Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Cracking a skill-specific interview, like one for Loom Fixing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Loom Fixing Interview

Q 1. Describe your experience with different types of looms (e.g., rapier, projectile, air-jet).

My experience spans across various loom types, each with its unique characteristics and challenges. I’ve extensively worked with rapier looms, known for their versatility in handling different fabric structures and yarn counts. Troubleshooting these often involves understanding the intricate interplay between the rapier’s movement, the reed, and the heddles. I’ve also gained considerable experience with projectile looms, appreciating their high speed and efficiency, particularly for simpler weaves. However, maintaining the precise projectile mechanism requires meticulous attention to detail and regular preventative maintenance to avoid costly downtime. Finally, my work with air-jet looms has provided insights into their high productivity and suitability for lightweight fabrics. The air pressure control and nozzle adjustments are critical in this system, requiring a keen understanding of airflow dynamics to achieve optimal weft insertion.

- Rapier Looms: I once resolved a recurring weft misinsertion problem on a rapier loom by identifying a slightly worn rapier gripper. Replacing the part swiftly restored efficiency.

- Projectile Looms: In another instance, I diagnosed a consistent weft breakage on a projectile loom caused by improper yarn tension settings. Fine-tuning the settings resolved the issue.

- Air-Jet Looms: On an air-jet loom, I addressed a weaving fault by adjusting the air pressure and nozzle orientation to optimize weft insertion into a particularly dense fabric.

Q 2. Explain the process of troubleshooting a loom shedding problem.

Troubleshooting a loom shedding problem involves a systematic approach. First, I visually inspect the shedding mechanism, focusing on the heddles, harness frames, and cam motion. A common cause is a broken or misaligned heddle, which can be identified by careful observation of the shed formation. Sometimes, the problem stems from incorrect cam timing or worn cam followers, leading to inconsistent shedding. I use a combination of visual inspection and trial-and-error adjustments to the cam mechanism, checking the shed formation after each small adjustment. I also verify the correct positioning and function of the shedding mechanism’s components, ensuring smooth and precise movement. If the issue persists after these checks, I examine the connection points between the camshaft and the shedding components for any signs of looseness or damage.

Imagine it like a finely tuned orchestra – each instrument (loom component) plays its part for the perfect harmony (weave). A single instrument out of tune (malfunctioning part) throws the whole piece off.

Q 3. How do you identify and fix weft yarn breakage issues?

Weft yarn breakage is a frequent issue, usually stemming from several sources. I begin by examining the yarn itself for defects like thin places, knots, or excessive fuzziness. Next, I check the yarn tension, ensuring it’s within the optimal range for the specific loom and yarn type. Incorrect tension can cause undue stress on the yarn, leading to breakage. I also inspect the weft insertion mechanism, paying close attention to the grippers (in rapier looms), the projectile (in projectile looms), or the air jets (in air-jet looms) for wear or misalignment. These mechanisms must smoothly and gently handle the yarn to avoid breakage. Finally, I scrutinize the reed for any damage that could be snagging or abrading the weft yarn. A systematic approach, starting from the yarn itself and moving progressively to the insertion mechanism, generally leads to a rapid identification of the root cause.

For example, I once solved a persistent weft breakage issue by simply replacing a worn-out reed. The new reed eliminated the snagging point, and the breakage ceased immediately.

Q 4. What are the common causes of warp yarn breakage, and how do you address them?

Warp yarn breakage is often caused by several factors. Excessive tension is a common culprit; either from incorrect settings on the warp beam or friction from misaligned guides. Defects within the yarn itself – like weak spots or inconsistencies in the spinning process – also contribute to breakage. Another frequent cause is damage inflicted by the reed, particularly if the reed dents are damaged or misaligned. Sharp edges or debris in the loom can also cause damage. Finally, improper sizing of the warp yarn can lead to increased breakage. I address these issues by carefully adjusting warp tension, visually inspecting the warp yarn for defects, checking the reed for damage, and ensuring the loom’s overall cleanliness to eliminate potential snagging points. Regular preventative maintenance and careful inspection during setup reduce the occurrence of warp yarn breaks significantly.

Think of the warp yarns as the building’s vertical supports; any weakness compromises the entire structure.

Q 5. Describe your experience with loom timing and adjustments.

