Are you ready to stand out in your next interview? Understanding and preparing for Operation of Optical Measurement Equipment interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Operation of Optical Measurement Equipment Interview

Q 1. Explain the principle of operation of an interferometer.

An interferometer works on the principle of wave interference, specifically the superposition of light waves. Imagine dropping two pebbles into a still pond; the resulting ripples overlap, creating areas of constructive and destructive interference. An interferometer does the same with light waves. A beam of light is split into two (or more) paths, and these beams travel different distances before being recombined. If the path lengths differ by an integer multiple of the wavelength, the waves constructively interfere, producing a bright fringe. If the path difference is a half-integer multiple of the wavelength, they destructively interfere, producing a dark fringe. By analyzing the resulting interference pattern, we can precisely measure changes in path length, which translates to extremely accurate measurements of distance, displacement, or refractive index.

For example, a Michelson interferometer splits a beam using a partially reflective mirror, sends the two beams along separate paths, and then recombines them. Any change in the distance of one arm relative to the other alters the interference pattern, allowing for highly sensitive displacement measurements – down to fractions of a wavelength of light! This principle is used in applications ranging from measuring surface roughness to detecting gravitational waves.

Q 2. Describe the different types of optical microscopes and their applications.

Optical microscopes magnify images for observation of small structures. Several types exist, each with its own strengths and applications:

- Brightfield Microscopes: These are the most common type. They illuminate the sample from below, and the image is formed by the light transmitted through the specimen. They are simple to use and suitable for general observation of stained samples.

- Darkfield Microscopes: These illuminate the sample from the side, so only light scattered by the specimen reaches the objective lens. This makes transparent specimens appear bright against a dark background, highlighting fine details otherwise invisible. It’s ideal for observing unstained, live microorganisms.

- Phase-Contrast Microscopes: These enhance the contrast of transparent specimens by converting phase shifts in the light waves passing through the sample into amplitude variations, making details like cell membranes clearly visible. They are frequently used in biology to study living cells without staining.

- Fluorescence Microscopes: These use fluorescent dyes or proteins to label specific structures within the sample. The sample is excited with a specific wavelength of light, and the emitted fluorescence light is collected to form the image. They are invaluable in cell biology, immunology, and other life science disciplines for visualizing specific molecules or structures.

- Confocal Microscopes: These use a pinhole to eliminate out-of-focus light, resulting in sharper, higher-resolution images of thick samples. They are widely used in various fields, including biology, materials science, and medicine.

The choice of microscope depends entirely on the application. For example, a brightfield microscope might suffice for observing a stained tissue sample, while a confocal microscope would be necessary for imaging the detailed 3D structure of a cell.

Q 3. How do you calibrate an optical power meter?

Calibrating an optical power meter involves comparing its readings to a known standard. This typically involves using a traceable calibrated source, often a calibrated laser diode or LED with a precisely known power output. The process usually involves:

- Connecting the Standard: Connect the calibrated light source to the optical power meter input.

- Reading the Reference Value: Record the power reading displayed by the meter.

- Adjusting (if necessary): Many power meters have calibration adjustments. Compare the meter reading with the known power of the standard. If a deviation exists, adjust the meter according to the manufacturer’s instructions to achieve agreement.

- Repeating Measurements: Repeat the measurement multiple times to ensure consistency and reduce random errors. A typical calibration involves numerous measurements at different power levels.

- Documentation: Thoroughly document all calibration steps, including the date, time, standard used, and the obtained calibration results.

The frequency of calibration depends on factors such as meter usage, environmental conditions, and the required accuracy. It’s crucial to follow the manufacturer’s recommendations for proper calibration procedures and frequency. A properly calibrated power meter ensures reliable and accurate measurements of optical power in various applications, such as telecommunications and optical sensing.

Q 4. What are the common sources of error in optical measurements?

Optical measurements are prone to various errors. These can be broadly categorized as:

- Environmental Factors: Temperature fluctuations, air currents, and vibrations can significantly affect the stability and accuracy of measurements.

- Source Instability: Variations in the power or wavelength of the light source can introduce errors. This is especially true for lasers with poor stability.

- Detector Noise: Electronic noise in the detector can lead to random fluctuations in the readings. Dark current in detectors needs to be considered and corrected for.

- Alignment Errors: Imperfect alignment of optical components can lead to significant losses and inaccurate measurements. This is critical in interferometry and microscopy.

- Scattering and Absorption: Scattering and absorption of light by the medium through which it travels (e.g., air, optical fibers) can attenuate the signal and lead to errors.

- Calibration Errors: Inaccurate or outdated calibration of equipment is a major source of systematic error.

