Unlock your full potential by mastering the most common 2D Pattern Making interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in 2D Pattern Making Interview

Q 1. Explain the difference between a sloper and a block.

Both slopers and blocks are foundational patterns in 2D pattern making, serving as the base for designing various garments. However, they differ significantly in their purpose and complexity.

A sloper is a basic, fitted pattern piece created directly from the body measurements of a specific individual. Think of it as a personalized blueprint, capturing the unique contours of that person’s body. It’s usually quite simple, often just a front and back bodice piece, and a sleeve. It’s less about standard sizing and more about capturing a particular shape.

A block, on the other hand, is a standardized, graded pattern that represents an average body type within a specific size range. It’s a more complex pattern incorporating seam allowances and ease (extra fabric for comfort and fit), built from a set of measurements representing an average body size. Designers use blocks as the foundation for creating a variety of styles, across a wide spectrum of sizes. Imagine it like a template that you can adapt and modify.

In essence, a sloper is highly individualized, while a block is generalized and scalable.

Q 2. Describe your experience with various pattern making software (e.g., Optitex, Gerber, Lectra).

I have extensive experience with several industry-standard pattern-making software packages, including Optitex, Gerber Accumark, and Lectra Modaris. My proficiency encompasses all aspects of these platforms, from initial design and grading to marker making and production planning.

With Optitex, I’m comfortable using its powerful 3D capabilities to create realistic garment simulations before production, saving time and resources by identifying fit issues early on. I’ve leveraged its advanced grading features to efficiently create multiple size ranges for various projects.

My experience with Gerber Accumark includes the creation of intricate patterns for complex garments, as well as its robust marker-making capabilities for optimized fabric utilization. This software’s strength lies in its meticulous precision and its ability to seamlessly integrate with a production workflow.

In Lectra Modaris, I’m proficient in developing and managing pattern libraries, utilizing its advanced grading options and automated processes for large-scale production. Its collaborative features are particularly beneficial for team-based projects.

Across all these platforms, I have consistently delivered high-quality patterns that meet client specifications and contribute to efficient manufacturing processes.

Q 3. How do you grade a pattern for different sizes?

Grading a pattern involves systematically scaling it up or down to create different sizes. This isn’t simply enlarging or reducing the entire pattern; it requires careful consideration of body proportions. Different body areas change at different rates as size increases or decreases.

The process typically involves:

- Identifying Key Points: Identifying critical points (e.g., bust point, waist point, hip point) on the original pattern.

- Creating a Grade Rule: Establishing grading rules based on standard measurements and industry best practices. These rules determine how much each area of the pattern should increase or decrease for each size increment. This might involve adding or subtracting specific amounts at key points.

- Applying the Grade Rule: Using pattern making software (or manually) to apply the grading rules to every point of the pattern. This ensures proportional scaling across all pattern pieces.

- Checking and Adjusting: Once graded, a thorough check is necessary to ensure all pieces are proportionate and maintain the original design’s aesthetic and fit.

For example, when grading a bodice pattern, the bust circumference will require a larger increase than, say, the shoulder width as size increases. Accurate grading ensures a consistent fit across the size range.

Q 4. Explain the process of creating a basic bodice block.

Creating a basic bodice block involves several key steps:

- Drafting from Measurements: Begin by taking accurate body measurements. These form the foundation of the pattern.

- Creating the Front and Back Bodice: Using these measurements, basic geometric shapes are drawn to create the basic front and back bodice pieces. These are simplified versions of the actual bodice.

- Adding Design Details: These basic shapes are then modified to reflect the desired style. For example, darts can be added to create shaping at the bust and waist.

- Seams and Allowances: Seam allowances are added to account for the stitching process. The amount of seam allowance depends on the fabric and construction methods.

- Ease: Additional fabric is often added to the pattern for comfort and movement; this is called ease. The amount of ease added will vary depending on the garment style.

- Testing and Adjusting: The completed pattern is tested on a dress form or a live model and adjusted for a proper fit. This involves meticulously testing and refining the pattern until the desired fit is achieved.

This process requires a keen eye for detail, a thorough understanding of body proportions, and a hands-on approach to refining the pattern through multiple fittings.

Q 5. How do you ensure accurate seam allowances in your patterns?

Ensuring accurate seam allowances is crucial for a well-fitting garment. Inaccurate seam allowances lead to ill-fitting garments that are too tight or too loose. I utilize several methods to guarantee precision:

- Using Software: Modern pattern-making software automatically adds seam allowances during the design process, ensuring consistency across all pattern pieces.

