Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Construction and Repair interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Construction and Repair Interview

Q 1. Describe your experience with blueprint reading and interpretation.

Blueprint reading is fundamental to construction. It’s like reading a map for a building, detailing every aspect from foundation to finish. My experience spans over 10 years, encompassing residential, commercial, and industrial projects. I’m proficient in interpreting various types of blueprints, including architectural, structural, mechanical, and electrical drawings. I understand how to decipher symbols, scales, dimensions, and specifications. For example, I can quickly identify wall thicknesses, beam sizes, plumbing layouts, and electrical conduit runs. I’ve even encountered projects with hand-drawn blueprints and learned to interpret them effectively. My ability to accurately read and interpret blueprints ensures that the construction process adheres precisely to the design specifications, minimizing errors and rework.

I’m familiar with different software for viewing and manipulating blueprints, like AutoCAD and Revit, allowing me to collaborate efficiently with architects and engineers. I can identify potential clashes or inconsistencies early in the process, preventing costly issues later. This proactive approach safeguards budget and schedule.

Q 2. Explain your understanding of building codes and safety regulations.

Building codes and safety regulations are paramount in construction. They’re the rules of the game, ensuring structures are safe, functional, and meet specific standards. My understanding covers a wide range of codes, including the International Building Code (IBC), local ordinances, and OSHA regulations. I’m familiar with requirements related to structural integrity, fire safety, accessibility, electrical systems, plumbing, and more. For instance, I know the precise requirements for installing fire-resistant materials, ensuring proper ventilation, and adhering to electrical grounding codes.

On every project, I prioritize safety. This means conducting regular safety meetings, enforcing personal protective equipment (PPE) usage, and ensuring that all work is done according to safety protocols. I’ve proactively identified and rectified potential hazards, such as unsafe scaffolding or improper equipment operation, preventing accidents and injuries. Compliance with codes and regulations isn’t just about avoiding penalties; it’s about ensuring the well-being of everyone involved in the project and the longevity of the structure itself.

Q 3. How do you handle unexpected problems or delays on a construction site?

Unexpected problems are inevitable in construction. Think of it like navigating a complex maze; there will be dead ends and unexpected turns. My approach involves a structured problem-solving methodology. First, I assess the situation thoroughly, identifying the root cause of the delay or problem. This often involves gathering input from the team and reviewing relevant documentation. Then, I explore various solutions, prioritizing those that are cost-effective and time-efficient. Effective communication is key here; keeping all stakeholders informed of the situation and the proposed solutions is crucial.

For instance, I once encountered an unexpected rock formation during excavation. My immediate response was to halt work, reassess the site, and consult with a geotechnical engineer. We then developed a revised plan, incorporating adjustments to the foundation design and mitigating the risk, which minimized the overall project delay. Effective communication with the client throughout the entire process ensured transparency and maintained trust.

Q 4. What experience do you have with project scheduling and management?

Project scheduling and management are integral aspects of successful construction projects. It’s about orchestrating a symphony of activities, ensuring everything runs smoothly and on time. My experience includes using various project management software, such as Microsoft Project and Primavera P6. I can develop detailed project schedules, including task dependencies, durations, and resource allocation. I’m also skilled in critical path analysis, helping to identify potential delays and adjust the schedule proactively.

On a recent large-scale renovation, I was responsible for managing the entire schedule, from demolition to final inspections. I employed a phased approach, breaking down the project into smaller, manageable tasks, and regularly monitored progress against the schedule. Utilizing Agile methodologies, we adjusted the schedule as needed, mitigating unforeseen issues and delivering the project on time and within budget. Regular communication with the client helped manage their expectations and kept them informed of any potential schedule changes.

Q 5. Describe your proficiency in using various hand and power tools.

Proficiency with hand and power tools is essential for any construction professional. Think of them as your artistic instruments. Over the years, I have gained extensive experience using a wide range of tools, from basic hand tools like hammers, saws, and levels, to more sophisticated power tools like drills, saws, and concrete cutters. I am also experienced with operating specialized equipment like forklifts and aerial lifts, always prioritizing safety.

I understand the nuances of each tool, ensuring proper operation and maintenance. For example, I know the difference between various drill bits and how to select the correct one for different materials. Safety is a primary consideration. I always adhere to safety regulations, ensuring proper use and maintenance of all tools, minimizing the risk of accidents.

Q 6. How do you ensure quality control throughout a construction project?

Quality control is the backbone of a successful construction project. It’s like being a quality inspector, ensuring every step meets the highest standards. My approach to quality control involves a multi-layered system, beginning with meticulous planning and design review. Regular inspections are conducted at various stages of the project to ensure that materials meet specifications, work is performed according to plans, and all safety regulations are adhered to. I use checklists and documentation to track progress and identify any potential issues.

For example, I’ll carefully inspect concrete pours for proper curing and finishing. I’ll verify that electrical wiring is installed correctly and meets code requirements. Thorough documentation of every step and inspection ensures accountability and allows for quick identification and rectification of any defects. This proactive approach reduces rework, minimizing costs and delays.

Q 7. What is your experience with different construction materials?

Experience with various construction materials is crucial for effective project management and execution. It’s like knowing your palette of colors as an artist. My knowledge spans a wide array of materials, including concrete, steel, wood, masonry, drywall, and various insulation products. I understand the properties of each material, their limitations, and best practices for handling and installation. For example, I know the different types of concrete and how to select the appropriate mix design for specific applications. I’m aware of the environmental impact of different materials and strive to choose sustainable options whenever feasible.

I’ve worked with both traditional and cutting-edge materials, including composite materials and sustainable building products. This breadth of knowledge allows me to make informed decisions about material selection, ensuring that the project meets its functional requirements, budget constraints, and aesthetic goals. Understanding material characteristics is critical for cost-effective construction and longevity of the project.

Q 8. Explain your understanding of different construction methods (e.g., framing, drywall, concrete).

Construction methods are the various techniques used to build structures. Different methods are chosen based on factors like project scale, budget, timeline, and the desired aesthetic.

- Framing: This involves creating the skeletal structure of a building using lumber. Think of it as the building’s bones. We use various types of framing, such as platform framing (building floors sequentially) or balloon framing (continuous studs from foundation to roof), each with its own advantages and disadvantages regarding cost and structural integrity. For example, in a residential project, platform framing is common due to its ease of construction and ability to adapt to various designs.

