Unlock your full potential by mastering the most common Roofing techniques interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Roofing techniques Interview

Q 1. Explain the different types of roofing materials and their applications.

Roofing materials vary greatly in durability, cost, and aesthetic appeal. The best choice depends on factors like climate, budget, and architectural style. Here are some common types:

- Asphalt Shingles: The most prevalent choice due to affordability and ease of installation. They come in various styles (3-tab, architectural) and colors. They are suitable for a wide range of climates but have a shorter lifespan compared to other options.

- Wood Shakes and Shingles: Offer a natural, rustic look. They are durable but require more maintenance and are susceptible to fire and insect damage. They’re best suited for areas with less extreme weather.

- Tile Roofing (Clay and Concrete): Extremely durable and long-lasting, offering excellent fire resistance. They are heavier than other options, requiring a stronger roof structure. Clay tiles are more susceptible to cracking than concrete.

- Metal Roofing (Steel, Aluminum, Copper): Incredibly strong, long-lasting, and energy-efficient. They are resistant to fire, insects, and rot but can be noisy during rain and more expensive upfront.

- Slate Roofing: The epitome of durability and longevity, lasting for centuries. Extremely heavy and expensive, requiring specialized installation.

Choosing the right material is crucial. For instance, in a hurricane-prone area, metal roofing’s strength is a significant advantage, while in a fire-risk zone, tile roofing provides superior protection.

Q 2. Describe the process of installing asphalt shingles.

Asphalt shingle installation is a meticulous process requiring precision. Here’s a breakdown:

- Preparation: Inspect the existing roof deck for damage. Repair or replace any damaged areas. Ensure the roof is clean and free of debris.

- Underlayment: Install a waterproof underlayment, such as felt paper or synthetic underlayment, over the decking. This provides an extra layer of protection against leaks.

- Starter Course: Begin by installing a starter course of shingles along the eaves. This provides a straight, even base for the rest of the shingles.

- Shingle Installation: Apply shingles in overlapping rows, working up the roof from the eaves to the ridge. Maintain proper shingle alignment and nail placement. The nails should penetrate the shingle and the underlayment to secure them properly.

- Ridge Cap Shingles: Install ridge cap shingles to finish the roofline. These shingles are specially designed to protect the ridge from water penetration.

- Clean Up: Remove all debris from the roof and surrounding areas.

Proper nailing is critical. Using too few nails can result in wind damage, and too many can puncture the shingle, leading to leaks. I always emphasize quality control at every step.

Q 3. How do you ensure proper ventilation in a roof system?

Proper roof ventilation is essential to prevent moisture buildup, which can lead to mold, rot, and ice dams. A well-ventilated roof system requires both intake and exhaust vents. Intake vents allow outside air to enter the attic, while exhaust vents allow the hot, moist air to escape.

Intake vents are usually located in the soffits (the area under the eaves), while exhaust vents are commonly located near the ridge. The balance between intake and exhaust is crucial. Too much intake without sufficient exhaust can lead to condensation. Conversely, too much exhaust without enough intake can limit air circulation.

Proper ventilation prolongs the life of your roof and prevents costly repairs.

Q 4. What are the common causes of roof leaks and how are they repaired?

Roof leaks are a common problem with various causes. Identifying the source is key to effective repair:

- Damaged Shingles: Cracked, curled, or missing shingles are common culprits. Repair involves replacing the damaged shingles.

- Flashing Issues: Flashing, the metal material used to seal joints and intersections, can deteriorate over time. Leaks around chimneys, vents, and valleys often result from flashing failure. Replacement is usually necessary.

- Poor Sealant: Sealant around penetrations (such as pipes) can crack and degrade, allowing water to enter. Removing old sealant and applying new sealant is the solution.

- Damaged Underlayment: Tears or punctures in the underlayment can allow water to penetrate the roof deck. Repairing or replacing the damaged underlayment is needed.

- Blocked Gutters: Clogged gutters can cause water to overflow and back up against the roof, leading to leaks. Regular gutter cleaning is crucial.

When repairing leaks, it’s vital to address the underlying cause, not just the symptom. For example, simply patching a damaged shingle without checking the underlayment can lead to recurrence of the leak.

