Unlock your full potential by mastering the most common Machine Tending interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Machine Tending Interview

Q 1. Describe your experience with different types of machine tending equipment.

My experience with machine tending equipment spans a wide range of technologies, from simple robotic arms loading CNC machines to complex automated systems involving conveyors, vision systems, and sophisticated robotic manipulators. I’ve worked with various types of robots, including articulated robots (the most common type), SCARA robots (ideal for pick-and-place operations in a horizontal plane), and delta robots (fast and precise for high-speed picking). I’m also familiar with different end-of-arm tooling (EOAT), such as grippers, vacuum cups, and magnetic grippers, chosen based on the specific part being handled. For instance, in one project involving delicate electronic components, we used specialized vacuum grippers to avoid damage. In another project with metal castings, robust grippers with force sensors were crucial to ensure a secure grip and avoid dropping the parts. I’ve also worked extensively with collaborative robots (cobots), which offer safety advantages by working alongside human operators.

Q 2. Explain the process of setting up a machine for operation.

Setting up a machine for operation is a methodical process that requires attention to detail. It begins with a thorough review of the machine’s operating manual and safety procedures. Next, I’d verify that all necessary tooling is installed correctly and securely. This includes checking for proper alignment and wear. Then, I’d load the raw materials, ensuring they’re properly positioned and secured. The machine’s control parameters are then configured based on the specific job requirements; this might include adjusting feed rates, spindle speeds, depths of cut (for CNC machines), or other relevant settings. A test run, often with a small batch, is crucial to ensure the process parameters are optimized, the quality of the output is acceptable, and no issues are present. Finally, I’d perform a final safety check before starting full-scale production.

For example, when setting up a CNC milling machine, I’d meticulously check the tool offsets using a probe or other measurement tools. Incorrect offsets could lead to inaccurate machining and potentially damage the part or the machine. Only after verifying all aspects of the setup would I proceed with the machining process.

Q 3. How do you ensure the quality of parts produced by the machine?

Ensuring part quality is paramount. My approach involves a multi-pronged strategy starting with rigorous setup procedures as described earlier. During the initial test runs and throughout production, I regularly monitor the machine’s performance and the quality of the parts produced. This often involves using various quality control methods, such as visual inspection, dimensional checks using calipers or CMM (Coordinate Measuring Machine), and functional testing where appropriate. Statistical Process Control (SPC) charts can be utilized to monitor key parameters and identify any trends indicating potential quality issues. Any deviations from specifications trigger immediate investigation to find and correct the root cause. In one instance, we identified a gradual decrease in part accuracy by meticulously examining the SPC chart. This led us to discover slight wear on the machine’s spindle, which was subsequently addressed through maintenance.

Q 4. What are the common safety precautions you take while operating a machine?

Safety is my top priority. Before operating any machine, I always ensure that I’m wearing appropriate personal protective equipment (PPE), such as safety glasses, hearing protection, and in some cases, gloves or a safety apron. I thoroughly inspect the machine for any signs of damage or loose components before starting it. I never operate the machine with any guards removed or bypassed, and I always follow the manufacturer’s lockout/tagout procedures for maintenance and repair. I maintain a clean and organized workspace to avoid tripping hazards, and I ensure that all emergency stop buttons are easily accessible and functional. Moreover, I’m trained in and follow all relevant safety regulations and company policies. The safety of myself and others is never compromised.

Q 5. How do you identify and troubleshoot common machine malfunctions?

Troubleshooting machine malfunctions begins with careful observation and data analysis. I first identify the symptoms of the malfunction – is it a sudden stop, a reduction in output quality, or an unusual noise? I then consult the machine’s manual and error codes to get a better understanding of the possible causes. I systematically check various components – sensors, actuators, electrical connections, and pneumatic systems – to pinpoint the problem. Logical diagnostic steps, such as checking for power supply issues, loose connections, or faulty sensors, are implemented. Specialized diagnostic tools, such as multimeters and oscilloscopes, are sometimes necessary. In one instance, a recurring machine jam was traced to a worn-out component in the material feeding system through systematic checks. Once identified, the faulty part was replaced, resolving the issue and preventing further downtime.

Q 6. Describe your experience with preventive maintenance procedures.