Minimizing these errors requires careful experimental design, the use of stable and well-characterized equipment, environmental control (temperature stabilization, vibration isolation), and proper calibration procedures. For instance, using an enclosed measurement setup can reduce the influence of air currents. Employing error correction algorithms can mitigate some of the effects of detector noise.

Q 5. Explain the concept of optical resolution and its limitations.

Optical resolution refers to the ability of an optical system to distinguish between two closely spaced objects. It’s fundamentally limited by the diffraction of light. When light passes through an aperture (like the lens of a microscope or telescope), it doesn’t form a perfect point image; instead, it spreads out due to diffraction, creating an Airy disk – a central bright spot surrounded by concentric rings. Two points will appear resolved only if their Airy disks are sufficiently separated. The Rayleigh criterion, a common rule of thumb, states that two points are resolved when the center of one Airy disk falls on the first minimum of the other.

This diffraction limit sets a fundamental constraint on resolution. It’s inversely proportional to the numerical aperture (NA) of the optical system and the wavelength of light. Higher NA and shorter wavelengths lead to better resolution. Techniques like super-resolution microscopy have pushed beyond this diffraction limit by using clever methods to circumvent the fundamental limitations, such as stimulated emission depletion (STED) or photoactivated localization microscopy (PALM).

Q 6. How do you ensure the accuracy and precision of optical measurements?

Ensuring the accuracy and precision of optical measurements demands a multifaceted approach:

- Proper Calibration: Regular and traceable calibration of all equipment is paramount. This establishes a known relationship between the instrument readings and the true values.

- Environmental Control: Maintaining stable temperature, humidity, and minimizing vibrations reduces environmental influences.

- Careful Alignment: Precise alignment of optical components is crucial to minimize signal loss and ensure accurate measurements.

- Statistical Analysis: Performing multiple measurements and using statistical methods to analyze the data help to identify outliers and estimate uncertainties.

- Error Correction: Implementing algorithms to correct for known sources of error, like detector noise or scattering, improves accuracy.

- Traceable Standards: Using traceable standards and calibration certificates establishes the link to internationally recognized standards.

- Appropriate Methodology: Choosing an appropriate measurement technique for the specific task is crucial. For example, using interferometry for high precision displacement measurements.

An example is in fiber optic communication where precise power measurements are needed. A combination of calibrated power meters, temperature-controlled environments, and statistical analysis of multiple measurements ensures reliable data for network performance monitoring and optimization.

Q 7. Describe your experience with different types of optical sensors.

My experience encompasses a wide range of optical sensors, including:

- Photodiodes: These are semiconductor devices that convert light into an electrical current. I’ve used them extensively for power measurements in optical communications and spectroscopy. Their response time and sensitivity vary significantly depending on the specific type.

- Photomultiplier Tubes (PMTs): These are highly sensitive detectors capable of measuring extremely low light levels. I’ve applied them in fluorescence microscopy and single-photon counting experiments. Their high gain comes at the cost of higher noise and increased complexity.

- Optical Fiber Sensors: These utilize changes in light propagation through an optical fiber to measure various physical parameters like temperature, strain, or pressure. I have experience with both extrinsic and intrinsic fiber optic sensors, understanding their advantages and limitations in different applications.

- Position Sensitive Detectors (PSDs): These sensors provide a precise measurement of the position of a light spot, enabling high-accuracy position tracking in applications like beam steering and optical alignment. I’ve worked with them in precision motion control systems.

Each sensor type has unique characteristics in terms of sensitivity, dynamic range, response time, and cost. The choice of sensor depends heavily on the specific application requirements. For instance, while PMTs excel in low-light conditions, photodiodes might be more appropriate for higher-intensity measurements.

Q 8. How do you troubleshoot common issues with optical equipment?

Troubleshooting optical equipment involves a systematic approach. First, I’d identify the symptom – is the output signal weak? Are there artifacts in the image? Is the equipment not powering on? Then, I’d move to a checklist approach.

- Check the basics: Power supply, connections (fiber optic cables, electrical connectors), and any external controls or software settings. A loose cable or incorrect setting can often be the culprit.

- Inspect the optical path: Look for any obvious damage, misalignment, or contamination (dust, fingerprints) on lenses, mirrors, or other optical components. A tiny speck of dust can severely impact image quality.

- Calibrate the system: Many optical instruments require regular calibration to ensure accuracy. Following the manufacturer’s instructions for calibration is essential. This might involve using reference standards or alignment procedures.

- Check for error messages: Modern instruments often have built-in diagnostics and display error messages. Understanding these messages is critical for rapid troubleshooting.

