you understand the principles. The OTDR displays a trace which represents the backscattered light intensity as a function of time. The time it takes for the light to travel to the far end of the fiber and return is directly proportional to the fiber length. The OTDR calculates this length automatically using the known speed of light in the fiber.

You’ll identify the far-end reflection on the trace, often denoted by a significant peak. The OTDR software then uses this information and the speed of light in the fiber to calculate the distance. It’s important to ensure that the correct refractive index of the fiber is entered in the OTDR’s configuration, as this affects the accuracy of the length calculation. The OTDR will usually display the calculated length in meters or kilometers, alongside the trace.

Imagine sending a sound signal down a long hallway and then waiting for the echo. The time the echo takes to return is directly related to the length of the hallway, and the OTDR operates on a similar principle.

Q 11. How do you troubleshoot a fiber optic link using an OTDR?

Troubleshooting a fiber optic link using an OTDR involves a systematic approach. First, you connect the OTDR to one end of the fiber and obtain a trace.

- Identify Events: Analyze the trace for any significant events, such as connectors, splices, and breaks. These will appear as distinct peaks or drops in the backscatter signal.

- Measure Loss: The OTDR will indicate the loss (attenuation) in dB at various points along the fiber, enabling you to identify areas with excessive attenuation, possibly due to bending, or micro-bends.

- Locate Faults: By measuring the distance to each event and correlating it with the cable map, you can pinpoint faults in the link.

- Analyze Reflections: High reflections can indicate connectors or splices with poor quality or misalignment.

- Assess Overall Link Health: The OTDR’s results allow assessment of the fiber link’s performance and whether it meets the necessary attenuation specifications.

For example, if you observe a significant loss at a specific point, it suggests that the fiber may have been damaged or improperly spliced in that region. Similarly, unexpected reflections point to connector issues that require further attention.

Q 12. Describe the process of performing a fiber optic loss budget calculation.

A fiber optic loss budget calculation is crucial for designing and implementing a fiber optic network. It helps ensure that the total loss in the system remains below an acceptable threshold. The goal is to keep the overall system loss lower than the receiver’s sensitivity. This guarantees a reliable and efficient data transmission.

The process typically involves:

- Identify Components: First, list all the fiber optic components, including fiber cables, connectors, splices, and any other passive components like couplers or splitters.

- Determine Component Losses: For each component, determine the insertion loss (for connectors and splices) or attenuation (for fiber cables) from manufacturer specifications or measurements.

- Calculate Total Loss: Sum up the losses of all the components along the path.

- Add Margins: Add safety margins (typically 1-3dB or more) to compensate for unexpected loss, aging, and future expansion. This accounts for degradation over time.

- Compare to Receiver Sensitivity: The total calculated loss (including margins) should be significantly less than the receiver’s sensitivity to ensure the signal-to-noise ratio remains acceptable for a reliable system.

For example, you might have a 10km fiber cable with 0.35dB/km attenuation, three connectors at 0.5dB each, and one splice at 0.2dB. The total loss is (10km * 0.35dB/km) + (3 * 0.5dB) + 0.2dB = 5.7dB. By adding a margin of 2dB, the total budget becomes 7.7dB. If your receiver can handle a loss of 10dB before significant signal degradation, you are within acceptable limits.

Q 13. What are the safety precautions to be considered while using an OTDR?

Safety is paramount when working with OTDRs. The most critical risk is eye damage from the powerful optical signal emitted. The OTDR laser light can be hazardous even with a low-power device.

- Eye Protection: Always wear appropriate eye protection rated for the laser wavelength of the OTDR. Never look directly into the fiber end or the OTDR’s output port.

- Proper Connections: Connect the fiber optic cables and OTDR components carefully to prevent accidental laser exposure.

- Safety Training: Ensure proper training on the safe handling and operation of OTDR equipment and fiber optic systems.

- Warning Signs: Post warning signs to alert others of potential laser hazards in the area while testing.

- Power Management: Always switch off the OTDR when not in use.

- Environmental Considerations:Be aware of environmental factors that might affect the testing process and your safety. For instance, working in wet conditions can pose additional electrical hazards.

Remember, a moment of carelessness can lead to severe eye injury. Strict adherence to safety protocols is non-negotiable.

Q 14. How do you calibrate an OTDR?

OTDR calibration is essential for maintaining accuracy. While some OTDRs have built-in self-calibration features, periodic calibration against traceable standards is recommended.