Loom timing is critical for successful weaving, affecting the synchronization of all the moving parts. My experience includes meticulous adjustments to timing mechanisms, ensuring precise coordination between the shedding, picking, and beating-up motions. I utilize the loom’s timing marks and diagrams as reference points, and I frequently employ trial-and-error methods, making small adjustments and assessing the impact on the weave. This involves a deep understanding of the loom’s mechanics and the relationship between different components. Incorrect timing can lead to a range of weaving faults like mispicks, mis-sheds, or broken yarns. I also have experience working with electronic and computerized loom controls, providing precise adjustments and diagnostics based on sensor data.

Precise timing is like a perfectly choreographed dance; every step (component) must be in perfect synchronicity for the whole performance (weave) to be successful.

Q 6. How do you maintain loom lubrication systems?

Maintaining loom lubrication systems is crucial for preventing wear and tear and ensuring smooth operation. This involves regularly inspecting oil levels, checking for leaks, and replacing or refilling lubricant as needed. I use the manufacturer’s recommendations for the type and amount of lubricant to be used for each part of the loom, paying particular attention to critical moving parts like bearings, cams, and gears. I also clean the lubrication points regularly to remove any dirt or debris that could clog or contaminate the lubricant. Using the correct lubricant and proper lubrication techniques are essential to prevent premature wear and maximize the loom’s lifespan. A well-lubricated loom runs smoothly, quietly, and efficiently.

Regular lubrication is like regular car maintenance; preventive measures save considerable trouble in the long run.

Q 7. Explain your process for inspecting and maintaining loom parts.

My inspection and maintenance process for loom parts is thorough and systematic. I start with a visual inspection of all components, checking for signs of wear, damage, or misalignment. This includes inspecting the heddles, reed, harnesses, and other moving parts. I also check the condition of the warp and weft yarn, looking for defects that could cause weaving problems. I use appropriate tools to measure critical dimensions and clearances, ensuring components are functioning within specifications. For instance, I measure the distance between the reed and the heddles to check for proper shedding. If I find any defects or worn parts, I replace or repair them immediately. This preventative approach avoids more extensive damage and keeps the loom running efficiently. Regular maintenance logs meticulously record all inspections, repairs, and replacements, ensuring accurate tracking of the loom’s condition.

Regular inspections act as a preventative measure, similar to regular medical checkups which help detect health issues early.

Q 8. How familiar are you with different types of loom sensors and their functions?

Loom sensors are crucial for monitoring and controlling the weaving process. My experience encompasses various types, including:

- Broken-end sensors: These detect broken warp yarns, stopping the loom to prevent further damage and wasted material. I’m proficient in identifying faulty sensors and their impact on weave quality – a misaligned sensor can lead to missed broken ends, affecting the finished fabric.

- Warp tension sensors: These monitor the tension of the warp yarns, ensuring evenness across the fabric. Incorrect tension can result in uneven fabric structure and weaving defects. I’ve handled various types including load cells and optical sensors, and understand the calibration and maintenance procedures for each.

- Shuttle position sensors: In shuttle looms, these sensors track the shuttle’s position and speed. Faults can lead to weaving irregularities or shuttle collisions. I can diagnose problems related to sensor misalignment, wiring issues, or sensor failure itself.

- Weft insertion sensors: These detect the successful insertion of the weft yarn. Failure can lead to missed picks and fabric flaws. I’ve worked with various types, including photoelectric sensors and mechanical limit switches.

Understanding the nuances of each sensor type is essential for efficient troubleshooting and preventative maintenance. For example, I once diagnosed a recurring broken-end detection issue by realizing the sensor was misaligned due to vibration, a seemingly minor detail with significant consequences.

Q 9. Describe your experience with loom electronics and troubleshooting electrical faults.

My experience with loom electronics extends to various aspects, from preventative maintenance to complex troubleshooting. I’m adept at reading electrical schematics, tracing wiring, and using multimeters and oscilloscopes to diagnose faults. Common issues I’ve addressed include:

- Identifying short circuits: Using a multimeter, I can pinpoint short circuits in wiring harnesses, often caused by frayed wires or damaged insulation.

- Locating faulty components: I can identify and replace faulty components such as relays, switches, and electronic control boards. For example, a malfunctioning relay might prevent the weft insertion mechanism from operating correctly.

- Troubleshooting PLC (Programmable Logic Controller) issues: Modern looms often rely on PLCs to control various functions. I am proficient in using programming software to diagnose and correct PLC errors and adapt programs as needed.