- Adding Allowances Manually: When working manually, I use a precise ruler and measuring tools to add seam allowances to the pattern pieces. This is usually done by adding a consistent distance to the edges of the pattern.

- Marking Seam Lines: After adding the seam allowances, I clearly mark the actual seam lines using a different color of pen or marker, clearly differentiating between the cut line and seam allowance lines.

- Verification: Before cutting the fabric, I always verify the seam allowances on several pattern pieces to catch any errors early on.

Maintaining consistent seam allowances across all pieces is critical for a well-fitting garment. For example, a 5/8 inch seam allowance on a sleeve must match the same seam allowance on the bodice to avoid fitting problems.

Q 6. Describe your experience with different fabrics and how it impacts pattern making.

Different fabrics have unique properties that significantly impact pattern making. The drape, weight, stretch, and texture of a fabric directly influence the final garment’s fit and drape. My experience encompasses a wide range of fabrics, including wovens, knits, and non-wovens.

Woven fabrics (like cotton, linen, silk) typically require less ease than knits. Their lack of inherent stretch means the pattern needs to be very precise.

Knit fabrics (like jersey, rib knit) have a degree of stretch. This must be accounted for during the pattern design process; the pattern will need to be smaller than usual to account for the stretch in the fabric.

Non-woven fabrics (like felt, interfacing) have their own challenges; some may not drape well, and others may lack structure, leading to adjustments in pattern design and construction.

Understanding how a fabric will behave is critical. For instance, a loosely woven fabric may require additional seam allowances to avoid fraying, while a heavy fabric may need wider seam allowances to allow for the bulk of the fabric at the seams.

Q 7. How do you handle pattern adjustments for fit issues?

Addressing fit issues requires a systematic approach combining pattern alteration techniques and a sound understanding of garment construction. I employ several methods to resolve common fit problems.

Common Fit Issues and Solutions:

- Tightness at the Bust/Waist/Hips: This often requires adding width to the pattern at the affected areas, potentially by adjusting darts or adding fullness.

- Loose Fit: If the garment is too loose, adjustments might involve reducing width at various points, adjusting darts, or taking in seams.

- Uneven Hemline: This often points to issues during pattern cutting or construction and may require careful checking of the pattern and fabric cutting.

- Shoulder Problems: Uneven shoulders might require alterations to the shoulder seams or adjustments to the sleeve cap.

The process involves identifying the problem area, understanding the underlying cause (e.g., incorrect measurements, inappropriate ease allowance), and implementing appropriate adjustments to the pattern. This may necessitate making a muslin (a test garment made of inexpensive fabric) for additional adjustments before cutting into the final fabric.

Addressing fit problems effectively demonstrates a mastery of pattern making and an ability to create perfectly tailored garments.

Q 8. What are the common problems encountered during pattern making and how do you solve them?

Common problems in pattern making often stem from inaccurate measurements, improper grading, or difficulties with fitting. Let’s break down some frequent issues and their solutions:

- Inaccurate Measurements: This is the foundation of any pattern. Using the wrong body measurements leads to ill-fitting garments. Solution: Always double-check measurements, use a measuring tape correctly, and consider taking multiple measurements to ensure accuracy. Consider using a sloper (a basic bodice or trouser block) as a foundation to ensure consistency.

- Grading Issues: Scaling a pattern to different sizes can introduce distortions if not done properly. Solution: Use professional grading software or meticulously hand-grade patterns, paying close attention to maintaining proportions and seam allowances across sizes. Understanding the nuances of each garment section’s grading requirements (e.g., sleeves often need more adjustment than bodices) is crucial.

- Fitting Problems: Even with accurate measurements and grading, a garment might need adjustments for individual body shapes. Solution: Create a muslin prototype (a test garment made from inexpensive fabric) to identify fit issues. This allows for alterations such as adjusting ease, changing the dart placement, or making other pattern adjustments before cutting into expensive fabric.

- Pattern Distortion: Incorrect cutting, stretching, or handling of fabric can distort the pattern pieces. Solution: Use sharp shears, cut on a flat surface, and use pattern weights to hold the pattern pieces in place while cutting. Pay attention to fabric grain direction to avoid distortion.

Addressing these issues proactively saves time, material, and frustration. A methodical approach and attention to detail are key.

Q 9. Explain your understanding of grainlines and their importance in pattern making.

