Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Regulatory Compliance (GMP/GLP) interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Regulatory Compliance (GMP/GLP) Interview

Q 1. Explain the difference between GMP and GLP.

GMP (Good Manufacturing Practice) and GLP (Good Laboratory Practice) are both quality systems designed to ensure the reliability and integrity of data, but they apply to different areas.

- GMP focuses on the manufacturing and production of pharmaceutical products, ensuring the consistent quality, safety, and efficacy of medicines. Think of it as the rules for making sure your medicine is safe and effective.

- GLP, on the other hand, governs the conduct of non-clinical laboratory studies, such as toxicology studies used to assess the safety of new drugs or chemicals before human trials. It’s the quality control for the science behind the medicine.

In essence, GMP is about the product, while GLP is about the data used to support the safety and efficacy of the product. For example, a GMP-compliant manufacturing plant produces the drug, and the GLP-compliant labs generate the pre-clinical toxicity data to support the drug’s registration.

Q 2. Describe the key principles of GMP.

The key principles of GMP revolve around ensuring the quality and safety of the final product. These include:

- Quality Management System (QMS): A robust system is essential, documenting all processes and procedures. Think of it as a detailed recipe that everyone follows meticulously.

- Personnel Training and Qualification: Staff must be properly trained and competent in their roles. Improper training is like trying to bake a cake without knowing how to use the oven.

- Facilities and Equipment: The manufacturing environment must be controlled, clean, and properly maintained. A dirty factory is a recipe for disaster.

- Materials Management: Careful control of raw materials and components from sourcing to storage is crucial. Using the wrong ingredient will ruin your cake.

- Production Process Control: Processes must be validated and controlled to ensure consistency. Every step must be precisely followed.

- Quality Control (QC) Testing: Regular testing verifies the quality and purity of the product at each stage. You’d taste-test your cake to ensure its deliciousness, right?

- Documentation and Record Keeping: Meticulous records are essential for traceability and accountability. Every step in the process must be recorded accurately.

- Complaint Handling: A system must be in place for handling and investigating product complaints effectively.

Adherence to these principles ensures that the final product meets the required quality standards, is safe for its intended use, and is consistent in its properties.

Q 3. What are the critical aspects of GLP compliance?

GLP compliance hinges on the reliability and integrity of non-clinical safety data. Critical aspects include:

- Study Design and Protocol: A detailed, pre-approved protocol guides the study’s execution, ensuring consistency and reproducibility. It’s the scientific blueprint for your experiment.

- Personnel Qualifications: Scientists conducting the studies must have the appropriate training and expertise. Imagine trying to perform complex experiments without the right skills.

- Facilities and Equipment: The laboratory environment and equipment must be properly maintained and calibrated. A broken scale can ruin an entire experiment.

- Standard Operating Procedures (SOPs): SOPs must be in place and followed rigorously for all procedures. Consistency is key in scientific research.

- Raw Data and Data Management: Raw data must be meticulously recorded, managed, and protected. Lost or manipulated data undermines the entire study.

- Quality Assurance (QA) Oversight: Independent QA oversight ensures the study’s compliance with GLP principles. A second pair of eyes can catch mistakes.

- Reporting and Archiving: Comprehensive study reports and archived data provide full transparency and traceability. Every detail needs to be documented and readily available.

Failure in any of these areas can compromise the integrity of the study results and impact decisions regarding drug development or product safety.

Q 4. How do you ensure data integrity in a GMP/GLP environment?

Data integrity is paramount in GMP/GLP environments. Ensuring data integrity requires a multi-faceted approach:

- ALCOA+ Principles: Data must be Attributable, Legible, Contemporaneous, Original, Accurate, and complete, and additionally, it must be Enduring and Available. This is the gold standard for data handling.

- Electronic Data Management Systems (EDMS): Implementing a validated EDMS provides a secure and auditable trail. Think of it as a secure digital record-keeping system.

- Access Control and Audit Trails: Restricting access to data and maintaining complete audit trails for all changes are essential. This ensures accountability and prevents unauthorized modifications.

- Data Backup and Recovery Procedures: Secure data backups are necessary to protect against data loss. It’s like having a backup copy of your important documents.

- Regular Data Integrity Audits: Periodic audits ensure compliance with data integrity policies and identify weaknesses. Regular checks keep everything running smoothly.

- Training on Data Integrity: Staff must be trained on proper data handling procedures. Knowledge is power in maintaining data integrity.

By adhering to these principles, you build a robust system that protects the integrity of your data, ensuring its reliability for regulatory submissions and decision-making.

Q 5. Explain your experience with deviation investigations.

