Cracking a skill-specific interview, like one for Fungal Fermentation and Biotechnology, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Fungal Fermentation and Biotechnology Interview

Q 1. Explain the different types of fungal fermentations used in industrial biotechnology.

Fungal fermentations in industrial biotechnology are broadly classified based on the type of metabolite produced and the process conditions. We can categorize them into:

- Solid-state fermentation (SSF): This involves growing fungi on a solid substrate, without free-flowing water. Think of it like mushrooms growing on a log – the fungus derives nutrients directly from the solid material. SSF is often used for producing enzymes, like amylases for starch breakdown, or specialized metabolites like certain antibiotics. Its advantages include low water usage and simpler equipment. However, controlling parameters like temperature and moisture can be challenging.

- Submerged fermentation (SmF): This is the most common type, where the fungus grows submerged in a liquid medium. This allows for better control over environmental parameters (pH, temperature, aeration) and efficient mixing. It’s widely used for large-scale production of various compounds, including citric acid, penicillin, and many other valuable pharmaceuticals and industrial enzymes. The major drawback is the need for more sophisticated and expensive bioreactors.

- Surface fermentation: This method is somewhat less common now, involving fungal growth on the surface of a liquid medium. Think of a shallow tray. While it has historical significance, it often leads to lower yields and greater contamination risks compared to SmF.

- Two-stage fermentation: This advanced technique involves two distinct phases – a growth phase followed by a production phase. This allows for optimized conditions to maximize biomass generation in the first stage and maximize the production of the target metabolite in the second stage. This approach is quite popular for the production of complex metabolites.

The choice of fermentation type depends heavily on the specific fungus, desired metabolite, and economic considerations.

Q 2. Describe the key factors influencing fungal growth and metabolite production in fermentation.

Fungal growth and metabolite production are significantly influenced by a complex interplay of factors. Think of it as a delicate ecosystem needing the right conditions to thrive. Key factors include:

- Nutrient availability: The type and concentration of carbon and nitrogen sources significantly impact both growth and metabolite formation. For example, the carbon source can affect the type of metabolites produced; certain sugars might favor one metabolite over another.

- pH: Most fungi have an optimal pH range for growth. A deviation from this optimal range can significantly affect both growth rate and the production of secondary metabolites. This is because pH affects enzyme activity.

- Temperature: Temperature is crucial, with an optimal range for both growth and metabolite production. Too high or too low a temperature can lead to reduced growth and altered metabolite profiles, potentially causing unwanted byproducts.

- Oxygen availability (aeration): Aeration is critical for aerobic fungi. Inadequate oxygen supply leads to decreased growth and shifts in metabolism, potentially leading to less of the desired product. Efficient oxygen transfer is important in submerged fermentation.

- Agitation/mixing: In submerged fermentation, proper mixing is vital for uniform nutrient distribution, adequate oxygen transfer, and cell suspension. The intensity of mixing needs careful control to avoid cell damage.

- Media composition: The specific salts, vitamins, and trace elements present in the fermentation medium significantly affect growth and metabolite production. We need to carefully formulate the medium to achieve optimal results.

- Stress conditions: Certain types of mild stress (e.g., nutrient limitation, osmotic stress) can sometimes enhance metabolite production – a phenomenon exploited in industrial settings.

Q 3. How do you optimize fungal fermentation processes for maximum yield and quality?

Optimizing fungal fermentation involves a systematic approach combining experimental design and process control. Think of it like fine-tuning a complex machine for peak performance. Here are some key strategies:

- Media optimization: Employing statistical experimental designs (e.g., Response Surface Methodology, DoE) to determine the optimal concentrations of carbon and nitrogen sources, pH, and other components of the fermentation medium. This allows for identification of the optimal conditions for both biomass growth and metabolite production.

- Bioreactor control: Precise control over parameters like temperature, pH, dissolved oxygen, and agitation within the bioreactor is essential. Real-time monitoring and automated control systems are often implemented.

- Strain improvement: Using techniques like mutagenesis and genetic engineering to enhance fungal strains for improved growth rates, higher metabolite yields, and reduced byproduct formation. This is where biotechnology makes a significant difference.

- Process optimization: Investigating the impact of different fermentation parameters (e.g., inoculum size, feed strategies, induction of metabolite production) on yield and quality. This involves a careful series of experiments.

- Downstream processing optimization: Improving the efficiency of product extraction and purification to maximize the yield of the desired metabolite and minimize costs. This part is often overlooked but can be as important as the fermentation process itself.

Optimization is often an iterative process involving multiple rounds of experiments and adjustments. Careful data analysis and modeling are crucial in this step.

Q 4. What are the common challenges encountered during fungal fermentation, and how are they addressed?

Fungal fermentations often encounter several challenges. Addressing these requires careful planning and troubleshooting. Common problems include:

- Contamination: Fungal cultures are susceptible to bacterial or other fungal contamination. Maintaining sterile conditions during inoculation, fermentation, and harvesting is crucial. This often involves using strict aseptic techniques and careful monitoring of the culture.

- Foam formation: Excessive foam can interfere with oxygen transfer and cause process disruptions. Anti-foaming agents are often added to control foam. The amount of anti-foaming agent often needs to be optimized; too much can inhibit fungal growth.

