The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Layouting and Cutting Vinyl Flooring interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Layouting and Cutting Vinyl Flooring Interview

Q 1. Explain the process of measuring a room for vinyl flooring installation.

Accurately measuring a room for vinyl flooring is crucial for a successful installation. It prevents material shortages and minimizes waste. The process involves several key steps:

- Clear the Room: Remove all furniture and obstructions to get a clear view of the floor.

- Measure Length and Width: Measure the length and width of the room in multiple places, as rooms are rarely perfectly rectangular. Record the longest measurement for both length and width.

- Identify Irregularities: Note any alcoves, recesses, doorways, or other irregularities that will require additional measurements and cutting. Sketch a floor plan, labeling these areas.

- Measure Irregular Areas: For irregular areas, break them down into smaller, easily measurable shapes (rectangles, triangles). Measure each shape separately and record the dimensions.

- Account for Doorways and Obstructions: Measure doorways and other areas where the flooring won’t be installed to ensure you subtract this area from your total calculation.

- Double-Check Measurements: Always double-check your measurements to avoid costly mistakes. A simple error can lead to significant material waste or shortages.

Example: Let’s say a room measures 12ft x 15ft, but has an alcove measuring 3ft x 2ft. You would calculate the total area as (12ft * 15ft) – (3ft * 2ft) = 174 sq ft.

Q 2. Describe different methods for calculating vinyl flooring material needs.

Calculating vinyl flooring needs involves a few methods, all starting with accurate room measurements (as described above). The most common methods include:

- Simple Area Calculation: This is used for rectangular rooms. Multiply the length by the width (Length x Width = Area). This provides a basic estimate but doesn’t account for waste.

- Complex Area Calculation: For irregularly shaped rooms, divide the space into smaller, regular shapes (rectangles, triangles). Calculate the area of each shape individually and add them together.

- Using Online Calculators: Many flooring retailers provide online calculators. These tools usually account for some waste but may not be perfectly accurate for highly irregular spaces.

Example (Simple): A 10ft x 12ft room has an area of 120 sq ft. Example (Complex): A room with a rectangular section (8ft x 10ft) and a triangular section (base 4ft, height 3ft) has a total area of (80 sq ft) + (0.5 * 4ft * 3ft) = 86 sq ft.

Q 3. How do you account for waste and overage when ordering vinyl flooring?

Accounting for waste and overage is critical to avoid running short on material. The amount of waste depends on several factors, including the complexity of the room shape, the pattern matching requirements of the vinyl, and the installer’s skill. Here’s how to approach it:

- Waste Percentage: Add a waste percentage to your total area calculation. For simple rectangular rooms, 5-10% might suffice. For complex layouts with many cuts, 10-15% or even more may be necessary.

- Pattern Matching: Certain vinyl flooring patterns require careful matching, leading to more waste. This should be considered when estimating overage.

- Professional Advice: Consult with the flooring retailer or a professional installer. They can offer informed advice based on the room’s complexity and the chosen flooring type.

Example: For a 100 sq ft room with a complex layout, adding a 15% overage would result in an order of 115 sq ft (100 sq ft + 15 sq ft).

Q 4. What tools and equipment are essential for accurate vinyl flooring layout and cutting?

Precision is key in vinyl flooring installation. The essential tools and equipment include:

- Measuring Tape: A high-quality, accurate measuring tape is paramount for precise measurements.

- Pencil: For marking cut lines on the flooring.

- Straight Edge: A long, straight edge (e.g., a metal ruler or a straight piece of wood) for accurate cutting.

- Utility Knife: A sharp utility knife with extra blades is crucial for clean cuts. A rotary cutter can also be very helpful.

- Floor Leveler: Necessary for leveling uneven subfloors.

- Underlayment (if required): Provides cushioning and helps to level minor imperfections.

- Safety Gear: Gloves, safety glasses, and knee pads protect you during the installation process.

- Chalk Line (Optional): Helps create straight lines for cutting.

The quality of your tools directly impacts the precision of your cuts and the overall look of the finished floor.

Q 5. Explain the importance of proper subfloor preparation for vinyl flooring.

Proper subfloor preparation is the foundation of a successful vinyl flooring installation. A poorly prepared subfloor can lead to unevenness, buckling, and premature wear. The preparation process typically involves:

- Cleaning: Thoroughly clean the subfloor to remove debris, dust, and any old adhesive residue.

- Leveling: Address any significant level variations. Use a floor leveler or self-leveling compound to achieve a smooth, even surface.

- Moisture Testing: Check the moisture content of the subfloor, particularly concrete, to ensure it’s within acceptable levels for vinyl flooring. Excessive moisture can damage the flooring.

- Repairing: Repair any damaged or cracked sections of the subfloor before installing the new flooring.

- Priming (If needed): A primer can enhance adhesion and prevent future issues.

