Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Irrigation Installation and Repair interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Irrigation Installation and Repair Interview

Q 1. Describe your experience with different irrigation system types (e.g., drip, sprinkler, etc.).

My experience spans a wide range of irrigation systems, from the most basic to complex designs. I’m proficient with sprinkler systems, both rotor and spray, understanding their varying throw distances, precipitation rates, and optimal nozzle selection for different landscape needs. For example, I’ve designed large-scale rotor systems for athletic fields, requiring precise calculations for water coverage and uniformity. I also have extensive experience with drip irrigation, which is ideal for water conservation and targeted watering of specific plants. This includes designing and installing both surface and subsurface drip systems, understanding the nuances of emitter spacing and pressure regulation. I’ve also worked with micro-sprinklers, which offer a balance between the efficiency of drip and the broader coverage of spray systems. These are particularly useful for smaller gardens and flowerbeds.

Furthermore, I’m familiar with other specialized systems such as soaker hoses and bubblers, each suited to particular landscape features and plant requirements. I consider each system’s strengths and limitations when recommending a design, ensuring the best solution for the specific project and client needs.

Q 2. Explain the process of designing an irrigation system for a residential property.

Designing a residential irrigation system involves a systematic approach. It begins with a thorough site assessment, including evaluating the property’s size, topography, soil type, existing vegetation, and water source. I’ll meticulously map out the landscape, identifying areas requiring irrigation. Next, I determine the water requirements for different plant types, considering their individual needs for water, factoring in factors like sun exposure and soil drainage. This informs the selection of the most appropriate irrigation system (drip, sprinkler, or a combination). I then design the system’s layout, determining the optimal placement of valves, pipes, and emitters/sprinkler heads to ensure even water distribution.

The design process also includes selecting appropriate equipment, such as valves, pumps, and controllers, based on the system’s size and water pressure. It’s critical to consider water pressure requirements to guarantee proper operation and avoid water wastage. Finally, I create detailed schematics and specifications that guide the installation process, ensuring efficiency and accuracy. For example, I recently designed a system for a client with a sloped yard. To optimize water distribution and prevent runoff, we used a combination of drip irrigation for delicate flowerbeds and strategically placed rotors for the lawn areas.

Q 3. How do you troubleshoot a low water pressure issue in an irrigation system?

Low water pressure in an irrigation system can stem from various causes. My troubleshooting process involves a systematic approach, starting with the most likely culprits. I’ll first check the main water supply to the system, ensuring adequate pressure from the municipal supply or well. Then, I’ll inspect the system’s pressure regulator, verifying it’s functioning correctly and set to the proper pressure. Low pressure might indicate a clogged filter or a faulty pressure regulator which needs to be cleaned or replaced.

Next, I’ll inspect the pipes for any leaks or clogs, paying close attention to areas prone to debris buildup. A clogged pipe can significantly reduce water flow. I might use specialized equipment such as a pressure gauge at various points in the system to pinpoint the location of the pressure drop. Finally, I’ll examine the valves, checking for any that are partially closed or malfunctioning. A comprehensive inspection of all components is vital in isolating the source of low pressure, ensuring efficient problem resolution.

Q 4. What are the common causes of sprinkler head malfunctions?

Sprinkler head malfunctions are common, and typically result from several causes. Clogged nozzles are the most frequent issue, often caused by mineral deposits, debris, or algae buildup. Regular cleaning or replacement of nozzles is often the solution. Another common cause is broken or damaged sprinkler heads, possibly due to impact or wear and tear, which can result in uneven water distribution or complete failure. Replacing faulty heads is usually the fix.

Mechanical issues like a broken diaphragm in a pop-up sprinkler or a malfunctioning gear drive in a rotor sprinkler can also cause problems, requiring repair or replacement of the entire head. Incorrectly adjusted nozzles can also lead to poor water coverage or excessive runoff. Finally, low water pressure within the system can reduce the sprinkler’s effective range and performance. Addressing these underlying issues often necessitates further investigation of the system’s overall pressure and flow.

Q 5. Describe your experience with different types of irrigation valves.

My experience encompasses various irrigation valve types, including diaphragm valves, piston valves, and solenoid valves. Diaphragm valves are robust and relatively simple, well-suited for larger systems. Piston valves provide high flow rates with exceptional durability and are ideal for high-pressure situations. Solenoid valves are electrically controlled, allowing for automated operation through controllers. They are often used in complex systems requiring precise timing and water flow regulation.

