Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Garage Door Opener Repair interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Garage Door Opener Repair Interview

Q 1. Explain the difference between chain drive, belt drive, and direct drive garage door openers.

The main difference between chain drive, belt drive, and direct drive garage door openers lies in how they transfer power from the motor to the garage door itself. Each type offers a unique balance of performance, noise level, and cost.

- Chain Drive: This is the most common and typically the most affordable type. A metal chain connects the motor to the door, pulling it open and closed. They are durable but can be quite noisy.

- Belt Drive: Belt drive openers use a reinforced rubber belt instead of a chain. This results in a quieter operation compared to chain drive openers. They’re generally smoother, but the belt can be more susceptible to wear and tear over time. Think of it like the difference between a bicycle chain and a bicycle belt.

- Direct Drive: This is the quietest and often considered the most sophisticated type. The motor is directly attached to the door’s trolley, eliminating the need for a chain or belt. This provides superior power and smooth, quiet operation. However, they usually come with a higher price tag.

For example, if noise is a major concern in your home, a belt drive or direct drive system would be preferable. If budget is your primary factor, a chain drive is a robust and reliable choice.

Q 2. Describe the safety features of a modern garage door opener.

Modern garage door openers are equipped with several safety features to prevent accidents and protect both people and property. These crucial features ensure safe operation.

- Safety Sensors/Reverse System: These infrared sensors are located near the bottom of the door’s tracks. If anything obstructs the path of the door—a pet, a child, or even a stray object—the sensors detect the obstruction, and the door immediately reverses to prevent injury or damage. This is a critical safety feature.

- Automatic Door Reversal: The door automatically reverses its operation upon encountering resistance. This is linked to the safety sensors but extends to any unexpected forces applied to the door during operation.

- Rolling Code Technology: This helps to prevent unauthorized access to your garage. Each time you use the remote, a unique code is transmitted, making it nearly impossible for someone to clone your signal.

- Emergency Release Cord: In case of a power outage or a malfunction in the opener’s mechanism, a manual release cord allows you to detach the door from the opener and open or close it manually.

Regular testing of these features ensures optimal safety and prevents accidents. The safety sensors should be tested monthly.

Q 3. How do you troubleshoot a garage door opener that won’t open or close?

Troubleshooting a garage door opener that won’t open or close involves a systematic approach. First, it’s essential to identify whether the problem stems from the power supply, opener mechanism, or the door itself.

- Check Power Supply: Ensure the garage door opener is plugged in and that the circuit breaker hasn’t tripped.

- Examine the Remote: Try the remote control from different distances and angles, and replace the batteries if necessary. If this works then there is a problem with the opener, not the remote.

- Inspect the Tracks: Check the tracks for any obstructions, misalignment, or damage. Debris can interfere with smooth operation. Minor adjustments might be necessary.

- Test Safety Sensors: Test the safety sensors using the procedure described below. If the opener doesn’t operate, cleaning the sensors and adjusting their alignment might solve the problem.

- Check the Limit Switches: These switches tell the opener when to stop moving. If they’re misaligned, the door may not fully open or close.

- Assess the Springs: If the springs are broken or stretched, they will likely prevent the door from opening or closing. Repairing or replacing them should only be done by a professional.

- Listen for Unusual Noises: Grinding, screeching, or other unusual sounds could indicate mechanical problems requiring professional attention.

Remember, working with garage door springs is dangerous. If you’re not experienced, it’s best to call a professional for any repairs involving the springs or major mechanical components.

Q 4. What are the common causes of a garage door opener malfunction?

Several common issues can lead to garage door opener malfunctions. Understanding these causes can help in preventative maintenance and quicker troubleshooting.

- Worn-out Parts: Over time, parts like the chain, belt, sprockets, rollers, and tracks can wear down, leading to malfunctions. Regular lubrication and inspection can extend their lifespan.