- Shear stress: High shear forces during agitation can damage fungal cells, reducing yields. Careful control of agitation speed and impeller design is essential. This involves optimizing the agitation speed so it is sufficient for oxygen transfer but not damaging to the cells.

- Oxygen limitation: Inadequate oxygen supply restricts growth and shifts metabolism, resulting in lower yields of the desired metabolite. Improving aeration strategies (e.g., using different types of impellers, increasing airflow rate) can alleviate this.

- Catabolite repression: Presence of preferred carbon sources (e.g., glucose) can repress the production of other metabolites. Careful control of nutrient feeding strategies is often necessary to overcome this. Often a fed-batch strategy can be beneficial.

Addressing these challenges often involves a combination of improved process control, strain improvement (to increase resistance to shear or contamination), and the use of novel bioreactor designs or operational strategies.

Q 5. Explain the principles of downstream processing for fungal metabolites.

Downstream processing for fungal metabolites involves the separation and purification of the target compound from the fermentation broth. It’s a crucial step that determines the final product’s quality and cost-effectiveness. The process generally involves several steps:

- Cell separation: Removing fungal biomass from the broth using techniques like centrifugation or filtration. The choice depends on the properties of the fungus and the metabolite.

- Primary extraction: Isolating the target metabolite from the clarified broth using methods like solvent extraction, adsorption, or precipitation. The choice depends on the chemical properties of the metabolite.

- Purification: Refining the extracted product to achieve the desired purity using techniques like chromatography (e.g., ion exchange, size exclusion, high-performance liquid chromatography, HPLC), crystallization, or membrane filtration. This can often be a multi-step process, and the specific methods chosen will be highly specific to the desired product.

- Formulation and drying: Preparing the purified product for use or storage, often involving drying (e.g., freeze-drying, spray drying) and formulation into a suitable form (e.g., powder, liquid). The final formulation needs to be appropriate for the intended application.

The specific downstream processing steps are tailored to the target metabolite’s properties and the desired level of purity. It’s a highly specialized area requiring expertise in separation science and engineering.

Q 6. Describe different methods for fungal strain improvement and selection.

Improving fungal strains is critical for enhancing fermentation performance. Techniques include:

- Mutagenesis: Inducing random mutations using physical (e.g., UV irradiation, gamma rays) or chemical mutagens. This creates a library of mutants, which are screened for desired traits (e.g., increased yield, improved growth, resistance to inhibitors). This is a classical method, but random mutagenesis is less efficient than targeted methods.

- Protoplast fusion: Fusing protoplasts (cells without cell walls) from two different fungal strains to combine desirable traits. This allows for the creation of novel hybrids with enhanced properties.

- Genetic engineering: Using recombinant DNA technology to introduce specific genes into the fungal genome. This allows for targeted modifications to enhance specific metabolic pathways, increasing yields or modifying the end-product. This is the most powerful method, but it requires sophisticated techniques and is often more expensive.

- Genome editing: Using CRISPR-Cas9 or other gene editing tools to precisely modify the fungal genome, allowing for targeted modifications with greater precision than traditional genetic engineering. This technology allows for more precise control over the changes made to the genome.

- Directed evolution: A powerful iterative process involving multiple rounds of mutagenesis, selection, and screening to gradually improve the strain’s performance over many generations. This mimics natural selection but in an accelerated, controlled environment.

Strain selection involves screening and testing the improved strains under various fermentation conditions to identify the best performer. This may involve assessing various parameters such as growth rate, product yield, and resistance to stress conditions.

Q 7. What are the various types of bioreactors used in fungal fermentation, and their advantages/disadvantages?

Various bioreactors are used in fungal fermentation, each with advantages and disadvantages:

- Stirred tank reactors (STRs): The most common type, using impellers for mixing and aeration. They’re versatile and relatively easy to operate but can cause shear stress on fungal cells. This can be problematic with filamentous fungi, which are often more sensitive to shear stress than single-celled organisms.

- Airlift bioreactors: Employing air for mixing and aeration; they minimize shear stress, making them suitable for shear-sensitive organisms. However, they may offer less precise control over mixing compared to STRs.

- Fluidized bed bioreactors: Used for immobilizing fungal cells, allowing for high cell densities and increased productivity. However, they can be more complex to operate and maintain.

- Packed bed bioreactors: Similar to fluidized bed bioreactors, using a packed bed of support material for cell immobilization. This can lead to improved productivity but can also suffer from problems such as limited oxygen transfer within the packed bed.

- Photobioreactors: Used for phototrophic fungi, allowing for light penetration. These bioreactors require careful design to ensure uniform light distribution throughout the culture.

The choice of bioreactor depends on factors like the fungal species, desired scale of production, shear sensitivity of the organism, cost, and process requirements. For example, a shear-sensitive filamentous fungus might be better suited to an airlift bioreactor than a stirred tank reactor.

Q 8. How do you ensure sterility and contamination control during fungal fermentation?

Maintaining sterility in fungal fermentation is paramount to prevent contamination and ensure the desired product’s purity. Think of it like baking a cake – you wouldn’t want unwanted ingredients ruining the recipe! We employ a multi-pronged approach, starting with meticulous aseptic techniques throughout the entire process.

