Cracking a skill-specific interview, like one for Garage Door Jackshaft Repair, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Garage Door Jackshaft Repair Interview

Q 1. Explain the difference between a chain drive and a belt drive garage door opener.

The main difference between chain and belt drive garage door openers lies in how they transmit power from the motor to the door. A chain drive uses a metal chain, similar to a bicycle chain, to connect the motor to the trolley that moves along the track. This results in a more noticeable, somewhat noisy operation. A belt drive, on the other hand, utilizes a reinforced rubber belt, offering a quieter and smoother operation. Think of it like the difference between an old-fashioned metal-on-metal clock ticking versus the quiet sweep of a modern quartz clock. Belt drives are generally preferred for their quieter operation and smoother movement, while chain drives are often more robust and can handle heavier doors.

Q 2. Describe the components of a typical jackshaft garage door opener system.

A typical jackshaft garage door opener system comprises several key components working in harmony:

- Jackshaft Motor: The powerful motor that drives the entire system. It’s compact and mounts directly to the shaft.

- Jackshaft: A sturdy shaft connected to the motor, providing the rotational force to open and close the door.

- Gearbox/Reduction System: Reduces the high speed of the motor to a slower, more powerful rotation suitable for moving the door.

- Arm/Tubes: Connects the jackshaft to the door’s trolley system.

- Trolley/Carrier: Moves along the track, connected to the door, and driven by the jackshaft.

- Limit Switches: Sensors that detect when the door is fully opened or closed, signaling the motor to stop.

- Control Board/Receiver: The brains of the operation; it manages all signals and controls the motor’s action.

- Remote Control/Wall Button: User interface to control the door’s operation.

- Safety Sensors/Photo Eyes: Essential safety features that stop the door’s movement if an obstruction is detected.

Q 3. How do you troubleshoot a jackshaft opener that won’t open or close?

Troubleshooting a jackshaft opener that won’t open or close requires a systematic approach. First, check the power supply – ensure the opener is plugged in and the breaker hasn’t tripped. Next, inspect the remote control and wall button batteries and check for proper signal transmission. If the opener makes a clicking or humming sound, the problem might be a mechanical issue, potentially a jammed track, obstructed photo eyes, or a broken spring. If there’s no sound, the problem might lie with the motor or control board. I would recommend visually inspecting the system for any obvious issues like broken parts or obstructions first. If the problem persists, checking the limit switches and ensuring proper alignment is crucial. A multimeter can test the motor and control board for voltage and continuity.

Q 4. What safety precautions should be taken when working with a garage door jackshaft?

Safety is paramount when working with garage door jackshafts. Always disconnect the power supply at the breaker before any repair or maintenance. Use appropriate safety gear such as gloves and eye protection. Never work under a raised door – it could unexpectedly fall. Ensure the door is properly supported to prevent accidental movement. If unsure about any step, consult a qualified professional. Remember, even a seemingly simple task can present unforeseen risks. Treat the entire system with respect and prioritize safety above all else.

Q 5. How do you diagnose a faulty motor in a jackshaft opener?

Diagnosing a faulty motor usually involves testing for power and continuity. With the power disconnected, use a multimeter to check if power is reaching the motor terminals. If power is present but the motor doesn’t function, the motor itself may be faulty. You can further check for continuity within the motor windings using the multimeter. If there is an open circuit or incorrect resistance readings, it indicates a problem within the motor that would require replacement. Note that testing motor windings involves working with potentially dangerous voltages, hence why the power must be disconnected beforehand. You also need a basic understanding of electrical systems before testing this kind of thing.

Q 6. Explain the process of installing a jackshaft opener on a standard garage door.

Installing a jackshaft opener involves several steps: First, carefully remove the old opener if applicable. Then, mount the jackshaft securely to the wall or header, ensuring it’s level. Attach the arm and tubes, connecting them to the trolley system. Next, carefully mount the trolley to the door and ensure its smooth movement along the track. Finally, wire the opener according to the manufacturer’s instructions, carefully connecting all the components, the motor, control board, limit switches and safety sensors. Test the system thoroughly by fully opening and closing the door several times. Remember to follow the manufacturer’s installation manual; every model might have slight differences.