My experience with deviation investigations involves a systematic approach focusing on root cause identification and corrective actions. I follow a structured process:

- Immediate Containment: First, we contain the problem to prevent further occurrences or impact.

- Investigation Team: A cross-functional team is assembled to investigate the deviation thoroughly.

- Data Collection: We gather all relevant data, including batch records, equipment logs, and personnel interviews.

- Root Cause Analysis (RCA): We use tools like the 5 Whys or Fishbone diagrams to identify the root cause(s).

- Impact Assessment: We determine the extent of the impact on the product, process, or study.

- Corrective Actions: We define specific corrective actions to prevent recurrence.

- Preventive Actions: We implement measures to prevent similar deviations in the future.

- Documentation: The entire investigation is meticulously documented, including findings, conclusions, and implemented actions.

For example, in one instance, we investigated a deviation in a manufacturing process where a critical parameter was outside the specification. Through our investigation, we identified a faulty sensor as the root cause. We replaced the sensor, recalibrated the equipment, and implemented additional checks to prevent future occurrences. The entire process was documented in a deviation report.

Q 6. Describe your experience with CAPA (Corrective and Preventive Action).

My experience with CAPA (Corrective and Preventive Action) involves a closed-loop system ensuring that deviations are addressed effectively and prevent recurrence. The process usually includes:

- Deviation Reporting and Investigation: Any deviation from established procedures is reported and thoroughly investigated, as previously discussed.

- Root Cause Determination: Through thorough investigation, the underlying cause of the deviation is pinpointed.

- Corrective Action Implementation: Specific actions are taken to correct the immediate problem. This might involve equipment repair, retraining, or procedural changes.

- Preventive Action Implementation: Steps are taken to prevent similar deviations in the future. This could involve process improvements, updated SOPs, or enhanced training.

- Effectiveness Verification: We verify the effectiveness of the corrective and preventive actions taken. This could involve monitoring key process parameters or conducting follow-up audits.

- Documentation and Review: The entire CAPA process is documented, reviewed, and approved, creating a closed-loop system.

In one case, we implemented a new training program to address recurring deviations related to incorrect equipment operation. The subsequent reduction in deviations confirmed the effectiveness of the CAPA.

Q 7. How do you handle audit findings?

Handling audit findings requires a professional and proactive approach. My typical steps include:

- Acknowledgement and Review: We acknowledge the audit findings promptly and review them carefully with the audit team.

- Assessment and Prioritization: We assess the severity and impact of each finding, prioritizing critical issues.

- Corrective Action Planning: We develop a plan to address each finding, including timelines and responsibilities.

- Implementation and Verification: We implement the corrective actions and verify their effectiveness.

- Documentation and Reporting: We document all actions taken and prepare a comprehensive response report for the auditor.

- Follow-up and Monitoring: We monitor the effectiveness of the corrective actions over time to ensure sustained compliance.

It’s crucial to maintain open communication with the auditor throughout the process, demonstrating a commitment to resolving the issues and improving compliance. A positive and collaborative approach builds trust and strengthens the relationship with regulatory authorities.

Q 8. What is your experience with change control processes?

Change control is the cornerstone of maintaining compliance and preventing deviations from established procedures in GMP/GLP environments. It’s a systematic process for evaluating, approving, and implementing changes to any aspect of a regulated process or system, ranging from equipment modifications to updates in Standard Operating Procedures (SOPs).

In my experience, I’ve been involved in change control processes across various projects, from minor updates to major equipment upgrades. This involves:

- Initiation: Clearly documenting the proposed change, its rationale, and potential impact. This usually involves completing a formal change control form.

- Evaluation: Assessing the potential risks associated with the change. This might involve impact assessments, risk assessments, and a review of existing validation data.

- Approval: Securing approval from relevant stakeholders, often through a change control board, based on the risk assessment and justification.

- Implementation: Implementing the approved change, ensuring proper documentation and training.

- Verification: Verifying that the implemented change meets the intended purpose and doesn’t introduce new problems. This could include revalidation or requalification activities.

- Closure: Formally closing the change control process once verification is complete and the records are archived.

For example, during a recent project, we implemented a new LIMS (Laboratory Information Management System). The change control process ensured that data integrity was maintained, user training was comprehensive, and the system was validated before going live. This meticulous approach prevented any disruptions to our GLP operations.

Q 9. How do you ensure compliance with regulatory requirements?

Ensuring regulatory compliance is a continuous effort, not a one-time task. It’s about building a culture of quality and adherence to regulations such as GMP (Good Manufacturing Practices) and GLP (Good Laboratory Practices). My approach involves several key strategies:

- Staying Updated: I constantly monitor changes in regulations and guidelines through reputable sources like the FDA, EMA, and relevant professional organizations. This ensures we’re always working with the latest requirements.