Think of the subfloor as the groundwork for a house – if the foundation is weak, the entire structure is at risk. The same is true for vinyl flooring; a properly prepared subfloor ensures a long-lasting and beautiful installation.

Q 6. Describe different types of vinyl flooring and their suitability for various applications.

Various types of vinyl flooring cater to different needs and budgets:

- Sheet Vinyl: Comes in large rolls, providing seamless coverage. Ideal for smaller rooms, as it requires fewer seams than tile.

- Vinyl Tile: Available in various sizes and styles, offering design flexibility. Better suited for rooms with many irregularities due to its modularity.

- Luxury Vinyl Plank (LVP) and Luxury Vinyl Tile (LVT): High-end options that mimic the look of hardwood or stone. Durable and water-resistant, they are excellent for high-traffic areas.

Suitability: Sheet vinyl is excellent for bathrooms and kitchens due to its water resistance. Vinyl tile is versatile and suitable for most applications. LVP and LVT are ideal for areas needing durability and a high-end aesthetic.

Q 7. How do you handle irregular room shapes and difficult cuts during vinyl flooring installation?

Handling irregular room shapes and difficult cuts requires patience, precision, and the right tools. Here’s a step-by-step approach:

- Detailed Measurements: Take very precise measurements of the irregular sections. Break down complex shapes into simpler geometric forms (rectangles, triangles, etc.).

- Accurate Templates: Create cardboard or paper templates to match the irregular areas. This allows for precise cutting without directly marking the expensive flooring.

- Test Cuts: Always test your cuts on scrap pieces of vinyl before making final cuts on the flooring material. This is an essential step to avoid mistakes.

- Careful Cutting: Use a sharp utility knife or rotary cutter to make precise cuts along the templates. Take your time and work slowly to maintain accuracy.

- Multiple Cuts: For highly irregular shapes, multiple cuts may be necessary. Consider using smaller pieces to create a mosaic effect in some cases.

Remember, precise measurements and careful cutting are crucial for a clean, professional finish. Don’t rush the process, as doing so may lead to costly errors and need for replacement of the material.

Q 8. Explain your approach to achieving precise cuts and minimizing material waste.

Precise cuts and minimal waste in vinyl flooring are paramount for both efficiency and a professional finish. My approach starts with meticulous measurement and planning. I always measure twice, and sometimes even three times, to ensure absolute accuracy before making any cuts. I utilize a combination of techniques depending on the project’s complexity. For straightforward cuts, a sharp utility knife and a metal straight edge are sufficient, guaranteeing clean, precise lines. For more intricate cuts, like fitting around pipes or creating curves, I employ a rotary cutter with various blades, offering greater control and precision. Before cutting, I always lay out the flooring pieces and mark them precisely. This allows for the most efficient use of materials, minimizing waste. I also prioritize using the largest possible pieces to reduce the number of cuts required. Think of it like a jigsaw puzzle – you want to use the biggest pieces first to fill in the major gaps before dealing with the smaller, more challenging ones.

For example, when installing flooring in a room with an L-shape, I carefully plan to minimize the number of cuts, possibly using a single larger piece for one section, and then strategically cutting the second section to minimize waste. This minimizes material waste and overall project costs. Waste pieces are often saved for smaller projects or repairs, increasing overall resource utilization.

Q 9. Describe your experience with various cutting tools, such as utility knives, shears, and electric cutters.

My experience encompasses a wide range of cutting tools. The utility knife remains a staple for its precision and versatility, especially for straight cuts. However, I always use a fresh blade to ensure a clean, crisp cut, preventing jagged edges that can affect the finished look. Shears are useful for cutting thinner vinyl sheets or trimming excess material, but I avoid using them for precision cuts because they can be less accurate. Electric cutters, on the other hand, are ideal for bulkier cuts and more complex shapes. They significantly expedite the process, especially on large projects. However, mastering control is crucial to avoid damage. The best tool selection depends on the specific job – a utility knife for intricate details and an electric cutter for efficiency on bulk cuts is my typical approach. I always prioritize safety, wearing appropriate safety glasses and gloves while using any cutting tool.

Q 10. How do you ensure accurate alignment and transitions between vinyl flooring sheets?

Accurate alignment and seamless transitions are crucial for a professional-looking vinyl floor. My process begins with carefully aligning the first sheet along a straight wall, using a level to ensure it’s perfectly straight and even. Subsequent sheets are then carefully butted against the preceding one, ensuring a tight and consistent fit. A slight overlap at seams is preferred as it ensures there is no visible gap between the sheets. Using a seam roller is essential for ensuring a tight, adhesive-bonded seal across the overlapped sections, eliminating visible gaps or inconsistencies. To check alignment, I frequently use a measuring tape and a speed square to ensure consistently straight and perpendicular seams throughout the room. This attention to detail is what separates a good installation from a great one – it’s the difference between noticing the seams and the seams disappearing into the overall floor finish.

