Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Garage Door Automation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Garage Door Automation Interview

Q 1. Explain the different types of garage door openers.

Garage door openers come in several varieties, each with its own strengths and weaknesses. The most common types are:

- Chain Drive Openers: These are the most traditional and often the most affordable. They use a metal chain to lift and lower the door. They’re durable but can be noisy.

- Belt Drive Openers: Quieter than chain drive openers, these use a reinforced rubber belt. They are gentler on the door and mechanisms and tend to be longer-lasting.

- Screw Drive Openers: These utilize a threaded steel rod to lift the door. They are known for their strong lifting power and quiet operation.

- Direct Drive Openers: The motor is directly connected to the door’s trolley, eliminating the need for a chain, belt, or screw. They’re very quiet and offer smooth, precise operation, but typically are the most expensive option.

The best type for you will depend on your budget, the weight of your garage door, and your desired noise level. For instance, a heavier garage door might require a screw drive or direct drive opener for reliable operation.

Q 2. Describe the safety features of modern garage door openers.

Modern garage door openers prioritize safety. Key features include:

- Safety Sensors (Infrared Beams): These are located near the bottom of the garage door’s tracks and prevent the door from closing if an object is in its path. If the beam is broken, the door will reverse immediately.

- Rolling Code Technology: This makes it nearly impossible for thieves to clone your remote and open your garage door. Each time you use the remote, a new code is transmitted.

- Automatic Reverse System: If the door encounters any obstruction while closing, it will automatically reverse to prevent damage or injury.

- Force Sensing Technology: The opener is programmed to stop or reverse if it detects excessive force, protecting both the door and the mechanism.

- Emergency Release Cord: This allows you to manually disconnect the opener from the door in case of power failure or malfunction. This is essential for being able to open or close the garage door even when the power is out.

These features work together to create a safe and reliable garage door system, minimizing the risk of accidents and security breaches.

Q 3. How do you troubleshoot a garage door that won’t open or close?

Troubleshooting a garage door that won’t open or close requires a systematic approach. First, check the power supply: is the opener plugged in and is the circuit breaker working? Then:

- Check the Remote: Try different remotes, or try using the wall-mounted button if your system has one.

- Inspect the Safety Sensors: Clean the lenses of any debris, and ensure they are aligned properly. The light should shine uninterrupted between the sensors.

- Examine the Tracks: Ensure that the tracks are clean, free of debris and properly aligned. Bent or damaged tracks can prevent the door from moving smoothly.

- Check the Springs and Cables: (Caution: This step is potentially dangerous; if you’re uncomfortable, call a professional.) Loose, broken, or frayed springs and cables should be repaired or replaced by a qualified technician. Never attempt this repair yourself unless you have experience.

- Check the Limit Switches: These switches tell the opener where to stop. Incorrectly set limit switches can cause the door to stop prematurely or travel too far.

- Listen for Unusual Noises: Grinding or squealing noises may indicate worn-out parts needing attention.

If the problem persists, contact a qualified garage door technician.

Q 4. What are the common causes of garage door opener malfunctions?

Many factors can cause garage door opener malfunctions. Some common culprits include:

- Worn-out Parts: Over time, components like the chain, belt, motor gears, and springs can wear out, leading to reduced performance or complete failure.

- Power Issues: A tripped circuit breaker, blown fuse, or power outage can prevent the opener from working.

- Faulty Remote Control: Dead batteries or a damaged remote can impede operation.

- Misaligned Tracks: Bent or damaged tracks can prevent the door from moving correctly.

- Problems with Safety Sensors: Obstructed or misaligned safety sensors will cause the door to stop or reverse.

- Broken Springs: Broken springs are extremely dangerous. The extreme tension can cause serious injury. Call a professional immediately if you suspect broken springs.

- Motor Failure: The opener’s motor may burn out due to age or excessive strain.

Regular maintenance, including lubrication of moving parts and inspection of components, can help prevent many of these malfunctions.

Q 5. Explain the process of installing a new garage door opener.

Installing a new garage door opener is a moderately involved process. It’s best to consult the manufacturer’s instructions for your specific model, but the general steps are:

- Disconnect the Old Opener: Disconnect the power and detach the old opener from the door.