- Implementing Robust Systems: We utilize comprehensive systems for document control, change control, deviation management, and quality risk management. These systems ensure traceability and accountability throughout all operations.

- Training and Education: Regular training is provided to all personnel to ensure a clear understanding of regulatory requirements and our internal procedures. This training reinforces best practices and fosters a culture of compliance.

- Internal Audits and Self-Inspections: We conduct regular internal audits to identify potential compliance gaps and implement corrective and preventive actions (CAPAs). This proactive approach prevents issues from escalating.

- External Audits: We actively participate in regulatory inspections and audits. These provide valuable external feedback and demonstrate our commitment to compliance.

- Continuous Improvement: Compliance is a journey, not a destination. We continually assess our systems and processes to identify areas for improvement and enhance compliance. We utilize techniques such as Lean and Six Sigma to streamline processes and improve efficiency without compromising compliance.

For instance, we recently updated our SOPs to reflect new FDA guidelines on data integrity, ensuring all our laboratory practices align with the updated requirements. This proactive approach not only demonstrates our commitment to compliance but also improves the overall quality of our work.

Q 10. Explain your understanding of document control systems.

A robust document control system is essential for ensuring data integrity and traceability in a regulated environment. It provides a centralized system for managing all documents related to manufacturing or laboratory processes. This includes SOPs, test methods, batch records, and training materials.

My experience includes working with electronic document management systems (EDMS) which offer benefits like version control, audit trails, and easy accessibility. Key features of an effective document control system include:

- Document Creation and Review: A clear process for creating, reviewing, and approving documents, including author, reviewer, and approver signatures (electronic or manual).

- Version Control: A mechanism for tracking document revisions, ensuring only the most current version is used. Obsolete versions are archived and easily retrievable.

- Distribution and Access Control: Controlled distribution of documents to authorized personnel only. Access rights are managed to ensure confidentiality and data integrity.

- Document Change Control: Any changes to documents follow a formal change control process, as previously discussed.

- Document Archiving and Retention: A system for securely archiving documents to meet regulatory requirements regarding record retention.

- Periodic Review and Updates: Regular review of documents to ensure they are current, accurate, and reflect best practices.

In practice, this translates to efficient workflow, improved accuracy, and demonstrable compliance. For example, our EDMS ensures that all personnel are working with the latest approved SOPs and that changes are tracked meticulously. This allows for complete traceability in case of any discrepancies or regulatory audits.

Q 11. Describe your experience with validation activities.

Validation is the process of demonstrating that equipment, systems, and processes consistently perform as intended. It’s crucial for ensuring the reliability and accuracy of results in GMP/GLP environments. My experience encompasses various validation activities, including:

- Equipment Qualification (EQ): This involves demonstrating that equipment is fit for its intended purpose. This includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ).

- Computer System Validation (CSV): Ensuring that computer systems used for data acquisition, processing, or storage meet regulatory requirements for data integrity. This includes risk assessment, design qualification, and operational qualification.

- Process Validation: Demonstrating that manufacturing processes consistently produce products that meet predetermined specifications and quality attributes. This often involves statistical analysis of data.

- Analytical Method Validation: Verifying that analytical methods used for testing are accurate, precise, sensitive, and specific. This involves validating parameters such as linearity, range, accuracy, precision, and limit of detection/quantification.

For instance, during the validation of a new HPLC system, I was responsible for conducting IQ, OQ, and PQ activities. This involved meticulously documenting every step, from installation verification to the performance testing of the system to ensure its suitability for the intended analytical methods. The comprehensive validation documentation allows us to demonstrate to regulatory agencies that our analytical results are reliable and accurate. The entire process was documented with clear evidence of successful completion and adherence to current Good Manufacturing Practices and relevant guidelines.

Q 12. What is your experience with quality risk management?

Quality Risk Management (QRM) is a systematic process for identifying, analyzing, evaluating, controlling, and reviewing risks to product quality. It’s a proactive approach that moves beyond simply reacting to problems. It involves using a structured framework to understand the potential risks and implement controls to mitigate them.

My experience incorporates using various QRM methodologies, such as FMEA (Failure Mode and Effects Analysis) and risk assessments based on ICH Q9 guidelines. This involves:

- Risk Identification: Identifying potential hazards that could impact product quality or patient safety.

- Risk Analysis: Assessing the likelihood and potential impact of identified risks.

- Risk Evaluation: Evaluating the significance of the risks based on the likelihood and impact assessment.

- Risk Control: Developing and implementing controls to mitigate identified risks. This could involve implementing new procedures, improving training, or investing in new technologies.