Q 5. Explain the importance of underlayment in roofing.

Underlayment is a crucial component of a roofing system, acting as a secondary waterproof barrier beneath the shingles. It protects the roof deck from water damage in the event that the shingles are compromised, preventing leaks and extending the life of the roof. Think of it as insurance for your roof.

There are different types of underlayment, including felt paper and synthetic underlayments. Synthetic underlayments offer advantages like better water resistance, breathability, and increased tear resistance. Proper underlayment installation is crucial. Overlapping layers should be sealed to avoid gaps. This protects the roof from wind-driven rain and moisture.

Q 6. Describe your experience with different flashing techniques.

Flashing is critical for preventing water penetration at critical areas like chimneys, valleys, and around vents. I’ve worked with various flashing materials, including galvanized steel, aluminum, and copper. The choice depends on the specific application and local climate.

For instance, around chimneys, I often use step flashing—overlapping metal pieces that follow the contours of the chimney and overlap with the shingles to create a watertight seal. For valleys, I prefer to use a closed valley system, which eliminates the potential for water to collect and penetrate under the shingles. Properly seamed flashing is essential. Overlapping pieces must be correctly sealed with sealant or counterflashing for complete protection.

My experience includes working with both traditional and modern flashing techniques, ensuring I select the best approach for the project requirements. Regular inspection of flashing is key for preventing future problems. Proper installation of flashing is crucial and can be the difference between a leak-free roof and costly repairs.

Q 7. How do you determine the slope of a roof?

Determining roof slope, also known as pitch, is essential for selecting appropriate roofing materials and ensuring proper drainage. Roof slope is expressed as a ratio of rise over run, typically as X/12, where X is the rise (vertical height) for every 12 inches of run (horizontal distance).

You can determine the slope using a simple method: measure the vertical rise from the eaves to the ridge and the horizontal run (the distance along the rafter from the eaves to the ridge). Divide the rise by the run to determine the ratio. For example, a 6-inch rise over a 12-inch run would be expressed as a 6/12 slope or a 6-in-12 pitch.

Alternatively, you can use a level and a measuring tape to measure the angle directly. Many roof calculators and online tools are available to help determine the slope from these measurements.

Understanding the slope helps in selecting appropriate shingles and ensuring proper water runoff. Steeper slopes allow for quicker water drainage, while gentler slopes may require specific materials and installation techniques.

Q 8. What safety measures do you take when working at heights?

Safety is paramount in roofing. Working at heights demands a rigorous approach. My team and I strictly adhere to OSHA regulations and best practices. This starts with a thorough pre-job safety briefing covering potential hazards, like uneven surfaces, falling objects, and electrical lines. We always use appropriate fall protection systems, such as harnesses, lanyards, and anchor points. These are inspected daily to ensure they are in perfect working order. We also utilize scaffolding or ladders that are correctly positioned and secured, ensuring proper weight distribution. Our crew is trained in rescue techniques and emergency response procedures, and we maintain a clear communication system on the job site. For example, I recently worked on a project where we had to install additional safety netting to protect workers and passersby below. The extra time and effort ensured everyone’s safety throughout the job.

- Daily safety checks of equipment.

- Use of appropriate PPE (Personal Protective Equipment).

- Regular training on safety protocols.

- Emergency response planning.

Q 9. How do you estimate the cost of a roofing project?

Estimating roofing costs involves a detailed breakdown. First, a thorough site assessment is crucial – measuring the roof area accurately and identifying the type of roofing material required. I then factor in the cost of materials (considering market fluctuations and bulk discounts), labor (accounting for crew size and project duration), and any necessary permits or disposal fees. Contingency for unexpected issues (e.g., rotted sheathing) is added, usually around 10%. For instance, if the material cost is $5,000, labor is $7,000, and permits are $500, a total of $12,500 is estimated. Applying the 10% contingency, the final estimate would be around $13,750. I present this breakdown transparently to clients, allowing for informed decision-making. My experience allows me to accurately anticipate potential issues and minimize cost overruns.

Q 10. Explain your experience with different roofing systems (e.g., low-slope, steep-slope).