- Mount the New Opener: Securely mount the new opener to the garage ceiling or wall, ensuring it’s level and properly supported.

- Attach the Trolley and Rail: Connect the trolley to the garage door and attach the rail to the opener.

- Install the Safety Sensors: Position the safety sensors on either side of the door’s path, following manufacturer guidelines for proper alignment.

- Connect the Power: Plug in the opener and restore power.

- Program the Remote Controls: Follow the instructions in the owner’s manual to program your remotes to operate the new opener.

- Test the Opener: Carefully test the opener several times to ensure it functions correctly and that all safety features are working properly.

Always prioritize safety throughout the installation process. If you’re not comfortable performing this installation yourself, hire a qualified professional. Improper installation can compromise safety and void warranties.

Q 6. How do you program a remote control for a garage door opener?

Programming a garage door opener remote varies depending on the brand and model. Most openers use either ‘learn’ or ‘dip switch’ methods. Check your opener’s manual for precise instructions. Generally, the process involves:

- ‘Learn’ Method: Locate the ‘learn’ button on the opener’s motor housing. Press and hold the button, then press the button on your new remote. The opener may flash a light indicating it has learned the code.

- Dip Switch Method: These remotes have tiny switches that you set to match a code printed on the opener’s motor. Set the switches accordingly, then test the remote.

If you encounter problems, consult your owner’s manual. Some openers require a specific sequence of actions to program remotes.

Q 7. Describe the different types of garage door sensors and their functions.

Garage door systems typically utilize several types of sensors:

- Safety Sensors (Infrared): These are the most critical sensors. They use infrared light beams to detect obstructions in the door’s path. If the beam is interrupted, the door stops and reverses to prevent accidents.

- Limit Switches: These mechanical switches tell the opener when to stop moving the door, either in the open or closed position. They ensure that the door doesn’t travel too far in either direction.

- Force Sensors: Some advanced openers use force sensors to detect excessive resistance or strain during door operation. This helps protect the door and opener from damage.

- Pressure Sensors (in some models): These sensors are less common but monitor the pressure on the door itself, potentially adding another layer of safety.

Regular inspection and cleaning of these sensors are important for maintaining the safety and proper functioning of your garage door system.

Q 8. How do you diagnose and repair problems with garage door sensors?

Diagnosing and repairing garage door sensor issues starts with understanding their purpose: they’re safety devices that prevent the door from closing on obstacles. A common problem is misalignment or obstruction. I begin by visually inspecting the sensors – those little infrared eyes mounted on either side of the door opening.

- Check for Obstructions: Anything blocking the sensor’s path, like toys, debris, or even a thin layer of dust, can disrupt the infrared beam. I carefully clear the path.

- Verify Alignment: The sensors need to be perfectly aligned for the infrared beam to connect. I check if they are level and facing each other directly. Sometimes, a slight adjustment is all that’s needed. I use a small level for precision.

- Test the Connection: I check the wiring connecting the sensors to the opener. Loose or damaged wires can interrupt the signal. I ensure that the wiring is securely connected and undamaged.

- Test the Sensors: Many openers have a test button. Pressing this button should initiate a test; the LED on each sensor should light up and remain lit when the sensors are properly aligned. If they don’t, I identify and resolve any issues based on the observations.

- Replace if Necessary: If the sensors are severely damaged or beyond repair, replacement is the only solution. This involves disconnecting the old sensors, correctly wiring the new ones, and verifying proper functionality.

For example, I once had a case where a spiderweb had subtly obstructed the sensor beam, causing intermittent malfunctions. Once I removed the web, the problem was instantly solved, highlighting the importance of thorough visual inspection.

Q 9. Explain the importance of regular maintenance for garage door openers.

Regular maintenance for garage door openers is crucial for safety, longevity, and smooth operation. Just like a car needs regular servicing, a garage door opener requires periodic attention to prevent costly repairs and ensure reliable functionality.

- Lubrication: Moving parts like hinges, rollers, and tracks benefit from regular lubrication. This reduces friction, noise, and wear, extending the lifespan of the components. I recommend using a silicone-based lubricant.