Grainlines are the lengthwise and crosswise yarns in a woven fabric, indicated by parallel lines on the pattern pieces. They are crucial because they dictate how the fabric will drape and hang. Understanding grainlines is paramount for achieving a professional-looking garment.

- Lengthwise Grain (Warp): Runs parallel to the selvage (the finished edge of the fabric). It offers the most stability and least stretch, ideal for the garment’s main vertical lines.

- Crosswise Grain (Weft): Runs perpendicular to the selvage. It has more give than the lengthwise grain.

- Bias Grain: Runs at a 45-degree angle to the selvage. It is the most stretchy and drapey grain.

Using the correct grainlines prevents twisting or distortion, leading to better drape and a more polished final product. For example, a dress made with the lengthwise grain on the bodice and skirt will hang smoother than one with the crosswise grain. A bias cut skirt, in contrast, will hang differently, showcasing its inherent drape.

Q 10. How do you create a dart manipulation?

Dart manipulation is a powerful technique used to shape a garment and create curves. It involves transferring the volume of a dart to another area, often to create a more flattering silhouette or to accommodate design elements.

Let’s consider moving a bust dart to a shoulder seam:

- Identify the Dart: Locate the bust dart on the pattern piece.

- Measure Dart Length and Width: Accurately measure the dart’s length and width.

- Determine New Location: Decide where you’ll place the manipulated dart, such as along the shoulder seam.

- Transfer the Dart: Cut along one dart leg, unfold the pattern piece, and tape the dart’s point to the new location along the shoulder seam.

- Reshape: Smooth the seamline, creating a new, curved line that represents the dart’s transferred volume.

- Test: Create a muslin to assess the fit and make necessary adjustments.

This process can be applied to various dart manipulations, such as moving waist darts to side seams or converting darts into gathers or pleats. The key is to maintain the original volume and adjust the shape to the desired silhouette.

Q 11. Describe your experience with creating patterns for different garment styles (e.g., dresses, trousers, jackets).

My experience spans a wide range of garment styles. I’ve successfully created patterns for various items, including dresses, trousers, and jackets.

- Dresses: From simple A-line dresses to more complex designs featuring princess seams, godets, or fitted bodices, I’ve worked with diverse dress styles, adapting patterns to suit various fabrics and design elements.

- Trousers: I’m adept at constructing patterns for different trouser styles, including straight-leg, tapered, wide-leg, and even tailored trousers, employing techniques such as French darts and inseam adjustments.

- Jackets: I have experience in creating patterns for jackets of various styles including tailored jackets, blazers, and even simpler casual jackets, understanding the specific construction needs for collars, lapels, and sleeves.

For example, I once developed a pattern for a bespoke evening gown that involved intricate draping and pattern manipulation to achieve a specific silhouette. This required careful consideration of fabric drape, body measurements, and design details. In another project, I adapted a basic trouser pattern to incorporate pockets and a tailored waistband for a more sophisticated look.

Q 12. How do you use notches and markings to accurately assemble a garment?

Notches and markings are essential for accurate garment assembly. They act as guides, ensuring pieces are positioned correctly during construction. They are small cuts or markings along the pattern edges.

- Notches: Small triangular cuts that act as visual aids. They are used to align pattern pieces, ensuring consistent seam placement. For example, notches help match the sleeve cap to the armhole accurately.

- Markings: These are small dots, lines, or symbols that indicate specific design elements such as dart placement, buttonholes, or pockets. These help with accurate positioning of details.

By carefully aligning notches and markings, you can achieve a well-fitting garment with accurate placement of design elements. Ignoring these markings can result in misaligned seams and an unprofessional finish. A well-placed notch can mean the difference between a perfectly fitted sleeve and one that is too high or too low.

Q 13. Explain your experience with using a digital cutting table.

I have extensive experience operating digital cutting tables. This automated system significantly enhances efficiency and accuracy in pattern cutting. I’m proficient in using various software programs to create and prepare cutting files, including nesting multiple pattern pieces optimally for minimal fabric waste.

The benefits of using a digital cutting table are numerous:

- Increased Efficiency: It significantly reduces the time spent manually cutting patterns, especially for large production runs.

- Improved Accuracy: The automated cutting process eliminates human error, resulting in more precise and consistent cuts.

- Reduced Waste: The software’s nesting capabilities minimize fabric waste, contributing to cost savings.

For example, I used a digital cutting table to produce patterns for a large order of uniforms. This streamlined process allowed for a faster turnaround time and significantly reduced material waste, saving both time and money for the client.

