Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Food Safety Assessment interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Food Safety Assessment Interview

Q 1. Describe your experience with implementing HACCP plans.

Throughout my career, I’ve been extensively involved in implementing and managing HACCP (Hazard Analysis and Critical Control Point) plans across diverse food production settings, from small-scale bakeries to large-scale meat processing facilities. My experience encompasses all stages, from initial hazard analysis and critical control point identification to the development and implementation of monitoring, corrective action, and verification procedures. For example, in a recent project with a seafood processing plant, I led a team in identifying potential hazards such as bacterial contamination and allergen cross-contamination. We then established critical control points at key stages like receiving raw materials, processing, and packaging, defining critical limits for temperature and time, and implementing monitoring systems. This resulted in a significant reduction in food safety incidents.

In another instance, I helped a small-scale organic farm implement a simplified HACCP plan focusing on the critical control points of harvesting, washing, and packaging of their produce. This involved training their staff on proper sanitation practices and temperature monitoring, ensuring the safe handling of their organic produce from farm to market. My approach always emphasizes a collaborative and practical methodology, tailored to the specific needs and resources of each operation.

Q 2. Explain the seven principles of HACCP.

The seven principles of HACCP provide a systematic approach to identifying and controlling food safety hazards. They are:

- Principle 1: Conduct a Hazard Analysis: Identify potential biological, chemical, and physical hazards that could occur at each stage of the food production process. Think of this like a detective’s investigation – we meticulously examine every step to find potential threats.

- Principle 2: Determine Critical Control Points (CCPs): Identify the specific steps in the process where control is essential to prevent or eliminate a hazard or reduce it to an acceptable level. These are the crucial points where we need to focus our attention.

- Principle 3: Establish Critical Limits: For each CCP, define measurable limits that must be met to ensure control. This is setting concrete, measurable standards – like a specific temperature or time limit.

- Principle 4: Establish Monitoring Procedures: Develop and implement procedures to monitor CCPs and ensure critical limits are being met. Regular checks and measurements are vital here – it’s like checking your car’s vital signs regularly.

- Principle 5: Establish Corrective Actions: Define corrective actions to be taken when monitoring indicates that a critical limit has not been met. Having a plan B (or C) is crucial if things go wrong.

- Principle 6: Establish Verification Procedures: Develop procedures to verify that the HACCP system is working effectively. Regular audits and reviews ensure the system remains effective over time.

- Principle 7: Establish Record-Keeping and Documentation Procedures: Maintain thorough records to document all aspects of the HACCP system. Thorough documentation is like keeping a detailed lab notebook for complete transparency and traceability.

Q 3. How do you identify and mitigate food safety hazards?

Identifying and mitigating food safety hazards requires a multi-faceted approach. It begins with a thorough hazard analysis, considering all potential sources of contamination – biological (bacteria, viruses, parasites), chemical (pesticides, toxins), and physical (glass, metal, bone fragments). This involves reviewing the entire food production chain, from raw material sourcing to final product distribution.

For instance, in a bakery, a hazard analysis might reveal the risk of Salmonella contamination from eggs. Mitigation strategies would include purchasing eggs from reputable suppliers with robust safety protocols, ensuring proper storage temperatures, and implementing strict hygiene practices throughout the egg-handling and baking processes. For chemical hazards, a thorough assessment of the ingredients used, including their origin and potential pesticide residues, would be crucial. Physical hazards are addressed by using metal detectors and visual inspection.

Risk assessment plays a crucial role in prioritizing hazards. We employ quantitative methods where possible, using data on the likelihood of a hazard occurring and the severity of its potential consequences. This enables us to focus resources on the most significant risks first.

Q 4. What are your strategies for ensuring food safety during storage and transportation?

Ensuring food safety during storage and transportation is critical. Proper temperature control is paramount, using refrigeration and freezing as necessary to inhibit microbial growth. For example, perishable goods must maintain a temperature below 4°C (39°F). This requires the use of appropriate temperature-controlled vehicles and storage facilities with regular monitoring and recording of temperatures. Furthermore, proper packaging plays a crucial role in preventing contamination and damage. This includes selecting packaging materials that protect the product from physical damage, moisture, and oxygen, and are appropriate for the type of food. First-In, First-Out (FIFO) inventory management is crucial to ensure that older products are used before newer ones, minimizing the risk of spoilage. Finally, effective transportation logistics, including appropriate handling and careful loading and unloading, help prevent damage and contamination during transit.

In practice, I’ve developed and implemented detailed Standard Operating Procedures (SOPs) for storage and transportation, specifying temperature requirements, packaging materials, handling instructions, and documentation requirements. Regular training and supervision of personnel are key to ensuring compliance with these SOPs.

Q 5. Describe your experience with GMPs (Good Manufacturing Practices).