Q 7. How do you adjust the travel limits on a jackshaft opener?

Adjusting travel limits is essential for ensuring the door opens and closes completely without hitting the floor or the ceiling. Most jackshaft openers have adjustment screws on the control board which control the upper and lower limits. By turning these screws you can alter how far the door travels. To adjust the upper limit, set the door at a higher position and manually adjust the screw until the door stops at the desired point. Similarly, set the door at the lower point to adjust the lower limit. Consult your specific opener’s manual for precise instructions as the location and operation may vary between models. Testing after each small adjustment is critical to avoid any damage.

Q 8. Describe how to program remotes for a jackshaft opener.

Programming jackshaft opener remotes varies slightly depending on the brand and model, but the general process involves putting the opener into ‘programming mode’. This usually involves pressing and holding a specific button on the motor unit itself. Consult your owner’s manual for the exact procedure for your specific opener. Once in programming mode, you’ll typically need to press and hold a button on the new remote within a short timeframe (often 30 seconds). The opener will then ‘learn’ the remote’s code. You’ll usually see a light flash or hear a beep to confirm successful programming. After successfully programming one remote, you can usually program additional remotes, following the same procedure. If you have trouble, always refer to your specific opener’s manual or contact the manufacturer’s customer support.

Example: Many LiftMaster jackshaft openers require you to press and hold the ‘Learn’ button on the motor unit, then press and hold a button on the new remote within 30 seconds. The indicator light will blink, confirming successful programming.

Q 9. What are the common causes of a jackshaft opener making unusual noises?

Unusual noises from a jackshaft opener often indicate a problem that needs attention. These sounds can range from squeaking and grinding to loud banging or clicking.

- Squeaking or Grinding: This often points to a problem with the belt or chain. Lubrication might be needed, or the belt/chain may be worn and need replacement.

- Loud Bangs or Clunks: These could signify loose hardware, a problem with the track, or a more serious issue with the motor or gear assembly. Check all the mounting bolts and make sure the track is securely attached.

- Clicking or Humming: This may suggest a problem with the motor itself, particularly if the door doesn’t move. It could be an issue with the motor capacitor, the motor windings, or even a power supply issue.

- Whirring or Screeching: This usually signals bearing issues within the motor or the jackshaft assembly. This often requires professional attention.

Troubleshooting Tip: When diagnosing, carefully listen to pinpoint the location of the noise. This helps isolate the problem to the motor, belt/chain, or other components.

Q 10. How do you identify and replace a broken belt or chain in a jackshaft system?

Replacing a broken belt or chain in a jackshaft system requires careful attention and the right tools. First, disconnect the power to the opener for safety.

- Identify the type: Determine whether your system uses a belt or chain drive.

- Access the drive: Carefully access the belt or chain. This often involves removing panels or accessing the mechanism from the back side of the opener.

- Remove the old belt/chain: Carefully remove the old, broken belt or chain, noting its routing carefully. If unsure, taking photos before disassembly is helpful.

- Install the new belt/chain: Install the new belt or chain following the same path as the old one. Make sure it’s properly seated on all pulleys and sprockets. This step can be easier with another person to help guide it and ensure it is aligned.

- Test the system: Reconnect the power and test the door operation cautiously. Listen for any unusual noises and make sure the door moves smoothly.

Important Note: It’s crucial to use the correct replacement belt or chain for your specific jackshaft opener model. Incorrect sizing can lead to further damage or even injury.

Q 11. What are the signs of a failing jackshaft motor?

A failing jackshaft motor exhibits several telltale signs.

- Slow operation: The door opens and closes much slower than usual.

- Unusual noises: As discussed earlier, grinding, humming, or clicking sounds frequently indicate motor problems.

