Are you ready to stand out in your next interview? Understanding and preparing for Specialty Tile Installations interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Specialty Tile Installations Interview

Q 1. Describe your experience with different types of tile (e.g., ceramic, porcelain, natural stone).

My experience encompasses a wide range of tile types, each demanding a unique approach. Ceramic tiles, known for their affordability and versatility, are perfect for many applications, from kitchen backsplashes to bathroom floors. However, they’re generally less durable than porcelain. Porcelain tiles, on the other hand, are denser and more water-resistant, making them ideal for high-traffic areas and wet environments. Their hardness also allows for thinner tiles, which can create a more elegant look. Natural stone, such as marble, granite, and travertine, offers unparalleled beauty and luxury. However, these materials require specialized handling due to their porosity and potential for staining and damage. For example, marble, while stunning, is susceptible to etching from acidic substances. I’ve worked extensively with each type, understanding their specific needs in terms of preparation, setting, and maintenance.

One project involved installing large-format porcelain tiles in a high-end residential bathroom. The challenge was ensuring a perfectly level surface to prevent cracking. Another involved a complex mosaic using several types of natural stone, where precise cuts and careful grout selection were paramount to achieve the desired aesthetic.

Q 2. Explain the process of preparing a substrate for tile installation.

Substrate preparation is arguably the most crucial step in successful tile installation. A poorly prepared substrate will inevitably lead to problems down the line, such as cracked tiles, grout failure, or even total installation failure. The process typically involves several steps:

- Cleaning: Removing all dust, debris, loose paint, or other contaminants from the surface. This might involve sweeping, vacuuming, and pressure washing, depending on the substrate.

- Repairing: Addressing any cracks, holes, or unevenness in the substrate. This can involve patching with appropriate materials like concrete or self-leveling compounds.

- Priming: Applying a primer to enhance adhesion and improve the overall bond between the substrate and the thin-set mortar. The choice of primer will depend on the substrate material (concrete, drywall, plywood, etc.).

- Leveling: Achieving a perfectly flat and level surface. This might involve using self-leveling compounds or other leveling techniques to ensure uniform tile adhesion and prevent unevenness.

Imagine trying to build a house on a foundation that’s all cracked and uneven—it’s a recipe for disaster! Similarly, a poorly prepared substrate will inevitably lead to problems with your tile installation.

Q 3. What are the different methods for setting tile, and when would you use each?

There are two primary methods for setting tile: thin-set and thick-set. Thin-set mortar is used for most tile installations, particularly with smaller and medium-sized tiles on reasonably flat surfaces. It provides a strong bond and is relatively easy to work with. Thick-set mortar, on the other hand, is used for larger tiles or where there are significant variations in the substrate’s level. It allows for greater leveling and adjustment.

I choose the method based on several factors, including tile size, substrate condition, and the overall design. For instance, in a recent project with large, heavy slate tiles on an uneven concrete floor, thick-set was necessary to achieve a level surface. For a smaller kitchen backsplash with ceramic tiles, however, thin-set was perfectly adequate.

Q 4. How do you ensure proper grout selection and application?

Grout selection and application are critical for both the aesthetic appeal and the longevity of a tile installation. Grout color should complement the tile, while grout type must be compatible with both the tile material and the installation environment. Epoxy grouts, for example, are more durable and water-resistant than cement-based grouts, making them ideal for wet areas like showers and pools. Cement-based grouts are more versatile and commonly used in other areas.

Proper application involves using a grout float to press the grout firmly into the joints, ensuring complete filling and a consistent surface. Excess grout must be removed promptly before it dries to prevent staining and unevenness. I always follow the manufacturer’s instructions for each specific grout type to ensure optimal performance.

Q 5. What safety measures do you take during tile installation?

Safety is paramount. I always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and dust masks, to protect myself from dust, chemicals, and sharp tile edges. When using power tools like wet saws, I ensure proper ventilation and always adhere to the manufacturer’s safety guidelines. Working at heights requires the use of proper scaffolding and fall protection equipment. Furthermore, I maintain a clean and organized worksite to prevent accidents.

For example, I always use a wet saw to cut tiles, minimizing dust generation and producing cleaner cuts. Proper ventilation is crucial when working with epoxy grouts due to their strong fumes.

Q 6. Describe your experience with waterproofing techniques in tile installations.

