Unlock your full potential by mastering the most common Asphalt Bidding interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Asphalt Bidding Interview

Q 1. Explain the process of preparing an asphalt bidding proposal.

Preparing a competitive asphalt bidding proposal is a meticulous process requiring a deep understanding of the project, accurate cost estimation, and a clear presentation of your company’s capabilities. It’s like baking a cake – you need the right ingredients (data), the right recipe (methodology), and the right presentation (proposal).

- Thorough Plan Review: Begin with a comprehensive review of the project plans and specifications. This includes understanding the scope of work, quantities of materials needed, and the required specifications for the asphalt mix design.

- Quantity Takeoff: Accurately determine the quantities of asphalt, aggregate, emulsion, and other materials required. This often involves using specialized software (discussed later).

- Cost Estimation: Develop a detailed cost estimate, including material costs, labor costs, equipment costs, transportation, and overhead. Consider factors like fuel price fluctuations and potential material shortages.

- Risk Assessment: Identify and quantify potential risks, such as weather delays, unexpected site conditions, or material price increases. This crucial step allows for contingency planning and accurate bidding.

- Proposal Writing: Prepare a professional and well-organized proposal that clearly outlines your understanding of the project, your proposed approach, your qualifications, your pricing, and your schedule. A compelling narrative can set you apart.

- Submission: Submit the proposal according to the stipulated deadline and requirements.

For example, I once worked on a project where we identified a potential risk of encountering unstable soil subsurface. We included a contingency in our bid to account for potential excavation and stabilization costs, which ultimately helped us win the project and manage potential cost overruns.

Q 2. How do you analyze project plans and specifications for asphalt bidding?

Analyzing project plans and specifications is the cornerstone of successful asphalt bidding. It’s like a detective carefully examining clues to solve a case. A thorough analysis ensures accuracy in cost estimation and avoids costly mistakes.

- Scope Definition: Clearly define the project scope – this includes the area to be paved, the type of asphalt to be used, and any additional work such as base preparation, milling, or striping.

- Material Specifications: Carefully review the specifications for the asphalt mix design, including the type and gradation of aggregate, binder content, and performance requirements.

- Site Conditions: Analyze site conditions, such as access roads, topography, potential obstructions, and proximity to material sources. These factors influence equipment selection and transportation costs.

- Quantities and Measurements: Precisely calculate quantities of materials needed using plans, specifications, and takeoff software. Verify dimensions and calculations to ensure accuracy. This includes quantities for base materials, asphalt layers, and other necessary components.

- Timeline and Schedule: Analyze the project timeline to determine the available working days and any potential scheduling constraints.

For instance, I once noticed a discrepancy in the plan drawings regarding the depth of existing pavement. A thorough site visit confirmed the discrepancy, and incorporating the actual depth significantly changed our material estimates, preventing a potentially costly error.

Q 3. Describe your experience with different asphalt paving types and their associated costs.

My experience encompasses a wide range of asphalt paving types, each with distinct characteristics and cost implications. Choosing the right type is as important as choosing the right tool for the job.

- Hot Mix Asphalt (HMA): This is the most common type and involves mixing aggregates and asphalt binder at high temperatures. Costs vary based on aggregate type, binder grade, and plant distance.

- Cold Mix Asphalt: This uses lower temperatures and typically involves liquid asphalt. Cost-effective for smaller projects, but may have lower performance characteristics. The costs are lower, particularly for smaller projects, due to less energy intensive processes.

- Polymer-Modified Asphalt: This enhances durability and performance, increasing initial costs but potentially reducing long-term maintenance. This is common where durability and extended lifespan are paramount.

- Porous Asphalt: Designed for water drainage, this type can be more expensive due to specialized aggregate selection and mix design.

Cost differences between these types can be significant – for example, polymer-modified asphalt can cost 15-25% more than standard HMA, but its extended lifespan can offset this over time.

Q 4. How do you account for potential risks and uncertainties in your asphalt bids?

