Cracking a skill-specific interview, like one for Coopering, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Coopering Interview

Q 1. Describe the different types of wood used in coopering and their suitability for various applications.

The choice of wood in coopering is crucial, impacting the barrel’s longevity, flavor imparted to its contents, and overall quality. Different woods possess unique properties influencing their suitability for specific applications.

- Oak: Arguably the most popular choice, especially American and French oak, known for its strength, durability, and ability to impart desirable flavors to wines and spirits. French oak, for instance, is often preferred for its finer grain and subtle vanilla notes. American oak tends to be more robust and imparts bolder, spicier flavors.

- Chestnut: Historically used extensively, chestnut offers good strength and water resistance, making it suitable for various applications, though it’s less common now.

- Maple: A lighter-colored wood, maple is sometimes used for food-grade barrels, especially those intended for non-aged products, as it imparts a less pronounced flavor profile.

- Other Woods: While less common for wine and spirits barrels, other woods like redwood, acacia, and even mulberry find niche uses in coopering, depending on the desired properties and the product stored within.

The choice of wood often depends on budget, the type of liquid to be aged, and the desired flavor profile. For instance, a distillery might choose American oak for a bolder bourbon, while a winery may select French oak for a more nuanced Chardonnay.

Q 2. Explain the process of selecting and seasoning wood for barrel construction.

Selecting and seasoning wood for barrel construction is a critical process influencing the final product’s quality and durability. The process begins with selecting logs from sustainably managed forests, prioritizing straight-grained, defect-free wood.

- Initial Selection: Cooperage mills carefully inspect logs, discarding those with knots, cracks, or other flaws that would compromise the stave’s integrity.

- Sawing: The logs are sawn into planks, carefully oriented to maximize the use of the straightest grain.

- Seasoning: This is arguably the most crucial step. The planks are air-dried for several years, often up to two years or more, allowing them to gradually lose moisture. This slow drying process prevents cracking and warping, critical for stave strength and longevity. Modern techniques sometimes include kiln drying but carefully managed to avoid compromising quality.

- Final Inspection: Once dried, the wood is inspected again to ensure it meets the required quality standards before it proceeds to the stave-making process.

Improper seasoning can lead to significant problems during barrel construction and ultimately result in leaking barrels or compromised flavor profiles for the stored product. The precise duration of air-drying varies based on climatic conditions and wood type.

Q 3. What are the key steps involved in making a stave?

Creating a stave is a precise process requiring skilled craftsmanship. Here’s a breakdown:

- Ripping: The seasoned wood planks are ripped (sawn) into staves of the desired thickness and width. The dimensions are crucial for creating a well-fitting barrel.

- Shaping: Each stave is carefully shaped using specialized tools, such as draw knives and spokeshaves, to achieve the correct croze (the groove at the end where the heads will fit) and the overall barrel curvature. The shaping process requires considerable skill to ensure consistent dimensions and a tight fit between staves.

- Planing: The stave’s surfaces are planed to ensure smoothness and uniformity. This is essential for creating a leak-proof barrel and a consistent surface area for charring, if necessary.

- Finishing (Optional): For some applications, the staves undergo further processes, such as charring (toasting), which imparts different flavor profiles and impacts the barrel’s permeability.

The precision needed at each stage is paramount to prevent leaks and ensure the barrel’s structural integrity. A skilled cooper can feel the wood’s grain and adjust their tools accordingly to avoid cracks or splits.

Q 4. How do you ensure the proper dimensions and shape of staves?

Ensuring proper stave dimensions and shape relies on a combination of skilled craftsmanship and specialized tools. Precision is key.

- Templates and Jigs: Coopers use templates and jigs to guide the shaping process, ensuring consistent dimensions and curvature across all staves.

- Measuring Tools: Precise measuring tools, including calipers and rulers, are used to verify stave dimensions throughout the process.

- Experienced Eye: Years of experience allow a cooper to visually assess the stave’s shape and make subtle adjustments to achieve the desired profile. The feel of the wood plays an important role in this assessment.

- Trial Assembly: Staves are often dry-assembled to check for fit before hooping. This allows for fine-tuning if necessary, ensuring a tight seal.

Modern technologies like laser cutting offer increased precision but often lack the nuanced understanding of wood grain that an experienced cooper brings to the process.

