Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Cut Pile Tufted Carpet Production interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Cut Pile Tufted Carpet Production Interview

Q 1. Explain the difference between cut pile and loop pile carpet.

The key difference between cut pile and loop pile carpets lies in how the yarn is presented on the surface. In cut pile carpet, the yarn loops are cut, creating a plush, soft surface with individual fibers standing upright. Think of a velvety shag rug – that’s cut pile. Loop pile carpet, on the other hand, keeps the yarn loops intact, resulting in a more durable and textured surface. Imagine a Berber carpet with its distinct loops – that’s loop pile. Cut pile offers a softer feel and often a more luxurious look, while loop pile is known for its resilience and stain resistance.

Q 2. Describe the tufting process in detail, including yarn feed, needle penetration, and backing application.

The tufting process is the heart of cut pile carpet manufacturing. It’s a high-speed operation where yarn is inserted into a primary backing material using specialized needles. Let’s break it down:

- Yarn Feed: Yarn is fed from large spools onto a precisely controlled mechanism that delivers it to the tufting needles at the correct speed and tension. The type of yarn and the desired pile density dictate the yarn feed rate.

- Needle Penetration: Hundreds of needles simultaneously penetrate the primary backing, carrying the yarn with them. These needles create loops in the yarn that are then cut to form the cut pile. The needle bar moves back and forth across the backing material, creating rows of yarn loops.

- Backing Application: The primary backing, often woven polypropylene or jute, provides a stable base for the tufts. A secondary backing, such as latex or other adhesive, is then applied to the back of the tufted fabric to further stabilize the carpet and add strength. This backing is crucial for the carpet’s dimensional stability and prevents unraveling.

Imagine it like sewing, but on a massive scale and with thousands of needles working simultaneously. The precision and speed involved are crucial for efficiency and consistent product quality.

Q 3. What are the common types of backing used in cut pile tufted carpets?

Several types of backing are used in cut pile tufted carpets, each offering different properties and cost points:

- Woven Polypropylene: A common and cost-effective option known for its strength and moisture resistance.

- Jute: A natural fiber backing providing good strength but less moisture resistance than polypropylene.

- Polyester: Offers good strength and moisture resistance, often used in higher-end carpets.

- Combination Backings: These combine materials like polypropylene and jute for a balance of strength, cost, and performance.

The choice of backing significantly impacts the carpet’s overall durability, stability, and cost. A higher-quality backing will generally result in a longer-lasting carpet.

Q 4. How does gauge and pile height affect the carpet’s density and appearance?

Gauge refers to the number of needles per inch in the tufting machine. A higher gauge (e.g., 1/8 inch gauge) means more needles and therefore more tufts per square inch, resulting in a denser carpet. Pile height, simply put, is the height of the yarn loops before cutting. A higher pile height creates a thicker, plusher carpet. The interplay between gauge and pile height significantly influences the carpet’s appearance and feel.

For example, a high-gauge, low-pile carpet will be dense and firm, while a low-gauge, high-pile carpet will be plush but less dense. The optimal combination depends on the desired look, feel, and performance characteristics of the final product.

Q 5. Explain the role of the primary backing and secondary backing in carpet construction.

The primary backing is the foundational layer of the carpet, providing structural integrity. It’s where the yarn tufts are anchored. The secondary backing is applied to the back of the tufted fabric. Its primary function is to add stability and prevent the primary backing from unraveling. It also enhances the carpet’s dimensional stability and often improves its resilience to wear and tear. The secondary backing can be a latex compound or other adhesive, or it can even be a secondary woven fabric. Think of it as reinforcement – like adding extra stitching to a garment to make it stronger.

Q 6. What are the different types of yarns used in cut pile tufted carpets and their properties?

A variety of yarns are used in cut pile tufted carpets, each with its own properties:

- Nylon: Highly durable, stain-resistant, and resilient. It’s a popular choice for high-traffic areas.

- Polyester: Offers good strength and stain resistance, often softer than nylon but potentially less durable in high-traffic settings.