Waterproofing is essential, especially in wet areas like showers and bathrooms. I utilize various waterproofing methods, depending on the specific requirements of the project. These include applying a liquid membrane to the substrate before tiling, using pre-formed shower pans, and installing waterproof backer boards. I always follow the manufacturer’s instructions carefully, ensuring complete coverage and proper overlaps to prevent water penetration. A properly waterproofed shower prevents water damage to the substrate and the surrounding structure.

For example, in a recent shower installation, I utilized a combination of a liquid membrane and waterproof backer board to create a completely sealed system. This ensured that water could not penetrate behind the tiles, preventing mold and mildew growth.

Q 7. How do you handle cutting and fitting tiles around complex shapes or obstacles?

Cutting and fitting tiles around complex shapes or obstacles requires precision and skill. I employ various techniques, including using a wet saw for straight cuts, an angle grinder for curved cuts, and nippers for smaller adjustments. Precise measurements and careful planning are crucial to minimize waste and ensure a seamless fit. Templates are often created to aid in cutting intricate shapes. For extremely complex areas, I might need to use custom-made tile pieces.

Consider a situation where you have a curved shower niche. I would first create a template of the niche using cardboard or heavy-duty paper, then use this template as a guide to cut the tiles to the precise shape and size. The final result would be a perfectly fitted niche with a professional, clean look.

Q 8. What are your methods for ensuring level and even tile installations?

Ensuring a level and even tile installation is paramount for a professional finish. It’s achieved through a meticulous process starting with the substrate preparation. Think of it like building a house – you wouldn’t build on an uneven foundation!

- Precise Substrate Preparation: Before any tile goes down, the surface must be perfectly flat and level. This often involves using self-leveling compound to address any imperfections. I use a laser level to constantly check for deviations and ensure consistent plane across the entire area.

- Accurate Layout: A well-planned layout is key. I carefully measure and mark the installation area, paying close attention to tile size and spacing to avoid uneven cuts at the edges. Creating a full-scale drawing beforehand helps to visualize and plan for any challenges.

- Consistent Mortar Bed: Applying a consistent thickness of mortar is crucial. This is where my experience comes in; I know how to judge the right amount of mortar for each tile to prevent any lippage (uneven tile heights) and to guarantee secure adhesion. I often use notched trowels to ensure even mortar distribution.

- Regular Level Checks: Throughout the installation process, I regularly check the level of the tiles using a level tool. This helps me to catch and correct any inconsistencies before they become major problems. It’s a continuous process, not just a one-time check.

For instance, on a recent bathroom remodel, I encountered a slightly bowed subfloor. Instead of rushing, I carefully leveled it using a self-leveling compound, ensuring a perfect base for a flawless tile installation.

Q 9. Explain your experience with different types of mortar and their applications.

My experience encompasses a wide range of mortars, each suited for specific applications and tile types. The choice of mortar significantly impacts the longevity and aesthetic of the tile installation.

- Thin-set Mortar: This is the most common type, ideal for most ceramic and porcelain tiles. It’s applied thinly and provides excellent adhesion. Different types exist, including modified thin-set (enhanced bonding properties, often used for large format tiles) and unmodified thin-set (for less demanding situations).

- Thick-set Mortar: Used for uneven substrates or when larger gaps need to be filled, this provides a more substantial bonding layer. I use this sparingly, as a thin-set is usually preferred for a cleaner installation.

- Epoxy Mortar: This high-performance mortar offers superior strength, water resistance, and chemical resistance. It’s the ideal choice for high-traffic areas, wet environments (pools, showers), and installations with demanding conditions. It is pricier, but the durability justifies the added cost.

- Latex-modified Mortar: This adds flexibility and improved bonding capabilities to the thin-set mortar. Ideal for installations on substrates prone to movement or cracking.

For example, when installing large-format porcelain tiles in a shower, I always opt for a high-quality modified thin-set or epoxy mortar to ensure optimal adhesion and water resistance. This guarantees the integrity of the shower floor for years to come.

Q 10. How do you maintain consistent grout lines during installation?

Maintaining consistent grout lines is crucial for a professional-looking installation. It’s all about precision and using the right tools. Imagine trying to draw perfect lines freehand – it’s nearly impossible; proper tools are essential.

- Spacers: Using consistent spacers (plastic or tile spacers) between tiles is fundamental. These create the gaps needed for grout and ensures uniform spacing throughout the installation.

