Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Computer Literacy (e.g., CAD, Estimating Software) interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Computer Literacy (e.g., CAD, Estimating Software) Interview

Q 1. Explain your experience with AutoCAD.

AutoCAD has been a cornerstone of my design workflow for over eight years. I’m proficient in 2D drafting and detailing, using commands like LINE, ARC, CIRCLE, and POLYLINE to create precise geometries. My experience extends to creating complex drawings, including site plans, floor plans, elevations, and sections for various projects, from residential homes to small commercial buildings. I’m also comfortable using AutoCAD’s annotation tools to add dimensions, text, and other necessary information. For example, on a recent project, I used AutoCAD to design a custom pergola, meticulously detailing every component and connection for fabrication. This included generating detailed construction drawings and generating material lists directly from the model.

Beyond basic drafting, I’ve utilized advanced features such as blocks, layers, and xrefs to manage complex designs efficiently. I understand the importance of layering for organization and ease of modification. My experience also includes using AutoCAD to generate 3D models for visualization and analysis, although I typically leverage more specialized software for advanced 3D modeling tasks.

Q 2. Describe your proficiency in Revit.

My Revit proficiency is centered around Building Information Modeling (BIM). I’ve used Revit extensively for architectural design, structural engineering, and MEP (Mechanical, Electrical, and Plumbing) coordination, for the past five years. I’m adept at creating and managing Revit families, ensuring that components are correctly parameterized and linked for accurate estimations and visualizations. For instance, I created a custom family for a specific type of window with integrated solar shading and linked it to a shared library for seamless implementation across multiple projects.

I’m also skilled in using Revit’s collaboration features, working within a BIM environment with other professionals to ensure model accuracy and coordination, thereby minimizing conflicts and potential errors during construction. Understanding the relationship between views, sheets, and schedules is crucial for producing clear and comprehensive documentation. My experience includes leveraging Revit’s analysis tools for energy modeling and clash detection, leading to more efficient and sustainable design solutions.

Q 3. What is your experience with 3D modeling software?

My 3D modeling experience goes beyond AutoCAD’s basic 3D capabilities. I’ve worked extensively with SketchUp for quick conceptual modeling and visualization, allowing me to rapidly iterate designs and explore various options. Its intuitive interface makes it ideal for initial design phases and client presentations. For more complex and detailed 3D modeling, particularly for rendering purposes, I utilize Blender. Blender’s power lies in its versatility and free and open-source nature. I’ve used it to create photorealistic renderings for proposals and marketing materials, bringing my designs to life for clients. I’m comfortable with various modeling techniques, including polygon modeling, NURBS modeling, and sculpting, depending on the project’s requirements.

Q 4. How familiar are you with BIM methodologies?

I have a strong understanding of BIM methodologies and their applications across the entire project lifecycle. I understand the importance of implementing a consistent and coordinated BIM execution plan. This includes defining roles and responsibilities, setting up shared model environments, and establishing clear data exchange protocols. I’m familiar with various BIM levels of detail (LOD) and can tailor my approach based on project requirements and the stage of design and construction. For example, early-stage designs might necessitate a lower LOD for initial feasibility studies, while construction drawings require a much higher LOD for precise construction documentation. The benefits of using BIM are numerous and include improved collaboration, reduced errors, improved cost control, and sustainable design practices. I’ve personally experienced the advantages of BIM in resolving design clashes before construction, significantly reducing costly rework.

Q 5. Explain your experience using estimating software (e.g., Sage, Timberline).

My experience with estimating software includes proficient use of Sage Estimating. I’m comfortable with the entire estimating process, from assembling the takeoff data to generating detailed cost estimates. This includes accurately quantifying materials, labor, and equipment costs, as well as applying appropriate markups and contingencies. I’m adept at creating detailed cost breakdowns and reports to support client proposals and project budgeting. I’m particularly skilled at leveraging the software’s reporting functionalities for tracking cost variances and identifying potential risks. For example, on a recent project, I used Sage Estimating to produce a comprehensive cost estimate that identified potential cost overruns and allowed for proactive risk mitigation strategies.

Q 6. How do you handle large datasets in CAD software?