- Olefin (Polypropylene): A durable and economical option known for its stain resistance and water repellency. It’s often used in outdoor carpets.

- Wool: A natural fiber offering excellent resilience, softness, and luxurious feel but at a higher cost.

The yarn selection depends on factors like budget, intended use, and desired aesthetic qualities. Each yarn type brings a unique set of benefits to the final carpet.

Q 7. Describe the process of heat setting and its importance in cut pile carpet production.

Heat setting is a crucial post-tufting process that stabilizes the carpet yarn. The carpet is subjected to high temperatures, typically using steam or hot air. This process sets the yarn fibers, reducing shrinkage, enhancing dimensional stability, and improving the overall durability and appearance of the carpet. It essentially locks the yarns into their shape and prevents them from shifting or stretching over time. This is particularly important for cut pile carpets, where the individual fibers need to remain upright and in place to maintain the desired texture and appearance.

Think of it like ironing a garment – it smooths out wrinkles and sets the fabric to its intended form. Heat setting ensures the carpet keeps its shape and looks its best for years to come.

Q 8. What are common quality control checks during cut pile carpet production?

Quality control in cut pile tufted carpet production is crucial for ensuring consistent quality and meeting customer expectations. It’s a multi-stage process starting from raw material inspection and extending to the finished product.

Fiber Inspection: We rigorously check the yarn for strength, evenness, color consistency, and the absence of defects before it even reaches the tufting machine. Imagine baking a cake – you wouldn’t use spoiled ingredients! Similarly, substandard yarn leads to a poor-quality carpet.

Tufting Process Monitoring: During tufting, we continuously monitor the machine’s performance, checking for consistent pile height, density, and evenness of the tufting pattern. We regularly measure pile height with specialized tools to ensure it conforms to the specifications. Irregularities can be caused by issues like needle penetration or yarn feeding.

Backing Inspection: The backing material, whether primary or secondary, is inspected for defects such as holes, tears, or inconsistencies in weight and strength. A weak backing compromises the carpet’s overall durability.

Dyeing and Finishing Checks: After dyeing, the carpet undergoes thorough quality checks for color uniformity and the absence of dye bleeding. Following the finishing process (e.g., latex application, shearing), we look for any imperfections such as uneven shearing or latex build-up. These issues would directly impact the carpet’s visual appeal and longevity.

Final Inspection: A final, meticulous inspection of the finished carpet rolls is conducted to identify any flaws that might have been missed earlier. This final step involves examining the whole carpet for defects like yarn pulls, shading inconsistencies, and other imperfections before it’s shipped.

Q 9. How do you identify and troubleshoot common tufting machine malfunctions?

Troubleshooting tufting machine malfunctions requires a systematic approach. It’s like diagnosing a car problem – you need to find the root cause, not just the symptom.

Needle Breakage: This is a common problem. Causes include bent needles, incorrect needle tension, or low-quality needles. The solution involves replacing the broken needle, adjusting tension settings, and ensuring the use of high-quality needles.

Yarn Breakage: This can be due to low yarn quality, tension issues, or problems with the yarn feed mechanism. We check yarn quality, adjust tension, and inspect and clean the yarn feed system.

Inconsistent Pile Height: This points to problems with needle penetration, incorrect settings on the tufting machine, or variations in yarn thickness. We recalibrate machine settings, check needle penetration, and ensure even yarn feeding.

Pattern Misalignment: Problems with the pattern chain or timing mechanism can lead to pattern misalignment. We inspect the pattern chain, adjust timings, and check for any obstructions.

Backing Issues: Wrinkles or slippage in the backing material can disrupt the tufting process. Addressing this involves smoothing the backing and tightening the rollers ensuring the backing material feeds smoothly and evenly.

Regular preventative maintenance, including lubrication and cleaning, is also crucial in preventing many malfunctions.

Q 10. Explain the process of dyeing and finishing cut pile tufted carpets.