My experience with Good Manufacturing Practices (GMPs) is extensive, encompassing the design and implementation of GMP programs across various food production environments. GMPs are the foundation of a robust food safety management system. They cover a broad range of operational aspects, including facility design and hygiene, sanitation protocols, personnel hygiene, pest control, and equipment maintenance.

For instance, in my work with a dairy processing plant, I oversaw the implementation of a comprehensive GMP program that addressed all aspects of the production process, from milk reception to product packaging. This included establishing stringent cleaning and sanitation protocols for equipment, implementing a comprehensive pest control program, and developing detailed SOPs for personnel hygiene and handwashing. Regular internal audits and staff training formed integral parts of the program, ensuring consistent compliance and ongoing improvement.

My approach emphasizes a proactive, preventative approach, addressing potential issues before they escalate into major problems. This ensures the production of high-quality, safe food products while maintaining high standards of hygiene and operational efficiency.

Q 6. What is your experience with food safety audits and inspections?

I have extensive experience with food safety audits and inspections, both as an auditor and as a facility manager undergoing audits. I understand the requirements of various regulatory bodies and industry standards, including GFSI (Global Food Safety Initiative) benchmarking schemes. I’ve led internal audits for various food companies, identifying areas for improvement and developing corrective action plans. This includes reviewing HACCP plans, GMP implementation, and traceability systems. I’ve also participated in external audits conducted by regulatory agencies and certification bodies, ensuring compliance with relevant regulations and standards.

The objective of an audit is not merely to identify non-conformances but to understand the root causes of any issues and implement lasting solutions to prevent recurrence. I’ve often found that proactive management and thorough documentation can significantly reduce the stress and disruptions associated with audits and inspections.

Q 7. How do you manage food recalls?

Managing a food recall is a complex and critical process requiring swift action and effective communication. My experience involves all phases, from initial identification of a potential hazard to the final resolution. The first step involves quickly confirming the presence of a hazard and determining the scope of the recall – which products, batches, and locations are affected. This requires a robust traceability system to quickly identify and isolate affected products.

Next, a coordinated recall strategy is developed, involving notifying distributors, retailers, and consumers about the recall. This usually involves contacting regulatory agencies and issuing public announcements. Effective communication is critical, ensuring accurate and timely information reaches all stakeholders. The physical retrieval and disposal of recalled products need to be meticulously managed. Finally, a thorough investigation is undertaken to determine the root cause of the problem and prevent future recurrences. Comprehensive documentation throughout the entire recall process is essential, ensuring accountability and transparency. This may also involve collaboration with regulatory agencies and external experts.

Q 8. Explain your understanding of foodborne illnesses and their prevention.

Foodborne illnesses, also known as food poisoning, are diseases caused by consuming contaminated food or beverages. These illnesses range in severity from mild discomfort to life-threatening conditions. They are caused by a variety of pathogens including bacteria (like Salmonella, E. coli, Listeria), viruses (like Norovirus, Hepatitis A), parasites (like Toxoplasma gondii), and toxins produced by these microorganisms.

Preventing foodborne illnesses requires a multi-faceted approach focusing on all stages of the food chain, from farm to table. This includes:

- Proper Food Handling: Maintaining hygiene, cooking food to safe internal temperatures, and preventing cross-contamination are crucial. For example, washing hands thoroughly before and after handling food, separating raw and cooked foods, and using separate cutting boards are vital steps.

- Safe Food Storage: Refrigerating perishable foods promptly at appropriate temperatures (below 40°F or 4°C) significantly reduces bacterial growth. Freezing food can also extend shelf life and reduce the risk of contamination.

- Good Manufacturing Practices (GMPs): In food processing facilities, GMPs encompass a wide array of practices to minimize contamination, including sanitation, pest control, and employee training on hygiene protocols.

- Supply Chain Management: Maintaining a robust supply chain system with rigorous quality checks at every point ensures that food products meet safety standards. Traceability systems help track food products back to their source in case of a contamination event.

- Consumer Education: Educating consumers on safe food handling practices is critical for minimizing the risk of foodborne illnesses at home.

Think of it like building a house: each step – from selecting quality materials to proper construction techniques – is vital to ensure a safe and sturdy structure. Similarly, each stage of food safety contributes to a safe and healthy food supply.

Q 9. How do you ensure the accuracy of food safety testing?

Ensuring the accuracy of food safety testing requires a rigorous approach that combines meticulous laboratory practices, proper sample collection and handling, and the use of validated methods.

Accuracy starts with proper sampling. Representative samples need to be collected to reflect the entire batch or lot. Samples must be transported and stored correctly to prevent deterioration or contamination during transit. The use of appropriate containers, temperature controls, and chain of custody documentation is critical.

Within the laboratory, method validation is crucial. This involves demonstrating that the chosen test methods are accurate, precise, specific, and reliable for the intended purpose. Quality control measures, including the use of positive and negative controls, ensure that the test results are not affected by any systematic error.