Handling large datasets in CAD software requires a strategic approach. Techniques like using proxy geometry (simplified representations of complex geometry) can significantly improve performance. Another crucial aspect is proper layer management and organization. Avoiding unnecessary objects and using external references (xrefs) effectively to link smaller files is key. Regularly purging and auditing the model removes unused data and improves performance. Optimizing the model’s complexity by simplifying geometry where appropriate without compromising accuracy is also important. Finally, utilizing the software’s performance optimization tools, such as hardware acceleration and graphics card settings, can significantly enhance responsiveness. Choosing the right file format and managing data compression and decompression effectively is also an important consideration.

Q 7. Describe your experience with creating detailed drawings.

Creating detailed drawings demands precision and attention to detail. My process begins with a clear understanding of the design intent and the requirements of the drawings. I focus on accurately representing all components and dimensions, ensuring clarity and consistency in presentation. The use of appropriate scales, line weights, and annotation styles is paramount in creating professional, readable drawings. I consistently adhere to industry standards and client-specific requirements for drawing formats and symbols. A meticulous approach to checking and verifying dimensions and annotations is essential before finalizing the drawings. My goal is to produce drawings that are not only technically accurate but also visually appealing and easily understood by the intended audience – be it contractors, fabricators, or clients.

Q 8. How do you ensure accuracy in your estimations?

Accuracy in estimations is paramount for successful project delivery. It’s not just about getting the numbers right; it’s about building confidence in the process and minimizing financial risks. I achieve this through a multi-pronged approach:

- Detailed Quantity Takeoff: I meticulously measure every element in the design using both digital and manual methods, ensuring comprehensive coverage. For instance, I’d carefully measure every wall, door, window, and fixture in a building plan, double-checking for consistency.

- Comprehensive Material List: A detailed list of materials, including quantities and unit costs, is crucial. I always source costs from multiple suppliers to compare and identify the most competitive pricing. This prevents relying on a single source that might have inflated prices.

- Labor Cost Breakdown: I break down labor costs into specific tasks, considering factors like crew size, productivity rates, and labor hours per unit. For example, I wouldn’t just estimate painting costs as a lump sum; I’d calculate the area, the number of coats needed, and the hourly rate for painters.

- Contingency Planning: Unexpected issues arise. I always incorporate a contingency percentage (usually 5-10%) to account for unforeseen circumstances, material price hikes, or changes during the project.

- Software Validation: I cross-check estimates generated by estimating software with manual calculations to ensure accuracy and catch any potential software glitches. This is a crucial step for avoiding costly errors.

- Regular Review and Updates: I routinely review and update estimates as the project progresses and more detailed information becomes available. This ensures the estimate reflects the current state of the project.

Through this combination of thoroughness and smart planning, I aim for estimations that are reliable and provide a strong foundation for project success.

Q 9. What are some common challenges in using CAD software and how do you overcome them?

CAD software is an indispensable tool, but it presents certain challenges. Here are a few I’ve encountered and my strategies for overcoming them:

- Software Complexity: Mastering the intricacies of CAD software requires consistent practice and learning. I address this by dedicating time to continuous learning through online courses, tutorials, and hands-on practice with new features. I also actively participate in online communities and forums to learn from peers.

- Data Management: Managing large datasets and ensuring file organization is essential. I utilize a structured file naming convention and leverage cloud storage for easy access and collaboration. I also regularly back up my files to prevent data loss.

- Drawing Errors: Mistakes are inevitable. Fortunately, CAD software offers tools for detecting and correcting errors, such as snap functions, constraints, and layer management. Regular checks and thorough reviews of drawings mitigate this issue.

- Software Compatibility: Different software versions and formats can create compatibility problems. Therefore, I consistently update my software and utilize universal file formats like DWG or DXF wherever possible.

- Render Times: Complex models can take a significant time to render. This problem can be mitigated by optimizing models for rendering, using powerful hardware, or exploring rendering techniques that suit specific tasks and hardware capabilities.

Proactive learning, efficient file management, and rigorous quality control are my key strategies to effectively manage and overcome these common CAD challenges.

Q 10. How do you manage revisions and updates in CAD projects?