- Inconsistent operation: The door may stall, reverse unexpectedly, or fail to operate entirely.

- Overheating: The motor casing may become unusually hot to the touch.

- Burning smell: A burning smell is a serious indication of motor failure and requires immediate attention.

- Tripping breaker: The motor may repeatedly trip the circuit breaker.

Example: If your door only moves a few inches before stopping and making a loud humming noise, it’s a strong indicator of a failing motor.

Q 12. How do you test the torque of a jackshaft motor?

Testing the torque of a jackshaft motor requires specialized tools and some technical expertise. It is usually done with a torque wrench capable of measuring the specific load capacity needed for the motor. This is best left to professionals. They will use equipment designed to precisely measure the rotational force the motor produces under various loads. This involves attaching the wrench to the motor’s output shaft, applying a load (like a calibrated weight), and measuring the resistance the motor overcomes. A low torque reading indicates a possible motor problem that may require repair or replacement.

Safety Note: Attempting to test motor torque without the proper training and equipment could lead to injury or damage to the motor.

Q 13. Explain the process of calibrating a jackshaft opener after installation or repair.

Calibration ensures the jackshaft opener knows the limits of its travel, preventing the door from hitting the ground or going too high. After installation or repair, follow these steps. Again, specific steps may vary slightly per model, so consult your manual.

- Locate the limit switches: These switches tell the opener when to stop. They’re usually adjustable.

- Open and Close: Manually open and close the door completely.

- Adjust limit switches: Using the opener’s controls, slowly open the door and adjust the limit switches. Repeat for closing.

- Test and Repeat: Test the system and adjust the limits as needed to ensure the door travels smoothly and stops correctly.

- Force Adjustment: Many openers have settings to adjust the force needed for operation. If the door is struggling or seems to be straining, this setting should be adjusted.

Example: If the door stops short of fully closing, you need to adjust the closing limit switch to allow more travel before the opener stops.

Q 14. What are the common safety features of modern jackshaft openers?

Modern jackshaft openers incorporate several important safety features to protect both people and the garage door itself.

- Force Sensing Technology: This detects obstructions during door movement and automatically reverses the door. This is crucial to prevent accidents.

- Auto-Reverse: If the door encounters an obstruction, it immediately reverses, preventing damage to the door or injury.

- Safety Sensors: Infrared sensors detect any obstruction in the door’s path and prevent it from closing.

- Emergency Release Cord: A manual release cord allows you to disconnect the opener and operate the door manually in case of power failure or malfunction.

- Power Disconnect: Easy access to power disconnection prevents accidental operation.

Importance: Regularly check these safety features to ensure they’re functioning correctly. A properly maintained system is much safer.

Q 15. How do you deal with a jackshaft opener that is malfunctioning due to power surges?

Power surges are a significant threat to jackshaft openers, often leading to fried circuit boards or motor damage. The first step is to always check your home’s electrical system. A surge protector specifically designed for garage door openers is a crucial preventative measure. It’s like a safety net for your opener. If a surge has already occurred, you’ll need to carefully inspect the opener’s control board for any visible signs of damage, such as burnt components or blown fuses. A multimeter can help pinpoint damaged components. If you find damage, replacing the control board is usually necessary. Sometimes, the motor itself might be affected, requiring its replacement. Always disconnect the power before any inspection or repair!

Example: I once had a client whose opener failed after a lightning strike. The control board was completely fried. Replacing it restored functionality, saving them the cost of a complete opener replacement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of replacing a limit switch in a jackshaft system.

Replacing a limit switch, which determines the up and down travel limits of your garage door, is a straightforward process. First, disconnect the power to the opener. Then, locate the limit switches—usually small, plastic boxes with adjustable screws. Note the current positions of the adjustment screws before you disconnect them. This helps you restore them to the previous settings. Next, carefully remove the old switch(es), noting how the wires are connected. Install the new switch, connecting the wires identically. Test the door operation, adjusting the limit switches until the door opens and closes fully without straining or stopping prematurely. This ensures safe operation and prevents damage to the door or opener.