Dyeing and finishing are crucial steps that transform the tufted carpet from a plain fabric to a finished product. Think of it as adding the finishing touches to a painting.

Dyeing: The dyeing process typically uses solution dyeing, where the yarn is dyed before tufting, ensuring color consistency throughout the carpet. Alternatively, piece dyeing is used on the finished tufted carpet, but this results in less color penetration and may lead to unevenness.

Heat Setting: After dyeing, the carpet undergoes a heat-setting process to improve the colorfastness and dimensional stability of the yarn. This helps prevent shrinkage or color bleeding.

Latex Application: A latex backing is applied to the back of the carpet to stabilize the tufts, prevent shedding, and increase the carpet’s overall durability. We must ensure even application to prevent stiffness or weakness in certain areas.

Shearing: The carpet undergoes shearing to even out the pile height, creating a consistent and smooth surface texture. This step is critical for achieving a uniform look and feel.

Inspection and Finishing Touches: Following the above stages, a rigorous quality inspection is performed, and final touches are added. This might include trimming loose threads or addressing other minor imperfections.

Q 11. Describe different methods for pattern creation in tufted carpets.

Pattern creation in tufted carpets involves several methods, each with its strengths and weaknesses.

Jacquard Attachment: This is the most versatile method, enabling intricate and complex designs. The jacquard mechanism uses punched cards or electronic controls to lift and lower the needles, creating the pattern. Think of it as a highly sophisticated loom. It allows for high-definition patterns.

Screen Printing: A stencil is used to apply a coating that prevents tufting in certain areas, creating a pattern. It’s simpler and less expensive than jacquard, but it has limitations in design complexity.

Hand-tufting: While labor-intensive, hand-tufting offers unparalleled design flexibility, particularly for bespoke or artistic creations. It is also how many custom, high-value carpets are produced.

Q 12. What are the safety precautions necessary while operating tufting machines?

Safety is paramount when operating tufting machines. These machines are powerful and can pose serious risks if not handled correctly.

Lockout/Tagout Procedures: Before performing any maintenance or repairs, always follow lockout/tagout procedures to prevent accidental start-ups.

Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including safety glasses, hearing protection, and closed-toe shoes. Gloves are also recommended to protect hands from yarn and machine parts.

Machine Guards: Ensure that all machine guards are in place and functioning correctly to prevent contact with moving parts.

Emergency Stop Procedures: Operators must be thoroughly trained on emergency stop procedures and the location of emergency shut-off switches.

Regular Maintenance: Regular maintenance and inspection of the machine helps prevent malfunctions that could lead to accidents.

Q 13. How does the choice of backing material impact the overall carpet performance?

The backing material significantly impacts the carpet’s performance. It’s the foundation upon which the entire carpet rests, like the frame of a house.

Durability: A strong backing provides excellent dimensional stability and resists stretching and tearing, ensuring the carpet lasts longer. Weaker backings can lead to premature wear and deformation.

Moisture Resistance: Some backing materials offer better moisture resistance than others, protecting the carpet from mold and mildew in humid environments.

Comfort: The backing can influence the carpet’s overall comfort and cushioning. A thicker backing typically provides more comfort underfoot.

Cost: Different backing materials come at various price points, impacting the overall cost of the carpet.

Common backing materials include jute, polypropylene, and various types of latex.

Q 14. Describe the importance of maintaining consistent tension during the tufting process.

Maintaining consistent tension during the tufting process is absolutely crucial for producing high-quality carpets. Inconsistent tension leads to a variety of issues. Think of it like playing a stringed instrument – if the strings are not properly tuned, the music will be off-key.

Even Pile Height: Consistent tension ensures that the tufts are inserted at the same depth, resulting in an even pile height and a uniform appearance. Uneven tension leads to variations in pile height, making the carpet look uneven and unprofessional.

Density and Durability: Consistent tension helps maintain the desired density of the tufts. Insufficient tension leads to a loosely packed carpet, reducing its durability and making it more susceptible to wear and tear.