My experience encompasses a wide range of roofing systems. Steep-slope roofing, often seen on residential homes, involves working with materials like asphalt shingles, clay tiles, or slate. I’m proficient in installing and repairing these systems, understanding the nuances of underlayment, flashing, and proper ventilation. Low-slope roofing, commonly found on commercial buildings, requires a different skillset, focusing on membrane systems like EPDM, TPO, or built-up roofing. These projects demand a thorough understanding of waterproofing techniques and proper slope drainage. I’ve worked extensively on both types. One notable project involved a complex low-slope roof requiring a specialized drainage system. My expertise in this area helped deliver the project on time and within budget. Another involved a historic home with unique slate tile roofing. Understanding historic restoration techniques helped me successfully complete the project while respecting the home’s character.

Q 11. Describe your experience with roof inspections and identifying potential problems.

Roof inspections are integral to preventative maintenance. I begin with a visual inspection, noting any signs of damage, such as missing shingles, cracked tiles, or damaged flashing. I then use specialized equipment, like drones or thermal imaging cameras, to identify hidden problems like moisture intrusion or insulation deficiencies. For example, a thermal scan might reveal areas of heat loss, indicating poor insulation or potential leaks. My detailed inspection reports identify the problems and suggest appropriate solutions, including immediate repairs, preventative maintenance, or a complete roof replacement. I recently identified hidden water damage in a client’s attic during an inspection, averting significant structural damage and saving the client substantial repair costs.

Q 12. How do you handle difficult clients or unexpected problems on a job site?

Handling difficult clients or unexpected problems requires patience and clear communication. When faced with a challenging client, I actively listen to their concerns, patiently explaining the technical aspects of the project in terms they can easily understand. Transparency is key, keeping them updated on any changes or delays. For unexpected problems, I focus on finding solutions quickly and efficiently. This often involves using my experience to devise creative workarounds. For instance, a recent project involved encountering unexpected rot in a rafter – I adapted the schedule, secured additional materials, and carefully repaired the area to avoid project delays. Open communication with the client about the unforeseen circumstance and the plan for addressing it kept any conflicts at bay.

Q 13. What are the building codes and regulations related to roofing in your area?

Building codes and regulations vary by location but are critical for safe and compliant roofing work. In my area, I’m up to date with local codes pertaining to slope requirements, wind uplift resistance, fire safety, and the use of specific materials. For example, I am familiar with the International Building Code (IBC) guidelines that govern the installation of various roofing materials and flashings. I always secure the necessary permits before commencing any project. Compliance isn’t just about avoiding penalties; it’s about ensuring a structurally sound and durable roof that protects the building and its occupants.

Q 14. Describe your experience with different types of roof penetrations (e.g., chimneys, vents).

Roof penetrations, such as chimneys, vents, and skylights, require specialized attention to prevent leaks. I’m experienced in properly flashing these elements to create a watertight seal. This involves using appropriate materials, like flashing tape, metal flashing, and sealants, ensuring they are correctly installed around the penetration to divert water away from the roof’s structure. Incorrect flashing around a chimney, for example, can lead to significant water damage. My attention to detail in these crucial areas minimizes the risk of future problems. I’ve worked with numerous types of penetrations and always prioritize durability and waterproofing in my installations.

Q 15. How do you manage a roofing crew and ensure efficient workflow?

Managing a roofing crew effectively requires a blend of strong leadership, clear communication, and meticulous planning. It’s like conducting an orchestra – each member has a specific role, and their synchronized efforts create a harmonious outcome.

- Clear Roles and Responsibilities: Before we even start, each crew member understands their exact tasks. This could be anything from material handling to installing shingles, ensuring everyone knows their contribution.

- Pre-Job Briefing: I always begin with a comprehensive briefing outlining the day’s goals, safety procedures, and potential challenges. This sets the tone and ensures everyone is on the same page.

- Efficient Material Management: I implement a system to track materials, ensuring we have the right quantity at the right place at the right time. This minimizes delays and waste. Think of it like a well-stocked kitchen – everything is readily available when needed.

- Regular Communication and Check-ins: I consistently check in with team members, addressing questions and solving problems promptly. Open communication prevents minor issues from escalating into major delays.