I remember a case where a seemingly intermittent power failure was affecting the shuttle drive. Through systematic testing, I discovered a corroded connection in a power distribution board, illustrating the importance of thorough diagnostics.

Q 10. How do you diagnose and repair problems with the reed?

Reed problems are a common cause of weaving defects. My diagnostic process involves:

- Visual Inspection: Checking for bent or broken dents, damaged reed cap, or general wear and tear. A damaged reed can cause broken warp yarns and create uneven fabric.

- Reed Beat-Up Check: Assessing the reed’s beating action to ensure proper weft insertion. Uneven beat-up can lead to fabric imperfections.

- Dent Spacing Measurement: Verifying the correct spacing between dents. Incorrect spacing impacts the fabric’s density and structure.

- Repair or Replacement: Depending on the damage, I either repair the reed (if possible and cost-effective) or recommend replacing it with a new one. This often involves specialized tools and techniques to ensure accurate installation and alignment.

For instance, I once identified a subtly bent dent that was causing inconsistent weft insertion, resulting in a visible flaw in the final fabric. Replacing that single dent prevented further damage and maintained production efficiency.

Q 11. How do you handle problems with the heald shafts?

Heald shaft problems can cause a range of weaving issues. My approach involves:

- Checking for broken heddles: These often cause broken warp yarns or missed sheds. I use various tools to carefully replace broken heddles.

- Inspecting heald shaft alignment: Misaligned heald shafts create uneven sheds, impacting fabric structure and causing weaving defects. This often requires precise adjustments and tools for accurate measurements.

- Evaluating heald shaft movement: Smooth, synchronized movement is essential. Problems can be due to worn parts or mechanical issues, which might need lubrication or part replacements.

- Assessing heddle frame condition: Inspecting for damage or wear and tear in the heddle frames. These frames support and guide the heddles; damage can lead to misalignment and broken heddles.

In one instance, a seemingly minor binding of one heald shaft led to significant shedding issues. After careful inspection, I found a small piece of debris causing the friction. Removing it solved the problem, highlighting the importance of thorough checks.

Q 12. Explain your experience with warp beam preparation and mounting.

Warp beam preparation and mounting is a critical step in the weaving process. My experience encompasses:

- Warp beam sizing: Determining the correct size and type of warp beam needed based on the yarn and fabric specifications. Incorrect sizing can affect warp tension and weaving efficiency.

- Warping: Preparing the warp yarns and winding them onto the beam accurately. I’m proficient in using different warping machines and techniques to ensure uniform tension and prevent yarn breakage.

- Beam mounting: Carefully mounting the warp beam onto the loom, ensuring proper alignment and tension. Improper mounting can lead to weaving faults.

- Tension control: Setting the correct tension to ensure even weaving and prevent yarn breakage. I can diagnose and fix any tension control issues.

I recall a situation where a poorly prepared warp beam led to repeated yarn breakage. By carefully inspecting the warping process and making adjustments to the tension control system, I eliminated the problem, emphasizing the significance of this preparatory phase.

Q 13. Describe your experience with cloth removal and roll changing.

Cloth removal and roll changing are essential for efficient production. My experience includes:

- Safe cloth removal: Using appropriate techniques and equipment to prevent damage to the finished fabric. I am meticulous in protecting the fabric from stretching, wrinkles or other damage during this stage.

- Roll changing procedures: Efficiently changing the cloth roll on the loom, minimizing downtime. This involves careful handling of the large cloth rolls and precise attachment of the new roll.

- Maintaining clean and orderly workspace: Keeping the area around the loom tidy to prevent accidents and improve overall efficiency.

I’ve always prioritized smooth roll changes to minimize downtime and maintain a consistent production flow. A well-organized approach to cloth removal and roll changing significantly contributes to overall production efficiency and fabric quality.

Q 14. What are the safety precautions you follow when working on a loom?

Safety is paramount in loom fixing. My safety practices include:

- Lockout/Tagout procedures: Always locking out and tagging out power sources before commencing any electrical work. This prevents accidental power-ups and protects against electrocution.

- Personal Protective Equipment (PPE): Consistently using appropriate PPE, including safety glasses, gloves, and hearing protection. This safeguards against injuries from moving parts and flying debris.

- Awareness of moving parts: Maintaining awareness of the loom’s moving components and avoiding contact with them while the machine is running or when power is not completely disconnected.