- Tightening Bolts and Screws: Over time, vibrations and use can loosen fasteners. Regularly checking and tightening them prevents components from coming loose or causing safety hazards.

- Cleaning: Dust and debris can accumulate in the tracks and motor housing, hindering performance. Cleaning these areas with a brush or compressed air helps ensure smooth operation.

- Inspecting Springs and Cables: Garage door springs and cables are under high tension. Regularly checking them for signs of wear, fraying, or breakage is paramount to preventing serious accidents or malfunctions. Professional inspection is crucial for this aspect.

- Checking Sensors and Safety Mechanisms: Ensuring the safety sensors and reversing mechanisms are functioning properly is crucial for safety. Regular tests and adjustments are essential.

- Battery Replacement (for remote controls): Weak batteries can result in unreliable operation. Replacing the batteries in remote controls periodically ensures consistent access to the garage.

Regular maintenance not only prevents costly repairs, it also reduces the risk of accidents. A well-maintained system operates more efficiently and quietly, providing years of trouble-free use.

Q 10. What are the safety precautions you take when working with garage door openers?

Safety is my top priority when working with garage door openers. These are powerful machines with potential hazards. My precautions include:

- Disconnecting Power: Before any work, I always disconnect the power to the opener – this prevents accidental activation. I don’t rely solely on the opener’s power switch; I switch off the breaker at the electrical panel.

- Supporting the Door: Before working on springs or cables, I securely support the door with appropriate equipment to prevent sudden drops, which can cause injury or damage. This often involves using a sturdy ladder or other supports.

- Using Proper Tools: I only use tools appropriate for the job and in good working condition. This helps prevent injuries and ensures efficient work.

- Wearing Protective Gear: Safety glasses, gloves, and closed-toe shoes are essential to protect against potential hazards like falling debris or sharp objects.

- Following Manufacturer Instructions: Always consulting and adhering to the manufacturer’s instructions for the specific model of opener is paramount. This ensures that all safety guidelines are followed.

- Awareness of High-Tension Springs: I am extremely cautious when working near garage door springs due to their immense potential energy. I utilize specialized tools and techniques to safely manage them.

A simple oversight can lead to serious injury. My safety protocols are not merely guidelines but a fundamental part of my professional practice.

Q 11. Describe your experience with different brands of garage door openers.