Q 14. How do you create a pattern from a sketch or design?

Creating a pattern from a sketch or design is a multi-step process that blends artistic interpretation with technical skills. Here’s a general approach:

- Analyze the Design: Carefully examine the sketch, noting key design elements like silhouette, seams, darts, and details.

- Develop a Base Pattern: Start with a sloper (basic block) that closely resembles the desired garment type (e.g., a bodice sloper for a dress). This provides a solid foundation for alterations.

- Add Design Elements: Incorporate the design details from the sketch onto the base pattern. This may involve adding seams, adjusting darts, creating new shapes, or manipulating existing ones.

- Drafting: Use technical drawing skills or specialized software to create the complete pattern, paying attention to seam allowances, grainline, and other crucial details.

- Test & Refine: Always create a muslin (prototype) from the pattern to test the fit and make necessary alterations. This iterative process is crucial for achieving the intended silhouette and fit.

For example, when creating a pattern for a complex asymmetric dress, I would start with a basic bodice block and then add, layer by layer, the design’s unique features, such as asymmetrical seams and draping. Muslin testing would be iterative and vital for refining the design.

Q 15. Describe your understanding of ease and its application in pattern making.

Ease, in pattern making, is the extra fabric added to a garment’s pattern pieces to allow for comfort and movement. It’s crucial for creating a well-fitting and wearable garment, as it accounts for the body’s curves, drape of the fabric, and desired looseness or snugness. Different types of ease are applied depending on the garment and its style.

There are several types of ease:

- Fullness Ease: This adds extra fabric for shaping and draping, like in gathered skirts or sleeves. Think of the beautiful fullness in a flowing maxi dress – that’s fullness ease in action!

- Ease for Body Movement: This accounts for the body’s range of motion. A snug-fitting top needs less ease than a loose-fitting shirt to allow for comfortable arm movement.

- Design Ease: This is the extra fabric used to achieve a specific design feature, such as creating a relaxed silhouette or a certain drape.

Applying ease incorrectly can lead to ill-fitting garments. For example, too much ease in a tailored jacket results in a shapeless garment, while too little can make it feel restrictive. Experienced pattern makers meticulously calculate the appropriate amount of ease for each garment section based on the fabric type, garment style, and desired fit.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you adjust patterns for different body types or sizes?

Adjusting patterns for different body types and sizes involves understanding body measurements and making corresponding pattern adjustments. This goes beyond simply scaling up or down. We need to consider variations in proportions, such as differing shoulder slopes, bust points, waistlines, and hip measurements.

There are several methods:

- Grading: This involves systematically increasing or decreasing pattern pieces’ dimensions based on standard size charts. This is often done using specialized grading software or manually.

- Individual Adjustments: For custom garments, I carefully take client measurements and make specific adjustments to the base pattern. For example, if a client has a high bust point, I’ll adjust the bust dart placement accordingly. Conversely, if they have broad shoulders, the shoulder seams need to be widened.

- Block Pattern Modification: For extensive size and fit modifications, I may adjust my basic block pattern – my foundation pattern. This ensures that future garments based on this adjusted block fit the specific body type better.

Accurate measurements are paramount. I use both standard body measurement charts and individual measurements, comparing them carefully to determine the best approach. Then, I carefully assess the fit of the muslin toile (explained below) to fine-tune these adjustments.

Q 17. What is your experience with toile making and fitting?

Toile making is an essential step in pattern making, particularly for custom garments or complex designs. A toile is a test garment made from inexpensive fabric, used to check the fit and overall design before cutting into the final fabric. It allows for modifications and adjustments based on how the garment looks and feels on the wearer.

My toile-making process involves:

- Pattern Cutting: Cutting out the pattern pieces from inexpensive muslin or cotton.

- Construction: Sewing the toile together, using basic seams and avoiding any intricate details that might obscure fit issues.

- Fitting: Fitting the toile on the client or model. Pinning, easing, and making necessary adjustments to achieve a good fit.

- Pattern Revision: Taking apart the toile and transferring the adjustments onto the original pattern pieces. This step may require several iterations for complex designs.

The experience gained from working with toiles helps me to anticipate and correct fit issues early in the process, saving time and materials later. It’s an iterative process that significantly improves the accuracy of the final garment.

Q 18. How do you ensure consistency in pattern making across multiple garments?

Consistency in pattern making across multiple garments is achieved through meticulous record-keeping and the use of standardized procedures. I maintain detailed pattern files with all the necessary information, including measurements, ease allowances, and any modifications made. This includes both digital and physical records.