The selection of the appropriate valve type depends on factors such as system pressure, flow rate requirements, and automation needs. For example, I’ve used solenoid valves in sophisticated smart irrigation systems, where they are controlled remotely by weather sensors and controllers. For less demanding applications, like smaller residential systems, diaphragm valves are often cost-effective and reliable. Understanding the strengths and weaknesses of each valve type enables me to select the most appropriate option for each individual project.

Q 6. How do you calculate the water requirements for a specific landscape?

Calculating water requirements for a landscape involves considering several factors. Firstly, I assess the evapotranspiration (ET) rate, which represents the water lost through evaporation from the soil and transpiration from plants. This rate varies significantly depending on factors such as climate (temperature, humidity, wind speed), plant type, and soil type. I use established formulas and weather data to estimate the ET rate for the specific location. Next, I calculate the area of each plant zone, grouping together plants with similar water requirements.

Then, I apply the ET rate to each zone’s area to determine the water needs of each plant group. This calculation considers soil type and its water-holding capacity—sandy soils require more frequent but less intense watering than clay soils, which retain water longer. The result is an estimate of how much water each zone needs, which informs the design of the irrigation system and the scheduling of the controller. This methodical approach ensures that the landscape receives the precise amount of water it needs, optimizing water usage and plant health.

Q 7. Explain your experience with backflow preventers and their importance.

Backflow preventers are crucial components of any irrigation system, safeguarding the potable water supply from contamination. They prevent the backflow of contaminated water from the irrigation system back into the municipal water supply. I have extensive experience installing and maintaining various types of backflow preventers, including double-check valves, reduced-pressure backflow preventers (RP), and pressure vacuum breakers (PVB). The selection of the appropriate type depends on local codes and the specific system’s pressure and flow requirements.

Regular testing and maintenance of backflow preventers are critical, as required by most jurisdictions. I am well-versed in the testing procedures and can perform the necessary tests to ensure that the backflow preventer functions correctly, preventing potential health hazards. For example, I recently worked on a project where a faulty backflow preventer was discovered during a routine inspection, preventing potential contamination of the drinking water supply. Replacing the faulty unit ensured the safety of the water supply.

Q 8. What are the safety precautions you take when working with irrigation systems?

Safety is paramount in irrigation work. Before starting any job, I always conduct a thorough site survey to identify potential hazards like underground utilities (gas, electric, water lines), uneven terrain, and the presence of wildlife. I then implement the following safety precautions:

- Personal Protective Equipment (PPE): This includes safety glasses, gloves (nitrile for chemical handling, leather for digging), steel-toe boots, and high-visibility clothing. For larger jobs, I’ll also use hard hats and hearing protection.

- Proper Tool Usage: I ensure all tools are in good working order and used according to manufacturer instructions. This includes regular maintenance and sharpening of shovels, spades, and other hand tools.

- Excavation Safety: When digging, I carefully mark out the area and use appropriate shoring or trench boxes to prevent cave-ins, particularly in deeper trenches. I always call 811 (or the equivalent in your region) to have underground utilities marked before digging.

- Chemical Handling: When using fertilizers or pesticides, I carefully follow the instructions on the label and wear appropriate PPE. I also ensure proper disposal of any leftover chemicals.

- Weather Awareness: I postpone work during severe weather conditions such as thunderstorms, high winds, or extreme heat. Heat stroke is a significant risk, so I take frequent breaks and stay hydrated.

- Emergency Procedures: I have a comprehensive emergency plan, including readily accessible first-aid kits and emergency contact information. Team members are trained in basic first aid and CPR.

For example, on a recent job involving the installation of a new sprinkler system, I discovered a buried gas line that wasn’t marked on the utility map. Immediate work stoppage, contacting the gas company, and a thorough reassessment of the layout averted a potentially dangerous situation.

Q 9. How do you identify and repair leaks in underground irrigation pipes?

Locating leaks in underground irrigation pipes requires a systematic approach. I start by visually inspecting the system for obvious signs of leaks, such as wet spots on the lawn or unusual water pressure readings. Then I employ the following techniques:

- Listening for Leaks: A simple, effective method involves using a listening device to detect the sound of escaping water. This works best in quieter areas.

- Water Pressure Test: By isolating sections of the pipe and monitoring pressure changes, I can pinpoint the area of the leak. A significant pressure drop usually indicates a leak in that segment.

- Leak Detection Dye: Adding a non-toxic dye to the water can help visualize the leak if it’s near the surface.

- Ground Penetrating Radar (GPR): For larger systems or deep leaks, GPR technology can provide accurate imaging of the pipe network, revealing the location and extent of the leak.