- Risk Review: Regularly reviewing the effectiveness of implemented controls and updating the risk assessment as needed.

A practical example would be conducting a risk assessment for a new manufacturing process. By employing FMEA, we identify potential failure points, assess their impact, and put in place preventive measures to avoid compromising product quality. This proactive approach helps prevent significant issues down the line, saving resources and ensuring high-quality product.

Q 13. How do you handle non-conformances?

Handling non-conformances (NCs) effectively is critical for maintaining compliance and product quality. A non-conformance is any instance where a product, process, or system doesn’t meet predetermined specifications or requirements. My approach follows a structured process:

- Identification and Documentation: Clearly document the NC, including its nature, location, date, and time of discovery. This usually involves completing a formal non-conformance report.

- Investigation: Thoroughly investigate the root cause(s) of the NC to prevent recurrence. This often involves interviewing personnel, reviewing records, and analyzing data.

- Corrective Action: Implement corrective actions to address the immediate problem and prevent its reoccurrence. This could involve process improvements, equipment repair, or retraining of personnel.

- Preventive Action: Implement preventive actions to prevent similar non-conformances from happening in the future. This could involve reviewing SOPs, strengthening quality control procedures, or updating equipment maintenance schedules.

- Verification and Closure: Verify the effectiveness of the implemented corrective and preventive actions. Once verified, the NC report is formally closed.

In a recent instance, a deviation was identified in a batch record. The investigation revealed a lack of clarity in the SOP. We implemented corrective actions by updating the SOP, retraining personnel, and conducting a thorough review of similar batches. By addressing the root cause and implementing preventive measures, we prevented similar deviations in the future.

Q 14. Explain your experience with internal audits.

Internal audits are a critical tool for assessing the effectiveness of our quality management system and ensuring ongoing compliance. I have extensive experience in planning, conducting, and reporting on internal audits.

My approach involves:

- Planning: Developing an audit plan that defines the scope, objectives, and schedule of the audit. This includes identifying the areas to be audited and selecting appropriate auditors.

- Conducting the Audit: Performing the audit according to the plan, collecting evidence, and documenting findings. This may involve reviewing documents, observing processes, and interviewing personnel.

- Reporting: Preparing an audit report that summarizes the findings, including both strengths and weaknesses. This report identifies non-conformances and makes recommendations for corrective and preventive actions.

- Follow-up: Following up on the implementation of corrective and preventive actions and verifying their effectiveness.

A recent internal audit of our analytical laboratory identified a gap in our equipment calibration procedures. This resulted in corrective actions to update our calibration SOP, improve training, and implement a more robust calibration schedule. The follow-up audit confirmed the effectiveness of these actions.

Q 15. Describe your experience with supplier audits.

Supplier audits are a critical component of ensuring the quality and compliance of materials and services used in regulated industries. My experience encompasses conducting both on-site and off-site audits, focusing on evaluating a supplier’s adherence to GMP/GLP principles and their own quality management system. This includes reviewing documentation, interviewing personnel, and observing manufacturing processes. For example, during an audit of a chemical supplier, I meticulously reviewed their Certificate of Analysis (CoA), ensuring it included the necessary parameters and met the required specifications. I also examined their calibration records for analytical instruments and their change control procedures for any modifications to their processes. I look for evidence that they proactively identify and mitigate risks to quality and compliance, not just react to issues.

I’ve also been involved in developing audit checklists tailored to specific suppliers and their products, ensuring comprehensive coverage of relevant regulatory requirements. In cases where non-conformances are identified, I work collaboratively with the supplier to develop and implement corrective and preventative actions (CAPAs) to address the issues. The goal is always to establish a strong, collaborative relationship built on mutual trust and a shared commitment to quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key elements of a quality management system (QMS)?

A Quality Management System (QMS) is a structured approach to managing and improving an organization’s processes to consistently meet customer and regulatory requirements. Think of it as a roadmap for achieving and maintaining quality. Key elements include:

- Quality Policy: A formal statement defining the organization’s commitment to quality.

- Responsibility and Authority: Clearly defining roles and responsibilities for quality-related activities.

- Resource Management: Ensuring sufficient resources (personnel, equipment, funding) are available to support the QMS.

- Product Realization: Managing the entire product lifecycle, from design and development through manufacturing and distribution.

- Measurement, Analysis, and Improvement: Continuously monitoring performance, identifying areas for improvement, and implementing corrective actions.

- Management Review: Regularly reviewing the effectiveness of the QMS and making necessary adjustments.

- Documentation and Records Management: Maintaining accurate and complete records to demonstrate compliance.