- Following established safety protocols: Adhering to the company’s safety guidelines and reporting any potential hazards immediately. This includes regular maintenance and inspections to identify potential risks.

Safety is not just a checklist but an ingrained mindset. For example, I always double-check my lockout procedures before starting any repairs, even if I’m familiar with the equipment. A moment of carelessness can have serious consequences.

Q 15. How do you prioritize loom repairs during peak production periods?

Prioritizing loom repairs during peak production hinges on a combination of factors: the severity of the malfunction, its impact on production output, and the available resources. We employ a tiered system. Critical repairs, those halting production or causing significant quality issues (like major warp breaks or weft misinsertions), receive immediate attention. High-priority repairs address issues that could lead to larger problems or reduced efficiency (e.g., consistent shedding irregularities). Medium-priority repairs are those impacting quality but not halting production, and these are scheduled for less busy times. Finally, low-priority repairs, such as minor adjustments or preventative maintenance tasks, are grouped and scheduled for downtime periods. This system utilizes a combination of visual inspection reports, real-time monitoring of loom performance data, and communication with the production floor.

For instance, if a key loom in a high-demand fabric production line experiences a major weft break, that repair takes precedence over adjusting the tension on a loom producing a less urgent fabric. Prioritization ensures minimal downtime while maintaining product quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with loom computer systems and software.

My experience with loom computer systems and software is extensive. I’m proficient in various systems, including those from companies like Stäubli, Sulzer, and Toyota. This involves programming, troubleshooting, and optimizing the electronic components that control essential functions like weft insertion, warp shedding, and selvedge formation. I’m familiar with using software for monitoring machine performance, diagnosing malfunctions through error codes, and adjusting parameters for optimal weaving. I’ve worked with both dedicated loom control systems and integrated Manufacturing Execution Systems (MES).

For example, I recently used a Stäubli system’s diagnostic tools to identify a recurring pattern of weft misinsertions. By analyzing the system logs and real-time data, we discovered a minor timing issue in the weft insertion mechanism’s control program. A simple code adjustment corrected the problem, preventing further production losses and fabric defects.

Q 17. Explain how you would diagnose a pattern defect in woven fabric.

Diagnosing pattern defects in woven fabric requires a systematic approach. First, I’d examine the fabric carefully to identify the nature of the defect – is it a consistent repeat, a random occurrence, or localized to a specific area? Then, I’d analyze the defect’s relationship to the warp and weft yarns. Is it a warp-related issue (e.g., broken ends, misplaced warp threads), a weft-related issue (e.g., missed picks, floats), or a combination of both? Next, I’d check the loom’s settings, examining the loom’s shedding mechanism, heddle frame movements, and the weft insertion process. I’d also consider factors such as yarn quality, tension, and the weaving pattern itself.

For example, if a consistent pattern defect shows mismatched colors, I’d check the heddle frame sequence or the warp yarn order. If the defect presents as uneven widths, I’d check the loom’s selvedge control system and possibly the tension of the warp yarns. A systematic approach helps to pinpoint the exact source of the problem within the loom and its related elements.

Q 18. How do you document maintenance and repairs performed on a loom?

I meticulously document all maintenance and repairs using a computerized maintenance management system (CMMS). This typically includes detailed records of the loom’s identification number, the date and time of the service, a description of the problem, the actions taken, parts replaced (with part numbers), and the labor hours involved. The system often generates work orders and tracks preventative maintenance schedules. Photos or videos are sometimes included to visually document the condition before and after repair. This comprehensive documentation is crucial for tracking loom performance, predicting potential issues, and ensuring compliance with industry standards.

For example, a record might read: ‘Loom ID: 1234; Date: 2024-10-27; Issue: Broken Reed; Action: Replaced Reed (Part # 5678); Labor Hours: 2; Technician: John Doe’. This level of detail is essential for efficient maintenance planning and cost analysis.

Q 19. What is your experience with preventative maintenance on looms?

Preventative maintenance is paramount in ensuring loom efficiency and extending its lifespan. My approach is proactive, involving regular scheduled inspections and lubrication of critical moving parts, checking for wear and tear on components like reeds, heddles, and shuttles, and cleaning the loom regularly to remove lint and debris. This also includes conducting regular electronic checks of the loom’s control system. I adhere to manufacturers’ recommended maintenance schedules and tailor them to the specific operating conditions. A well-maintained loom experiences fewer breakdowns, reduces production downtime, and improves overall fabric quality.

