Cracking a skill-specific interview, like one for OSHA Hazardous Communication, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in OSHA Hazardous Communication Interview

Q 1. What are the key elements of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS)?

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon system designed to ensure consistent classification and communication of chemical hazards worldwide. It aims to reduce confusion caused by differing national systems. Key elements include:

- Classification of Chemicals: GHS provides criteria for classifying chemicals based on their health, environmental, and physical hazards. This involves assigning hazard classes (e.g., flammable, toxic, corrosive) and categories (e.g., acute toxicity Category 1, 2, 3) depending on the severity of the hazard. Think of it like a grading system for chemical dangers.

- Labeling of Chemicals: Standardized labels are required, including pictograms (graphic symbols representing hazards), signal words (danger or warning), hazard statements (describing the nature of the hazard), precautionary statements (advising on how to minimize risks), and supplier identification. The label acts as a quick warning system.

- Safety Data Sheets (SDS): GHS mandates the creation of comprehensive SDSs providing detailed information about the chemical’s properties, hazards, safe handling, storage, and emergency procedures. It’s the detailed instruction manual for a chemical.

For example, a highly flammable liquid would be classified under the Flammable Liquids hazard class and its label would include a flame pictogram, the signal word ‘Danger’, and appropriate hazard and precautionary statements. Its SDS would include detailed information on its flash point, flammability limits, and firefighting procedures.

Q 2. Explain the role of Safety Data Sheets (SDS) in OSHA’s HazCom Standard.

Safety Data Sheets (SDSs) are crucial under OSHA’s HazCom Standard because they provide the detailed information necessary for workers to understand and handle hazardous chemicals safely. They are the central repository of information. The standard mandates that employers provide access to SDSs for all hazardous chemicals in the workplace. Think of the SDS as a comprehensive chemical fact sheet.

Each SDS contains 16 sections, covering topics like chemical identification, hazards identification, composition/information on ingredients, first-aid measures, fire-fighting measures, accidental release measures, handling and storage, exposure controls/personal protection, physical and chemical properties, stability and reactivity, toxicological information, ecological information, disposal considerations, transport information, regulatory information, and other information. This detailed information allows employers and employees to make informed decisions on safe handling, storage, use, and emergency response for hazardous materials.

For instance, an SDS for a corrosive acid would detail its reactivity with other materials, the personal protective equipment (PPE) required for handling, and emergency procedures in case of accidental spills.

Q 3. Describe the requirements for labeling hazardous chemicals under OSHA’s HazCom Standard.

OSHA’s HazCom Standard requires that containers of hazardous chemicals be labeled with specific information to alert workers to potential hazards. Labels must include:

- Product Identifier: The chemical’s name or common name.

- Signal Word: ‘Danger’ (for more severe hazards) or ‘Warning’ (for less severe hazards).

- Hazard Pictograms: Standardized symbols representing specific hazard classes (e.g., flame for flammability, skull and crossbones for acute toxicity).

- Hazard Statements: Descriptions of the chemical’s hazards.

- Precautionary Statements: Instructions on how to handle and use the chemical safely.

- Supplier Identification: Name, address, and contact information of the chemical supplier.

The label must be durable, legible, and located in a prominent position on the container. Labels for secondary containers (i.e., containers filled from a larger container) must also adhere to these requirements. For example, a bottle of concentrated sulfuric acid would have a label with a corrosive pictogram, the signal word ‘Danger’, and appropriate hazard and precautionary statements.

Q 4. How do you determine if a chemical is hazardous under OSHA’s HazCom Standard?

Determining if a chemical is hazardous under OSHA’s HazCom Standard involves considering its classification under the GHS. This involves evaluating whether the chemical meets the criteria defined in the GHS for any of the hazard classes.

Several resources are used to determine hazard classification, including:

- Supplier-provided information: Labels and SDSs are the primary sources, providing classification information determined by the chemical manufacturer or importer.

- Hazard Communication Standard (HCS): The standard itself contains detailed guidelines and criteria for classifying chemicals based on various hazards.

- Other regulatory sources: Other federal, state, or local regulations might provide additional classification information.