The calibration process usually involves connecting the OTDR to a calibrated fiber optic reference standard (with known loss, reflection, etc.) and adjusting the instrument to match the known values. This calibration may involve adjusting parameters within the OTDR’s software. This could include things such as the refractive index, which affects the distance measurement, as well as other parameters specific to the OTDR’s hardware. This usually must be performed by a qualified technician, and the procedures are often outlined in the specific OTDR’s instruction manual. Some higher-end OTDRs may have built-in test routines that check the operation of internal components against their original specifications, and thus can indicate if recalibration is needed.

The frequency of calibration depends on factors such as the OTDR’s usage, environment, and required accuracy. A well-maintained OTDR calibration will ensure that it consistently delivers reliable and accurate results, which is critical for network maintenance and troubleshooting.

Q 15. Explain the difference between OTDR and power meter testing.

An OTDR (Optical Time Domain Reflectometer) and a power meter both test fiber optic links, but they do so in fundamentally different ways. Think of it like this: a power meter is like a simple light meter—it only measures the overall light intensity at the end of the fiber. An OTDR, on the other hand, is like a sophisticated radar system for fiber optics. It sends a pulse of light down the fiber and analyzes the reflections that come back, revealing details about the fiber’s characteristics along its entire length.

A power meter simply tells you if light is reaching the end of the fiber and how much. It can’t pinpoint the location of faults or identify the type of connector or splice. An OTDR, however, can precisely locate faults, measure fiber attenuation (signal loss), identify connector and splice loss, and even reveal the type of fiber used. In essence, an OTDR provides a comprehensive ‘map’ of the fiber, while a power meter gives only a single, endpoint measurement.

For example, imagine a long fiber optic cable with a broken section. A power meter would simply show a low or zero signal. The OTDR, however, would pinpoint the exact location of the break, along with the overall attenuation of the fiber before the break.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the limitations of OTDR testing?

While incredibly powerful, OTDR testing does have limitations:

- Dead zones: After a significant event like a splice or connector, the OTDR needs time for the back-reflected signal to die down before it can detect the next event. This creates a ‘blind spot’ called a dead zone. The length of the dead zone is dependent on several factors, including the OTDR’s pulse width.

- Minimum detectable loss: OTDRs have a minimum loss detection threshold; very small losses or gradual attenuation might not be noticeable.

- Fiber type dependency: OTDRs are designed for specific fiber types. Using an OTDR optimized for single-mode fiber on multi-mode fiber will lead to inaccurate measurements.

- Polarization Mode Dispersion (PMD): PMD can affect the accuracy of OTDR measurements, especially in long-haul high-bandwidth systems. We’ll discuss this further below.

- Cost and complexity: OTDR equipment can be expensive, and the interpretation of OTDR traces requires specialized training.

Understanding these limitations is crucial for accurate interpretation of OTDR test results. For example, if you have numerous connectors close together, you’ll observe multiple overlapping dead zones making it difficult to resolve individual events.

Q 17. How do you handle different types of connectors (e.g., SC, FC, LC) during OTDR testing?

Handling different connector types during OTDR testing is straightforward, but requires attention to detail and the right adapters. Most modern OTDRs include a range of connector adapters (SC, FC, LC, ST, etc.) that allow connection with the tested fiber. Before beginning, you must select the appropriate adapter for your connector type, ensuring a clean and secure connection.

Cleaning is vital. Any dirt or debris on the connector end faces can introduce significant loss and affect the accuracy of measurements. Using a fiber optic cleaning pen or wipes before connecting the OTDR is essential. Incorrectly connected adapters can cause high reflection readings. Careful inspection before and after connection ensures accurate results.

For example, if you’re testing a link with SC connectors at both ends and the OTDR uses LC connectors, you would need to use SC-to-LC adapters on both ends. Always double-check that all connectors and adapters are cleanly mated to prevent erroneous readings.

Q 18. What are the different types of fibers (single-mode, multi-mode) and their impact on OTDR measurements?

The two main types of fiber are single-mode and multi-mode. This impacts OTDR measurements significantly because of the way light propagates through each type.

- Single-mode fiber: Single-mode fiber has a smaller core diameter, allowing only one mode (path) of light to propagate. This results in less modal dispersion (light spreading), leading to higher bandwidth and longer transmission distances. OTDR traces on single-mode fiber typically show sharp, well-defined events.