Q 11. Explain your process for installing vinyl flooring around obstacles such as pipes and doorways.

Installing around obstacles like pipes and doorways requires careful planning and precise cutting. For pipes, I measure the circumference of the pipe and carefully trace this onto the vinyl sheet, then cut carefully using a utility knife. I often use a jigsaw for complex curves to create a precise fitting. For doorways, I measure the doorjamb carefully and use a combination of straight cuts and curved cuts to fit the flooring snugly. A good technique is to cut a slightly larger piece, leaving a small gap that can be concealed with the door frame or trim. Pre-cutting the vinyl to the correct size, accounting for expansion and contraction gaps, is essential, along with using a sharp utility knife to create clean, professional edges around the obstacles.

I remember one project where we had to fit the flooring around a very unusual curved wall. I used a combination of templates, careful tracing, and a jigsaw to create the precise cuts needed, and the final result looked seamless and professional. This shows that pre-planning and adapting to the situation are pivotal in achieving a great final product, overcoming even the most challenging obstacles.

Q 12. How do you handle expansion and contraction gaps in vinyl flooring installation?

Expansion and contraction gaps are crucial for preventing buckling or warping of the vinyl flooring, especially in areas with fluctuating temperatures and humidity. I always leave an expansion gap of approximately 1/4 inch to 1/2 inch around the perimeter of the room and between sheets. This gap allows the flooring to expand and contract without putting undue stress on the seams or causing damage. The gap is then concealed by baseboards or trim, ensuring a clean finish. The size of the expansion gap varies depending on the specific type of vinyl and the manufacturer’s recommendations. Ignoring this is a common mistake that leads to future problems. It’s an important detail that ensures the longevity of the installed flooring.

Q 13. Describe your experience with different types of vinyl flooring adhesives.

My experience includes working with various vinyl flooring adhesives, each with its own properties and applications. Water-based adhesives are popular for their low VOC emissions and ease of cleanup, ideal for indoor environments. However, they often have a longer drying time. Pressure-sensitive adhesives are convenient for quick installations, but may not be as durable in high-traffic areas. Modified acrylic adhesives are a versatile choice, providing a good balance of adhesion, drying time, and durability. The choice of adhesive depends heavily on the type of vinyl flooring being used, the subfloor condition, and the specific project requirements. For instance, a moisture-resistant adhesive is essential if the subfloor has any potential for moisture issues. I always follow the manufacturer’s instructions for both the flooring and the adhesive to ensure optimal performance and longevity of the flooring.

Q 14. What are the common problems encountered during vinyl flooring installation, and how do you address them?

Common problems during vinyl flooring installation include uneven subfloors, improper adhesive application, inadequate expansion gaps, and incorrect cutting. Uneven subfloors can lead to ripples or bumps in the finished floor. This is addressed by leveling the subfloor before installation. Improper adhesive application can result in poor adhesion or lifting of the flooring, usually dealt with by removing the affected sections, cleaning the subfloor, and reapplying the adhesive correctly. Inadequate expansion gaps can cause buckling or warping, while incorrect cutting leads to uneven seams or poor fitting around obstacles. Thorough planning, using appropriate tools and techniques, and paying close attention to detail are crucial for avoiding these issues. Always inspecting the subfloor for imperfections and adhering strictly to the manufacturer’s instructions is vital. Most importantly, recognizing problems early is key to implementing a timely and efficient solution.

Q 15. How do you ensure the proper curing time for vinyl flooring adhesive?

Proper curing time for vinyl flooring adhesive is crucial for a successful installation. It ensures the adhesive achieves its maximum bond strength, preventing future issues like lifting or seams separating. The specific curing time depends heavily on the type of adhesive used, the temperature and humidity of the environment, and the manufacturer’s recommendations. Always check the adhesive’s data sheet; it will provide the minimum recommended time before applying foot traffic, as well as the time needed for full curing.

For example, a fast-drying, water-based adhesive might only need a few hours before light foot traffic, but a full 24-48 hours for heavy furniture. Conversely, a solvent-based adhesive will likely require a much longer curing time, possibly up to several days. I always err on the side of caution; I’d rather wait an extra day than risk compromising the integrity of the installation.

In practice, I create a detailed installation plan that includes the adhesive’s curing time. This plan is provided to the client, along with instructions regarding restrictions on foot traffic and furniture placement during the curing period. Thorough communication is key to preventing client frustration and ensuring a positive outcome.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with heat welding vinyl seams.

Heat welding vinyl seams is a critical skill for creating seamless and durable vinyl flooring installations. It involves using a specialized heat welding tool to melt and fuse the edges of two vinyl sheets together. I’m proficient in using various types of heat welding tools, from basic hand-held units to more sophisticated automatic welders. Proper technique is paramount to avoid burning the vinyl or creating weak seams.