Pattern Consistency: In patterned carpets, consistent tension is essential for maintaining the clarity and precision of the design. Uneven tension can distort the pattern or make it unclear.

Reduced Machine Wear: Consistent tension reduces stress on the tufting machine components, extending the machine’s life and decreasing maintenance costs.

Q 15. Explain the concept of carpet density and how it relates to durability.

Carpet density refers to the number of tufts per square inch (or square meter) and the weight of the yarn used. It’s a crucial factor determining the carpet’s durability and lifespan. Think of it like this: a densely packed carpet is like a tightly woven fabric – more resistant to wear and tear. A less dense carpet, on the other hand, will show wear and matting more quickly.

Higher density generally equates to better durability. A carpet with more tufts packed closer together will be more resistant to crushing, shedding, and wear from foot traffic. The type of yarn also plays a role; a heavier yarn in a high-density carpet will further enhance durability.

For example, a high-traffic area like a hallway would benefit from a carpet with a high density and durable yarn, while a low-traffic bedroom might tolerate a lower density carpet.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of cutting methods used to produce cut pile carpet?

Cut pile carpets employ several cutting methods to create the desired pile height and texture. The primary methods include:

- Heat-setting: This involves using heated blades to cut the loops of the carpet, creating a uniform, consistent cut pile. It’s common for many styles and is efficient for mass production.

- Scissors Cutting: A more traditional method, this uses sharp blades to cut the loops, offering more control over the pile texture. It can create a more varied look but is less efficient than heat-setting.

- Laser Cutting: A newer technology employing lasers to cut the pile. This method offers precision and can create intricate designs, but can be cost-prohibitive for large-scale production.

The choice of cutting method depends on factors like the desired carpet look, production volume, and budget constraints.

Q 17. How do you calculate production efficiency in a cut pile tufting operation?

Calculating production efficiency in cut pile tufting involves assessing several key metrics. It’s not just about how many square yards are produced but also the quality and speed of production.

We typically measure it in terms of:

- Square Yards per Hour (SYPH): This is a primary indicator of production speed. We track the total square yardage produced divided by the number of operational hours.

- Machine Uptime Percentage: This represents the percentage of time the tufting machine is actually producing carpet (as opposed to being down for maintenance or repairs). A high uptime percentage reflects better efficiency.

- Defect Rate: The percentage of carpet produced with flaws such as yarn breaks, missed tufts, or uneven pile. A low defect rate indicates higher efficiency and quality control.

Overall efficiency is assessed by analyzing these metrics together. For instance, a high SYPH might be offset by a high defect rate, suggesting areas for improvement in the process.

Q 18. Describe different methods for improving the efficiency of the tufting process.

Improving tufting process efficiency involves several strategies:

- Preventative Maintenance: Regularly scheduled maintenance on machines minimizes downtime and ensures consistent performance. A well-maintained machine runs faster and produces higher-quality carpet.

- Operator Training: Well-trained operators are more efficient and reduce errors. Regular training sessions and refresher courses improve both speed and product quality.

- Process Optimization: Analyzing the workflow to identify bottlenecks. This might involve adjustments to the machine settings, raw material handling, or even the layout of the production floor. Lean manufacturing principles can be extremely valuable here.

- Automation: Incorporating automated systems for tasks like yarn feeding or quality control can significantly enhance speed and reduce human error.

- Improved Raw Materials: Utilizing higher-quality yarns that are less prone to breakage can contribute to higher production efficiency.

For example, a factory I worked with significantly increased its SYPH by implementing a new preventative maintenance schedule and retraining its operators on best practices.

Q 19. What are the environmental considerations in cut pile carpet manufacturing?

Environmental considerations in cut pile carpet manufacturing are increasingly crucial. The industry faces pressure to reduce its environmental footprint through various measures.

- Sustainable Raw Materials: Using recycled or sustainably sourced materials like recycled fibers (PET) or yarns made from renewable resources minimizes environmental impact.

- Reduced Water Consumption: Implementing water-efficient dyeing and finishing processes can reduce water usage in the manufacturing process.