- Broken Springs: Garage door springs are under tremendous tension. A broken spring can prevent the door from opening or closing, and attempting to repair it yourself is dangerous.

- Faulty Remote Control: Low or dead batteries, signal interference, or a broken remote can prevent the opener from responding.

- Safety Sensor Issues: Obstructions, misalignment, or damage to the safety sensors can prevent the door from operating correctly.

- Power Issues: A tripped circuit breaker, faulty wiring, or a power outage can also stop the opener from functioning.

- Motor Problems: Motor burnout or malfunction is usually indicated by unusual noises or a complete lack of operation.

Regular maintenance, such as lubricating moving parts and inspecting the system for wear, can significantly reduce the frequency of these malfunctions.

Q 5. How do you diagnose a problem with a garage door opener’s remote control?

Diagnosing problems with a garage door opener’s remote control involves a systematic process of elimination.

- Check the Batteries: Replace the batteries in the remote with fresh ones. This is the most common cause of remote issues.

- Test the Range: Try operating the remote from different distances and angles. Signal strength can be affected by interference.

- Check for Obstructions: Ensure there are no significant obstacles between the remote and the receiver. Metal objects or thick walls can interfere with the signal.

- Try a Different Remote: If you have multiple remotes, try using a different one. This helps to determine if the problem lies with the remote itself or the opener’s receiver.

- Check the Receiver: In some cases, the receiver might be malfunctioning. A technician can test the receiver and replace it if necessary.

- Try Re-programming the Remote: If possible, refer to the owner’s manual to reprogram the remote to the receiver.

Sometimes, electronic interference from other devices can affect the remote’s performance. If all else fails, consulting a professional is recommended.

Q 6. Explain the process of replacing a broken garage door opener spring.

Replacing a broken garage door spring is extremely dangerous and should only be attempted by experienced professionals. These springs are under immense tension, and incorrect handling can result in serious injury or death.

Never attempt this repair yourself. The process involves precise measurements, specialized tools, and a deep understanding of spring mechanics and safety procedures. A qualified garage door technician has the knowledge and equipment to safely replace the springs, ensuring proper tension and preventing accidents.

Calling a professional for this repair is the safest and most reliable approach.

Q 7. How do you test the safety sensors on a garage door opener?

Testing the safety sensors on your garage door opener is a simple yet crucial safety check that should be performed regularly (at least monthly).

- Locate the Sensors: These sensors are usually located on either side of the garage door’s opening, near the bottom of the tracks.

- Observe the Lights: When the door is closed, the sensors should have a small light indicating that they are working. If the lights aren’t on, check for obstructions or misalignment.

- Test the Sensors: Slowly close the garage door. As the door approaches the sensors, it should automatically reverse when the light beam is interrupted. Use a small object (like a pencil) to interrupt the beam. If the door doesn’t reverse, it indicates a problem with the sensors.

- Check for Alignment: If the sensors don’t work properly, adjust their alignment to ensure the infrared beams are correctly aligned.

- Clean the Sensors: Dust or debris can interfere with the sensors’ operation. Use a soft cloth to gently clean the sensor lenses.

Regular testing of these sensors is vital to ensure the door’s safety mechanism remains functional, thereby protecting people and pets.

Q 8. Describe the steps involved in installing a new garage door opener.

Installing a new garage door opener involves several crucial steps. Think of it like building with LEGOs – each piece needs to be carefully connected for the whole thing to work smoothly.

- Preparation: First, disconnect the old opener from the power supply and the garage door itself. Safety first!

- Mounting the Opener: Next, securely mount the new opener to the ceiling or wall, following the manufacturer’s instructions. The height and position are vital for optimal operation.

- Attaching the Trolley: Carefully connect the trolley (the moving part that attaches to the garage door) to the opener’s motor using the provided chain or belt.

- Connecting the Door: This is where precision is key. Attach the trolley to the garage door’s lifting mechanism, ensuring it’s aligned correctly. A misalignment can lead to uneven lifting and potential damage.

