Warning: search_filter(): Argument #2 ($wp_query) must be passed by reference, value given in /home/u951807797/domains/techskills.interviewgemini.com/public_html/wp-includes/class-wp-hook.php on line 324

Unlock your full potential by mastering the most common Bioreactor Operation and Maintenance interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Bioreactor Operation and Maintenance Interview

Q 1. Describe your experience with different types of bioreactors (e.g., stirred tank, airlift, photobioreactor).

My experience encompasses a wide range of bioreactor types, each suited to different applications. Stirred tank bioreactors, the workhorses of the industry, are highly versatile and allow for precise control of parameters like mixing and oxygen transfer. I’ve extensively used them for microbial and mammalian cell cultures. Airlift bioreactors, with their simpler design and lower shear forces, are ideal for shear-sensitive cells like plant or hybridoma cells. I’ve worked with them in the development of various therapeutic proteins. Finally, photobioreactors are crucial for photosynthetic organisms. My experience includes optimizing light penetration and gas exchange in these systems for algae cultivation for biofuel production. Each bioreactor type presents unique operational challenges and requires a tailored approach to ensure optimal cell growth and product yield. For instance, maintaining appropriate mixing in stirred tank reactors to prevent settling and ensuring uniform light distribution in photobioreactors are critical aspects of my expertise.

Q 2. Explain the principles of sterile technique in bioreactor operation.

Sterile technique in bioreactor operation is paramount to prevent contamination, which can ruin an entire batch and cause significant financial losses and delays. It’s like preparing a delicate cake – any contamination will ruin the final product. We employ a multi-layered approach. This starts with thorough cleaning and sterilization of all equipment using steam-in-place (SIP) or chemical sterilization methods. The bioreactor vessel and all connecting lines undergo a rigorous sterilization cycle before inoculation. Media preparation is conducted under aseptic conditions, often involving filtration through 0.22 μm filters to remove bacteria and other microorganisms. Throughout the process, we maintain a sterile environment by using laminar flow hoods for media transfers and employing strict aseptic practices during sampling and harvesting. Regular environmental monitoring helps us detect any potential contamination early. Think of it as having multiple checkpoints to ensure a clean process.

Q 3. How do you monitor and control pH, dissolved oxygen, and temperature in a bioreactor?

Monitoring and controlling pH, dissolved oxygen (DO), and temperature are critical for maintaining optimal cell growth and product quality. We use in-line sensors integrated into the bioreactor system for continuous monitoring. For pH, we typically employ pH probes, and we automatically adjust the pH using acid or base addition. Dissolved oxygen is measured using DO probes and controlled by adjusting the airflow rate or by sparging with oxygen-enriched air. Temperature is monitored and controlled using temperature probes and a heating/cooling system. Sophisticated control systems, often using programmable logic controllers (PLCs), allow for precise and automated control of these parameters, maintaining them within narrow ranges defined by the specific cell line and process. For example, for a mammalian cell culture, maintaining a specific temperature range is vital, as temperature fluctuations can cause cellular stress and alter protein production. Regular calibration of sensors is key to ensuring accurate measurements. Imagine it like monitoring your car’s engine – keeping its parameters within their specified ranges guarantees smooth operation.

Q 4. What are the common causes of foam formation in a bioreactor, and how do you control it?

Foam formation is a common problem in bioreactors, particularly during high cell density cultivations. Proteins and other components in the culture medium can contribute to foaming. This can lead to problems with gas exchange and mixing. The main causes include high concentrations of proteins, polysaccharides, or lipids in the broth. We employ various strategies to control foaming. Antifoam agents, which are specifically designed to reduce surface tension, are commonly added. The addition of these agents is typically automated based on the foam level detected by foam sensors. Mechanical methods such as using impellers with a design that minimizes foam production can also be employed. In severe cases, a foam breaker system can be integrated into the bioreactor. This is like managing a head of beer; you don’t want it overflowing, but you need a controlled release to prevent spilling.

Q 5. Describe your experience with bioreactor cleaning and sterilization procedures (CIP/SIP).

Cleaning and sterilization (CIP/SIP) are crucial for maintaining bioreactor integrity and preventing cross-contamination between batches. CIP (Cleaning-in-Place) involves cleaning the bioreactor using automated cycles of cleaning solutions, including detergents and acids, followed by thorough rinsing with sterile water. SIP (Sterilization-in-Place) involves sterilizing the system with steam under pressure. The entire process, including the validation and documentation, needs to be fully compliant with regulatory standards like GMP (Good Manufacturing Practices). A well-defined Standard Operating Procedure (SOP) is critical to ensuring that the process is carried out consistently and correctly. This includes careful record keeping and documentation of every step. In my experience, we use a combination of CIP and SIP processes, tailored to the specific bioreactor design and the type of culture. A thorough cleaning and sterilization process is crucial to maintain the sterility of the entire process chain and ensuring the quality of products produced. It’s like washing dishes; if not done properly, you risk contaminating the next meal.