- Safety First: Safety is paramount. I enforce strict safety protocols, provide appropriate personal protective equipment (PPE), and conduct regular safety briefings to reinforce best practices.

For example, on a complex slate roof installation, I’d assign specific teams to material handling, underlayment installation, slate placement, and finishing. Regular communication ensures a smooth and efficient process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with using specialized roofing tools and equipment?

My experience with specialized roofing tools and equipment is extensive. I’m proficient in using a wide range of tools, from basic hand tools like hammers and pry bars to sophisticated power equipment like nail guns, roofing nailers, and power washers.

- Power Tools: I’m highly skilled with pneumatic and electric nail guns, ensuring consistent and efficient fastening of roofing materials. I understand the importance of selecting the right nail gun for the specific material (e.g., different gauges for asphalt shingles vs. metal roofing).

- Safety Equipment: My experience includes proper use and maintenance of safety harnesses, fall arrest systems, and scaffolding. Safety is paramount, and I ensure compliance with all relevant regulations.

- Specialized Equipment: I’m familiar with using equipment like roof jacks, roof ladders, and various types of lifts for accessing and working on different roof styles and heights.

- Maintenance and Repair: I’m not just proficient in using these tools; I know how to maintain and troubleshoot them. A broken nail gun on a job site can bring everything to a halt, so preventative maintenance is crucial.

For instance, in a recent project involving a steep-sloped metal roof, we utilized a specialized magnetic tool to handle the metal sheets safely and efficiently, preventing accidental damage. My expertise in maintaining these tools ensures minimal downtime and maximum productivity.

Q 17. Explain your knowledge of different roofing warranty options.

Roofing warranties vary significantly in terms of coverage and duration. Understanding these options is crucial for both the homeowner and the contractor.

- Manufacturer’s Warranties: These warranties cover defects in the roofing materials themselves, such as shingle granule loss or material failure. The length of these warranties can range from 10 to 50 years, depending on the material and manufacturer.

- Workmanship Warranties: These warranties, offered by the roofing contractor, cover the quality of the installation. A reputable contractor will provide a robust workmanship warranty that addresses issues like leaks and improper installation for a specific period (typically 1-10 years).

- Hybrid Warranties: Some manufacturers offer combined warranties that cover both materials and workmanship. These offer a comprehensive protection package.

- Understanding Limitations: Warranties often have limitations and exclusions. For example, damage caused by extreme weather events might not be covered. It’s vital to carefully read the warranty document and understand what is and isn’t included.

In my experience, I always discuss warranty options with clients upfront, explaining the nuances of each type and ensuring they select the coverage best suited to their needs and budget. Transparency is key to building trust and managing expectations.

Q 18. Describe your experience with repairing damaged roofing materials.

Repairing damaged roofing materials requires a thorough assessment of the damage and the appropriate repair techniques. This isn’t just about patching holes; it’s about restoring the roof’s integrity and preventing further damage.

- Assessment: First, a careful inspection is needed to identify the extent of the damage. Is it a small crack, a larger hole, or more extensive damage? The type of material also dictates the repair method.

- Material Selection: The repair material must be compatible with the existing roofing material. Using an incompatible material can lead to future issues.

- Repair Techniques: Different materials require different repair techniques. For example, patching asphalt shingles might involve using a specialized sealant and patching material, while repairing a metal roof might require patching and sealing with a compatible sealant.

- Safety: Working on a damaged roof can be dangerous. I always prioritize safety, using appropriate safety harnesses and fall protection equipment.

For example, repairing a puncture in an EPDM rubber roof involves cleaning the area, applying an appropriate adhesive, and patching the area with a compatible rubber patch. The patch needs to be properly adhered to ensure a waterproof seal. Improper repair can lead to leaks and water damage.

Q 19. How do you deal with different weather conditions while working on a roof?

Weather is a significant factor in roofing work, impacting both safety and productivity. Dealing with varying conditions requires flexibility, preparedness, and a focus on safety.

- Safety Precautions: Working in extreme heat or cold requires extra precautions. Heatstroke is a real concern in hot weather, so I ensure crew members stay hydrated and take frequent breaks. In cold weather, frostbite is a risk, and we use appropriate clothing and take shorter work intervals.