- Waste Management: Effective waste management strategies, including recycling yarn scraps and reducing landfill waste, are essential for sustainability.

- Energy Efficiency: Investing in energy-efficient equipment and processes minimizes energy consumption and greenhouse gas emissions. This can also impact the overall cost-effectiveness of production.

- Chemical Management: Using low-VOC (Volatile Organic Compounds) dyes and adhesives reduces air pollution and improves worker safety.

Many manufacturers now focus on obtaining certifications like ISO 14001 for Environmental Management to demonstrate their commitment to sustainability.

Q 20. Explain the role of different types of adhesives in carpet backing.

Adhesives play a crucial role in securing the carpet’s primary backing and secondary backing. The choice of adhesive depends on factors like the carpet type, the desired performance, and the environmental considerations.

- Primary Backing Adhesives: These hold the tufted carpet face to the primary backing material (often jute or polypropylene). They need strong adhesion and flexibility to withstand the stresses of installation and use. Common types include latex-based adhesives.

- Secondary Backing Adhesives: These adhere the primary backing to a secondary backing (often a foam or felt layer). The selection here depends on the specific secondary backing material and the desired characteristics of the finished carpet. Water-based adhesives are often used.

The adhesive must possess the right balance of strength, flexibility, and environmental compatibility. Latex is a common choice, but there is ongoing research into sustainable alternatives that offer similar performance without the negative environmental impact.

Q 21. How do you ensure consistent color throughout a large carpet production run?

Maintaining consistent color throughout a large production run requires meticulous attention to detail throughout the entire process.

- Precise Dyeing: Using automated dyeing machines with precise controls ensures consistent dye application to the yarn. Regular calibration and quality checks of the dyeing equipment are vital.

- Batch Control: Dyeing in controlled batches ensures uniformity. Each batch needs to meet stringent color specifications to avoid variations across different parts of the carpet.

- Color Management System: Utilizing a sophisticated color management system that tracks and standardizes color throughout the process is crucial. This often involves spectrophotometers for precise color measurement.

- Yarn Storage and Handling: Proper storage and handling of dyed yarn prevent color degradation or contamination before tufting.

- Regular Quality Control: Samples from each batch must be inspected to check for color consistency, using tools like spectrophotometers for objective color assessment.

Ignoring these steps can lead to noticeable color variations, requiring costly rework or even rejection of entire batches.

Q 22. What are the common causes of defects in cut pile tufted carpets?

Defects in cut pile tufted carpets are unfortunately common, stemming from various stages of the production process. Think of it like baking a cake – if one ingredient is off or a step is missed, the final product suffers. These defects can significantly impact the final look, feel, and durability of the carpet.

- Yarn-related issues: Uneven yarn dyeing, inconsistent yarn thickness, or using low-quality yarn can lead to variations in color, texture, and pile height. Imagine a cake with unevenly distributed chocolate chips – it wouldn’t look appealing.

- Tufting machine malfunctions: Problems with the needle bar, gauge, or the yarn feed system can result in missed stitches, uneven pile density, and tuft shedding. This is like a cake with parts that are underbaked due to oven problems.

- Backing fabric flaws: Defects in the backing fabric, such as holes, inconsistent weight, or poor adhesion, can weaken the carpet and cause premature wear. The cake equivalent would be a cracked baking pan leading to an unevenly baked cake.

- Latex application issues: Uneven or insufficient latex application can lead to poor tuft adhesion and backing delamination. It’s akin to not having enough frosting to hold the cake layers together.

- Finishing and handling issues: Improper cutting, heat-setting, or handling during shipping can also contribute to defects such as cutting damage or uneven pile.

Identifying the root cause requires careful examination of the finished carpet and a review of the entire production process. A systematic approach, starting with the raw materials and following each step, is essential for effective defect prevention.

Q 23. How do you handle customer complaints related to carpet quality?