For instance, I schedule regular lubrication of the shuttle race and cam shafts to prevent friction and wear. Early detection of wear and tear on heddles allows for their timely replacement, preventing major production disruptions later on. This preventative approach helps reduce unexpected repairs and ensures consistent operational efficiency.

Q 20. What are the key performance indicators (KPIs) you use to assess loom efficiency?

Key Performance Indicators (KPIs) I use to assess loom efficiency include:

- Overall Equipment Effectiveness (OEE): This measures the percentage of time the loom is producing good quality fabric. It considers availability, performance, and quality rates.

- Mean Time Between Failures (MTBF): This measures the average time between loom breakdowns, indicating reliability.

- Mean Time To Repair (MTTR): This reflects the efficiency of repairs and the time taken to get the loom back into operation.

- Production Rate (meters/hour or pieces/hour): This tracks the speed and output of the loom.

- Fabric Quality Rate: This quantifies the percentage of defect-free fabric produced, highlighting potential quality issues.

By monitoring these KPIs, we can identify bottlenecks, optimize maintenance schedules, and continuously improve loom performance.

Q 21. Describe a time you had to troubleshoot a complex loom problem.

I once encountered a complex problem involving a seemingly intermittent fault causing weft yarn breakage on a high-speed air-jet loom. The issue was not consistent, making diagnosis challenging. The initial steps involved carefully examining the yarn path, checking for any signs of abrasion or damage. We then used the loom’s diagnostic software to analyse the air pressure settings and the timing of the weft insertion process. After several hours of investigation, we discovered a minute piece of debris lodged in a crucial part of the air-jet nozzle. This tiny obstruction was causing inconsistent air pressure and leading to yarn breaks. Once removed, the problem resolved itself, highlighting the importance of thorough investigation and attention to even the smallest details.

This incident underscores the need for methodical troubleshooting, combining practical experience with the utilization of advanced diagnostic tools provided by modern loom systems. The experience reinforced the necessity of patience, attention to detail, and systematic elimination of possible causes when facing complex loom issues.

Q 22. What are the different types of loom drives and their advantages/disadvantages?

Loom drives are the heart of any weaving machine, responsible for controlling the speed and timing of the weft insertion process. There are several types, each with its own strengths and weaknesses.

- Positive Drives (e.g., Cam Drives): These use cams or other mechanical components to directly control the movement of the shuttle or weft insertion system. They offer precise control and are robust, but can be complex, expensive to maintain, and inflexible to changes in weave patterns. Think of it like a very precise clockwork mechanism – reliable but not easily adaptable.

- Negative Drives (e.g., Drop Box Drives): In this system, the weft is released by a dropping mechanism, and the timing is determined indirectly. These are simpler and less expensive than positive drives but can be less precise and potentially lead to more weft misalignment. It’s like using gravity to guide the weft; less precise but less complex.

- Electronic Drives (e.g., Servo Motor Drives): These use electronic controllers and motors to manage the weft insertion, offering highly precise control, variable speeds, and adaptability to complex weave structures. This is the modern approach, offering flexibility and precise control like a sophisticated, programmable robot arm.

The best choice depends on factors such as the desired weaving speed, fabric complexity, budget, and required maintenance level. For high-speed, high-precision weaving, electronic drives are preferred. For simpler weaves, negative drives might be sufficient.

Q 23. How do you handle communication with loom operators regarding maintenance issues?

Effective communication with loom operators is crucial for smooth operations and preventing downtime. My approach involves a combination of proactive and reactive strategies.

- Proactive Communication: Regular shift briefings where I highlight potential issues, review maintenance schedules, and explain any upcoming changes. I also use visual aids like checklists and diagrams to clarify complex maintenance procedures.

- Reactive Communication: When a problem occurs, I prioritize clear and concise communication, explaining the issue, the solution, and any safety precautions. I listen actively to the operator’s observations as they often provide valuable insight into the problem. I ensure that communication is two-way, fostering a collaborative problem-solving environment.

- Documentation: Maintaining detailed records of maintenance activities, including communication logs, helps track issues, improve efficiency, and ensure accountability. This also aids in training new operators.

For example, if a weft misalignment occurs, I wouldn’t just fix it; I’d explain to the operator why it happened (e.g., worn shuttle, incorrect tension), how to prevent it in the future, and what to watch out for.