Accreditation by a recognized organization such as ISO 17025 demonstrates compliance with international quality standards, providing a higher degree of confidence in the testing results. Regular internal audits and proficiency testing ensure consistent performance and competence of the laboratory staff.

Finally, data analysis and interpretation are critical. Results should be carefully reviewed to identify any discrepancies or outliers, and appropriate conclusions should be drawn based on established criteria. The entire process, from sample collection to report generation, must be meticulously documented to maintain transparency and traceability.

Imagine a doctor diagnosing an illness: an inaccurate test result could lead to incorrect treatment. Similarly, inaccurate food safety tests can have serious consequences, leading to unsafe food products reaching consumers.

Q 10. Describe your experience with allergen control programs.

My experience with allergen control programs includes developing and implementing comprehensive programs for various food processing facilities. These programs are designed to prevent cross-contamination and ensure the safety of products for consumers with food allergies.

A key component is establishing strict allergen control zones within the facility, separating the handling of allergenic ingredients from other ingredients. This includes dedicated equipment, utensils, and even separate production lines for allergen-containing products. Thorough cleaning and sanitization procedures between production runs are critical to avoid cross-contamination.

Labeling is another crucial aspect. Accurate allergen labeling is mandated by law, and programs must ensure that all products are properly labeled to clearly indicate the presence of any major allergens such as peanuts, tree nuts, milk, eggs, soy, wheat, fish, and shellfish. This requires meticulous ingredient tracking and verification throughout the supply chain.

Employee training is paramount. All personnel involved in handling ingredients must be thoroughly trained on allergen awareness, prevention strategies, and the importance of adhering to established protocols. Regular audits and inspections are vital to ensure the effectiveness of the program and identify any potential weaknesses.

In one instance, I helped implement a new allergen control system for a bakery that resulted in a significant decrease in reported allergic reactions to their products. This involved a complete overhaul of their procedures, including establishing separate prep areas for products containing nuts, regular employee training and reinforcement, and implementation of a rigorous cleaning schedule.

Q 11. What is your experience with food safety documentation and record-keeping?

Food safety documentation and record-keeping are essential for demonstrating compliance with regulations, tracing contamination sources, and continuous improvement. This involves maintaining comprehensive and accurate records throughout the entire food production process.

Critical documents include HACCP (Hazard Analysis and Critical Control Points) plans, which identify potential hazards and implement control measures. Supplier certifications and ingredient specifications ensure the safety and quality of incoming materials. Production records document parameters such as temperature, time, and processing steps. Cleaning and sanitization logs demonstrate the effectiveness of cleaning procedures. Calibration records for equipment and instruments verify their accuracy. Employee training records confirm that staff have received adequate training on food safety protocols.

These documents are typically maintained using a combination of paper-based systems and electronic databases. Proper storage and retrieval mechanisms are critical for ensuring document integrity and accessibility. Records must be readily available for inspection by regulatory authorities. I’ve consistently implemented and maintained these systems using both manual and electronic methods, ensuring traceability and auditability.

A robust documentation system is like a ship’s log: it provides a detailed record of the journey, enabling course correction and demonstrating safe passage. In the event of a recall, comprehensive documentation is critical in identifying the source of a problem.

Q 12. How do you interpret and apply food safety regulations?

Interpreting and applying food safety regulations requires a thorough understanding of relevant legislation, standards, and guidelines. This involves staying up-to-date on changes in regulations and adapting company policies accordingly.

I begin by identifying which relevant regulations apply to the specific products and operations of the company. This may involve researching federal, state, and local laws, as well as industry-specific standards (e.g., FDA, USDA, GFSI). I analyze the requirements and ensure the company’s practices align with these legal mandates.

Gap analysis helps identify any discrepancies between current practices and regulatory requirements. This analysis then informs the development of action plans to bring the company into full compliance. This might include modifying procedures, implementing new technologies, or providing additional training to staff.

I’ve successfully implemented regulatory compliance programs across various food processing facilities. I am well versed in interpreting standards such as the FDA’s Food Safety Modernization Act (FSMA) and Global Food Safety Initiative (GFSI) standards. Understanding the nuances of these regulations and effectively translating them into practical applications within a given facility is a critical skill.

Compliance is not just about avoiding penalties; it’s about protecting consumers and maintaining the company’s reputation. Think of it as following a recipe: following instructions carefully ensures a successful outcome. Similarly, following food safety regulations ensures the production of safe food.

Q 13. Explain your understanding of food safety training programs.

Effective food safety training programs are critical for ensuring that all personnel understand and follow proper procedures. These programs must be tailored to the specific needs of the workforce, encompassing all levels of employees, from management to line workers.

Comprehensive training should cover topics such as hygiene practices, allergen awareness, safe food handling techniques, hazard identification and control, and proper use of equipment. The training should be engaging, interactive, and use a variety of methods such as classroom instruction, hands-on demonstrations, and online modules.

Regular refresher training is necessary to reinforce key concepts and address any changes in regulations or company procedures. Training effectiveness should be assessed through tests, observations, and documented competency evaluations. Training records should be maintained to demonstrate compliance with requirements.