Managing revisions and updates in CAD projects requires a systematic approach. My process usually involves:

- Version Control: I use the software’s built-in revision history or a dedicated version control system (like Git for larger projects) to track all changes and revert to previous versions if needed.

- Naming Conventions: Clear and consistent file naming conventions (e.g., ProjectName_RevisionNumber_Date) are essential to avoid confusion. For example,

BuildingDesign_Rev2_20241027.dwgclearly indicates the revision number and date. - Change Logs: I maintain detailed change logs documenting all modifications, including the date, author, and description of the changes. This is invaluable for tracking progress and troubleshooting any issues.

- Cloud Storage: Cloud-based storage facilitates collaboration and ensures all team members have access to the most up-to-date version of the drawings. It also provides backups and data protection.

- Communication: Open communication within the team is crucial. Regular meetings and updates keep everyone informed about revisions and potential conflicts.

By consistently applying these strategies, I ensure that all team members are working with the most current and accurate drawings, streamlining the project workflow.

Q 11. What is your experience with different file formats used in CAD?

My experience encompasses a wide range of CAD file formats, including:

- DWG (AutoCAD Drawing): This is a native format for AutoCAD and is widely used across the industry, offering excellent compatibility.

- DXF (Drawing Exchange Format): DXF acts as a neutral format that allows data exchange between different CAD software packages.

- DWF (Design Web Format): This format is suitable for sharing designs across platforms and viewing them without the need for CAD software.

- PDF (Portable Document Format): PDFs are used for sharing final drawings and creating high-quality prints, though they typically cannot be edited.

- SKP (SketchUp): Used for 3D modeling and design, often for architectural visualization.

- STEP (Standard for the Exchange of Product data): A neutral format for transferring 3D models between different CAD systems.

Understanding the strengths and limitations of each format is crucial for selecting the appropriate one for a specific task, ensuring seamless collaboration and data exchange.

Q 12. Explain your understanding of geometric dimensioning and tolerancing (GD&T).

Geometric Dimensioning and Tolerancing (GD&T) is a symbolic language used to precisely define the size, form, orientation, location, and runout of features on a part or assembly. It goes beyond basic dimensions by specifying acceptable variations or tolerances. It uses symbols to convey information more concisely and unambiguously than traditional methods.

For instance, a basic dimension might say a hole should be 10mm in diameter. GD&T could add information about the allowable deviation from that 10mm, its position relative to other features, and its roundness. This ensures that the part functions correctly within its intended application.

My understanding extends to interpreting and applying GD&T symbols and principles to create detailed and unambiguous engineering drawings. This is vital for ensuring manufactured parts meet the required specifications, thus preventing costly rework or failures.

Q 13. Describe your experience with quantity takeoff.

Quantity takeoff is the process of extracting quantities of materials and labor required for a construction project from design documents. My experience encompasses both manual and digital methods.

- Manual Takeoff: This involves using blueprints and a measuring instrument to manually calculate quantities of materials like concrete, lumber, or roofing tiles. While time-consuming, it offers a great understanding of the drawings and a chance to identify potential discrepancies.

- Digital Takeoff: I’m proficient in using specialized estimating software to automate this process. These software packages can extract quantities directly from CAD drawings, saving time and enhancing accuracy. Software such as On-Screen Takeoff or PlanSwift allow for automated area calculations and material quantity estimations from digital blueprints.

- Software Proficiency: I leverage features such as automated calculations, customizable reports, and integration with other project management tools for optimal efficiency.

Irrespective of the method, I always cross-check my results to ensure accuracy and consistency. A thorough quantity takeoff forms the backbone of accurate estimations and project planning.

Q 14. How do you incorporate cost fluctuations into your estimations?

Cost fluctuations are inherent in construction. I address this by implementing a few strategies:

- Market Research: I regularly monitor material and labor costs through industry publications, supplier websites, and market reports to stay updated on price trends.

- Historical Data: Leveraging historical cost data from previous projects provides a baseline for predicting future costs and allows for informed adjustments based on past performance.

- Escalation Clauses: Incorporating escalation clauses into contracts protects against significant price increases during the project lifecycle. These clauses typically adjust prices based on established indices or agreed-upon percentages.