- Sterilization of equipment and media: Autoclaves are used to sterilize fermenters, media components, and other equipment by using high-pressure steam. Filters, like 0.22 µm membrane filters, are crucial for sterilizing air and liquids that can’t withstand autoclaving.

- Environmental control: Fermentation takes place in clean rooms or controlled environments with HEPA filters to minimize airborne contaminants. This is particularly important for working with fungi that are sensitive to environmental changes.

- Aseptic handling procedures: Strict adherence to aseptic techniques, including proper sterilization of instruments, use of sterile gloves, and working under a laminar flow hood, is crucial during media preparation, inoculation, and sampling. Regular training for personnel is also essential.

- Monitoring and detection: Regular monitoring of the fermentation broth for microbial contamination is done via visual inspection and microbiological tests, like plating on different growth media to detect unwanted organisms. Early detection allows for timely intervention.

For example, in industrial penicillin production, stringent sterility is crucial. Any contamination would not only reduce the yield but also compromise the quality and safety of the final product.

Q 9. Explain the role of media optimization in fungal fermentation.

Media optimization is the cornerstone of successful fungal fermentation. The growth medium provides all the nutrients the fungus needs – think of it as a perfectly balanced meal. A well-optimized medium enhances fungal growth, increases product yield, and improves product quality.

Optimization involves selecting the right carbon source (e.g., glucose, lactose), nitrogen source (e.g., ammonium sulfate, yeast extract), and other essential nutrients (e.g., minerals, vitamins). The pH, temperature, and dissolved oxygen levels are also critical parameters. We typically use a combination of experimental approaches to optimize the media.

- One-factor-at-a-time (OFAT): This method systematically varies each parameter while keeping others constant. It’s simple but time-consuming.

- Response Surface Methodology (RSM): This statistical technique allows for the simultaneous optimization of multiple parameters, leading to more efficient and effective results. It’s more complex but more powerful.

- Design of Experiments (DOE): DOE methods allow us to conduct fewer experiments while obtaining maximum information. These statistical methods are widely used.

For instance, in the production of citric acid by Aspergillus niger, the carbon source (e.g., sucrose or molasses) plays a crucial role in the yield. Careful optimization of the carbon source and other nutrients can significantly improve citric acid production.

Q 10. Discuss the importance of quality control and assurance in fungal fermentation processes.

Quality control and assurance (QA/QC) in fungal fermentation ensures the consistent production of high-quality products that meet predefined specifications. It’s like quality checking every step in making a cake to guarantee it tastes perfect every time! We establish stringent QA/QC protocols at each stage.

- Raw material testing: Incoming raw materials, including carbon and nitrogen sources, are tested for purity, contamination, and appropriate composition.

- In-process controls: Regular monitoring of fermentation parameters (pH, temperature, dissolved oxygen, biomass, and product concentration) during the process ensures the process remains within the desired range.

- Product testing: The final product is rigorously tested for purity, potency, identity, and safety, employing various analytical techniques (HPLC, GC-MS, etc.).

- Documentation and traceability: Detailed records of all aspects of the fermentation process, including raw materials, parameters, and testing results, are meticulously maintained to ensure traceability and compliance with regulations. This is critical for regulatory approvals and ensures the reliability of the final product.

Think of antibiotic production; rigorous QA/QC is essential to ensure the product meets its potency and purity standards and is safe for human consumption.

Q 11. How do you analyze and interpret data from fungal fermentation experiments?

Analyzing and interpreting data from fungal fermentation experiments is crucial for optimizing the process. We use a combination of statistical analysis and visualization techniques.

Data analysis typically involves:

- Descriptive statistics: Calculating means, standard deviations, and other descriptive statistics to summarize the data.

- Inferential statistics: Employing t-tests, ANOVA, or regression analysis to test hypotheses and draw conclusions about the effects of different parameters on the process.

- Visualization: Creating graphs and charts (e.g., growth curves, product concentration profiles) to visualize the data and identify trends and patterns. Software such as Excel, specialized statistical packages (like R or SAS), and fermentation monitoring software are used for this purpose.

For example, by analyzing growth curves, we can determine the optimal growth phase for product formation. Regression analysis can help establish relationships between media composition and product yield.

Q 12. Describe your experience with scale-up and scale-down of fungal fermentation processes.

Scaling up and scaling down fungal fermentation processes involves adapting the process from the laboratory (small scale) to industrial (large scale) production or vice versa. This requires careful consideration of several factors.

Scale-up involves increasing the production volume, which necessitates changes in fermenter design, agitation, aeration, and temperature control to maintain optimal conditions. We often use scale-up strategies like maintaining constant power input or constant impeller tip speed.

Scale-down is essential for process development and optimization. It allows us to conduct experiments at a smaller scale, saving costs and resources. However, maintaining the same physiological conditions as in large-scale fermentation can be challenging. We need to consider the effects of scale on oxygen transfer rate, heat transfer, and mixing.

For example, scaling up penicillin production from a 5-liter fermenter to a 50,000-liter fermenter requires significant changes in equipment and process parameters to ensure consistent yields and quality. Conversely, scale-down is used to mimic industrial conditions in the lab to optimize media and process parameters before large-scale production.

Q 13. Explain the principles of metabolic engineering in fungal biotechnology.

