Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Plying interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Plying Interview

Q 1. Describe the different types of plywood and their applications.

Plywood is a versatile material made from thin layers of wood veneer, glued together with the grain of adjacent layers oriented at right angles to one another. This cross-grain construction gives plywood exceptional strength and stability compared to solid wood. Different types exist, primarily categorized by their core and face veneer types, and intended applications.

- Softwood Plywood: Commonly made from softwood species like pine or fir. It’s relatively inexpensive and suitable for applications where high strength isn’t paramount, such as sheathing for walls and roofs in construction. Think of the framing of a house – often softwood plywood forms the base layer.

- Hardwood Plywood: Made from hardwood species like oak, maple, or birch. It’s more expensive but offers superior strength, durability, and a smoother finish, ideal for furniture, cabinetry, and fine woodworking projects. Consider a high-end kitchen; hardwood plywood provides both strength and a beautiful finish.

- Marine Plywood: Specifically designed for exterior applications and marine environments. It uses completely waterproof glues and often features exterior-grade veneers resistant to rot and decay. A boat hull is a prime example of where marine plywood’s durability is essential.

- Film Faced Plywood: This plywood has a thin layer of plastic film bonded to one or both faces. It provides a protective surface, making it highly resistant to scratches, moisture, and abrasion. Construction sites often utilize this for formwork, as the plastic film allows for easy release and clean-up.

- Structural Plywood: Engineered for structural applications, often used in construction. It undergoes rigorous quality control to ensure strength and stability. Think load-bearing walls or floor systems.

Q 2. Explain the process of plywood manufacturing, from veneer to finished product.

Plywood manufacturing is a multi-stage process, starting with the selection of logs. Here’s a breakdown:

- Log Preparation: Logs are debarked and cut into smaller sections called ‘bolts’.

- Veneer Peeling: Bolts are then peeled into thin sheets of veneer using rotary lathes. This process creates continuous sheets, similar to rolling out dough.

- Veneer Drying: The freshly peeled veneer is dried in large kilns to reduce moisture content, preventing warping and decay.

- Veneer Grading & Sorting: Veneer sheets are inspected and sorted based on quality, with defects minimized. This is crucial for the final product’s quality.

- Layup: Veneers are layered with the grain direction alternating (cross-grain), usually with an odd number of plies for balanced strength. The core layers are often less expensive than the face veneers.

- Glue Application: An adhesive is spread evenly onto the veneer sheets before layering.

- Hot Pressing: The layered veneers and glue are pressed together under high heat and pressure in a large press. This cures the adhesive and bonds the layers permanently. Imagine a giant, heated sandwich press!

- Cooling & Trimming: The pressed plywood sheets are cooled and then trimmed to the desired size.

- Finishing (Optional): Further treatments like sanding, painting, or laminating may be applied, depending on the intended use.

- Quality Control Inspection: Final inspection for defects before packaging and shipment.

Q 3. What are the key quality control checks performed during plywood production?

Rigorous quality control is vital in plywood manufacturing to ensure consistent quality and meet industry standards. Checks are performed at various stages:

- Veneer Quality: Inspection for knots, splits, and other defects before layering. Veneer thickness is also checked for consistency.

- Glue Application: Ensuring uniform glue spread and correct glue line thickness to prevent weak points.

- Hot Pressing: Monitoring temperature and pressure to ensure proper curing of the adhesive and prevent voids or delamination.

- Moisture Content: Measuring the moisture content of the finished plywood to prevent warping or shrinking.

- Dimensional Stability: Checking for warping, bowing, or cupping. This ensures the plywood is flat and stable.

- Strength Testing: Performing tests to measure the plywood’s strength and stiffness, verifying that it meets specifications.

- Visual Inspection: Final visual inspection for surface defects, imperfections, and any imperfections that may impact product usability.

Q 4. How do you identify defects in plywood?

Identifying defects in plywood requires a keen eye and understanding of potential issues. Common defects include:

- Knots: Concentrations of wood grain that can weaken the plywood. Large or loose knots are significant defects.

- Splits and Checks: Cracks or separations in the veneer, often caused by drying or handling. These reduce strength.

- Delamination: Separation of the veneer layers, indicating glue failure. This is a major structural defect.