I’ve developed and delivered numerous training programs on food safety, incorporating interactive elements like scenarios and quizzes to enhance engagement. My approach emphasizes practical application and problem-solving to ensure trainees can readily apply learned concepts in their daily tasks. This approach ensures effective knowledge transfer and improves the overall food safety culture within an organization.

A well-trained workforce is like a well-oiled machine, operating efficiently and safely. Regular training is essential to prevent breakdowns and ensure that everyone is working towards the same goal: food safety.

Q 14. Describe a time you had to resolve a food safety issue.

During my time at a large-scale meat processing facility, we experienced a significant increase in the number of reported cases of Listeria monocytogenes contamination in our ready-to-eat products. This was a critical situation requiring immediate action to prevent further contamination and potential recalls.

First, we initiated a thorough investigation to identify the source of the contamination. This involved reviewing production records, environmental monitoring results, and sampling various equipment and surfaces. We used a combination of traceback investigations and environmental sampling to pinpoint potential sources.

The investigation revealed that the contamination was likely originating from a specific piece of equipment in the slicing and packaging area. The equipment was immediately taken out of service, and we implemented a rigorous cleaning and sanitization protocol, including a deep cleaning of the entire production line.

We also reviewed and revised our existing HACCP plan, incorporating additional control measures such as increased monitoring of critical control points and improved employee training on sanitation procedures. We collaborated with external experts in microbiology and food safety to review our findings and provide recommendations for enhancing our prevention measures.

In the end, we successfully identified and mitigated the source of contamination, preventing a larger outbreak and recall. This experience reinforced the importance of rigorous monitoring, rapid response, and effective root cause analysis in managing food safety incidents.

Q 15. How do you prioritize food safety tasks and responsibilities?

Prioritizing food safety tasks requires a structured approach. I utilize a risk-based methodology, prioritizing tasks based on their potential impact on consumer health and the likelihood of occurrence. This involves a Hazard Analysis and Critical Control Points (HACCP) plan, which identifies potential hazards at each stage of food production, processing, and distribution. For instance, if a critical control point like temperature control in a freezer malfunctions, that immediately becomes the highest priority, outweighing, say, a less critical task like scheduling staff training (though that’s still vital and should be addressed promptly). I use tools like risk matrices to visually represent and rank the severity and probability of various hazards, allowing for efficient resource allocation.

My approach also considers regulatory compliance deadlines. Meeting legal requirements always takes precedence. Finally, I incorporate a proactive element, prioritizing preventative measures such as regular equipment maintenance and staff training to reduce the risk of hazards in the first place. Think of it like a firefighter; we’re constantly preparing for the worst, but also actively preventing fires from even starting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate food safety information to different audiences?

Communicating food safety information effectively hinges on tailoring the message to the audience. For highly trained food safety professionals, technical language and complex data are suitable. However, for production line workers, clear, concise instructions and visual aids are crucial. I use various methods including training manuals, presentations, interactive workshops, and even short videos demonstrated by colleagues. For consumers, I advocate for clear labeling, accessible websites with FAQs, and straightforward communication in marketing materials. Imagine explaining the proper handwashing technique: for scientists, you’d focus on microbial reduction, whereas for a child, it’s more about getting rid of ‘germs’ that make you sick.

Feedback mechanisms are crucial. I actively seek feedback from each audience segment to ensure messages are understood and acted upon. This iterative process ensures clear communication across all levels, preventing misinterpretations and promoting a strong food safety culture.

Q 17. What is your experience with pest control in food processing environments?

My experience with pest control in food processing environments is extensive. I’m familiar with Integrated Pest Management (IPM) strategies, which focus on preventing pest infestations through proactive measures rather than solely relying on pesticides. This involves regular inspections, identifying potential entry points (cracks, gaps), implementing physical barriers (screens, sealing), and employing sanitation practices that eliminate food sources attractive to pests. I’ve overseen the implementation of monitoring systems, including sticky traps and pheromone traps, to detect early infestations. Choosing appropriate pesticides, applying them correctly and according to regulations (e.g., ensuring no pesticide residue on food products) is paramount. Documentation of all pest control activities is vital for traceability and regulatory compliance, and I always ensure this is meticulously maintained.

In one instance, we identified a rodent infestation in a warehouse. By implementing IPM, including enhanced sanitation, sealing entry points, and strategic trap placement, we successfully eradicated the problem without disrupting production. The key was a collaborative effort involving sanitation, maintenance, and production staff.

Q 18. Describe your understanding of sanitation procedures and protocols.