For instance, in a pharmaceutical setting, a robust QMS ensures that drug products are consistently manufactured to the highest quality standards, meeting all regulatory requirements and patient safety expectations. A well-implemented QMS facilitates traceability, allowing for quick identification and resolution of issues if problems arise.

Q 17. Explain your understanding of 21 CFR Part 11.

21 CFR Part 11 outlines the Food and Drug Administration’s (FDA) regulations for electronic records and electronic signatures in the pharmaceutical and other regulated industries. It aims to ensure the integrity, authenticity, and reliability of electronic data. Key aspects include:

- Validation: Electronic systems must be validated to ensure they operate as intended and produce reliable results.

- Security: Robust security measures must be in place to protect electronic records from unauthorized access, alteration, or deletion.

- Audit Trails: Detailed audit trails must track all changes made to electronic records.

- Electronic Signatures: Electronic signatures must meet specific requirements to ensure authenticity and accountability.

Imagine a situation where a pharmaceutical company is using an electronic batch record system. 21 CFR Part 11 mandates that this system must be validated to demonstrate its accuracy and reliability. The system must also maintain secure audit trails that clearly record all user actions, such as data entry and approval. Any deviation from established procedures must be thoroughly documented and investigated. Failure to comply can result in significant regulatory repercussions, including warning letters or even product recalls.

Q 18. How do you ensure data security in a regulated environment?

Data security in a regulated environment is paramount. My approach involves a multi-layered strategy encompassing:

- Access Control: Limiting access to data based on the principle of least privilege. Only authorized personnel should have access to sensitive information.

- Data Encryption: Encrypting sensitive data both in transit and at rest to prevent unauthorized access even if a breach occurs.

- Regular Security Audits: Conducting regular security audits to identify vulnerabilities and ensure compliance with security policies and regulations.

- Antivirus and Malware Protection: Implementing robust antivirus and malware protection software to prevent infections and data loss.

- Data Backup and Recovery: Maintaining regular backups of critical data to ensure business continuity in the event of data loss.

- Employee Training: Providing regular training to employees on data security best practices, including password management and phishing awareness.

For example, in a clinical trial setting, patient data is highly sensitive and protected under various regulations. Implementing robust access controls, encryption, and audit trails is crucial. We may use data masking techniques to further protect patient privacy, while still allowing researchers to analyze aggregated data.

Q 19. Explain your experience with electronic records and signatures.

My experience with electronic records and signatures (ERES) is extensive, focusing on ensuring compliance with 21 CFR Part 11. I’ve worked with various systems, from electronic laboratory notebooks (ELNs) to manufacturing execution systems (MES). My responsibilities have included system validation, implementation, and training. A key focus is always on establishing and maintaining the integrity of the electronic data. For example, I’ve worked with systems that utilized digital signatures to ensure the authenticity of data and prevent unauthorized modifications. In one project, we implemented a system to track deviations from standard operating procedures, providing a complete audit trail of all changes and approvals. This system was validated according to 21 CFR Part 11, and rigorous training was provided to all personnel to ensure proper usage. Understanding the nuances of electronic signatures, including their legal weight and implications, is a critical part of this role.

Q 20. Describe your experience with training and competency assessment.

Training and competency assessment are essential components of a robust quality management system. My approach involves developing and delivering training programs tailored to the specific needs of the personnel and regulatory requirements. This includes creating training materials, conducting training sessions, and assessing employee competency through both written and practical examinations. I emphasize hands-on training whenever feasible, utilizing simulations and practical exercises to reinforce learning. After training, competency is evaluated through a mix of methods such as observation during job performance, testing, and documented demonstrations. For example, in a pharmaceutical manufacturing setting, training might involve practical demonstrations on proper aseptic techniques. Ongoing training and skills assessment are crucial for maintaining compliance and improving overall quality.

Q 21. What is your approach to problem-solving in a compliance context?

My approach to problem-solving in a compliance context is systematic and data-driven. I use a structured approach such as the DMAIC (Define, Measure, Analyze, Improve, Control) methodology or similar problem-solving frameworks. This begins with clearly defining the problem, gathering data to understand its root cause, and then developing and implementing effective solutions. For example, if a batch of product fails to meet specifications, I would investigate the entire manufacturing process, review batch records, analyze environmental monitoring data, and interview personnel to identify the root cause. The findings are then documented and presented, leading to corrective actions to prevent recurrence and potential improvements to processes. Collaboration with cross-functional teams is crucial in this process to gain diverse perspectives and ensure the solution is effective and sustainable. Following implementation, continuous monitoring ensures that the solution remains effective and that the issue does not recur.

Q 22. How do you stay up-to-date with regulatory changes?