- Line Tracing: This involves using a specialized tool that traces the path of the pipe to aid in locating the leak. It works by following the electrical conductivity of the pipe.

Once located, repair depends on the type and severity of the leak. Small punctures are often repaired using a repair coupling, while larger leaks or significant pipe damage often necessitate excavation and replacement of the affected pipe section. I always backfill the area carefully to prevent future settlement and damage to the pipe.

Q 10. Describe your experience with irrigation control systems (e.g., timers, controllers).

I have extensive experience with various irrigation control systems, ranging from simple mechanical timers to sophisticated weather-based smart controllers. I’m proficient in installing, programming, and troubleshooting these systems. My experience includes:

- Mechanical Timers: I understand how to properly set run times, adjust watering schedules, and maintain these simpler systems, including routine cleaning and lubrication.

- Digital Controllers: I’m comfortable installing and programming Rain Bird, Hunter, Toro, and other popular brands of digital controllers. This includes setting up custom watering schedules based on soil type, plant needs, and weather data.

- Smart Controllers: I have experience integrating smart controllers with weather sensors, soil moisture sensors, and even smartphone applications for remote control and monitoring. These systems enable efficient water management through automated adjustments based on real-time data. For example, I recently installed a smart controller that reduced water consumption by 20% for a residential client by incorporating weather forecasts and soil moisture data.

I understand the importance of proper controller settings to avoid overwatering or underwatering, which can lead to plant damage or water waste. I always discuss the client’s specific needs and preferences to ensure that the irrigation controller is configured correctly for their landscape.

Q 11. How do you maintain and winterize an irrigation system?

Regular maintenance is crucial for maximizing the efficiency and lifespan of an irrigation system. My maintenance procedures include:

- Spring Startup: Inspecting all components (valves, pipes, heads) for damage or leaks, clearing any debris, and adjusting heads to ensure proper coverage.

- Regular Inspections: Conducting periodic checks throughout the growing season to identify and address minor problems before they escalate into major repairs.

- Head Adjustments: Ensuring sprinkler heads are properly aligned and adjusted to provide even water distribution and avoid overwatering or dry spots. This includes checking pressure and flow rates.

- Valve Flushing: Regularly flushing valves to remove sediment and debris that can affect performance and cause clogging.

- Winterization: This is essential in climates with freezing temperatures to prevent damage to pipes and components. The process typically involves draining the entire system, including pipes, valves, and backflow preventers.

During winterization, I use air compressors to blow out water from the lines and thoroughly inspect all components for any damage that may have occurred during the season. If needed, I replace damaged parts before the onset of winter. Failure to winterize can result in burst pipes and costly repairs in the spring. This is important to note, particularly with different pipe materials where each requires a different winterization approach.

Q 12. What experience do you have with different types of irrigation pipe materials?

My experience encompasses various irrigation pipe materials, each with its advantages and disadvantages. I understand the properties of each type and select the most appropriate material based on the project’s specific requirements:

- PVC (Polyvinyl Chloride): A common, cost-effective option known for its durability and resistance to corrosion. However, it can become brittle in freezing temperatures. This is why proper winterization is critical.

- Polyethylene (PE): Highly flexible and resistant to freezing, making it ideal for areas with harsh winters. It’s also relatively lightweight and easy to install.

- CPVC (Chlorinated Polyvinyl Chloride): Offers greater resistance to heat and pressure than PVC, making it suitable for higher-pressure applications. Like PVC, proper winterization is important.

- Aluminum or Galvanized Steel: Strong and durable, but more susceptible to corrosion than plastic pipes. They are often found in older systems and require more maintenance.

For example, on one project, the client requested an underground irrigation system in a region known for its harsh winters. Given the risk of freeze-thaw cycles, I recommended and installed PE pipes to ensure long-term system integrity and minimize the risk of pipe failure.

Q 13. Explain your experience with installing different types of emitters.

I have experience installing a variety of emitters, each designed for different applications and water needs:

- Spray Heads: For large areas requiring wide coverage, I select appropriate spray heads based on the desired throw distance and water pressure.

- Drip Emitters: For precise water delivery to individual plants or rows, I install drip emitters, choosing from various flow rates and configurations (in-line, pressure compensating) to meet the plant’s water requirements.

- Rotary Heads: For circular coverage, I install rotary heads, ensuring the correct nozzle is used for the desired throw distance and water pressure.

- Rotor Heads: Similar to rotary heads, but typically used for larger areas with higher water flow rates.