- Professional judgment: For complex or novel chemicals, expert chemical assessment may be required.

If a chemical meets the criteria for any hazard class in the GHS, it must be considered hazardous and handled accordingly. The process often requires referring to the SDS and comparing the chemical’s properties to the classification criteria laid out in the GHS. For example, a substance exhibiting a specific flashpoint would be classified as flammable.

Q 5. What are the employer’s responsibilities under OSHA’s HazCom Standard?

Employers have significant responsibilities under OSHA’s HazCom Standard to ensure worker safety. These responsibilities include:

- Develop and implement a written HazCom program: This program outlines procedures for handling hazardous chemicals, including labeling, SDS access, and employee training.

- Obtain and maintain SDSs for all hazardous chemicals: SDSs must be readily accessible to all employees who work with those chemicals.

- Ensure proper labeling of all containers: All containers of hazardous chemicals, both primary and secondary, must be properly labeled.

- Provide employee training: Employees must receive training on the hazards of the chemicals they use, the proper handling procedures, and emergency response.

- Provide appropriate PPE: Employers must provide workers with the necessary personal protective equipment to minimize exposure to hazardous chemicals.

- Maintain records: Employers are required to maintain records related to the HazCom program, including training records and SDS inventories.

Failure to meet these responsibilities can result in significant OSHA penalties and legal liabilities.

Q 6. What are the employee’s rights under OSHA’s HazCom Standard?

Employees have crucial rights under OSHA’s HazCom Standard designed to protect their health and safety. These include:

- The right to know: Employees have the right to access SDSs for all hazardous chemicals they handle. This information empowers them to understand the associated hazards and adopt appropriate safety precautions.

- The right to training: Employees have the right to receive adequate training on the hazards of the chemicals they work with, proper handling procedures, and emergency response actions. This ensures their understanding of potential risks and how to mitigate them.

- The right to a safe workplace: Employers must provide a safe workplace free from unnecessary exposure to hazardous chemicals. This includes appropriate labeling, handling, storage, and protective equipment.

- The right to report hazards: Employees have the right to report any concerns about hazardous chemicals or lack of safety measures without fear of retaliation.

These rights are critical for ensuring a safe and healthy work environment. Employees should actively exercise these rights to ensure their well-being.

Q 7. Explain the importance of employee training in hazardous communication.

Employee training is paramount in effective hazardous communication. It bridges the gap between hazard information and worker safety. Comprehensive training ensures employees understand the risks associated with the chemicals they handle and how to mitigate those risks.

Effective training should cover:

- Hazard identification: How to recognize hazardous chemicals through labels, SDSs, and other means.

- Safe handling procedures: Proper techniques for using, storing, and disposing of hazardous chemicals.

- Emergency procedures: Actions to take in case of spills, leaks, or other emergencies.

- Personal protective equipment (PPE): How to select, use, and maintain appropriate PPE.

- The importance of following all safety rules and regulations: Compliance is key to minimize potential risks.

Regular refresher training is crucial, especially when dealing with new chemicals or changes in procedures. Imagine a scenario where an employee doesn’t know the hazards of a corrosive liquid and accidentally splashes it on their skin—proper training prevents such accidents. Regular training programs help keep employees updated on the latest safety information and procedures, reducing the likelihood of accidents and injuries.

Q 8. Describe the different types of hazards addressed by OSHA’s HazCom Standard.

OSHA’s HazCom Standard addresses a wide range of chemical hazards that can pose risks to employee health and safety. These hazards aren’t limited to just immediately dangerous situations; they encompass a spectrum of potential dangers. Think of it like this: some hazards are like a sudden punch, while others are more like a slow poison. The standard covers:

- Physical Hazards: These are hazards related to the physical properties of a chemical, such as flammability (like gasoline), explosivity (like dynamite), corrosivity (like battery acid), and reactivity (chemicals that can violently react with each other). Imagine working with a highly flammable solvent – a physical hazard is the risk of a fire or explosion.