- Utilize diagnostic tools: Many systems have built-in test modes or provide access to detailed sensor readings. These can help pinpoint the exact source of the issue.

- Consult documentation: The manufacturer’s manuals usually contain extensive troubleshooting sections and diagrams.

- Seek expert help: If the problem persists after attempting these steps, it’s time to contact the equipment manufacturer or a qualified service technician.

For instance, I once worked on a system where a seemingly small misalignment in the laser beam resulted in significant measurement errors. Careful adjustment using alignment tools quickly solved the problem.

Q 9. What safety precautions should be taken when operating optical measurement equipment?

Safety is paramount when working with optical measurement equipment. The specific precautions depend on the type of equipment, but here are some general guidelines:

- Eye protection: Always wear appropriate laser safety eyewear when operating laser-based systems. The eyewear must be rated for the specific laser wavelength and power level. Never look directly into the beam.

- Laser safety training: Operators should receive proper training on laser safety procedures and regulations.

- Proper handling: Handle optical components carefully, avoiding scratches or contamination. Use lint-free cloths and appropriate cleaning solutions.

- High voltage: Some equipment utilizes high-voltage power supplies. Ensure proper grounding and isolation to prevent electric shock.

- Radiation safety: Some systems might involve other forms of radiation (e.g., UV, X-rays) requiring specialized safety protocols and protective gear.

- Environmental controls: Maintain a clean and stable environment to avoid vibrations or temperature fluctuations that could affect measurement accuracy.

- Emergency procedures: Be familiar with emergency shutdown procedures and reporting protocols.

Ignoring these precautions could lead to serious injury, such as eye damage or electric shock. Safety is non-negotiable.

Q 10. Explain the difference between precision and accuracy in optical measurements.

Precision and accuracy are crucial concepts in optical measurements, but they’re distinct. Think of it like archery:

- Accuracy refers to how close a measurement is to the true value. In archery, this is how close your arrows land to the bullseye.

- Precision refers to how close repeated measurements are to each other. In archery, this is how closely grouped your arrows are, regardless of whether they hit the bullseye.

A measurement can be precise (arrows tightly grouped) but inaccurate (far from the bullseye), or it can be accurate (arrows hitting near the bullseye) but imprecise (arrows scattered). Ideally, we want both high accuracy and high precision. In optical metrology, precision might be affected by factors like instrument noise or repeatability, while accuracy might depend on proper calibration and environmental factors.

Q 11. How do you interpret data obtained from optical measurement equipment?

Interpreting data from optical measurement equipment involves several steps:

- Data visualization: First, visualize the data using appropriate graphs, charts, or images. This often provides initial insights.

- Statistical analysis: Analyze the data using statistical methods to determine the mean, standard deviation, and other relevant parameters. This helps quantify precision and identify outliers.

- Error analysis: Account for potential sources of error, such as instrument noise, environmental factors, or limitations of the measurement technique. This crucial step helps to assess the uncertainty of the measurements.

- Comparison to standards: Compare the measurements to known standards or reference values whenever possible. This helps to assess accuracy and identify any systematic errors.

- Data validation: Evaluate the plausibility of the results. Do they make sense given the expected behavior of the system under study?

- Report generation: Finally, prepare a comprehensive report detailing the measurement process, the obtained results, the error analysis, and the conclusions.

For example, if we’re measuring the diameter of a fiber optic, we might use statistical methods to determine the average diameter and the standard deviation to express the uncertainty in the measurement.

Q 12. Describe your experience with data analysis software used in optical metrology.

I have extensive experience with various data analysis software packages commonly used in optical metrology. These include:

- MATLAB: A powerful tool for signal processing, image analysis, and statistical analysis. I’ve used it extensively for analyzing interferometric data, processing images from microscopes, and developing custom algorithms for data reduction.

- LabVIEW: I have used LabVIEW for instrument control, data acquisition, and visualization, particularly when working with complex optical systems that require real-time data processing.

- Python with scientific libraries (NumPy, SciPy, Matplotlib): Python’s versatility and extensive libraries make it an excellent choice for a wide range of data analysis tasks in optical metrology. I have used it extensively for custom data processing and automation of analytical workflows.

- Commercial software packages specific to certain instruments: Many manufacturers provide dedicated software packages for their optical instruments. I am proficient in using such software packages to analyze data from specific equipment.

My proficiency extends beyond simple data analysis to include developing custom algorithms and scripts for automated data processing and analysis to improve efficiency and reduce human error.

Q 13. What is the significance of wavelength in optical measurements?