Example: If your door is not fully closing or opening, the limit switches are likely the culprits. This requires precision adjustment of the switches to match the door’s travel distance.

Q 17. How do you troubleshoot a jackshaft opener that is intermittently working?

Intermittent operation points towards a connection or component issue. Start by inspecting all wiring connections for looseness or damage. Pay close attention to the connections at the motor, control board, and limit switches. A loose wire can cause the system to act erratically. Next, check the motor itself for signs of overheating or damage. Then investigate the control board; its failure frequently causes intermittent operation. A multimeter can help diagnose bad capacitors or other electronic components. Finally, don’t overlook the power supply—a fluctuating voltage could be the root cause of the intermittent problem. If the problem persists after these checks, a professional inspection is advisable.

Example: A client experienced their door occasionally failing to open. The issue stemmed from a corroded connection at the motor. Cleaning and tightening the connection resolved the issue.

Q 18. How do you handle a situation where a garage door is stuck due to a jackshaft problem?

A stuck garage door due to jackshaft problems necessitates a cautious approach. First, ensure the power is disconnected to prevent further damage or injury. Try to identify what’s causing the blockage—is it a mechanical issue within the jackshaft assembly, a problem with the door itself, or a problem with the track? Attempt to manually disengage the opener from the door. This often involves a release cord or manual override mechanism. This will allow you to manually open the door. Once the door is free, carefully inspect the jackshaft for any obvious obstructions or damaged parts. If you cannot identify or fix the problem, it’s best to call a professional.

Example: A broken chain often causes the door to get stuck. Disconnecting the opener and manually pulling the door up usually allows access for chain repair.

Q 19. Describe the different types of jackshaft motors and their applications.

Jackshaft motors vary primarily in power and features. DC motors are common, known for their quiet operation and smooth movement. They’re often found in residential applications. AC motors, while less common in jackshafts, offer high torque but can be noisier. Belt-driven motors utilize a belt to transfer power from the motor to the shaft, reducing stress on the motor and offering smoother operation. Direct-drive motors connect directly to the shaft, providing efficient power transfer. The choice depends on the door’s weight and desired features. Heavier doors often require more powerful motors.

Example: A light residential door might use a low-power DC motor, while a heavier commercial door would benefit from a more robust AC or high-torque DC motor.

Q 20. How do you ensure proper lubrication for a jackshaft opener?

Proper lubrication is crucial for extending the life of your jackshaft opener. Most jackshaft systems have moving parts like chains, gears, and the jackshaft itself that require periodic lubrication. Use a high-quality garage door lubricant, avoiding WD-40 or similar products as they tend to attract dirt and can damage the system over time. Apply a small amount of lubricant to the chain and any visible moving parts, ensuring even coverage. Do this approximately every 3-6 months or more frequently in harsh environments. Wipe off any excess lubricant to avoid attracting dust.

Example: Neglecting lubrication can cause squeaking noises and premature wear on the system, eventually leading to more costly repairs.

Q 21. What tools and equipment are essential for jackshaft opener repair and installation?

Effective jackshaft opener repair and installation requires specific tools. Essential tools include: a voltage tester (multimeter), screwdrivers (Phillips and flathead), wrenches (various sizes), pliers, a socket set, wire strippers/cutters, a ladder, safety glasses, and work gloves. Depending on the specific repair, you might also need special tools for chain tension adjustment, motor removal, and control board access. For installations, additional tools for mounting and aligning the opener may be necessary. Safety is paramount – always disconnect the power before working on any electrical components.

Example: A multimeter is critical for testing voltage and continuity, ensuring safe operation and identifying faulty components.

Q 22. How do you maintain a jackshaft opener to prevent future problems?

Maintaining your jackshaft opener is crucial for longevity and preventing costly repairs. Think of it like regular car maintenance – small preventative steps save you from major breakdowns later. A simple routine can significantly extend its lifespan.