Accounting for risk in asphalt bidding is paramount. It’s like navigating a ship in stormy seas – you need to prepare for the unexpected.

- Weather Delays: Incorporate contingencies for potential weather delays, especially rain, which can significantly impact productivity. Historical weather data is essential.

- Unforeseen Site Conditions: Account for potential challenges such as unexpected subsurface conditions (rock, unstable soil), which might require extra excavation or stabilization work.

- Material Price Fluctuations: Factor in potential increases in material costs using market analysis and future price projections. Hedging strategies can mitigate these risks.

- Labor Shortages: Consider potential labor shortages and their impact on project scheduling and labor costs. This could involve using a contingency for higher labor costs or potential overtime.

- Equipment Failures: Factor in potential equipment downtime due to maintenance or repairs. This can be mitigated through regular maintenance schedules and contingency budgeting.

I once used a Monte Carlo simulation to model the probability of various risks and their impact on project costs. This allowed me to develop a more robust bid that factored in the uncertainty associated with these potential issues.

Q 5. What software or tools do you use for asphalt quantity takeoffs and cost estimation?

Technology is indispensable in asphalt quantity takeoff and cost estimation. I utilize a combination of software and tools to ensure accuracy and efficiency. It’s like having a powerful toolkit for construction.

- AutoCAD/Civil 3D: For plan review, accurate measurements, and generating digital terrain models.

- PlanSwift/CountOn: For performing quantity takeoffs, automatically calculating material quantities based on the project plans and specifications.

- Spreadsheets (Excel): For organizing cost data, calculating material costs, labor costs, equipment costs, and generating comprehensive cost breakdowns.

- Project Management Software (e.g., Primavera P6): For scheduling and tracking project progress.

Example: Using PlanSwift, I can import digital plans and automatically calculate the area of pavement, enabling precise material estimation.

Q 6. How do you develop a comprehensive cost breakdown for an asphalt project?

Developing a comprehensive cost breakdown is like creating a detailed financial roadmap for the project. It’s crucial for accurate bidding and effective project management.

- Material Costs: This includes the cost of asphalt, aggregates, emulsions, and other materials, considering transportation costs and potential price fluctuations.

- Labor Costs: This accounts for the wages and benefits of all personnel involved, including paving crews, equipment operators, and supervisors.

- Equipment Costs: This includes the cost of renting or owning paving equipment, rollers, and other machinery, including fuel and maintenance.

- Transportation Costs: This includes the costs of transporting materials and equipment to and from the project site.

- Overhead Costs: This includes indirect costs such as insurance, permits, and administrative expenses.

- Profit Margin: A reasonable profit margin is essential to ensure the project’s financial viability. It accounts for the business’s profit.

- Contingency: A percentage added to cover unforeseen costs or potential delays.

For example, I would use a spreadsheet to organize each cost category, calculate totals, and then summarize these costs for the overall bid. A clear cost breakdown increases the credibility of your bid and supports a transparent relationship with the client.

Q 7. Explain your understanding of different bidding methods (e.g., competitive, negotiated).

Understanding different bidding methods is essential for strategic bidding. Each method has its own advantages and disadvantages, and choosing the right one depends on the project and client.

- Competitive Bidding: This involves submitting a sealed bid along with other contractors, and the lowest responsible bidder typically wins. It’s a highly competitive environment requiring accurate cost estimation and aggressive yet responsible pricing.

- Negotiated Bidding: This involves direct negotiation with the owner or their representative. This allows for a more collaborative approach, and detailed discussions are possible. This can be a more flexible approach and may be used for complex or specialized projects.

- Design-Bid-Build: The owner provides complete design documents, and contractors bid on the construction based on those designs. This is the most commonly used method.

- Design-Build: The contractor is responsible for both the design and construction, offering more flexibility and integration but requiring more expertise from the bidding contractor.