Wavelength is fundamental in optical measurements because it dictates the interaction of light with matter. Different wavelengths of light are absorbed, reflected, refracted, or scattered differently by materials. This property is exploited in various optical measurement techniques:

- Spectroscopy: Analysis of how a material interacts with light at different wavelengths to identify its composition.

- Interferometry: Uses the interference of light waves of a specific wavelength to measure distances or surface profiles with high precision.

- Colorimetry: Measurement of color using specific wavelengths of light, important in many industrial and scientific applications.

- Optical microscopy: Choosing appropriate wavelengths (e.g., UV for fluorescence microscopy) allows visualization of specific features or structures in a sample.

For example, in interferometry, the accuracy of the measurement is directly tied to the stability and precision of the wavelength of the light source. A laser with an unstable wavelength would lead to unreliable measurements.

Q 14. Explain the concept of diffraction and its impact on optical measurements.

Diffraction is the bending or spreading of light waves as they pass through an aperture (opening) or around an obstacle. This phenomenon is a consequence of the wave nature of light and has significant implications for optical measurements:

- Resolution limits: Diffraction limits the resolution of optical systems. It sets a fundamental limit on how finely we can distinguish between two closely spaced objects. The smaller the aperture, the more pronounced the diffraction.

- Image blurring: Diffraction causes blurring and spreading of light in optical images, particularly at the edges of objects.

- Diffraction gratings: Diffraction gratings, with precisely ruled grooves, are used to separate light into its constituent wavelengths (spectroscopy). The spacing of the grooves determines the diffraction pattern.

- Measurement error: In precision measurements, diffraction effects must be taken into account and potentially corrected for. This is particularly relevant in microscopy, interferometry, and other high-resolution techniques.

For instance, when trying to measure the width of a very fine fiber using a microscope, diffraction effects will limit the accuracy of the measurement, leading to an uncertainty that cannot be entirely eliminated.

Q 15. How do you handle outliers or anomalies in your optical measurement data?

Handling outliers in optical measurement data is crucial for ensuring the accuracy and reliability of results. My approach involves a multi-step process. First, I visually inspect the data using scatter plots and histograms to identify potential outliers – these are data points significantly deviating from the overall trend. Then, I employ statistical methods. A common technique is to calculate the standard deviation and identify points falling outside a pre-defined number of standard deviations from the mean (e.g., three standard deviations). Another approach is using robust statistical measures like the median absolute deviation (MAD), which is less sensitive to outliers than the standard deviation.

If an outlier is deemed a genuine error (e.g., due to a malfunctioning sensor or environmental interference), it’s removed from the dataset. However, I carefully document the removal and justify the decision. If the outlier is suspected to be a valid, albeit unusual, measurement, I investigate the source. This may involve re-checking the experimental setup, reviewing the calibration records, and potentially repeating the measurement. In some cases, outlier detection algorithms, such as Grubbs’ test or the Chauvenet’s criterion, can be used to more formally assess the probability of a point being an outlier. Finally, I always compare the results obtained with and without the outliers to evaluate the impact of their removal on the overall conclusions. For instance, if removing a single outlier drastically changes the calculated refractive index, further investigation is warranted.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of optical fibers and their characteristics.

My experience encompasses various optical fiber types, including single-mode and multi-mode fibers, as well as specialty fibers like polarization-maintaining fibers and photonic crystal fibers. Single-mode fibers, characterized by a core diameter small enough to support only one propagation mode, are ideal for long-distance communication due to their low dispersion and attenuation. Multi-mode fibers, with larger core diameters supporting multiple modes, are generally used for shorter distances and where higher bandwidth isn’t critical. The trade-off is their higher dispersion, which can limit their transmission capabilities at longer distances.

Polarization-maintaining fibers are crucial in applications requiring maintaining a specific polarization state, like interferometry or optical sensing. Their special design prevents polarization mixing during transmission. Photonic crystal fibers, with their unique periodic structure, offer remarkable properties like enhanced nonlinearity, tailored dispersion, and capabilities for guiding light in unusual ways, making them useful for a broad range of specialized applications such as supercontinuum generation and sensing.

I’ve worked extensively with the characterization of these fibers, measuring their attenuation, dispersion, and modal properties using specialized equipment like optical spectrum analyzers, optical time-domain reflectometers (OTDRs), and polarization controllers. Understanding their distinct characteristics is vital for optimizing system performance in different applications.

Q 17. How do you perform alignment procedures for optical systems?

Precise alignment is paramount in optical systems. The approach varies depending on the system’s complexity and the components involved. For simpler systems involving collimated beams and lenses, I use techniques like spatial filtering, adjusting the lens position to achieve a minimum beam diameter at the focal plane, and optimizing for a clean, circular spot profile. I frequently use techniques like knife-edge scanning to verify beam profile and alignment. Visual inspection with a beam profiler camera is also important. For more complex systems, like interferometers or optical microscopes, I use precision alignment stages with micrometric adjustments and often rely on automated alignment procedures guided by a computer.