Key strategies:

- Consistent Measurement System: Always use the same measurement system (e.g., metric or imperial) and take measurements in a consistent manner.

- Digital Pattern Storage: I store digital pattern files in a well-organized manner, allowing for easy retrieval and comparison across projects. Using vector-based software allows me to make changes without losing quality.

- Pattern Grading Software: This streamlines the process of scaling patterns to different sizes and ensures consistent sizing across multiple garments.

- Standard Operating Procedures (SOPs): I follow established procedures for each step of the pattern-making process. This consistency in techniques minimizes variability.

By maintaining these standards, I can reproduce consistent results, ensuring a high level of quality and accuracy across multiple garments, even if they are made at different times or by different people.

Q 19. Explain your approach to troubleshooting pattern fit issues.

Troubleshooting pattern fit issues involves a systematic approach that goes beyond just adding or subtracting fabric. I carefully analyze the areas where the garment is fitting poorly.

My strategy typically follows these steps:

- Identify the Problem Area: Pinpoint the specific areas where the garment is too tight, too loose, or pulling.

- Analyze the Cause: Determine the likely cause of the fit problem. Is it incorrect measurements, insufficient ease, improper pattern construction, or an error in cutting?

- Review the Pattern: Examine the original pattern pieces for any errors in drafting or grading.

- Make Adjustments: Make targeted adjustments to the pattern, based on the identified cause of the problem. These adjustments might involve altering seam lines, adding or removing darts, or changing the shape of the pattern pieces.

- Test and Iterate: Make a new toile with the adjusted pattern to test the changes. Repeat this process until a satisfactory fit is achieved. I often take detailed notes and photos of adjustments at each step.

Troubleshooting requires a keen eye for detail and a deep understanding of garment construction. It’s often an iterative process involving several attempts to perfect the fit.

Q 20. How do you manage your time effectively during a pattern-making project?

Effective time management in pattern making is crucial for meeting deadlines and maintaining productivity. I employ various strategies to optimize my workflow.

My approach involves:

- Detailed Project Planning: I carefully plan each project, breaking it down into smaller, manageable tasks. This includes estimating the time required for each step.

- Prioritization: I prioritize tasks based on their urgency and importance. This ensures that critical tasks are completed on time.

- Time Blocking: I allocate specific time blocks for different tasks, helping me to stay focused and avoid distractions.

- Efficient Techniques: I use efficient techniques, such as using software for pattern grading and digital pattern manipulation, to save time.

- Regular Breaks: Taking regular breaks helps maintain focus and prevents burnout. This approach, counterintuitively, increases efficiency.

By using these methods, I can efficiently manage time and deliver high-quality results within the allocated timeframe. This also minimizes stress and helps me stay on top of multiple projects simultaneously.

Q 21. How familiar are you with different types of pattern drafting techniques?

I’m familiar with several pattern drafting techniques, including both flat pattern drafting and draping.

Flat Pattern Drafting involves creating a 2D pattern directly on paper using measurements and calculations. This method is very precise and requires a strong understanding of garment construction and body proportions. Common methods include:

- Basic Block Method: Creating a foundational pattern that can be altered for different garment styles.

- Sloper Method: Creating a base pattern from body measurements to which design details are added.

Draping involves creating a 3D pattern on a dress form using fabric directly. This allows for a more intuitive approach to creating complex shapes and designs. It’s especially beneficial for creating garments with close-fitting shapes and complex curves. Both techniques have their own advantages and disadvantages, and the best technique is chosen based on the specific project. I am adept at switching between the methods based on project needs, often incorporating elements of both.

Q 22. Describe your experience with working with different types of patterns.

My experience encompasses a wide range of pattern types, from basic slopers – the foundation patterns for various garments – to complex, multi-piece designs for tailored clothing, knitwear, and even technical outerwear. I’m proficient in drafting patterns for both woven and knit fabrics, understanding the crucial differences in drape and structure that dictate design choices. For example, a tailored jacket pattern requires precise seam allowances and structured interfacing, unlike a flowing knit dress pattern which allows for more ease and stretch. I’ve worked extensively with patterns for menswear, womenswear, and children’s wear, adapting techniques for different body types and sizing systems. I’m comfortable using both traditional manual drafting methods and digital pattern-making software, and I’m skilled in grading patterns to accommodate different sizes.

- Slopers: These foundational patterns are the building blocks of my work, enabling efficient design iteration and customization.