- Accurate Layout: A meticulously planned layout significantly reduces the need for tricky cuts, minimizing variations in grout line width.

- Careful Tile Placement: Each tile is carefully positioned, ensuring the spacers are correctly placed and held securely until the mortar sets. I often use leveling systems to guarantee consistent plane while the mortar is curing.

- Regular Checks: Regularly checking the grout line width during the installation process prevents discrepancies.

I recently used 1/8-inch spacers for a subway tile backsplash. The consistent spacing resulted in a clean, professional-looking finish that was pleasing to the client.

Q 11. How do you troubleshoot common tile installation problems (e.g., lippage, cracking)?

Troubleshooting tile installation problems is a crucial part of my expertise. Experience helps anticipate and resolve issues efficiently. Let’s address common problems.

- Lippage: Uneven tile heights. This often stems from inconsistent mortar application or an uneven substrate. The solution involves carefully removing the affected tiles, leveling the substrate, and reinstalling them with consistent mortar application and using a leveling system.

- Cracking: Cracks can be due to poor substrate preparation, improper mortar selection, or movement in the substrate. This requires investigating the root cause. It might involve replacing the substrate if severely damaged, using a more flexible mortar, or employing crack isolation membranes.

- Hollow Tiles: If tiles sound hollow when tapped, it signifies insufficient mortar beneath. This requires removing the loose tiles and reapplying mortar properly.

- Grout Issues: Uneven grout lines, cracked grout – these point to improper grout application or grout selection. Careful attention during grout installation is crucial, including proper mixing and curing time. In some cases, regrouting is necessary.

In one instance, a client experienced lippage after a DIY attempt. I identified inconsistent mortar application as the culprit and, by redoing the problematic areas with precise application and using a leveling system, I delivered a smooth, even finish.

Q 12. Describe your experience with large-format tile installation.

Large-format tile installation demands extra precision and attention to detail. These tiles are heavier, more prone to breakage, and require specialized techniques.

- Substrate Preparation: Imperfections in the substrate are amplified with large tiles. Extremely flat substrates are essential. This often involves extensive work with self-leveling compounds.

- Mortar Selection: Modified thin-set or epoxy mortars are crucial for superior adhesion and to support the weight. The right notched trowel for the tile size ensures proper coverage.

- Careful Handling: Large tiles are fragile and require careful handling to avoid chipping or breaking. This involves using proper lifting techniques and protective coverings.

- Support Systems: Leveling systems are invaluable; they ensure consistent plane during curing and prevent lippage.

- Cutting: Precise cutting is needed, often requiring specialized tools like a wet saw with diamond blades.

I recently completed a project involving 24×48 inch porcelain tiles. The use of a high-quality epoxy mortar, combined with a precise leveling system, was essential for ensuring a flawless installation that withstood the tiles’ weight and size.

Q 13. What experience do you have with different tile installation patterns (e.g., running bond, herringbone)?

My experience includes various tile installation patterns, each demanding specific skills and techniques.

- Running Bond: This classic pattern is straightforward but requires precise spacing for a clean look. The consistent use of spacers is critical.

- Herringbone: This requires careful planning and precise cutting to maintain consistent angles and patterns. Accurate layout and pre-cutting are vital.

- Basketweave: This more complex pattern involves intersecting rows of tiles, and precise measurements and cutting are vital for ensuring a symmetric outcome.

- Diagonal: Installing tiles diagonally adds a dynamic element to the space. It requires careful planning of cuts and precise alignment of tiles.

For a recent project, the client chose a herringbone pattern for their kitchen backsplash. This required a detailed layout plan and meticulous cutting, ensuring all angles perfectly aligned for a truly stunning outcome.

Q 14. How do you manage waste and disposal during a tile project?

Responsible waste management is crucial for any professional tile installation. It’s not just about environmental responsibility but also about efficiency and cost-effectiveness.

- Careful Cutting: Minimizing waste starts with precise planning and cutting techniques. Using a wet saw allows for more controlled cuts, reducing material loss.

- Waste Segregation: Different waste materials (cardboard, plastic, broken tiles, etc.) are segregated for proper disposal according to local regulations. This ensures efficient recycling and minimizes environmental impact.

- Disposal: I adhere to all local regulations and utilize appropriate waste disposal methods for each material type.

- Material Reuse: Whenever possible, I utilize leftover materials for smaller areas or for future projects.