Staying current with regulatory changes in GMP/GLP is crucial. My approach is multi-faceted and proactive, not reactive. I subscribe to reputable regulatory newsletters and journals, such as those published by the FDA, EMA, and industry associations like the PDA. I actively participate in webinars and conferences, networking with peers and experts to gain insights into emerging trends and interpretations. Additionally, I meticulously track updates on relevant websites and utilize regulatory intelligence platforms that provide alerts on new guidance documents, amendments, and enforcement actions. Think of it like following a stock portfolio – constant monitoring is necessary to avoid unexpected losses (compliance violations).

- Regulatory Newsletters & Journals: These provide summaries and analyses of new regulations.

- Webinars & Conferences: These offer direct access to regulatory experts and networking opportunities.

- Regulatory Intelligence Platforms: These provide real-time alerts and updates on regulatory changes.

Q 23. Describe a time you had to deal with a critical compliance issue.

In a previous role, we discovered a significant deviation during a routine audit of our stability program. Several batches of a pharmaceutical product showed degradation exceeding the established acceptance criteria. This was a critical compliance issue because it posed a risk to product quality and patient safety.

My immediate response involved assembling a cross-functional team comprising quality control, quality assurance, and production personnel. We initiated a thorough investigation, meticulously documenting all findings. This involved reviewing batch records, analytical data, and environmental monitoring data to pinpoint the root cause. We identified a problem with a specific piece of equipment that had not been properly calibrated.

We implemented corrective and preventative actions (CAPA), including recalibrating the equipment, retraining personnel, and enhancing our quality control procedures. We also reported the issue to the relevant regulatory agency, demonstrating transparency and a commitment to rectifying the situation. The situation taught me the importance of robust quality systems, proactive monitoring, and clear communication during crises.

Q 24. How do you prioritize tasks in a demanding compliance role?

Prioritizing tasks in a compliance role requires a structured approach. I employ a risk-based prioritization method. I assess each task based on its potential impact on compliance, considering factors such as regulatory severity, business impact, and timeline. I then categorize tasks as high, medium, or low priority. High-priority tasks, such as addressing critical audit findings or responding to regulatory inquiries, take precedence. I utilize project management tools to track progress, set deadlines, and ensure efficient allocation of resources. This ensures that critical compliance activities are never neglected while still allowing for the completion of other important tasks. It’s similar to triage in a hospital – the most critical cases are dealt with first.

- Risk Assessment: Evaluating the potential impact of non-compliance.

- Prioritization Matrix: Categorizing tasks based on urgency and importance.

- Project Management Tools: Tracking progress and deadlines.

Q 25. Explain your experience with different regulatory agencies (e.g., FDA, EMA).

I’ve worked extensively with both the FDA and EMA, navigating their unique requirements and expectations. My experience with the FDA primarily involves navigating the intricacies of cGMP regulations for pharmaceutical manufacturing. This included submitting documentation for new drug applications (NDAs) and dealing with inspections. With the EMA, my experience focuses on the implementation of GMP guidelines in the context of EU legislation. This includes understanding the requirements for marketing authorizations (MAs) and navigating their inspection process. The key difference lies in their specific regulatory frameworks and guidance documents; however, the underlying principles of GMP remain consistent. Understanding these nuances ensures compliance with both regulatory bodies.

Q 26. Describe your familiarity with specific GMP guidelines (e.g., ICH Q7).

ICH Q7A, Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients, is a guideline I’m intimately familiar with. I understand its comprehensive requirements for the manufacturing of APIs, from raw material selection and process validation to quality control testing and documentation. I’ve been involved in several projects where we’ve implemented and audited against the specific requirements of ICH Q7A. This includes developing and reviewing manufacturing processes, ensuring compliance with current Good Manufacturing Practices (cGMPs), and working with analytical testing to confirm quality and compliance with specifications.

For example, I’ve directly participated in the development and implementation of robust quality systems aligned with ICH Q7A, including change control, deviation management, and CAPA procedures. My understanding also extends to related guidelines, such as ICH Q6A and Q6B, which deal with specifications and impurities in drug substances. Having practical experience in these aspects ensures I can guide and support teams to navigate these complex regulatory requirements.

Q 27. How do you ensure effective communication within a compliance team?

Effective communication within a compliance team is paramount. I foster open and transparent communication using several strategies. Regular team meetings are held to discuss ongoing projects, address challenges, and share best practices. We utilize a collaborative platform for document sharing and communication, providing immediate access to information. I encourage open dialogue and feedback, actively listening to team members’ concerns and perspectives. This creates a culture of trust and mutual respect, resulting in a more cohesive and efficient team. Clear and concise communication is key – avoiding ambiguity and ensuring everyone is on the same page is crucial to maintain a smoothly functioning team.