- Health Hazards: These are hazards related to the chemical’s ability to cause harm through various routes of exposure (inhalation, skin contact, ingestion). Examples include carcinogens (cancer-causing agents), mutagens (agents that cause genetic mutations), reproductive toxins (harming reproductive systems), respiratory sensitizers (causing allergic reactions in the lungs), and many others. Think of asbestos as a classic example of a health hazard due to its carcinogenic properties.

- Environmental Hazards: While not directly focused on employee health, the standard indirectly addresses this by encouraging environmentally responsible handling and disposal of chemicals. This is important for overall safety and compliance.

OSHA’s HazCom Standard aims to ensure employees are aware of all these potential hazards and provided the necessary information and training to work safely with hazardous chemicals.

Q 9. How frequently should SDSs be updated?

SDSs (Safety Data Sheets) must be updated whenever new information becomes available that could affect worker safety. There’s no fixed time interval. Think of it like this: if a new study reveals a previously unknown health hazard associated with a chemical, the SDS needs updating immediately. Manufacturers and importers are responsible for keeping SDSs current, and they often update them when a product formulation changes significantly, or when new toxicology data becomes available. You should always check the revision date on the SDS to confirm its currency. As an employer, it’s crucial to maintain a system for staying updated and replacing outdated SDSs promptly.

Q 10. What is the purpose of a hazard communication program?

The purpose of a hazard communication program is to ensure that employees are informed about the hazardous chemicals they handle and are trained on how to work safely with those chemicals. It’s all about prevention. The program acts as a comprehensive safety net, preventing accidents and injuries through education, proper labeling, and easy access to crucial safety information. Imagine it as a multi-layered approach:

- Training: Employees receive appropriate training on the hazards of the chemicals they use, the proper handling procedures, and emergency response procedures.

- Labeling: All containers of hazardous chemicals are properly labeled in accordance with OSHA standards, including pictograms, signal words, hazard statements, and precautionary statements.

- SDS Access: Employees have ready access to SDSs for every hazardous chemical they handle. A well-organized system must be in place.

- Program Documentation: Detailed records of training, SDS inventory, labeling procedures, and other crucial elements must be maintained.

A robust HazCom program protects employees, improves workplace safety, and demonstrates a commitment to compliance.

Q 11. How do you handle a situation where an SDS is missing or incomplete?

A missing or incomplete SDS is a serious issue because it leaves employees vulnerable. Here’s how you should handle it:

- Identify the Chemical: Determine the exact chemical for which the SDS is missing or incomplete.

- Contact the Supplier: Immediately contact the supplier or manufacturer of the chemical and request a copy of the current SDS. This is the primary source of reliable information.

- Temporary Controls: While waiting for the SDS, implement appropriate temporary controls to minimize exposure to the chemical. This might involve restricting access, providing personal protective equipment, or increasing ventilation.

- Document the Situation: Keep detailed records of your attempts to obtain the SDS, the temporary measures implemented, and the date the SDS was ultimately received.

- Training: Ensure that employees handling the chemical receive the necessary training based on available information. You may need to rely on other sources, but always maintain the highest safety standards.

Never allow employees to handle chemicals without the required SDS information. The absence of crucial information can have major safety consequences.

Q 12. Describe your experience with implementing a HazCom program.

In my previous role at a manufacturing plant, I was responsible for developing and implementing a comprehensive HazCom program from the ground up. This included:

- Chemical Inventory: Conducting a thorough inventory of all hazardous chemicals used in the facility.

- SDS Management: Establishing a system for receiving, updating, and readily accessing SDSs for all identified chemicals. We used a dedicated software system to manage this efficiently.

- Labeling System: Implementing a comprehensive labeling system ensuring all containers are properly labeled according to OSHA requirements. We used standardized labels and trained personnel to ensure consistency and accuracy.

- Employee Training: Developing and conducting comprehensive training programs for all employees, covering the hazards of specific chemicals, proper handling procedures, and emergency response protocols. The training included hands-on demonstrations and assessments.

- Auditing and Updates: Regularly auditing the program for compliance and continuously updating it based on changes in regulations, new chemicals, or new information.

This resulted in a significant reduction in chemical-related incidents and a notable improvement in employee safety awareness and compliance. The program received positive feedback from OSHA during subsequent inspections.