Metabolic engineering in fungal biotechnology involves modifying the metabolic pathways of fungi to improve the production of desired products or eliminate the formation of unwanted by-products. Think of it as fine-tuning a biological machine to enhance its efficiency. This is often achieved through genetic modification techniques.

- Gene overexpression: Increasing the expression of genes involved in the synthesis of the target product can significantly enhance yields.

- Gene knockout: Deleting genes that are involved in the formation of unwanted by-products can improve the purity and yield of the desired product.

- Pathway engineering: This more complex approach involves modifying multiple genes to engineer a completely new pathway or reroute existing metabolic pathways to produce a desired product. For instance, this could be redirecting carbon flow towards a specific molecule.

For example, metabolic engineering techniques have been used to improve the production of various pharmaceuticals, such as artemisinin (an antimalarial drug) and statins (cholesterol-lowering drugs), by optimizing the production pathways in fungal hosts such as Saccharomyces cerevisiae (yeast) and Aspergillus species.

Q 14. What are some examples of commercially important products produced through fungal fermentation?

Fungal fermentation plays a vital role in the production of numerous commercially important products. Here are a few examples:

- Antibiotics: Penicillin, cephalosporin, and many other antibiotics are produced through fungal fermentation. These are life-saving drugs used to combat bacterial infections.

- Organic acids: Citric acid (used in food and beverages), lactic acid (used in food and pharmaceuticals), and gluconic acid (used as a food additive) are produced industrially through fungal fermentation.

- Enzymes: Various enzymes like amylases, proteases, and lipases, used in various industries (food, textile, detergent), are produced by fungal fermentation.

- Vitamins: Riboflavin (vitamin B2) and other vitamins are produced by microbial fermentation, including various fungi.

- Pharmaceuticals: Beyond antibiotics, fungi are used to produce many other pharmaceuticals, including statins and immunosuppressants.

- Food and beverages: Fungi are involved in the production of certain cheeses, fermented foods, and alcoholic beverages.

This illustrates the wide-ranging impact of fungal fermentation on various sectors of our economy and our daily lives.

Q 15. Describe different methods for characterizing fungal metabolites.

Characterizing fungal metabolites, the diverse array of molecules produced by fungi, is crucial for understanding their biological roles and potential applications. This involves a multi-faceted approach employing various techniques depending on the desired information.

Chromatographic techniques: High-Performance Liquid Chromatography (HPLC) and Gas Chromatography-Mass Spectrometry (GC-MS) are workhorses, separating and identifying metabolites based on their physical and chemical properties. HPLC is particularly useful for thermally labile compounds, while GC-MS excels in volatile metabolite analysis. For instance, we might use HPLC to quantify the production of specific antibiotics during fermentation, or GC-MS to profile the volatile organic compounds produced by a mushroom strain, providing insights into its aroma profile.

Spectroscopic techniques: Nuclear Magnetic Resonance (NMR) spectroscopy provides structural information about metabolites without the need for prior separation. It’s invaluable for identifying novel compounds. Imagine discovering a new anti-cancer agent; NMR would be crucial in determining its structure and subsequently understanding its mechanism of action.

Mass spectrometry: Beyond GC-MS, other MS-based techniques like Liquid Chromatography-Mass Spectrometry (LC-MS) and Matrix-Assisted Laser Desorption/Ionization-Time of Flight Mass Spectrometry (MALDI-TOF MS) allow for high-throughput metabolite profiling, useful for comparing metabolite production under different fermentation conditions or between different fungal strains.

Bioassays: These assays assess the biological activity of metabolites. For example, an antimicrobial assay might test the effectiveness of a fungal extract against various bacterial strains, identifying potential new antibiotics. In a past project, we employed bioassays to screen for compounds with anti-inflammatory properties, leading to the identification of a promising lead compound from a marine fungus.

The choice of technique often depends on the specific metabolites of interest, the scale of analysis, and the available resources. Often a combination of these approaches is employed for comprehensive characterization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the regulatory requirements for manufacturing fungal-derived products?

Manufacturing fungal-derived products involves navigating a complex regulatory landscape that varies depending on the intended application and geographical location. Generally, regulatory bodies like the FDA (in the US) and the EMA (in Europe) scrutinize the manufacturing process and the final product to ensure safety and efficacy.

Good Manufacturing Practices (GMP): Adherence to GMP guidelines is paramount, ensuring consistent quality, purity, and safety throughout the production process. This encompasses aspects like facility design, equipment maintenance, personnel training, and documentation. We’ve always strictly followed GMP standards throughout our operations, which is integral to receiving regulatory approval for our products.

Product safety testing: Rigorous testing is required to assess toxicity, stability, and potential contaminants. This may involve various assays, including genotoxicity, cytotoxicity, and sterility tests. Every batch of our fungal-based enzyme products undergoes extensive testing to ensure its safety for its intended use.

Registration and approvals: Depending on the product (e.g., food ingredient, pharmaceutical, industrial enzyme), specific registration and approval processes need to be followed. This often involves submitting detailed documentation, including manufacturing processes, quality control data, and safety assessment reports. The approval process can be lengthy and rigorous, requiring careful preparation and coordination with regulatory agencies.

Intellectual property protection: Patents and other forms of intellectual property protection can secure the commercial viability of a fungal-derived product. Protecting our innovations has always been a strategic priority.