Sanitation procedures and protocols are the cornerstone of food safety. They cover all aspects of cleaning and sanitizing food contact surfaces, equipment, and the facility itself. This starts with a thorough cleaning process to remove visible soil and food residues, followed by sanitization to eliminate harmful microorganisms. Effective protocols involve detailed Standard Operating Procedures (SOPs) outlining each step: pre-cleaning, washing, rinsing, sanitizing, and air-drying. Critical factors include the correct selection and concentration of cleaning and sanitizing agents, appropriate contact time, and proper water temperature. Regular monitoring and validation of the sanitation process are essential, often including ATP bioluminescence testing to ensure cleanliness.

I’ve designed and implemented sanitation programs for several food processing facilities. Key aspects include training employees on proper sanitation techniques, establishing a schedule for cleaning and sanitizing specific areas, implementing a system for monitoring and documenting the process, and ensuring that all cleaning equipment is properly maintained and calibrated.

Q 19. How do you ensure the effectiveness of cleaning and sanitizing agents?

Ensuring the effectiveness of cleaning and sanitizing agents involves several key steps. First, selecting the right agent for the specific application is crucial. Different agents are effective against different types of microorganisms and soil. Secondly, proper concentration and contact time are critical. Using a solution that is too weak or not leaving it on the surface long enough will not provide sufficient cleaning or sanitation. I regularly check the concentration of cleaning and sanitizing solutions using test strips or other methods to ensure they are within the specified range. Water temperature also plays a crucial role; many sanitizers are more effective at higher temperatures. Finally, thorough rinsing is essential to remove any residue of the cleaning or sanitizing agent that might leave behind a taste or potentially cause harm.

To verify effectiveness, we regularly conduct microbial testing on surfaces after sanitation. This allows us to confirm the reduction in microbial load and identify any potential issues with the sanitation process. This data informs any necessary adjustments to our protocols or agents.

Q 20. What are your experience and knowledge about food irradiation?

Food irradiation is a food preservation technique that uses ionizing radiation to eliminate pathogens and extend shelf life. While it’s a safe and effective technology approved by many regulatory bodies, it’s essential to understand the process and its limitations. Different types of radiation (gamma rays, electron beams, X-rays) are used, each with different penetration depths and effectiveness. The dose of radiation applied is critical; too little won’t be effective, while too much can degrade the quality of the food. The safety of irradiated food is well-established; the process does not make food radioactive, and the resulting products meet stringent safety standards. I’ve worked with facilities that use irradiation for spices, herbs, and fruits, and have been involved in evaluating its effectiveness and ensuring compliance with regulations.

A crucial aspect is consumer perception. Clear and accurate labeling is vital to communicate that the food has been irradiated. Educating consumers about the safety and benefits of this technology can help address concerns and promote acceptance.

Q 21. What is your understanding of food preservation techniques?

Food preservation techniques aim to extend the shelf life of food and prevent spoilage by inhibiting microbial growth. These techniques can be categorized into several groups:

- Thermal Processing: This includes methods such as canning, pasteurization, and sterilization, which use heat to kill microorganisms.

- Non-Thermal Processing: This encompasses methods like high-pressure processing (HPP), pulsed electric fields (PEF), and irradiation (discussed above), which use non-heat methods to eliminate microorganisms or inhibit their growth.

- Low-Temperature Preservation: Refrigeration and freezing slow down microbial growth and enzymatic activity, significantly extending shelf life.

- Water Activity Reduction: Methods like drying, dehydration, and the addition of salt or sugar reduce the available water for microbial growth.

- Modified Atmosphere Packaging (MAP): This involves altering the gaseous atmosphere within packaging to inhibit microbial growth and extend shelf life. For example, reducing oxygen levels can prevent aerobic spoilage.

My experience encompasses all these methods, and selecting the appropriate technique depends on the specific food product and its characteristics. The effectiveness of each method is assessed through shelf-life studies and sensory evaluation to ensure that the quality and safety of the food are maintained.

Q 22. How do you maintain food safety during recipe changes or process modifications?

Maintaining food safety during recipe or process changes requires a systematic approach, focusing on hazard analysis and critical control points (HACCP). Think of it like building with LEGOs – each brick represents a step in the process. Changing a brick (recipe or process) requires careful consideration of how it affects the entire structure (food safety).

- Hazard Analysis: We start by identifying any potential hazards introduced by the change. For example, a new ingredient might introduce allergens, or a modified cooking temperature could impact bacterial growth. This involves reviewing ingredient specifications, assessing potential risks, and conducting any necessary testing.

- Critical Control Point (CCP) Assessment: We determine if the change affects any existing CCPs (steps where control is crucial to prevent or eliminate a hazard) or introduces new ones. For instance, a change in cooking time could affect a CCP relating to pathogen inactivation.

- Validation: We then validate the modified recipe or process through testing and trials. This may include microbiological testing, sensory evaluation, and shelf-life studies to ensure the product remains safe and meets quality standards. We use validated methods based on established food safety standards.

- Documentation: All changes, including the hazard analysis, CCP assessment, validation results, and updated procedures, are thoroughly documented. This is essential for traceability and auditing purposes.