Q 5. Detail the process of assembling staves to form a barrel.

Assembling staves into a barrel is a demanding yet elegant process that involves careful precision and skilled technique.

- Setting Up: The shaped staves are carefully placed in a cooper’s jig or a truing machine to ensure they are aligned correctly. The croze at the end of each stave should be aligned to ensure proper fitting of the heads.

- Tightening: Initially, loose hoops are placed to hold the staves together. As the cooper adds more hoops, the staves are progressively tightened. The cooper may use mallets to ensure a snug fit between staves. This step is critical to preventing leaks.

- Hooping: The process of progressively tightening the hoops is crucial. The hoops are driven down tightly and evenly, ensuring that all staves are under equal pressure to form a strong, watertight barrel.

- Head Insertion: Once the body of the barrel is formed, the heads (circular wooden pieces) are inserted into the crozes at both ends, ensuring a tight and leak-proof seal.

This process requires considerable strength and skill, and the cooper must ensure even pressure across all staves to prevent leaks or uneven stress.

Q 6. Explain the importance of proper hooping techniques.

Proper hooping techniques are paramount to the success of a barrel. The hoops hold the staves together, creating the barrel’s structural integrity and preventing leaks. Improper hooping can lead to failure of the barrel.

- Even Tension: Hoops must be tightened evenly around the barrel’s circumference. Uneven tension can cause stress on specific staves, leading to warping or leaks.

- Proper Seating: Hoops must be seated correctly in their grooves to prevent slipping or loosening over time. The hoops should fully engage with the stave’s grooves to create maximum strength and stability.

- Appropriate Hoop Material: The selection of hoop material is critical, influenced by barrel size, intended use, and desired lifespan.

A well-hooped barrel can last for decades, while poorly hooped barrels might fail quickly. The process requires significant experience and a feel for the correct tension.

Q 7. What types of hoops are used in coopering and what are their advantages and disadvantages?

Various types of hoops are used in coopering, each with advantages and disadvantages:

- Wooden Hoops: Traditionally used, wooden hoops are strong and aesthetically pleasing but can be prone to expansion and contraction with changes in humidity, potentially leading to loosening over time. They also require more careful maintenance and are susceptible to breakage.

- Metal Hoops: Modern barrels often use steel or aluminum hoops, offering superior strength, resistance to expansion and contraction, and longer lifespan. Steel hoops are exceptionally strong but can be more challenging to work with and may impart a metallic taste if not properly treated.

- Combination Hoops: Some barrels use a combination of wood and metal hoops – often a wooden hoop in the middle for the aesthetic and metal hoops at the ends for added strength.

The choice of hoop type often depends on factors such as the barrel’s size, intended use, cost, and aesthetic preferences. For example, high-end wine barrels often utilize a combination hoop design, and smaller barrels may use all-wood hoops.

Q 8. Describe the process of charring barrels and its effect on the final product.

Charring a barrel, a crucial step in coopering, involves carefully burning the interior staves to a specific level. This process, often done over an open flame or in a controlled kiln, isn’t just about aesthetics; it profoundly impacts the final product, particularly in wine and spirit aging.

The degree of charring, usually classified as light, medium, or heavy toast, influences the barrel’s interaction with the contents. Light toasting adds subtle vanilla and caramel notes, while medium toast brings more pronounced spice and smoky flavors. Heavy toasting imparts a bolder, more intense character, often with charred wood notes. The charring also creates pores in the wood, increasing the surface area available for interaction and extraction of compounds from the barrel into the liquid. For example, a heavily charred bourbon barrel will impart a significant smoky profile to the whiskey, unlike a lightly toasted wine barrel.

The charring process also affects the barrel’s permeability. A heavier char will lead to more porous wood, allowing for a greater exchange of oxygen, which can influence the maturation rate of the aging product within.

Q 9. How do you check for leaks in a finished barrel?

Checking for leaks in a finished barrel requires a methodical approach. First, we visually inspect the barrel for any obvious gaps or cracks in the staves or between the staves and the heads. Then, we perform a pressure test. This often involves filling the barrel completely with water and carefully observing for any seepage. We let the barrel sit for a considerable amount of time, sometimes overnight, then closely examine all seams.