In interferometry, for example, I initially align the optical components using a combination of visual inspection and an initial auto-alignment algorithm. Then, I fine-tune the system iteratively by monitoring the interferogram and optimizing fringe contrast and shape. This often involves adjustments to mirror positions, beam splitters, and other components with sub-micron precision. During this process, I make use of feedback loops based on sensor information to actively minimize errors and achieve optimal interference conditions. Laser power optimization also plays an important part to avoid saturation of detectors and ensure accurate signal acquisition.

Q 18. What are the advantages and disadvantages of different optical measurement techniques?

Various optical measurement techniques exist, each with its advantages and disadvantages. For example, interferometry offers extremely high precision and resolution, perfect for measuring small displacements or surface roughness but can be sensitive to environmental vibrations and requires careful alignment. Spectroscopy, on the other hand, is well-suited for analyzing the spectral content of light sources, allowing the identification of materials based on their absorption or emission characteristics. However, the spectral resolution may be limited by the instrument’s capabilities.

Techniques like ellipsometry excel in measuring thin film thickness and optical constants, while scattering techniques can be used to characterize particle size distributions. The choice of technique depends on the specific application and measurement requirements. For example, for measuring the refractive index of a liquid, refractometry might be the ideal technique due to its speed and ease of operation. But if very high precision is needed, interferometry or ellipsometry might be preferred. Factors to consider include the accuracy, precision, cost, measurement time, required expertise, and sensitivity to environmental factors.

Q 19. Explain your experience with different types of optical filters.

My experience includes a wide range of optical filters, including bandpass, notch, longpass, and shortpass filters. Bandpass filters transmit light within a specific wavelength range while blocking light outside this range. These are crucial for isolating particular spectral lines in spectroscopic measurements. Notch filters, conversely, block a narrow range of wavelengths while transmitting others and are useful for suppressing unwanted spectral lines. Longpass and shortpass filters transmit light above or below a specified cutoff wavelength, respectively; they are used to shape the spectral profile of a light beam.

Beyond these basic types, I’ve also worked with more specialized filters like dichroic filters (reflecting some wavelengths and transmitting others), polarizing filters (transmitting light of a specific polarization), and interference filters (providing higher wavelength selectivity through interference effects). The choice of filter is highly dependent on the application. For instance, in fluorescence microscopy, dichroic filters are essential for separating excitation and emission wavelengths. In astronomy, narrow bandpass filters are used to isolate specific emission lines from celestial objects. Selection involves considering factors like center wavelength, bandwidth, transmission efficiency, and optical density.

Q 20. How do you select the appropriate optical measurement equipment for a specific application?

Selecting appropriate optical measurement equipment requires a thorough understanding of the application’s specific needs. The first step is to clearly define the measurement objective: what parameter needs to be measured, what is the required accuracy and precision, and what is the relevant wavelength range? Next, I consider the sample characteristics: its size, shape, optical properties, and potential environmental factors influencing the measurement. Then, I evaluate the available equipment considering factors like sensitivity, resolution, measurement speed, ease of use, cost, and maintenance requirements. For instance, for high-precision measurements of surface roughness, an interferometric microscope might be necessary, whereas for simple refractive index measurements, a simple Abbe refractometer could suffice.

I might create a table to compare various instruments based on their specifications and capabilities. I then weigh up the trade-offs between different parameters and choose the instrument that best meets the specifications while considering budget constraints and the availability of technical expertise. Often, I consult technical specifications, datasheets, and user manuals before making a decision. In some cases, I conduct proof-of-concept experiments using different instruments to confirm which is optimal for a specific task. Selecting the right equipment is crucial for obtaining accurate, reliable, and efficient measurement results. A well-informed choice minimizes errors, saves time, and optimizes the overall measurement process.

Q 21. Describe your experience with maintaining and repairing optical equipment.

Maintaining and repairing optical equipment requires meticulous care and expertise. Routine maintenance includes regular cleaning of optical components with appropriate cleaning materials to prevent dust and contamination. I always follow the manufacturer’s instructions for cleaning procedures and carefully handle delicate components such as lenses and mirrors. Calibration procedures are carried out regularly using traceable standards to ensure accuracy and reliability. For example, I regularly calibrate power meters and optical spectrum analyzers against certified reference standards. This ensures the measurements remain accurate within the specified tolerances.