- Micro-Sprinklers: Used for smaller areas and individual plants, providing a gentle and even water application.

Proper emitter selection is crucial for efficient irrigation and preventing water waste. For instance, using high-flow spray heads in a small area can lead to runoff and wasted water. I always take into account the plant type, spacing, and soil conditions when choosing the right emitter type and flow rate for each application.

Q 14. How do you handle conflicts or challenges with clients or contractors on a project?

Conflict resolution is a key aspect of project management. I approach challenges by fostering open communication and collaboration:

- Active Listening: I actively listen to understand the concerns of clients and contractors. I ask clarifying questions to ensure I fully grasp their perspectives.

- Professional Communication: I communicate clearly and concisely, both verbally and in writing. I provide timely updates and address concerns promptly.

- Collaborative Problem-Solving: I work collaboratively with all stakeholders to find mutually acceptable solutions. This may involve brainstorming alternative approaches or compromising on certain aspects.

- Mediation: If necessary, I act as a mediator to facilitate discussions and help resolve disputes between conflicting parties. My goal is to maintain a professional and respectful atmosphere.

- Documentation: I meticulously document all communications, agreements, and changes to the project scope. This ensures clarity and avoids misunderstandings later.

For example, on a recent project, a dispute arose between the client and a subcontractor regarding the installation of a specific component. By facilitating open communication, documenting everyone’s concerns, and proposing a compromise that met both parties’ needs, I successfully resolved the issue and maintained a positive working relationship.

Q 15. What software or tools do you use for irrigation design and calculations?

For irrigation design and calculations, I utilize a combination of software and tools. My go-to software is Hydraworks, a powerful program that allows for precise design of various irrigation systems, from drip to sprinkler. It helps with calculating water flow, pressure, and pipe sizing, ensuring optimal system performance. I also use AutoCAD for creating detailed system layouts and integrating the irrigation design into the overall landscape plan. In addition to software, I rely on tools like flow meters to accurately measure water flow rates during system testing and pressure gauges to monitor pressure at different points within the system. This combination allows me to create efficient and effective irrigation systems tailored to specific site needs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure proper water distribution throughout an irrigation system?

Ensuring proper water distribution is paramount in irrigation design. This is achieved through a multi-pronged approach. Firstly, accurate site analysis including soil type and topography is crucial. This informs the choice of irrigation method (drip, sprinkler, etc.) and emitter spacing. For example, sandy soil requires more frequent, shorter watering intervals compared to clay soil. Secondly, proper pipe sizing is essential to maintain sufficient pressure and flow across the entire system. Undersized pipes lead to pressure loss and uneven water distribution. I also use pressure regulating valves at strategic locations to maintain consistent pressure throughout. Lastly, regular system audits with flow measurements at various points help identify and address any blockages or issues with water distribution. Imagine it like a network of roads – the pipes need to be of appropriate size, and regulators ensure smooth and even traffic flow across all sections.

Q 17. Describe your experience with pressure regulating devices.

I have extensive experience with various pressure regulating devices. These are essential for maintaining consistent pressure across different zones of an irrigation system. I regularly work with pressure reducing valves, which lower high-pressure main lines to a more suitable pressure for the individual zones. Pressure regulating valves help maintain consistent pressure within specific zones, even when water demand fluctuates. I’ve also worked with flow control valves, which regulate the flow rate of water to each zone, ensuring that water is distributed evenly, even if there are elevation changes across the landscape. In one particular project, we utilized a combination of pressure reducing and regulating valves to ensure even water distribution across a steeply sloped vineyard. Without these valves, the lower sections would have been over-watered, while the higher sections would have suffered from inadequate irrigation.

Q 18. What is your understanding of water conservation techniques in irrigation?

Water conservation is a core principle of my work. I employ several techniques to optimize water usage. Smart irrigation controllers, programmed with weather data, adjust watering schedules based on actual evapotranspiration (the combined effect of evaporation and plant transpiration), preventing unnecessary watering. Soil moisture sensors provide real-time information about soil moisture levels, allowing for more precise watering schedules. Drip irrigation and micro-spray systems are incredibly efficient methods, delivering water directly to the plant roots, minimizing evaporation and runoff. In addition, I ensure efficient system design, which minimizes water loss through leaks or pressure drops. We recently implemented a soil moisture monitoring system for a large municipal park, reducing water consumption by over 30% without compromising plant health.

Q 19. How do you read and interpret irrigation system blueprints?