Q 6. How do you troubleshoot common bioreactor problems, such as sensor malfunctions or leaks?

Troubleshooting bioreactor problems requires a systematic approach. Sensor malfunctions, for example, can be addressed by first checking for calibration errors. If the problem persists, the sensor might need replacement. Leaks are dealt with by visual inspection, pressure testing, and identifying the source of the leak. In my experience, a detailed log of operational parameters and alarms helps pin down the source of problems. For example, a sudden drop in DO could indicate a leak in the gas supply line or a malfunction in the oxygen mass flow controller. Similarly, erratic pH readings could be due to a faulty sensor or contamination. Understanding the interplay between different parameters and using process knowledge is crucial for effective troubleshooting. In cases of recurring issues, a more in-depth investigation might be required involving engineering support. Troubleshooting bioreactor problems is like detective work, requiring careful analysis and a logical approach to pinpoint the issue.

Q 7. Explain your understanding of bioreactor process parameters and their impact on cell growth and product yield.

Bioreactor process parameters significantly influence cell growth and product yield. Parameters like temperature, pH, DO, and nutrient concentrations are crucial for optimizing cell metabolism. For instance, maintaining optimal DO levels ensures sufficient oxygen supply for respiration and prevents the accumulation of toxic metabolites. Similarly, appropriate nutrient feeding strategies are essential for sustaining cell growth and maximizing product yield. Incorrect pH levels can disrupt cell metabolism and lead to reduced productivity. Temperature impacts enzyme activity and cellular processes. My understanding involves carefully balancing these parameters to achieve the desired growth rate and product quality. For example, in a microbial fermentation process, controlling substrate concentration and dissolved oxygen is critical for efficient metabolism and product formation. Data analysis and modeling play a critical role in identifying optimal process parameters to maximize overall production efficiency.

Q 8. What are the safety precautions you take when working with bioreactors?

Safety is paramount in bioreactor operation. My approach is built on a multi-layered strategy encompassing personal protective equipment (PPE), stringent operating procedures, and robust emergency response plans. Before any work, I always don PPE appropriate for the task, which might include lab coats, gloves, safety glasses, and sometimes respirators, depending on the specific bioreactor and the substances involved. We follow strict protocols for sterilization and disinfection of the bioreactor and all associated equipment to prevent contamination and the risk of infection. This includes using autoclaves for sterilization and employing appropriate chemical disinfectants like hydrogen peroxide or ethanol. We also have comprehensive emergency shut-down procedures in place, covering power failures, equipment malfunctions, or spills. Regular training and drills ensure the team’s preparedness to handle various scenarios safely and effectively. Finally, risk assessments are conducted for every experiment or process, identifying potential hazards and implementing mitigating controls. For example, working with genetically modified organisms requires additional safety measures, such as containment facilities and specialized waste disposal protocols.

Q 9. Describe your experience with bioreactor automation and control systems.

I have extensive experience with bioreactor automation and control systems, primarily using Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. In my previous role, we utilized a sophisticated SCADA system to monitor and control multiple bioreactors simultaneously. This system allowed for real-time monitoring of critical parameters such as pH, dissolved oxygen (DO), temperature, agitation speed, and foam level. We programmed setpoints for these parameters, and the system automatically adjusted various actuators, like pumps and valves, to maintain optimal conditions. For example, if the DO level dropped below a preset threshold, the system would automatically increase the airflow rate. Furthermore, the system generated detailed logs of all operational parameters, which were crucial for data analysis and process optimization. My expertise also includes programming and troubleshooting PLCs, often using ladder logic programming. I’ve worked with various sensors and actuators, integrating them seamlessly into the automated control system. The automation not only improves consistency and efficiency but also significantly reduces the risk of human error.

Q 10. How do you perform data logging and analysis in a bioreactor system?