My experience includes working with different vinyl thicknesses and types, requiring adjustments to the welding temperature and speed. I always use a consistent speed and even pressure to ensure a strong, uniform weld that is barely visible. Before welding, I thoroughly clean and prepare the seams, ensuring they are properly aligned and free from debris. A poorly prepared seam can lead to a weak weld, and a weak weld is a failure point, potentially leading to costly repairs.

Imagine trying to weld two pieces of plastic together with a soldering iron. If you apply too much heat, you’ll melt the plastic, ruining the material. Conversely, too little heat results in a weak bond. Heat welding vinyl requires the same precision and practiced skill, and I pride myself on achieving consistently clean, strong seams.

Q 17. Explain your understanding of safety precautions when working with cutting tools and adhesives.

Safety is my number one priority. When working with cutting tools like utility knives, sharp blades and box cutters, I always use appropriate safety measures. This includes wearing cut-resistant gloves, using a cutting mat to protect the surface underneath, and keeping the blades sharp to prevent slipping. Sharp tools are less likely to slip and cause injury.

- Cutting Tools: Always use a sharp blade, never force cuts, and keep the cutting area clear of obstructions. Dispose of used blades properly.

- Adhesives: Work in a well-ventilated area, use respirators as needed, wear appropriate safety glasses and gloves to prevent skin and eye contact. Proper ventilation prevents inhalation of fumes, and gloves protect skin from irritation and chemical burns.

For example, before starting any project, I always brief my team on the safety protocols, including the proper handling and disposal of waste materials, the use of safety equipment, and the importance of reporting any injuries or accidents immediately. I also emphasize the importance of regular equipment checks to ensure the safe and efficient operation of tools.

Q 18. How do you handle customer complaints or issues related to vinyl flooring installation?

Handling customer complaints is a critical aspect of my job. I approach each situation with empathy and professionalism. I actively listen to the client’s concerns, acknowledging their frustration and validating their experience. The goal isn’t to argue or dismiss their concerns but to understand the root cause of the issue.

My approach typically involves:

- Thorough Inspection: I begin by carefully inspecting the area in question, documenting any visible defects or inconsistencies.

- Identify the Cause: Based on the inspection, I determine the probable cause – was it improper installation, faulty materials, or unforeseen circumstances?

- Develop a Solution: Once the cause is identified, I create a plan of action, whether it requires repair, replacement, or a combination of both.

- Communication: I provide clear, transparent communication to the client, explaining the findings and outlining the proposed solution. Realistic expectations are set to avoid future disputes.

For example, I once had a client who complained about buckling in their new vinyl flooring. Upon inspection, I discovered the subfloor wasn’t properly prepared – it was uneven, leading to stress on the vinyl. I clearly explained the issue to the client and proposed a solution involving re-leveling the subfloor before reinstalling the flooring. Transparency and clear communication resolved the situation, and the client was ultimately satisfied.

Q 19. Describe your experience with various types of underlayment for vinyl flooring.

My experience encompasses a wide range of underlayments, each with its own properties and applications. These include foam underlayments (various densities and thicknesses), rubber underlayment, cork underlayment, and even more specialized options for specific situations.

- Foam Underlayment: Provides cushioning, sound insulation, and moisture protection. The density and thickness determine its level of comfort and support.

- Rubber Underlayment: Offers excellent durability and moisture resistance, often used in high-traffic areas or areas prone to spills.

- Cork Underlayment: A natural material that provides cushioning, insulation, and moisture resistance, while also adding a level of warmth and comfort underfoot. It’s a more premium option.

The selection of underlayment is never arbitrary. It’s based on several factors, which I’ll elaborate on in the next answer.

Q 20. How do you determine the appropriate underlayment for a specific vinyl flooring installation?

Choosing the right underlayment is a critical step in ensuring the success and longevity of a vinyl flooring installation. I consider several factors when making this selection:

- Type of Vinyl Flooring: Sheet vinyl, planks, and tiles have different requirements. Thicker vinyl might not need as much cushioning.

- Subfloor Condition: An uneven subfloor requires a thicker underlayment to level it out and prevent problems like buckling or cracking. A smooth, level subfloor may only need a thin underlayment for added cushioning.

- Ambient Conditions: High humidity requires underlayment with good moisture resistance. Conversely, low humidity might allow for a more diverse selection.

- Intended Use of the Space: High-traffic areas necessitate a more durable underlayment, capable of withstanding significant wear and tear.

- Client Budget: Underlayments range widely in price. I always discuss the options with the client, emphasizing the value proposition of each choice and balancing cost with performance.

For instance, in a bathroom, I’d always recommend a moisture-resistant underlayment like rubber or a high-density foam. In a bedroom, a comfortable foam underlayment might suffice, unless there are specific concerns about sound insulation.

Q 21. What are the key differences between sheet vinyl and vinyl planks/tiles?

Sheet vinyl and vinyl planks/tiles are both popular choices, but they differ significantly in their installation and overall characteristics.