Q 28. Describe your experience with metrics and reporting related to compliance.

My experience with compliance metrics and reporting involves designing and implementing key performance indicators (KPIs) to track compliance performance. This includes metrics such as the number of audits conducted, the rate of non-conformances, and the time taken to resolve CAPAs. I use data visualization techniques to present these metrics in a clear and concise manner, enabling stakeholders to understand our compliance posture and identify areas for improvement. This data-driven approach allows us to make informed decisions and proactively address potential compliance risks. Reporting regularly to upper management on the state of compliance is crucial to ensure ongoing support and resource allocation. Think of it like a dashboard for a car – you need to monitor key indicators to ensure a smooth and safe journey.

Key Topics to Learn for Regulatory Compliance (GMP/GLP) Interview

Acing your Regulatory Compliance (GMP/GLP) interview requires a strong understanding of both the theoretical framework and practical application of these crucial regulations. This isn’t just about memorizing rules; it’s about demonstrating how you can apply your knowledge to solve real-world problems.

- GMP (Good Manufacturing Practices): Understanding the core principles of GMP, including documentation, validation, deviation management, and change control. Consider how these principles ensure product quality and patient safety.

- GLP (Good Laboratory Practices): Focus on the principles of GLP, such as study design, data integrity, and quality assurance in laboratory settings. Think about how GLP ensures the reliability and validity of test results.

- Regulatory Inspections & Audits: Prepare for questions about your experience with regulatory inspections, including understanding inspection procedures and responding to findings. Practice your ability to explain processes clearly and concisely.

- CAPA (Corrective and Preventive Actions): Master the CAPA process, including identifying root causes, implementing corrective actions, and preventing future occurrences. Be prepared to discuss examples of your effective CAPA involvement.

- Quality Systems & Documentation: Demonstrate a thorough understanding of the importance of robust quality systems and meticulous documentation. Prepare to discuss how you ensure compliance with relevant regulations.

- Risk Management in GMP/GLP: Understand how risk assessment and mitigation strategies are applied within a GMP/GLP framework. Be ready to provide examples of your experience in this area.

- Specific Regulations (e.g., 21 CFR Part 11, ICH Guidelines): Familiarize yourself with relevant regulations and guidelines applicable to your specific area of expertise within GMP/GLP. Be prepared to discuss specific requirements and your understanding of their implications.