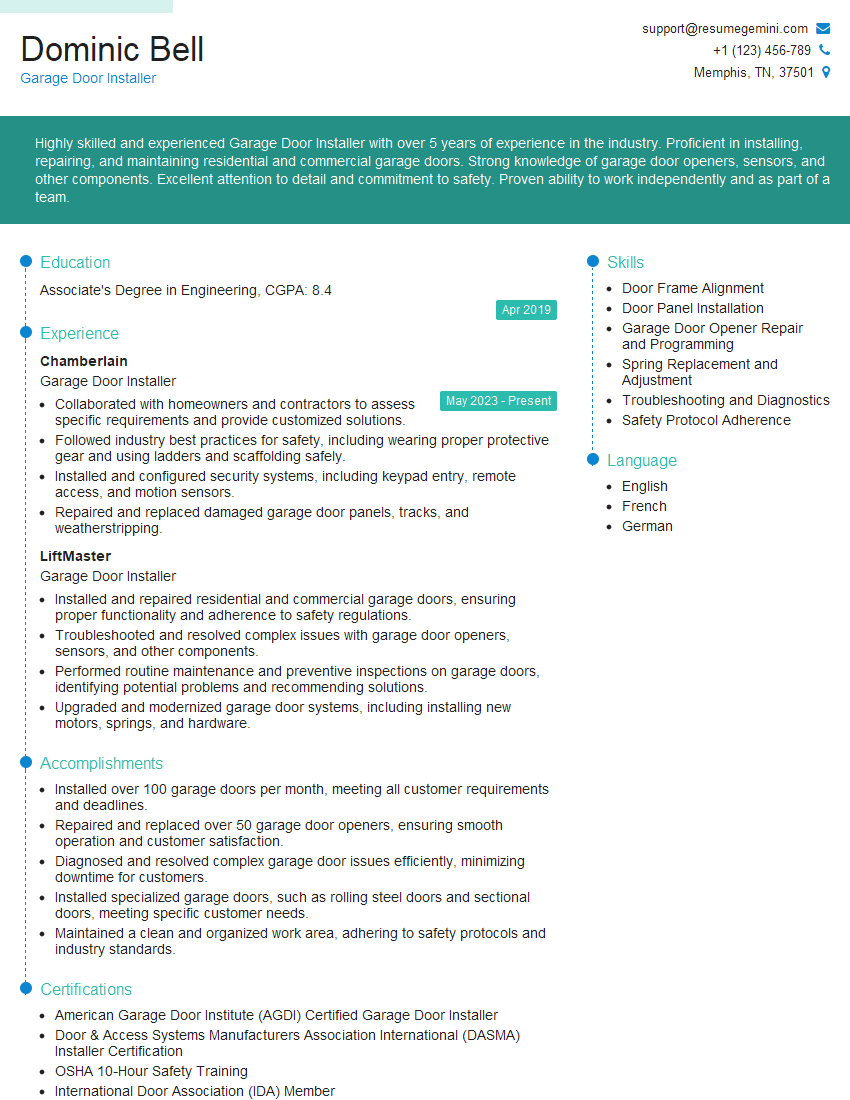

I have extensive experience with various garage door opener brands, including Chamberlain, LiftMaster, Genie, Craftsman, and others. Each brand has its own design nuances, features, and troubleshooting procedures.

- Chamberlain/LiftMaster: These brands often share similar designs and components, making troubleshooting relatively straightforward. I’m very familiar with their safety sensors and logic boards.

- Genie: Genie openers frequently utilize different motor designs and control systems, requiring a slightly different approach to diagnostics and repair.

- Craftsman: Craftsman openers often utilize a range of components from various manufacturers, which means my troubleshooting needs to be adaptable to different systems.

My experience encompasses both belt-driven and chain-driven openers, direct-drive systems, and various control methods. This broad exposure allows me to quickly identify problems regardless of the brand or model.

For example, I recently repaired a complex issue with a Genie Intellicode opener which involved diagnosing a faulty control board. My experience with different brands’ nuances helped me diagnose the problem efficiently.

Q 12. How do you handle customer complaints about garage door openers?

Handling customer complaints involves a systematic approach focused on understanding the issue, providing a solution, and ensuring customer satisfaction.

- Active Listening: I begin by carefully listening to the customer’s description of the problem without interruption. I aim to understand their concerns fully.

- Gathering Information: I ask clarifying questions to gain a complete understanding of the situation, including the symptoms, the frequency of the problem, and any relevant history.

- Troubleshooting: I apply my diagnostic skills to identify the root cause. This may involve remote troubleshooting via phone or an on-site visit.

- Providing Solutions: Once the issue is identified, I clearly explain the necessary repairs or adjustments and provide a transparent cost estimate. I always offer multiple options if applicable.

- Following Up: After the repair, I follow up with the customer to ensure their satisfaction and address any remaining concerns. Positive feedback is essential for my reputation.

I aim to turn a negative experience into a positive one by providing prompt, efficient, and professional service. A satisfied customer is the best advertisement.

Q 13. Explain the process of repairing a broken garage door spring.

Repairing a broken garage door spring is extremely dangerous and should only be attempted by experienced professionals. The springs are under immense tension, and a sudden release can cause serious injury or death. I strongly advise against DIY repairs.

The process involves:

- Safety First: Completely disconnect the power to the garage door opener. Use proper safety equipment, including gloves and eye protection.

- Assess the Damage: Carefully inspect the broken spring to determine the type (extension or torsion) and the extent of damage.

- Secure the Door: Use appropriate methods to securely support the garage door, preventing it from falling unexpectedly.

- Remove the Broken Spring: This involves carefully releasing the tension from the spring using specialized tools, gradually reducing the pressure to prevent sudden releases. This step is crucial and requires advanced knowledge and experience.

- Install the New Spring: Using the appropriate tools and techniques, carefully install the new spring, ensuring it is properly tensioned and aligned.