Q 13. Explain the differences between pictograms, signal words, and hazard statements.

These three elements—pictograms, signal words, and hazard statements—work together on a chemical label to convey hazard information clearly and concisely. Think of them as different pieces of a puzzle that form a complete picture of the chemical’s dangers:

- Pictograms: These are standardized symbols that visually represent specific hazards. For example, a flame represents flammability, an explosion represents explosivity, and a skull and crossbones represent acute toxicity. They’re designed to be universally understood, regardless of language.

- Signal Words: These are words that indicate the severity of the hazard. The two signal words used are “Danger” (indicates severe hazard) and “Warning” (indicates less severe hazard). The signal word provides an immediate indication of the hazard level.

- Hazard Statements: These are standardized phrases that describe the specific nature of the hazard. For example, “May cause cancer” or “Causes serious eye irritation.” They provide the specific health, physical, or environmental effects of the chemical.

Together, these elements paint a complete picture of the potential risks associated with a particular chemical.

Q 14. How do you ensure that all employees have access to SDSs?

Ensuring all employees have access to SDSs requires a multi-pronged approach. It’s not enough to just have the SDSs; they need to be easily accessible and understandable. Here’s how I’ve successfully handled this in the past:

- Centralized Location: Maintain a central, easily accessible location for SDSs, such as a dedicated computer or server with appropriate software. This is particularly important for larger companies or those with multiple sites.

- Physical Copies: Keep physical copies readily available in the areas where hazardous chemicals are used. This is especially valuable for employees who may not have regular computer access.

- Digital Access: Provide digital access via a searchable database, a shared network drive, or a dedicated SDS management software. This allows for easy searching and retrieval.

- Training: Train employees on how to access and understand the information provided in SDSs, including how to use the software or search system if applicable.

- Regular Updates: Ensure that SDSs are updated regularly and that employees are aware of the updates.

- Language Considerations: Provide SDSs in the language(s) understood by all employees.

By employing a combination of these methods, you can ensure that all employees have the information they need to work safely with hazardous chemicals.

Q 15. What are the penalties for non-compliance with OSHA’s HazCom Standard?

Penalties for non-compliance with OSHA’s HazCom Standard can be severe and vary depending on the severity and nature of the violation, as well as the employer’s history of compliance. OSHA can issue citations with significant fines, ranging from a few hundred dollars for minor infractions to tens of thousands of dollars for serious or willful violations. These fines can be multiplied if multiple violations are found. Beyond monetary penalties, OSHA can also issue serious or willful violation citations, which severely impact an employer’s safety record and can lead to increased scrutiny in future inspections. In extreme cases, OSHA can even pursue criminal charges, particularly if a violation directly results in a worker’s death or serious injury. For example, a company failing to provide adequate Safety Data Sheets (SDS) or employee training could face thousands of dollars in fines. A willful violation, such as deliberately ignoring a known hazard, could lead to significantly higher penalties and potential criminal prosecution.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you stay current with changes in OSHA’s HazCom Standard?

Staying current with changes in OSHA’s HazCom Standard is crucial for maintaining compliance. I achieve this through a multi-pronged approach. Firstly, I regularly review OSHA’s website, specifically the updates and publications section, for any changes or new interpretations of the standard. Secondly, I subscribe to relevant industry newsletters and publications that provide updates and analysis of OSHA’s regulatory changes. Thirdly, I actively participate in professional development courses and workshops focused on OSHA HazCom, which offer valuable insights from experienced professionals and updates on recent developments. Finally, I maintain a network of contacts within the occupational safety and health field, fostering information sharing and discussions on current best practices. This combined strategy ensures I’m always abreast of the latest requirements and best practices.

Q 17. Describe your experience with auditing HazCom compliance.