- Drywall: This is the process of installing gypsum boards (drywall panels) to create interior walls and ceilings. It’s like putting the ‘skin’ on the building’s skeleton. Proper drywall installation is crucial for fire resistance and sound insulation. Different thicknesses and types of drywall are selected depending on the requirements, such as moisture-resistant drywall for bathrooms.

- Concrete: Concrete is a fundamental material used in foundations, slabs, and structural elements. Pouring and finishing concrete requires precision and attention to detail to achieve the desired strength and finish. We consider factors like the concrete mix design (ratio of cement, aggregate, and water) and curing process (maintaining optimal moisture and temperature) to ensure its durability. For instance, in high-rise construction, specialized high-strength concrete mixes and precise pouring techniques are employed.

Understanding these methods is vital for effective project management and quality control. A lack of expertise in any one of them can lead to structural issues, cost overruns, and schedule delays.

Q 9. How do you manage a team of construction workers?

Managing a construction team requires strong leadership, communication, and organizational skills. I leverage a collaborative approach, focusing on clear communication of goals, roles, and expectations.

I establish a system for daily task assignments, progress tracking, and regular team meetings to address concerns, ensure everyone is on the same page, and maintain open communication. I also prioritize safety and implement strict safety protocols, conducting regular safety briefings and ensuring compliance with all regulations. Motivation is key; I celebrate team successes and acknowledge individual contributions to foster a positive and productive work environment. Conflict resolution is an integral part – I encourage open dialogue and find solutions that benefit the entire team and the project. For example, on a recent project, a disagreement between two team members regarding the best approach to a specific task was resolved through a collaborative problem-solving session, ultimately leading to an innovative and efficient solution.

Q 10. Describe your experience with cost estimation and budgeting.

Cost estimation and budgeting are critical for successful construction projects. My approach begins with a thorough understanding of the project scope, including detailed plans, specifications, and material lists. I utilize various estimation techniques, including detailed quantity take-offs (measuring the exact amount of materials required) and parametric estimation (using historical data and algorithms). Software like estimating programs helps in calculating material costs, labor costs, and equipment rentals. I build in contingency reserves to account for unforeseen issues and risks. Regular monitoring and adjustments are crucial; I regularly compare actual costs against the budget and adjust accordingly. Transparency is key; I maintain detailed records and provide regular updates to clients on cost performance.

For instance, on a recent renovation project, I used a combination of detailed quantity take-offs and parametric estimation based on similar past projects, resulting in a budget that was within 2% of the final cost. This accuracy was critical for the project’s success and client satisfaction.

Q 11. How do you handle conflicts with subcontractors or clients?

Conflicts can arise, but a proactive and professional approach is essential. I emphasize clear communication and documentation. I start by carefully listening to all parties involved and understanding their perspectives. I then work to identify the root cause of the conflict. Fairness and objectivity are paramount. I might facilitate mediation, encouraging compromise and finding mutually acceptable solutions. In extreme cases, formal dispute resolution mechanisms might be necessary, but I always strive to resolve issues amicably before resorting to such measures. For instance, in one situation involving a subcontractor’s delay, open communication helped us identify the issue—a lack of specific instructions—and collaboratively implement a revised schedule that met everyone’s needs.

Q 12. What is your experience with risk assessment and mitigation on construction sites?

Risk assessment and mitigation are paramount for safety and project success. I employ a systematic approach involving identifying potential hazards (e.g., falls, electrical hazards, equipment malfunctions), analyzing their likelihood and potential consequences, and developing strategies to mitigate those risks. This includes implementing safety protocols, providing appropriate personal protective equipment (PPE), conducting regular site inspections, and ensuring compliance with safety regulations. I maintain detailed records of risk assessments and mitigation plans. For example, on a recent high-rise project, a detailed risk assessment identified the potential for falls from heights. Mitigation strategies included implementing strict fall protection measures, such as using safety harnesses and guardrails, and providing comprehensive training to all workers.

Q 13. How familiar are you with various types of repairs (e.g., plumbing, electrical, drywall)?

I possess extensive experience across various repair types.

- Plumbing: I’m proficient in troubleshooting leaks, repairing pipes, installing fixtures, and understanding plumbing codes.

- Electrical: My expertise extends to wiring repairs, troubleshooting electrical faults, installing lighting fixtures, and ensuring adherence to electrical safety regulations.

- Drywall: Beyond installation, I can repair holes, cracks, and damaged sections, ensuring a smooth and seamless finish.

This broad skill set allows me to manage and oversee diverse repair projects effectively and ensure a high standard of workmanship. For example, I recently resolved a recurring plumbing leak in an older building by identifying a corroded pipe section and efficiently replacing it, preventing further water damage.

Q 14. Explain your troubleshooting skills regarding common construction issues.

Troubleshooting skills are essential in construction. My approach is methodical, beginning with a thorough examination of the issue, gathering information, and identifying potential causes. I then prioritize the most likely causes and systematically test them using appropriate tools and techniques. Documentation is crucial; I maintain detailed records of the troubleshooting process, including observations, tests performed, and solutions implemented. For instance, when faced with an electrical circuit breaker tripping repeatedly, I would systematically check for overloads, short circuits, and faulty wiring. By methodically investigating each potential cause, I successfully located and rectified a loose wire connection causing the problem.

Q 15. What software programs are you proficient in (e.g., AutoCAD, Revit)?

My proficiency in software extends to several industry-standard programs crucial for efficient construction and repair projects. I’m highly skilled in AutoCAD, using it extensively for 2D drafting, creating detailed plans, and generating precise drawings for various building components. My expertise also encompasses Revit, a Building Information Modeling (BIM) software. I leverage Revit for 3D modeling, creating detailed building models that allow for better visualization and coordination among different disciplines involved in a project. This improves accuracy and reduces errors during construction. Furthermore, I’m familiar with project management software like Microsoft Project, which I use for scheduling, resource allocation, and tracking project progress. Finally, I have experience with estimating software to generate accurate and competitive bids.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize tasks and manage multiple projects simultaneously?