- Warping: Curvature or bowing of the plywood sheet, often caused by uneven moisture content.

- Voids: Unfilled spaces within the plywood structure, reducing strength.

- Surface Defects: Scratches, dents, or imperfections in the veneer surface. These are primarily aesthetic concerns but can also affect functionality in some cases.

Detection involves visual inspection, often using a moisture meter and tapping to identify weak areas or delamination. A careful examination of the edges and surfaces is essential.

Q 5. What are the common types of wood veneer used in plywood?

The choice of wood veneer greatly impacts the plywood’s properties, appearance, and cost. Common veneer types include:

- Oak: A strong, durable hardwood with a beautiful grain, ideal for high-end furniture and cabinetry.

- Maple: A hard, dense hardwood known for its smooth, light-colored surface, often used in furniture and flooring.

- Birch: A strong, relatively inexpensive hardwood with a fine texture, widely used in general construction and furniture.

- Pine: A softwood species, offering affordability and ease of workability, typically used in construction applications.

- Poplar: A relatively soft hardwood known for its smooth surface and paintability, often used for painting or other finishing.

The choice of veneer depends heavily on the intended use and budget. Hardwood veneers typically cost more than softwood veneers.

Q 6. Explain the role of adhesive in plywood production.

The adhesive plays a crucial role in plywood production, bonding the veneer layers together to create a strong, stable panel. The adhesive must provide strong adhesion between the veneers, be resistant to moisture (especially in exterior applications), and maintain its integrity over time. A poor adhesive choice leads to delamination and compromises the structural integrity of the plywood.

The adhesive is responsible for distributing stresses uniformly across the layers, ensuring that the plywood behaves as a single, unified unit under load. The adhesive’s properties directly affect the plywood’s final strength, durability, and water resistance.

Q 7. What are the different types of adhesives used in plywood manufacturing?

Several types of adhesives are used in plywood manufacturing, chosen based on the intended application and desired properties:

- Phenolic Resins: Excellent water resistance and durability, suitable for exterior-grade plywood and marine applications. They are very strong and provide high heat resistance.

- Urea-Formaldehyde (UF) Resins: More cost-effective than phenolic resins, suitable for interior applications. They are less water-resistant than phenolic resins.

- Melamine-Urea-Formaldehyde (MUF) Resins: A combination of urea and melamine resins, offering improved water resistance compared to UF resins, suitable for interior or exterior use (depending on specific resin type).

- Polyvinyl Acetate (PVAc) Emulsions: Used in some lower-grade plywood applications, offering lower cost but also lower water resistance.

The selection of the adhesive is a critical decision as it determines the performance and longevity of the plywood product.

Q 8. How does the grain direction affect the strength of plywood?

The grain direction in plywood significantly impacts its strength. Plywood is made by layering thin sheets of wood veneer, and the strength depends heavily on how these veneers are oriented. Each veneer layer has a grain direction, and arranging these layers creates different properties.

Specifically, the strength is maximized when the grain direction of adjacent plies is perpendicular (cross-grained). This arrangement provides resistance to bending and shear forces in both directions. Imagine a brick wall: bricks laid horizontally and vertically are much stronger than a wall with only horizontally stacked bricks. Similarly, alternating grain direction in plywood significantly enhances its overall strength and dimensional stability.

Conversely, if all veneers run in the same direction (parallel-grained), the plywood becomes weaker, prone to splitting, and less stable. This arrangement is suitable only for applications where strength in a single direction is needed.

Q 9. What are the common grading standards for plywood?

Plywood grading standards vary slightly depending on the region and governing organization, but generally assess aspects like veneer quality, glue-line strength, and the presence of knots or defects. Common grading systems categorize plywood based on face and core veneer quality. For instance, a common system might use letters like A, B, C, and D to represent different grades. An ‘A’ grade typically represents a smooth surface with minimal imperfections, while a ‘D’ grade indicates a rough surface with more knots or defects.

The grading is often expressed as a combination, such as A-B, representing the quality of the front and back veneers, respectively. A higher grade typically indicates better appearance and strength. For structural applications, the core veneer quality is also crucial; higher-grade cores provide better strength and stability.