On a large commercial project, meticulous waste management saved the client significant money on disposal fees. Proper segregation and minimizing waste through precise cuts were critical to this success.

Q 15. Explain your experience with installing tile on various surfaces (e.g., concrete, drywall, wood).

My experience with tile installation spans a wide range of surfaces, each requiring a unique approach. Concrete is a relatively straightforward substrate, offering excellent stability. The key is ensuring it’s clean, level, and properly primed before tiling. Drywall, on the other hand, requires more attention to detail. It needs a robust backer board like cement board installed first to provide the necessary strength and moisture resistance. Failing to do so can lead to cracked tiles or the tiles falling off entirely. Wood subfloors present the most challenges. They need to be completely stable and flat, often requiring a self-leveling compound to address unevenness. Furthermore, a moisture barrier is crucial to prevent water damage and warping. I’ve successfully installed tile on all three surfaces numerous times, adapting my techniques based on the substrate’s specific characteristics.

- Concrete: Priming is vital to ensure proper adhesion. I typically use a concrete bonding primer.

- Drywall: Always use a cement backer board and ensure all joints are properly taped and mudded for a smooth surface.

- Wood: A waterproof membrane, such as a polyethylene sheet, is essential before installing the backer board. This prevents moisture from migrating up from the wood.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of tile failure and how can they be prevented?

Tile failure stems from several common issues, most of which are preventable with proper planning and execution. Improper substrate preparation is a major culprit. Uneven surfaces, inadequate moisture barriers, and insufficient bonding are frequent causes of cracked tiles, loose tiles, and grout failure. Using the incorrect thin-set mortar or failing to allow sufficient drying time for the mortar can also lead to problems. Lastly, choosing the wrong tile type for the intended area, such as using ceramic tiles in a high-traffic commercial space instead of porcelain tiles can lead to early wear and tear.

- Prevention: Thorough substrate preparation, including cleaning, leveling, and priming, is paramount. Using the right type of mortar and adhering to manufacturer’s drying recommendations are also crucial. Proper grout selection and application are also key to longevity. Choosing tiles that are appropriate for the environment and application is critical.

Q 17. How do you determine the quantity of materials needed for a tile project?

Accurately determining material quantities requires careful measurement and calculation. I start by precisely measuring the area to be tiled. Then, I account for waste, typically adding 10-15% to the total square footage. This allows for cuts, breakage, and potential errors. For example, if a project requires 100 square feet of tile, I would order at least 110-115 square feet. The same principle applies to thin-set mortar, grout, and any other materials, considering the manufacturer’s coverage rates.

I always verify these calculations with the client to ensure agreement and avoid any potential shortages or excessive material costs. We will also review the tile layout and patterns to refine the quantity calculations.

Q 18. Describe your experience using different power tools related to tile installation.

My experience encompasses a range of power tools essential for efficient and precise tile installations. I’m proficient in using wet saws for cutting tiles to exact dimensions, ensuring clean and accurate cuts, especially with intricate patterns or complex designs. Angle grinders with diamond blades are invaluable for cutting through thicker or tougher tiles and for creating specific shapes. I also regularly use a tile nipper for smaller, more delicate cuts. Finally, a handheld electric mixer ensures consistent and even mixing of thin-set mortar, eliminating lumps and ensuring optimal bonding.

Safety is always my top priority when using power tools. I always wear appropriate safety gear, including eye protection, hearing protection, and a dust mask to mitigate health risks.

Q 19. What methods do you use to ensure the longevity and durability of your tile installations?

Ensuring the longevity and durability of my tile installations involves a multi-faceted approach. Proper substrate preparation, as discussed earlier, is foundational. I pay meticulous attention to details like ensuring a level surface and using the correct type of backer board. I always use high-quality materials—thin-set mortar, grout, and sealant—following manufacturers’ instructions precisely. I also use appropriate expansion joints to accommodate building movement, preventing stress cracks in the tile. Finally, I always advise clients on proper maintenance, like regular cleaning and avoiding harsh chemicals, to extend the life of their tile installation.

Q 20. How do you manage time and resources effectively during a tile project?

Effective time and resource management is crucial in any tile project. I begin by creating a detailed project schedule, outlining each stage, from substrate preparation to grout cleaning. This detailed plan helps me allocate the necessary time for each task, including potential unforeseen delays. Resource management involves ordering materials in advance to avoid delays, and having the right tools available when needed. I also factor in the weather conditions and ensure the space is properly prepared before starting work.