Handling customer complaints regarding carpet quality is crucial for maintaining customer satisfaction and brand reputation. It’s about treating each complaint as a valuable learning opportunity. My approach involves a structured process:

- Active Listening and Empathy: I begin by actively listening to the customer’s concerns, showing empathy and validating their feelings. This helps build trust and rapport.

- Detailed Information Gathering: I gather detailed information about the complaint, including photos of the defect, the carpet’s installation date, and usage conditions. The more information I have, the better I can understand the situation.

- Defect Analysis: I analyze the reported defect, using my technical knowledge to determine the likely cause. Is it a manufacturing defect, installation error, or something else?

- Appropriate Solution: Based on the analysis, I propose a solution. This may include repair, replacement, a partial refund, or a combination of options. Transparency is key here; I explain the rationale behind the chosen solution.

- Follow-Up: I follow up with the customer to ensure that they are satisfied with the resolution. A positive resolution can turn a negative experience into a positive one.

For instance, if a customer complains about uneven pile height, I would investigate whether it’s due to a machine malfunction during production, improper installation, or perhaps even damage caused after installation. The solution would then be tailored to the identified cause.

Q 24. Describe your experience with different types of tufting machines.

My experience encompasses a wide range of tufting machines, from older, more manual models to the latest high-speed automated systems. Each machine type has its own strengths and weaknesses. For example:

- Single Needle Machines: These older machines are slower but offer greater control and are often used for specialized or smaller production runs. They are like a skilled craftsman hand-crafting a beautiful piece of furniture.

- Multi-Needle Machines: These are more common in high-volume production. They are faster and more efficient but require more precise maintenance and skilled operators. They are like a well-oiled assembly line in a modern factory.

- High-Speed Electronic Machines: These state-of-the-art machines offer high speed, precision, and advanced features like automated pattern control and yarn tension management. These are the top-of-the-line machines, providing amazing output and consistency.

My expertise lies not just in operating these machines, but also in understanding their mechanical workings, troubleshooting malfunctions, and optimizing their performance for maximum efficiency and quality. I’ve worked on machines from various manufacturers, allowing me to adapt quickly to different systems and settings.

Q 25. Explain the importance of preventative maintenance on tufting machinery.

Preventative maintenance on tufting machinery is paramount for ensuring consistent production, minimizing downtime, and maintaining product quality. It’s like regularly servicing your car to prevent major breakdowns – far less costly and disruptive in the long run.

- Regular Inspections: Daily visual inspections of critical components such as needles, yarn guides, and the backing fabric feed system are essential to detect potential problems early on.

- Scheduled Maintenance: Regular lubrication, cleaning, and replacement of worn parts according to the manufacturer’s recommendations are crucial. This minimizes wear and tear and extends the lifespan of the equipment.

- Calibration and Adjustment: Regular calibration of the machine’s various settings, such as needle penetration depth and yarn tension, is vital for maintaining consistent tuft height and density.

- Operator Training: Properly trained operators can identify and report potential problems promptly, preventing minor issues from escalating into major breakdowns.

Neglecting preventative maintenance can lead to costly repairs, production delays, and inconsistent carpet quality. A proactive maintenance program is a significant investment in operational efficiency and product excellence.

Q 26. How do you maintain optimal yarn tension during the tufting process?

Maintaining optimal yarn tension is critical in cut pile tufting, directly impacting the quality, appearance, and durability of the finished carpet. Think of it as the tension on a violin string – too tight, and it breaks; too loose, and it sounds dull. The ideal tension must be carefully controlled.

Several factors influence yarn tension, and maintaining it involves a multi-pronged approach:

- Proper Machine Setup: This involves correctly setting the tension mechanisms on the tufting machine based on the yarn type and desired pile height. Different yarn types have different optimal tension requirements.

- Yarn Quality Control: Using consistent, high-quality yarn with uniform thickness and twist minimizes variations in tension. Inconsistent yarn leads to inconsistencies in the finished product.

- Regular Monitoring: Continuous monitoring of yarn tension during the tufting process using tension meters is crucial for early detection of any deviations from the optimal level. Early detection prevents significant problems.