Furthermore, specific standards exist for marine plywood, emphasizing durability and resistance to moisture. This often involves using higher-grade veneers and specific waterproof adhesives. Consulting regional building codes or industry standards is essential for ensuring the correct grade for any application.

Q 10. How do you determine the moisture content of plywood?

Determining the moisture content of plywood is crucial for ensuring its quality and preventing issues such as warping or splitting. The most accurate method involves using a moisture meter. These meters employ either electrical resistance or pin-type sensors to measure the moisture level within the wood. A calibrated meter is essential for precise measurements.

The process usually involves inserting the sensor probes into several areas of the plywood sample, avoiding knots or damaged areas. The readings are then averaged to obtain a representative moisture content value, typically expressed as a percentage. This percentage reflects the amount of water present in the wood relative to its dry weight.

Knowing the moisture content is vital because wood expands and contracts with changes in moisture levels. Maintaining optimal moisture content during manufacturing and storage helps prevent later issues. If the plywood is too dry, it may become brittle; if it’s too wet, it might swell or warp.

Q 11. Describe the different types of plywood presses used in manufacturing.

Several types of presses are used in plywood manufacturing, each with advantages and disadvantages. The choice depends on production volume, desired quality, and cost considerations.

- Hot Plate Presses: These presses are relatively simple, consisting of heated plates that apply pressure to the veneer layers. They are suitable for smaller-scale operations but have limitations in terms of speed and efficiency.

- Cold Presses: These presses use hydraulic pressure without significant heat, making them suitable for specific veneer types that might be damaged by high temperatures. They are slower than hot presses.

- Roll Presses: These presses use continuously rotating rollers to apply pressure and often heat to the veneer sheets. They are highly efficient for high-volume production but require significant initial investment.

- Continuous Presses: These are highly automated systems that continuously feed and press veneer sheets. They are the most efficient but represent a major capital investment.

The selection of the press type is crucial for optimizing production and quality. For example, roll presses are ideal for mass production of standard plywood, while hot plate presses might suit smaller workshops creating specialized products.

Q 12. Explain the importance of maintaining consistent temperature and pressure during pressing.

Maintaining consistent temperature and pressure during the pressing process is paramount for producing high-quality plywood with uniform properties. Inconsistent conditions lead to uneven bonding, weak areas, and potentially internal stresses, which can result in warping or delamination later.

Temperature affects the curing process of the adhesive. Insufficient heat may result in incomplete curing, leading to weak bonds. Conversely, excessive heat may scorch the veneer or cause the adhesive to degrade. Consistent pressure ensures that all the veneers are compressed evenly, creating a tight bond throughout the panel. Insufficient pressure may result in voids or weak spots, while excessive pressure can crush the veneer.

Imagine baking a cake: a consistent oven temperature and baking time are crucial for a uniformly baked product. Similarly, consistent temperature and pressure in plywood pressing ensure the structural integrity and quality of the final product.

Q 13. What are the common problems encountered during plywood production and how do you address them?

Several problems can occur during plywood production. Common issues include:

- Glue-line problems: Uneven glue distribution, insufficient curing, or poor adhesive quality can cause weak or failed bonds.

- Veneer defects: Knots, splits, or other defects in the veneer can weaken the plywood or affect its appearance.

- Warping or bowing: Inconsistent moisture content, temperature fluctuations during pressing, or improper stacking can lead to warping.

- Delamination: Separation of the veneer layers, often due to weak glue lines or internal stresses.

Addressing these problems often involves a combination of preventative measures and corrective actions. Preventative measures include using high-quality materials, carefully controlling environmental conditions, and employing proper pressing techniques. Corrective actions may involve inspecting the product for defects, re-pressing flawed panels, or adjusting the production process.

Q 14. How do you troubleshoot a problem with a plywood press?

Troubleshooting a plywood press involves a systematic approach. First, identify the specific problem: is it a quality issue in the plywood (e.g., weak bonds, warping), or a mechanical issue with the press itself (e.g., uneven pressure, malfunctioning heating elements)?

For quality issues, check the following:

- Adhesive: Ensure correct adhesive type and application.

- Veneer: Inspect for defects and moisture content.

- Press settings: Verify temperature and pressure are consistent and appropriate.