Q 24. What is your experience with different types of weaving fabrics?

My experience encompasses a wide range of weaving fabrics, from basic cotton and linen to more complex blends and technical textiles.

- Plain Weaves: Simple over-under patterns, ideal for basic fabrics like cotton sheets or linen towels.

- Twill Weaves: Diagonal patterns created by floating warp yarns, resulting in durable fabrics like denim or gabardine.

- Satin Weaves: Characterized by long floats creating a lustrous surface, used in fabrics like satin or charmeuse.

- Jacquard Weaves: Complex patterns achieved by controlling individual warp yarns, leading to intricate designs in upholstery fabrics or tapestries.

- Pile Weaves: Create raised loops or cut pile, resulting in fabrics like velvet, corduroy, or terry cloth.

Understanding the specific characteristics of each fabric type is vital for selecting appropriate loom settings, warp and weft materials, and maintenance procedures. For instance, a delicate silk satin would require different loom adjustments and maintenance compared to a robust denim.

Q 25. How do you stay up-to-date with advancements in loom technology?

Staying current with loom technology is critical in this dynamic industry. I actively utilize several methods to keep my knowledge sharp:

- Industry Publications and Journals: I regularly read trade magazines and journals specializing in textile machinery and weaving techniques. This gives me insights into the latest innovations and research.

- Trade Shows and Conferences: Attending industry events allows for direct interaction with manufacturers, viewing the latest equipment, and learning about upcoming technologies through presentations and workshops.

- Manufacturer Websites and Documentation: I regularly check the websites of major loom manufacturers for updates, manuals, and training materials.

- Online Courses and Webinars: Many online platforms offer specialized courses in textile engineering and loom maintenance. This enables convenient, self-paced learning.

- Networking with Peers: Participating in professional networks and forums provides opportunities to share experiences and learn from others in the field.

For example, I recently attended a workshop on the latest advancements in sensor technology for predictive maintenance in weaving machines, which helps to reduce downtime and optimize maintenance schedules.

Q 26. Describe your experience with various types of loom healds.

My experience covers a variety of loom healds, each designed for specific weaving requirements:

- Steel Healds: Robust and durable, suitable for high-speed weaving and heavier fabrics. However, they can be more susceptible to breakage if improperly maintained.

- Reed Healds: Used for finer fabrics, offering flexibility and precise yarn control. They require more delicate handling to avoid damage.

- Plastic Healds: Lighter and less expensive than steel, suitable for certain applications. However, they might not be as durable for heavy-duty weaving.

- Heald Frames: The way healds are mounted and controlled varies depending on loom type (e.g., dobby, jacquard). Understanding the mechanics of each system is vital for efficient maintenance and repair.

Proper heald maintenance is essential for preventing yarn breakage and ensuring the quality of the woven fabric. Knowing how to identify worn or damaged healds and replace them efficiently is a critical skill for a loom technician.

Q 27. What is your approach to training new loom technicians?

Training new loom technicians is a structured process I approach with a layered methodology:

- On-the-Job Training: I start with hands-on experience, guiding them through basic maintenance tasks under close supervision. This provides practical learning in a real-world setting.

- Classroom Instruction: I use presentations, diagrams, and manuals to explain the theory behind loom operation and maintenance procedures. This establishes a foundation of knowledge before practical application.

- Mentorship Program: I pair new technicians with experienced colleagues who act as mentors. This allows for continuous learning and fosters teamwork.

- Simulation Training: Using software simulations or virtual reality tools can provide a safe and controlled environment to practice troubleshooting and repair procedures.

- Ongoing Evaluation and Feedback: Regular assessments, feedback sessions, and performance reviews allow for continuous improvement and identification of areas needing further training.

My goal isn’t just to teach them to fix looms; it’s to cultivate problem-solving skills, safety awareness, and a thorough understanding of the weaving process. A well-trained technician becomes an asset to the entire operation.

Q 28. Explain your familiarity with health and safety regulations in the textile industry.

Health and safety is paramount in the textile industry. My familiarity with regulations covers several key areas:

- Machine Guarding: Ensuring all moving parts of the loom are properly guarded to prevent accidental injuries. Regular inspections are vital to maintain safety.

- Personal Protective Equipment (PPE): Enforcing the use of appropriate PPE, including safety glasses, hearing protection, and gloves, depending on the task. I provide proper training on the use and importance of PPE.