My experience with auditing HazCom compliance involves a systematic approach that ensures comprehensive coverage. I begin by reviewing the employer’s written HazCom program, checking for completeness, accuracy, and adherence to OSHA standards. This includes verifying the accuracy of the chemical inventory, reviewing SDSs for completeness and accessibility, and assessing the effectiveness of employee training programs. Next, I conduct on-site observations, examining the workplace for proper labeling of chemicals, storage practices, and the availability of appropriate PPE. I also interview employees to assess their understanding of chemical hazards and their comfort level in handling hazardous materials. Finally, I compile my findings into a detailed report, highlighting any areas of non-compliance and providing recommendations for corrective actions. For instance, in a recent audit, I found a company lacking updated SDSs for several chemicals. This prompted immediate corrective action, preventing potential safety hazards and avoiding costly fines.

Q 18. How do you communicate effectively about chemical hazards to employees with diverse backgrounds?

Communicating effectively about chemical hazards to employees with diverse backgrounds requires a multifaceted strategy focusing on clarity, accessibility, and inclusivity. I utilize various communication methods tailored to the specific needs of the workforce. This includes providing training materials in multiple languages, employing visual aids like diagrams and pictograms, and offering hands-on demonstrations. I also leverage different learning styles, incorporating interactive sessions, question-and-answer periods, and role-playing to engage learners effectively. Crucially, I ensure that the information is presented in a clear and simple manner, avoiding technical jargon as much as possible. For example, when working with a workforce containing limited English proficiency, I use visual aids and incorporate translators into the training process. The goal is to ensure every employee understands the potential risks and how to mitigate them.

Q 19. Explain how you would handle a chemical spill incident.

Handling a chemical spill incident requires a swift and methodical response. My approach begins with immediate evacuation of personnel from the affected area to prevent exposure. Next, I would assess the situation, identifying the spilled chemical and its potential hazards. Using the appropriate SDS, I would determine the necessary personal protective equipment (PPE) required, including gloves, eye protection, and respirators. I would then contain the spill using absorbent materials, preventing further spread and environmental contamination. The next step involves cleaning up the spill, following the manufacturer’s recommendations outlined in the SDS. Finally, I would dispose of the contaminated materials appropriately, following all relevant regulations. Documentation of the incident, including personnel involved, cleanup procedures, and disposal methods, is essential for future reference and regulatory compliance. Properly trained personnel familiar with the site’s chemical inventory and spill response plan is crucial for effective and safe incident management.

Q 20. How do you ensure proper disposal of hazardous waste according to OSHA standards?

Ensuring proper disposal of hazardous waste according to OSHA standards necessitates meticulous adherence to regulations and best practices. First, I identify the hazardous waste based on its chemical composition, using the SDS to determine the appropriate disposal methods. Next, I ensure the waste is properly packaged and labeled according to local, state, and federal regulations, including using appropriate containers and labels to prevent leaks and misidentification. I would then coordinate with a licensed hazardous waste disposal company, verifying their credentials and ensuring they are authorized to handle the specific type of waste. Detailed records are maintained throughout the entire process, documenting the generation, handling, transportation, and disposal of hazardous waste. This record keeping ensures traceability and compliance with regulatory requirements. Failure to follow these steps can lead to severe penalties and environmental damage.

Q 21. Describe your experience with using different types of Personal Protective Equipment (PPE).

My experience encompasses a wide range of Personal Protective Equipment (PPE), including respirators, gloves, eye protection, and protective clothing. I’m familiar with selecting the appropriate PPE based on the specific hazards associated with a given chemical. For example, when dealing with corrosive chemicals, I’d use chemical-resistant gloves and protective eyewear. When working with airborne hazards, I’d select respirators with appropriate cartridges to filter out specific contaminants, ensuring a proper fit test is conducted prior to use. With regards to protective clothing, I have experience using various types, including acid suits, coveralls, and aprons, based on the level of protection required. I’m also knowledgeable about the proper inspection, maintenance, and storage of PPE to ensure its effectiveness and longevity. Regular training and refresher courses keep my knowledge current and ensure that I’m employing best practices in PPE selection and utilization.

Q 22. What is your understanding of the hierarchy of hazard controls?

The hierarchy of hazard controls is a fundamental principle in occupational safety and health. It prioritizes control methods to eliminate or minimize worker exposure to hazards, starting with the most effective and progressing to less effective methods. Think of it like a ladder, with the most effective controls at the top.