Reading and interpreting irrigation system blueprints requires a detailed understanding of irrigation symbols and conventions. I am proficient in reading standard symbols for pipes, valves, fittings, and emitters. A blueprint will show the layout of the entire system, including the location of the water source, pump, main lines, valves, and individual zones. It indicates pipe diameters, valve types, and emitter spacing. By carefully reviewing the blueprint, I can determine the system’s components, their connections, and understand the overall design approach. The blueprint also includes information on the system’s pressure and flow rates, which are essential for troubleshooting and maintenance. This is like reading a map for a plumbing network, where every symbol and line denotes a specific component and flow path.

Q 20. What are your troubleshooting skills for pump issues in an irrigation system?

Troubleshooting pump issues involves a systematic approach. I start by checking the power supply to ensure the pump is receiving electricity. Then, I inspect the pump impeller for any damage or debris that may impede flow. I also use a pressure gauge to measure the discharge pressure. Low pressure might indicate a blockage in the pipes or a problem with the pump itself. High pressure might suggest a blockage downstream. I will also check for leaks in the pump or piping system. If the pump is not priming properly, I examine the priming system. Finally, if the problem persists, I might need to check the motor windings for electrical issues. This systematic, step-by-step approach helps isolate the problem quickly and efficiently. This is like diagnosing a car engine problem – you need to check various components and systems one by one to pinpoint the exact issue.

Q 21. Explain your experience with soil testing and how it impacts irrigation design.

Soil testing is crucial for effective irrigation design. I frequently use soil testing to determine soil type, texture, and drainage characteristics. This information is essential for selecting the appropriate irrigation method and determining the frequency and duration of watering. For instance, sandy soils drain quickly and require more frequent, shorter watering periods compared to clay soils, which retain moisture for longer periods. The soil’s water-holding capacity dictates the frequency of irrigation. Soil testing also helps determine nutrient levels and pH, which affect plant health and water uptake. Based on the soil test results, I design the irrigation system to deliver the optimal amount of water at appropriate intervals to support healthy plant growth. This information is used to determine the type and spacing of emitters or sprinklers. For example, a poorly draining soil might require drip irrigation with wider spacing to avoid waterlogging, while a sandy soil might require more frequent irrigation with a higher emitter density.

Q 22. How do you determine the appropriate spacing for sprinkler heads?

Determining the appropriate sprinkler head spacing is crucial for efficient and uniform irrigation. It depends on several factors, primarily the sprinkler’s throw distance (the radius of its water coverage), the nozzle type, and the desired overlap between adjacent sprinklers.

Process:

- Identify Sprinkler Type and Nozzle: Each sprinkler and nozzle combination has a specified throw distance, often found in the manufacturer’s specifications. For example, a rotor sprinkler with a specific nozzle might have a throw of 30 feet.

- Consider Site Conditions: Wind, slope, and terrain can significantly impact the throw distance. A windy area might necessitate closer spacing to ensure adequate coverage.

- Calculate Spacing: Generally, you aim for a 50-75% overlap between adjacent sprinklers. This prevents dry spots and ensures even water distribution. So, for a 30-foot throw, spacing would be roughly 15-22.5 feet (30ft * 50% to 70%).

- Field Testing: After installation, it’s essential to test the system and make adjustments. Observing the water distribution pattern will indicate whether spacing needs fine-tuning. You might use catch cans to measure the water distribution uniformity.

Example: On a flat, windless area with 35-foot throw sprinklers, you’d likely space them around 17-24 feet apart to achieve appropriate overlap and ensure adequate coverage across the entire lawn.

Q 23. What experience do you have with repairing or replacing irrigation pumps?

I have extensive experience in diagnosing and repairing various irrigation pump issues. This includes both centrifugal and submersible pumps. My experience spans troubleshooting electrical problems (wiring, motor issues, capacitor failures), mechanical problems (bearing wear, seal leaks, impeller damage), and hydraulic issues (low pressure, cavitation).

Repair Process: I typically follow a structured approach:

- Assessment: Identifying the problem – low pressure, no water flow, unusual noises, etc.

- Diagnostics: Using pressure gauges, multimeters, and other tools to isolate the fault. This could involve checking power supply, inspecting wiring, measuring pressure, and examining the pump for physical damage.

- Repair or Replacement: Replacing faulty components like seals, impellers, motors, or capacitors as needed. In some cases, total pump replacement is the most cost-effective solution.

- Testing: Thoroughly testing the pump after repair or replacement to ensure it’s functioning correctly and meeting the required pressure and flow rates.