- Wiring: Carefully connect the power and any safety sensors. Double-check your wiring against the diagram provided. Incorrect wiring can cause malfunctions or even hazards.

- Programming Remote Controls: Learn to program your remotes to communicate correctly with the new opener. This usually involves pressing and holding specific button combinations, often outlined in the manual.

- Testing: Finally, thoroughly test the opener to ensure it opens and closes the door smoothly, stops at the right points, and that all safety features are functioning. If you encounter problems, check your wiring and connections first.

For example, I once installed an opener in a garage with unusually high ceilings. We needed to use extra-long chains to accommodate the height, and extra care was taken to ensure perfect alignment to avoid strain on the motor.

Q 9. How do you adjust the travel limits on a garage door opener?

Adjusting travel limits is like fine-tuning a musical instrument – you need to get the ‘pitch’ just right. These limits tell the opener where to stop when opening and closing. Incorrect limits can lead to the door hitting the ground or ceiling, causing damage.

Most openers have limit switches which are adjusted using small screws. To adjust the upper limit, open the door completely and use the appropriate screw to tell the opener the ‘top’ position. For the lower limit, close the door and adjust the lower limit screw.

The process usually involves operating the opener’s control and making small adjustments until the door stops at precisely the desired positions. Always test after each adjustment and consult your owner’s manual for detailed instructions specific to your opener model. The process varies slightly depending on the brand and model of the opener. Some have a learn function or use dip switches, which are detailed in your owner’s manual.

Imagine trying to adjust the travel limits without proper guidance – you could risk damaging the door or opener.

Q 10. What are the different types of garage door opener motors?

Garage door opener motors come in a few varieties, each with its own pros and cons. They’re like different car engines – some are better suited to specific tasks or environments.

- Chain Drive: These are the most common and are generally known for their durability and affordability. The chain provides mechanical linkage to the trolley. They can be a bit noisy.

- Belt Drive: Quieter than chain drives, belt-driven openers use a reinforced rubber belt to move the trolley. They offer a quieter operation but can be slightly more expensive.

- Screw Drive: These openers are incredibly strong and usually very quiet. They use a threaded rod for lifting. However, they are often more expensive than chain or belt drive options.

- Direct Drive: These newer openers are extremely quiet and smooth operating. A motor directly connects to the door carriage rather than a separate drive system.

Choosing the right motor depends on factors like budget, noise tolerance, and the weight of your door.

Q 11. How do you identify and fix a problem with a garage door opener’s circuit board?

Troubleshooting a circuit board can feel like detective work, but with a systematic approach, it’s manageable. It’s crucial to remember that working with electrical components requires caution.

- Safety First: Always disconnect the power supply before attempting any repairs.

- Visual Inspection: Carefully examine the circuit board for any obvious signs of damage, such as burn marks, loose connections, or broken components. Sometimes you’ll see a clear sign of the problem.

- Check Components: Using a multimeter, test the various components on the board, like capacitors and transistors, to check their values. If you lack experience, it’s best to call a professional.

- Consult Schematics: Many circuit boards have schematics (diagrams) printed on them. This will help you trace connections and identify the faulty components.

- Replacement: If a component is faulty, replacement is usually the best option. Attempting repairs on the board yourself can be complex and might make things worse. It’s often more cost-effective to replace the entire circuit board.

For example, I once found a capacitor that had puffed up like a small balloon. This is a clear sign of failure, requiring replacement of the part or entire board.

Q 12. What are the common safety precautions you take when working with garage door openers?

Safety is paramount when working with garage door openers. Think of it like working on a car – you don’t want any surprises.

- Disconnect Power: Always disconnect the power supply to the opener before performing any maintenance or repairs.

- Use Proper Tools: Use the right tools for the job, and ensure they are in good working order.