- Multi-mode fiber: Multi-mode fiber has a larger core diameter, allowing multiple modes of light to propagate. This leads to more modal dispersion, resulting in lower bandwidth and shorter transmission distances. OTDR traces on multi-mode fiber can show broader, less-defined events due to the different modes’ varying arrival times.

OTDRs are specifically designed for either single-mode or multi-mode fiber, and using the wrong type will lead to inaccurate measurements. The OTDR’s software will be calibrated to accommodate the appropriate refractive index and other characteristics for accurate distance and loss calculations.

Q 19. How do you interpret an OTDR trace with multiple events?

Interpreting an OTDR trace with multiple events requires a systematic approach. First, the trace will show the fiber’s overall attenuation, which is measured in dB/km (decibels per kilometer). Then, you analyze the individual events (splices, connectors, faults). Each event appears as a reflection, which is a peak on the trace. The height of the peak represents the loss, measured in dB, at that point, while the horizontal position indicates the distance of that event from the OTDR.

Start by identifying the largest events first: major losses, which typically indicate breaks or severe problems. Smaller events might be splices or connectors. The trace’s distance scale helps locate these events along the fiber length. Compare the backscatter levels from the reference points(start and end) with the event amplitudes to compute the loss for each individual event. Consider factors such as dead zones, temperature, and the type of fiber to help determine what each event represents. It’s sometimes helpful to annotate the trace to mark the events and associated details.

For example, a large negative peak indicates a major loss, often a fiber break. Small peaks with consistent spacing could be multiple splices. A gradual increase in attenuation might indicate a bend in the fiber or gradual degradation.

Q 20. What is the impact of temperature and humidity on OTDR measurements?

Temperature and humidity can significantly affect OTDR measurements. Temperature changes alter the refractive index of the fiber, influencing the speed of light and thus the distance measurements. High humidity can also lead to changes in the fiber’s attenuation characteristics, possibly producing inaccurate loss readings. Additionally, temperature variations can affect the OTDR’s internal components leading to errors in signal processing.

Many modern OTDRs have temperature compensation features that try to mitigate these effects. However, extreme temperature fluctuations or high humidity can still impact the accuracy. Therefore, it’s essential to record the ambient temperature and humidity during the test and include this information in the test report. If possible, try to perform testing under controlled environmental conditions to reduce the impact of temperature and humidity. Temperature-controlled environments are particularly important for long-haul fiber optic testing where minor inconsistencies can become magnified over long distances.

Q 21. Explain the concept of polarization-mode dispersion (PMD) and its effect on OTDR testing.

Polarization Mode Dispersion (PMD) is a phenomenon in optical fibers where the two polarization states of light travel at different speeds. This difference in speed causes a broadening of the optical pulse, leading to signal distortion and limiting the bandwidth of the fiber. This effect is more pronounced in longer fibers and at higher data rates.

In OTDR testing, PMD can affect the accuracy of measurements, particularly in the assessment of attenuation and the location of events. The spread caused by PMD can make it harder to resolve closely spaced events or to accurately determine the extent of loss at a particular point. The impact of PMD is more significant for longer fibers and higher bit-rate systems.

Advanced OTDRs incorporate techniques to mitigate the effects of PMD, but it’s still a factor to consider, especially in long-haul high-bandwidth applications. When dealing with long links, it’s often crucial to account for this effect during data analysis. The PMD effects might require special analysis techniques like performing multiple measurements and averaging the results to reduce the variability introduced by PMD.

Q 22. Describe different OTDR trace analysis software and their features.

OTDR trace analysis software is crucial for interpreting the raw data gathered from an OTDR test. These software packages offer a range of features to help technicians analyze fiber optic networks. Think of them as sophisticated image editors for fiber optic traces.

- Basic Features: Most software packages provide basic features like trace display, event identification (faults, connectors, splices), distance measurement, attenuation calculation, and loss budgeting. You’ll see the raw OTDR trace – a graph showing signal loss over distance – and the software helps you pinpoint specific events.

- Advanced Features: More advanced software offers features like automated report generation, multiple trace overlay (comparing different tests), advanced analysis tools to identify specific fault types (e.g., macrobends), and 3D visualization of the fiber network. Some even include database functionalities for managing numerous test results and network maps.

- Examples of Software: Many OTDR manufacturers offer their own proprietary software, and there are also third-party analysis tools available. Popular examples include the software packages bundled with OTDRs from companies like Viavi Solutions, EXFO, and Yokogawa. These differ in their user interfaces and specific features, but the core functionalities remain similar.