Staying abreast of evolving regulatory requirements and maintaining meticulous documentation are crucial for successful commercialization of fungal-derived products.

Q 17. How do you troubleshoot problems related to fungal growth or metabolite production?

Troubleshooting fungal growth or metabolite production problems requires a systematic approach, combining observation, experimentation, and a solid understanding of fungal biology.

Identifying the problem: First, meticulously characterize the issue. Is there slow growth? Reduced metabolite yield? Contamination? Changes in morphology? Careful observation and documentation are essential. We always start by carefully documenting the observations in a lab notebook.

Investigating potential causes: Once the problem is defined, systematically investigate potential causes. Is it a media issue (incorrect composition, pH, sterilization)? Is the inoculum quality sufficient? Are the environmental parameters (temperature, aeration, agitation) optimal? Are there any signs of contamination? A methodical approach, eliminating potential causes one by one, is crucial.

Testing hypotheses: Formulate hypotheses based on the potential causes. Design controlled experiments to test these hypotheses. For example, if we suspect a media problem, we’d prepare different media formulations to test their effect on fungal growth. Data analysis and statistical testing are important here.

Implementing corrective actions: Based on experimental results, implement corrective actions to address the identified problem. This could involve adjusting media composition, improving sterilization techniques, optimizing environmental parameters, or implementing a new strain selection strategy. We always maintain detailed records of corrective actions and their effectiveness.

Preventing future issues: Once a problem is resolved, analyze the root cause to prevent recurrence. This might involve improving quality control measures, modifying the fermentation process, or enhancing the strain used.

Troubleshooting is an iterative process. It often requires persistence, attention to detail, and a willingness to adapt strategies based on the results of experiments.

Q 18. Describe your experience with different types of fungal cultures (e.g., submerged, solid-state).

My experience encompasses both submerged and solid-state fermentation, each with its distinct advantages and challenges.

Submerged fermentation (SmF): SmF involves cultivating fungi in a liquid medium. This allows for precise control over environmental parameters (temperature, pH, aeration) and enables efficient mass transfer, leading to higher yields in some cases. SmF is ideally suited for large-scale production and is widely used for the industrial production of antibiotics, enzymes, and other metabolites. In my previous role, we optimized SmF for the production of a commercially relevant lipase enzyme, significantly enhancing its yield through careful control of aeration and nutrient supply.

Solid-state fermentation (SSF): SSF involves cultivating fungi on a solid substrate, often agricultural residues like rice bran or wheat straw. This approach is more sustainable, utilizing waste materials and reducing reliance on costly media components. SSF is advantageous for the production of certain enzymes and metabolites where the solid substrate plays a key role in the production process. I have extensive experience with SSF in the production of fungal biomass for animal feed, optimizing substrate composition and moisture content to maximize growth and nutritional value. We explored the use of various agricultural by-products in this project, selecting the most cost-effective and efficient substrate.

The choice between SmF and SSF depends on factors such as the target metabolite, the scale of production, and the cost-effectiveness of the process. I’m comfortable working with both techniques and am able to select the optimal method based on project requirements.

Q 19. Explain the role of genetics and genomics in fungal biotechnology.

Genetics and genomics are revolutionizing fungal biotechnology, providing powerful tools for strain improvement and the discovery of novel products.

Strain improvement: Genetic engineering techniques like gene knockout, overexpression, and gene editing (CRISPR-Cas9) allow us to modify fungal genomes to enhance metabolite production, improve stress tolerance, or alter other desirable traits. We used CRISPR to enhance the production of a specific secondary metabolite in a Penicillium strain, resulting in a significant increase in yield.

Genomic analysis: Genomic sequencing allows us to study the entire fungal genome, identifying genes involved in metabolite biosynthesis, regulation, and stress response. This information is valuable for designing targeted genetic modifications to improve fermentation performance. For instance, we used comparative genomics to identify genes responsible for improved thermotolerance in a particular fungal strain.

Metagenomics: Metagenomics studies the genetic material of microbial communities, enabling the discovery of novel fungal strains with desirable properties from diverse environmental sources. This provides a vast untapped reservoir of genetic diversity for biotechnological applications.

Systems biology: By integrating genomic and transcriptomic data with other ‘omics’ data (proteomics, metabolomics), we can develop a comprehensive understanding of the complex regulatory networks controlling fungal growth and metabolite production. This enables the development of rational strategies for strain improvement and process optimization. The application of system biology to our research led to the identification of previously unknown regulatory factors impacting secondary metabolite production.

The integration of genetics and genomics is essential for the advancement of fungal biotechnology, enabling the development of improved fungal strains and processes for producing valuable products.

Q 20. Discuss the importance of sustainable practices in fungal fermentation.

Sustainable practices are crucial in fungal fermentation to minimize environmental impact and ensure long-term viability of the industry.

Waste utilization: Employing agricultural residues and industrial byproducts as substrates reduces reliance on expensive, energy-intensive media components and minimizes waste disposal issues. This reduces environmental footprint and can lead to economic advantages.

Energy efficiency: Optimizing fermentation processes to reduce energy consumption, including improved aeration strategies and waste heat recovery, are essential for sustainability. In one project, we explored using alternative energy sources to power our fermenters, significantly reducing our carbon footprint.