For mechanical issues:

- Pressure gauges: Check for accurate readings and uniform pressure distribution across the platens.

- Heating elements: Inspect for proper function and temperature consistency.

- Hydraulic system: Check for leaks or malfunctions in the hydraulic system of the press.

- Maintenance logs: Review maintenance records to identify any potential issues.

Often, a combination of these checks and adjustments will resolve the problem. If not, seeking expert assistance is recommended.

Q 15. What are the safety precautions involved in working with plywood?

Working with plywood, while generally safe, requires awareness of potential hazards. The primary concerns revolve around sharp edges, splinters, and dust inhalation.

- Eye Protection: Always wear safety glasses or goggles to protect your eyes from flying debris during cutting and sanding. Imagine a tiny sliver of wood flying into your eye – safety glasses are your best friend!

- Respiratory Protection: Plywood cutting and sanding generates fine dust, which can irritate the lungs and, in some cases, lead to serious respiratory problems. Use a dust mask, preferably an N95 respirator, especially when working in enclosed spaces or for extended periods. Think of it as your invisible shield against harmful airborne particles.

- Hand Protection: Wear work gloves to protect your hands from splinters and cuts. This is especially crucial when handling rough-cut plywood or using sharp tools.

- Hearing Protection: Power tools like circular saws and routers can be incredibly loud. Use earplugs or earmuffs to prevent hearing damage from prolonged exposure to noise.

- Proper Tool Use: Always use the correct tools for the job and ensure they are sharp and well-maintained. A dull blade increases the risk of splintering and requires more force, increasing the chance of injury.

- Clean Workspace: Keep your work area clean and organized to prevent tripping hazards and reduce the risk of accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the proper handling and storage of plywood?

Proper handling and storage of plywood is essential to maintain its quality and prevent damage. Plywood is susceptible to moisture damage and warping, so careful attention is required.

- Flat Storage: Store plywood flat on a level surface to prevent warping. Avoid stacking it directly on the ground; use pallets or supports to allow for air circulation. Think of it like a stack of pancakes— you wouldn’t want them to get squished!

- Dry Storage: Keep plywood in a dry environment, ideally with a relative humidity of around 40-60%. Avoid storing it outdoors or in damp areas. Moisture is the plywood’s worst enemy.

- Protection from Elements: Protect plywood from direct sunlight and rain, as these can cause discoloration and deterioration. Covering it with a tarp can help.

- Proper Stacking: When stacking sheets, use separators between layers to prevent sticking and allow for air circulation. Think of it like giving each sheet its own little breathing room.

- Weight Considerations: Plywood sheets can be heavy. Use proper lifting techniques and, when necessary, ask for assistance to avoid back injuries.

- First-In, First-Out System: Implement a system where older plywood is used first to prevent it from deteriorating in storage.

Q 17. What are the environmental considerations related to plywood production?

The environmental impact of plywood production is a significant concern. The industry is increasingly focusing on sustainable practices to minimize its footprint.

- Deforestation: The primary environmental concern is deforestation due to the harvesting of timber. Sustainable forestry practices, including reforestation and responsible logging, are crucial to mitigating this impact. Using certified wood from sustainably managed forests is essential.

- Greenhouse Gas Emissions: The manufacturing process generates greenhouse gas emissions. Efforts are underway to reduce these emissions through improved energy efficiency and the use of renewable energy sources.

- Waste Management: Plywood production generates waste materials like sawdust and scraps. Recycling and responsible waste management are vital to minimize landfill waste and reduce environmental pollution. Many manufacturers are exploring innovative uses for wood waste.

- Water Usage: The production process uses water. Minimizing water consumption and utilizing water-efficient technologies are essential for sustainability.

- Chemical Use: Some plywood manufacturing processes involve the use of chemicals. Reducing the use of harmful chemicals and employing safer alternatives are vital to environmental protection.

Consumers can support sustainable plywood production by choosing products from certified sustainable sources and supporting manufacturers committed to environmentally responsible practices.

Q 18. Describe the different types of finishes applied to plywood.

A wide variety of finishes can be applied to plywood, enhancing its appearance, durability, and protecting it from the elements. The choice of finish depends on the application and desired aesthetic.