- Sheet Vinyl: Comes in large rolls, providing a seamless, unified look. It’s generally easier to install, requiring fewer seams. However, it can be more challenging to handle and install in larger rooms due to its weight and unwieldiness. Large sheets are great for creating uninterrupted expanses of color and pattern but are less forgiving of subfloor imperfections.

- Vinyl Planks/Tiles: Sold in individual pieces, offering greater design flexibility and easier installation around obstacles. Damage is more easily contained, as a single plank or tile can be replaced rather than the entire sheet. They are also more suitable for uneven subfloors because the individual pieces conform better.

Think of it this way: sheet vinyl is like painting a wall – a large, continuous surface. Planks and tiles are like putting up individual bricks – smaller, more manageable pieces, allowing for greater design options and adaptability. The choice depends on the project’s requirements, client preference, and the characteristics of the space.

Q 22. Explain the importance of maintaining clean working conditions during vinyl flooring installation.

Maintaining a clean work environment during vinyl flooring installation is paramount for several reasons. It directly impacts the quality of the final installation, the longevity of the floor, and even the safety of the installers. Think of it like baking a cake – a messy kitchen leads to a messy cake!

- Preventing Contamination: Dust, debris, and even small particles can get trapped under the vinyl, leading to uneven surfaces, bubbles, and a less-than-perfect finish. A clean floor ensures proper adhesion.

- Improved Adhesion: A clean subfloor allows for optimal bonding between the adhesive and the vinyl. This prevents lifting, peeling, and other common problems.

- Enhanced Safety: A clean workspace minimizes tripping hazards, reduces the risk of accidents with tools, and makes it easier to work efficiently and safely. A clear workspace means fewer distractions.

- Professionalism: A clean workspace reflects professionalism and care for the client’s property. It also significantly improves the overall experience for the client. It demonstrates respect for their home and project.

In practice, this means regular sweeping, vacuuming, and damp mopping before starting the installation. Protecting the existing flooring with drop cloths or other protective materials is equally crucial. Proper disposal of waste materials is also a key component of maintaining clean working conditions.

Q 23. How do you manage your time and prioritize tasks during a vinyl flooring installation project?

Effective time management is crucial for successful vinyl flooring installations. On large projects, I use a combination of planning and flexible execution to ensure timely completion.

- Detailed Planning: I always begin with a thorough assessment of the project, including measurements, material calculations, and a detailed schedule. This allows for the pre-emptive purchase of materials and minimizes delays.

- Task Prioritization: I prioritize tasks based on their dependencies. For example, subfloor preparation must be completed before vinyl installation can begin. I use tools like checklists to stay organized.

- Team Communication: On larger projects, effective communication within the team is key. Daily check-ins ensure everyone is on track and address potential roadblocks promptly. This requires clear delegation of roles and responsibilities.

- Contingency Planning: Unexpected issues, such as material defects or subfloor problems, are inevitable. Building some buffer time into the schedule minimizes stress and potential project overruns.

For example, on a recent large commercial project, we experienced a delay in material delivery. By proactively communicating with the client and readjusting our schedule, we managed to complete the project with minimal disruption, showing our ability to adapt quickly and effectively.

Q 24. Describe your experience working as part of a team on large-scale vinyl flooring projects.

I have extensive experience collaborating on large-scale vinyl flooring projects. Teamwork is essential for efficiency and quality outcomes in these projects.

- Shared Responsibility: Each team member has a specific role and responsibility, contributing to the overall project success. This may include subfloor prep, cutting and laying vinyl, and finishing tasks.

- Clear Communication: Open communication among team members is critical for identifying and resolving problems quickly. Daily briefings or meetings keep everyone aligned.

- Collaboration and Mutual Support: Team members provide support when needed, ensuring the project stays on schedule. A supportive environment encourages problem-solving and efficiency.

- Respectful Work Habits: Working in a positive and respectful environment leads to higher productivity and creates a positive outcome.

In one instance, working on a large hospital project, one team member noticed a slight inconsistency in the subfloor. By immediately communicating this to the team lead, we prevented a major problem later on. The early identification and swift collaboration saved time and costs.

Q 25. How do you ensure that the final vinyl flooring installation meets the client’s expectations and specifications?

Meeting client expectations and specifications is the cornerstone of my work. It’s about clear communication, meticulous execution, and attention to detail.

- Detailed Client Consultation: I begin by having a thorough consultation with the client, discussing their vision, preferred styles, and budget. This includes reviewing samples, discussing the project specifics, and answering questions.

- Accurate Measurements and Planning: Precise measurements are essential. Any miscalculations can lead to material waste and delays. I take multiple measurements and verify them before proceeding.

- Regular Updates and Communication: I keep clients informed throughout the process, providing regular updates on progress and addressing any concerns immediately. This maintains trust and transparency.

- Final Inspection and Feedback: Before considering the project complete, I conduct a thorough final inspection with the client, ensuring the installation meets their specifications and addressing any concerns before project sign-off.