Data logging and analysis are integral to successful bioreactor operation. We use a combination of automated data acquisition systems and manual recordings. The SCADA system automatically logs data at pre-defined intervals, typically every few seconds or minutes. This data includes all the critical process parameters mentioned earlier, along with information on media additions, sampling events, and any manual interventions. This raw data is then exported to a database or spreadsheet program for further analysis. We use statistical software packages such as R or specialized bioprocess software to analyze this data, looking for trends, identifying potential problems, and optimizing the process. We use various statistical methods, including regression analysis, to correlate process parameters with cell growth and product yield. For instance, we might analyze the correlation between dissolved oxygen and specific growth rate to fine-tune the aeration strategy. Visualizations, such as graphs and charts, are crucial for quickly identifying anomalies and facilitating informed decision-making. Data integrity is critical, so we have robust procedures for data validation and backup.

Q 11. Explain your understanding of different cell culture techniques used in bioreactors.

My experience encompasses a wide range of cell culture techniques employed in bioreactors, including suspension cultures, adherent cultures, and perfusion cultures. Suspension cultures, where cells grow freely in the liquid media, are common for many cell lines. Adherent cultures, requiring cells to attach to a surface, necessitate specialized bioreactors, such as those with microcarriers or hollow fiber systems. We have successfully implemented both types of culture in different projects. Perfusion cultures, which continuously remove spent media and replace it with fresh media, are particularly advantageous for high-density cell cultures as they help to maintain optimal conditions and improve cell productivity. Selecting the appropriate cell culture technique depends on the specific cell line, desired product, and overall process goals. For instance, if high cell density is required and a large amount of product is needed, perfusion culture may be preferred over batch culture. Each method requires careful consideration of factors like media formulation, agitation, aeration, and temperature control to ensure optimal cell growth and product yield. I have personally optimized several processes involving these culture techniques, leading to improved efficiency and output.

Q 12. What are the key performance indicators (KPIs) you monitor in bioreactor operation?

Key Performance Indicators (KPIs) in bioreactor operation are crucial for monitoring process efficiency and product quality. We meticulously track several critical parameters: cell density (e.g., cell count, viable cell concentration), cell viability, specific growth rate, substrate consumption rate (e.g., glucose, glutamine), product concentration (e.g., antibody titer), and process parameters such as dissolved oxygen, pH, temperature, and agitation. We regularly analyze these KPIs to identify bottlenecks or deviations from the expected performance. For example, a decrease in specific growth rate might indicate a nutrient limitation, necessitating adjustments to the media formulation or feeding strategy. We also monitor process parameters to ensure optimal conditions for cell growth and product formation. A deviation from the ideal pH range could negatively impact cell viability and product quality. Continuous monitoring of these KPIs allows for proactive interventions, ultimately leading to a consistent and high-quality product.

Q 13. How do you ensure the quality and consistency of bioreactor operations?

Ensuring the quality and consistency of bioreactor operations involves a comprehensive approach encompassing standardized operating procedures (SOPs), rigorous quality control (QC) measures, and proactive maintenance strategies. SOPs meticulously define every step of the process, from media preparation to harvesting, ensuring consistency across different runs and operators. QC checks are conducted at various stages to monitor the quality of the media, cell culture, and the final product. We employ various analytical techniques, such as flow cytometry and HPLC, to assess cell viability, product concentration, and purity. Regular calibration and maintenance of equipment, including sensors, pumps, and other components, are essential to minimize variability and prevent malfunctions. A proactive approach to maintenance, including preventive maintenance schedules, helps to prevent unexpected downtime and ensures the reliable operation of the bioreactor system. Comprehensive documentation of all procedures and results is vital for traceability and regulatory compliance.

Q 14. Describe your experience with bioreactor scale-up and scale-down.

Bioreactor scale-up and scale-down are critical aspects of bioprocess development. Scaling up involves increasing the bioreactor volume to produce larger quantities of the desired product, while scaling down involves reducing the volume for research or process optimization purposes. My experience includes both, utilizing various scale-up strategies, including geometric similarity, constant power input, and constant shear rate. Geometric similarity aims to maintain the same geometric ratios between different bioreactor sizes. Constant power input ensures that the energy dissipation rate per unit volume remains consistent, minimizing the impact of scale on cell growth and product formation. Constant shear rate maintains the same shear forces on the cells, important for shear-sensitive cells. Scaling down typically involves maintaining the key process parameters like oxygen transfer rate, mixing time, and shear rate to ensure that the smaller-scale bioreactor accurately represents the larger-scale operation. Successful scale-up and scale-down require careful consideration of mass transfer limitations, mixing efficiency, and the impact of scale on cell growth and product formation. I’ve used computational fluid dynamics (CFD) modeling to aid in scale-up and scale-down strategies to predict the performance of different bioreactor sizes.