- Paints: Paints offer excellent protection and a wide range of colors and finishes (e.g., matte, gloss, satin). They are easy to apply but may require multiple coats for full coverage.

- Stains: Stains penetrate the wood, enhancing the natural grain pattern while providing some protection. They offer a more natural look compared to paints.

- Varnishes: Varnishes provide a clear protective layer, highlighting the wood’s natural beauty. They are durable and resistant to water and scratches.

- Lacquers: Lacquers dry quickly and offer a smooth, hard finish. They are suitable for both interior and exterior applications, depending on the formulation.

- Polyurethanes: Polyurethanes are durable and offer excellent protection against moisture and abrasion. They are available in various finishes and are a popular choice for furniture and flooring.

- Oil finishes: Oil finishes penetrate the wood, enhancing its natural color and providing some protection. They offer a more natural and less glossy finish than other options.

Proper surface preparation, including sanding and cleaning, is essential before applying any finish to ensure optimal adhesion and a smooth, even finish.

Q 19. What are the advantages and disadvantages of using plywood in construction?

Plywood offers several advantages, making it a popular choice in construction, but also has some limitations.

- Advantages:

- Cost-effective: Generally less expensive than solid wood.

- Strength and Stability: Offers good strength-to-weight ratio and dimensional stability.

- Versatile: Can be used in a wide variety of applications.

- Easy to Work With: Relatively easy to cut, shape, and finish.

- Large Sheet Sizes: Available in large sheets, reducing the need for numerous joints.

- Disadvantages:

- Susceptible to Moisture: Prone to warping and delamination if exposed to excessive moisture.

- Edge Quality: Edges can be prone to chipping and fraying.

- Formaldehyde Emissions: Some plywood contains formaldehyde, which can be a health concern. Look for low-formaldehyde or formaldehyde-free options.

- Not as Strong as Solid Wood: Not as strong as solid wood in certain applications, particularly when exposed to heavy loads.

Q 20. How do you select the appropriate type of plywood for a specific application?

Selecting the appropriate plywood depends on the specific application. Consider these factors:

- Intended Use: What will the plywood be used for? Exterior applications require exterior-grade plywood, while interior applications can use interior-grade plywood. High-stress applications may require thicker or higher-grade plywood.

- Grade: Plywood grades indicate the quality of the veneer faces. Higher grades have fewer knots and imperfections, suitable for visible surfaces. Lower grades are suitable for less visible areas, like sheathing.

- Species: Different wood species offer varying properties. Some species are more durable and resistant to moisture than others.

- Thickness: The thickness of the plywood depends on the intended use and load-bearing requirements.

- Core Construction: The type of core (e.g., solid core, veneer core) influences strength and stability. Solid cores are stronger and more resistant to warping than veneer cores.

- Formaldehyde Emissions: Consider the level of formaldehyde emissions, particularly for interior applications. Look for certifications indicating low formaldehyde content.

For instance, for building a bookshelf, a higher-grade plywood with a nice face veneer would be appropriate. For subflooring, a lower-grade, thicker plywood would be more suitable. Always consult with a professional if you’re unsure which type of plywood to choose for a particular project.

Q 21. What are the different methods for cutting and shaping plywood?

Plywood can be cut and shaped using various methods, depending on the desired precision and the size of the project.

- Circular Saw: Ideal for straight cuts and cutting larger sheets. A good circular saw will minimize chipping and provide clean cuts. Use a fine-toothed blade for better results. Consider a rip fence for accuracy.

- Jigsaw: Suitable for intricate curves and cutouts. Use blades appropriate for the thickness of the plywood. Working slowly and carefully will minimize tearout.

- Table Saw: A highly accurate option for straight cuts, particularly for ripping (cutting along the grain) or crosscutting (cutting against the grain). Use a fence for precise cuts and push blocks for safety.

- Router: Used for creating various profiles and edges, as well as decorative elements. Various bits are available for different shapes and sizes. Use jigs and templates for repeatable results.

- Hand Saw: Suitable for smaller cuts and less precise work. A fine-toothed hand saw is recommended to minimize tearout.

- CNC Router: For large-scale projects and highly accurate cuts, CNC routers are an efficient choice; they offer programmable cutting paths.