- Test and Adjust: After installation, carefully test the door’s operation, checking for proper balance and smooth movement.

Incorrect installation can lead to malfunctions, damage, and serious injuries. Improper tension could cause the spring to snap unexpectedly, posing significant risks.

Q 14. How do you replace a broken garage door cable?

Replacing a broken garage door cable is another task requiring expertise and caution, due to the high tension involved.

The process includes:

- Safety Precautions: Just like with spring repairs, completely disconnect the power to the opener and take all necessary safety measures including securing the door to prevent it from falling.

- Assess the Damage: Inspect the broken cable to identify the location and extent of the break.

- Release Tension: Carefully release the tension on the cable using specialized tools, taking precautions to prevent sudden snaps or releases.

- Remove the Broken Cable: Remove the damaged cable from the drums and pulleys.

- Install the New Cable: Carefully feed the new cable through the tracks and pulleys, ensuring proper alignment and tension. This typically involves adjusting the drums to maintain the correct tension.

- Test and Adjust: Test the door’s operation to ensure smooth movement and proper alignment. Re-tensioning may be required.

Incorrect cable installation can lead to malfunctions, potential damage, and create significant safety risks. This is not a DIY task, always call a professional!

Q 15. What are the different types of garage door tracks and how do they work?

Garage door tracks are the crucial pathways guiding the door’s movement. There are primarily two types: standard and high-lift.

- Standard Tracks: These are the most common, featuring a curved track at the top, enabling the door to fold upwards and park neatly under the ceiling. Think of it like a gentle ‘S’ curve. This is great for standard ceiling heights.

- High-Lift Tracks: Designed for higher ceilings or situations where you need more vertical clearance beneath the door when it’s open. These tracks are generally straighter, allowing the door to travel further upwards. Imagine a more vertical ‘U’ shape. This helps prevent a low-hanging garage door from obstructing vehicles or equipment.

Both track types operate on a simple principle: rollers attached to the door run along the track, guided by the track’s shape. The opener’s motor then pulls the door along the track, up or down, via a cable and drum system. Regular lubrication of the tracks and rollers is essential for smooth, quiet operation and to prevent damage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting and repairing various garage door components.

Troubleshooting and repairing garage doors involves a systematic approach. My experience spans addressing issues across a wide range of components. For example, a common problem is a noisy door, often stemming from worn rollers or a misaligned track. I’d diagnose this by inspecting the rollers for wear and tear, checking the track alignment using a level, and then adjusting or replacing components as needed.

Another frequent issue involves opener malfunctions. These can range from simple power supply problems (checking fuses, circuit breakers, and power connections) to more complex motor or sensor failures, requiring specialized testing equipment to identify the root cause. I’m experienced in working with various opener brands and models, from Chamberlain and LiftMaster to more niche brands.

In one memorable case, a client experienced sudden stopping mid-cycle. After systematic checks, I discovered a damaged limit switch, preventing the opener from sensing the door’s fully open/closed positions. A quick replacement restored full functionality. This highlights the importance of thoroughly examining all potential causes before jumping to conclusions.

Q 17. How familiar are you with different types of garage door materials (wood, aluminum, etc.)?

My familiarity with garage door materials is extensive. I’ve worked with numerous types:

- Wood: Offers a classic, customizable aesthetic but requires regular maintenance (painting, sealing) to prevent weather damage and rot. I understand the importance of choosing the right type of wood and finishes for longevity.

- Aluminum: Durable, lightweight, and resistant to rust. It’s a popular choice for its low maintenance requirements, though it can dent more easily than steel.

- Steel: The most common material due to its strength, affordability, and resistance to damage. Steel doors can be insulated for better energy efficiency.

- Fiberglass: Offers good insulation and is relatively lightweight, but can be more susceptible to scratches and dents than steel.

Understanding the properties of each material is crucial for choosing the right door for a specific climate and application, along with offering appropriate maintenance advice.

Q 18. Explain your understanding of the electrical systems associated with garage door automation.

Garage door automation relies on a relatively simple, yet critical, electrical system. Typically, it involves a 120-volt AC power supply that feeds the garage door opener’s motor and control circuitry. Safety mechanisms are a top priority.