Next Steps

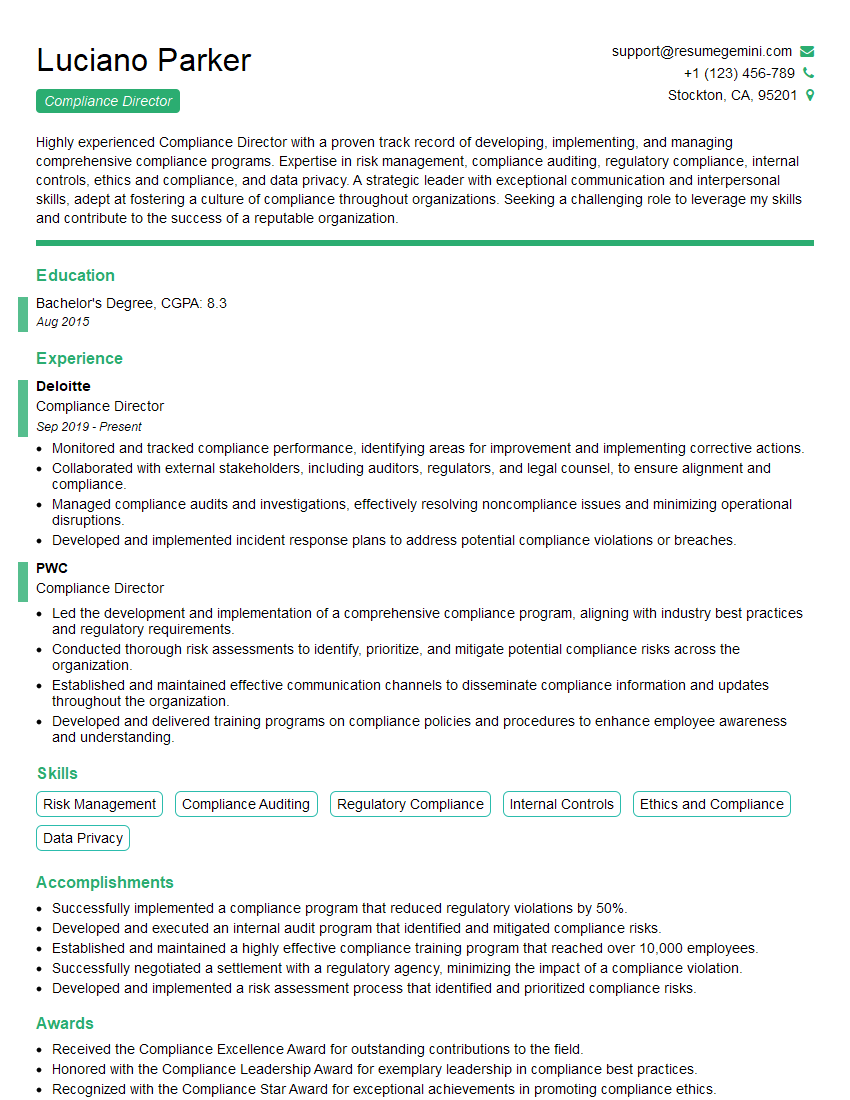

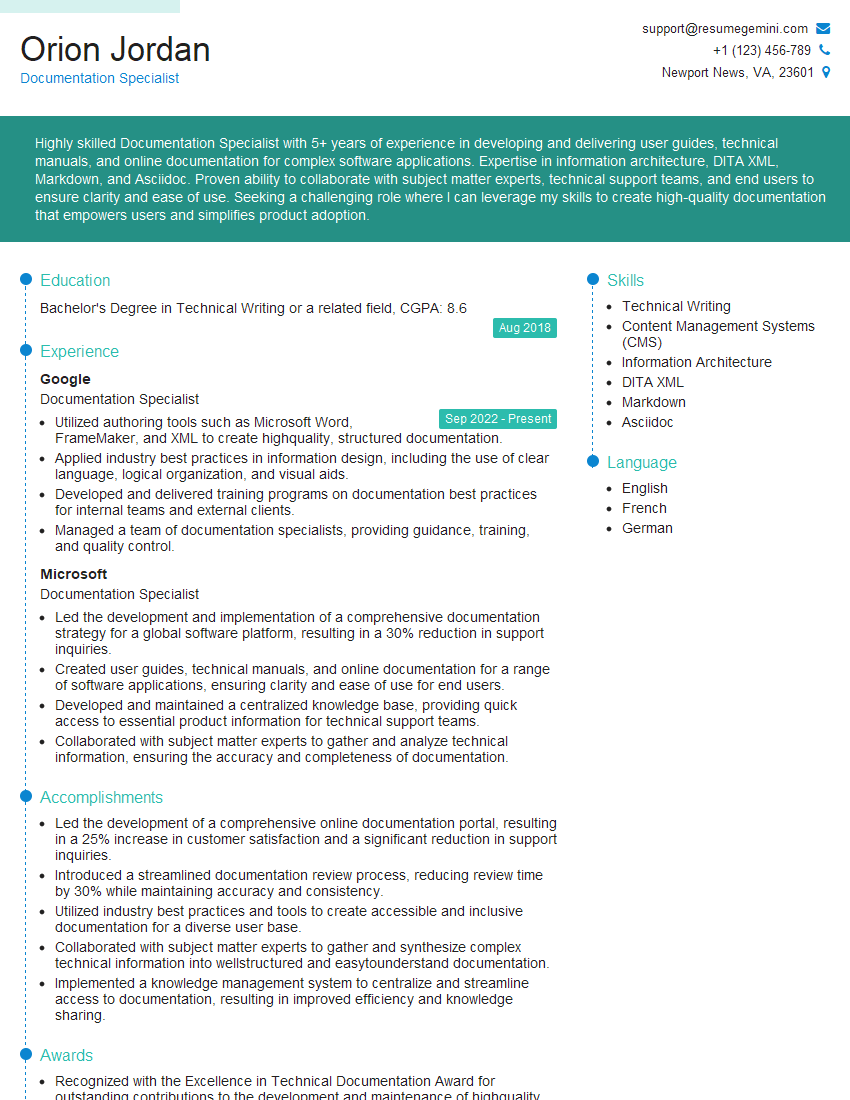

Mastering Regulatory Compliance (GMP/GLP) is essential for career advancement in the pharmaceutical, biotechnology, and related industries. It demonstrates your commitment to quality, safety, and regulatory adherence – highly valued skills in today’s competitive job market. To maximize your job prospects, crafting an ATS-friendly resume is crucial. This is where ResumeGemini can be invaluable. ResumeGemini provides a user-friendly platform to build a professional and impactful resume, significantly increasing your chances of landing that dream interview. Examples of resumes tailored to Regulatory Compliance (GMP/GLP) roles are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?