Always remember safety precautions when using power tools, such as wearing eye protection, hearing protection, and gloves. Practice makes perfect – take your time and ensure your tools are sharp and properly maintained for better results.

Q 22. Explain the importance of using proper tools and equipment when working with plywood.

Using the right tools and equipment when working with plywood is paramount for safety, efficiency, and achieving a high-quality finish. Improper tools can lead to damage, injury, and wasted materials.

- Cutting: A sharp circular saw with a fine-tooth blade is crucial for clean cuts. A dull blade will cause splintering and tear-out, especially on thinner plywood sheets. Using a track saw improves accuracy significantly for straight cuts.

- Drilling: Use drill bits specifically designed for wood, avoiding excessively aggressive speeds that can cause blowout on the exit side. A pilot hole before driving screws is also essential to prevent splitting.

- Sanding: Various grits of sandpaper, from coarse to fine, are necessary for achieving a smooth surface. Random orbital sanders are preferred for even sanding, reducing the risk of sanding marks.

- Fastening: Choosing the correct screws and appropriate countersinking bits prevents damage to the plywood and ensures a strong, neat joint. Using a countersink bit prevents the screw head from damaging the surface.

- Clamping: Adequate clamping is essential, especially when gluing plywood. Using the correct type of clamp (bar clamps, etc.) and applying the right pressure prevent glue squeeze-out and ensures strong bonding.

For example, when building cabinets, using a jigsaw with a dull blade will result in ragged edges requiring extensive sanding, increasing labor and reducing the final product’s quality. Using the proper tools makes the difference between a professional-looking finish and an amateur one.

Q 23. How do you estimate the amount of plywood needed for a project?

Estimating plywood accurately is crucial for minimizing waste and material costs. It requires careful planning and measurement. The process involves breaking down the project into its individual components and calculating the required plywood dimensions for each piece.

- Detailed Drawings: Start with detailed drawings or plans that clearly specify the dimensions of each plywood component.

- Component Dimensions: Carefully measure the dimensions of each plywood piece, accounting for any cuts, joints, or waste during fabrication. Add extra material to account for potential errors in cutting.

- Sheet Size Consideration: Remember the standard sheet sizes of plywood (e.g., 4′ x 8′). Layout the pieces on a sheet to minimize waste, using software or physically drawing on the sheet if you’re planning it out on paper.

- Waste Factor: Always include a waste factor to accommodate for cuts, mistakes, and imperfections in the plywood. A 10-15% waste factor is usually reasonable, depending on the project complexity.

- Verify Calculations: Double-check all calculations to avoid errors. One mistake can lead to needing another whole sheet.

For instance, if you’re building a simple shelf, you’d measure the shelf’s length and width, account for the thickness of the material and add some extra. Then, consider the type of cut you’ll be using (e.g., rip cut versus crosscut) and the standard plywood sheet dimensions to determine the best arrangement.

Q 24. What are the differences between hardwood and softwood plywood?

Hardwood and softwood plywood differ significantly in their properties, primarily due to the type of wood used in their construction. These differences impact their application and cost.

- Hardwood Plywood: Made from hardwood veneers like oak, maple, cherry, or birch. It offers superior strength, durability, stability, and a more refined, aesthetically pleasing finish. It’s often more expensive than softwood plywood.

- Softwood Plywood: Made from softwood veneers such as pine, fir, or spruce. Generally less expensive and readily available, softwood plywood is lighter and less strong than hardwood plywood. It is frequently used for applications where high strength or aesthetic appeal aren’t crucial.

For example, hardwood plywood is often chosen for high-end furniture and cabinetry due to its strength and beauty, whereas softwood plywood is frequently used for subflooring, sheathing, or less visible structural elements in construction projects.

Q 25. How do you interpret plywood specifications and drawings?

Plywood specifications and drawings are essential for selecting and using the correct plywood for a project. Understanding these documents helps prevent errors and ensures the project meets requirements.

- Grade: Plywood grades (e.g., A, B, C, D) indicate the quality of the veneer faces. Higher-grade veneers are smoother and more defect-free. The grade is typically indicated in the specification.

- Thickness: The thickness is usually specified in fractions of an inch (e.g., 1/4″, 3/4″). It is vital for structural applications.