Prioritizing tasks and managing multiple projects requires a structured approach. I typically begin by employing a prioritization matrix, evaluating tasks based on urgency and importance. This allows me to focus on high-impact, time-sensitive tasks first. For instance, if I’m overseeing multiple projects, I’ll prioritize tasks based on deadlines and potential impact on overall project timelines. I use project management tools such as Gantt charts to visualize the timeline for each project and track progress against milestones. Furthermore, I maintain consistent communication with clients and project teams to ensure alignment and address any arising issues promptly. Regular team meetings help in efficient information sharing and coordinated effort. I also believe in delegating tasks effectively to team members based on their strengths and experience. This ensures that tasks are completed efficiently and within the planned time frame.

Q 17. What is your experience with sustainable construction practices?

Sustainable construction practices are a core principle in my approach to building and repair. I have extensive experience integrating sustainable materials, such as reclaimed wood, recycled steel, and locally sourced products, minimizing the environmental impact of projects. I’m proficient in designing energy-efficient buildings, incorporating features like improved insulation, high-performance windows, and solar panels to reduce energy consumption. Moreover, I understand the importance of water conservation and have implemented strategies such as rainwater harvesting and low-flow fixtures in various projects. Waste management is another key aspect, and I’ve been involved in projects employing strategies for minimizing construction waste and diverting materials from landfills. For example, on a recent renovation project, we reused salvaged bricks and repurposed lumber, significantly reducing material costs and environmental impact.

Q 18. Describe a time you had to adapt to a changing project scope.

During a recent commercial building renovation, the client unexpectedly requested a significant change to the original scope – a complete redesign of the interior layout midway through the project. Initially, this caused some disruption to the timeline and budget. However, I immediately held a meeting with the team and the client to assess the changes and their implications. We analyzed the revised design, identified any potential conflicts with existing work, and created a revised schedule and budget. The team adapted quickly, using agile methodologies to manage the changes effectively. We prioritized tasks based on the new requirements, communicated openly with the client about potential delays and additional costs, and ensured transparency throughout the process. Ultimately, we successfully completed the project despite the significant change in scope, maintaining a positive working relationship with the client.

Q 19. How do you ensure the safety of yourself and your crew on a job site?

Safety is paramount on any job site. Before any work commences, I conduct thorough site safety inspections, identifying potential hazards like uneven surfaces, exposed wires, and inadequate lighting. I then implement appropriate safety measures, such as providing personal protective equipment (PPE) like hard hats, safety glasses, and high-visibility vests to all crew members. Regular safety meetings are conducted to reinforce safe work practices, emphasizing the importance of proper tool use, fall protection, and hazard awareness. We follow strict protocols for handling hazardous materials, and I ensure that all crew members are trained in emergency response procedures. Additionally, I maintain detailed records of all safety inspections, training sessions, and incident reports to ensure compliance with all safety regulations and to continuously improve our safety practices. I believe a strong safety culture is built through consistent vigilance and proactive measures, creating an environment where everyone feels safe and responsible for their own safety and the safety of others.

Q 20. What is your experience with different types of foundations?

My experience encompasses various foundation types, each suited to different soil conditions and building loads. I’m familiar with shallow foundations like spread footings, which are suitable for stable soil and lighter structures. I also have experience with deeper foundations, including pile foundations, ideal for unstable or soft soil, and caissons, used when bearing capacity needs to be significantly increased. Slab-on-grade foundations, commonly used in residential construction, are also within my expertise. The selection of the right foundation type is crucial, and I carefully assess soil conditions, building weight, and other factors before making a recommendation. For example, on a recent project involving a waterfront property with unstable soil, we opted for a pile foundation to ensure stability and prevent settlement. I understand the importance of proper design and installation to ensure the long-term stability and durability of the foundation.

Q 21. Explain your knowledge of different roofing systems.

My knowledge of roofing systems covers a wide range of materials and techniques. I’m experienced with asphalt shingle roofs, a common and cost-effective option, and understand their installation, maintenance, and repair. I also have experience with tile roofs, known for their durability and aesthetic appeal, but requiring specialized installation techniques. Metal roofing, offering excellent longevity and weather resistance, is another area of my expertise. Furthermore, I’m familiar with flat roofing systems, often using materials like EPDM or TPO membranes, and the critical details involved in ensuring proper waterproofing. The selection of a roofing system depends on several factors, including the building’s architecture, climate, and budget. For example, in a high-wind area, a metal roof might be the preferred option due to its superior wind resistance. Each system has its strengths and weaknesses, and I make sure to choose the most appropriate solution for each project, ensuring proper ventilation and water drainage to maximize its lifespan.

Q 22. Describe your experience with the installation of HVAC systems.

My experience with HVAC system installation spans over 15 years, encompassing a wide range of projects from residential retrofits to large-scale commercial installations. I’m proficient in all phases, from initial design review and material procurement to the final commissioning and testing. This includes working with various systems such as split systems, packaged units, and VRF systems. For example, on a recent commercial project, we installed a sophisticated VRF system in a new office building. This required precise planning to ensure proper airflow and efficient energy distribution throughout the building, involving detailed ductwork design and meticulous refrigerant line installation. I am adept at troubleshooting issues during installation, ensuring the systems operate optimally. I’m also familiar with various refrigerants and their environmental impact, ensuring compliance with all relevant regulations.

- Experience with different HVAC system types: Split systems, packaged units, VRF systems, geothermal heat pumps.

- Proficiency in all installation phases: Design review, material procurement, installation, testing and commissioning.

- Troubleshooting and problem-solving skills during installation.

- Knowledge of refrigerants and their environmental impact.

Q 23. How do you maintain accurate records and documentation throughout a project?

Maintaining accurate records and documentation is crucial for successful project completion and future reference. I utilize a combination of digital and physical methods to ensure comprehensive documentation. This includes daily logs detailing work performed, material usage, and any unforeseen issues encountered. I also employ project management software to track progress, manage budgets, and store digital copies of all relevant documents, such as blueprints, permits, and inspection reports. For instance, we use a cloud-based system to ensure all team members have access to the most up-to-date information in real time. Detailed photographic evidence is also crucial, documenting the ‘before’ and ‘after’ of each stage, which is invaluable for resolving disputes or making future repairs. This meticulous approach ensures clarity, accountability, and efficient project flow.