- Elimination: This is the best control method. It involves removing the hazard entirely. For example, replacing a hazardous chemical with a less hazardous alternative.

- Substitution: Replacing a hazardous chemical with a less hazardous one that achieves the same function. Using water-based paint instead of oil-based paint is an example.

- Engineering Controls: These are physical changes to the workplace that reduce exposure. Examples include ventilation systems to remove fumes, enclosed systems to prevent spills, or guarding machinery to prevent contact.

- Administrative Controls: These are work practice changes or policies. Examples are rotating employees to limit exposure, implementing lockout/tagout procedures, or providing extra training.

- Personal Protective Equipment (PPE): This is the last line of defense and should only be used when other controls aren’t feasible or sufficient. PPE includes gloves, respirators, safety glasses, etc. It’s crucial to remember that PPE protects the *person*, not the *hazard* itself.

Following this hierarchy ensures the most effective protection for workers. Prioritizing elimination and substitution reduces reliance on less effective controls like PPE, which can fail or be improperly used.

Q 23. How would you determine the appropriate PPE for a specific task involving hazardous chemicals?

Determining the appropriate PPE requires a thorough hazard assessment. This involves identifying the specific chemicals involved, the tasks being performed, and the potential routes of exposure (inhalation, skin contact, ingestion). The Safety Data Sheet (SDS) for each chemical is crucial. It lists the potential health hazards and recommends appropriate PPE.

For example, if a worker is handling concentrated hydrochloric acid, the SDS will likely recommend chemical-resistant gloves, a lab coat, and eye protection. For a task involving airborne particulate matter, a respirator with the appropriate filter may be needed. The selection of PPE is never arbitrary; it’s dictated by the specific hazards present and the task being performed. I always ensure that the chosen PPE is compatible with other PPE and the work environment, to avoid creating new hazards.

Training on proper PPE use and selection, along with regular inspection and maintenance of the PPE, are also critical to effectiveness.

Q 24. How do you handle conflicting information on an SDS?

Conflicting information on an SDS is a serious concern, as it undermines the reliability of this crucial document. My approach involves:

- Verify the source: Ensure the SDS is from a reputable supplier and is the most recent version. Older versions may contain outdated or inaccurate information.

- Contact the manufacturer: Directly contact the chemical manufacturer or supplier to clarify any discrepancies. They are the ultimate authority on the product’s hazards and safe handling.

- Consult other resources: Refer to other reliable sources, such as relevant scientific literature or government agencies like NIOSH (National Institute for Occupational Safety and Health) for additional information. This cross-referencing can help resolve ambiguities.

- Document everything: Thoroughly document all inquiries, responses, and resolutions to maintain a clear record of the issue and its resolution.

- Update the SDS: Once the conflicting information is resolved, update the SDS with the corrected information to ensure accuracy and consistency. The updated SDS should be readily accessible to all employees.

Ignoring conflicting information can lead to inadequate safety measures, endangering workers. Resolving these conflicts is paramount for maintaining a safe work environment.

Q 25. Describe your experience with conducting HazCom training.

I have extensive experience delivering HazCom training, adapting my approach to the specific needs of the audience and the workplace. My training sessions are interactive and engaging, avoiding a purely lecture-based format. I utilize a variety of methods, including presentations, videos, hands-on activities, and practical demonstrations. For instance, I have developed and delivered training programs covering topics such as proper SDS interpretation, selecting appropriate PPE, understanding chemical labeling, and responding to chemical spills.

I always tailor the training to the specific hazards present in the workplace. If a company uses a variety of chemicals, I ensure the training covers the most relevant hazards and provides targeted safety information. Post-training assessments are crucial to gauge comprehension and ensure everyone understands their responsibilities.

I also emphasize the importance of ongoing training and refresher courses to maintain awareness of changes in regulations or workplace hazards.

Q 26. What are the key differences between OSHA’s HazCom Standard and other relevant regulations (e.g., DOT, EPA)?