- Contingency Buffers: As mentioned earlier, a contingency buffer in the initial estimate provides a cushion against unforeseen cost increases or price volatility. The buffer should be adjusted based on the level of uncertainty and market conditions.

- Value Engineering: If costs escalate significantly, I’ll collaborate with the project team to explore value engineering options. This involves identifying potential cost savings without compromising project quality or functionality.

By being proactive, informed, and flexible, I ensure that cost fluctuations don’t derail project budgets or timelines.

Q 15. How do you handle conflicting data or information within CAD models?

Conflicting data in CAD models can stem from various sources: merging different models, outdated revisions, or even simple human error. Handling this requires a methodical approach. First, I thoroughly investigate the source of the conflict. This often involves comparing the conflicting elements visually and checking their properties. For instance, if two walls overlap in a building model, I’d examine their dimensions, materials, and associated data to understand the discrepancy. Then I determine the most accurate or preferred version. This decision may involve collaborating with the project team to resolve ambiguities. Finally, I implement the solution, making sure to document any changes to maintain version control. This might involve deleting the conflicting geometry, adjusting coordinates, or using layer management to prioritize the correct version. Think of it like editing a document – you need to understand the changes and ensure consistency before finalizing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How proficient are you in using layers, blocks and xrefs in AutoCAD?

I’m highly proficient in using layers, blocks, and external references (xrefs) in AutoCAD. Layers are essential for organizing drawings. I use them to separate elements by type (e.g., walls, doors, electrical), discipline (architectural, structural, MEP), or status (drafting, finalized). This makes managing complex models much easier. For example, I might assign different lineweights and colors to layers to enhance visual clarity and distinguish different elements easily. Blocks are like reusable components – I often create blocks for standard elements (doors, windows, fixtures) to streamline the design process and ensure consistency. Xrefs allow me to incorporate external drawings into my current project. This is crucial for collaboration, particularly when multiple disciplines are involved. For example, structural engineers may use xrefs to link their structural model into the architectural model. Imagine building a house with pre-fabricated components – blocks provide those ready-made components for easy insertion, while xrefs connect the work of different specialists involved in the construction.

Q 17. What is your experience with rendering and visualization software?

My experience with rendering and visualization software includes extensive use of programs like V-Ray, Lumion, and Enscape. I’m adept at creating photorealistic renderings and walkthrough animations to effectively communicate designs to clients and stakeholders. Rendering transforms the technical CAD model into a compelling visual experience. For example, I’ve used Lumion to generate walkthroughs for potential buyers, allowing them to visualize themselves inside a space before construction. This also helps in identifying design flaws that might be difficult to spot in a 2D plan. V-Ray is more powerful for detailed renders needed for final presentations and marketing, letting me adjust lighting, materials and textures to achieve a high level of realism. I am proficient at setting up lighting schemes, adjusting material properties, and post-processing to achieve the desired visual output, reflecting the details and the overall atmosphere of a design.

Q 18. How do you collaborate with other team members using CAD software?

Collaboration is key in CAD projects. I utilize cloud-based platforms like Autodesk BIM 360 or similar tools for shared model access and version control. This allows multiple team members to work on the same model simultaneously while tracking changes and minimizing conflicts. I also leverage model-sharing techniques, such as xrefs, to integrate contributions from various disciplines. Effective communication is just as important. I regularly engage in design reviews, using online meeting software and the shared model to discuss progress, address issues, and ensure consistency. It’s like a collaborative writing session, where everyone contributes and edits the same document but in a controlled and organised manner. Clear communication protocols and efficient use of collaborative tools are paramount.

Q 19. Explain your understanding of the building information modeling (BIM) process.

Building Information Modeling (BIM) is a process that goes beyond simple CAD drafting. It involves creating and managing a digital representation of physical and functional characteristics of a facility. BIM leverages intelligent 3D models containing data about every aspect of the building, from geometry and materials to cost estimates and energy performance. The BIM process involves several key stages: conceptual design, schematic design, design development, construction documentation, and facility management. At each stage, the model is enriched with more detailed information. Think of it like building a LEGO castle: you start with a basic structure and progressively add details like walls, towers, and features. The BIM model functions similarly, becoming more comprehensive as the project unfolds. BIM fosters greater collaboration amongst designers, engineers, contractors, and other stakeholders throughout the project lifecycle. The benefits include improved coordination, reduced errors, and enhanced visualization which leads to better decision-making and cost savings.