Regular communication with the client and any other involved parties keeps everyone informed of progress and addresses any potential issues promptly, preventing unnecessary delays.

Q 21. What is your experience with working from blueprints or technical drawings?

I have extensive experience interpreting blueprints and technical drawings. This is essential to translate the design vision into a precise and accurate tile installation. I carefully review drawings to understand the tile layout, material specifications, and any unique design features. My ability to accurately read and interpret plans ensures that the final installation matches the design exactly. I’m also comfortable working with clients or designers to clarify any ambiguities or potential challenges before commencing the project.

For example, if the drawings show a complex mosaic pattern, I would meticulously plan the cutting and layout to ensure a flawless outcome. Proper interpretation of drawings is critical for a successful project.

Q 22. How do you handle unexpected challenges or changes during a tile installation?

Unexpected challenges are par for the course in tile installation. My approach is always proactive and methodical. First, I thoroughly assess the situation. Is it a substrate issue? A problem with the tile itself? A design change? Once identified, I carefully weigh my options, consulting with the client if necessary. For example, if I discover uneven subflooring during a large format porcelain tile installation, simply continuing could lead to cracking. Instead, I’d immediately address it – perhaps using self-leveling compound to create a perfectly flat surface before proceeding. If a tile arrives damaged, I wouldn’t hesitate to contact the supplier for a replacement, documenting everything carefully with photos. Communication with the client is key – keeping them informed every step of the way ensures transparency and avoids unnecessary stress.

I also have contingency plans. For instance, I always carry a variety of grout colors on-hand to account for minor discrepancies or last-minute client requests. Flexibility and resourcefulness are critical. Ultimately, the goal is to deliver a flawless installation, even when faced with unexpected hurdles.

Q 23. Describe your experience with working with clients or contractors.

I thrive on collaboration. I’ve worked extensively with both clients and contractors, always aiming for a seamless experience. With clients, I prioritize clear communication, providing realistic timelines and managing expectations. I believe in showing, not just telling. I often present samples and mock-ups to ensure complete understanding of the final look and feel. Before starting any project, a detailed scope of work is created and reviewed together, minimizing the risk of misunderstandings. With contractors, it’s about mutual respect and effective coordination. I’m adept at scheduling my work around other trades, ensuring a smooth workflow on the construction site. For example, I’ll coordinate with the plumber to ensure the necessary access is available before installing tiles around fixtures.

My goal is to be a reliable and trusted partner throughout the entire process, from initial design consultation to final walkthrough.

Q 24. What are your preferred methods for cleaning and maintaining installed tile?

Cleaning and maintaining tile is crucial for longevity and aesthetics. My preferred method involves a two-step process. First, I use a pH-neutral cleaner specifically designed for tile and grout. Harsh chemicals can damage the grout and dull the tile’s finish. I avoid abrasive cleaners and scouring pads as well, opting for soft cloths or microfiber mops. For stubborn stains, a solution of warm water and white vinegar can be effective. It’s important to rinse thoroughly to avoid residue.

Secondly, and this is often overlooked, regular sealing is essential, especially for grout. Sealing protects the grout from water damage, staining, and mold growth. I recommend resealing every 1-2 years, depending on the traffic and the type of grout. For maintenance, regular sweeping or vacuuming prevents dirt and grit from accumulating, minimizing the need for harsh cleaning.

Q 25. What are your knowledge of different types of grout and their suitability for different environments?

Grout selection is vital; the wrong choice can compromise the durability and aesthetics of the tile installation. I’m familiar with various types, including epoxy, cement-based, and sanded/unsanded grout. Epoxy grout is exceptionally strong, stain-resistant, and waterproof, making it perfect for high-moisture areas like showers and pools. However, it’s more expensive and requires specialized cleaning techniques. Cement-based grout is a cost-effective and versatile option, suitable for most indoor environments. Sanded grout is used for wider grout lines (over 1/8 inch), while unsanded is for narrower lines. The choice depends on the tile size, the desired aesthetic, and the environment’s demands.

For instance, in a commercial kitchen with heavy foot traffic, I might opt for epoxy grout for its superior durability and stain resistance. In a residential bathroom, cement-based grout might be sufficient, providing a good balance of performance and cost.