Preventive maintenance is key to minimizing downtime and ensuring consistent machine performance. My experience includes performing routine tasks such as lubricating moving parts, cleaning and inspecting sensors, checking for wear and tear on critical components, and verifying the accuracy of machine tools. I follow predefined maintenance schedules provided by the manufacturer and also note any anomalies during operations that could require extra attention. Preventive maintenance also includes regular calibration of measuring devices and ensuring proper functionality of safety systems. Proper documentation of all maintenance activities is also crucial for tracking performance and identifying potential issues before they become major problems. A well-maintained machine operates more efficiently and produces higher-quality parts, reducing long-term costs.

Q 7. How do you handle unexpected downtime or machine breakdowns?

Handling unexpected downtime or breakdowns involves a rapid, organized response. First, I ensure the safety of myself and others by securing the machine and following appropriate lockout/tagout procedures. Then, I try to quickly diagnose the problem using the methods described earlier. If the issue is beyond my immediate capabilities, I immediately report the problem to the appropriate maintenance personnel, providing them with all relevant information such as error codes and observations. During downtime, depending on the situation, I might implement temporary workarounds or prioritize other tasks to minimize production impact. A detailed log of the incident, including the nature of the problem, downtime duration, corrective actions taken, and lessons learned, is maintained to prevent future recurrences. The goal is to restore machine operation as quickly and safely as possible while minimizing disruption to production.

Q 8. What is your experience with different types of tooling and fixtures?

My experience with tooling and fixtures spans a wide range, encompassing various types used in CNC machining, robotic milling, and automated assembly. I’m proficient in selecting, installing, and maintaining tooling such as end mills, drills, reamers, and taps, ensuring proper clamping and alignment for optimal performance. Fixture experience includes designing and implementing custom fixtures for complex part geometries, using techniques like 3-2-1 clamping to minimize workpiece movement and ensure repeatability. For instance, I once designed a fixture using quick-change tooling that reduced setup time by 40% on a high-volume production line. I’m familiar with various materials for tooling and fixtures, including hardened steel, carbide, and various plastics, and understand the trade-offs between durability, cost, and precision.

- Experience with Quick-Change Tooling: Significantly reduced machine downtime and increased throughput.

- Experience with Modular Fixtures: Allowed for flexible adaptation to different part designs and reduced the cost associated with specialized tooling.

- Experience with Tool Pre-setting: Ensured high precision and repeatability in machining operations.

Q 9. How familiar are you with Programmable Logic Controllers (PLCs)?

My PLC programming skills are extensive. I’m proficient in several PLC platforms, including Allen-Bradley and Siemens, and have experience with ladder logic, function block diagrams, and structured text programming. I can design, implement, and troubleshoot PLC programs to control machine automation systems, including input/output (I/O) management, safety systems, and motion control. I’ve worked on projects involving complex sequential control, data logging, and integration with SCADA systems. For example, I once debugged a PLC program that was causing a production bottleneck by identifying a timing issue in the ladder logic that was delaying a critical process. This involved careful analysis of the PLC program, use of diagnostic tools, and subsequent modification of the program to address the timing flaw.

Example Ladder Logic Snippet (Allen-Bradley): //Illustrative only, syntax might vary depending on the specific PLC and version.XIC I:0.0 OTE O:0.0This simple snippet shows a contact (XIC) monitoring input I:0.0 and energizing an output O:0.0 when the input is ON. This is a basic building block for more complex PLC programs.

Q 10. Describe your experience with reading and interpreting blueprints or schematics.

I possess a strong ability to read and interpret blueprints, schematics, and other technical documents. I can understand dimensional tolerances, material specifications, and assembly instructions. I utilize these documents to program CNC machines, configure robotic systems, and ensure proper setup and operation of automated machinery. I understand various drawing standards, including ANSI and ISO. For instance, in a recent project involving the setup of a new robotic welding cell, I used the provided schematics to correctly interface the robot controller with the PLC system and ensure the safe and efficient operation of the welding process. I regularly use CAD software to interpret 3D models and generate necessary tooling designs or modifications, further enhancing my understanding of part designs and the processes involved in their creation.

Q 11. How do you ensure the accurate and efficient loading and unloading of materials?

Accurate and efficient loading and unloading are critical to maximizing machine uptime and minimizing errors. My approach focuses on several key areas: First, I ensure proper material handling equipment is used, selecting conveyors, robots, or other systems appropriate for the material’s size, weight, and fragility. Second, I optimize the loading/unloading sequence to minimize cycle time and avoid collisions. This often involves programming robotic systems or creating custom fixtures to handle parts effectively. Third, I implement robust quality control measures, such as vision systems or automated gauging, to ensure that only properly prepared parts are loaded into the machine, preventing errors and scrap. Finally, effective process documentation and standardized operating procedures are essential. For example, I implemented a vision system on a machine tending application that automatically rejected parts with dimensional inconsistencies before they were processed by the machine, leading to a significant reduction in scrapped parts.