Q 20. How do you ensure your CAD models comply with industry standards?

Ensuring CAD model compliance with industry standards requires a multi-faceted approach. First, I thoroughly research and understand the relevant standards for the specific project and region. These standards might relate to building codes, material specifications, or design guidelines. I then configure my CAD software settings to comply with these standards, selecting appropriate units, drawing templates, and annotation styles. During the modeling process, I rigorously check the model against these standards, verifying dimensions, clearances, and material properties. Think of this as a checklist to ensure every aspect of the design follows regulation. Regular quality checks and utilizing tools like automated design rule checkers help flag potential inconsistencies early. Documentation of the compliance process is crucial for ensuring accountability and traceability. Ultimately, this detailed approach helps reduce costly rework and ensures the design meets all legal and regulatory requirements.

Q 21. What is your experience with scripting or automation in CAD software?

I have experience with scripting and automation in AutoCAD using AutoLISP and Dynamo. AutoLISP allows for creating custom functions to automate repetitive tasks and streamline workflows. For example, I’ve written scripts to automate the creation of standard details or to extract data from drawings for reports. Dynamo, a visual programming language, is even more powerful for automating complex tasks and integrating with other software platforms. This allows the creation of more sophisticated custom tools that can work across different CAD platforms. Imagine having a script that automatically generates all the dimensions of every part of a complex machine – this reduces time-consuming manual tasks, allowing for focus on design decisions rather than tedious repetitive work. Automation isn’t just about speed; it also improves accuracy and consistency.

Q 22. How do you manage and organize your CAD files and projects?

Managing CAD files and projects effectively is crucial for efficiency and preventing errors. My approach is based on a robust, multi-layered system. Firstly, I utilize a clear and consistent file naming convention. This typically includes project name, date, revision number, and file type (e.g., ProjectAlpha_20240308_RevA_FloorPlan.dwg). This makes locating specific files incredibly easy.

Secondly, I leverage folder structures mirroring the project’s organizational hierarchy. For example, a large project might have folders for architectural drawings, structural drawings, MEP (Mechanical, Electrical, Plumbing) drawings, and specifications. Each of these top-level folders could then be further sub-divided. This organized system prevents files from becoming lost in a chaotic mess.

Thirdly, I rely heavily on version control. I utilize cloud-based storage solutions with version history features (such as Autodesk BIM 360 or similar). This allows me to easily revert to previous versions if needed, track changes, and collaborate effectively with team members. Finally, regular backups to both local and cloud storage are non-negotiable for data security and disaster recovery.

For example, during a recent large-scale commercial building project, this system ensured that over 500 CAD files were easily accessible and manageable, contributing significantly to the project’s timely completion.

Q 23. Explain your process for creating and updating construction estimates.

Creating and updating construction estimates is an iterative process requiring attention to detail and accuracy. I start by thoroughly reviewing the project plans and specifications to fully understand the scope of work. This includes identifying all materials, labor, and equipment required.

Next, I utilize estimating software (like PlanSwift or On-Screen Takeoff) to quantify the quantities of materials needed based on the drawings. This software helps to automate calculations and reduce the risk of manual errors. For example, using takeoff software to calculate the square footage of flooring for a building is significantly faster and more precise than manual measurements.

Then, I develop a detailed cost breakdown using a standardized format including labor costs (based on prevailing wage rates and productivity), material costs (sourced from vendors and current market prices), equipment costs (rental or ownership), and contingency allowances. Regular updates involve tracking actual costs against the estimates and making necessary adjustments based on changes in the project scope, material prices, or labor rates. This ensures the estimate remains accurate and reflects the current project status.

Finally, I meticulously document every aspect of the estimation process, including all sources and assumptions used in the calculations. This transparent process aids in auditing, facilitates future projects, and provides a solid basis for discussions with clients.