- Emergency Procedures: Thorough knowledge of emergency protocols, including how to respond to accidents, equipment malfunctions, and fire hazards. Regular drills and training help ensure preparedness.

- Ergonomics: Understanding and implementing ergonomic principles to minimize the risk of musculoskeletal injuries for operators. This includes proper workstation design and lifting techniques.

- Hazardous Materials Handling: Safe handling, storage, and disposal of chemicals and other hazardous materials used in the weaving process. Compliance with all relevant environmental regulations is essential.

My commitment is to maintain a safe work environment by adhering to all relevant industry standards and regulations and continuously educating operators on safe working practices.

Key Topics to Learn for Loom Fixing Interview

- Loom Mechanics: Understanding the fundamental components of a loom, including heddles, harnesses, reed, shuttle, and other essential parts. This includes their function and interaction during the weaving process.

- Warping and Weaving Techniques: Mastering different warping methods and their applications, and understanding various weaving techniques like plain weave, twill weave, satin weave, and their variations. Practical experience in setting up warps and executing different weaves is highly beneficial.

- Troubleshooting Common Loom Issues: Developing a systematic approach to identifying and resolving common problems like broken warp threads, shed irregularities, weft misalignment, and other operational issues. This includes preventative maintenance strategies.

- Loom Types and Their Applications: Familiarity with different types of looms (e.g., floor looms, table looms, countermarch looms) and their suitability for various weaving projects and materials. Understanding the advantages and limitations of each type.

- Fabric Structure and Design: Understanding the relationship between loom settings and the resulting fabric structure. This includes knowledge of yarn types, their properties, and how they influence the final product. Being able to translate design concepts into loom settings is crucial.

- Safety Procedures and Best Practices: Prioritizing safety in the loom fixing process, including the proper handling of tools and materials, awareness of potential hazards, and adherence to safety regulations.

- Maintenance and Repair: Understanding preventative maintenance techniques and basic repair procedures for loom components. This includes recognizing signs of wear and tear and taking appropriate action.