Water management: Minimizing water usage throughout the process, implementing water recycling systems, and employing water-efficient technologies are crucial. We implemented a closed-loop water recycling system, significantly reducing water consumption in our fermentation facility.

Bioremediation: Using fungi to remediate pollutants or degrade waste materials offers a sustainable approach to environmental cleanup. We’ve actively investigated the use of fungi for treating agricultural runoff, reducing the environmental burden of agricultural practices.

Reduced chemical usage: Minimizing the use of chemicals (e.g., solvents, antibiotics) throughout the fermentation process and downstream processing is important to reduce environmental pollution and protect human health. We explored alternative methods for controlling fungal contamination, replacing harsh chemicals with more environmentally friendly methods.

Sustainability is not just an environmental imperative but also a business opportunity, leading to cost savings and enhanced brand image. Integrating sustainable practices into every stage of the fermentation process is paramount for the long-term success of fungal biotechnology.

Q 21. Describe your experience with different analytical techniques used in fungal fermentation (e.g., HPLC, GC-MS).

My experience with analytical techniques in fungal fermentation is extensive, with HPLC, GC-MS, and other techniques playing crucial roles in monitoring and optimizing the process.

HPLC (High-Performance Liquid Chromatography): HPLC is routinely used to quantify metabolites, particularly those that are heat-labile or non-volatile. It’s been essential for monitoring the production of various antibiotics, enzymes, and other valuable compounds during fermentation. In one project, we developed an HPLC method for rapidly analyzing the concentration of a key intermediate in the biosynthesis of a target metabolite.

GC-MS (Gas Chromatography-Mass Spectrometry): GC-MS is invaluable for analyzing volatile metabolites, giving insights into the flavor and aroma profiles of fungal products, and identifying potential contaminants. For instance, it has been used in the analysis of volatile organic compounds produced during mushroom cultivation and the identification of fungal-derived flavor components in food products.

LC-MS (Liquid Chromatography-Mass Spectrometry): LC-MS combines the separation power of HPLC with the detection capabilities of mass spectrometry, making it a highly versatile tool for metabolite profiling. This has been crucial in identifying novel metabolites and elucidating metabolic pathways.

Spectroscopic techniques: Techniques like NMR (Nuclear Magnetic Resonance) spectroscopy provide structural information about purified metabolites, essential for compound identification and characterization. We’ve regularly used NMR for structural elucidation of novel fungal-derived compounds.

Other techniques: Depending on the specific research questions, other techniques such as spectrophotometry (measuring absorbance of light), enzymatic assays (assessing enzyme activity), and various immunological assays (e.g., ELISA) play important roles. These methods are tailored to specific research needs.

The selection of analytical techniques depends heavily on the specific research question or application, and often a combination of techniques provides the most comprehensive information. I am proficient in interpreting data from these analytical platforms to guide process optimization and product development.

Q 22. How do you validate a fungal fermentation process?

Validating a fungal fermentation process ensures it consistently produces the desired product with the required quality and quantity. This involves a multi-stage approach focusing on both process parameters and product characteristics. Think of it like baking a cake – you need to ensure the recipe (process) and the final cake (product) meet your standards every time.

- Process Validation: This confirms that all critical process parameters (temperature, pH, agitation, aeration, nutrient feeding strategy) are consistently maintained within pre-defined ranges. We use statistical process control (SPC) charts to monitor these parameters throughout the fermentation run, looking for any deviations outside acceptable limits. For example, we might monitor pH using online sensors and plot the data on a control chart to detect any drift.

- Product Validation: This verifies that the final product meets predefined specifications for purity, potency, and other relevant quality attributes. This often involves sophisticated analytical techniques such as HPLC (High-Performance Liquid Chromatography) to measure the concentration of the target metabolite, or mass spectrometry to confirm its identity and purity. We’ll establish acceptance criteria for these quality attributes before the validation begins.

- Scale-up Validation: When transferring the process from lab-scale to pilot plant or industrial scale, we need to validate that the process remains consistent and efficient at the larger scale. This involves careful consideration of factors such as oxygen transfer rates, mixing efficiency, and heat transfer. We’ll often perform scale-down experiments to help guide the scale-up process and identify potential challenges beforehand.

Ultimately, a successful validation demonstrates that the fermentation process is robust, reliable, and capable of delivering a consistent, high-quality product.

Q 23. Explain your understanding of Design of Experiments (DOE) in optimizing fungal fermentation.

Design of Experiments (DOE) is a powerful statistical tool for optimizing fungal fermentation processes. Instead of changing one parameter at a time (which is inefficient and can miss interactions), DOE allows us to systematically vary multiple factors simultaneously and analyze their effects on the response variables (e.g., product yield, productivity, purity). Think of it as a smart way to explore the fermentation landscape.

For example, we might use a factorial design to investigate the impact of temperature, pH, and substrate concentration on the production of a specific enzyme. By running a carefully designed set of experiments, we can identify the optimal combination of these factors that maximizes enzyme production. We would then use statistical software (like Minitab or JMP) to analyze the data and create response surface models to visualize the relationship between the factors and the response. This allows us to pinpoint the optimal conditions, even if they lie outside the range of our initial experiments. Furthermore, DOE can also be used to identify the robustness of the process; that is, the ability of the process to consistently produce high-quality product even when parameters slightly deviate from the optimum.