The system uses a series of safety sensors (photoelectric eyes) that detect any obstacles in the door’s path, halting operation to prevent accidents. These sensors work by emitting and receiving infrared light beams. If the beam is broken, the door reverses. The opener also incorporates a limit switch system that determines the fully open and fully closed positions of the door. These switches are crucial for the opener’s proper operation and safety.

I’m proficient in diagnosing electrical faults, including wiring issues, faulty sensors, motor problems, and power supply defects. I also understand the importance of working with electricity safely, always following relevant safety regulations and using appropriate safety equipment.

Q 19. What experience do you have with installing and configuring Wi-Fi enabled garage door openers?

I have significant experience installing and configuring Wi-Fi enabled garage door openers. This involves more than just plugging it in. It includes understanding the opener’s specific networking protocols (typically utilizing a proprietary app or integrating with smart home ecosystems like Alexa or Google Home).

The process involves connecting the opener to the home’s Wi-Fi network, often requiring an in-depth understanding of router settings, network security, and troubleshooting network connectivity issues. I also help clients understand the security implications, like setting strong passwords and enabling two-factor authentication where available. I’m familiar with different brands and their associated apps, and I can guide clients through the setup process, ensuring seamless integration with their smart home systems.

A recent installation involved a client who had trouble connecting their new MyQ-enabled opener to their 5GHz network. After troubleshooting, we discovered the opener only supported 2.4GHz. Switching to the 2.4GHz network resolved the issue promptly, illustrating the importance of checking compatibility specifications.

Q 20. How do you handle emergency calls for malfunctioning garage doors?

Emergency calls require a rapid and efficient response. My protocol involves first gathering information about the problem: Is the door stuck open or closed? Are there any sounds or unusual behaviors? This helps me prioritize the response and determine the necessary tools and equipment.

Once onsite, I systematically assess the situation. This could range from a simple power outage (easily resolved by checking the circuit breaker or power cord) to more complex mechanical or electrical failures. I prioritize safety first – ensuring the area is secured and the door is stabilized if needed. I work efficiently to diagnose the problem and implement the necessary repairs or temporary solutions, aiming to restore functionality as quickly and safely as possible.

I understand the urgency clients feel with a malfunctioning garage door, especially when it affects accessibility or security. Therefore, my communication style is calm and reassuring, keeping the client updated on my progress throughout the process.

Q 21. Describe your experience working with different types of garage door security systems.

Garage door security systems range from basic keypad entry systems to more advanced integrated security systems. I’m familiar with various types, including:

- Keypad Entry: Offers a simple and convenient way to control access using a personalized code.

- Remote Control Openers: Utilize radio frequency signals to open and close the door from a distance. I’m familiar with the rolling code technology that enhances security by preventing code duplication.

- Smart Home Integration: Modern openers integrate with smartphone apps and smart home systems, offering remote access and control, along with features like notifications and scheduling.

- External Security Sensors: These can integrate with broader home security systems to monitor the garage door’s status and trigger alerts in case of unauthorized access.

Understanding the strengths and weaknesses of each system is crucial in advising clients on the best solution to meet their needs and security concerns. I emphasize the importance of regularly changing codes and keeping security systems updated with the latest firmware to protect against vulnerabilities.

Q 22. What software or diagnostic tools are you familiar with in relation to garage door automation?

Diagnosing and repairing garage door automation systems often involves specialized software and diagnostic tools. My experience encompasses a range of technologies, including:

Manufacturer-Specific Software: Most major brands like LiftMaster, Chamberlain, and Genie provide proprietary software for their openers, often used for programming remotes, configuring settings (like force limits and auto-close delays), and accessing diagnostic codes. For instance, the MyQ app allows remote monitoring and control of compatible garage door openers.

Multimeters: These are essential for checking voltage levels, continuity, and current in the electrical circuits of the opener. I use them routinely to identify short circuits, faulty wiring, and problems with the motor’s power supply.

Logic Analyzers (in complex cases): For advanced troubleshooting of digital control boards, a logic analyzer can help decipher signals and pinpoint problems within the opener’s microcontroller.