Another effective method is a vacuum test. A vacuum pump creates a pressure differential, and any leaks will easily be identified by escaping air bubbles. For very fine leaks, we can use a combination of water and a food-safe dye, allowing us to precisely locate the source. A high-quality barrel should hold water for a significant amount of time (a couple of days) without any leakage. Any significant leaks must be repaired using traditional coopering techniques.

Q 10. Explain the different types of barrel finishes and their applications.

Barrel finishes are applied to the interior of the barrel to modify the flavor profile imparted to the aging product. These finishes can significantly alter the taste and aroma, adding complexity and depth. There are several types, each with its unique application:

- Toasted: This is a simple heating process, usually done before charring, that caramelizes sugars in the wood, resulting in softer vanilla and caramel flavors. This is commonly used in wine and spirit barrels.

- Charred: As described earlier, this involves burning the interior staves. Different levels of charring (light, medium, heavy) result in varying levels of smoky, spicy, and charred wood flavors.

- Extracted: This involves using different types of wood for staves (e.g., different oak species) to impart distinct flavors. The wood is carefully chosen for its unique flavor profiles, providing a particular nuance. For instance, French oak is known for its vanilla and spice notes, while American oak tends toward coconut and vanilla.

- Specialized Finishes: Some cooperages offer specialized finishes, such as those involving infusions of different fruitwoods or even herbs, to impart very unique flavor characteristics. A whiskey maker might choose a barrel previously used for sherry to get added complexity and sweetness.

The choice of finish depends on the specific product being aged and the desired final flavor profile. Winemakers, for instance, often prefer lighter toasting or specialized finishes, while distilleries might opt for heavier charring for whiskey or rum.

Q 11. What are common problems encountered during the coopering process and how are they addressed?

Coopering, a craft demanding precision, presents various challenges. One common issue is stave splitting, often caused by improper seasoning of the wood or stress during barrel assembly. We address this by carefully selecting well-seasoned wood and employing techniques to minimize stress during the construction phase. Another is improper head fitting, which can lead to leaks. This is usually solved by adjusting the head and using appropriate tools to ensure a tight fit.

Variations in wood density can also create inconsistencies. This is managed through careful selection and sorting of staves before assembly. Finally, tools can wear down or become damaged, impacting precision and efficiency. Regular maintenance and timely replacement of tools are vital. These are not just cosmetic issues; inconsistencies can result in leaks, impacting the final product and storage.

Q 12. Describe the tools and equipment used in a cooperage.

The tools and equipment used in a cooperage are specialized and varied, reflecting the precision and skill required. These include:

- Shaving Horse: A workhorse for shaping staves.

- Drawknife: Used for initial shaping and smoothing of staves.

- Froe: A splitting tool for cleaving wood.

- Adze: For shaping the croze (groove) in the staves.

- Croze Irons: For forming and shaping the croze accurately.

- Bending Irons: Help in shaping the staves to the required curve.

- Driving Irons: To join staves during assembly.

- Barrel Hoops: Metal hoops are used to fasten the assembled staves.

- Hoop Driver: A heavy-duty tool to drive hoops securely.

- Steam Box: To steam the staves and make them pliable for bending.

Modern cooperages may also utilize power tools like planers, and specialized equipment for charring and finishing.

Q 13. How do you maintain and repair damaged barrels?

Maintaining and repairing damaged barrels involves a blend of traditional and modern techniques. Minor cracks or splits can often be repaired by using special wood glue and carefully clamping the affected area. If the damage is more extensive, replacement of damaged staves might be necessary, a process that requires skilled coopering techniques. Repairing leaks often involves recrozing (re-shaping the groove) and re-hooping. The affected area should be completely cleaned and dried before starting the repair, to ensure proper adhesion.

Larger repairs sometimes require partial disassembly, cleaning, and reassembly. Damaged hoops can be replaced, using tools to carefully remove the damaged sections and fit in new hoops. Regular inspections and proactive maintenance can minimize major repairs; the earlier minor issues are detected, the easier they are to fix.

Q 14. What safety precautions are essential when working with coopering tools and machinery?