Q 15. What are the different types of sensors used in bioreactors, and how do they work?

Bioreactors rely on a suite of sensors to monitor and control crucial parameters for optimal cell growth and product formation. These sensors provide real-time data, enabling precise adjustments to maintain a stable and productive environment. Different sensor types measure various aspects of the bioprocess.

pH Sensors: These use electrodes to measure the acidity or alkalinity of the culture medium. Maintaining the correct pH is critical as it directly impacts cell viability and metabolic activity. Think of it like maintaining the right soil pH for a plant – too acidic or too alkaline, and the plant struggles. A deviation from the set point triggers an automated adjustment of base or acid addition.

Dissolved Oxygen (DO) Sensors: These sensors, often employing electrochemical principles (Clark-type electrodes), measure the amount of oxygen dissolved in the culture medium. Oxygen is essential for aerobic cell cultures; insufficient oxygen leads to cell death and reduced product yield. Maintaining optimal DO levels is crucial, and these sensors trigger automated adjustments of aeration and agitation rates. Imagine it as providing the right amount of air to a fish tank; too little, and the fish suffocate; too much, and the water becomes unsuitable.

Temperature Sensors: These typically use thermocouples or resistance temperature detectors (RTDs) to monitor the temperature of the bioreactor. Temperature is vital because enzymes and cells have optimal temperature ranges for their function. Fluctuations outside these ranges can compromise cell health and product quality. Imagine baking a cake – the precise temperature is crucial for a successful outcome.

Foam Sensors: These detect the presence and level of foam in the bioreactor. Excessive foam can impede gas transfer and even cause overflow. Foam detection triggers the addition of antifoam agents. This is crucial to prevent disruptions to the fermentation process.

Optical Sensors: These increasingly important sensors use various optical techniques (e.g., turbidity, fluorescence, Raman spectroscopy) to measure cell density, substrate concentration, and even product concentration in real-time, offering more nuanced process control.

Pressure Sensors: These measure the pressure within the bioreactor, providing insights into gas flow, headspace pressure, and potential leaks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with preventative maintenance of bioreactor systems.

Preventative maintenance is paramount in bioreactor operation, ensuring equipment reliability and preventing costly downtime. My experience encompasses a structured approach, involving:

Regular Inspections: This includes visual checks for leaks, corrosion, and wear and tear on components like tubing, sensors, and seals. I document all findings meticulously.

Calibration and Verification: I rigorously calibrate sensors (pH, DO, temperature) using certified standards, ensuring accuracy and reliability of measurements. Calibration logs and certificates are meticulously maintained. Incorrect measurements can lead to suboptimal process conditions.

Cleaning and Sterilization: Following each bioprocess run, I implement stringent cleaning and sterilization protocols to remove any residual cells, media, or product. This involves chemical cleaning (CIP – Clean-in-Place) and steam sterilization (SIP – Sterilization-in-Place) to prevent contamination and ensure consistent product quality. I meticulously document every step of the cleaning and sterilization process, ensuring traceability and compliance.

Spare Parts Management: I maintain an inventory of critical spare parts, ensuring minimal downtime in the event of a failure. This includes having back-up sensors, pumps, and other essential components readily available. Knowing that you have the right spare parts on hand provides peace of mind and allows for rapid repairs.

Documentation: Complete and accurate documentation is key. I maintain detailed logs of all maintenance activities, including dates, performed actions, and calibration results. This facilitates traceability and ensures compliance with regulatory guidelines.

For instance, in one instance, during a routine inspection, I identified slight corrosion on a valve. By addressing this early, we prevented a major leak and potential contamination, saving significant costs and avoiding a production halt.

Q 17. How do you handle deviations from standard operating procedures during bioreactor operation?

Deviations from standard operating procedures (SOPs) require a prompt and systematic response. My approach involves:

Immediate Investigation: First, identify the cause of the deviation. Is it due to a sensor malfunction, a change in media composition, or human error? Detailed investigation helps prevent future occurrences.

Risk Assessment: Assess the potential impact of the deviation on product quality, safety, and regulatory compliance. This informs the next steps.

Corrective Actions: Implement appropriate corrective actions to bring the process back within acceptable limits. This might involve adjusting parameters, replacing faulty components, or even halting the process, depending on the severity.

Documentation: Meticulously document all aspects of the deviation, including the cause, corrective actions taken, and their effectiveness. Detailed documentation is crucial for thorough investigation and preventative measures in the future.

Deviation Report: Prepare a deviation report detailing the event, analysis, and corrective actions. This report is reviewed and approved by relevant personnel and forms part of the batch record.