- Tailored Garments: I have extensive experience in creating patterns for jackets, coats, trousers, and skirts, requiring precision and attention to detail.

- Knitwear: I understand the unique properties of knit fabrics and adapt patterns to account for stretch and recovery.

- Digital Pattern Making: Proficient in using industry-standard software such as [mention specific software, e.g., Adobe Illustrator, Pattern Design Software] to create, modify, and grade patterns efficiently.

Q 23. What is your experience with pattern making for different sewing techniques?

My experience with pattern making extends to various sewing techniques. This includes flat-felled seams for durable garments, French seams for a clean finish on delicate fabrics, bound seams for a professional look, and zipper application for various closure types. For example, a tailored jacket might require flat-felled seams for strength, while a lingerie garment would necessitate French seams for a smooth, invisible finish. I’m also experienced with techniques like darts, pleats, gathers, and easing to shape and manipulate fabric. Understanding how a specific sewing technique will impact the final garment’s appearance and durability is integral to my pattern design process. I consider the seam allowances and construction details during the initial pattern drafting stage to ensure a smooth and efficient sewing process. I’ve also worked with various finishing techniques, including buttonholes, button attachments and facing application.

- Flat-felled Seams: Used for durability in workwear or outerwear.

- French Seams: Used for a clean finish in fine garments.

- Bound Seams: Professional and durable seam finish, ideal for outerwear and upholstery.

- Zipper Application: Expertise in invisible, center front, and other zipper techniques.

Q 24. How do you deal with tight deadlines and pressure in a pattern making environment?

Meeting tight deadlines is a crucial aspect of my role. I manage pressure by prioritizing tasks effectively, utilizing time management techniques, and maintaining clear communication with my team and clients. For example, if a deadline is approaching rapidly, I prioritize the most crucial elements of the pattern first, ensuring the core design is complete before moving to finer details. I also break down large projects into smaller, manageable steps. This allows me to track progress, identify potential bottlenecks early on and adjust my workflow accordingly. Proactive communication is crucial; I keep stakeholders informed of my progress and any potential roadblocks. I’m adept at working under pressure and delivering high-quality results even within constrained timeframes.

Q 25. Explain your understanding of different pattern measurements and techniques.

Understanding pattern measurements and techniques is fundamental to my work. This includes standard body measurements like bust, waist, hip, and shoulder width, as well as more nuanced measurements necessary for specific design elements. I utilize different techniques depending on the garment style and the client’s requirements. For example, I might use a sloper (basic bodice block) as a starting point and then adjust it according to the design details, such as adding darts for shaping or incorporating ease (additional fabric for comfort). I’m also familiar with various grading methods to create a range of sizes and maintain consistent proportions across different sizes. Understanding ease, seam allowances, and grainlines is essential for accurate pattern making. Accurate measurements are taken and recorded, and then these measurements are translated into the pattern pieces according to the chosen design and construction method.

- Body Measurements: Accurate measurement taking is essential for a well-fitting garment.

- Ease: Understanding the difference between ease and fitting is crucial for garment comfort.

- Seam Allowances: Accurate seam allowances ensure consistent garment assembly.

- Grading: Scaling patterns to create multiple sizes while maintaining proportion.

Q 26. How do you work effectively in a team environment in pattern making?

Effective teamwork is essential in pattern making. I believe in open communication, collaboration, and a willingness to share knowledge and expertise. I actively participate in team discussions, contributing my ideas and offering support to colleagues. I’m comfortable working with designers, sewers, and other pattern makers to ensure a smooth workflow. For instance, I’ve worked in teams where I was responsible for the technical aspects of pattern creation, while others focused on design or sampling. By clearly defining roles and responsibilities, we ensured a cohesive and efficient process leading to a high-quality end product. I’m adept at providing constructive feedback and incorporating suggestions from others. I value a collaborative approach where different perspectives contribute to the final product.

Q 27. How do you stay current with new trends and techniques in pattern making?

Staying current in the fast-paced world of pattern making requires continuous learning. I regularly attend industry conferences and workshops, read relevant trade publications, and follow influential designers and pattern makers online. I also actively experiment with new techniques and technologies, exploring innovative materials and software. For example, I recently attended a workshop on digital pattern cutting and have started incorporating these techniques into my workflow. Moreover, studying contemporary fashion trends helps me anticipate and address the evolving demands of the industry. By staying informed and adaptable, I can consistently provide innovative and high-quality pattern solutions.