Safety is paramount in a cooperage. Sharp tools like froes, drawknives, and adzes require extreme caution and proper training. Eye protection (safety glasses), cut-resistant gloves, and sturdy footwear are essential. When using power tools, following the manufacturer’s safety instructions is mandatory, including the use of appropriate guards and hearing protection. The steam box operates under high pressure and requires careful handling to prevent burns.

Proper ventilation is critical when working with wood and charring processes, as wood dust and fumes can be hazardous. Working in a well-lit and organized environment minimizes the risk of accidents. Finally, regular maintenance and inspection of equipment are critical for safe operation; damaged or worn-out tools should be repaired or replaced promptly.

Q 15. What is the difference between a tight barrel and a slack barrel?

The difference between a tight barrel and a slack barrel lies in how tightly the staves are fitted together and the resulting degree of permeability. A tight barrel has staves that are meticulously fitted, creating a very small space between them. This minimizes air and liquid exchange, leading to slower aging and less evaporation (ullage). Think of it like a well-sealed container; it keeps the contents well-protected. A slack barrel, on the other hand, has more space between the staves, allowing for greater oxygen interaction with the contents. This increases evaporation and often leads to a faster, more pronounced aging process. Imagine a slightly leaky container; it allows for more interaction with the surrounding environment. The choice between tight and slack depends largely on the type of product and the desired aging profile.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of barrel toasting and its impact on flavor.

Barrel toasting is a crucial step in cooperage where the interior of the barrel is heated to varying degrees. This process alters the wood’s chemical composition, influencing the final flavor of the aged product. The level of toasting, typically categorized as light, medium, or heavy, determines the intensity of the impact. Light toasting enhances subtle vanilla and caramel notes, whereas medium toasting brings out more pronounced toasty and spicy flavors. Heavy toasting introduces richer, smoky, and even slightly charred characteristics. For example, a heavily toasted barrel might be ideal for a bold bourbon, while a lightly toasted barrel suits a delicate white wine. The toasting process caramelizes sugars within the wood and creates various compounds that interact with the liquid, imparting a unique flavor signature. It’s a delicate balance; over-toasting can lead to bitter or unpleasant flavors.

Q 17. How does the grain orientation of the staves affect the barrel’s strength and performance?

The grain orientation of the staves significantly impacts barrel strength and performance. Radial staves, cut perpendicular to the tree’s growth rings, are stronger and less prone to leakage. They are the preferred choice for high-quality barrels because of their structural integrity. The tight grain structure resists expansion and contraction better than other orientations. Tangential staves, cut parallel to the growth rings, are less expensive, but they are more likely to leak and expand or contract significantly with changes in temperature and humidity, potentially compromising the barrel’s structural soundness. Imagine radial staves as tightly woven fabric, offering strength and resistance, whereas tangential staves are like loosely woven fabric, more prone to stretching and tearing.

Q 18. What are the key quality control measures in coopering?

Quality control in coopering is paramount. It begins with the selection of high-quality wood, typically white oak for bourbon barrels. The process involves rigorous checks at each stage:

- Stave Inspection: Checking for knots, cracks, and other defects.

- Joint Tightness: Ensuring staves are precisely fitted to minimize leakage.

- Heading Precision: Perfecting the heads to create a secure seal.

- Toasting Control: Monitoring temperatures and duration to achieve the desired level of toasting.

- Leak Testing: Thoroughly testing the barrel for leaks after assembly.

- Barrel Sizing: Ensuring the barrel meets the specified dimensions.

Q 19. Describe the different types of barrels used for various alcoholic beverages.

Different alcoholic beverages require barrels with specific characteristics.

- Bourbon Whiskey: Typically uses new, charred American white oak barrels.

- Scotch Whisky: Often uses ex-bourbon barrels or sherry casks.

- Wine: Utilizes a variety of barrels, including French oak for its subtle notes, and American oak for its bolder flavors.

- Cognac: Frequently employs French oak barrels, often older ones, imparting specific aging characteristics.

- Rum: May use ex-bourbon barrels, ex-sherry casks, or even new oak barrels, depending on the desired profile.

Q 20. How does the size and shape of a barrel affect its functionality?