Q 12. What is your understanding of different machine control systems?

I’m familiar with various machine control systems, from simple manual controls to sophisticated CNC and PLC-based systems. My experience includes working with different control interfaces such as HMIs (Human Machine Interfaces), touch screens, and custom software applications. I understand the principles of feedback control, motion control, and safety interlocks. For example, I’ve worked with CNC machines employing G-code programming and Siemens 840D control systems. I’m comfortable configuring and troubleshooting these systems, as well as working with newer systems incorporating advanced technologies such as predictive maintenance using sensors and machine learning algorithms.

Q 13. Explain your experience with data collection and reporting procedures.

Data collection and reporting are integral to improving machine efficiency and overall process optimization. I’m proficient in using various data acquisition methods, from direct readings from machine sensors to employing data logging software and industrial networking protocols such as Ethernet/IP or Profinet. This data is then used to create reports that track key performance indicators (KPIs) such as Overall Equipment Effectiveness (OEE), cycle time, scrap rates, and downtime reasons. I have experience using various software tools for data analysis and visualization, such as spreadsheets, databases, and dedicated manufacturing execution systems (MES). For example, in a recent project, I implemented a system that tracked machine downtime reasons in real-time. This enabled me to identify recurring issues and implement preventative measures, resulting in a substantial increase in overall machine uptime.

Q 14. How do you maintain cleanliness and orderliness in your work area?

Maintaining a clean and orderly workspace is paramount for safety and efficiency. My approach involves a structured system of 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain. This includes regularly cleaning and organizing tools, materials, and equipment, ensuring that everything has a designated place. I follow all safety regulations for handling potentially hazardous materials and maintaining a clutter-free work environment to minimize the risk of accidents. Regular preventative maintenance on machines and equipment also plays a significant role in maintaining cleanliness and orderliness, as it prevents spills, leaks, and other issues that can lead to a messy workspace. For example, I instituted a daily cleaning schedule for the machine tending cell I was responsible for, which involved allocating specific time slots for cleaning and maintenance tasks and assigning responsibility to individual team members. This led to a noticeable improvement in the cleanliness and efficiency of the workspace.

Q 15. Describe your experience with working in a team environment.

Teamwork is crucial in machine tending, where efficient collaboration ensures smooth operations and optimal productivity. My experience spans various team structures, from small, focused units to larger, multi-disciplinary teams. In a recent project involving the implementation of a new automated loading system, I actively participated in brainstorming sessions with engineers, technicians, and operators to identify potential bottlenecks and develop solutions. I thrive in collaborative environments, contributing my expertise while actively listening to and valuing the insights of my colleagues. My communication skills are honed to bridge any knowledge gaps and ensure everyone understands the tasks and goals. For example, during a machine malfunction, I collaborated effectively with the maintenance team to diagnose the problem, implementing a temporary fix while coordinating the repair. This involved clear communication, concise reporting, and actively contributing to the solution, highlighting my ability to work both independently and as a crucial member of a collaborative team.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks and manage your time effectively?

Effective time management and task prioritization are essential for maximizing productivity in machine tending. I use a combination of techniques to manage my workload effectively. I employ a system that prioritizes tasks based on urgency and impact, utilizing tools like Kanban boards (both physical and digital) to visualize workflow and progress. I also leverage time-blocking to allocate specific time slots for critical tasks, minimizing interruptions and maximizing focus. For example, during a period of high production demand, I prioritized preventative maintenance tasks to avoid costly downtime later, allocating specific time blocks before and after peak production hours for this purpose. Proactive planning and anticipating potential delays are key; I regularly review my schedule and adjust as needed, ensuring efficient use of my time. This proactive approach minimizes stress and keeps projects on schedule, while maintaining high quality output.

Q 17. Describe your experience with using different measurement tools.