Troubleshooting requires a systematic approach. When a malfunction occurs, I start by inspecting the system for obvious problems like loose connections or damaged components. Then, I check the instrument’s logs and error messages for clues. If the problem persists, I might resort to more advanced diagnostic techniques such as analyzing the output signals with an oscilloscope or other diagnostic tools. Repairs may involve replacing damaged components, adjusting alignments, or even performing more complex repairs requiring specialized tools and knowledge. In some cases, I consult service manuals, contact the manufacturer’s support, or call on specialized technicians for advanced repairs. Preventive maintenance significantly reduces downtime and extends the lifespan of the equipment.

Q 22. How do you document and report your optical measurement results?

Documenting and reporting optical measurement results requires a systematic approach to ensure accuracy, traceability, and clarity. My process begins with meticulous data logging during the measurement process itself. This includes recording all relevant parameters like equipment settings (e.g., wavelength, integration time, power levels), environmental conditions (temperature, humidity), and sample identification. I utilize specialized software to collect and process this data, often including automated data acquisition and analysis.

Following data acquisition, I perform a thorough analysis, often involving statistical methods to determine uncertainties and assess data validity. The report itself follows a standardized format, typically including:

- Introduction: Briefly outlining the purpose of the measurement and the methodology employed.

- Methods: Detailed description of the instruments used, their calibration status, and measurement procedure.

- Results: Presentation of the measured data, usually in tabular and graphical format, including error bars representing uncertainties. I use appropriate figures and charts to visualize the data and make key findings readily apparent.

- Analysis: Interpretation of the results in the context of the measurement objectives, highlighting any significant findings and deviations from expected values. This may include calculations derived from the raw data, such as optical density or refractive index.

- Conclusion: Summarizing the key findings and conclusions, often with recommendations for further action or improvements.

- Appendix (if necessary): Includes raw data, calibration certificates, and other supporting documentation for complete transparency and traceability.

All reports are reviewed for accuracy and completeness before distribution to ensure the highest level of professional standards are met. For example, in a recent project involving the characterization of optical fibers, I meticulously documented every step, from fiber preparation to power measurements, ensuring a clear and unambiguous record of the entire process.

Q 23. Explain your familiarity with relevant safety standards and regulations for optical equipment.

Safety is paramount when working with optical equipment, particularly lasers. My familiarity with relevant safety standards and regulations, such as those from ANSI (American National Standards Institute), IEC (International Electrotechnical Commission), and OSHA (Occupational Safety and Health Administration), is comprehensive. These standards cover aspects such as laser safety classification, eye and skin protection, proper equipment handling, and emergency procedures.

I understand the importance of laser safety classes, knowing the potential hazards of different laser types and power levels. I always select appropriate personal protective equipment (PPE), such as laser safety eyewear with the correct optical density (OD) rating, and ensure proper laser enclosure or beam path control measures are implemented. Additionally, I am familiar with the required safety signage and labeling procedures to ensure a safe working environment for myself and others. Before operating any laser system, I thoroughly review the safety manual and perform all necessary safety checks. In my experience, this diligent approach has prevented potential accidents and ensured a safe work environment.

Q 24. What are the key performance indicators (KPIs) for optical measurement systems?

Key performance indicators (KPIs) for optical measurement systems vary depending on the specific application, but some common metrics include:

- Accuracy: How closely the measured values match the true values. This is often expressed as a percentage error or deviation from a known standard.

- Precision: The repeatability and reproducibility of measurements. A system with high precision yields consistent results under similar conditions.

- Resolution: The smallest measurable change in the optical quantity being measured (e.g., wavelength, power, or intensity).

- Sensitivity: The ability to detect small changes in the optical signal.

- Linearity: The consistency of the system’s response across the entire measurement range. A linear response is ideal.

- Stability: The consistency of the system’s output over time, under constant conditions. Drift can significantly impact accuracy.

- Dynamic Range: The range of measurable signals that the system can accurately handle.

- Measurement speed/throughput: Relevant in high-volume applications.

For instance, in a fiber optic characterization application, accuracy in measuring attenuation and dispersion is crucial; while in optical spectroscopy, high resolution is essential for differentiating closely spaced spectral lines. Regular calibration and maintenance of the equipment are critical for maintaining these KPIs within acceptable limits.

Q 25. Describe a time you had to troubleshoot a complex optical measurement issue.

During a project involving the measurement of thin-film optical coatings, we experienced unexpectedly high levels of scattering in our measurements. The initial readings were inconsistent and far from the expected values. The first step involved verifying the equipment calibration and stability. We confirmed that the equipment was functioning correctly by performing a series of control measurements on a known standard sample.