The size and shape of a barrel directly impact its functionality. Larger barrels offer a higher surface area-to-volume ratio, resulting in slower aging due to less interaction between the liquid and the wood. Smaller barrels exhibit the opposite effect, leading to faster, more intense aging. The shape, while typically cylindrical, can also vary, with certain wine barrels having a slightly conical shape. These variations influence the interaction of the liquid with the wood and can influence the extraction of different flavor compounds. The size also affects the storage capacity and overall handling logistics.

Q 21. What are the environmental considerations in coopering?

Environmental considerations in coopering are significant. Sustainable forestry practices are crucial to ensure a long-term supply of high-quality oak. Minimizing waste during the barrel-making process is important, and many cooperages now utilize innovative techniques to reduce their environmental footprint. The toasting process requires careful management to minimize air pollution, and responsible disposal of wood waste is essential. Water usage during the coopering process should be minimized, and coopers should seek methods to improve water efficiency. Many are also adopting sustainable methods like using renewable energy in their operations.

Q 22. How do you calculate the volume of a barrel?

Calculating the volume of a barrel isn’t as straightforward as calculating a simple cylinder due to its bulging shape. We typically use approximations, with the most common being the formula derived from approximating the barrel as a combination of cylinders and frustums (truncated cones).

One common method involves measuring the diameter at three key points: the bung diameter (largest diameter), the head diameter (smallest diameter), and the length of the barrel. Then, we use a formula that accounts for these variations. A simplified version of this formula, suitable for many barrels, is:

Volume ≈ πL/6 * (2Db + Dh)Where:

Volumeis the volume of the barrel.πis pi (approximately 3.14159).Lis the length of the barrel.Dbis the bung diameter.Dhis the head diameter.

For greater accuracy, particularly with significantly bulging barrels, more complex formulas exist, sometimes involving multiple diameter measurements or using advanced mathematical models. I’ve often used specialized software for precision in such cases, particularly when working with wine barrels where accuracy is paramount for fermentation and aging.

Q 23. What are the different types of coopering joints?

Coopering joints are the heart of barrel construction, and different joints are suited to different purposes and barrel styles. The most common are:

- Croze Joint: This is the fundamental joint for connecting the staves. The ends of each stave are carefully shaped to fit snugly into a groove (the croze) cut into the barrel’s head. It’s a crucial joint for watertightness and structural integrity. Think of it as the interlocking bricks of a well-constructed wall. The precision of this cut is critical.

- Tab and Groove (or Tongue and Groove): Similar to the croze, but instead of relying on a purely shaped groove, it uses a tongue projecting from one stave and a corresponding groove on the adjoining stave for added strength and alignment. You’ll often find this used in conjunction with the croze for added security.

- Butt Joint: A simpler joint where the ends of the staves meet directly, often reinforced with additional hoops. This is typically found in less demanding applications or for certain barrel types.

The choice of joint depends on factors such as the desired barrel strength, the type of liquid to be stored, and even the traditions of the cooperage. Each joint requires specific tools and a high level of skill to execute properly.

Q 24. Explain the process of repairing a damaged hoop.

Repairing a damaged hoop is a delicate process requiring precision and patience. The success of the repair hinges on careful assessment of the damage and selecting the correct approach.

Steps for Repairing a Damaged Hoop:

- Assessment: Examine the damaged hoop for cracks, breaks, or significant bends. Determine the extent of the damage.

- Removal (if necessary): Carefully remove the damaged hoop using specialized tools to avoid further damaging the staves. This might involve carefully using a hoop driver to work the hoop free.

- Replacement or Repair: If the hoop is beyond repair, replace it with a new hoop of the correct size and material. If it’s just a minor bend or crack, attempt to straighten it or fill small cracks with suitable epoxy. Care must be taken to not weaken the hoop in the process.

- Reinstallation: Carefully reinstall the repaired or new hoop using a hoop driver, tightening it evenly to restore the barrel’s shape and stability. This requires a delicate touch to avoid damaging the wood or overtightening the hoop.

- Inspection: After reinstallation, inspect the barrel for any leaks or structural weaknesses.

Remember, using the correct tools, particularly hoop drivers and specialized hammers, is key for a professional repair. Improper techniques can easily lead to further damage.

Q 25. Describe your experience with different wood types (oak, chestnut, etc.)

My experience spans various wood types, each with its unique properties and suitability for coopering.