- Automated Tension Control: Modern tufting machines often incorporate automated tension control systems that dynamically adjust yarn tension based on real-time feedback. This enhances consistency.

- Operator Training: Experienced operators are trained to recognize signs of incorrect tension and make the necessary adjustments quickly, preventing defects.

Inconsistent yarn tension can lead to uneven pile height, loose tufts, and poor overall carpet quality. Therefore, maintaining optimal tension is a continuous process requiring attention to detail and proactive measures.

Q 27. Describe your experience with quality control systems and procedures.

My experience with quality control systems and procedures is extensive. I’ve implemented and managed various QC systems, always striving for continuous improvement. A robust system includes the following key elements:

- Incoming Raw Material Inspection: Thoroughly inspecting yarn and backing fabrics for defects before they enter the production process minimizes the risk of producing defective carpets. This is the first line of defense against quality issues.

- In-Process Quality Checks: Regular checks during the tufting process, including checks on yarn tension, pile height, and stitch density, ensure that the process remains within acceptable parameters.

- Final Product Inspection: A thorough inspection of the finished carpets before they leave the facility identifies and removes any defective rolls. This includes visual checks for defects, as well as checks on physical properties like pile height and density.

- Statistical Process Control (SPC): Using SPC methods allows for continuous monitoring and analysis of process parameters, identifying trends and potential problems before they become major issues. This is a proactive approach to quality management.

- Defect Tracking and Analysis: Maintaining detailed records of defects, including their causes and frequency, helps to identify patterns and areas for improvement. This facilitates problem-solving and process optimization.

I’ve seen firsthand the benefits of a well-designed QC system. It not only improves product quality but also reduces waste, increases production efficiency, and enhances customer satisfaction.

Q 28. What are your strategies for improving team productivity in a carpet manufacturing environment?

Improving team productivity in a carpet manufacturing environment requires a multi-faceted approach that focuses on motivation, training, and efficient workflow. It’s about fostering a culture of teamwork and continuous improvement.

- Empowerment and Motivation: Giving team members a sense of ownership and responsibility for their work, and recognizing their contributions through rewards and incentives, increases motivation and productivity.

- Skill Development and Training: Investing in comprehensive training programs that equip employees with the necessary skills and knowledge to perform their jobs effectively is crucial. This reduces errors and improves efficiency.

- Lean Manufacturing Principles: Implementing Lean manufacturing principles to eliminate waste, streamline processes, and improve workflow can significantly boost productivity. This involves identifying and eliminating bottlenecks.

- Communication and Collaboration: Encouraging open communication and collaboration among team members ensures that information flows smoothly and problems are addressed promptly. Regular team meetings to discuss challenges and solutions are highly beneficial.

- Ergonomic Workspaces: Creating comfortable and ergonomic workspaces can reduce fatigue and improve worker safety, indirectly increasing productivity. Happy workers are productive workers.

- Performance Feedback: Providing regular, constructive feedback helps workers improve their performance and identify areas where they can be more efficient. This ensures continuous learning and development.

Ultimately, building a highly productive team requires a holistic approach that addresses both individual and team needs. It’s a continuous process of assessment, improvement, and adaptation.

Key Topics to Learn for Cut Pile Tufted Carpet Production Interview

- Tufting Process Fundamentals: Understanding the entire tufting process, from yarn preparation to backing application, including primary backing types and their impact on carpet performance.

- Yarn Selection and Properties: Knowing the characteristics of different yarn types (e.g., nylon, polyester, wool) and their suitability for various carpet applications. Practical application includes understanding how yarn choice affects durability, texture, and cost.

- Needle Selection and Gauge: The relationship between needle selection, gauge, and the final carpet density and appearance. This includes understanding how to adjust needle parameters for different carpet styles.

- Backing and Adhesive Application: Mastering the techniques for applying primary and secondary backing materials, understanding the importance of proper adhesive application for dimensional stability and longevity.