In competitive bidding, even a small margin of error in your cost estimation can make the difference between winning and losing. Negotiated bidding, while potentially less competitive, allows for adjustments and clarifications, leading to a more accurate and robust project.

Q 8. How do you handle changes in scope or unforeseen circumstances during an asphalt project?

Handling scope changes in asphalt projects requires a proactive and systematic approach. It starts with a well-defined contract that includes clear clauses for change orders. When unforeseen circumstances arise – say, unexpected subsurface conditions like bedrock or unstable soil – I immediately document the issue with photos and detailed notes. Then, I communicate transparently with the client, outlining the problem, the potential impact on the schedule and budget, and proposed solutions. We work collaboratively to agree on a change order that outlines the revised scope of work, the associated costs, and the adjusted timeline. Crucially, I utilize a robust change management system, meticulously tracking all revisions, approvals, and associated documentation. This prevents disputes and ensures everyone is on the same page throughout the process. For instance, on a recent project, we encountered unexpected utility lines. We documented everything, presented options to the client (re-routing, adjusting the design, etc.), and reached a mutually agreeable change order before proceeding. This saved us time and kept the project on track.

Q 9. Describe your experience with negotiating contracts for asphalt projects.

Negotiating asphalt contracts demands a strong understanding of both the technical aspects and the business side of the project. My experience includes negotiating everything from unit price contracts to lump-sum agreements. I begin by thoroughly reviewing the client’s specifications, understanding their priorities (e.g., schedule, budget, material quality). Then, I develop a comprehensive bid that clearly outlines our costs, including materials, labor, equipment, and contingency. During negotiations, I focus on building a relationship of trust and transparency. I’m prepared to discuss potential trade-offs – for example, a slightly tighter schedule in exchange for a fixed price – and always seek mutually beneficial solutions. I’m adept at using market data and industry benchmarks to support my pricing proposals and address any client concerns. One successful negotiation involved securing a large project by offering a value engineering solution that saved the client money while meeting their quality requirements. This showcased our expertise and secured a long-term partnership.

Q 10. How do you ensure accuracy in your cost estimations for asphalt projects?

Accuracy in cost estimation is paramount for success in asphalt bidding. I use a multi-faceted approach combining detailed quantity take-offs, accurate material pricing, and realistic labor and equipment costing. I start with a thorough site investigation, meticulously measuring the area to be paved and accounting for all aspects – including excavation, base preparation, and asphalt paving. My team and I utilize specialized software for precise quantity calculations and integrate current market prices for asphalt, aggregates, and fuel. We factor in potential risks and contingencies, such as weather delays or unexpected subsurface conditions, into our cost estimates. A crucial element is historical data analysis – reviewing past projects to refine our labor and equipment cost estimations and identify potential challenges. This helps us fine-tune our models and enhance prediction accuracy. For example, by analyzing past projects, we discovered a correlation between weather patterns and productivity rates, allowing for more accurate contingency planning.

Q 11. What are some common mistakes to avoid when preparing an asphalt bid?

Several common mistakes can significantly impact the competitiveness and profitability of asphalt bids. One major error is underestimating the costs, particularly labor and equipment costs. This often stems from insufficient site investigation or inaccurate quantity take-offs. Another common pitfall is failing to account for potential risks and contingencies, leading to budget overruns. Inadequate attention to details in the bid document, like missing clauses or unclear specifications, can also cause problems later. Furthermore, overlooking permits, insurance, and other administrative costs can result in financial setbacks. Finally, submitting a bid without a thorough understanding of the project scope and the client’s requirements can lead to misunderstandings and disputes. We avoid these mistakes by having a multi-stage review process and a dedicated team focusing on quality control.

Q 12. How do you manage and track your bid progress?