Q 28. Describe your experience with industrial sewing and pattern making techniques.

My experience in industrial sewing and pattern making includes working with high-volume production methods and understanding the unique requirements of industrial sewing machines. This involves designing patterns that are efficient to produce on a large scale, considering factors such as fabric consumption, seam allowances, and ease of assembly. I understand the limitations and capabilities of industrial sewing machines, optimizing patterns for maximum efficiency. I’ve worked with various industrial sewing techniques, including bar tacking, topstitching, and specialized seam finishes commonly used in industrial settings. I’ve also worked with different types of industrial fabric, including heavier weight fabrics often used for outerwear and workwear. This experience allows me to create patterns that are not only aesthetically pleasing but also practical and efficient for mass production.

Key Topics to Learn for Your 2D Pattern Making Interview

Acing your 2D Pattern Making interview requires a solid understanding of both theory and practical application. Focus your preparation on these key areas:

- Fundamentals of Measurement and Drafting: Mastering accurate measurements, understanding grading principles, and utilizing various drafting techniques are foundational. Consider practicing with different body types and sizes.

- Software Proficiency: Demonstrate your expertise in industry-standard 2D pattern making software. Be prepared to discuss your experience with specific programs and features, highlighting your efficiency and problem-solving skills.

- Pattern Alterations and Adjustments: Interviewers often assess your ability to adapt patterns to fit various silhouettes and styles. Practice making adjustments for different body shapes and design requirements. Showcase your understanding of fit and drape.

- Understanding Fabric Properties and their Impact on Pattern Design: Discuss how fabric characteristics (drape, stretch, weight) influence pattern design and construction. Illustrate your knowledge by explaining how you would adjust a pattern for different fabrics.

- Production Techniques and Workflow: Demonstrate your understanding of the entire pattern making process, from initial design concept to the finished pattern. Discuss your experience with different production methods and workflows, and your ability to optimize efficiency.

- Problem-Solving and Critical Thinking: Be ready to discuss instances where you encountered challenges in pattern making and how you overcame them. Highlight your analytical skills and ability to find creative solutions.

Next Steps: Unlock Your Career Potential

Mastering 2D pattern making opens doors to exciting opportunities in the fashion and textile industries. To maximize your chances of landing your dream role, invest time in creating a strong, ATS-friendly resume that showcases your skills and experience effectively. This is where ResumeGemini can help!