Q 24. How familiar are you with different types of estimating methodologies?

I am familiar with several estimating methodologies, each with its own strengths and weaknesses. These include:

- Unit Price Estimating: This involves assigning unit prices (e.g., cost per square foot, per linear foot) to different work items. It’s simple and quick but less precise for complex projects.

- Detailed Quantity Takeoff Estimating: This method involves a thorough takeoff of quantities from plans, providing a precise estimate but requiring more time and expertise.

- Assembly Estimating: This is based on pre-defined assemblies (e.g., a complete bathroom fixture) with known costs, useful for repetitive tasks but less flexible for unique designs.

- Parametric Estimating: This uses algorithms and data to estimate costs based on project parameters like area, volume, and complexity. It’s ideal for large-scale projects but requires sophisticated software and data.

My experience allows me to select the most appropriate methodology based on the specific project requirements. For example, a simple residential project might benefit from unit price estimating, while a large commercial project will require a more detailed quantity takeoff approach.

Q 25. Describe your experience with cost control and project budgeting.

Cost control and project budgeting are critical aspects of construction management. My experience involves establishing a detailed budget at the outset, meticulously tracking expenses throughout the project lifecycle, and proactively identifying and addressing cost overruns. This often involves using project management software to monitor actual costs against the budget.

I regularly prepare cost reports that compare budgeted versus actual costs, highlighting any variances. These reports identify potential issues, such as material price increases or labor shortages, allowing for timely corrective action. For instance, in one project, early detection of a significant increase in steel prices allowed for proactive negotiations with subcontractors and substitution of materials to minimize budget impact.

Implementing a change management process, where all changes to the scope are documented, evaluated, and costed before implementation, is vital for cost control. This includes issuing change orders that reflect the impact on the overall budget. Regular communication with stakeholders about budget performance is also key to maintaining transparency and accountability.

Q 26. What is your experience with risk assessment in estimating?

Risk assessment in estimating is crucial for preparing realistic and robust estimates. I incorporate risk assessment by identifying potential risks during the estimation process and quantifying their potential impact on the project budget and schedule.

Common risks include material price fluctuations, labor shortages, unforeseen site conditions, and changes in regulations. Each risk is assessed based on its likelihood and potential impact (often using a risk matrix). This leads to creating contingency reserves to cover potential cost overruns. The size of the contingency reserve is determined by the assessed risk levels. For example, a high-risk project in a volatile market might require a larger contingency reserve than a low-risk project with stable material costs.

Furthermore, I incorporate sensitivity analysis into my estimates. This involves testing the effect of changes in key assumptions (such as material costs or labor rates) to determine the estimate’s robustness and potential vulnerabilities.

Q 27. How do you utilize data analysis to improve the accuracy of your estimations?

Data analysis plays a significant role in improving estimation accuracy. I leverage historical project data, market trends, and industry benchmarks to refine my estimation models. This involves using spreadsheets or dedicated data analysis tools to identify patterns and correlations in past projects.

For example, by analyzing past projects, I can identify relationships between project size, complexity, and cost. This information can inform future estimates, leading to greater accuracy. Similarly, tracking material prices over time enables me to anticipate potential fluctuations and build appropriate contingencies into my estimates.

Statistical analysis techniques, such as regression analysis, can further enhance accuracy by identifying key factors influencing project costs and building predictive models. By combining historical data with advanced analytical techniques, I can develop more accurate and reliable estimates, minimizing the chance of cost overruns.

Q 28. How do you present your estimations and findings to clients or stakeholders?

Presenting estimations and findings to clients and stakeholders requires clarity, conciseness, and visual appeal. My approach involves preparing comprehensive reports that summarize the estimate, including a detailed cost breakdown, assumptions made, and risk assessments. These reports are often accompanied by clear visuals, such as charts and graphs, that illustrate key findings.

I utilize presentation software (like PowerPoint or Keynote) to present my findings in an engaging and easily understandable manner. My presentations focus on key findings and implications, avoiding overwhelming the audience with excessive technical details. For instance, instead of focusing on granular material quantities, I’ll focus on the overall project cost, highlighting key cost drivers and potential risks.