Example: A 2^3 factorial design investigating three factors (temperature, pH, substrate concentration) with two levels each (high and low) would require 8 experiments.Q 24. What are the safety considerations associated with working with industrial fungi?

Working with industrial fungi presents several safety considerations, primarily focused on preventing exposure to potentially harmful spores or metabolites. These are crucial aspects of safe laboratory and industrial practices.

- Spore inhalation: Many fungal spores are allergenic or potentially pathogenic. We employ strict containment measures such as biosafety cabinets (class II BSCs) and appropriate personal protective equipment (PPE) including respirators to prevent spore inhalation. Processes are also often designed in closed systems to minimize spore release.

- Mycotoxin production: Some fungi produce mycotoxins, which are secondary metabolites that are toxic to humans and animals. Appropriate safety protocols and analytical methods are implemented to ensure that mycotoxin levels in the final product and the fermentation environment remain below acceptable limits. Regular monitoring and testing are essential.

- Inflammability and explosiveness: Some fermentation substrates and products can be flammable or explosive, necessitating strict adherence to fire safety regulations and the use of explosion-proof equipment in the fermentation facility. Proper ventilation is also vital to prevent the buildup of flammable gases.

- Occupational exposure: Workers need to be trained on proper handling procedures and to recognize the potential hazards associated with the specific fungi and substrates they’re working with. Regular health monitoring might also be necessary.

Risk assessment is paramount. A thorough risk assessment should be conducted before any work with industrial fungi begins to identify and mitigate potential hazards.

Q 25. How do you handle and manage data generated from fungal fermentation experiments?

Data management in fungal fermentation is critical for reproducibility, analysis, and regulatory compliance. We employ a structured approach involving several steps.

- Data Acquisition: Data is collected from various sources, including fermentation monitoring systems (online sensors for pH, temperature, dissolved oxygen, etc.), analytical instruments (HPLC, GC-MS), and manual measurements. We utilize data loggers and LIMS (Laboratory Information Management Systems) to automate data acquisition and improve data integrity.

- Data Storage: Data is stored in a secure, centralized database (e.g., a LIMS or a cloud-based system) with version control and access permissions to ensure data integrity, traceability, and auditability.

- Data Cleaning and Preprocessing: Raw data often requires cleaning and preprocessing before analysis. This includes handling missing values, outliers, and data transformations (e.g., normalization, standardization). We typically use statistical software like R or Python for this task.

- Data Analysis: We use statistical software to analyze the data, focusing on exploring trends, identifying correlations between variables, and building predictive models. This allows us to optimize the fermentation process and ensure consistent product quality.

Proper data management is essential for regulatory compliance and efficient process optimization. A well-defined data management plan helps maintain data integrity and facilitates efficient data analysis and interpretation.

Q 26. Describe your experience with statistical analysis of fermentation data.

Statistical analysis is fundamental to interpreting fermentation data and drawing meaningful conclusions. My experience includes applying various statistical methods to analyze data from numerous fermentation experiments.

- Descriptive Statistics: Calculating means, standard deviations, and other descriptive statistics to summarize data and identify trends. For example, we might calculate the average yield and standard deviation from multiple fermentation runs to assess process consistency.

- Inferential Statistics: Using statistical tests (t-tests, ANOVA, etc.) to compare different experimental conditions or groups. For example, we might use ANOVA to compare the yields from different nutrient feeding strategies.

- Regression Analysis: Developing mathematical models to predict the response variables (e.g., product yield) based on process parameters. Linear regression, multiple regression, and nonlinear regression techniques are commonly used. For instance, we might develop a model to predict the product yield as a function of temperature, pH, and substrate concentration.

- Multivariate Analysis: Applying techniques like PCA (Principal Component Analysis) and PLS (Partial Least Squares) to analyze datasets with many variables, identifying important factors influencing the fermentation process.

I am proficient in using statistical software packages like R, Python (with libraries like SciPy and Statsmodels), and Minitab for conducting these analyses and generating insightful reports.

Q 27. Explain your experience with process analytical technology (PAT) in fungal fermentation.

Process Analytical Technology (PAT) plays a crucial role in improving the efficiency and understanding of fungal fermentation processes. PAT involves using real-time monitoring and advanced analytical techniques to understand and control a process better. This is especially valuable for complex processes like fermentation.

In my experience, we’ve utilized various PAT tools:

- Online sensors: Real-time monitoring of critical process parameters like pH, temperature, dissolved oxygen, and CO2 evolution rate. These sensors provide continuous data streams which can be used for process control and early detection of deviations.

- Spectroscopy: Techniques like NIR (Near-Infrared) spectroscopy provide rapid, non-destructive measurements of metabolite concentrations and other process parameters directly within the fermenter, reducing reliance on traditional offline analytical methods.

- Imaging techniques: Microscopic imaging can be used to monitor the morphology and growth of fungal mycelia, allowing for better understanding of the fermentation process dynamics. This provides valuable insights that go beyond simple bulk measurements.

- Data integration and modelling: Combining data from multiple PAT tools with process control systems and advanced modeling techniques (like chemometrics and machine learning) facilitates optimization and improved process understanding. We use this to develop sophisticated predictive models that can anticipate problems and optimize process parameters automatically.