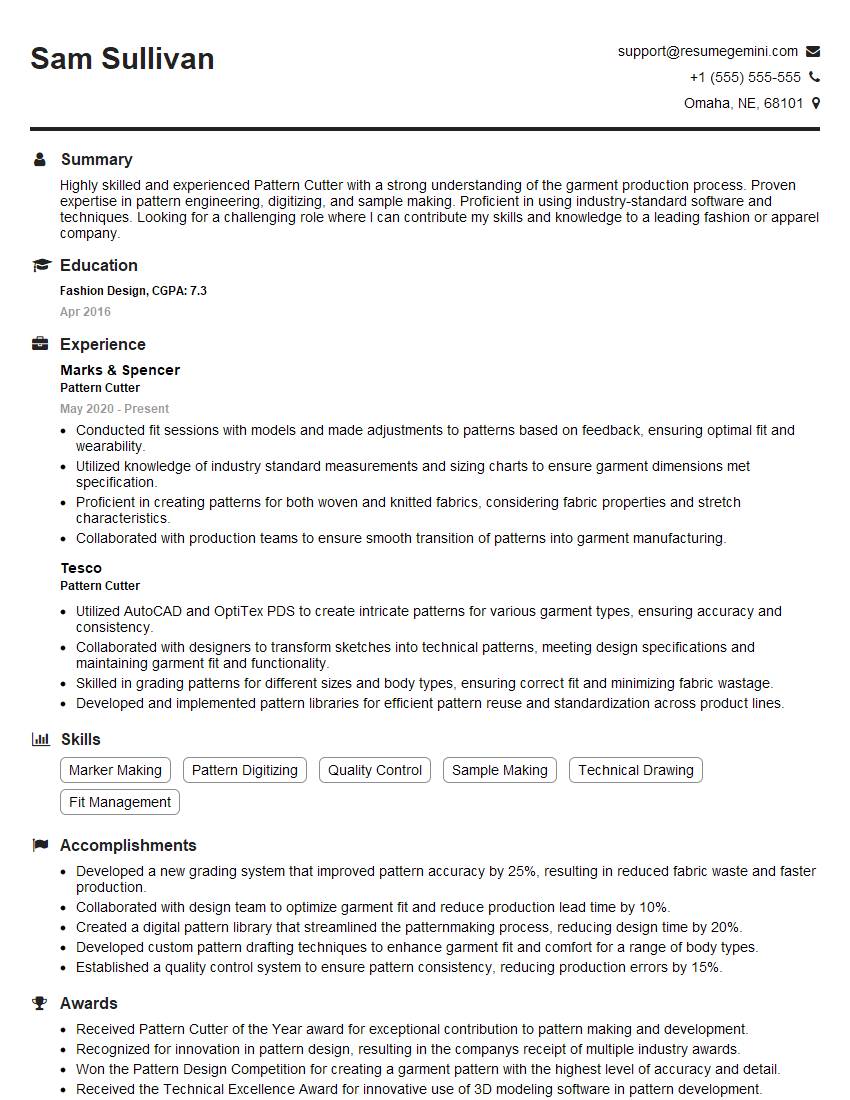

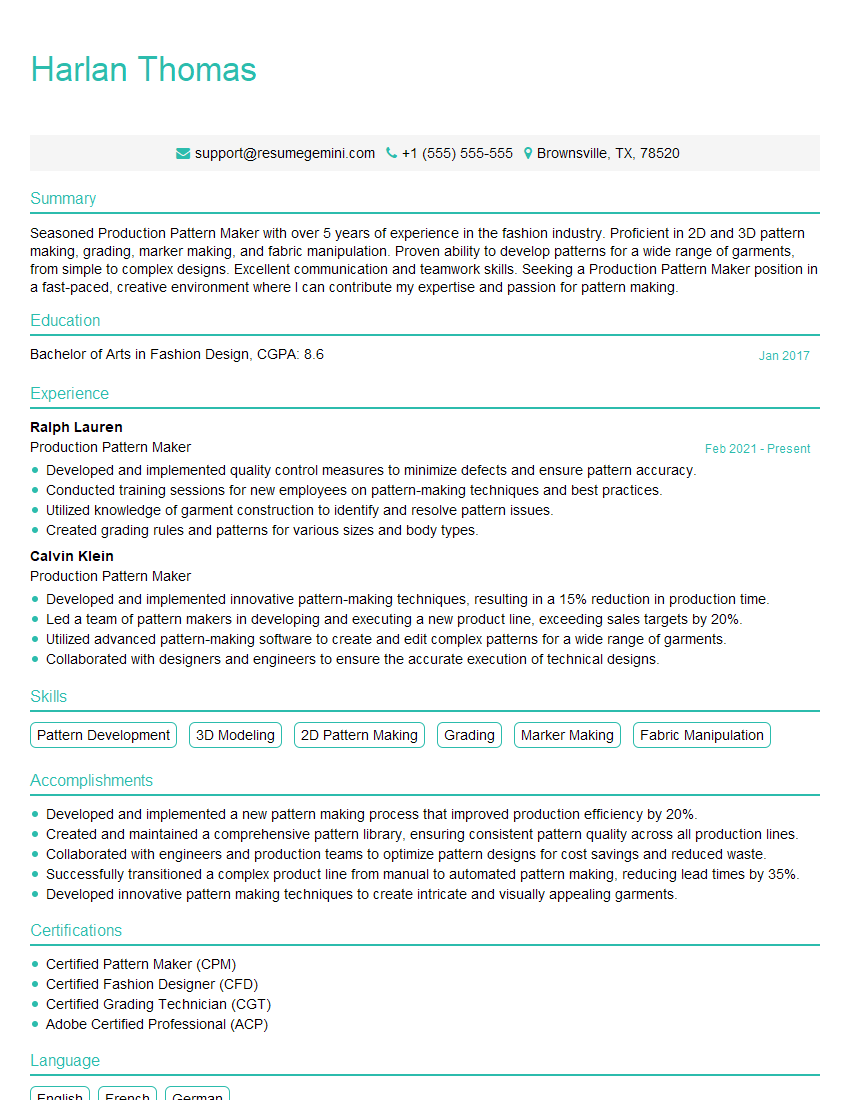

ResumeGemini provides a powerful platform to build a professional resume that gets noticed by recruiters. They offer valuable tools and resources to ensure your resume is optimized for Applicant Tracking Systems (ATS), increasing your visibility and securing more interview opportunities. Examples of resumes tailored specifically to 2D Pattern Making professionals are available to inspire you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?