- Wear Protective Gear: Consider wearing safety glasses and gloves to protect yourself from injuries.

- Secure the Door: Use a manual release mechanism to detach the door from the opener, ensuring the door cannot fall unexpectedly. This is especially crucial when working on the motor or trolley.

- Follow Instructions: Always refer to the manufacturer’s instructions and safety guidelines for your specific opener model.

Never attempt repairs if you are unsure how to proceed safely. Calling a professional is always a better choice than risking injury.

Q 13. How do you deal with a customer who is frustrated with a garage door opener problem?

Dealing with frustrated customers requires empathy and professionalism. Think of it like conflict resolution – you need to understand their perspective and find a solution.

- Listen Empathetically: Let the customer fully explain their problem without interruption. Show that you understand their frustration.

- Ask Clarifying Questions: Ask questions to gather more details about the issue to ensure accurate diagnosis.

- Explain the Process: Explain clearly what steps you’ll take to troubleshoot and resolve the problem.

- Keep Them Informed: Keep the customer updated throughout the process. This helps build trust and reduce anxiety.

- Offer Solutions: Provide solutions that address the customer’s needs and concerns. Even if you can’t immediately fix the problem, offering a timeline and alternative solutions can alleviate frustration.

For example, I once had a customer who was extremely upset because their garage door was stuck. I listened patiently, reassured them that I would fix the problem, and then explained step-by-step what I was doing. This helped diffuse their frustration and restore their trust.

Q 14. Explain the importance of regularly maintaining a garage door opener.

Regular maintenance is crucial for the longevity and safe operation of your garage door opener. Think of it like servicing your car – preventative maintenance keeps it running smoothly and prevents costly repairs down the line.

- Lubrication: Lubricate the moving parts, like the chain or belt, and the rollers on the tracks. This reduces friction and extends the life of these components.

- Inspection: Regularly inspect the opener for any signs of wear and tear, such as loose screws, damaged cables, or rust.

- Safety Sensor Check: Test the safety sensors to ensure they’re properly aligned and working correctly. This prevents accidental injury.

- Tighten Connections: Check for any loose screws or bolts and tighten them as needed. This ensures everything is securely fastened.

- Cleanliness: Regularly clear away any dust, debris, or cobwebs from the tracks and moving parts. This helps prevent jams and malfunctions.

By performing regular maintenance, you can prevent costly repairs and ensure that your garage door opener operates safely and efficiently for many years to come. A small amount of preventative maintenance goes a long way.

Q 15. Describe your experience with different brands of garage door openers.