- Daily logs of work performed, material usage and issues encountered.

- Project management software for tracking progress, budget and document storage.

- Digital and physical document storage (cloud-based systems, physical filing).

- Photographic and video documentation.

Q 24. How familiar are you with different types of concrete mixes and their applications?

My understanding of concrete mixes extends beyond just knowing the basic components (cement, aggregates, water). I’m familiar with different types including ready-mix concrete, pre-mixed concrete, and specialized mixes like high-strength concrete, rapid-setting concrete, and fiber-reinforced concrete. The choice of mix depends heavily on the application. For instance, high-strength concrete is ideal for structural elements where significant load-bearing is required, while rapid-setting concrete might be used for quick repairs or in situations where early strength is critical. Fiber-reinforced concrete enhances durability and crack resistance, often employed in pavement or exposed structures. I can assess a project’s needs and specify the appropriate mix design to achieve the desired strength, workability, and durability. Understanding the slump test and other quality control measures is also vital to guarantee the integrity of the concrete.

- Ready-mix, pre-mixed, and specialized concrete mixes (high-strength, rapid-setting, fiber-reinforced).

- Understanding the application and properties of various concrete mixes.

- Proficiency in concrete testing and quality control (slump test).

- Knowledge of mix design principles to achieve desired properties.

Q 25. What is your understanding of load-bearing structures?

Load-bearing structures are the foundational elements of a building, designed to support the weight of the structure itself, as well as any additional loads like people, furniture, and equipment. Understanding these structures is fundamental to construction safety and integrity. I’m knowledgeable about various load-bearing components like columns, beams, walls, and foundations. It’s crucial to understand how these components interact and transfer loads through the structure. For example, a poorly designed foundation can lead to settling and cracks, compromising the entire building’s stability. Similarly, improperly sized beams or columns could lead to structural failure under excessive load. My experience includes working with engineers’ plans and specifications to ensure that all load-bearing elements are correctly installed and meet building codes. Calculations related to load distribution and safety margins are critically important aspects of this work.

- Understanding of various load-bearing components (columns, beams, walls, foundations).

- Knowledge of load transfer mechanisms within a structure.

- Ability to interpret engineering plans and specifications related to load-bearing structures.

- Awareness of building codes and safety regulations.

Q 26. Describe your problem-solving approach when encountering structural issues.

My problem-solving approach to structural issues is systematic and data-driven. When faced with a problem, I begin with a thorough investigation to identify the root cause. This includes visual inspections, reviewing structural drawings, and potentially using non-destructive testing methods like ultrasound to assess the condition of the materials. Once the root cause is identified, I develop several potential solutions, evaluating their feasibility, cost-effectiveness, and long-term impact. This often involves collaboration with engineers and other specialists. For example, if I detect significant foundation settling, I would consult a geotechnical engineer to assess the ground conditions and recommend appropriate remediation techniques, such as underpinning or soil stabilization. The chosen solution is always implemented with safety as the paramount concern, ensuring compliance with all applicable building codes and regulations.

- Systematic investigation to identify the root cause of structural issues.

- Collaboration with engineers and other specialists.

- Development and evaluation of multiple solutions.

- Implementation of the chosen solution with safety as the top priority.

Q 27. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations is a top priority in all my projects. This involves understanding and adhering to local, state, and federal regulations concerning waste disposal, hazardous materials handling, and air and water quality. I’m familiar with various permits and licensing requirements and maintain detailed records of all materials used and disposed of. For example, we meticulously track asbestos abatement procedures, ensuring that all materials are handled and disposed of according to EPA guidelines. We also ensure that all demolition and construction waste is properly sorted and recycled whenever possible, minimizing environmental impact. Furthermore, we utilize sustainable materials and practices whenever feasible to contribute to a greener construction industry. Staying updated on the evolving environmental regulations is crucial to maintain compliance and protect the environment.

- Understanding and adherence to local, state, and federal environmental regulations.

- Proper handling and disposal of hazardous materials.

- Waste management and recycling practices.

- Use of sustainable materials and construction methods.

- Knowledge of relevant permits and licensing requirements.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are in the range of $100,000 to $120,000 per year, commensurate with my experience and qualifications. This is based on my extensive experience, proven track record, and the specific responsibilities of this position. I am open to discussing this further based on the complete compensation package and the long-term growth opportunities offered.

Key Topics to Learn for Construction and Repair Interview

- Building Codes and Regulations: Understanding local, state, and national building codes is crucial for safe and legal construction practices. This includes knowledge of permit processes and inspections.

- Blueprint Reading and Interpretation: Proficiency in reading and interpreting blueprints is essential for understanding project specifications and executing tasks accurately. Practice translating drawings into practical steps.

- Material Selection and Estimation: Learn to choose appropriate materials based on project needs, budget constraints, and environmental considerations. Mastering quantity take-offs for accurate material estimations is vital.

- Safety Procedures and Regulations: Demonstrate a strong understanding of OSHA regulations and best practices for workplace safety, including the use of personal protective equipment (PPE) and hazard identification.

- Common Repair Techniques: Be prepared to discuss various repair techniques for different materials (e.g., drywall, concrete, plumbing, electrical). Highlight your problem-solving skills in addressing common repair issues.

- Project Management Fundamentals: Even for smaller projects, understanding project scheduling, budgeting, and resource allocation is valuable. Discuss your ability to manage time effectively and work within constraints.

- Tools and Equipment: Familiarize yourself with the proper use and maintenance of various hand and power tools commonly used in construction and repair. Be ready to discuss your experience with specific equipment.

- Troubleshooting and Problem-Solving: Highlight your ability to identify problems, assess solutions, and implement repairs effectively. Provide examples of how you’ve overcome challenges on previous projects.