Q 26. How do you handle difficult cuts or mitering of tiles?

Difficult cuts and mitering require precision and the right tools. I use a combination of wet saw and tile nippers for intricate cuts. The wet saw, with its diamond blade, provides clean, straight cuts for most applications. For complex shapes or curves, I use tile nippers, carefully breaking the tile along scored lines. Mitering, creating angled cuts for seamless transitions, requires practice and patience. I always use a miter box and a scoring tool to ensure accuracy. This approach minimizes chipping and ensures a professional, polished finish.

For example, achieving a perfect miter on a decorative mosaic tile necessitates multiple precise cuts and meticulous attention to detail.

Q 27. What is your experience with using specialized tools for tile installation (e.g., tile saws, nippers)?

Proficiency with specialized tools is essential for quality tile installations. I’m experienced in using various tools, including wet saws (both manual and automated), tile nippers, grout floats, spacers, and various types of mixing equipment. I understand the nuances of each tool and how to use them effectively and safely. For example, the speed and depth of cut on a wet saw needs to be adjusted depending on the tile type. Too fast or too deep and you risk cracking the tile. Using the right size grout float is essential for achieving uniform grout lines. I am also familiar with using laser levels to ensure perfectly aligned installations.

Regular maintenance and careful handling of these tools are crucial for extending their lifespan and ensuring accuracy.

Q 28. Describe your experience with installing Schluter Systems or similar waterproofing products.

I have extensive experience with Schluter Systems and similar waterproofing membranes, which are critical for preventing water damage in wet areas. I understand the importance of proper installation, following manufacturer guidelines meticulously. This includes installing the membrane correctly over the substrate, ensuring complete coverage and proper overlaps. I know the different types of Schluter products and when to use them, such as Kerdi-Board for shower niches and Kerdi-Drain for efficient water drainage. I also pay close attention to sealing all joints and penetrations to ensure a waterproof barrier. Proper installation of these systems significantly extends the lifespan of a tile installation and prevents costly water damage issues.

A improperly installed waterproofing membrane can lead to serious problems such as mold growth and structural damage; therefore I always treat this stage with great care and attention to detail.

Key Topics to Learn for Specialty Tile Installations Interview

- Understanding Different Tile Types: Explore the properties, applications, and limitations of various tile materials (ceramic, porcelain, glass, natural stone, etc.). Consider their suitability for different environments and design styles.

- Installation Techniques: Master the practical application of various installation methods, including thin-set mortar application, proper spacing and grouting techniques, and working with different substrates (concrete, drywall, etc.).

- Advanced Installation Methods: Familiarize yourself with specialized installation techniques such as large format tile installation, intricate mosaic work, and the use of specialized tools and equipment.

- Troubleshooting and Problem Solving: Practice identifying and resolving common installation issues, such as lippage, cracking, and uneven surfaces. Understanding the root causes and appropriate solutions is crucial.

- Adhesive and Grout Selection: Learn to select the appropriate adhesives and grouts based on the tile type, substrate, and environmental conditions. Understanding their properties and limitations is key.

- Safety Regulations and Practices: Demonstrate knowledge of relevant safety regulations and best practices for handling tile materials, operating power tools, and maintaining a safe work environment.

- Design and Aesthetics: Gain an understanding of tile layout design, patterns, and overall aesthetic considerations. Being able to discuss design choices and their impact is valuable.

- Estimating and Project Management: Develop skills in estimating material quantities, labor costs, and project timelines. Understanding project management basics is beneficial.