- Species: The type of wood used (e.g., pine, oak) will affect strength, appearance, and cost. Drawings often will call for the wood species by name.

- Dimensions: Drawings will show the overall dimensions of the plywood sheets and the cut pieces needed for the project.

- Treatment: Some plywood is treated for moisture resistance (e.g., exterior-grade plywood) which is crucial to note for outdoor applications. This is commonly denoted in the specifications.

For example, a drawing might specify ‘3/4″ thick, A-grade, oak plywood’ for the cabinet doors, while indicating ‘1/2″ thick, C-grade, pine plywood’ for the cabinet back panel. These specifications help choose the right materials while managing costs.

Q 26. What is the difference between exterior and interior grade plywood?

The key difference between exterior and interior grade plywood lies in their glue and treatment. This impacts their resistance to moisture and their suitability for specific applications.

- Exterior-Grade Plywood: Uses waterproof or exterior-grade glue, making it resistant to moisture and rot. It’s suitable for outdoor projects such as decks, siding, and boat construction. This type will have a special designation such as ‘Exterior’ on the panel.

- Interior-Grade Plywood: Uses interior-grade glue, not as resistant to moisture. Using this outside can lead to warping, delamination, and rot. Suitable for interior applications such as walls, cabinetry, and shelving.

Using exterior-grade plywood for interior projects is fine and may offer additional durability, but using interior-grade for exterior projects leads to failure and requires replacement. The cost difference is usually minimal, so the best practice is to use the correct grade for the application.

Q 27. Describe your experience with different plywood manufacturing equipment.

My experience encompasses a variety of plywood manufacturing equipment, from raw material handling to the final product. This includes:

- Log Debarkers: These machines remove bark from logs before they’re processed into veneers.

- Veneer Lathes: These rotary lathes slice logs into thin sheets of veneer. Different types exist for varied log sizes and veneer thicknesses.

- Dryers: Veneers are dried to control moisture content, crucial for preventing warping. Kiln drying and various other drying systems are used.

- Lay-up Machines: These machines precisely arrange veneers into layers, cross-layering to maximize strength.

- Hot Presses: High pressure and temperature bond the layers of veneer with glue, creating the plywood sheets.

- Sanding Machines: Large-scale sanding machines ensure smooth surface finishes on the plywood sheets. These can range from belt sanders to automated systems.

- Cutting and Sizing Equipment: After pressing, the plywood sheets are cut to standard sizes or custom dimensions using saws and other cutting tools.

I’ve worked with both older, more manual machines and state-of-the-art automated systems, giving me a broad perspective on the manufacturing process and different approaches to efficiency and quality control. Each machine requires specific operational knowledge and maintenance.

Q 28. What are some industry best practices for efficient and safe plywood production?

Best practices in plywood production focus on safety, efficiency, and sustainability. These include:

- Safety Protocols: Strict adherence to safety regulations is essential, including proper use of personal protective equipment (PPE), machine guarding, and regular safety training for all personnel. This minimizes risks of injury from moving machinery and sharp tools.

- Optimized Lay-up: Efficient lay-up techniques minimize waste and maximize the use of veneer sheets. Software and optimized designs help with this.

- Process Monitoring: Closely monitoring the entire process ensures consistent quality and identifies potential issues early. Modern technology helps monitor glue application, drying, pressing, and more.

- Waste Management: Implementing effective waste management practices reduces environmental impact. This includes recycling wood scraps and using environmentally friendly glues and finishing materials.

- Quality Control: Rigorous quality control measures, including regular inspections and testing, guarantee that plywood meets required standards. This is crucial to ensure consistency.

- Preventive Maintenance: Regular maintenance and repair of equipment are essential for preventing breakdowns, improving efficiency, and ensuring safety.

For example, utilizing modern software to optimize veneer placement reduces waste by up to 20%. Implementing such processes reduces material costs and contributes to environmental sustainability.

Key Topics to Learn for Plying Interview

- Fundamentals of Plying: Understanding the core principles and definitions related to plying (assuming “plying” refers to a specific technical skill or industry. Replace with the actual definition if known). This includes theoretical underpinnings and common terminology.

- Practical Applications of Plying: Explore real-world examples and case studies demonstrating the application of plying techniques in various scenarios. Consider projects or problems solved using plying methods.