While OSHA’s HazCom standard focuses on workplace chemical safety, other regulations address different aspects of chemical handling and transportation. Here’s a comparison:

- OSHA’s HazCom Standard (29 CFR 1910.1200): This standard mandates the creation and distribution of SDSs, proper labeling of hazardous chemicals, employee training, and a written hazard communication program. It covers the communication of chemical hazards in the workplace.

- DOT (Department of Transportation) Regulations: These regulations govern the safe transportation of hazardous materials, including labeling, packaging, and shipping documentation. Focus is on transportation safety.

- EPA (Environmental Protection Agency) Regulations: EPA regulations cover the production, use, storage, and disposal of hazardous chemicals, aiming to protect the environment. The focus is on environmental protection.

These regulations are complementary; they don’t contradict each other but address different facets of chemical management. For example, a company must comply with DOT regulations to ship hazardous materials, OSHA’s HazCom standard to handle them safely in the workplace, and EPA regulations for proper disposal.

Q 27. How do you ensure the accuracy and accessibility of safety data sheets?

Ensuring the accuracy and accessibility of SDSs is crucial. My approach involves:

- Centralized SDS Management System: Implement a system (physical or digital) to store and organize SDSs. This ensures easy access for all employees. A digital system offers additional benefits, such as automatic updates and improved searchability.

- Regular Updates: SDSs should be reviewed and updated regularly to reflect any changes in the chemical composition, hazards, or safe handling procedures. Suppliers usually provide updated SDSs; proactive monitoring is vital.

- Version Control: Clearly indicate the version number and date of each SDS to prevent the use of outdated information.

- Translation Services: If the workforce includes non-English speakers, ensuring SDSs are available in their native language is essential.

- Accessibility: SDSs should be easily accessible in the workplace, either through a centralized location or an online database. Employees must know where to locate them.

Maintaining accurate and easily accessible SDSs is a critical element of a successful hazard communication program. It empowers employees to work safely by providing them with the information they need to avoid hazards.

Q 28. Explain your experience with investigating and reporting incidents related to hazardous chemicals.

Investigating and reporting incidents involving hazardous chemicals requires a systematic approach. My experience includes conducting thorough investigations that identify the root causes of incidents, including near misses. I follow these steps:

- Secure the Scene: Prioritize the safety of personnel and prevent further exposure.

- Gather Information: Collect evidence, such as witness statements, photographs, and any remaining chemicals.

- Identify Root Causes: Analyze the incident to pinpoint contributing factors, such as inadequate training, improper PPE use, or equipment malfunction.

- Implement Corrective Actions: Develop and implement measures to prevent similar incidents from occurring in the future. This might involve improved training, revised procedures, or new equipment.

- Document Everything: Maintain detailed records of the incident, the investigation, and the corrective actions taken. This documentation is vital for continuous improvement and compliance.

- Report to OSHA (if applicable): Report incidents that meet OSHA’s reporting requirements promptly and accurately.

A well-conducted investigation not only addresses the immediate consequences of an incident but also serves as a valuable learning experience for improving workplace safety. This preventative aspect is crucial in minimizing future hazards.

Key Topics to Learn for OSHA Hazardous Communication Interview

- Hazard Communication Standard (HCS): Understand the core elements of the HCS, including its purpose, scope, and key provisions. Be prepared to discuss its evolution and recent updates.

- GHS (Globally Harmonized System): Explain the principles of GHS and how it impacts the classification and labeling of hazardous chemicals. Practice applying GHS criteria to real-world scenarios.

- Safety Data Sheets (SDS): Demonstrate a thorough understanding of SDS content, interpretation, and proper handling. Be ready to explain how to locate and utilize critical information within an SDS.

- Labeling Requirements: Explain the requirements for proper chemical labeling, including signal words, pictograms, hazard statements, and precautionary statements. Discuss the practical implications of incorrect labeling.

- Employee Training: Discuss the employer’s responsibility for providing effective employee training on hazardous communication. Outline the key components of a comprehensive training program.

- Written Hazard Communication Program: Explain the components of a written hazard communication program and its importance in ensuring compliance. Be prepared to discuss practical implementation strategies.

- Recordkeeping and Documentation: Understand the requirements for maintaining accurate records of chemical inventories, employee training, and incident reports related to hazardous materials.