- Oak: White oak is the king in coopering. Its tight grain, durability, and resistance to water make it ideal for wine and spirit barrels. The different oak species (French, American, etc.) impart varying flavors and aromas to the stored liquid, which is a crucial factor for winemakers and distillers. I’ve worked extensively with both American and French oak, noticing the distinct differences in grain structure and resulting barrel characteristics.

- Chestnut: Chestnut offers good durability and workability but is less widely used than oak. Its grain is often straighter, leading to potentially easier stave construction, but it’s less resistant to weathering.

- Other Woods: Other woods, such as redwood and certain types of pine, have been used historically but are less common now due to the superior properties of oak.

Understanding the wood’s grain direction, moisture content, and potential for cracking or warping is crucial for successful coopering. I’ve learned to adapt my techniques to the unique characteristics of each wood type. For example, I might adjust the hoop spacing for certain woods to allow for seasonal expansion and contraction.

Q 26. How do you handle variations in wood quality?

Variations in wood quality present a constant challenge in coopering. I employ several strategies to manage this:

- Careful Selection: I meticulously select staves, prioritizing those with tight grain, minimal knots, and consistent thickness. Defective staves are rejected to maintain the barrel’s structural integrity and watertightness. I’ve developed a keen eye for spotting flaws in the wood.

- Adaptive Techniques: For staves with minor imperfections, I often adjust my tooling techniques to minimize their impact. This may involve careful shaping or fitting to accommodate a knot or a slight variation in thickness.

- Grading and Sorting: Staves are graded according to their quality, and those of similar quality are grouped together to ensure uniformity in barrel construction. This avoids mixing significantly different wood qualities within a single barrel.

- Quality Control: Regular inspections throughout the construction process ensure early identification and correction of any issues arising from wood quality variations. This minimizes the chance of flawed barrels making it to the final stages.

Managing wood quality variability is a crucial skill for any experienced cooper. It’s more than just skill; it’s about careful observation and problem-solving throughout the process.

Q 27. Explain your experience with different coopering techniques (traditional vs. modern).

My experience encompasses both traditional and modern coopering techniques, each with its advantages and limitations.

Traditional Coopering: This relies on hand tools and time-honored techniques passed down through generations. It involves a high level of skill and craftsmanship and often results in unique and high-quality barrels. However, it is significantly more time-consuming and labor-intensive, limiting production.

Modern Coopering: This incorporates power tools and machinery to increase efficiency and production. While it may lead to greater consistency, it can sometimes compromise the craftsmanship and unique characteristics of the hand-made barrels. I’ve personally used machinery like automated stave shapers while maintaining a focus on the quality and precision inherent to the traditional process.

I believe the ideal approach involves a careful balance. I strive to leverage modern efficiencies where appropriate without sacrificing the quality and artistry that define traditional coopering. This often involves employing modern tools for specific tasks, while maintaining a strong commitment to the manual precision that remains critical to the best coopering.

Q 28. What are your strengths and weaknesses as a cooper?

Strengths: My primary strengths lie in my meticulous attention to detail, extensive experience with diverse wood types and coopering techniques, and my ability to adapt to varying wood qualities. I’m highly skilled in both traditional hand-tool techniques and the use of modern machinery, allowing for flexibility in production. My dedication to precision ensures high-quality, durable barrels. I also value collaboration and strive to meet client needs and expectations effectively.

Weaknesses: Like any craftsman, I am sometimes challenged by the unpredictable nature of wood. While my experience helps mitigate this, unexpected imperfections or variations can require more time and resourcefulness than anticipated. Also, while proficient in various coopering techniques, I can always improve my efficiency in specific areas. I’m actively working on refining my techniques to consistently meet the high standards I set for myself.

Key Topics to Learn for Coopering Interview

- Wood Selection and Properties: Understanding different wood types, their grain structure, and suitability for various cooperage projects. Practical application: Explaining the choice of wood for specific barrel types (e.g., wine, whiskey).

- Coopering Tools and Techniques: Familiarity with traditional and modern tools used in coopering, including adzes, crozes, and shaping tools. Practical application: Describing the process of assembling staves and hoops.

- Stave Preparation and Shaping: Detailed knowledge of techniques for preparing and shaping staves to ensure tight joints and structural integrity. Practical application: Explaining how to address irregularities in stave dimensions.