For example, if the DO level dropped unexpectedly, I would first check the aeration system, then the DO sensor calibration. Depending on the findings, I might increase aeration, recalibrate the sensor, or even investigate potential issues with the impeller. Every step is documented.

Q 18. Describe your experience with troubleshooting and resolving bioreactor malfunctions.

Troubleshooting bioreactor malfunctions requires a systematic and analytical approach. My experience utilizes a structured methodology:

Symptom Identification: First, clearly define the problem. Is the bioreactor not agitating? Is there a temperature deviation? Is there a contamination alert?

Data Review: Analyze historical data, sensor readings, and process parameters to identify any patterns or anomalies leading to the malfunction.

Component Check: Systematically check individual components (pumps, sensors, valves, etc.) to locate the root cause of the problem. Visual inspections, functional tests, and electrical checks are common strategies.

Diagnostic Tools: Utilize diagnostic tools to pinpoint the issue. This might include specialized software for troubleshooting the control system or using multimeters to check for electrical faults.

Corrective Actions: Implement the necessary repairs, replacements, or adjustments to resolve the malfunction. This might range from replacing a faulty sensor to repairing a leaking valve.

Documentation: Document every step of the troubleshooting process, including the problem description, diagnostic steps, solutions implemented, and the outcome. This is essential for future reference and continuous improvement.

In one instance, a bioreactor experienced unexpected temperature fluctuations. Through systematic checks, I found a malfunctioning temperature sensor. Replacing the sensor immediately resolved the issue, minimizing the risk to the cell culture.

Q 19. What are the regulatory requirements for bioreactor operation and documentation?

Regulatory requirements for bioreactor operation and documentation are stringent and vary depending on the application (e.g., pharmaceuticals, food, cosmetics). Generally, they focus on:

Good Manufacturing Practices (GMP): These guidelines are crucial for ensuring consistent product quality, safety, and efficacy. GMP covers all aspects of bioreactor operation, from equipment qualification and maintenance to personnel training and documentation.

Validation: Bioreactor systems and processes must be validated to ensure they consistently meet predetermined specifications and quality attributes. This includes equipment qualification (IQ, OQ, PQ) and process validation.

Documentation: Detailed and accurate documentation is essential. This includes batch records, maintenance logs, calibration records, deviation reports, and cleaning validation documentation. These records demonstrate compliance with regulatory requirements and provide traceability.

Safety Procedures: Strict safety procedures are mandatory to prevent accidents and protect personnel. This includes safe handling of chemicals, proper equipment operation, and emergency response plans.

Data Integrity: Maintaining data integrity is vital. This involves ensuring accuracy, reliability, consistency, and traceability of all data collected during bioreactor operation.

Specific regulations vary by region (e.g., FDA in the US, EMA in Europe) and may be further defined based on the product being manufactured.

Q 20. How do you ensure the integrity of bioreactor systems?

Ensuring the integrity of bioreactor systems is paramount for safety, product quality, and regulatory compliance. This is achieved through a multi-faceted approach:

Regular Inspection and Maintenance: Proactive preventative maintenance, as discussed earlier, is essential. This includes regular visual inspections, calibration checks, and cleaning and sterilization to detect and address potential issues promptly.

Leak Detection: Implementing leak detection systems and regularly checking for leaks are crucial to prevent contamination and ensure the integrity of the system.

Sterility Assurance: Stringent sterilization procedures (SIP) are required to eliminate microbial contamination. This includes validation of the sterilization process to ensure its effectiveness.

Material Selection: Choosing biocompatible materials resistant to corrosion and degradation is critical. Materials must withstand the harsh conditions within the bioreactor and prevent leaching of contaminants.

Sensor Integrity: Regular calibration and validation of sensors are essential to guarantee the accuracy of measurements. Faulty sensors can lead to suboptimal process conditions and compromise product quality.

Operator Training: Well-trained operators are crucial in maintaining system integrity through adherence to SOPs and the ability to identify and respond appropriately to potential issues.

For example, a regular pressure test can help detect even small leaks in the system, preventing significant issues later.

Q 21. Explain your understanding of bioreactor process validation.

Bioreactor process validation is a critical aspect of demonstrating that the bioreactor system and process consistently produce a product that meets predetermined quality attributes. This involves a rigorous process to ensure regulatory compliance and product safety.

Process Development: This initial phase focuses on defining the critical process parameters (CPPs) that significantly influence product quality. These parameters are carefully identified and controlled through the validation process.