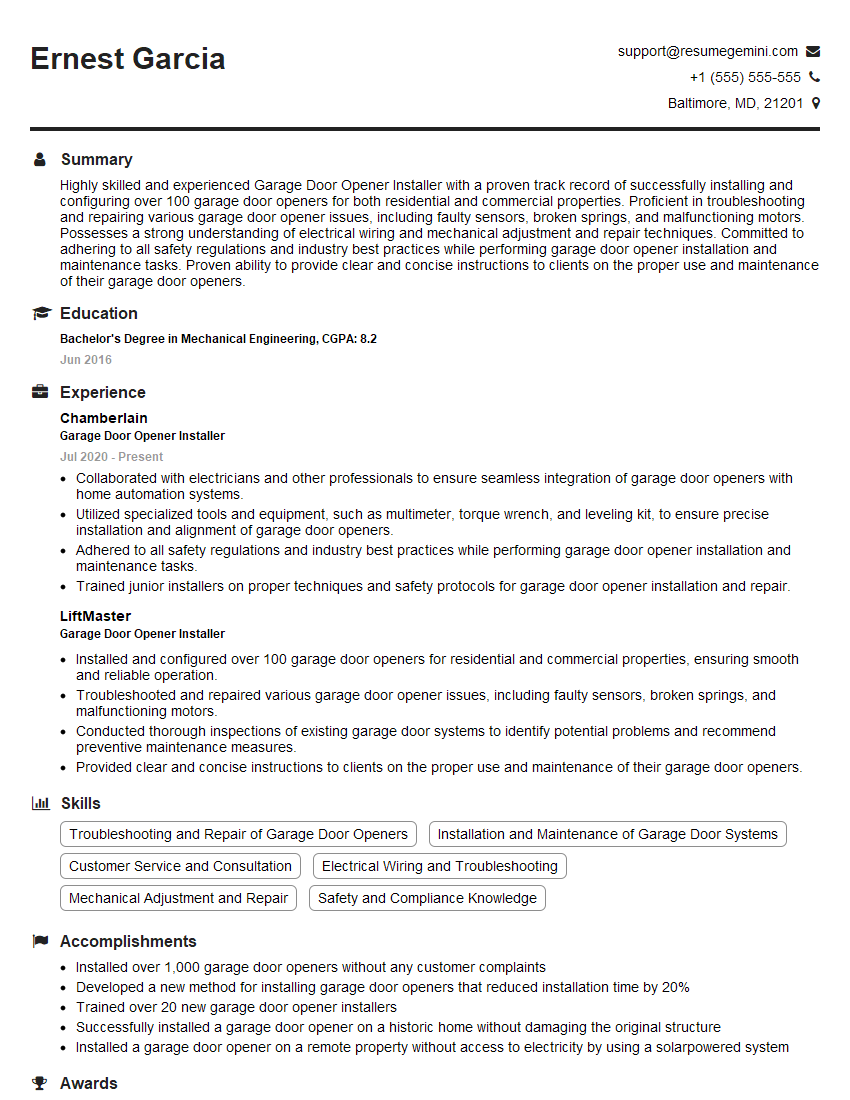

Over the years, I’ve worked extensively with a wide range of garage door opener brands, including LiftMaster, Chamberlain, Craftsman, Genie, and more. Each brand has its own design nuances, strengths, and weaknesses. For instance, LiftMaster is known for its robust belt-drive systems, while Genie often utilizes chain-drive systems. Craftsman, often sold through Sears, usually offers a good balance of features and price. Understanding these differences is crucial because troubleshooting and repair methods can vary slightly. A common problem I’ve encountered is the use of incorrect replacement parts; a part from one brand might not be fully compatible with another, even if it seems similar. So, accurate identification of the brand and model is paramount to efficient repairs.

For example, I recently worked on a Genie opener where the logic board failed. While the symptoms were similar to a LiftMaster opener failure (the door wouldn’t close), the replacement board and its installation process were different. My experience allows me to quickly identify these brand-specific differences and effectively resolve the issue.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle emergency calls related to garage door openers?

Emergency calls demand immediate attention and a methodical approach. My priority is to ensure safety and quickly get the garage door operational. I start by gathering information: the nature of the problem, the brand and model of the opener, and any recent incidents. Then, I prioritize based on urgency – a completely inoperable door that’s trapping a car inside is a higher priority than a slow-opening door. Upon arrival, I perform a quick visual inspection, focusing on obvious problems like broken springs (which I *never* directly handle in an emergency, as they are incredibly dangerous), power outages, or jammed tracks. Once the immediate safety issues are addressed, I begin the diagnosis and repair. I always inform the customer of potential costs before beginning any major repairs.

I remember one night I received a call about a broken opener leaving a family stranded with a car in the garage. I arrived within an hour, identified a broken chain, and used a temporary fix to get the door working safely until a proper replacement could be installed the next day. The relief on their faces was incredibly rewarding.

Q 17. What tools and equipment do you commonly use in garage door opener repair?