Recently, a client was particularly concerned about the seamlessness of the transition between different flooring areas. We carefully planned the layout, employed precision cutting techniques, and used high-quality transition strips, exceeding their expectations and resulting in a stunning final product.

Q 26. What are some common mistakes to avoid during vinyl flooring installation?

Several common mistakes can significantly impact the quality of a vinyl flooring installation. Avoiding these is crucial for a long-lasting and beautiful floor.

- Improper Subfloor Preparation: This is the most common mistake. Uneven, unclean, or damp subfloors lead to bubbling, lifting, and overall poor adhesion.

- Incorrect Acclimation: Vinyl flooring needs time to acclimate to the room’s temperature and humidity before installation. Failure to do so results in expansion and contraction issues, causing problems after the installation.

- Poor Seam Alignment: Misaligned seams are visually unappealing and can cause weak points in the flooring.

- Inadequate Adhesive Application: Insufficient or uneven adhesive application results in poor adhesion and potential lifting.

- Ignoring Manufacturer’s Instructions: Always follow the manufacturer’s instructions for installation, acclimation, and adhesive use.

For example, neglecting the acclimation period can lead to significant issues down the line. The vinyl may shrink or expand, creating gaps, buckles, or even complete failure of the flooring, requiring costly repairs.

Q 27. Describe your experience with different types of seaming techniques for vinyl flooring.

Seaming techniques are crucial for achieving a seamless look in vinyl flooring installations, especially with larger areas. My experience encompasses several methods.

- Heat Welding: This is a common method for creating a strong, virtually invisible seam, especially for sheet vinyl. A special welding tool melts the edges of the vinyl together, creating a watertight seal.

- Cold Welding: This method utilizes a special adhesive to bond the seams of vinyl flooring. It’s faster than heat welding but may not be as durable in high-traffic areas.

- Seaming Tape: Seaming tapes provide a simpler and faster solution for some types of vinyl. However, the seam might be more visible, and durability may be an issue depending on the tape quality and traffic.

The choice of technique depends on the type of vinyl, the location, and the desired outcome. For instance, heat welding is preferred in areas with high moisture like bathrooms, while cold welding might be suitable for less demanding areas.

Q 28. How do you troubleshoot issues such as bubbling or lifting in a vinyl flooring installation?

Bubbling and lifting are common problems in vinyl flooring installations. Effective troubleshooting requires careful diagnosis and appropriate solutions.

- Identify the Cause: Bubbling and lifting can be caused by trapped air, inadequate adhesive, moisture underneath, or improper subfloor preparation. Careful examination is crucial.

- Small Bubbles: Small bubbles can sometimes be dealt with by carefully piercing the bubble and pressing out the air. For larger areas, more thorough action is needed.

- Lifting Edges: Lifting edges often require lifting the affected section of vinyl, cleaning the subfloor, applying additional adhesive, and firmly pressing the vinyl back down.

- Persistent Issues: If bubbling or lifting persists, it may indicate underlying problems such as a damp subfloor or poor quality adhesive. In such cases, the affected section may need to be removed and re-installed.

I recently encountered a situation where sections of vinyl were lifting in a kitchen area. After careful investigation, we determined it was caused by moisture trapped beneath the subfloor. We addressed the moisture issue before reinstalling the affected areas, resulting in a long-lasting fix.

Key Topics to Learn for Layouting and Cutting Vinyl Flooring Interview

- Understanding Room Dimensions and Shapes: Accurately measuring spaces, including irregular shapes and accounting for obstacles like doorways and columns. Practical application: Developing efficient cutting plans to minimize waste.

- Material Calculations and Waste Management: Determining the necessary amount of vinyl flooring to order, factoring in waste and considering different patterns and cuts. Practical application: Creating detailed material lists and optimizing layouts for cost-effectiveness.

- Vinyl Flooring Types and Properties: Familiarizing yourself with different types of vinyl (sheet, tile, plank), their properties (thickness, durability, installation methods), and appropriate applications. Practical application: Recommending suitable flooring options based on project requirements.

- Cutting Techniques and Tools: Mastering various cutting techniques using utility knives, rotary cutters, and specialized flooring tools. Practical application: Producing clean, precise cuts to ensure a professional finish.

- Seam Placement and Finishing: Understanding how to effectively place seams for optimal appearance and durability, and applying appropriate seam sealants. Practical application: Creating seamless transitions between flooring sections.

- Troubleshooting Common Installation Issues: Identifying and resolving problems like uneven subfloors, gaps, and pattern mismatches. Practical application: Providing solutions to maintain quality and meet project deadlines.

- Safety Procedures and Best Practices: Understanding and adhering to safety regulations related to handling cutting tools and materials. Practical application: Maintaining a safe and efficient work environment.