However, the problem persisted. We then systematically investigated potential sources of error. This involved checking for any contamination on the sample surface, ensuring that the sample was properly aligned in the measurement setup, and inspecting the optical components of the measurement system for any defects or misalignment. It turned out that microscopic dust particles, invisible to the naked eye, were causing the unwanted scattering. By implementing a more rigorous cleaning procedure for both the sample and the optical components, using compressed air and isopropyl alcohol, and by working in a cleaner environment, we significantly reduced the scattering and obtained consistent and accurate results. This experience highlighted the importance of thorough investigation and attention to detail when troubleshooting complex optical measurement issues.

Q 26. How familiar are you with statistical process control (SPC) in optical metrology?

Statistical Process Control (SPC) is a crucial aspect of optical metrology, ensuring consistent quality and identifying potential issues before they impact the end product. I am proficient in applying SPC techniques to analyze measurement data and monitor the performance of optical measurement systems.

I utilize control charts, such as Shewhart charts and CUSUM charts, to track measurement data and identify trends, shifts, or outliers that may indicate a process that is going out of control. By monitoring the data in this manner, I can detect issues like equipment drift, changes in environmental conditions, or variations in the quality of the samples being measured. For example, I used control charts in a project involving the production of optical lenses. By continuously monitoring the refractive index measurements, I identified a small but consistent drift in the measurement system. This timely intervention prevented the production of a batch of lenses that would have fallen outside the acceptable tolerance range.

This proactive approach reduces the chances of defective parts and improves overall process efficiency and quality. Furthermore, I understand the principles of capability analysis and process improvement methodologies like Six Sigma, and apply these methods to optimize optical measurement processes and minimize variability.

Q 27. Describe your experience with different types of optical coatings.

My experience encompasses various types of optical coatings, including dielectric, metallic, and hybrid coatings.

Dielectric coatings, typically made of multiple layers of different dielectric materials (e.g., SiO2, TiO2), are used for applications like anti-reflection coatings, high-reflection coatings (mirrors), and beam splitters. I have experience measuring the performance of these coatings using techniques like spectrophotometry to characterize their reflectance and transmittance properties across a range of wavelengths.

Metallic coatings, such as aluminum or gold coatings, are primarily used for their high reflectivity in specific wavelength regions. I understand the differences in reflectivity and conductivity that different metals offer. My work involves evaluating the surface quality, adhesion, and reflectivity of these coatings.

Hybrid coatings combine dielectric and metallic layers to achieve specific optical properties. I’ve also worked with coatings designed for specialized applications such as polarization control, and have the knowledge to properly measure parameters like the extinction ratio.

Understanding the deposition methods used to create these coatings, such as evaporation, sputtering, or sol-gel processing, allows me to interpret the resulting optical properties and assess the quality of the coating. This knowledge is essential for troubleshooting issues and optimizing the coating process for desired performance characteristics.

Q 28. How do you ensure the traceability of your optical measurements?

Ensuring traceability in optical measurements is critical for maintaining accuracy and reliability. This is achieved through a combination of techniques:

- Calibration of equipment: All optical instruments are regularly calibrated against traceable national or international standards (e.g., NIST in the US). I meticulously document calibration dates, results, and the standards used. This is crucial for proving the accuracy of the measurement equipment.

- Standard reference materials (SRMs): Using certified SRMs with known optical properties allows for verification of measurement accuracy and allows for easy cross-checking and inter-comparison of results.

- Chain of custody: Maintaining detailed records of the handling and usage of samples and equipment is essential, ensuring a clear and documented chain of custody from initial measurement to final reporting. This minimizes any chances of misidentification or sample degradation.

- Data management systems: Utilizing appropriate software for data acquisition, processing, and storage allows for easy retrieval and analysis of measurement results. The software used should be validated and documented.

- Documentation: Complete and accurate documentation of all procedures, including calibration, measurements, and data analysis, is crucial for demonstrating traceability and validating the results. Using standardized templates and electronic record-keeping significantly aids in this.

By adhering to these principles, I can ensure the long-term validity and reliability of all optical measurements, and provide robust evidence for the accuracy of our results. This meticulous approach instills confidence in the data’s integrity for both internal and external stakeholders.

Key Topics to Learn for Operation of Optical Measurement Equipment Interview

- Fundamentals of Optics: Understanding principles like reflection, refraction, diffraction, and interference – their impact on measurement accuracy.

- Types of Optical Measurement Equipment: Familiarize yourself with various instruments like interferometers, spectrometers, ellipsometers, and their respective applications (e.g., surface profile measurement, spectral analysis, thin film characterization).