My experience with measurement tools encompasses a wide range, from basic calipers and micrometers for precise dimensional checks to advanced laser measurement systems for complex part geometries. I’m proficient in using dial indicators for surface flatness and runout measurements, and I regularly employ CMM (Coordinate Measuring Machines) for high-precision dimensional inspection. Understanding the capabilities and limitations of each tool is crucial; for example, while CMMs provide very high accuracy, their use might not be justified for routine checks, whereas calipers offer sufficient accuracy for many tasks. Calibration and maintenance of these tools is critical to ensure accuracy and reliability; I regularly perform these tasks, adhering to strict protocols and maintaining detailed records. I’ve also trained others in the proper use and maintenance of these tools, ensuring consistent quality across the team.

Q 18. How do you adapt to changing work priorities and processes?

Adaptability is a cornerstone of success in machine tending, as priorities and processes frequently shift in response to changing production demands or unexpected issues. I approach change proactively, seeking to understand the rationale behind it and actively participate in the implementation of new processes. For instance, when our production line shifted from one product to another, requiring a reconfiguration of the machinery and tooling, I readily adapted, quickly mastering the new setup and training my colleagues on the updated procedures. My approach involves actively seeking clarification on new processes, asking questions to ensure a thorough understanding, and contributing suggestions to improve efficiency. A flexible mindset and a willingness to embrace new challenges are crucial for navigating the ever-changing landscape of manufacturing. Continuous learning is a key factor; I regularly seek out opportunities to enhance my skills and knowledge through workshops and professional development initiatives.

Q 19. What is your experience with different types of manufacturing processes?

My experience encompasses a range of manufacturing processes, including milling, turning, grinding, and drilling. I’m familiar with both CNC (Computer Numerical Control) and manual machine operation. In my previous role, I worked extensively with CNC milling machines, programming and operating them to manufacture complex parts with high precision. I’ve also worked with automated assembly lines, understanding the integration of various machines to achieve a complete manufacturing process. Furthermore, I possess hands-on experience with various material types, including metals (steel, aluminum, brass), plastics, and composites, understanding the unique properties and machining requirements of each. This diverse experience allows me to contribute effectively across various manufacturing settings. For example, troubleshooting issues with a particular material, like resolving chatter during high-speed milling of aluminum, leverages my deep understanding of material properties and machine parameters.

Q 20. How familiar are you with various quality control standards and procedures?

I’m familiar with various quality control standards and procedures, including ISO 9001, and have practical experience implementing these standards in manufacturing environments. This includes understanding and following documented procedures, conducting regular inspections using various measurement tools, and accurately documenting findings. I’m adept at identifying defects, root causes, and corrective actions. For example, implementing a Statistical Process Control (SPC) chart to monitor a critical dimension throughout a production run. Understanding statistical methods enables me to proactively identify trends and prevent defects before they significantly impact production. My experience also includes working with quality assurance teams to address non-conformances, proposing and implementing corrective actions to prevent recurrence. This includes contributing to continuous improvement initiatives to improve overall product quality.

Q 21. Describe your problem-solving skills in the context of machine tending.

Problem-solving is a daily occurrence in machine tending. My approach is methodical and systematic. I begin by thoroughly defining the problem, gathering all relevant data, including error messages, machine logs, and visual inspections. Then, I systematically investigate potential causes, using a structured troubleshooting approach (often a decision tree or a 5-Why analysis). For instance, when a machine repeatedly jammed, I systematically checked each stage of the process, from raw material feed to finished product output, eventually identifying a misalignment in the clamping mechanism. Once the root cause is identified, I implement corrective actions and document the solution for future reference. This proactive approach reduces downtime, improves efficiency, and enhances overall process reliability. I also believe in continuous learning; each problem encountered becomes a valuable learning opportunity to refine my troubleshooting skills and preventative strategies.

Q 22. Explain your experience with using safety equipment and personal protective equipment (PPE).

Safety is paramount in machine tending. My experience encompasses consistent and meticulous use of all mandated PPE, including safety glasses, hearing protection, steel-toe boots, and appropriate gloves depending on the machine and task. I’m trained on the proper donning and doffing procedures for each piece of equipment and understand the specific hazards they protect against. For instance, when working with a CNC lathe, I always wear safety glasses to shield against flying debris and hearing protection to mitigate the constant high-pitched noise. Beyond the standard PPE, I’m also proficient in using specialized equipment like machine-specific guards and emergency shut-off devices. I proactively inspect all PPE before each shift to ensure it’s in good working order and immediately report any damage or deficiencies.

Q 23. How do you ensure compliance with all safety regulations and procedures?