For example, when changing a recipe from using fresh herbs to dried herbs, we’d need to assess if the reduction in moisture could lead to increased microbial growth. We’d address this by possibly adjusting cooking time or adding preservatives. This change and its validation would be thoroughly documented.

Q 23. Explain your experience with food safety management systems (e.g., ISO 22000).

I have extensive experience implementing and maintaining ISO 22000, a globally recognized food safety management system standard. Think of it as a comprehensive blueprint for food safety, ensuring consistency and traceability throughout the entire food chain. My experience includes:

- Gap Analysis and Implementation: Conducting gap analyses to identify discrepancies between existing practices and ISO 22000 requirements, followed by developing and implementing corrective actions to achieve compliance.

- Documentation and Record Keeping: Developing and maintaining comprehensive documentation, including food safety policies, procedures, and records, ensuring traceability throughout the entire process. This involves detailed logging of everything from temperature readings to supplier audits.

- Internal Audits: Performing regular internal audits to assess the effectiveness of the food safety management system and identify areas for improvement. This is like a self-check to ensure the system is functioning as designed.

- Management Review: Participating in management review meetings to evaluate the performance of the food safety management system and make strategic decisions. This helps refine the system based on data and insights.

- Supplier Management: Implementing effective supplier management programs to ensure that all raw materials and ingredients meet food safety standards. This involves thorough checks and possibly on-site visits to supplier facilities.

In a previous role, I successfully implemented ISO 22000 in a food processing facility, resulting in a significant reduction in non-conformances and improved product safety. This involved training staff, streamlining processes, and establishing robust quality control measures.

Q 24. Describe your experience with microbial testing methods.

My experience encompasses a wide range of microbial testing methods, both traditional and advanced. Think of these methods as different tools for detecting the presence and levels of microorganisms in food. My expertise includes:

- Traditional Culture Methods: Plate counts, MPN (Most Probable Number) methods, and enrichment techniques for detecting various bacteria, yeasts, and molds. These are like basic detective work, identifying the suspects by their characteristics.

- Rapid Methods: ATP bioluminescence, ELISA (Enzyme-Linked Immunosorbent Assay), and PCR (Polymerase Chain Reaction) for faster detection of specific pathogens like Salmonella or Listeria. These methods provide a much quicker diagnosis, potentially preventing widespread contamination.

- Molecular Methods: Advanced techniques like real-time PCR for highly sensitive and specific detection of microorganisms. These are cutting-edge techniques providing greater speed and accuracy.

For example, I’ve used plate counts to monitor the microbial load in ready-to-eat salads, and PCR to detect Listeria monocytogenes in processed meats. The choice of method depends on the specific food product, the target organism, and the required turnaround time.

Q 25. How do you identify and respond to potential food contamination incidents?

Responding to potential food contamination incidents requires a swift and systematic approach. Think of it as a fire drill – rapid response and effective communication are key. My approach involves:

- Immediate Containment: Isolating the potentially contaminated product to prevent further distribution. This is the first priority to stop the spread.

- Traceability Investigation: Using traceability systems to determine the source of the contamination and identify all potentially affected batches. This is like retracing steps to find the origin of the problem.

- Root Cause Analysis: Conducting a thorough investigation to determine the root cause of the contamination, often involving environmental monitoring and employee interviews. Understanding ‘why’ is crucial for preventing recurrence.

- Corrective Actions: Implementing corrective actions to eliminate the root cause and prevent future occurrences. This may involve sanitation improvements, staff retraining, or supplier changes.

- Communication and Notification: Communicating with relevant authorities (like regulatory agencies) and customers, as needed. Open communication is crucial for transparency.

In one instance, we discovered E. coli contamination in a batch of ground beef. We immediately isolated the affected product, traced it back to a specific supplier, and notified the relevant authorities. This also prompted a thorough review of our supplier selection and verification procedures.

Q 26. What is your knowledge on the different types of food safety certifications?

Many food safety certifications exist, each demonstrating a commitment to specific standards. Think of them as badges of honor, proving adherence to best practices. These include:

- ISO 22000: Food safety management system certification, focusing on the overall food safety management system.

- BRCGS (British Retail Consortium Global Standards): Widely recognized certification for food manufacturers focusing on food safety and quality.

- IFS (International Featured Standards): Another global food safety standard, emphasizing quality management and supplier relationships.

- SQF (Safe Quality Food): A comprehensive food safety and quality certification program, often used across various sectors.

- HACCP-based certifications: Many certifications incorporate HACCP principles, demonstrating a commitment to hazard analysis and control. These vary in specific requirements depending on the organization or jurisdiction.

The choice of certification depends on customer requirements, target markets, and the specific type of food product. For example, a company exporting to the EU might require IFS or BRCGS certification.

Q 27. How do you stay updated on the latest food safety regulations and best practices?