- Calibration and Maintenance Procedures: Learn about proper calibration techniques, routine maintenance tasks, and troubleshooting common issues to ensure accurate and reliable measurements. Understanding the importance of preventative maintenance is crucial.

- Data Acquisition and Analysis: Mastering the process of acquiring data from optical instruments, understanding data formats, and employing appropriate software for data analysis and interpretation.

- Error Analysis and Uncertainty Quantification: Learn to identify and quantify sources of error in optical measurements and understand how to minimize their impact on results. This shows a strong understanding of experimental rigor.

- Safety Procedures and Regulations: Demonstrate knowledge of safety protocols associated with operating optical measurement equipment, including laser safety and proper handling of sensitive components.

- Practical Applications in Specific Industries: Research how optical measurement equipment is used in your target industry (e.g., semiconductor manufacturing, quality control, research and development). Be ready to discuss specific applications relevant to your experience.

- Troubleshooting and Problem-Solving: Be prepared to discuss your approach to diagnosing and resolving issues that may arise during operation and maintenance. Consider common problems and your systematic troubleshooting methodology.

Next Steps

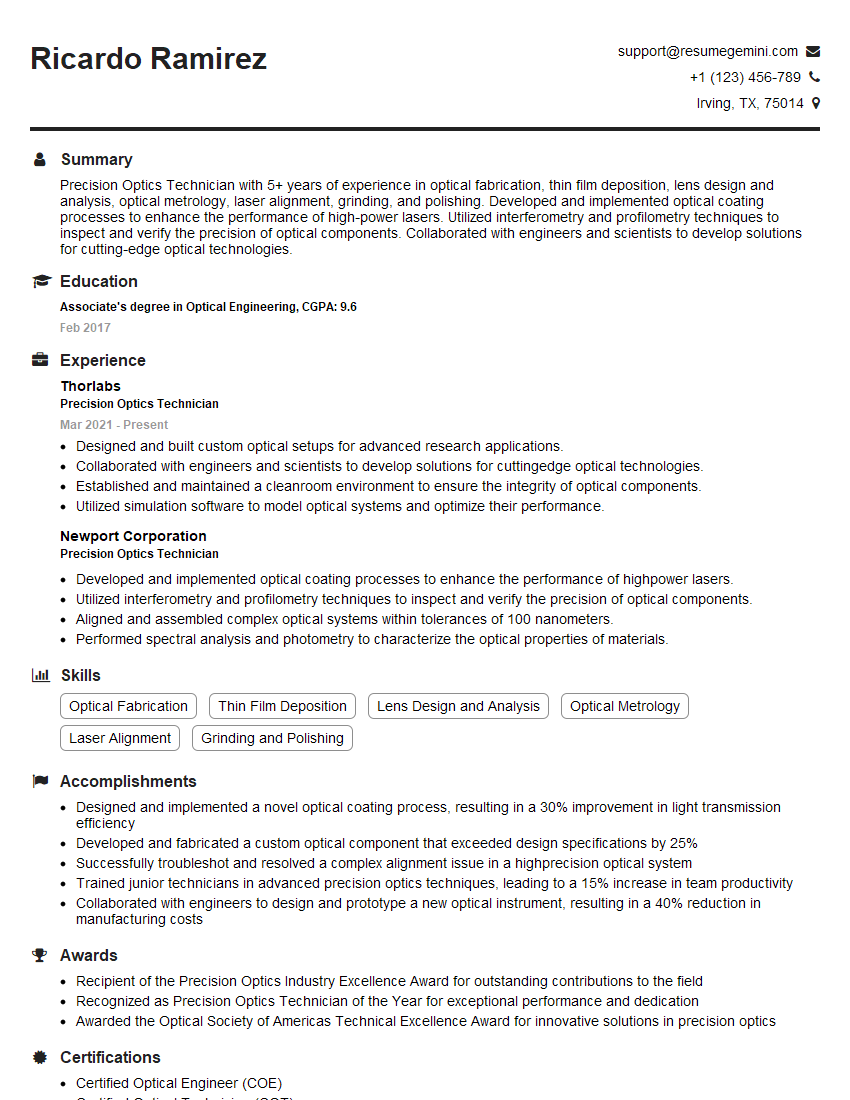

Mastering the operation of optical measurement equipment opens doors to exciting career opportunities in diverse and technologically advanced fields. A strong understanding of these principles is highly valued by employers seeking skilled and reliable technicians and engineers. To significantly enhance your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your capabilities. ResumeGemini provides examples of resumes tailored specifically to roles involving the operation of optical measurement equipment, helping you present your qualifications in the best possible light. Invest time in crafting a compelling resume – it’s your first impression on a potential employer.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?