- Lubrication: Regularly lubricate moving parts like the chain, sprockets, and rollers with a garage door lubricant. This reduces friction and wear, preventing premature damage. Imagine the difference between a well-oiled bike chain and a rusty one – the smooth operation is noticeable and prevents seizing.

- Inspection: Monthly visual inspections are key. Check for loose bolts, frayed cables, or any signs of damage to the rail, chain, or other components. Early detection prevents minor issues from escalating into major problems.

- Cleaning: Dust and debris can accumulate and interfere with the opener’s performance. Periodically clean the tracks and surrounding areas with a brush and vacuum. Think of it as spring cleaning for your garage door – a tidy system runs more efficiently.

- Tightening: Periodically check and tighten all bolts and fasteners. Loose components can lead to misalignment and premature wear. This simple step often prevents many common issues.

- Testing the Safety Sensors: Regularly test the safety sensors to ensure they are functioning correctly. These are critical for safety, preventing accidental closure on obstacles. A simple test involves placing an object in the door’s path to verify the automatic reversal.

Q 23. Explain the importance of safety sensors in a jackshaft garage door system.

Safety sensors are paramount in a jackshaft system, or any garage door system for that matter. They are the critical safety feature that prevents accidents by detecting obstacles in the door’s path. These infrared sensors emit and detect beams; if an object interrupts the beam during the door’s closing cycle, the door immediately reverses. Think of them as the ‘eyes’ of your garage door, ensuring it operates safely.

Without functioning sensors, the door could close on a person or object, leading to potential injury or damage. This is why regular testing, as mentioned earlier, is so crucial. A malfunctioning sensor can lead to a potentially dangerous situation, so keeping them in top shape should be a top priority.

Q 24. How do you diagnose and repair problems related to the opener’s control board?

Diagnosing control board issues requires a methodical approach. The control board is the ‘brain’ of the opener, and problems here can manifest in various ways – the door may not open or close, it might make unusual noises, or the remote might not respond. The first step is always safety: disconnect power to the opener before any inspection or repair.

- Visual Inspection: Look for burned components, loose wires, or any obvious physical damage on the control board itself. Sometimes, a simple visual inspection can reveal the problem.

- Testing Components: Use a multimeter to test the voltage and continuity of various components on the board to identify faulty parts. This requires some basic electronics knowledge, but it’s a common troubleshooting technique.

- Check Wiring: Examine all wiring connections to and from the control board for any loose or damaged wires. A loose connection can prevent proper operation.

- Consult Schematics: Refer to the opener’s wiring diagram to trace the circuit and identify the source of the malfunction. Manufacturers usually provide diagrams for this purpose.

- Replace the Board: If you’ve identified a faulty component or cannot pinpoint the problem, replacing the control board is often the most efficient solution. Remember to purchase the correct replacement part for your specific model.

Remember: If you are not comfortable working with electronics, it is always best to consult a professional technician.

Q 25. Describe the process of replacing the rail assembly in a jackshaft opener.

Replacing the rail assembly is a more involved process that requires careful attention to detail. This is not a DIY project for the inexperienced. The rail assembly is a crucial structural component; any mistakes could compromise the safety and functionality of your door.

- Disconnect Power: First, disconnect the power supply to the opener.

- Remove the Old Rail: Carefully remove the old rail assembly, taking note of how the components are connected. Take pictures as you go, as it helps with reassembly.

- Prepare the New Rail: Ensure the new rail assembly is compatible with your opener model. Install the new rail assembly, following the manufacturer’s instructions carefully. Often this involves aligning it correctly with the jackshaft and other components.

- Reconnect Components: Reconnect all the components, ensuring proper alignment and secure connections. This includes the chain, sprocket, and any other components connected to the rail.

- Test the Operation: After reassembly, carefully test the door operation to ensure it moves smoothly and quietly. Observe for any signs of binding or unusual noises.

- Reconnect Power: Finally, restore power to the opener.