Understanding how these tools work together allows for a comprehensive diagnosis and efficient repair. For example, if a garage door opener doesn’t respond to the remote, I’d first check the remote’s battery, then use a multimeter to verify power at the opener, and finally resort to the manufacturer’s software to check for error codes within the opener’s control system.

Q 23. How do you ensure compliance with relevant safety regulations when working on garage doors?

Safety is paramount in garage door automation. Compliance with regulations like those set by UL (Underwriters Laboratories) and local building codes is non-negotiable. My approach includes:

Regular Inspections: Before any work, I meticulously inspect the entire system, paying close attention to the opener’s safety features (like the force-reversal mechanism that prevents injury if something obstructs the door), the door’s balance, and the condition of the tracks and springs. Any potential hazards are addressed first.

Proper Use of Safety Equipment: I always wear safety glasses, gloves, and appropriate footwear. When working with springs, I use specialized tools designed to safely manage their tension, avoiding potential injury from sudden release.

Adherence to Manufacturer’s Instructions: Each opener and door system has specific safety instructions; I religiously follow these guidelines during installation, repair, or maintenance.

Force Testing: After repairs, I perform a thorough force test to ensure the door opens and closes smoothly without exceeding safe force limits. This is critical to prevent accidental injury or damage.

Ignoring safety procedures can lead to serious accidents. A real-world example is incorrectly adjusted spring tension which could cause the door to fall unexpectedly, posing a significant risk. Therefore, I prioritize adherence to best practices and safety standards above all else.

Q 24. Explain your experience with different types of garage door drive mechanisms (belt drive, chain drive, etc.)?

I have extensive experience with various garage door drive mechanisms. Each type has its own advantages and disadvantages:

Chain Drive: The most common and typically the most affordable. They are durable and powerful but can be noisy. Regular lubrication is crucial to minimize noise and wear.

Belt Drive: Quieter and smoother operation than chain drives, offering a more refined experience. They are typically more expensive but provide a longer lifespan with less maintenance. The belts themselves can degrade over time, requiring replacement.

Screw Drive: These openers use a threaded rod to lift the door. They provide very smooth and quiet operation but are typically the most expensive and are more complex to repair.

Direct Drive: A newer technology where the motor is directly connected to the door, eliminating the need for chains, belts, or screws. They’re known for their quietness and efficiency.

The choice of drive mechanism depends on factors like budget, noise tolerance, and desired longevity. In my work, I assess the client’s needs and recommend the best option for their specific circumstances. For example, a client concerned about noise would be better served with a belt or direct drive opener.

Q 25. How would you diagnose a garage door that is making unusual noises?

Unusual noises from a garage door are often indicative of a problem. My diagnostic process is systematic:

Identify the Source: Is the noise coming from the opener motor, the tracks, the rollers, or the springs?

Visual Inspection: I carefully examine the entire system, looking for loose parts, damaged rollers, bent tracks, or worn-out components. A visual check often reveals the culprit.

Listen Closely: Different sounds indicate different problems. A grinding noise might suggest worn rollers or tracks. A squeaking noise might indicate dry rollers or hinges. A loud bang might signify a problem with the springs.

Test Operation: I operate the door manually and with the opener to pinpoint the exact moment the noise occurs. This helps isolate the faulty component.

Lubrication Test: Sometimes, the problem is simply insufficient lubrication. Applying lubricant to moving parts can often resolve minor noise issues.

For example, a loud clicking noise often points to a problem with the limit switches which need adjustment. Through careful observation and testing, I can accurately diagnose the issue and recommend appropriate repairs.

Q 26. What are the common issues associated with older garage door systems?

Older garage door systems often present unique challenges. Common issues include:

Worn Springs: Over time, garage door springs lose their tension, making the door difficult to open or close, or causing it to become unbalanced.

Damaged Rollers and Tracks: These components wear down from constant use, causing noise, binding, and potentially derailment.

Faulty Limit Switches: These switches regulate the door’s opening and closing positions. Failure can lead to the door not opening or closing fully or stopping unexpectedly.

Outdated Openers: Older openers often lack modern safety features and may be less reliable.