- Troubleshooting and Problem-Solving in Plying: Develop your ability to identify, diagnose, and resolve common issues related to plying. Practice explaining your problem-solving approach in a structured manner.

- Advanced Techniques in Plying: Research and familiarize yourself with more complex aspects of plying. This could involve specialized tools, techniques, or methodologies.

- Plying within the Broader Context: Understand how plying integrates with other related fields or technologies. Highlighting this interconnectedness demonstrates a holistic understanding.

- Ethical Considerations in Plying (if applicable): Explore any ethical implications or best practices related to the use of plying techniques.

Next Steps

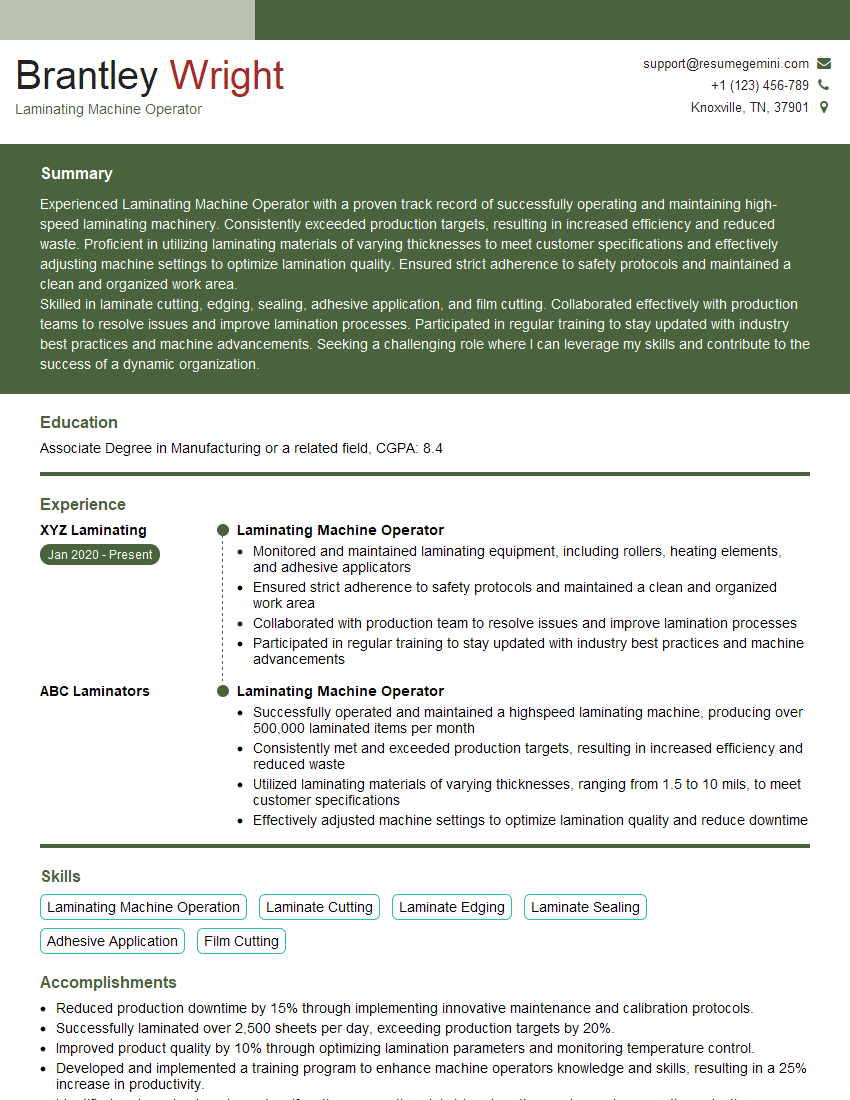

Mastering plying opens doors to exciting career opportunities and significant professional growth. To maximize your chances of landing your dream role, it’s crucial to present your skills and experience effectively. An ATS-friendly resume is your first impression – make it count! ResumeGemini is a trusted resource that can help you craft a professional and compelling resume tailored to highlight your plying expertise. Examples of resumes specifically tailored to plying roles are available to guide you. Invest the time in creating a strong resume; it’s an investment in your future success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?