Equipment Qualification (EQ): This involves demonstrating that the equipment is fit for its intended purpose. It encompasses Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ).

Process Validation: This stage demonstrates that the manufacturing process consistently delivers a product of the desired quality. This often involves conducting multiple runs under different conditions to confirm robustness and reliability.

Documentation: Detailed documentation is critical, including protocols, results, deviations, and reports. This forms part of the regulatory submission and ensures traceability and compliance.

Continuous Monitoring: Ongoing monitoring of the process is essential to maintain consistent performance. This includes tracking critical parameters and investigating any deviations.

Process validation is like baking a cake with a recipe. You need to demonstrate that the same recipe, when followed properly, consistently yields a cake of the desired quality. Any deviation from this recipe needs to be investigated and understood.

Q 22. What software or systems are you familiar with for bioreactor monitoring and control?

My experience encompasses a wide range of bioreactor monitoring and control software and systems. I’m proficient in using systems like Biostat B-Twin, Applikon’s Biocontroller, and GE’s Xcellerex systems. These systems allow for real-time monitoring of critical parameters such as pH, dissolved oxygen (DO), temperature, agitation speed, and foam levels. Beyond hardware-specific systems, I’m also comfortable working with SCADA (Supervisory Control and Data Acquisition) systems, which provide a centralized platform for monitoring and controlling multiple bioreactors simultaneously. These often integrate with data historians for long-term trend analysis. Furthermore, I’ve utilized software for data analysis and process optimization, including MATLAB and Excel with relevant add-ins for statistical analysis and modeling of bioprocess data.

For example, during a recent project involving the production of a monoclonal antibody, the Biostat B-Twin system provided invaluable real-time data, enabling immediate adjustments to the DO level through automated control loops. This prevented any oxygen limitation that could have negatively affected cell growth and product yield. In another instance, I used MATLAB to analyze historical data from a fermentation run to identify correlations between nutrient feeding strategies and final product titer, informing future process improvements.

Q 23. Describe your experience with cell line development and selection for bioreactor applications.

Cell line development and selection are critical for successful bioreactor applications. My experience involves the entire process, from initial cell line screening and cloning to stable cell line generation and characterization. I am familiar with various techniques, including: limiting dilution cloning, flow cytometry for sorting cells based on specific markers, and transfection methods for introducing desirable genes.

Once a candidate cell line is identified, rigorous characterization is essential. This includes evaluating growth characteristics in different media formulations, assessing product yield and quality, and evaluating the cell line’s robustness to various stresses (e.g., temperature fluctuations, pH changes). We typically perform small-scale bioreactor cultivations to assess scalability and optimize culture conditions before proceeding to larger-scale production.

For instance, in a past project producing a recombinant protein, we screened numerous clones, eventually selecting one with superior growth characteristics, high product yield, and stable expression. We subsequently optimized its growth media and performed several rounds of adaptation in increasingly larger bioreactors before finally achieving a robust and efficient production process.

Q 24. How do you manage waste from bioreactor operations?

Waste management in bioreactor operations is crucial from both environmental and regulatory perspectives. We adhere to strict protocols to ensure safe and responsible disposal. The type of waste management strategy depends on the specific nature of the bioprocess and the regulatory requirements in place. Generally, our approach involves several key steps:

- Neutralization and inactivation: This is the first step in treating the cell culture broth, often involving the addition of chemicals to neutralize the pH and inactivate any potentially infectious agents. This is particularly important when working with mammalian cells or pathogens.

- Solid-liquid separation: The cell debris and other solid components are separated from the liquid effluent through processes like centrifugation or filtration. This helps concentrate the waste and makes further processing more efficient.

- Wastewater treatment: The liquid effluent undergoes further treatment to reduce the concentration of organic matter and other potentially harmful substances before being safely discharged according to local regulations. This might involve techniques like anaerobic digestion or activated sludge treatment.

- Hazardous waste disposal: Any hazardous waste, such as contaminated filters or used media components, is disposed of according to established safety regulations and often through specialized waste disposal companies.

Proper documentation and record-keeping of all waste streams and disposal methods are crucial for compliance with environmental regulations and maintaining traceability.

Q 25. What are your experiences with different types of media and feed strategies?

My experience spans various media types and feed strategies tailored to different cell lines and products. For instance, I’ve worked with both chemically defined media and complex media formulations, depending on the cell line’s nutritional requirements. Chemically defined media offer greater consistency and reproducibility but can sometimes be more expensive. Complex media, such as those supplemented with serum, often support better cell growth but introduce potential batch-to-batch variability.