Next Steps

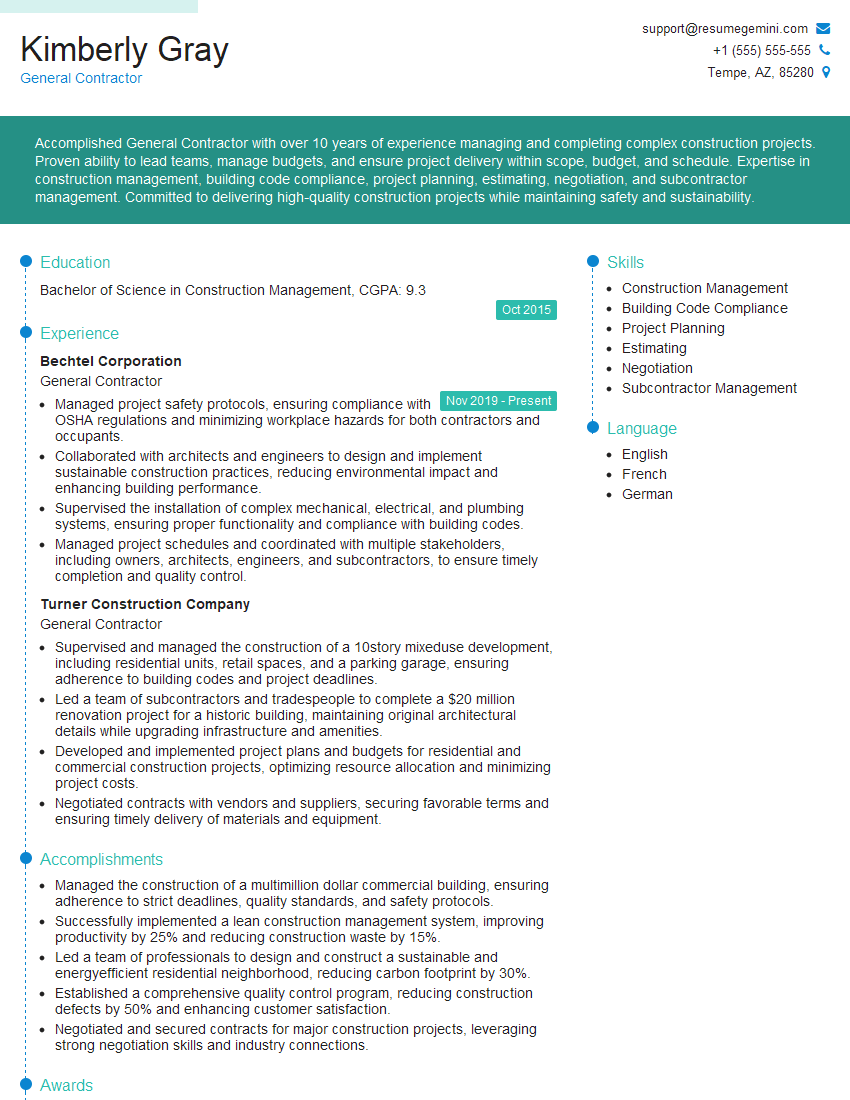

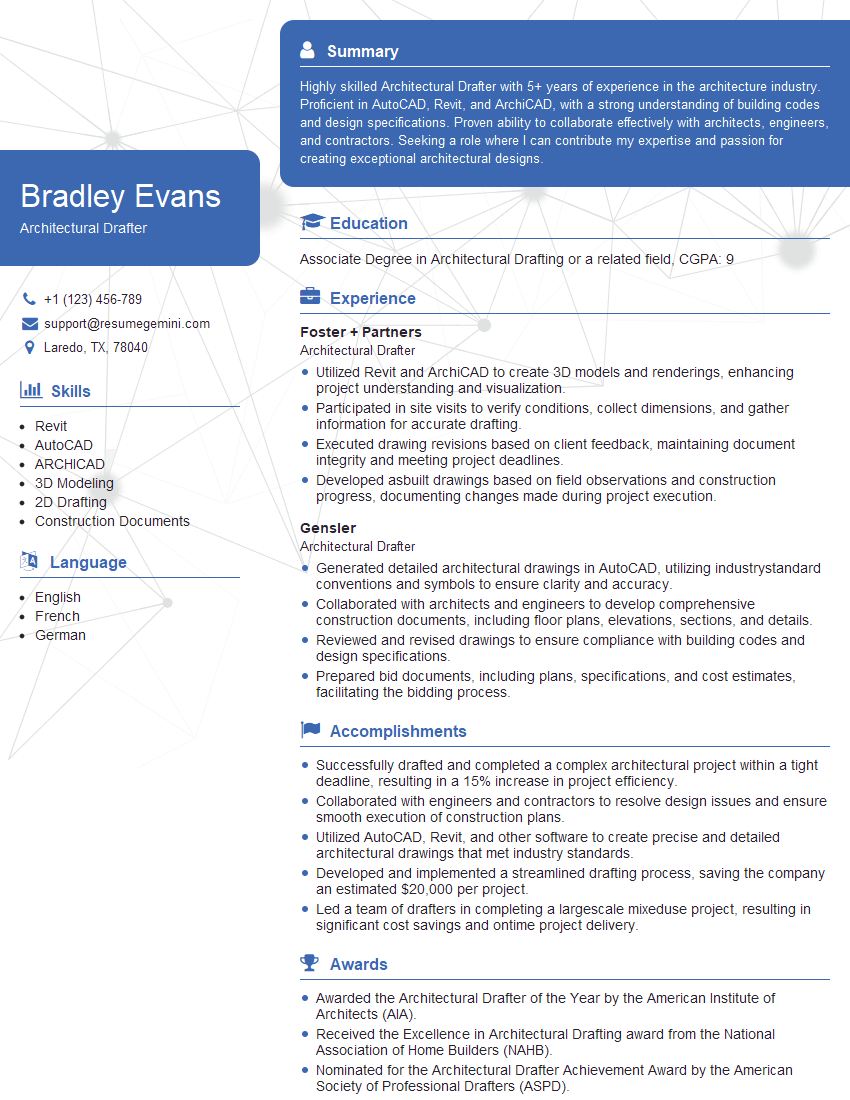

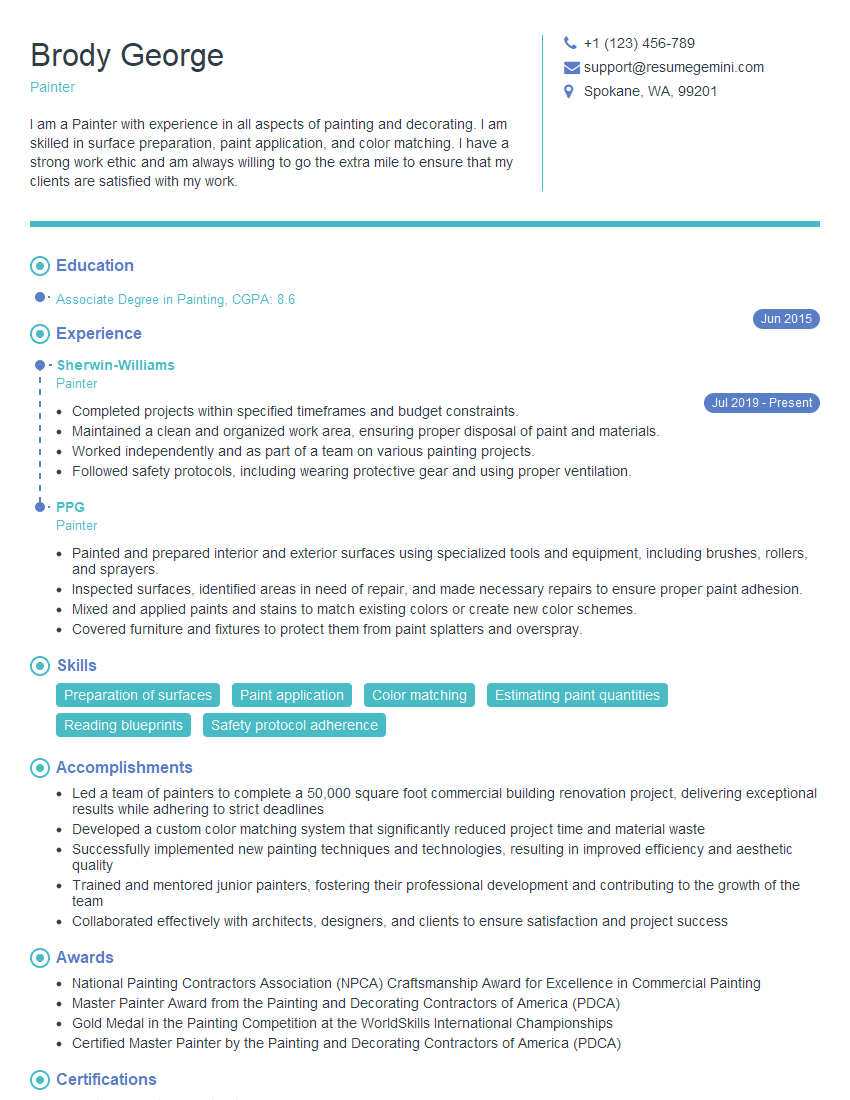

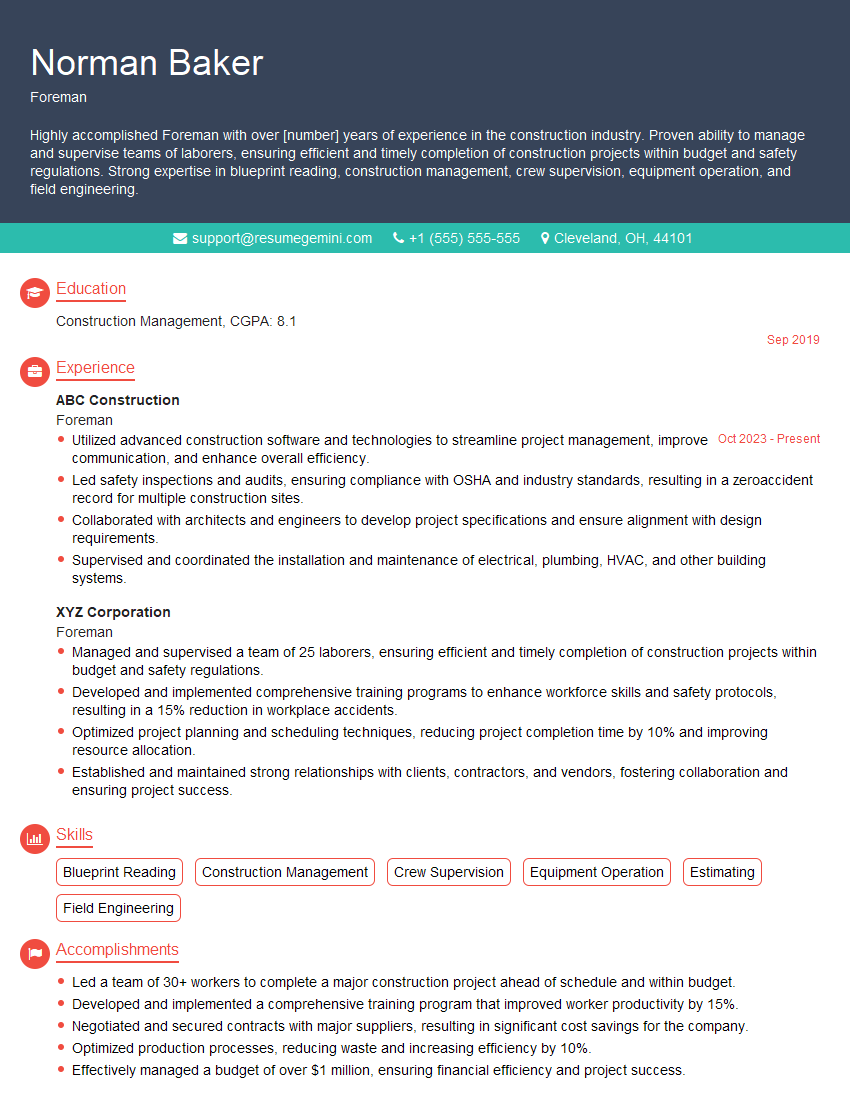

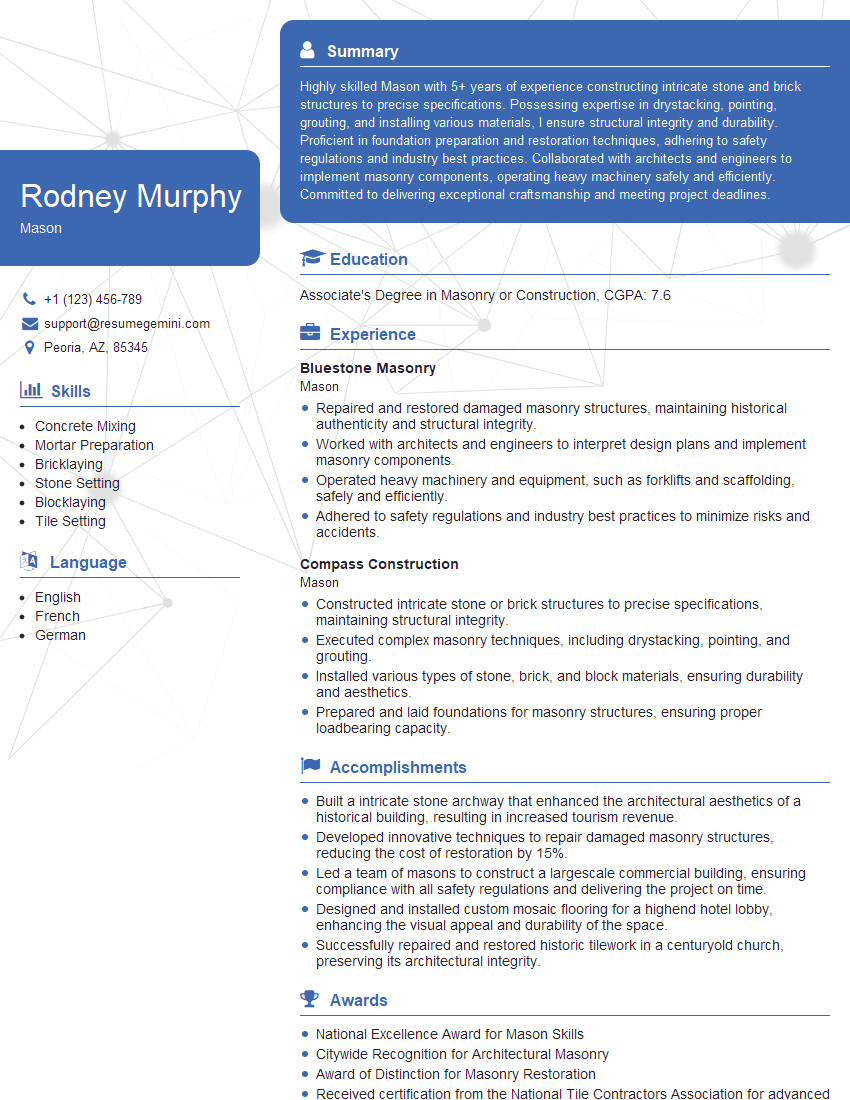

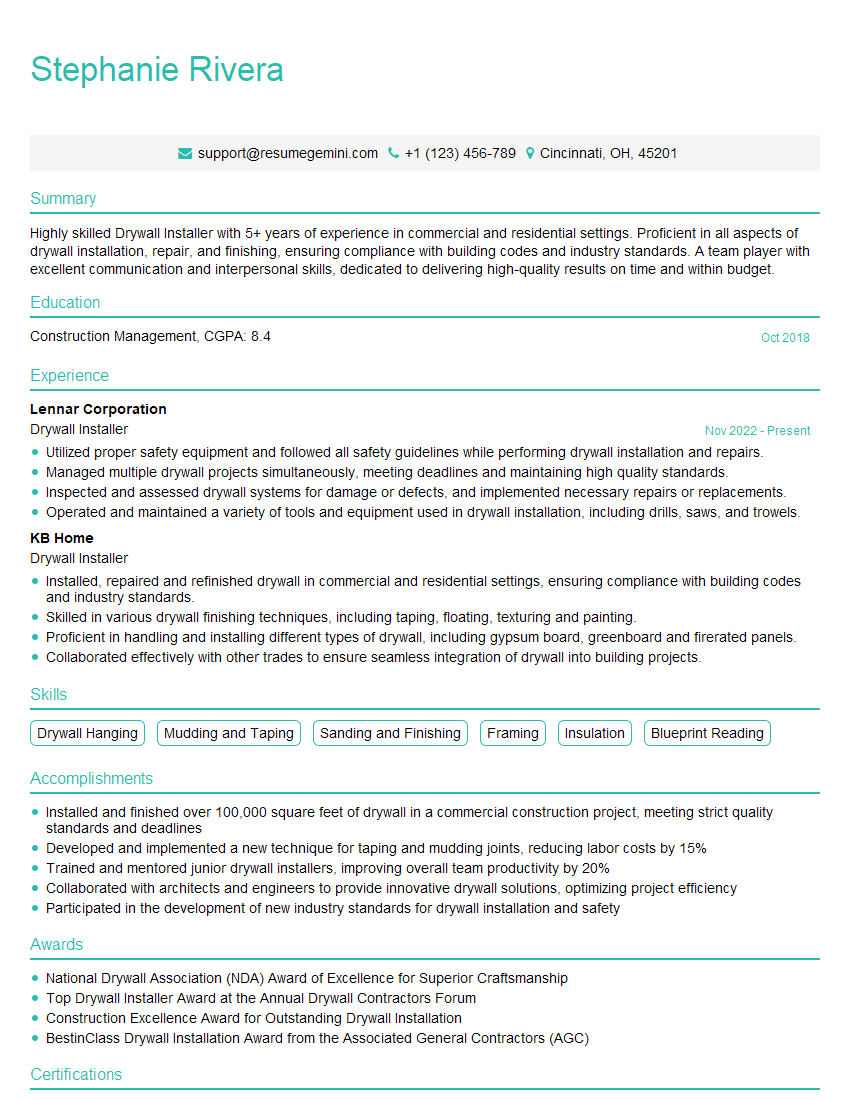