Next Steps

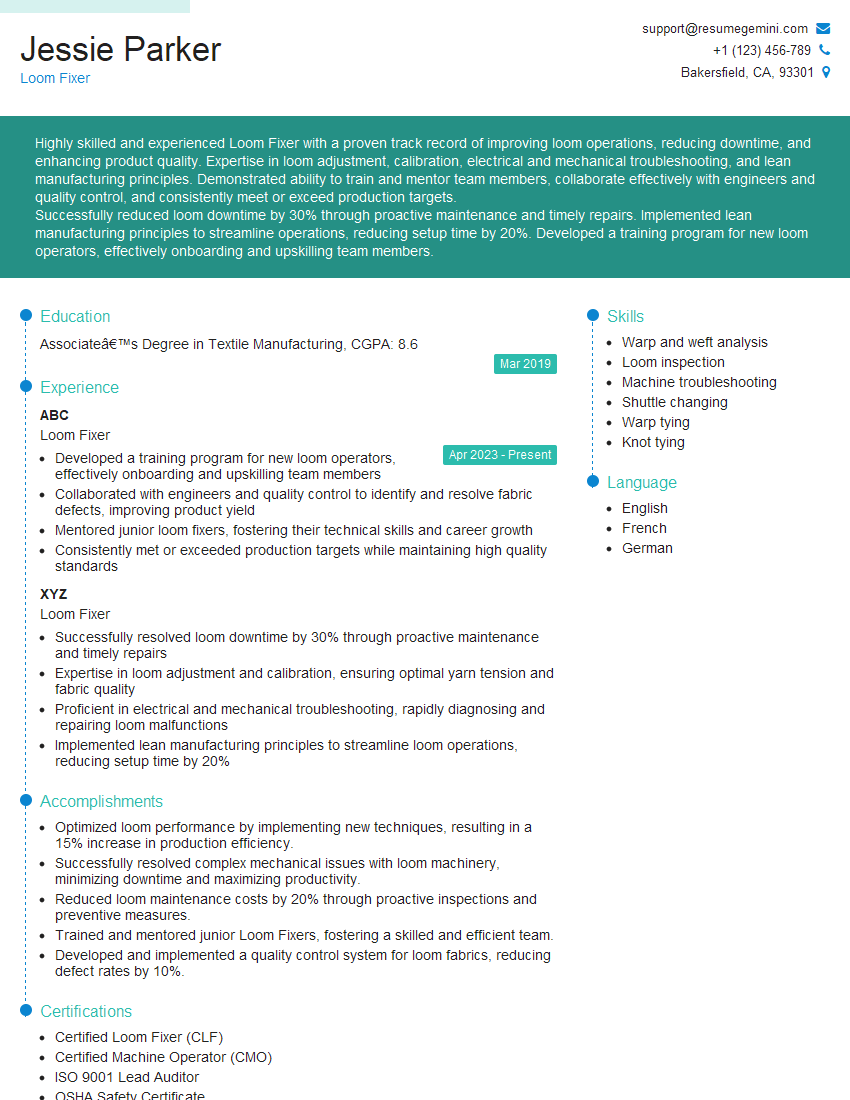

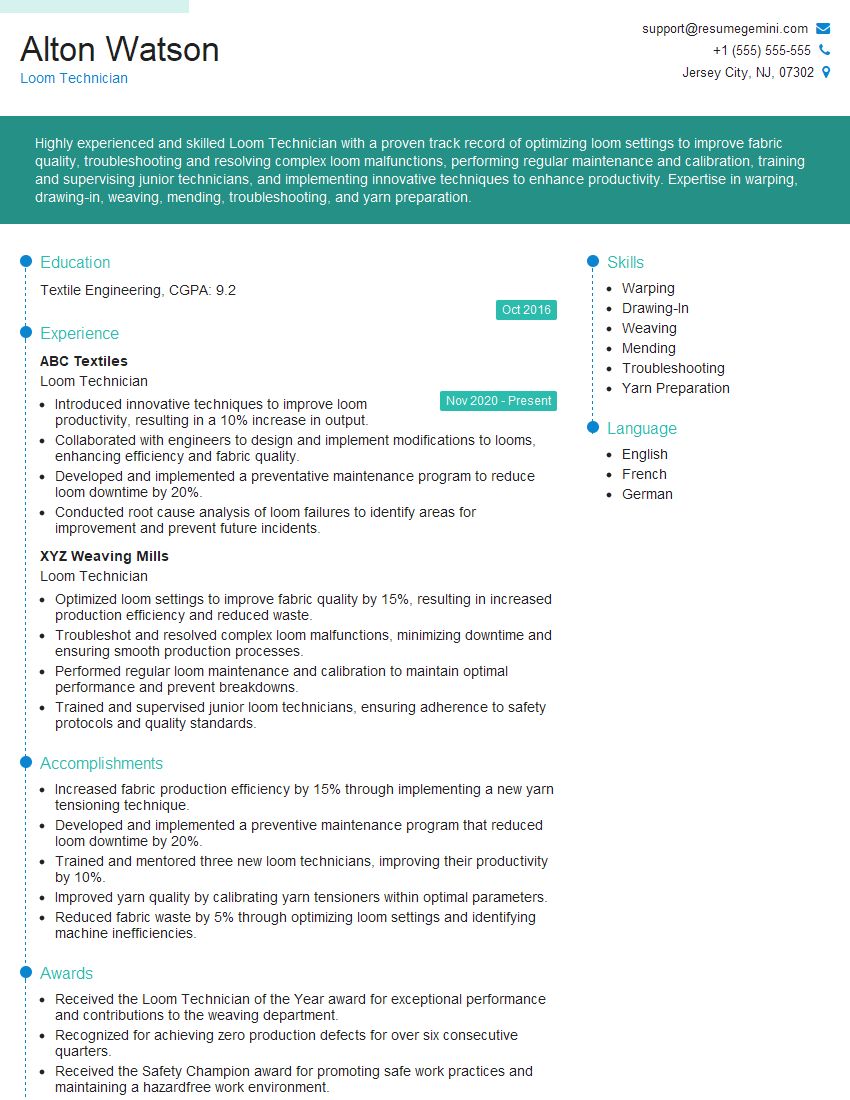

Mastering loom fixing is vital for a successful and rewarding career in the textile industry, opening doors to diverse roles and specialized opportunities. To enhance your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience effectively. We strongly recommend using ResumeGemini to craft a professional and impactful resume. ResumeGemini provides a user-friendly platform to build a strong resume and examples of resumes tailored to Loom Fixing are available to guide you. Take this opportunity to present your expertise in the best possible light!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?