My toolkit is comprehensive and constantly evolving with technological advancements. Essential tools include a voltage tester (critical for safety!), various screwdrivers (Phillips and flathead, in various sizes), pliers (needle-nose and lineman’s), wrenches, sockets, a multimeter for diagnosing electrical problems, a ladder for safe access, and lubrication sprays (like WD-40 or a garage door specific lubricant). For more complex issues, I also use specialized tools like logic board testers, remote control programmers, and even diagnostic software specific to certain brands of openers. Safety equipment like gloves and safety glasses are always part of my kit.

Beyond the tools, access to parts is crucial. I maintain a stock of commonly needed parts like limit switches, safety sensors, belts, chains, and remote controls. Having these on hand ensures quicker repair times.

Q 18. How do you diagnose and repair a garage door opener that makes unusual noises?

Unusual noises from a garage door opener are often indicative of a problem. The first step is to pinpoint the source of the noise—is it coming from the motor, the chain/belt, the trolley, or the door itself? Common culprits include worn-out chain/belt components (they may squeak or click), a failing motor (grinding or humming), loose components (rattling or banging), or obstructed tracks (scraping or grinding).

Troubleshooting steps:

- Visual Inspection: Carefully examine the entire opener system for loose screws, damaged tracks, or obstructions.

- Lubrication: Apply appropriate lubricant to moving parts like the chain/belt and hinges.

- Motor Test: Listen carefully to the motor when the door operates. Unusual sounds like grinding or excessive humming might point to a failing motor.

- Limit Switch Check: Inspect and adjust the limit switches, which control the door’s opening and closing limits. Incorrect settings can cause the motor to strain.

- Sensor Check: Check the safety sensors at the bottom of the door for alignment and obstructions. These sensors prevent the door from closing on objects.

Q 19. Describe your experience working with different types of garage door materials (wood, steel, aluminum).

My experience encompasses working with garage doors constructed from various materials, each presenting unique challenges. Steel doors are common and relatively robust, although they can dent and rust. Wooden doors offer a more aesthetic appeal, but are susceptible to warping, rot, and damage from weather. Aluminum doors are lightweight and corrosion-resistant but can be less durable. The material of the door itself doesn’t directly impact the opener repair, but it influences the overall garage door system’s performance and longevity. For example, a heavier wooden door will put more strain on the opener motor compared to a lighter aluminum door. This is important to consider when recommending maintenance or upgrades to a customer.

One instance involved a customer with a warped wooden door, leading to binding and excessive strain on the opener. While I repaired the opener, I also advised the homeowner about the door’s condition and the need for eventual door maintenance or replacement to prevent further damage to their system.

Q 20. How do you explain complex technical issues to non-technical customers?

Explaining complex technical issues to non-technical customers requires clear, concise communication and relatable analogies. I avoid using technical jargon whenever possible. Instead, I use simple terms and analogies to illustrate the problem. For example, instead of saying “the capacitor is failing,” I might explain, “Imagine the capacitor is like a battery for the motor; it’s getting weak, so the motor isn’t getting enough power to work correctly.”

I also use visual aids when possible – showing the customer the damaged part, or using diagrams to explain the system’s workings. It’s crucial to listen carefully to the customer’s concerns and address their questions patiently. A satisfied customer is one who understands the problem, the solution, and feels they have been treated with respect and clarity.

Q 21. What is your experience with troubleshooting power supply issues in garage door openers?

Troubleshooting power supply issues is a common part of garage door opener repair. These can range from simple problems like blown fuses or tripped circuit breakers to more complex issues involving wiring faults or problems with the opener’s power supply itself. I start with a visual inspection of the power cord, circuit breaker, and wiring connections to the opener. I use a voltage tester to check for power at the opener’s connection point. If there’s no power, I trace the circuit back to the breaker box, ensuring the breaker is not tripped and the wiring is intact.

If power is present but the opener doesn’t work, I use a multimeter to test the voltage at various points within the opener itself, helping pinpoint the location of the fault. This might involve checking the power supply board, motor, or other electrical components. In some cases, the issue might be a faulty wall switch that needs replacement.