Feed strategies are also crucial for optimizing cell growth and product yield. I’ve employed various strategies, including: fed-batch cultivation (where nutrients are added incrementally throughout the cultivation), continuous cultivation (where nutrients are continuously supplied while removing waste products), and perfusion cultures (similar to continuous cultivation, but with cell retention). The choice of strategy depends on factors such as cell line characteristics, product formation kinetics, and process economics. For example, in a fed-batch process, we might use glucose as a limiting substrate and carefully control its feeding rate to maintain optimal cell growth and avoid byproduct formation. The selection of the feed strategy requires a strong understanding of cell metabolism and careful modeling.

Q 26. Describe your problem-solving approach when dealing with unexpected events during a bioreactor run.

My approach to problem-solving during unexpected bioreactor events is systematic and data-driven. It involves a series of steps:

- Immediate Assessment: The first step is to quickly and accurately assess the situation. What parameter is deviating from the setpoint? What is the magnitude of the deviation? Is the deviation trending? Is it affecting other parameters?

- Data Analysis: Review the bioreactor data to identify potential causes. Are there any trends in the data that precede the event? Are there any correlations between different parameters?

- Hypothesis Generation: Based on the data analysis, formulate hypotheses about the root cause of the problem. Consider factors like contamination, sensor malfunctions, media issues, or equipment failure.

- Verification and Validation: Test the hypotheses by performing appropriate investigations. This might involve taking samples for analysis, checking sensor calibrations, inspecting equipment, or running simulations.

- Corrective Action: Once the root cause is identified, take appropriate corrective actions to mitigate the problem and restore the bioreactor to normal operating conditions. This may involve adjusting process parameters, replacing equipment, or modifying the culture strategy.

- Root Cause Analysis (RCA): After resolving the issue, perform a thorough RCA to understand the underlying causes and prevent similar events from recurring in the future. This is often done by a team to ensure a comprehensive view of the issue.

For example, in one instance, an unexpected drop in pH was traced back to a faulty sensor. This was verified through calibration and replacement of the sensor, demonstrating the importance of systematic problem-solving.

Q 27. Explain your understanding of aseptic processing and contamination control in bioreactors.

Aseptic processing and contamination control are paramount in bioreactor operations. Contamination can compromise product quality, yield, and even lead to safety risks. My approach emphasizes prevention through stringent procedures and proactive monitoring. This includes:

- Facility design: The bioreactor facility must have a design that minimizes the risk of contamination. This includes features like controlled airflows, HEPA filters, and dedicated access zones to limit the introduction of contaminants.

- Equipment sterilization: All equipment that comes into contact with the bioreactor or cell culture should be thoroughly sterilized using methods like autoclaving, gamma irradiation, or other appropriate techniques.

- Media preparation: Media preparation is usually performed under strict aseptic conditions using sterile filtration and validated procedures.

- Aseptic techniques: Strict aseptic techniques are followed during all aspects of bioreactor operation, including inoculation, sampling, and harvesting, minimizing the risk of microbial contamination.

- Environmental monitoring: Regular environmental monitoring is carried out to detect the presence of any contaminants. This includes sampling air, surfaces, and equipment.

- Real-time monitoring: Real-time monitoring of critical parameters like pH, DO, and temperature helps detect deviations that might indicate contamination.

In addition to these preventative measures, we have established robust procedures for handling suspected contamination, including isolation of the affected bioreactor, thorough investigation, and appropriate remediation steps. Consistent training and adherence to established standard operating procedures (SOPs) is key to maintaining an aseptic environment.

Key Topics to Learn for Bioreactor Operation and Maintenance Interview

- Sterilization Techniques: Understanding and applying various sterilization methods (e.g., steam-in-place, autoclaving) for bioreactor components and media preparation. Practical application includes troubleshooting sterilization failures and ensuring sterility throughout the process.

- Bioreactor Control Systems: Mastering the principles of automated bioreactor control, including pH, temperature, dissolved oxygen, and foam control. Practical application involves interpreting sensor data, troubleshooting system malfunctions, and adjusting control parameters to optimize cell growth and product yield.

- Cell Culture and Fermentation Principles: A solid understanding of microbial physiology, growth kinetics, and metabolic pathways relevant to bioreactor processes. Practical application includes selecting appropriate media formulations, monitoring cell growth and productivity, and identifying and resolving culture-related issues.

- Sensor Calibration and Maintenance: Proficiency in calibrating and maintaining various sensors (pH, DO, etc.) to ensure accurate and reliable data acquisition. This includes understanding the principles of sensor operation and troubleshooting common sensor malfunctions.