- Scheduling: I avoid working during storms or high winds, as it’s simply too dangerous. We reschedule jobs as needed to ensure safety.

- Material Protection: Materials need protection from rain and extreme temperatures. We use tarps and other protective coverings as necessary.

- Adaptability: I’m adaptable and can adjust the work schedule to take advantage of favorable weather windows.

For example, on a recent project, we had to postpone work due to a sudden thunderstorm. Rescheduling prevented accidents and ensured the integrity of the materials.

Q 20. What are your experience with different types of insulation used in roofing?

Roof insulation plays a vital role in energy efficiency and thermal comfort. I’m familiar with various insulation types used in roofing applications.

- Fiberglass Batt Insulation: This is a common and cost-effective option, offering good thermal resistance. It’s relatively easy to install but can be prone to settling over time.

- Spray Foam Insulation: Spray foam insulation offers excellent air sealing and thermal performance. It adheres to various surfaces, filling gaps and cracks effectively. This is a great option for older roofs with gaps.

- Rigid Foam Board Insulation: This type of insulation comes in various thicknesses and provides high R-value (thermal resistance) per inch. It’s often used in conjunction with other insulation types or as a standalone solution in certain applications.

- Cellulose Insulation: Made from recycled paper, cellulose is a sustainable and effective insulation option. It can be blown into place, filling irregularities well.

Selecting the right insulation depends on factors like budget, climate, and roof design. In cold climates, a higher R-value insulation is typically preferred to maximize energy savings.

Q 21. Describe your experience with moisture barriers and their importance.

Moisture barriers are crucial for protecting the roof structure from water damage. They act as the first line of defense against moisture intrusion, preventing leaks and mold growth.

- Types of Moisture Barriers: Common moisture barriers include felt underlayment, synthetic underlayment, and ice and water shields. Ice and water shields are specifically designed to prevent ice damming and are often used in vulnerable areas like valleys and eaves.

- Installation: Proper installation is essential for effective moisture barrier performance. Overlapping seams need to be properly sealed to prevent moisture from penetrating.

- Importance: Moisture barriers prevent water from seeping into the underlying structural components of the roof, preventing rot, mold growth, and costly repairs down the line.

- Ventilation: It’s crucial to ensure adequate ventilation within the roof assembly to prevent moisture buildup. Moisture barriers work best in conjunction with proper ventilation.

Imagine a raincoat – a moisture barrier acts like that raincoat, protecting the underlying structure from the elements. Neglecting proper installation and maintenance is like having a raincoat with holes – it defeats the purpose entirely.

Q 22. How do you determine the best roofing solution for a particular project?

Choosing the right roofing solution involves a meticulous process. It’s not just about aesthetics; it’s about finding the perfect balance between budget, durability, climate, and the building’s architectural style. First, I conduct a thorough site assessment, considering factors like roof pitch, existing structure, local climate (including snowfall, rainfall, and wind speeds), and the client’s budget and aesthetic preferences.

For instance, a low-slope roof in a region with heavy snowfall would benefit from a robust, durable membrane roofing system like TPO (Thermoplastic Polyolefin) or EPDM (Ethylene Propylene Diene Monomer), designed to handle the weight and potential ice damming. Conversely, a steep-sloped roof in a dry climate might be ideal for clay tiles or asphalt shingles, offering a classic look with adequate protection.

Next, I analyze the building’s structural integrity to ensure it can adequately support the chosen roofing material’s weight. I also discuss the client’s long-term goals and maintenance preferences. Some materials require more upkeep than others. Finally, I present a detailed proposal outlining the various options, their pros and cons, associated costs, and estimated lifespan, empowering the client to make an informed decision.

Q 23. What are some common roofing issues you’ve encountered and how you resolved them?

Throughout my career, I’ve encountered a range of roofing issues. One common problem is leaking roofs, often caused by damaged flashing around chimneys, vents, or skylights. To resolve this, I first locate the leak’s source using various techniques like water testing and visual inspection. Then, I carefully repair or replace the damaged flashing, ensuring a watertight seal using high-quality sealant and proper installation techniques.