- Emergency Response Procedures: Discuss the role of hazardous communication in emergency response planning and execution. Be familiar with procedures for spills, leaks, and other incidents involving hazardous chemicals.

- Compliance Audits and Inspections: Explain the importance of regular compliance audits and how they help to identify and address potential hazards. Be prepared to discuss the potential consequences of non-compliance.

- Practical Application: Be ready to discuss how you would apply your knowledge of OSHA Hazardous Communication in a real-world workplace scenario, such as developing a training program or investigating a workplace incident involving hazardous materials.

Next Steps

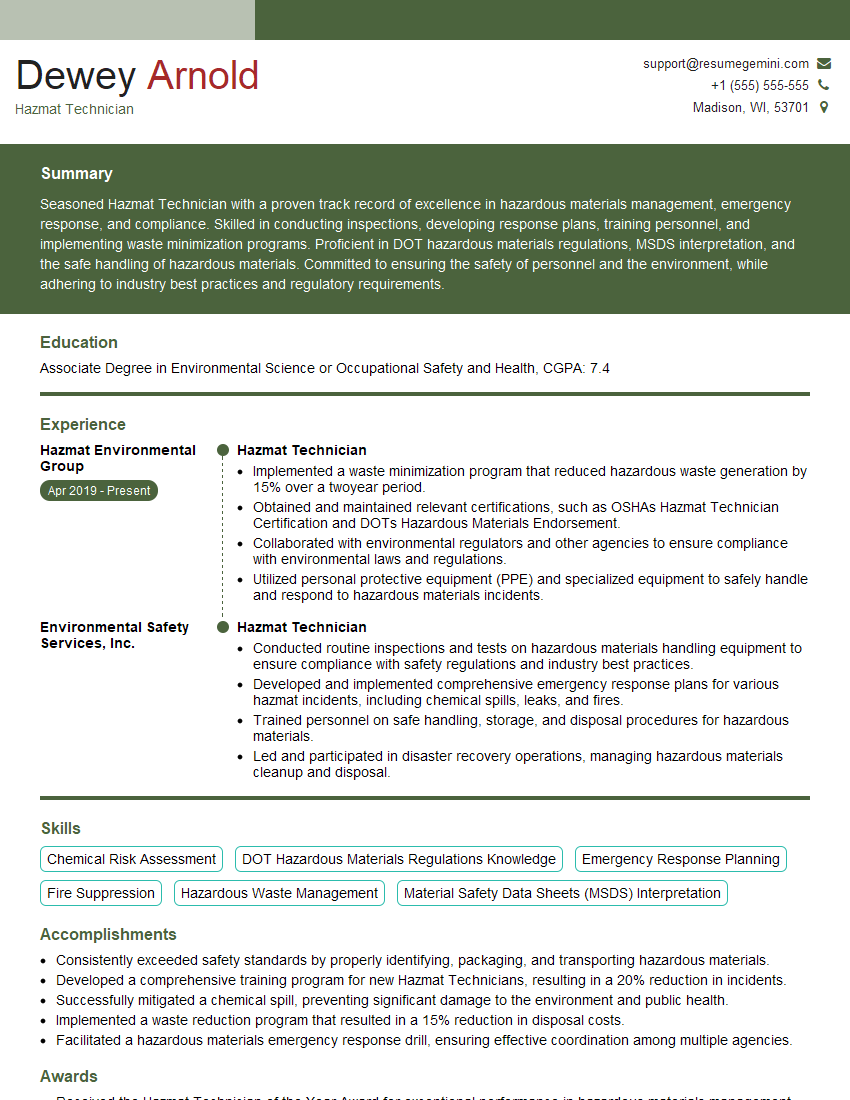

Mastering OSHA Hazardous Communication demonstrates a commitment to workplace safety and significantly enhances your career prospects in various industries. A strong understanding of this crucial standard is highly sought after by employers, opening doors to advanced roles and increased earning potential. To maximize your job search success, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your qualifications. Examples of resumes specifically designed for OSHA Hazardous Communication roles are available for your review. This will help you present your expertise effectively and increase your chances of securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?