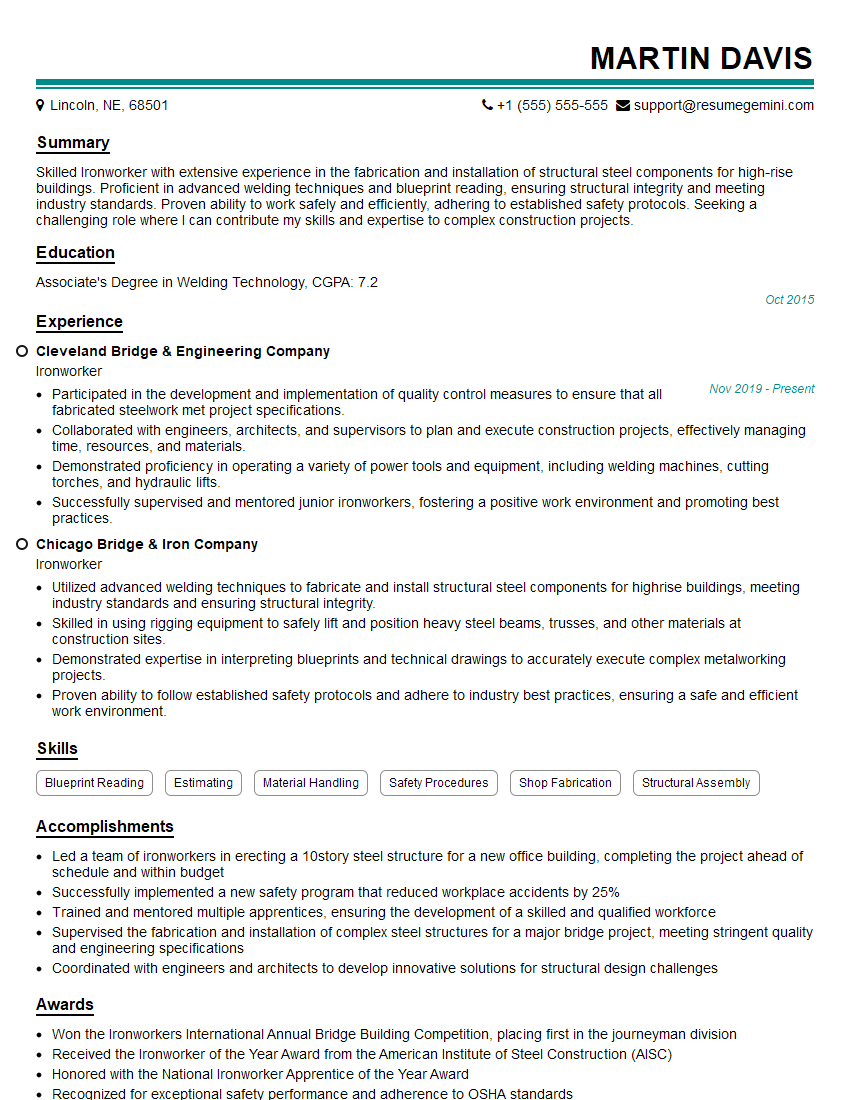

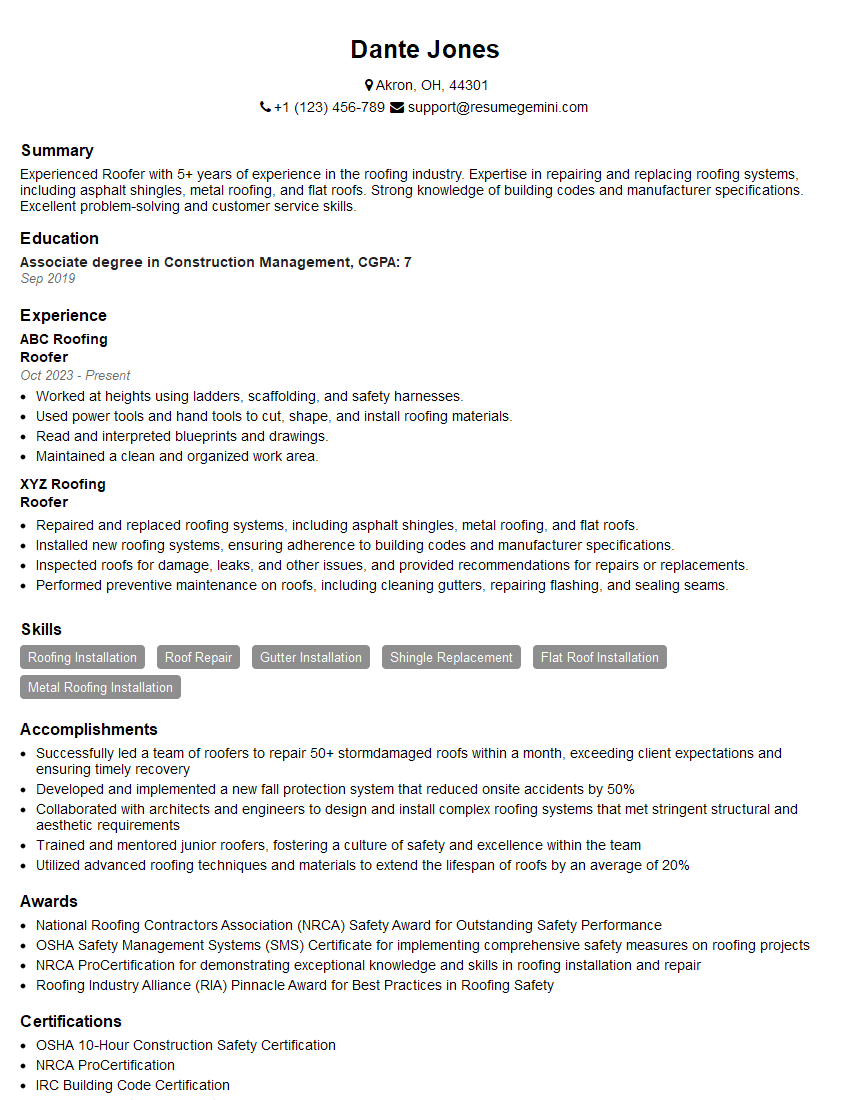

Mastering the fundamentals of Construction and Repair opens doors to a rewarding and diverse career path with excellent growth potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is crucial for ensuring your application gets noticed by potential employers. To help you build a professional and effective resume that highlights your skills and experience, we recommend using ResumeGemini. ResumeGemini provides a streamlined and user-friendly platform to build a top-tier resume, and we offer examples of resumes tailored specifically for the Construction and Repair industry to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?