Electrical Issues: Wiring can degrade or become damaged over time, causing intermittent operation or complete failure.

When dealing with older systems, a thorough inspection is critical. I prioritize safety when working with older, potentially less robust springs and components. Replacing outdated parts with newer, safer versions is often necessary to improve both performance and safety.

Q 27. Describe your experience with troubleshooting and repairing issues related to remote access systems for garage doors.

Troubleshooting and repairing remote access systems for garage doors involves a multi-step approach:

Connectivity Issues: I check the Wi-Fi signal strength, router configuration, and the opener’s network connection. Many issues stem from poor internet connectivity or network configuration problems. Sometimes, simply restarting the router resolves the issue.

App Problems: If the problem is with the mobile app (like MyQ), I verify the app version and look for updates. Sometimes, a corrupted app cache requires reinstallation.

Openers Firmware: Outdated firmware on the garage door opener can also cause compatibility problems. Updating the opener’s software is a key troubleshooting step.

Security Concerns: I address security concerns by ensuring the system uses strong passwords and is updated regularly with the latest security patches. If a security breach is suspected, I guide the homeowner on securing their system.

Hardware Malfunctions: If the problem persists, I may need to inspect the opener’s internal components (circuit boards, antennas) to look for hardware failures that might require repair or replacement.

For example, if a homeowner reports intermittent connectivity, I start by checking the network signal strength and router logs. If the problem persists, I’d then check the opener’s network settings and possibly update the firmware. A systematic, step-by-step approach helps efficiently isolate and solve the problem.

Q 28. How do you stay updated on the latest advancements and technologies in garage door automation?

Staying updated in the rapidly evolving field of garage door automation is crucial. My strategies include:

Industry Publications and Websites: I regularly read trade magazines and online resources focusing on garage door technology and automation. This keeps me informed about new products, safety regulations, and industry best practices.

Manufacturer Training: I participate in training programs offered by major garage door opener manufacturers. These programs often cover new products, troubleshooting techniques, and updated safety protocols.

Professional Organizations: Membership in professional organizations provides access to continuing education, networking opportunities, and industry insights. This allows me to stay abreast of advancements and exchange information with other professionals.

Online Courses and Webinars: I take advantage of online courses and webinars that offer in-depth training on specific technologies and repair techniques.

Continuous learning is essential. The industry is constantly innovating, from smart home integration to improved safety features and more energy-efficient motors. Staying current ensures I can offer my clients the best possible service and solutions.

Key Topics to Learn for Your Garage Door Automation Interview

- Safety Mechanisms and Regulations: Understanding the critical safety features in garage door openers, including photoelectric sensors, force-limiting technology, and compliance with relevant safety standards (e.g., UL 325).

- Drive Mechanisms and Motors: Familiarize yourself with different types of motors used in garage door automation (e.g., chain drive, belt drive, screw drive), their operational principles, and troubleshooting common motor issues.

- Control Systems and Programming: Learn about the different control systems (e.g., wall-mounted keypads, remote controls, smart home integration) and their programming aspects. Understanding how to troubleshoot programming errors will be valuable.

- Troubleshooting and Maintenance: Develop your ability to diagnose and repair common problems, such as malfunctioning sensors, broken springs, or faulty wiring. Knowing preventative maintenance procedures is also crucial.

- Installation and Setup Procedures: Be prepared to discuss your experience (if any) with installing and setting up garage door openers, including considerations for proper alignment, balance, and safety.

- Smart Home Integration: Understand how garage door openers integrate with smart home ecosystems (e.g., Amazon Alexa, Google Home), including the protocols and communication methods used.

- Power Supply and Electrical Considerations: Be familiar with the electrical requirements for garage door openers, including voltage, amperage, and wiring configurations. Understanding potential electrical hazards is essential.

- Common Issues and Solutions: Prepare to discuss common problems encountered in garage door automation and demonstrate your problem-solving skills by outlining effective solutions.

Next Steps

Mastering garage door automation opens doors to exciting career opportunities in a growing industry. Demonstrating a comprehensive understanding of these systems is key to securing your dream role. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to the Garage Door Automation field to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?