Staying updated on food safety regulations and best practices is crucial in this ever-evolving field. Think of it like continuously upgrading your software – you need to stay current to avoid vulnerabilities. My approach includes:

- Subscription to Professional Journals and Newsletters: Staying informed through publications like the Journal of Food Protection or industry-specific newsletters. This keeps me up-to-date on research, new technologies, and regulatory changes.

- Attendance at Conferences and Workshops: Participating in conferences and workshops organized by relevant organizations such as the FDA or industry associations. Networking and learning from experts is invaluable.

- Monitoring Regulatory Websites: Regularly checking websites of regulatory agencies like the FDA (Food and Drug Administration), USDA (United States Department of Agriculture), and EFSA (European Food Safety Authority) for updates on regulations and guidance documents.

- Professional Development Courses: Undertaking continuous professional development courses to enhance knowledge and skills in specific areas of food safety.

For example, I regularly check the FDA’s website for updates on foodborne illness outbreaks and new regulations on food labeling and additives. This proactive approach allows me to quickly adapt my practices to the current standards.

Q 28. Describe your experience working with a multidisciplinary team to address food safety concerns.

Collaborating with a multidisciplinary team is essential for effective food safety management. Think of it like a well-orchestrated orchestra – each instrument (team member) plays a crucial part in creating a harmonious whole (safe food). My experience includes working with:

- Microbiologists: Collaborating on microbial testing and interpretation of results.

- Chemists: Working together on chemical analysis and identifying potential contaminants.

- Production Staff: Ensuring that food safety procedures are implemented effectively on the production floor.

- Quality Control Staff: Collaborating on product inspections and monitoring of food safety parameters.

- Management: Communicating risk assessments and recommendations to upper management.

In a past project involving a suspected allergen cross-contamination incident, I collaborated with our microbiologists to conduct specific tests, production staff to investigate workflows, and management to implement corrective actions and communicate with affected customers. The multidisciplinary approach ensured a thorough investigation and swift resolution.

Key Topics to Learn for Food Safety Assessment Interview

- Hazard Analysis and Critical Control Points (HACCP): Understand the principles, implementation, and documentation requirements of HACCP plans. Consider practical applications in various food production settings.

- Foodborne Illness Prevention: Explore common pathogens, their sources, and methods of control. Think about how to implement preventative measures throughout the food chain, from farm to table.

- Good Manufacturing Practices (GMPs) and Sanitation: Master the principles of GMPs and their role in minimizing contamination risks. Be prepared to discuss sanitation procedures and their effectiveness.

- Food Safety Regulations and Standards: Familiarize yourself with relevant legislation and industry standards (e.g., FDA regulations, ISO 22000). Be ready to discuss compliance and auditing processes.

- Allergen Control and Management: Understand the importance of allergen labeling, prevention of cross-contamination, and management of allergen-related risks.

- Food Safety Auditing and Inspections: Prepare to discuss the various types of food safety audits, inspection procedures, and corrective actions.

- Traceability and Recall Systems: Learn about the importance of traceability systems in identifying and addressing food safety issues, and how to effectively manage a product recall.

- Data Analysis and Interpretation in Food Safety: Be prepared to discuss how data is used to monitor and improve food safety programs. This could include statistical process control or other relevant techniques.