Next Steps

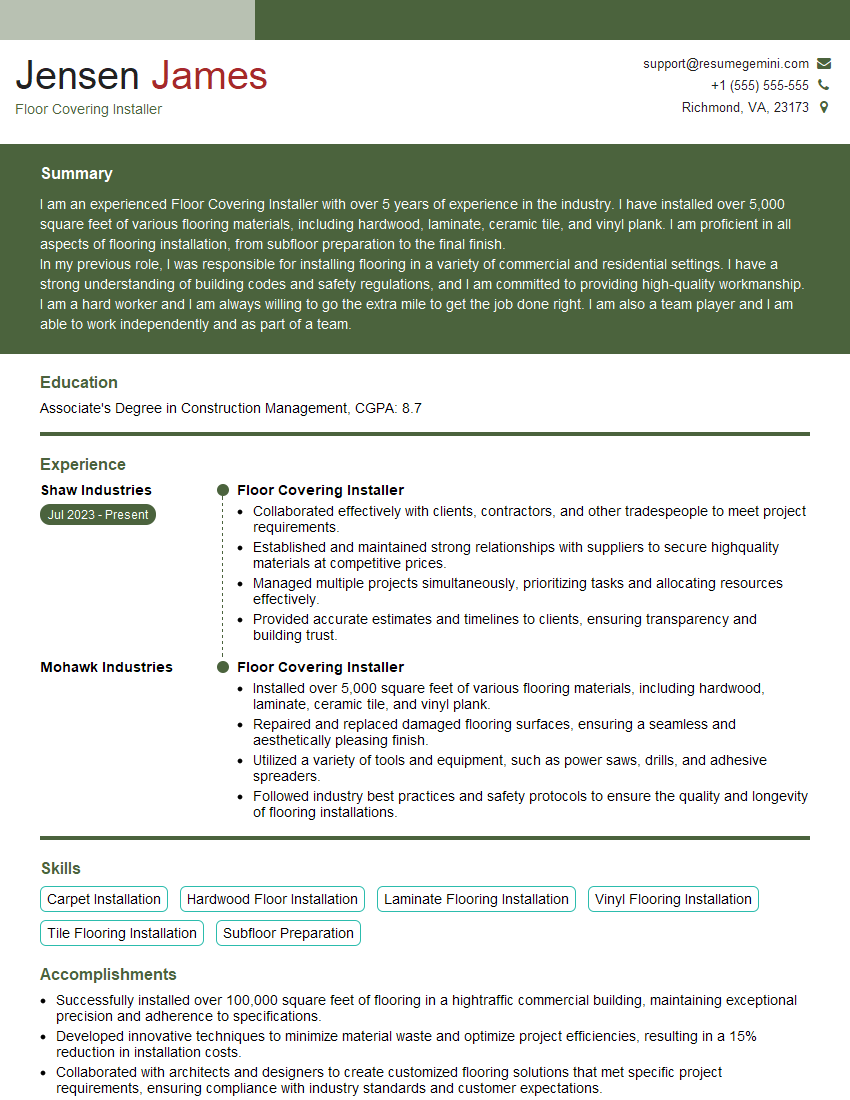

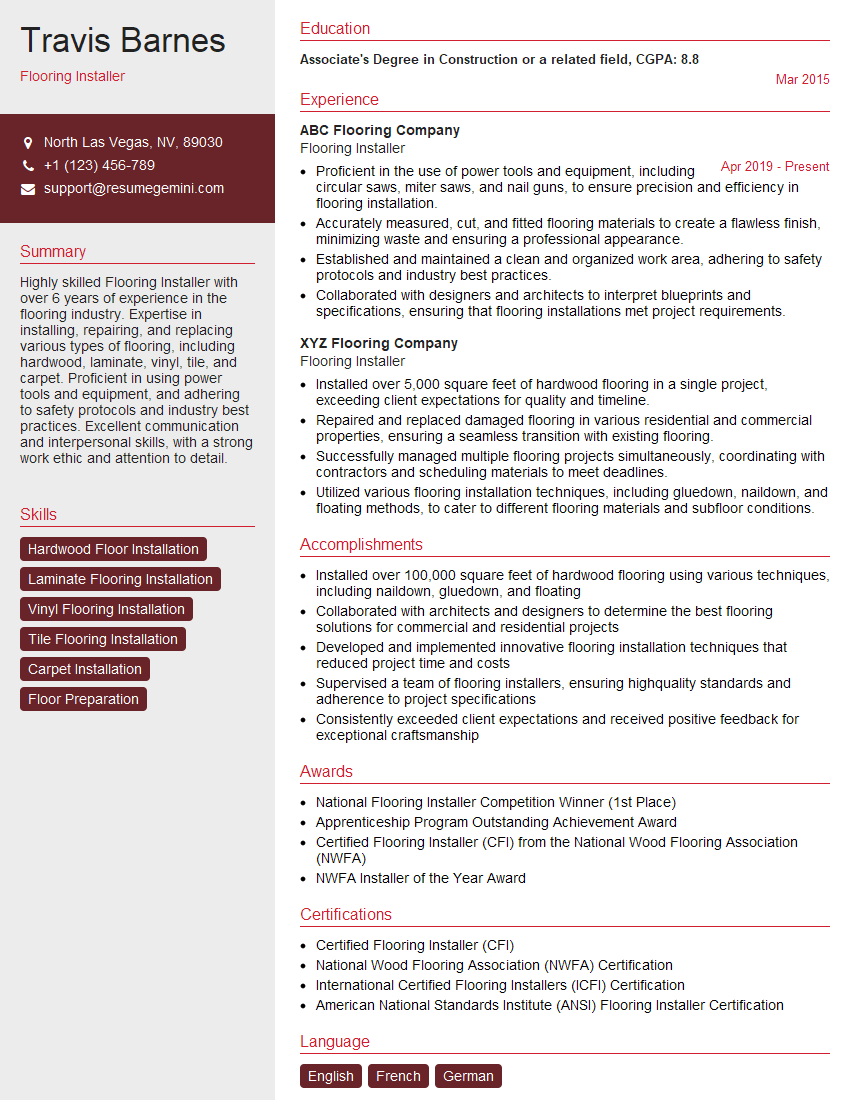

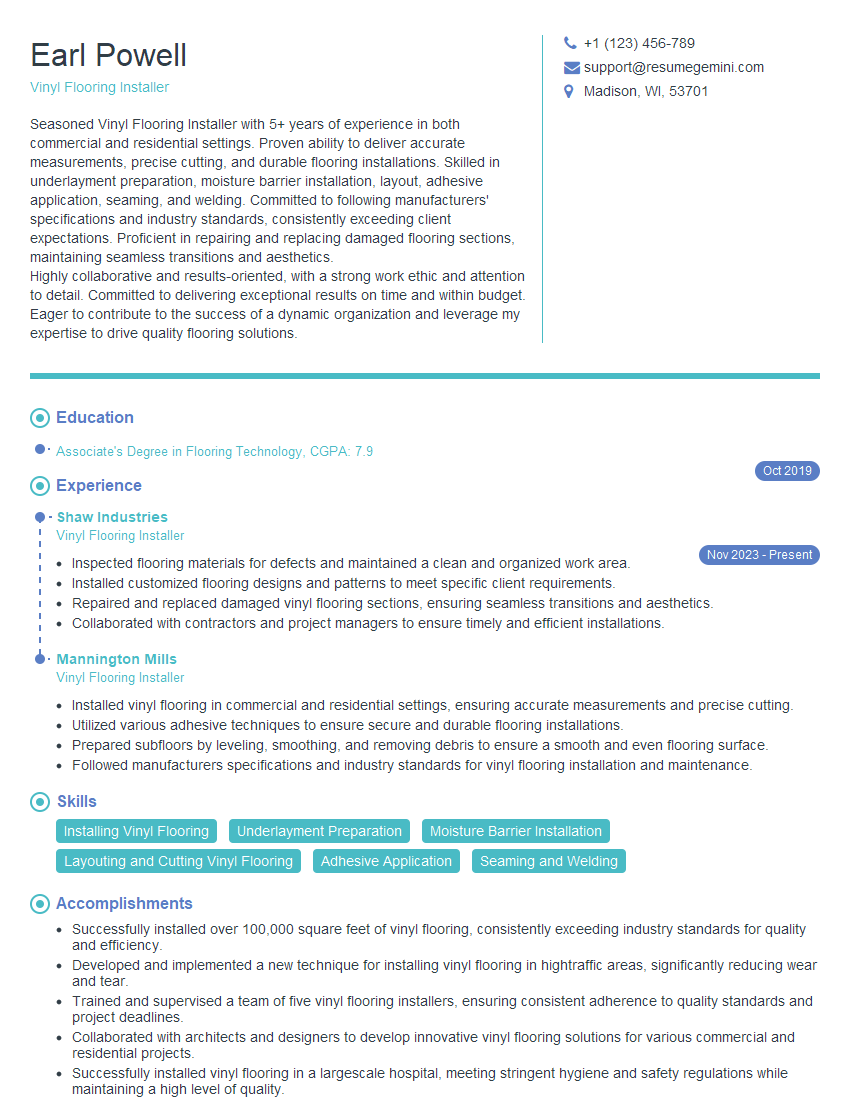

Mastering the art of laying and cutting vinyl flooring opens doors to a rewarding career with excellent growth potential. Proficiency in this skillset demonstrates attention to detail, problem-solving abilities, and practical hand-on expertise – qualities highly valued by employers. To significantly increase your job prospects, it’s crucial to create a professional and ATS-friendly resume that showcases your skills effectively. ResumeGemini is a trusted resource to help you build a compelling resume that highlights your unique qualifications. Examples of resumes tailored specifically to Layouting and Cutting Vinyl Flooring are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?