Crucially, I ensure open communication and am available to address any questions or concerns from clients and stakeholders. This collaborative approach builds trust and ensures that everyone is on the same page regarding the project’s budget and potential risks.

Key Topics to Learn for Computer Literacy (e.g., CAD, Estimating Software) Interview

- CAD Software Fundamentals: Understanding the interface, basic drawing tools (lines, arcs, circles), and essential commands. This includes navigating the workspace efficiently and creating simple 2D drawings.

- 3D Modeling Techniques (if applicable): Explore extrusion, revolution, and other 3D modeling methods. Practice creating and manipulating 3D models, focusing on accuracy and efficiency.

- Estimating Software Proficiency: Learn how to input data accurately, generate estimates, and understand the underlying calculations. Familiarize yourself with different types of estimates (e.g., preliminary, detailed).

- Data Management and Organization: Mastering file management within CAD and estimating software is crucial. Practice organizing projects, layers, and data for efficient workflow and easy retrieval.

- Blueprint Reading and Interpretation: Develop the ability to understand and interpret architectural and engineering drawings. This is essential for accurate model creation and estimation.

- Problem-Solving in CAD/Estimating: Practice troubleshooting common errors, resolving discrepancies in data, and finding solutions to technical challenges within the software.

- Advanced Features (if applicable): Depending on the specific software used, explore advanced features like rendering, animation, or specialized tools relevant to your field. Highlight your ability to quickly learn new features.

- Software-Specific Knowledge: Focus on the specific CAD and estimating software mentioned in the job description. Emphasize your experience and proficiency with the requested programs.