Example: I recently repaired a submersible pump that was exhibiting low pressure. After diagnostics, I found a worn impeller. Replacing the impeller restored the pump’s performance to the manufacturer’s specifications. I always document repairs thoroughly, including part numbers and maintenance procedures.

Q 24. Describe your familiarity with different irrigation system components.

My familiarity with irrigation system components is comprehensive, encompassing everything from the water source to the sprinkler heads. I’m proficient with:

- Water Source: Wells, municipal water lines, reservoirs

- Pumps: Centrifugal, submersible, booster pumps

- Piping: PVC, HDPE, galvanized pipes, various fittings and valves

- Backflow Preventers: Understanding the different types and their proper installation and maintenance is crucial for preventing water contamination.

- Filtration Systems: Screen filters, sand filters, and other filtration systems for removing debris and protecting the system.

- Control Systems: Timers, rain sensors, solenoid valves, and advanced irrigation controllers.

- Sprinklers: Various types of sprinklers including rotor, spray, drip, and pop-up.

- Emitters: Drip emitters, micro-sprinklers

I understand the interdependencies of these components and how malfunctions in one area can affect the entire system. This holistic understanding allows me to effectively troubleshoot and repair irrigation systems.

Q 25. Explain your approach to addressing a complex irrigation system problem.

My approach to complex irrigation problems is systematic and methodical. It involves a step-by-step process:

- Thorough Assessment: A detailed examination of the entire system, gathering information about its history, recent changes, and current symptoms. This includes reviewing system schematics or creating one if it’s absent.

- Data Collection: Precise measurements of pressure, flow rate, and water distribution at various points in the system. Using diagnostic tools, I can identify areas of dysfunction.

- Hypothesis Formation: Based on the assessment and data, I develop hypotheses about the possible causes of the problem. This often involves considering multiple possibilities.

- Testing and Validation: Systematically testing each hypothesis through observation and experimentation. This might involve isolating sections of the system, replacing components, or adjusting settings.

- Solution Implementation: Implementing the most effective solution and verifying its efficacy.

- Documentation: Meticulously documenting the problem, the diagnostic process, the implemented solution, and the results.

This systematic approach helps to ensure that the root cause of the problem is addressed, not just the symptoms. It also allows for efficient troubleshooting, reducing downtime and unnecessary repairs.

Q 26. How do you manage your time and prioritize tasks on an irrigation project?

Effective time management and task prioritization are vital on any irrigation project. I use a combination of techniques:

- Detailed Planning: Creating a comprehensive project schedule that outlines all tasks and their dependencies. I utilize project management software to track progress and adjust timelines as needed.

- Prioritization: Prioritizing tasks based on urgency and importance. Critical tasks impacting the overall system functionality are tackled first. This might include addressing critical leaks before tackling aesthetic issues.

- Resource Allocation: Efficiently allocating resources such as equipment, materials, and personnel to ensure smooth workflow and minimize delays.

- Regular Monitoring: Regularly monitoring progress against the schedule and making adjustments as needed. This proactive approach helps to prevent setbacks and keep the project on track.

- Communication: Maintaining clear and consistent communication with clients and stakeholders to manage expectations and address any concerns promptly.

Example: On a large-scale irrigation project, I’d prioritize repairing a major leak that’s causing significant water loss before installing new sprinkler heads in a less critical area. This ensures efficient resource usage and minimizes water waste.

Q 27. What is your experience with different types of filtration systems for irrigation?

My experience encompasses various filtration systems used in irrigation, each suited to different water quality challenges:

- Screen Filters: These are the most basic, removing larger debris such as leaves and twigs. They are relatively inexpensive and easy to maintain but require frequent cleaning.

- Sand Filters: More effective than screen filters, they remove finer sediment and suspended particles. They require backwashing periodically to remove accumulated sediment.

- Disc Filters: Offer higher filtration efficiency than sand filters, removing finer particles and improving water clarity. They are self-cleaning and require less maintenance.

- Media Filters: Use specialized filter media (anthracite, garnet, etc.) for enhanced filtration capabilities. They effectively remove a wide range of particles and are suitable for applications with high sediment loads.

The selection of an appropriate filtration system depends on factors like water quality, system size, and budget constraints. For instance, a system with high sediment would benefit from a sand filter or a more advanced media filter, while a small residential system might only need a simple screen filter.

Q 28. How do you ensure the accuracy of irrigation system measurements?

Accuracy in irrigation system measurements is paramount for efficient and effective irrigation. I use several methods to ensure precision:

- Calibration of Equipment: Regularly calibrating measuring instruments like pressure gauges and flow meters is essential. This ensures that measurements are accurate and reliable.