- Troubleshooting and Problem Solving: Developing a systematic approach to troubleshooting common bioreactor operational issues. This includes analyzing process data, identifying potential causes of deviations, and implementing corrective actions.

- Good Manufacturing Practices (GMP): Familiarity with GMP principles and their application in bioreactor operations. Practical application includes maintaining accurate records, adhering to safety protocols, and ensuring compliance with regulatory requirements.

- Cleaning and Sanitation Procedures: Understanding and applying effective cleaning and sanitation procedures to prevent contamination and ensure bioreactor integrity. This includes selecting appropriate cleaning agents and validating cleaning efficacy.

- Preventive Maintenance: Developing and implementing a preventive maintenance program to minimize downtime and extend the lifespan of bioreactor equipment. This includes scheduling routine inspections, replacements, and repairs.

Next Steps

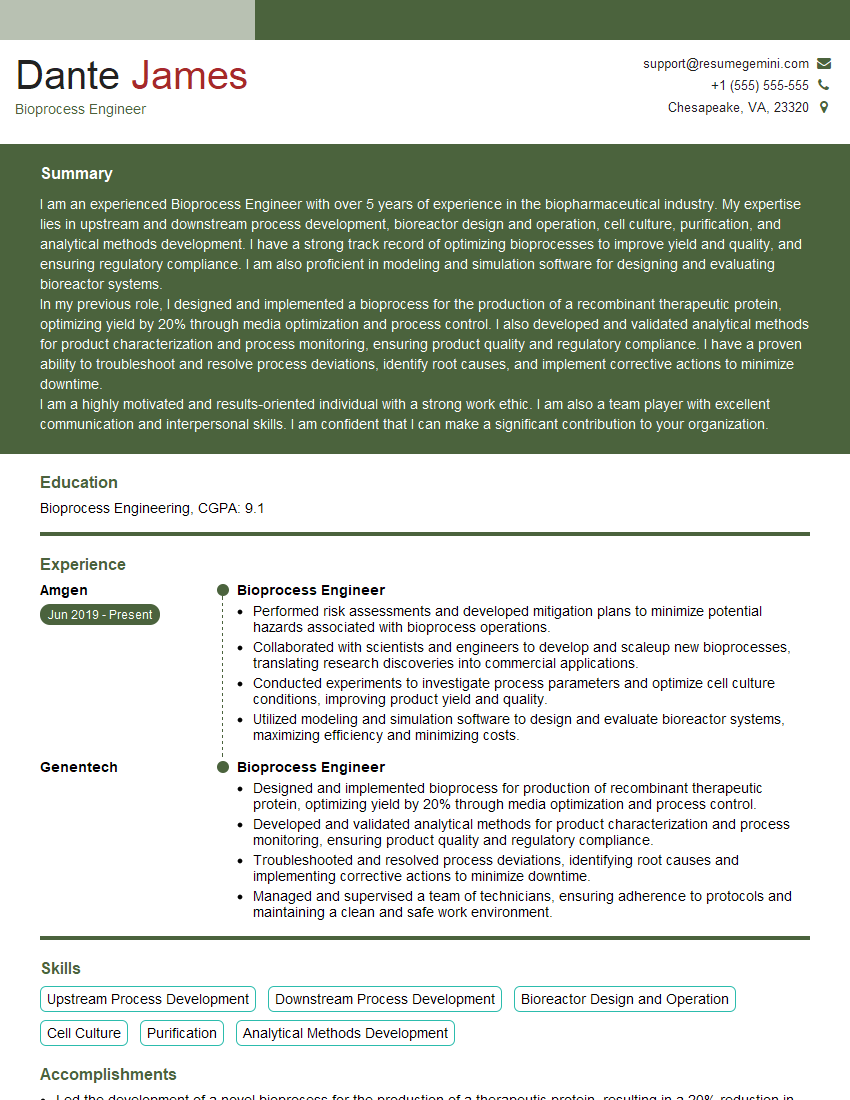

Mastering Bioreactor Operation and Maintenance opens doors to exciting and rewarding careers in the biotechnology and pharmaceutical industries. To maximize your job prospects, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience. We provide examples of resumes specifically designed for Bioreactor Operation and Maintenance professionals to help you get started. Invest time in creating a strong resume – it’s your first impression on potential employers!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent a social media marketing agency that creates 15 engaging posts per month for businesses like yours. Our clients typically see a 40-60% increase in followers and engagement for just $199/month. Would you be interested?”

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?