Next Steps

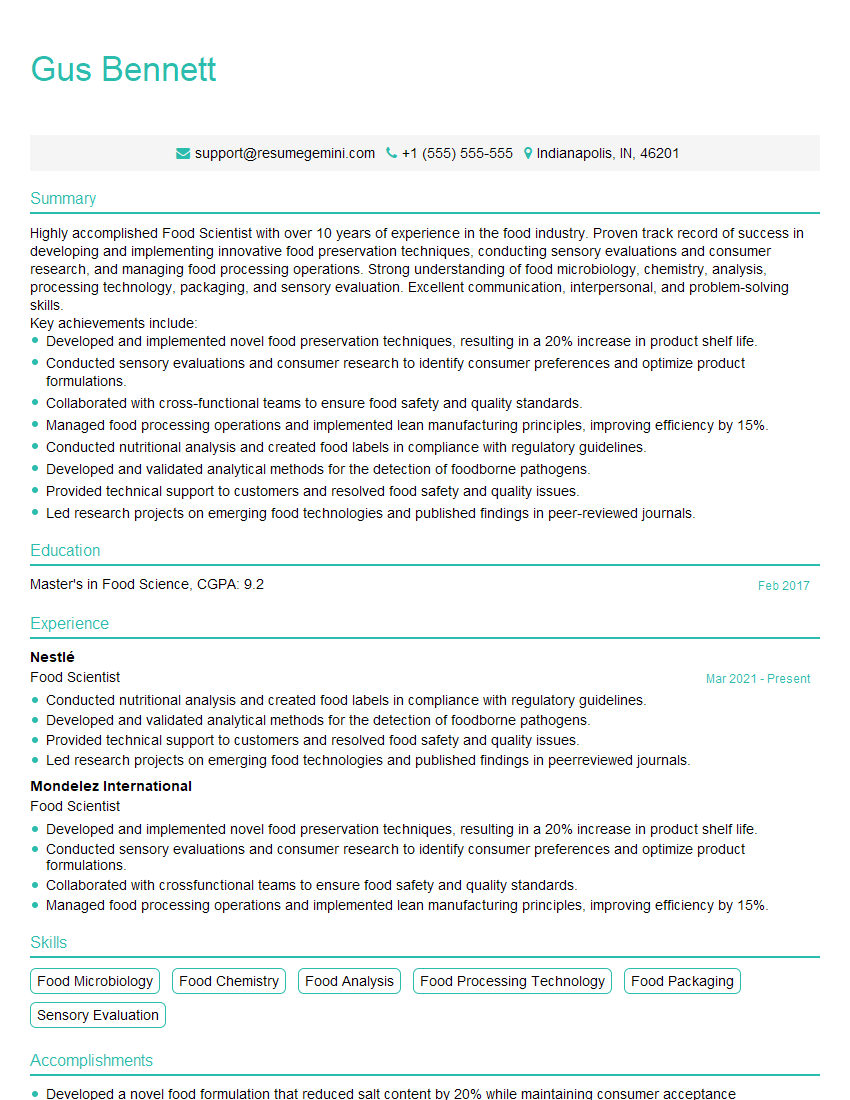

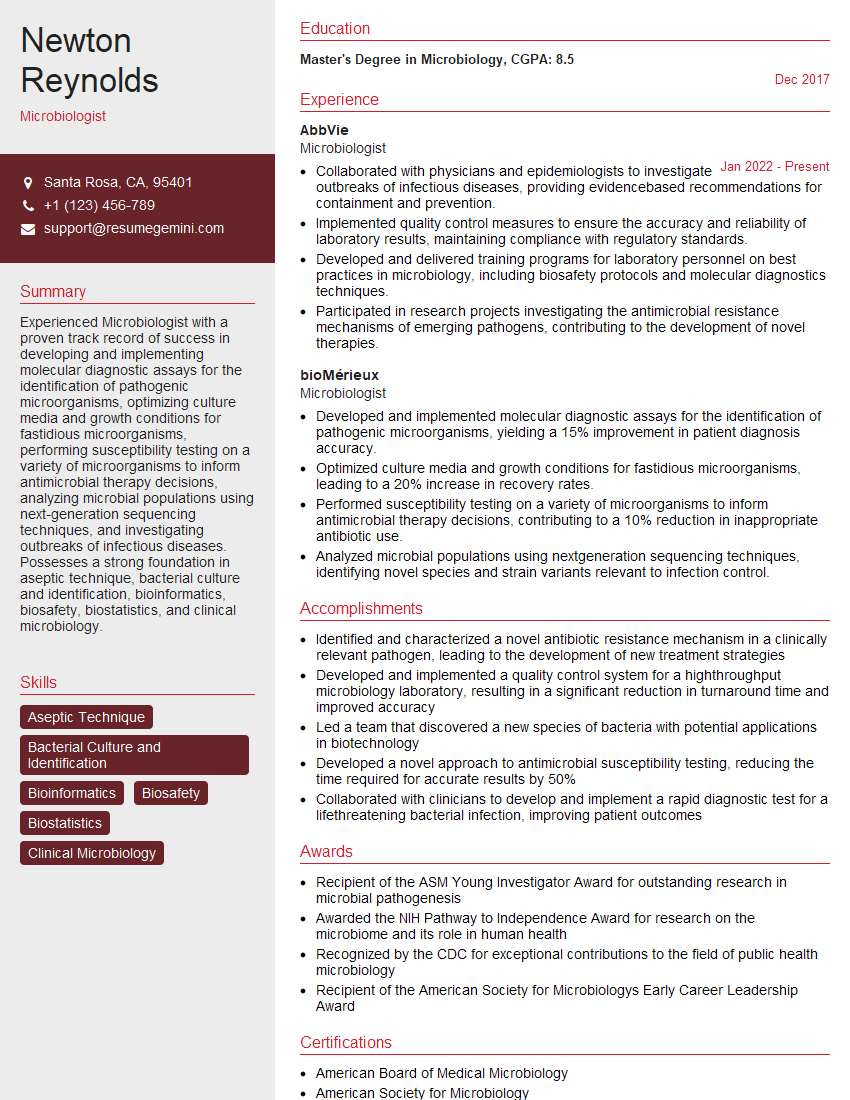

Mastering Food Safety Assessment is crucial for career advancement in the food industry, opening doors to higher-level roles and greater responsibility. A strong resume is your key to unlocking these opportunities. Crafting an ATS-friendly resume significantly increases your chances of getting your application noticed by recruiters. To help you build a compelling and effective resume, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and offers examples of resumes specifically tailored to Food Safety Assessment roles, helping you present your skills and experience in the best possible light. Invest in your future – build a resume that reflects your expertise and potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?