Throughout this process, accuracy is key. A misaligned rail can lead to issues like binding or premature wear of other components. Always refer to the manufacturer’s instructions for your specific model.

Q 26. How do you identify the correct replacement parts for a specific jackshaft model?

Identifying the correct replacement parts is crucial for a successful repair. Using the wrong parts can lead to compatibility issues and even damage other components. The model number is your best friend here.

- Locate the Model Number: Find the model number of your jackshaft opener. This is usually found on a sticker on the opener itself, or in the owner’s manual.

- Contact the Manufacturer: Use the model number to contact the manufacturer or an authorized dealer. They can provide you with the correct part numbers for your specific model. Often, they have detailed diagrams and part lists available.

- Online Part Databases: Many online retailers specialize in garage door parts. Their websites usually have search functions allowing you to search by model number.

- Check Local Suppliers: Check with local garage door repair companies or suppliers. They often have a stock of common replacement parts and can help identify the correct part if you bring them the model number.

Always verify compatibility before purchasing. A quick call to the supplier can save you time and effort in the long run.

Q 27. What are the common causes of opener failure in high-traffic commercial settings?

High-traffic commercial settings place significantly more stress on jackshaft openers. The constant use leads to faster wear and tear. Imagine the difference between a family car and a taxi cab – the taxi experiences much faster wear.

- Increased Wear and Tear: Frequent cycling of the door leads to increased wear on the chain, sprockets, rollers, and other mechanical components.

- Overuse and Overheating: Continuous operation can cause overheating of the motor and other components, leading to premature failure. Think of a constantly running engine – it’s going to heat up much quicker.

- Environmental Factors: Harsh environmental conditions like extreme temperatures or humidity can accelerate the deterioration of components.

- Lack of Maintenance: In busy commercial settings, preventive maintenance might be overlooked, which further exacerbates the wear and tear.

In these environments, proactive maintenance, more frequent inspections, and potentially more robust components are crucial for preventing frequent failures.

Q 28. How would you handle a client complaint regarding a faulty jackshaft installation?

Handling client complaints requires a professional and empathetic approach. The goal is to resolve the issue efficiently and maintain a positive relationship. A faulty installation reflects on my work, so addressing the complaint thoroughly is important.

- Listen Attentively: Listen carefully to the client’s concerns and gather all relevant information regarding the problem. Let them express their frustrations without interruption.

- Thorough Inspection: Conduct a thorough on-site inspection to determine the cause of the problem. This might involve inspecting the installation, checking the wiring, and testing the opener’s operation.

- Transparent Communication: Clearly explain the findings of the inspection and provide a detailed explanation of the necessary repairs. This keeps the client informed and demonstrates my expertise.

- Swift Resolution: Work quickly and efficiently to resolve the issue. This shows the client that I am committed to rectifying the problem. The quicker the resolution, the better.

- Follow-Up: After completing the repairs, follow up with the client to ensure they are satisfied with the outcome. This demonstrates a commitment to customer satisfaction.

In some cases, a partial or full refund might be necessary depending on the severity of the issue. Maintaining open communication is key to a successful resolution.

Key Topics to Learn for Garage Door Jackshaft Repair Interview

- Jackshaft Motor Functionality: Understanding DC motor operation, torque, speed control, and limitations within the context of garage door operation.

- Troubleshooting Common Issues: Diagnosing problems like noisy operation, erratic movement, complete failure, and limited travel. This includes practical application of diagnostic tools and techniques.

- Safety Procedures and Precautions: Highlighting safe practices for working with electricity, moving parts, and potentially heavy garage doors. Understanding relevant safety regulations.

- Component Identification and Repair: Familiarization with the various components of a jackshaft system (motor, gears, limit switches, sensors, etc.) and common repair procedures, including replacement techniques.

- Wiring Diagrams and Schematics: Ability to read and interpret electrical diagrams to troubleshoot wiring faults and perform repairs.

- Calibration and Adjustment: Understanding how to properly calibrate limit switches and adjust tension to ensure smooth and reliable door operation.