Next Steps

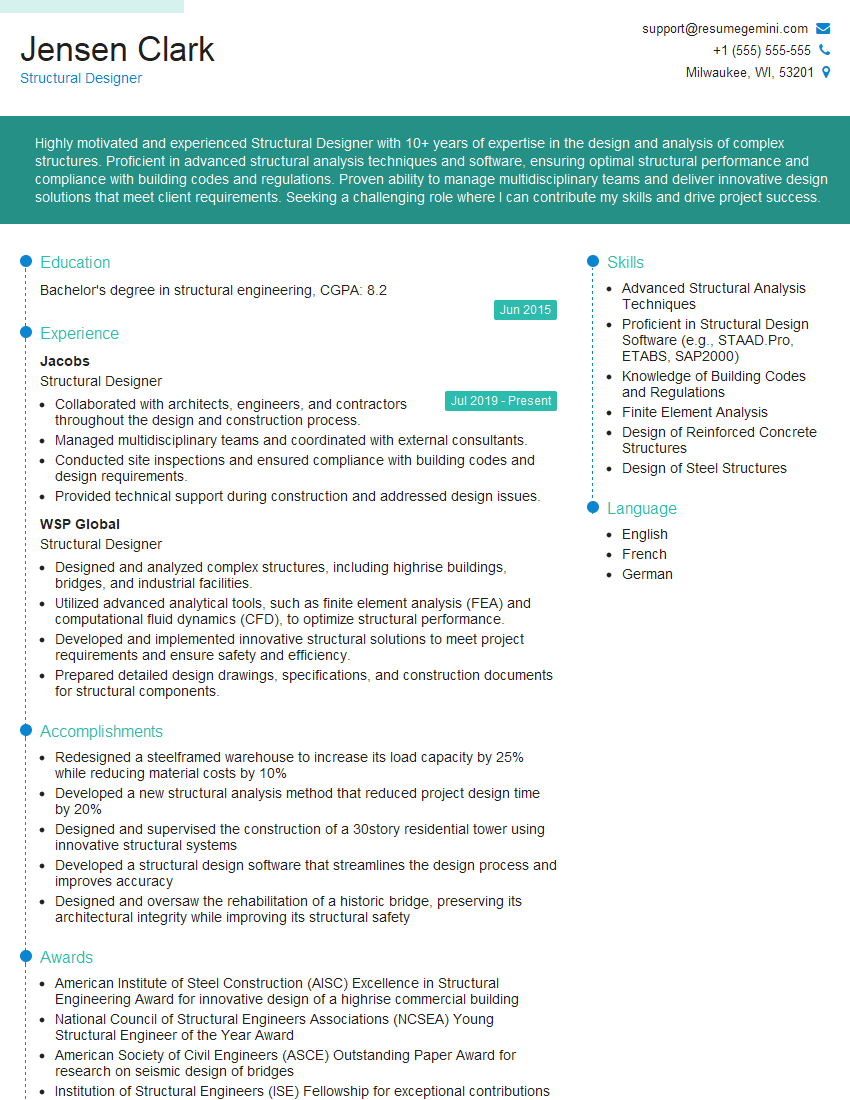

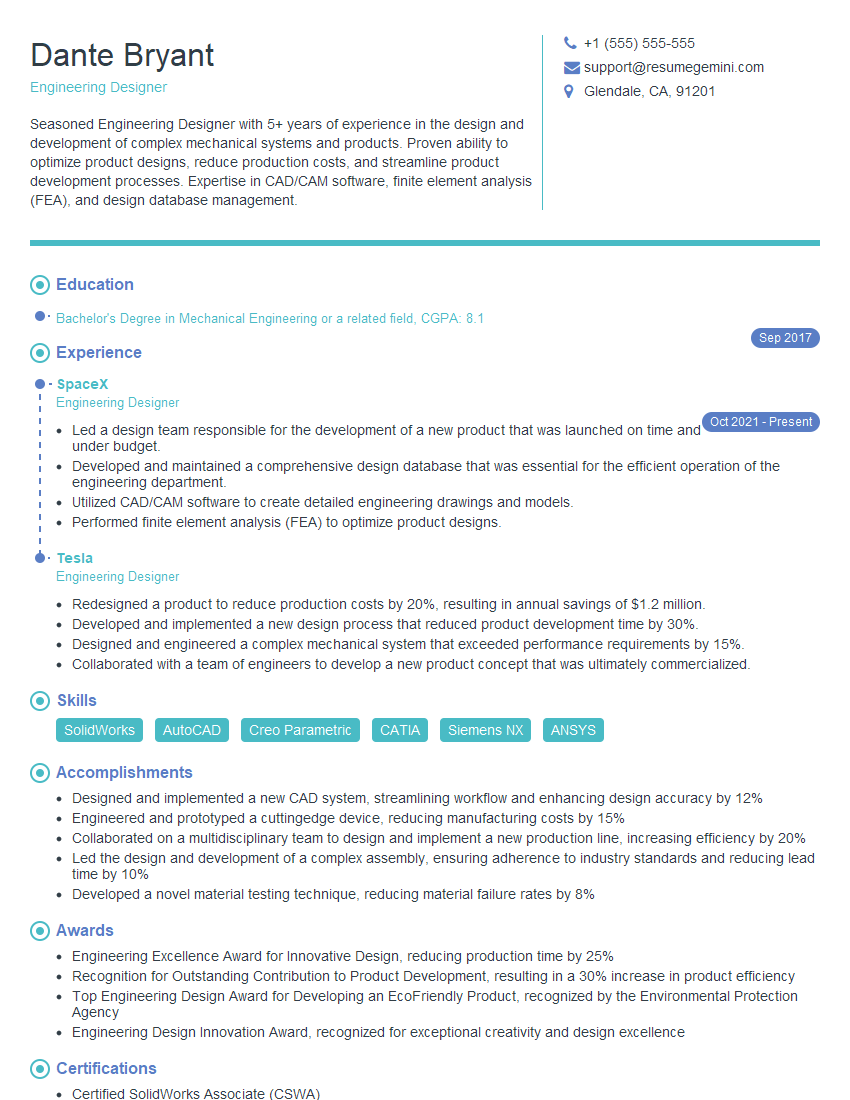

Mastering computer literacy skills in CAD and estimating software is crucial for career advancement in many technical fields. These skills demonstrate your efficiency, accuracy, and ability to contribute effectively to projects. Building a strong, ATS-friendly resume is key to landing your dream job. We strongly encourage you to use ResumeGemini to create a professional and impactful resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to Computer Literacy roles, featuring CAD and Estimating Software expertise, to help guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?