- Proper Measurement Techniques: Following established procedures for taking measurements. For instance, pressure should be measured at specific points in the system, and flow rates should be measured using appropriate methods, considering factors like pipe diameter and velocity.

- Multiple Measurements: Taking multiple measurements at different times and locations to confirm readings and identify any anomalies.

- Data Logging: Recording all measurements meticulously and using data logging equipment where appropriate. This helps in identifying trends and patterns over time.

- Advanced Tools: Employing advanced tools such as ultrasonic flow meters for non-invasive flow rate measurements or smart irrigation controllers that provide real-time system data.

Example: When measuring pressure, I’d use a calibrated pressure gauge at various points in the system, noting the readings and time. Repeating this process helps identify if pressure drops are consistent, indicating a potential blockage or leak, or if they are intermittent, suggesting a more complex issue.

Key Topics to Learn for Your Irrigation Installation and Repair Interview

- Water Source & System Design: Understanding different water sources (wells, municipal water), pump types, and designing efficient irrigation layouts for various landscapes. Consider factors like soil type, water pressure, and plant needs.

- Pipe Installation & Joining Techniques: Mastering techniques for various pipe materials (PVC, HDPE), including proper trenching, bedding, backfilling, and using different joining methods (fusion welding, solvent welding, threading). Be prepared to discuss safety procedures and best practices.

- Valve Selection & Installation: Knowing the different types of valves (ball valves, gate valves, backflow preventers) and their applications. Understanding pressure regulation and proper installation to prevent leaks and malfunctions.

- Sprinkler & Drip Irrigation Systems: Familiarity with different sprinkler types (rotary, impact, spray), drip irrigation components (emitters, tubing), and their appropriate application based on landscape design and water conservation requirements.

- Troubleshooting & Repair: Diagnosing common problems like leaks, low water pressure, clogged emitters, and malfunctioning valves. Discuss your approach to systematic troubleshooting and repair techniques, including the use of specialized tools.

- Irrigation Control Systems: Understanding timer operation, rain sensors, and other automated irrigation control systems. Discuss programming and maintenance of these systems.

- Water Conservation & Efficiency: Demonstrate knowledge of water-wise irrigation practices, including soil moisture monitoring, smart irrigation controllers, and drought-tolerant landscaping.

- Safety Regulations & Best Practices: Discuss relevant safety standards and regulations related to excavation, pipe installation, and working with electrical components.