- Preventive Maintenance: Discussing routine maintenance tasks to prevent future issues and extend the lifespan of the jackshaft system.

- Different Jackshaft Systems: Familiarity with various types of jackshaft systems, their strengths, and weaknesses. This includes understanding the differences between various manufacturers and models.

- Customer Service and Communication: Highlighting the importance of clear and professional communication with customers, explaining technical issues in a relatable way.

Next Steps

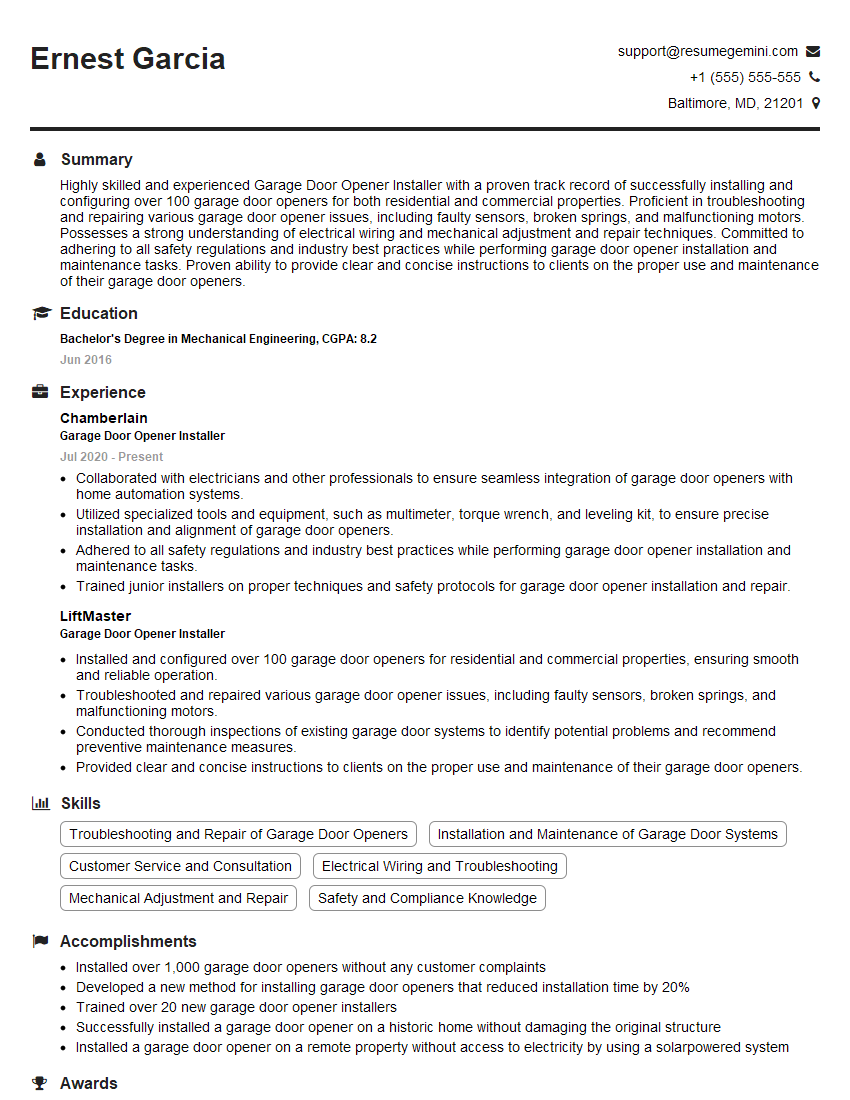

Mastering Garage Door Jackshaft Repair positions you for a rewarding career with excellent growth potential in a consistently in-demand field. Your expertise in troubleshooting, repair, and maintenance will be highly valued. To maximize your job prospects, create a strong, ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that stands out. Take advantage of their tools and resources – examples of resumes tailored to Garage Door Jackshaft Repair are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?