Another frequent issue is damaged shingles due to age, extreme weather, or impact damage. We carefully assess the extent of the damage. In case of minor damage, replacing only the affected shingles is often sufficient. If the damage is widespread, a partial or full roof replacement might be necessary, depending on the severity and the overall roof’s condition. The key is to address the problem promptly to prevent further damage and water penetration. Finally, improper installation is a frequent culprit. We always follow strict guidelines to ensure a well-installed roof.

Q 24. Explain your knowledge of different roofing drainage systems.

Effective drainage is critical for roof longevity. Several systems are employed, each with its strengths and weaknesses. Gravity-based systems are the most common, relying on the roof’s slope to channel water towards gutters and downspouts. Gutters must be properly sized and sloped to prevent water backup. Downspouts should lead water away from the foundation to prevent water damage. Properly sized gutters are crucial, especially in areas with high rainfall.

Internal drainage systems are often used in flat roofs. These systems involve a network of internal pipes and drains to collect and direct water away from the roof. Regular maintenance is crucial to prevent blockages. French drains, situated along the perimeter of a building, are used to divert excess water away from the foundation, complementing the main drainage system.

Each system needs regular inspection and cleaning to remove debris, leaves, and other obstructions that can hinder water flow, potentially causing leaks or damage.

Q 25. How do you ensure the longevity and durability of a roof?

Ensuring a roof’s longevity requires a multi-pronged approach, starting with proper material selection tailored to the specific climate and building type. Quality materials are more expensive upfront, but they offer a much longer lifespan and lower overall cost. Proper installation is paramount; a poorly installed roof, no matter how high-quality the materials, will fail prematurely.

Regular maintenance is vital. This includes annual inspections to identify and address minor issues before they escalate into significant problems. Cleaning gutters and downspouts at least twice a year prevents clogs that can lead to water damage. Addressing minor repairs promptly is crucial. Ignoring small problems will lead to substantial costs later on.

Finally, protecting the roof from external factors, such as tree branches that could damage shingles or ice dams from improperly insulated attics, is essential for maximizing its lifespan.

Q 26. Describe your experience with maintaining and cleaning roofing systems.

Maintaining and cleaning roofing systems is an ongoing process, not a one-time event. Routine inspections should be performed at least annually, checking for damaged shingles, loose flashing, clogged gutters, and signs of water damage. Depending on the climate and roofing material, more frequent inspections might be necessary.

Cleaning gutters and downspouts is a crucial aspect of maintenance, ideally performed twice a year, in spring and autumn. Removing debris prevents water from backing up onto the roof. Power washing can be effective for cleaning certain roofing materials, but it’s crucial to use the correct pressure to avoid damage. For delicate materials, gentler cleaning methods should be employed.

I always advise clients on the importance of regular maintenance to extend their roof’s life and avoid costly repairs down the line. We provide preventative maintenance packages to address this need.

Q 27. Explain your understanding of sustainability and eco-friendly roofing options.

Sustainability is increasingly important in roofing. Eco-friendly options include using recycled materials, such as recycled rubber in roofing membranes, or utilizing plant-based materials like bamboo or sustainably harvested wood. Cool roofs, which reflect sunlight and reduce energy consumption for cooling, are another sustainable choice. They use materials with high solar reflectance index (SRI) values.

Proper disposal of old roofing materials is vital for environmental responsibility. Many materials can be recycled, reducing landfill waste. Choosing roofing systems with a long lifespan minimizes the need for frequent replacements, lowering the overall environmental impact. It’s important to consider the entire life cycle of a roofing material – from manufacturing and transportation to disposal – when evaluating its sustainability.

Examples of eco-friendly options include vegetated roofs (green roofs) which offer insulation, stormwater management and aesthetic benefits, and solar panels which can also generate energy.

Key Topics to Learn for Roofing Techniques Interview

- Roofing Materials: Understanding the properties, applications, and limitations of various roofing materials (e.g., asphalt shingles, tile, metal, flat roofing membranes). This includes knowing appropriate uses for different climates and building types.

- Roofing Installation Techniques: Mastering the practical skills and procedures involved in installing different roofing systems. Consider the steps involved, from underlayment to flashing and finishing.

- Roof Safety and Regulations: Demonstrating a strong understanding of OSHA safety regulations and best practices for working at heights. This includes proper fall protection techniques and hazard identification.