A memorable case involved a customer who believed their opener was faulty. After a thorough check, I discovered the problem was a loose neutral wire at the breaker panel – a simple fix that restored power to their opener.

Q 22. How do you determine the cause of a garage door opener that opens/closes too slowly?

A garage door opener that’s sluggish could be due to several factors. Think of it like a car – if it’s slow to accelerate, there’s something hindering its power. The most common culprits are worn-out or damaged components.

Motor issues: A failing motor struggles to provide sufficient power, leading to slow operation. This often manifests as a noticeable slowdown, especially when the door is heavily loaded (e.g., with items stored in the attic).

Track problems: Bent or misaligned tracks create friction, reducing the opener’s efficiency. Imagine a car trying to drive on a bumpy road – it’ll take more effort and go slower. This can be easily diagnosed by visually inspecting the tracks for bends or obstructions.

Roller problems: Worn or seized rollers introduce friction similar to the track issues. This problem might be accompanied by squeaking noises. Replacing them is a straightforward repair.

Lubrication: Lack of proper lubrication in the moving parts contributes significantly to slow operation. Just like regular oil changes for a car, periodic lubrication keeps things moving smoothly.

Spring tension: Incorrect spring tension can also affect the speed, although this is often accompanied by other symptoms. Over-tensioned springs can lead to dangerous situations, so this should only be assessed by a professional.

Diagnosing the problem involves a methodical approach: I’d start by visually inspecting the tracks and rollers for damage, then check the motor’s power supply and finally assess the lubrication. If the issue persists, I’d use a multimeter to check the motor’s power draw and look for further mechanical issues.

Q 23. What are the different types of lubricants used for garage door opener maintenance?

The right lubricant is crucial for extending the lifespan of your garage door opener. Using the wrong type can actually cause damage! I typically use a few different types depending on the component:

Silicone-based spray lubricant: This is ideal for moving parts like rollers, hinges, and tracks. It provides excellent lubrication without attracting dust or dirt. It’s important to use a silicone-based spray, as others can attract and trap dirt that might cause damage.

White lithium grease: This is thicker and better suited for parts that experience heavier loads or need more durable lubrication, such as gear mechanisms. It provides a long-lasting protective layer.

Dry Teflon lubricant: This is a specialized lubricant that’s excellent for places where you want minimal oil residue, like the motor and electrical components. It’s best applied sparingly.

Important note: Never use WD-40. While it may provide temporary lubrication, it evaporates quickly and can actually attract dirt, leading to increased friction and wear.

Q 24. What is your experience with repairing or replacing broken gears or sprockets in a garage door opener?

Repairing or replacing broken gears or sprockets is a common task. It requires precision and the right tools. I’ve handled numerous cases where the gears were stripped or broken due to age, wear, or accidental damage (like something getting caught in the mechanism).

The process generally involves disassembling the opener to access the gears, carefully removing the broken components, and installing the new parts. This is a relatively straightforward job for an experienced technician, but it necessitates careful attention to detail and the correct alignment of components. Sometimes, it is cost-effective to replace the entire gear assembly for convenience. Incorrect replacement can lead to the motor burning out or other major mechanical failure. In those cases, a replacement is often more affordable than a repair.

Q 25. How do you determine the correct type and size of replacement parts for a specific garage door opener model?

Identifying the correct replacement parts is critical. I always start by identifying the make and model of the garage door opener. This information is usually found on a sticker affixed to the opener itself or in the owner’s manual.

Once I know the model, I use this information to search for parts online or through my supplier’s catalog. Many manufacturers have detailed diagrams and part lists available on their websites. This ensures that the replacement parts are precisely compatible with the specific opener model. When ordering, I always double-check the part numbers to avoid ordering the wrong item.

Q 26. Describe your experience with different types of garage door opener limit switches.