- Quality Control and Inspection: Familiarizing yourself with common quality defects in cut pile tufted carpets and the procedures for identifying and addressing them. This includes understanding industry standards and testing methodologies.

- Maintenance and Troubleshooting: Developing problem-solving skills related to common issues encountered in the production process, such as yarn breaks, machine malfunctions, and quality control issues.

- Production Efficiency and Optimization: Exploring strategies to improve production efficiency, minimize waste, and maximize output while maintaining high quality standards. This includes understanding production line flow and optimization techniques.

- Health and Safety Regulations: Demonstrating an awareness of the relevant health and safety regulations and practices within a carpet manufacturing environment.

Next Steps

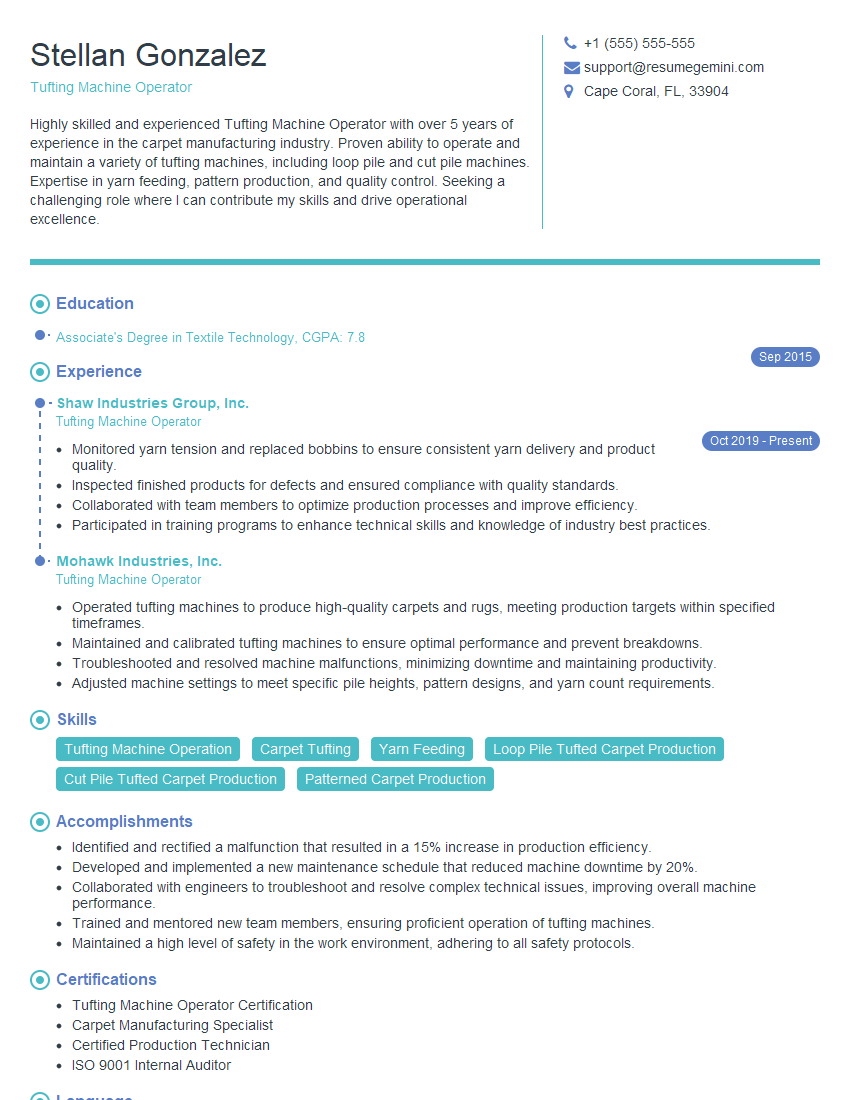

Mastering Cut Pile Tufted Carpet Production opens doors to exciting career opportunities within the textile industry, offering diverse roles with increasing responsibility and potential for growth. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience in this field. Examples of resumes specifically tailored to Cut Pile Tufted Carpet Production are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?