Next Steps

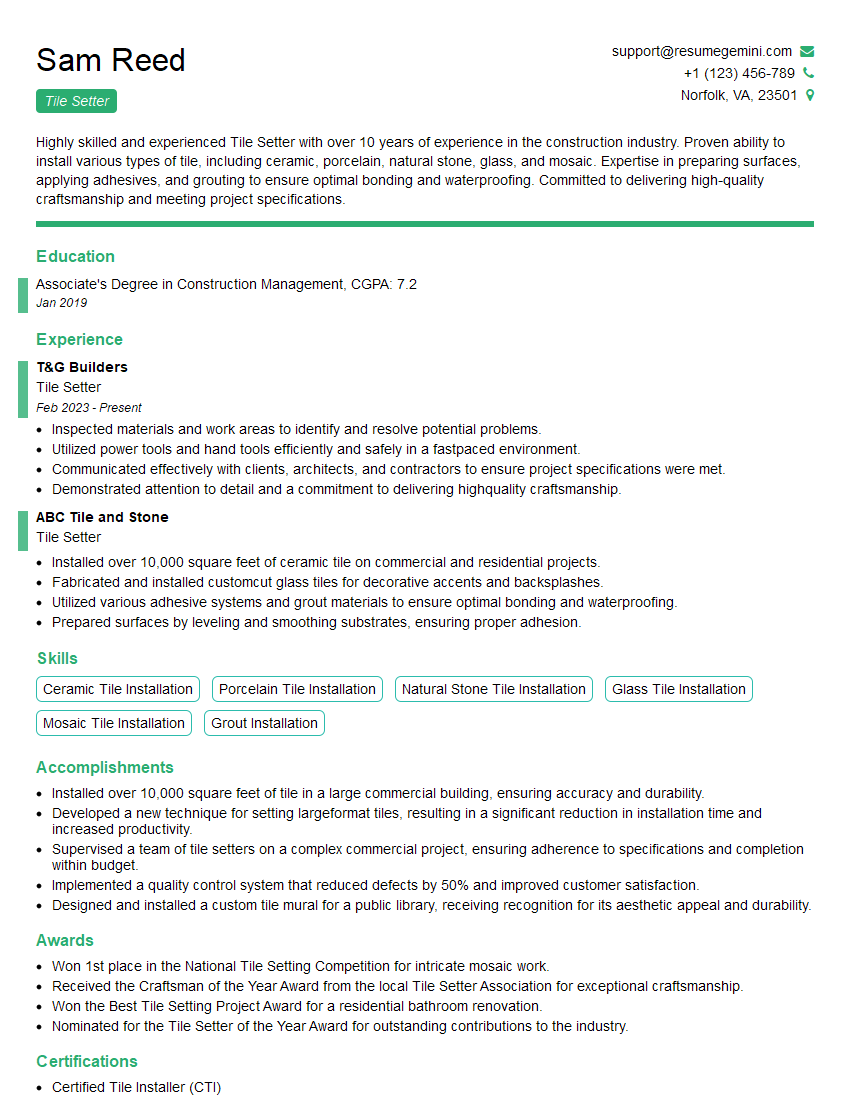

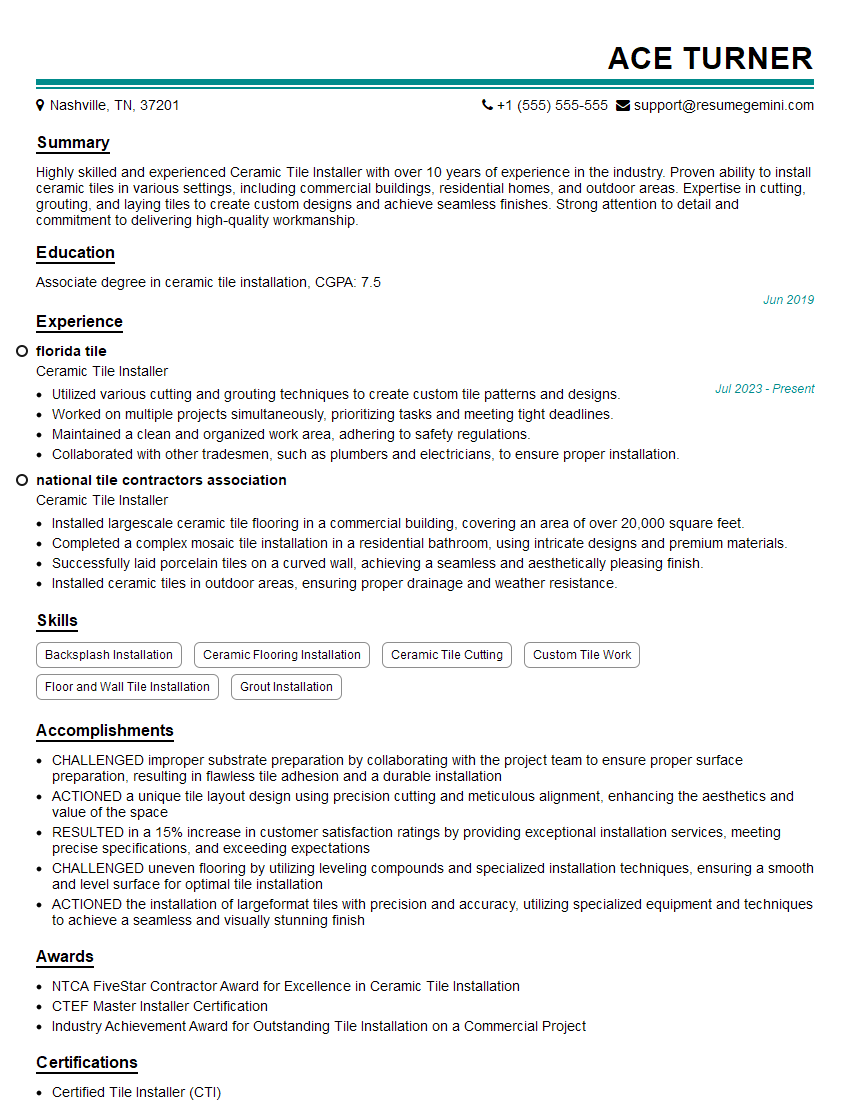

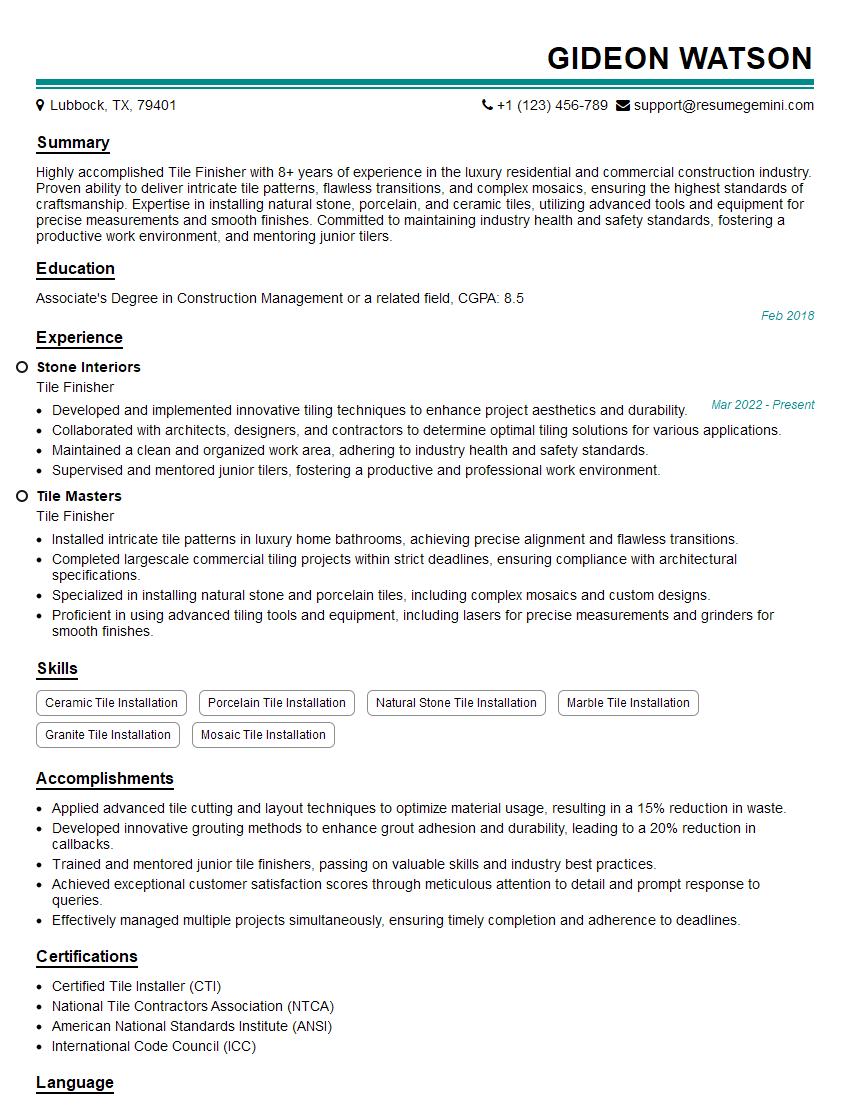

Mastering specialty tile installations opens doors to rewarding careers with excellent earning potential and opportunities for advancement. A strong understanding of these techniques is highly sought after by employers. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to Specialty Tile Installations are available to guide you through this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?