- Roof Repair and Maintenance: Knowing how to identify and address common roofing problems, such as leaks, damaged flashing, and shingle deterioration. Understanding preventative maintenance techniques is crucial.

- Blueprint Reading and Estimation: Ability to interpret architectural plans to understand roofing scope and accurately estimate materials and labor costs for projects.

- Problem-Solving and Troubleshooting: Showcase your ability to diagnose roofing issues, develop effective solutions, and explain your decision-making process clearly.

- Tools and Equipment: Familiarity with the various tools and equipment used in roofing, understanding their proper use and maintenance.

- Weather Considerations: Demonstrate an understanding of how weather conditions impact roofing installations and repairs. Discuss safety precautions and adaptations needed.

Next Steps

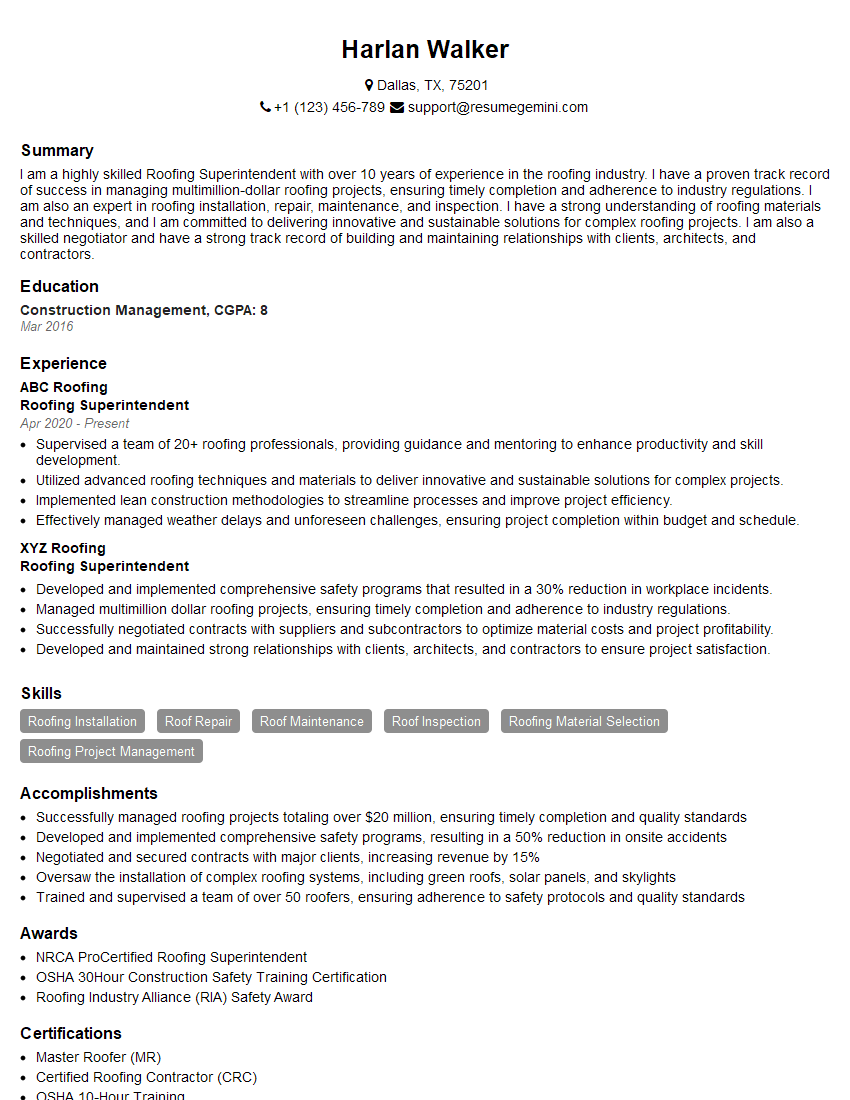

Mastering roofing techniques is essential for career advancement in the construction industry, opening doors to higher-paying positions and specialized roles. A strong resume is your key to unlocking these opportunities. To increase your chances of getting noticed by Applicant Tracking Systems (ATS) and recruiters, craft a compelling and ATS-friendly resume. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to roofing techniques are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?