Next Steps

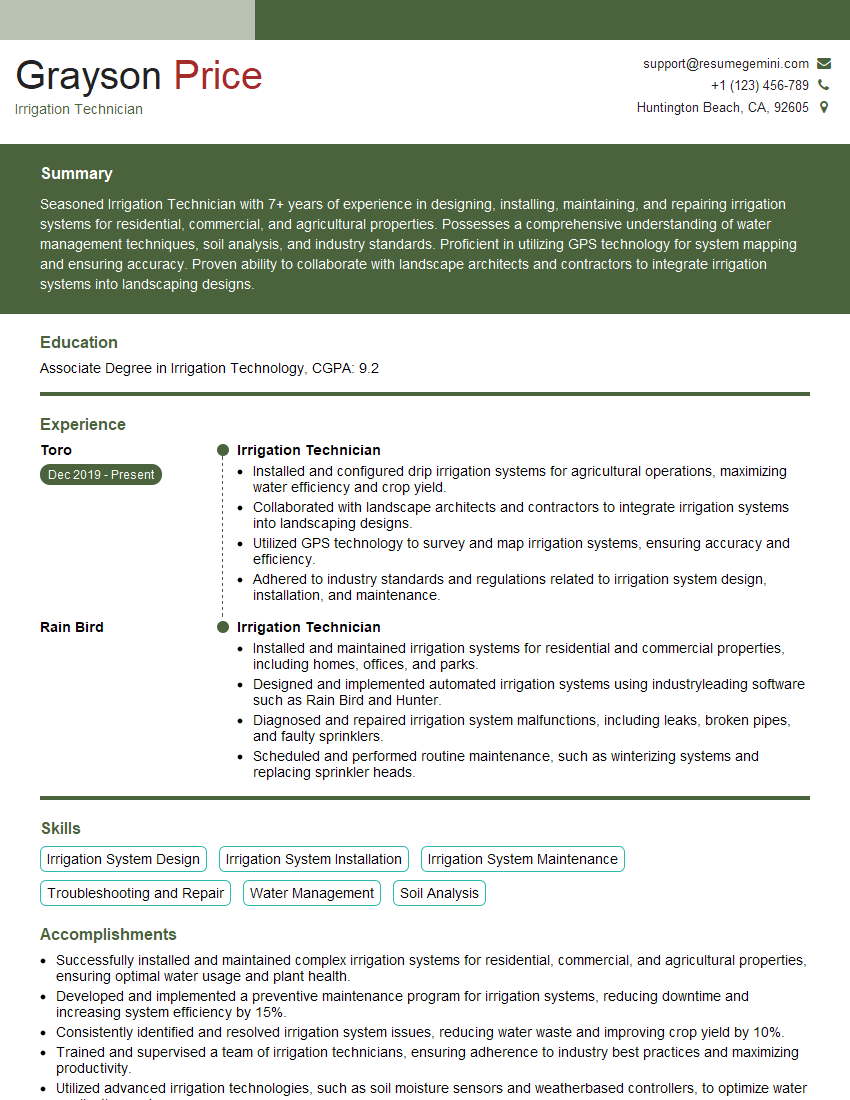

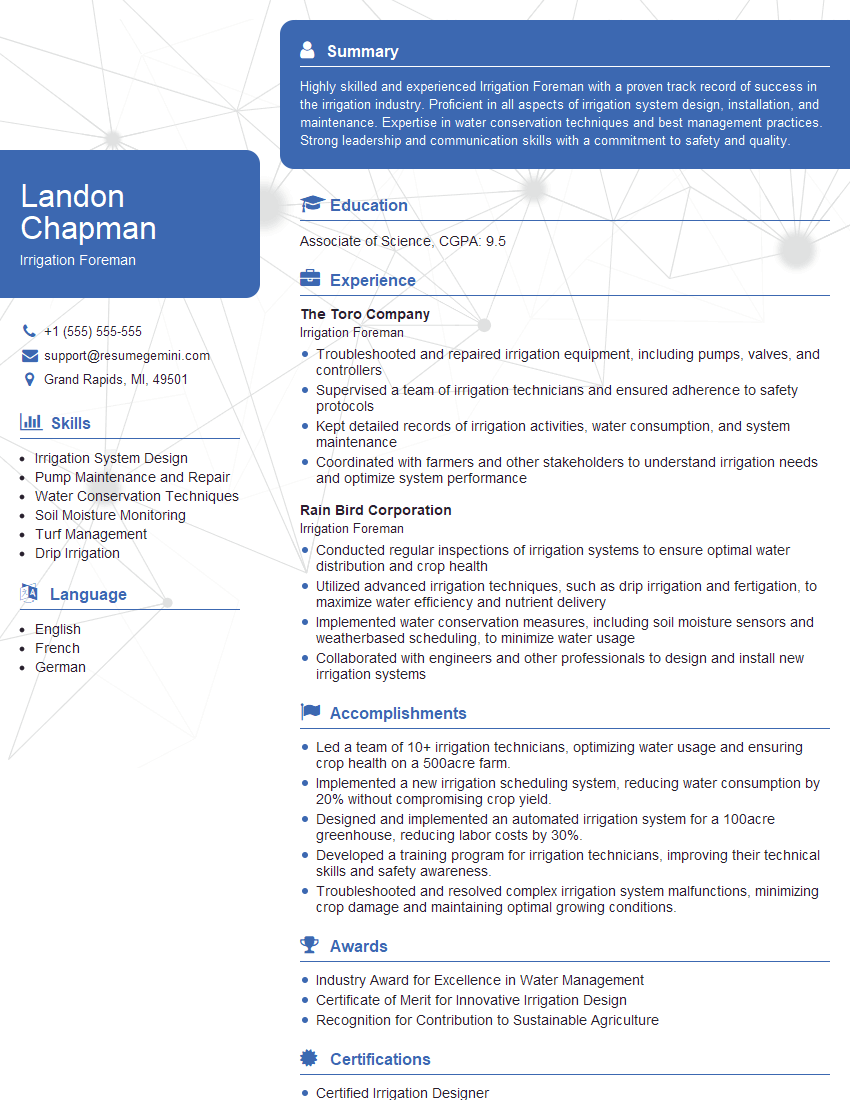

Mastering Irrigation Installation and Repair opens doors to a rewarding career with opportunities for growth and specialization. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume increases your chances of getting your application noticed. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides helpful tools and resources, including examples of resumes tailored to the Irrigation Installation and Repair field, to help you create a document that truly highlights your qualifications. Take advantage of these resources and confidently present yourself as the ideal candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?