Limit switches are essential for safety and proper operation. They tell the opener when to stop the door’s movement. I’ve worked with various types:

Mechanical limit switches: These are older models and use mechanical adjustments to set the open and close limits. They’re reliable but require precise adjustments.

Electronic limit switches: These are more modern and use electronic sensors to detect the door’s position. These are usually more accurate and easier to adjust.

Optical limit switches: These utilize infrared sensors to precisely monitor the position of the door. They are very accurate and often found on high-end openers.

Troubleshooting often involves checking the switch’s wiring, ensuring they’re clean and making sure the switch itself isn’t faulty. Proper adjustment is critical – improperly adjusted limit switches can lead to the door not closing completely or opening too far, which could be a safety hazard.

Q 27. How do you ensure the safety of both yourself and the customer during a repair?

Safety is my top priority. I always start by disconnecting the power to the garage door opener before beginning any repair. This is crucial to prevent accidental operation and potential injury.

I also inspect the area for potential hazards, such as loose objects near the door that could be caught in the moving mechanism. I wear appropriate safety gear, including gloves and eye protection. During the repair itself, I proceed carefully and methodically, avoiding any sudden or jerky movements that could lead to accidents. I explain each step of the process to the customer to keep them informed, and if anything unexpected occurs, I immediately stop the work and reassess the situation.

Q 28. Explain your experience with troubleshooting and repairing roller and track issues related to garage door openers.

Roller and track issues are extremely common. Problems range from simple misalignment to severe damage. I systematically troubleshoot these problems by:

Visual inspection: I thoroughly examine the tracks for bends, obstructions, or rust. I also check the rollers for wear, damage, or misalignment.

Track alignment: If the tracks are bent, I’ll often be able to straighten minor bends using specialized tools. Severe bends may require track replacement.

Roller replacement: Worn or damaged rollers are replaced – it’s a relatively straightforward repair that significantly improves the door’s operation and reduces noise.

Lubrication: I lubricate the tracks and rollers to reduce friction and ensure smooth operation. Again, the correct type of lubricant is essential to avoid attracting dust and debris.

Tension adjustments: Depending on the issue, the door spring tension might require adjustment, but this should only be handled by someone experienced, due to the potential danger of improperly tensioned springs.

In some cases, the tracks are so severely damaged that they need complete replacement. This usually involves removing the old tracks, installing the new ones, and realigning the rollers.

Key Topics to Learn for Your Garage Door Opener Repair Interview

- Understanding Opener Mechanisms: Learn the inner workings of various opener types (belt drive, chain drive, screw drive), including their components and how they interact.

- Troubleshooting Common Issues: Gain practical experience diagnosing problems like opener malfunctions, remote control issues, safety sensor problems, and limit switch adjustments. Practice explaining your diagnostic process clearly.

- Safety Procedures and Practices: Demonstrate a strong understanding of safety protocols when working with garage door openers, including proper handling of electrical components and ensuring safe operation.

- Repair and Maintenance Techniques: Develop proficiency in replacing worn parts, lubricating moving components, and performing routine maintenance to extend opener lifespan. Be ready to discuss specific repair procedures.

- Working with Different Brands and Models: Familiarize yourself with popular brands and models, understanding their unique features and potential troubleshooting needs. Highlight your adaptability to various systems.

- Electrical Troubleshooting: Develop a strong understanding of basic electrical principles relevant to garage door openers, including wiring diagrams, voltage checks, and identifying faulty components.

- Customer Service and Communication: Practice explaining technical concepts clearly and concisely to non-technical audiences. Emphasize your ability to build rapport and provide excellent customer service.

- Code Reading and Programming (if applicable): If the role involves advanced troubleshooting or installation, be prepared to discuss your experience with reading and potentially modifying code within the opener’s control system.

Next Steps

Mastering garage door opener repair opens doors to a rewarding career with excellent earning potential and opportunities for advancement. To maximize your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the Garage Door Opener Repair field to guide you in creating a winning application. Invest the time to create a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?