- Hooping and Assembly: Understanding the process of assembling staves, applying hoops, and ensuring water-tightness. Practical application: Troubleshooting common issues during assembly.

- Finishing and Maintenance: Knowledge of various finishing techniques and maintenance procedures to protect cooperage products. Practical application: Discussing the importance of proper barrel care and storage.

- Quality Control and Inspection: Understanding the quality control processes involved in coopering, including leak testing and dimensional checks. Practical application: Identifying potential defects and suggesting solutions.

- Health and Safety: Awareness of safety procedures and regulations related to using sharp tools and working with wood. Practical application: Describing safe work practices in a cooperage environment.

- Cooperage History and Traditions: Understanding the history and evolution of coopering, including traditional techniques and modern innovations. Practical application: Discussing the impact of technology on coopering practices.

Next Steps

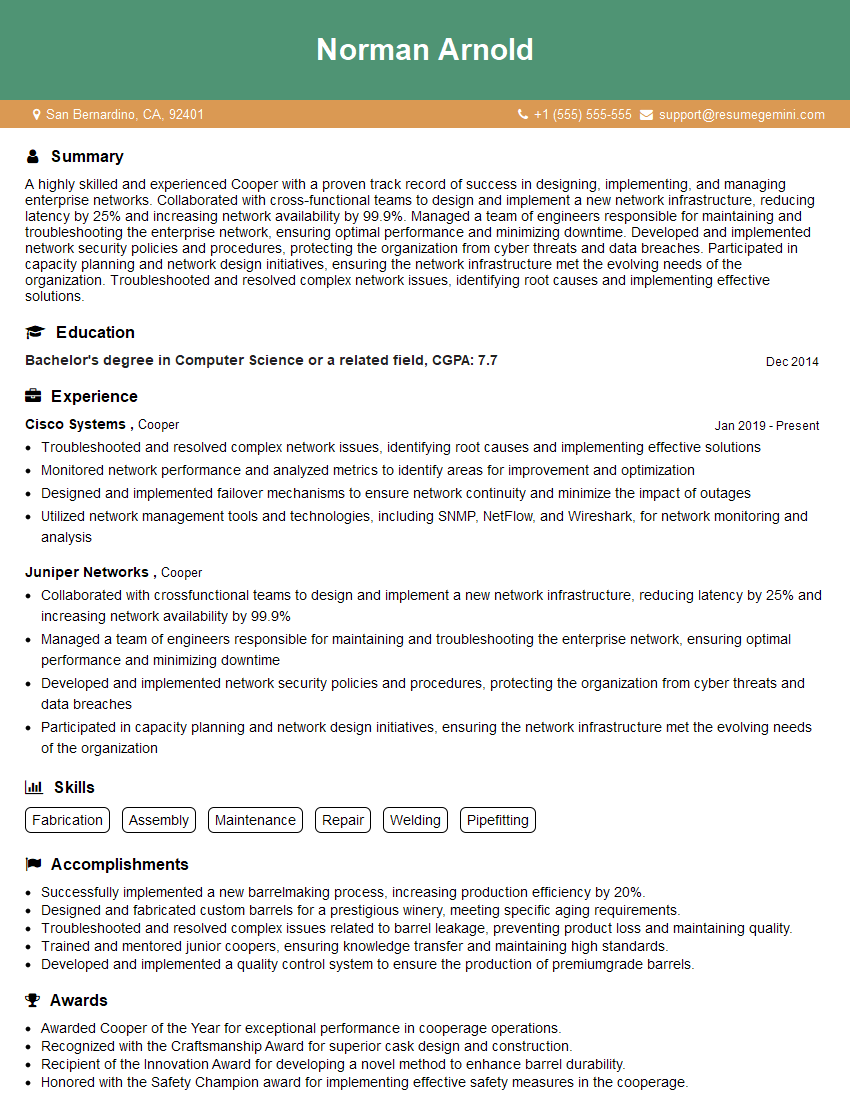

Mastering coopering opens doors to a rewarding career in a skilled trade with a rich history. To enhance your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by potential employers. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your coopering expertise. ResumeGemini provides examples of resumes tailored specifically to the coopering industry, giving you a head start in showcasing your qualifications. Take the next step towards your dream career – build your winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?