Compliance with safety regulations is non-negotiable. I meticulously follow all company policies, OSHA guidelines, and any manufacturer-specific instructions for the machinery I operate. This includes regular safety training, participating in safety meetings, and actively looking for potential hazards. I’m always aware of lockout/tagout procedures (ensuring machinery is properly de-energized before maintenance) and understand the importance of reporting any near-miss incidents or unsafe conditions immediately. A specific example would be my adherence to strict procedures before cleaning or performing maintenance on a robotic arm – always powering it down completely and using appropriate lockout/tagout procedures before any physical interaction.

Q 24. Describe your experience with documenting machine operations and maintenance activities.

Detailed documentation is crucial for efficient machine tending. I’m experienced in maintaining comprehensive logs of machine operations, including production counts, downtime reasons, material usage, and quality control checks. I utilize both digital and physical methods, using CMMS (Computerized Maintenance Management Systems) software for tracking maintenance schedules and repair records. For example, if a machine malfunctions, I meticulously document the error message, the time of the failure, the steps taken to troubleshoot the problem, the solution implemented, and the resulting downtime. This detailed information is vital for preventative maintenance, identifying recurring issues, and improving overall machine performance. I also maintain meticulous logs of the materials used, which is crucial for inventory management and cost control.

Q 25. How do you improve efficiency and reduce waste in the machine tending process?

Improving efficiency and reducing waste involves a multi-pronged approach. Firstly, I focus on optimizing machine settings based on the specific job requirements. This includes fine-tuning speeds, feeds, and tool paths to maximize output while minimizing material waste. Secondly, I’m proficient in identifying and eliminating bottlenecks in the production process, often through streamlining workflows and improving material handling techniques. For example, I might suggest reorganizing the workspace to reduce travel time or implement a system for better material organization. I also actively participate in continuous improvement initiatives, proposing solutions to reduce downtime and improve overall productivity. Finally, regular preventative maintenance reduces unexpected downtime and increases the lifespan of machinery, thus minimizing waste in the long run.

Q 26. How would you handle a situation where a machine produces defective parts?

When defective parts are produced, my immediate action is to stop the machine and isolate the problem. I meticulously inspect the defective parts to identify the root cause. This could involve examining the raw materials, checking the machine settings, or assessing the tooling. Once the cause is identified, I take corrective action, which might involve adjusting machine parameters, changing tools, or replacing faulty components. I then meticulously document the entire incident, including the number of defective parts, the cause of the defect, and the corrective measures taken. Furthermore, I follow established procedures for handling and disposing of defective parts, ensuring they’re separated from good parts and handled in accordance with company policies and safety regulations.

Q 27. What are your strengths and weaknesses as a machine tender?

My strengths include meticulous attention to detail, strong problem-solving skills, and a proactive approach to safety. I’m highly adaptable and readily learn new technologies and processes. My experience with various machine types and software makes me a versatile asset. However, my weakness is sometimes getting overly focused on perfection, which can occasionally slow down the process. To address this, I’m working on improving my time management skills and prioritization techniques, which will allow me to maintain high quality while ensuring timely completion of tasks.

Q 28. Where do you see yourself in five years in the field of machine tending?

In five years, I envision myself as a skilled and experienced machine tending supervisor or a highly proficient CNC programmer and operator. I plan to further develop my expertise in advanced manufacturing techniques, particularly in areas like automation and robotics. This will allow me to contribute to a more efficient and technologically advanced manufacturing environment. My goal is to become a valuable asset to a company, contributing to improved productivity and continuous process optimization while mentoring and training newer team members.

Key Topics to Learn for Your Machine Tending Interview

- Machine Operation & Safety: Understanding the specific machinery you’ll be operating, including safety protocols, emergency procedures, and lockout/tagout procedures. Practical application: Be prepared to discuss your experience following safety regulations and troubleshooting minor malfunctions safely.

- Quality Control & Inspection: Identifying defects in materials or finished products, understanding quality control metrics, and implementing corrective actions. Practical application: Describe your experience with quality checks, identifying defects, and documenting findings.

- Maintenance & Troubleshooting: Basic machine maintenance, identifying and resolving minor issues, and understanding preventative maintenance schedules. Practical application: Share examples of how you’ve performed basic maintenance or troubleshooting tasks, highlighting your problem-solving skills.

- Production Processes & Efficiency: Understanding the overall production process, identifying bottlenecks, and suggesting improvements to efficiency. Practical application: Discuss instances where you improved efficiency or identified areas for improvement in a production setting.