For example, during a recent project, we used software that allowed us to overlay traces from multiple tests on the same cable, helping us identify a subtle degradation over time that wasn’t immediately obvious in a single trace. This early detection saved us from a major network outage.

Q 23. How do you generate a test report after an OTDR measurement?

Generating an OTDR test report is the final and crucial step in the testing process. It provides a documented record of the fiber optic link’s condition. Think of it like a medical report for the fiber optic cable.

The process typically involves these steps:

- Data Import: Load the OTDR trace data from the instrument into the analysis software.

- Event Identification and Characterization: Identify and classify all events on the trace, such as connectors, splices, and faults. The software will typically automatically identify these, but manual verification and adjustments are often necessary. This includes recording the loss at each event.

- Loss Budget Calculation: The software computes the total loss budget across the length of the fiber, comparing it to the allowed budget for the system.

- Report Customization: Customize the report with relevant details such as date, time, test location, fiber type, OTDR model, and testing parameters used. Often you can add additional comments or notes.

- Report Generation: Generate the final report which usually includes the OTDR trace, a table summarizing the identified events with loss measurements, the overall loss budget summary, and the aforementioned additional information.

- Report Review and Approval: Before finalizing, review the report for accuracy and completeness. Often, a supervisor will need to approve the report.

The report should be clear, comprehensive, and easily understandable by all stakeholders, ensuring transparency and compliance.

Q 24. What are the different types of OTDR pulses and their applications?

OTDR pulses are the short bursts of light sent into the fiber. Different pulse widths affect the test’s resolution and range. Imagine them as flashes of light probing the fiber.

- Narrow Pulses (short pulse width): Provide higher resolution, allowing for better identification of closely spaced events like splices and connectors. However, this comes at the cost of reduced range. Think of it like a high-resolution camera zoom – excellent detail but a limited field of view.

- Wide Pulses (long pulse width): Offer a longer range because the light travels farther before attenuation becomes too high for detection, but they have lower resolution. Similar to a wide-angle lens – you see more, but the details are less sharp.

- Applications: Narrow pulses are preferred for testing shorter links and where high accuracy in locating events is crucial (e.g., identifying faults in dense metropolitan areas). Wide pulses are suitable for testing long-haul links or when the exact location of minor events is less critical. Often, a test might use a combination of pulse widths – a wider pulse for an initial overview and a narrow pulse to fine-tune specific areas of interest.

For example, testing a short patch cord connecting equipment would call for a narrow pulse for precise location of any imperfections. Conversely, testing a long undersea cable would require a much wider pulse to reach the end.

Q 25. How do you deal with non-linear effects in OTDR measurements?

Non-linear effects, such as stimulated Brillouin scattering (SBS) and stimulated Raman scattering (SRS), can distort OTDR measurements. They’re like echoes and interference within the fiber optic signal that complicate the readings.

Here’s how we address these effects:

- Pulse Width Selection: Using shorter pulses can minimize these effects. Narrower pulses reduce the chances of inducing these non-linear effects compared to using longer pulses.

- Averaging: Multiple traces can be averaged to reduce the impact of noise and random variations that can be caused or exacerbated by these effects. This gives you a more representative signal.

- Wavelength Selection: Choosing a wavelength less susceptible to non-linear effects can be beneficial. Certain wavelengths are more prone to SBS or SRS than others, so choosing wisely can help.

- Power Control: Lowering the OTDR’s output power reduces the chances of stimulating non-linear effects, but this will also reduce the measurable range.

- Specialized Analysis Techniques: Advanced software packages may offer specialized analysis tools or algorithms to compensate for some of the distortions caused by non-linear effects.

Careful planning and execution of the test are key to minimizing the impacts of non-linear effects. We often need to carefully consider the trade-offs between range and resolution and also the potential for non-linear scattering at the specific wavelengths we are working with.

Q 26. How do you choose the appropriate OTDR for a specific application?

Choosing the right OTDR depends heavily on the specific application. It’s like selecting the right tool for a job.

Key factors to consider:

- Fiber Type: Different OTDRs are designed to work with different types of fiber (single-mode, multi-mode, etc.). Make sure your OTDR is compatible with your fiber.

- Wavelength: The OTDR’s operating wavelength should match the wavelength used in the system being tested. 1310nm and 1550nm are common wavelengths for optical communications.