The implementation of PAT in fungal fermentation not only improves process efficiency but also enhances product quality, reduces production costs, and simplifies scale-up and validation procedures. It enables a more proactive and data-driven approach to process development and manufacturing.

Key Topics to Learn for Fungal Fermentation and Biotechnology Interview

- Fundamentals of Fungal Biology: Understand fungal morphology, physiology, genetics, and metabolic pathways relevant to fermentation processes. This includes exploring different fungal species used in biotechnology.

- Fermentation Processes: Master the principles of submerged and solid-state fermentation, including bioreactor design, optimization, and process control. Consider the impact of environmental factors (temperature, pH, aeration) on fungal growth and product formation.

- Enzyme Production and Applications: Explore the production of industrially relevant enzymes from fungi, such as amylases, cellulases, and pectinases. Understand their applications in various industries (food, textile, biofuel).

- Bioactive Compound Production: Learn about the production of pharmaceuticals (antibiotics, statins), food additives, and other valuable metabolites using fungal fermentation. Focus on understanding the biosynthetic pathways involved.

- Genetic Engineering of Fungi: Grasp the techniques used to modify fungal strains for improved production yields, altered metabolite profiles, or enhanced enzyme activity. Familiarity with CRISPR-Cas9 technology is advantageous.

- Downstream Processing: Understand the techniques used to recover and purify valuable products from fermentation broths, including filtration, chromatography, and crystallization.

- Quality Control and Assurance: Learn about the methods used to ensure the quality and safety of fungal fermentation products, including sterility testing and regulatory compliance.

- Scale-up and Process Economics: Explore the challenges and strategies involved in scaling up fungal fermentation processes from laboratory to industrial scale, considering cost-effectiveness and sustainability.

- Troubleshooting and Problem Solving: Develop your ability to diagnose and solve common problems encountered during fungal fermentation, such as contamination, low yields, and process deviations. Practice analyzing data and proposing solutions.

Next Steps

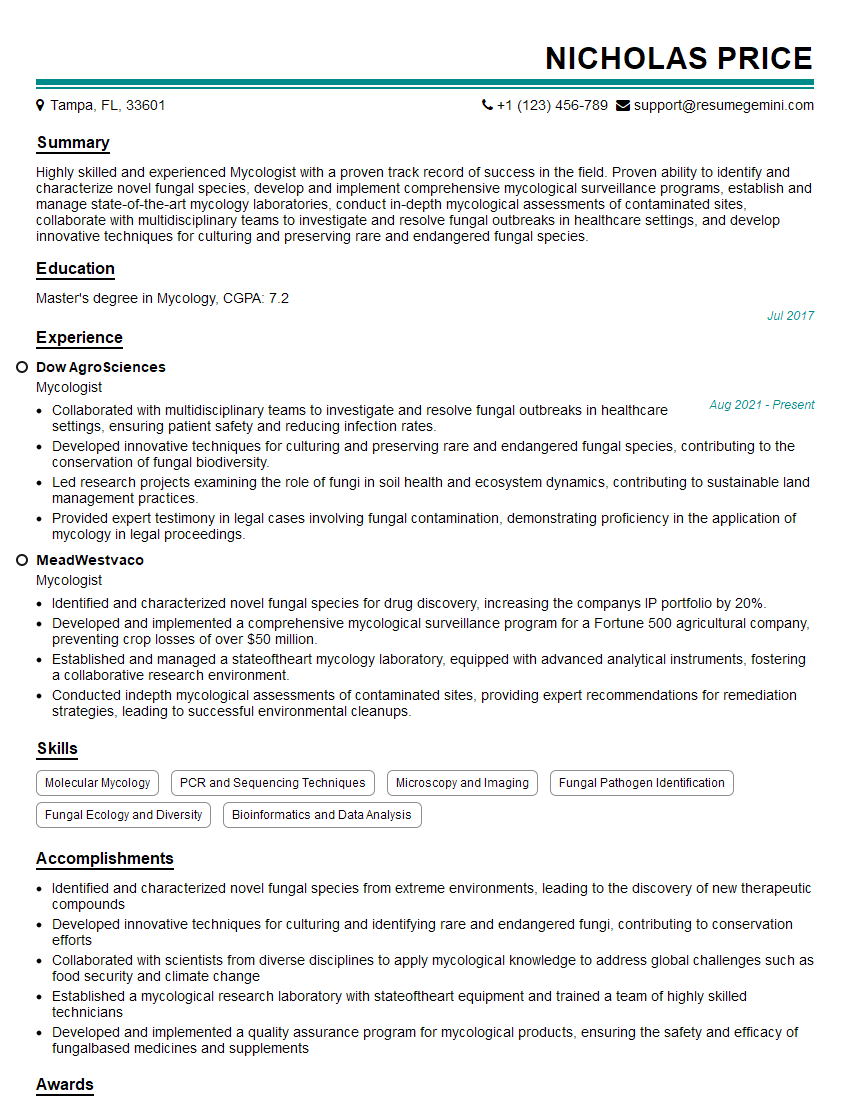

Mastering Fungal Fermentation and Biotechnology opens doors to exciting careers in various sectors, including pharmaceuticals, food processing, biofuels, and environmental remediation. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your specific field. Examples of resumes tailored to Fungal Fermentation and Biotechnology are available to guide you. Invest the time in crafting a strong resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Amazing blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?