- Data Collection & Analysis: Gathering and analyzing production data to track performance, identify trends, and improve overall output. Practical application: Discuss your experience with data logging and analysis, even if it’s basic record-keeping.

- Teamwork & Communication: Effective communication with supervisors and colleagues, collaborating on tasks, and working as part of a team. Practical application: Provide examples demonstrating your teamwork and communication skills in a manufacturing environment.

Next Steps

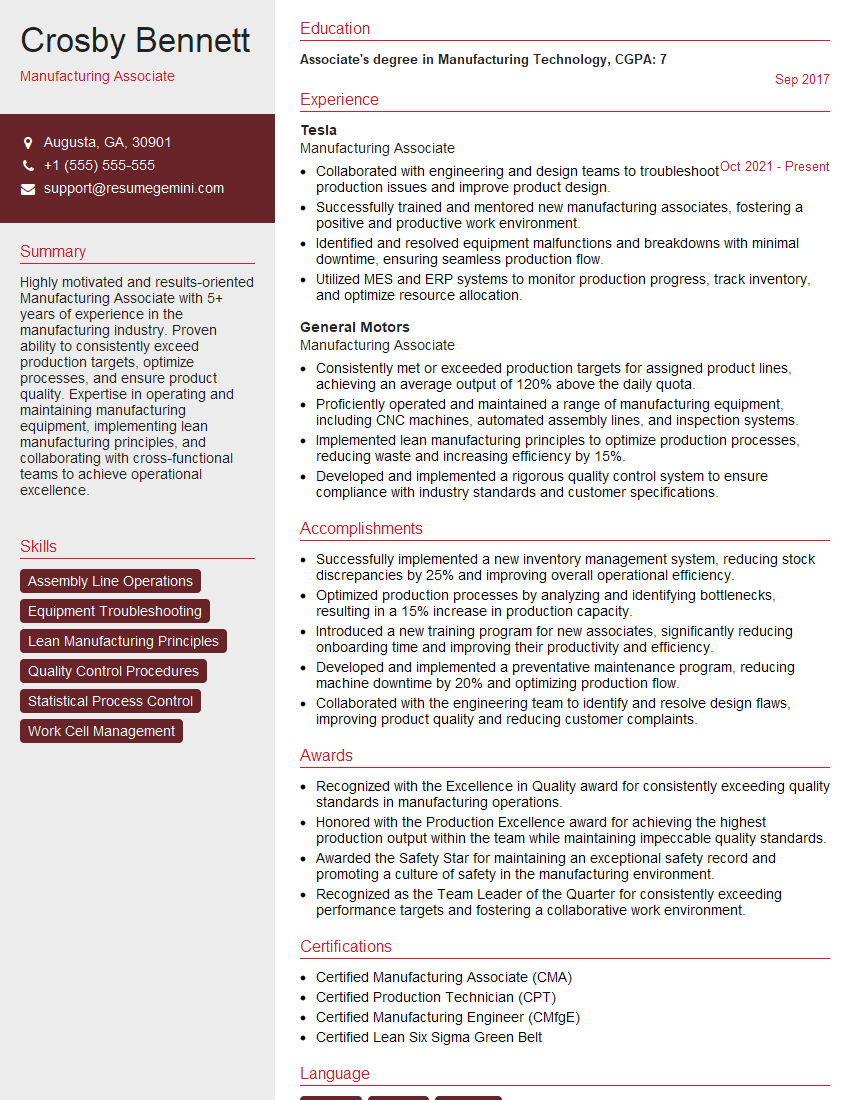

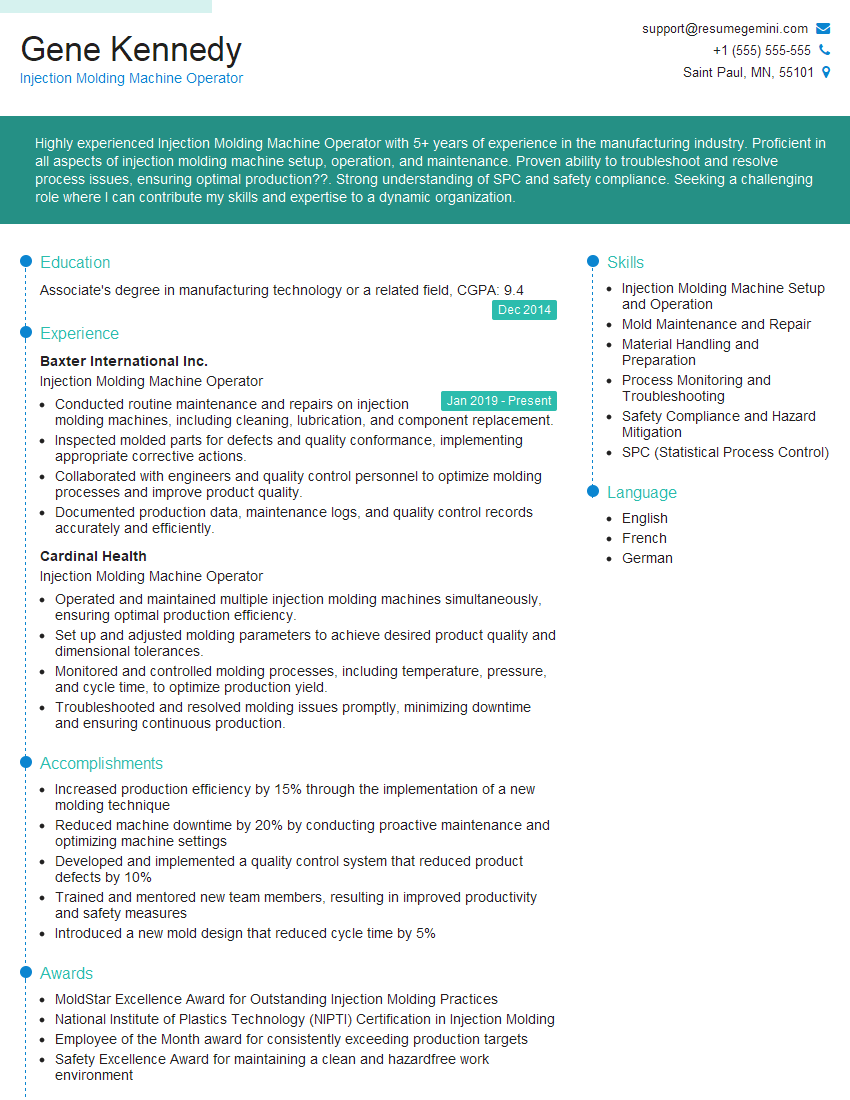

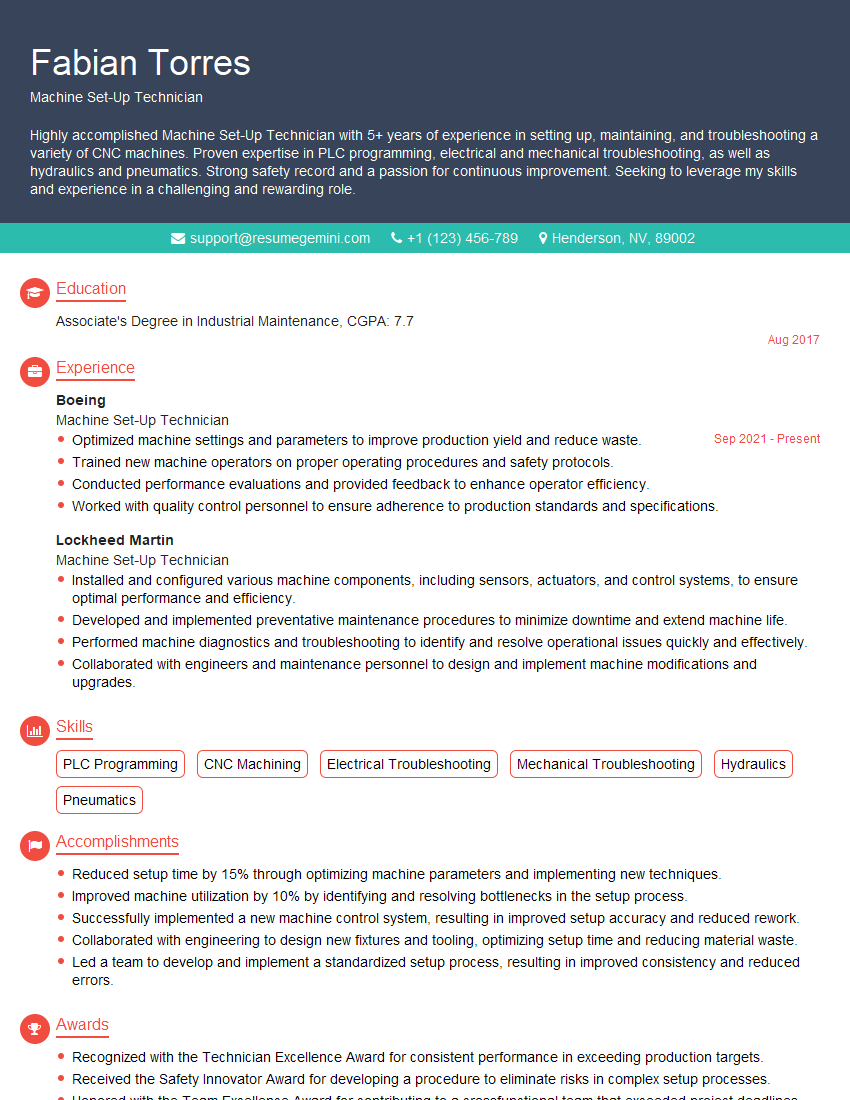

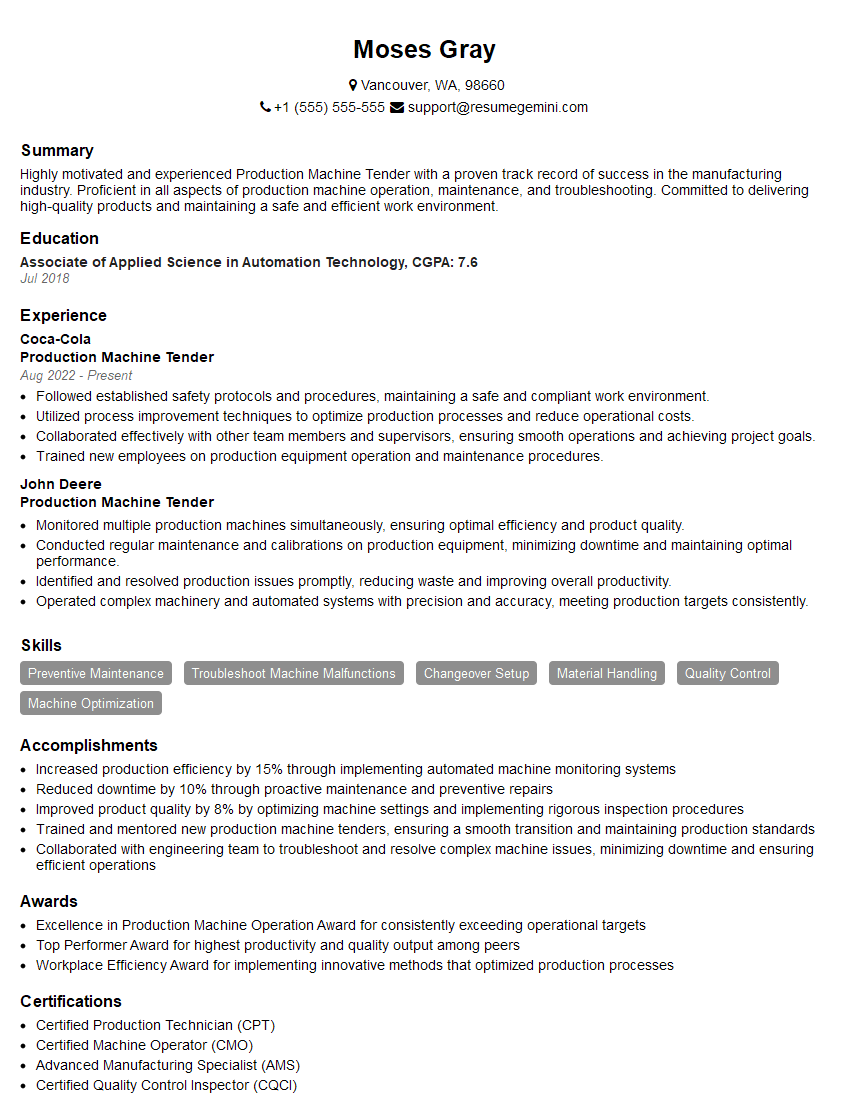

Mastering Machine Tending opens doors to a rewarding career with excellent growth potential, offering opportunities for advancement into supervisory roles or specialized technical positions. To maximize your job prospects, a well-crafted, ATS-friendly resume is essential. ResumeGemini can help you create a professional and impactful resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to Machine Tending positions to help you get started. Invest the time to build a strong resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?