- Dynamic Range: This determines the OTDR’s ability to detect weak reflections from distant events. A higher dynamic range is needed for longer links and links with high loss.

- Resolution: This dictates the precision with which events can be located. Higher resolution is crucial for locating events closely spaced together.

- Dead Zone: The dead zone is a region near the OTDR where events cannot be reliably detected. A shorter dead zone is beneficial for identifying faults near connectors.

- Range: The maximum distance the OTDR can accurately measure.

- Portability and Interface: Consider whether the OTDR needs to be portable or if it’s for a fixed location testing scenario. Also, consider the type of interface – USB, Ethernet, etc.

For instance, testing a short fiber optic cable inside a building requires a different OTDR than testing a long submarine cable. The building cable would necessitate a portable device with high resolution, while the submarine cable would require a unit with a high dynamic range and long range capabilities.

Q 27. Explain the concept of dynamic range in OTDR testing.

Dynamic range in OTDR testing is the difference between the strongest and weakest signals the OTDR can detect. Think of it as the instrument’s ability to ‘see’ both bright and faint reflections along the fiber.

It’s expressed in decibels (dB). A higher dynamic range allows the OTDR to measure events across a wider range of attenuation (signal loss). This is crucial because signals weaken as they travel down the fiber. The further the signal travels the fainter it will be. A high dynamic range means you can detect weaker signals originating from further down the fiber.

A higher dynamic range is crucial for:

- Long-haul links: Signals attenuate significantly over long distances.

- High-loss links: Links with high connector or splice losses require a greater dynamic range to detect far-end events.

- Precise fault location: A higher dynamic range allows the detection of small reflections which can more accurately pinpoint the location of small faults.

For example, a link with many splices will require an OTDR with a higher dynamic range to detect small reflections from those splices, even if they are located a long distance away from the OTDR. A low dynamic range would result in the OTDR failing to identify these events, presenting an incomplete picture of the fiber’s condition.

Q 28. What are some common problems encountered during OTDR testing and their solutions?

Several common problems can occur during OTDR testing. These often involve troubleshooting the equipment, the test setup, or understanding the trace itself.

- Incorrect Pulse Width Selection: Choosing a pulse width that’s too narrow will limit the range, while one that’s too wide might obscure closely-spaced events.

- Dead Zone Effects: Events within the dead zone near the OTDR input will be masked or missed.

- Reflections from Connectors/Splices: These reflections can sometimes be misinterpreted as faults. Careful analysis and knowledge of the link map are needed to interpret these correctly.

- Non-linear Effects: Stimulated Brillouin Scattering and Stimulated Raman Scattering can distort the trace. Using appropriate techniques helps to minimize their impact.

- Poor Connector Preparation: Poorly cleaned or damaged connectors can lead to significant loss, requiring careful inspection and cleaning.

- Incorrect Fiber Type Selection: Testing a single-mode fiber with an OTDR designed for multi-mode fiber, or vice-versa will yield inaccurate results.

- Environmental Factors: Temperature fluctuations can affect optical signal strength and cause errors in measurements.

Solutions involve careful planning, correct equipment setup, using the appropriate test parameters, and thorough analysis of the trace. For example, if you encounter a large loss near a connector, the solution might be to re-clean the connector or replace it. Non-linear effects can be addressed through lower power settings or a shorter pulse width.

Key Topics to Learn for OTDR (Optical Time Domain Reflectometer) Testing Interview

- Fundamentals of OTDR Operation: Understand the basic principles behind how an OTDR works, including the generation and detection of backscattered light.

- Interpreting OTDR Traces: Learn to identify key features on an OTDR trace, such as events, attenuation, and reflections. Practice analyzing different trace scenarios to diagnose potential issues.

- OTDR Parameters and Settings: Become familiar with various OTDR settings (pulse width, wavelength, averaging) and their impact on trace quality and accuracy. Understand how to optimize these settings for different fiber types and testing scenarios.

- Fiber Optic Basics: Possess a strong understanding of fiber optic components (connectors, splices, etc.) and their impact on OTDR traces. Be prepared to discuss different fiber types and their characteristics.

- Troubleshooting OTDR Measurements: Develop problem-solving skills to identify and resolve common issues encountered during OTDR testing, such as noise, dead zones, and inaccurate measurements.

- Practical Applications of OTDR: Be able to discuss real-world applications of OTDR testing, such as fiber fault location, fiber characterization, and network installation verification. Prepare examples from your experience or research.

- OTDR Trace Analysis Software: Familiarize yourself with common OTDR software packages and their capabilities. Demonstrate an understanding of how software aids in data analysis and reporting.

- Safety Procedures: Understand and be able to articulate safe working practices related to OTDR testing and fiber optic work in general.

Next Steps

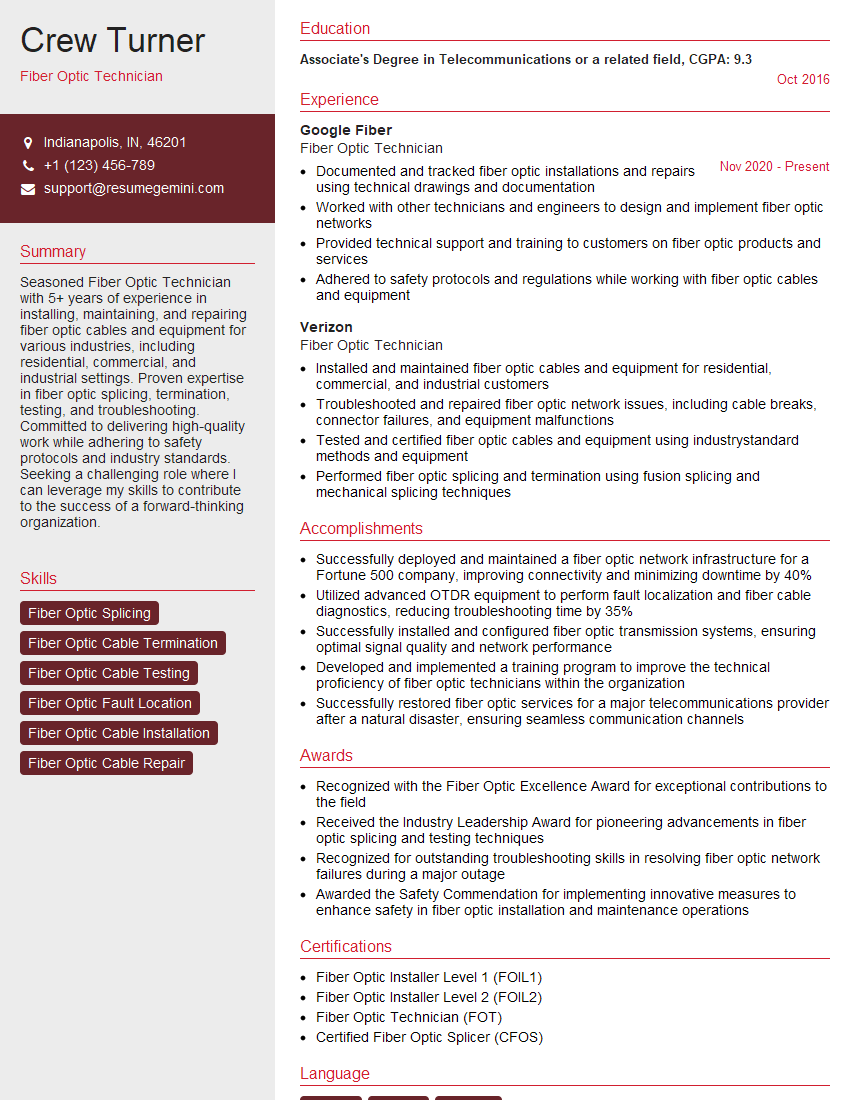

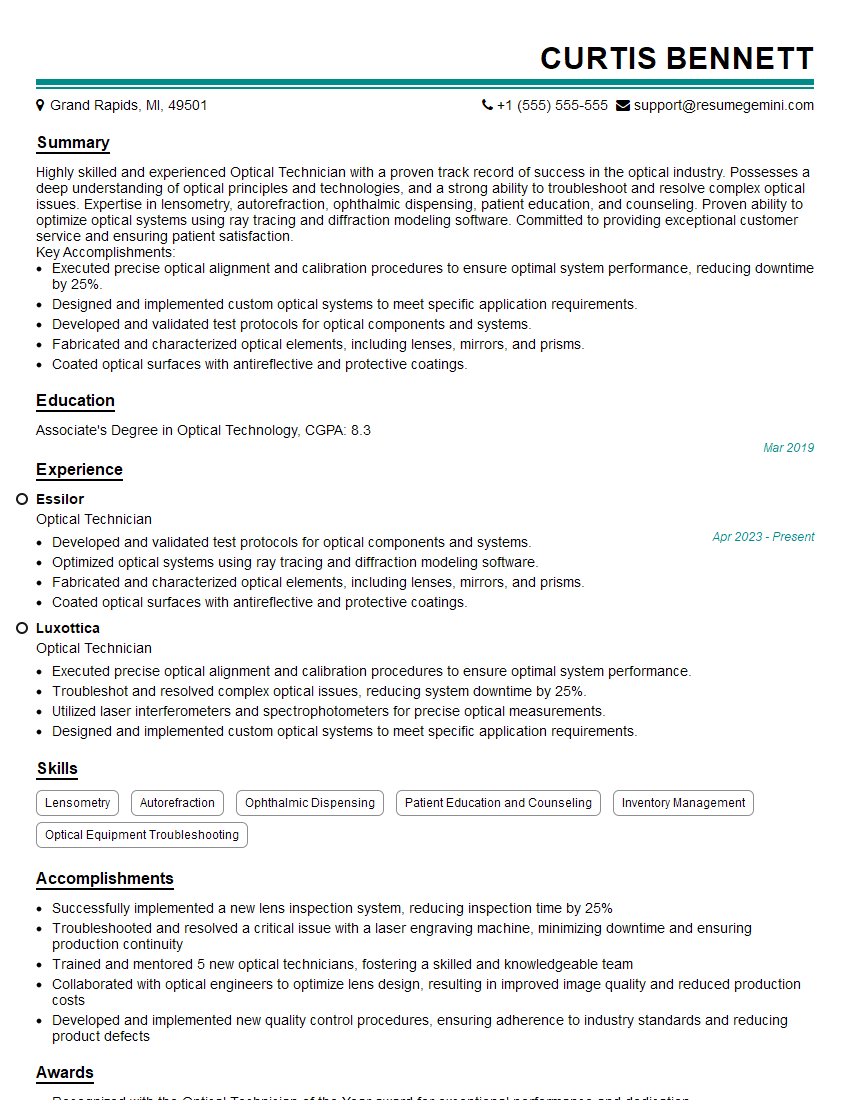

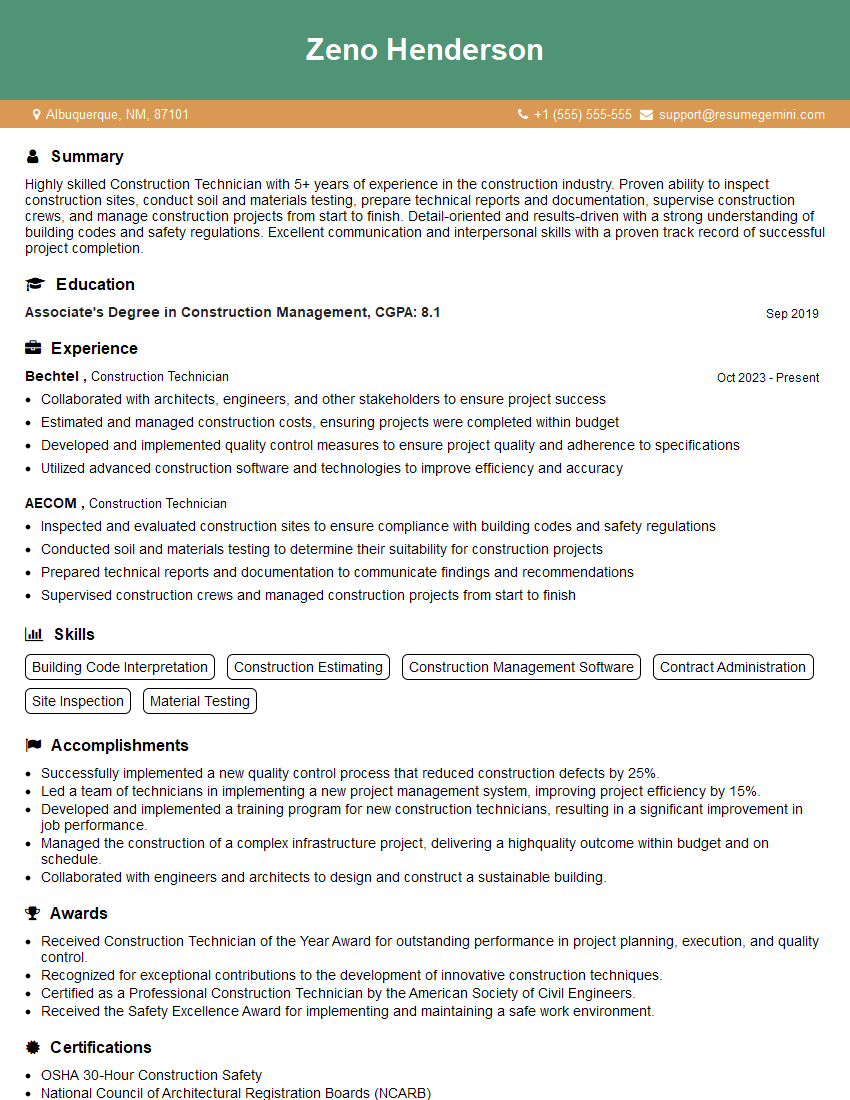

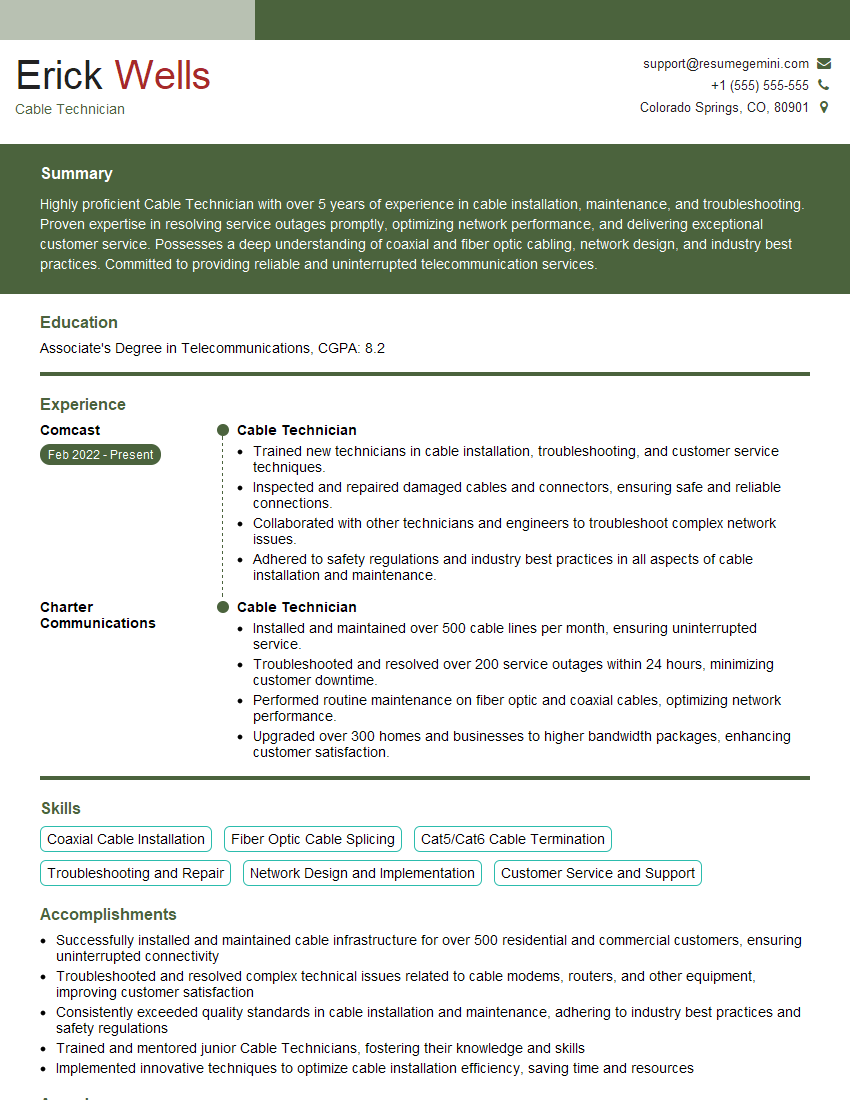

Mastering OTDR testing opens doors to exciting career opportunities in telecommunications, networking, and fiber optic industries. A strong understanding of OTDR principles and practical applications is highly sought after. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that stands out. Examples of resumes tailored to OTDR testing are available to guide you through the process. Investing time in crafting a compelling resume significantly increases your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?