Managing and tracking bid progress requires a robust system combining project management software and meticulous documentation. I use specialized software to create detailed schedules and assign tasks to team members. We track the progress of each stage of bid preparation, from site investigation and quantity take-offs to cost estimation and document review. We also maintain a centralized repository for all bid-related documents, ensuring easy access and collaboration among the team. Regular meetings are held to assess progress, identify potential issues, and make necessary adjustments. Key performance indicators (KPIs) are established and monitored to track efficiency and identify areas for improvement. For example, we use KPIs to monitor the time taken for each stage of bid preparation and identify bottlenecks in the process. This allows for proactive intervention and prevents delays.

Q 13. How familiar are you with different types of asphalt binders and aggregates?

I have extensive familiarity with various asphalt binders and aggregates, understanding their properties and their impact on pavement performance. Asphalt binders, commonly categorized by penetration grade or performance grade (PG), influence the pavement’s stiffness, durability, and resistance to cracking. I’m familiar with different PG grades and their suitability for various climatic conditions. Aggregates, the mineral component of asphalt concrete, vary widely in their source, size, shape, and gradation. I’m knowledgeable about different aggregate types – such as crushed stone, gravel, and slag – and how their characteristics affect the mixture’s strength, stability, and texture. Choosing appropriate binders and aggregates is crucial for designing pavements that meet the required performance standards and longevity. For example, I would select a high-PG binder for areas with extreme temperature fluctuations to prevent cracking, and a well-graded aggregate blend for optimal density and stability.

Q 14. Explain your understanding of compaction requirements for asphalt paving.

Compaction is crucial for ensuring the density, strength, and durability of asphalt pavements. Insufficient compaction leads to voids, making the pavement susceptible to rutting, cracking, and premature failure. I understand and adhere to project specifications and industry standards for compaction. This involves using appropriate compaction equipment, such as rollers, and achieving the required density as measured by nuclear density gauges or other approved methods. The number of roller passes, roller type (static or vibratory), and rolling pattern are carefully chosen based on factors such as asphalt mix design, lift thickness, and ambient temperature. Monitoring the compaction process, adjusting techniques as needed, and documenting all compaction data are essential to ensure the final product meets specifications. For instance, on a recent project, we carefully monitored the temperature of the asphalt mix and adjusted the rolling pattern to ensure optimal compaction despite fluctuating temperatures.

Q 15. How do you determine the appropriate equipment and labor for an asphalt project?

Determining the right equipment and labor for an asphalt project is crucial for profitability and timely completion. It’s a multi-step process involving careful analysis of the project specifications and local conditions.

- Project Scope Review: First, we thoroughly review the project plans, noting the area to be paved, thickness requirements, type of asphalt, and any special considerations like drainage or curb work. This gives us the foundation for equipment needs.

- Equipment Selection: Based on the project size, we select appropriate equipment. For smaller projects, a smaller paver and support equipment might suffice. Larger projects demand larger pavers, possibly multiple ones, along with more efficient material handling equipment like dump trucks, rollers, and milling machines. We factor in the condition of the existing road surface, which might necessitate milling before paving, thus requiring additional equipment.

- Labor Force Calculation: We then estimate the labor required. This involves determining the number of skilled operators (paver operators, roller operators, etc.), laborers for material handling and cleanup, and potentially supervisors depending on project complexity. We utilize historical data on productivity rates for each task and adjust based on anticipated site conditions (e.g., difficult terrain will require more time and potentially more labor).

- Estimating Software: I use estimating software (more on this in a later answer) that assists in optimizing equipment and labor allocation, ensuring cost-effectiveness while maintaining quality. It helps to model different scenarios and identify potential bottlenecks.

- Example: For a large highway project, we’d likely use multiple large pavers operating in tandem, numerous dump trucks, several rollers (both static and pneumatic), milling machines, and a substantial labor force, possibly including multiple crews working shifts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with subcontractors on asphalt projects.

Subcontractor management is critical in asphalt paving. I have extensive experience working with subcontractors specializing in areas like excavation, milling, curb and gutter work, and even specialized asphalt types. My approach prioritizes clear communication and strong contracts.

- Selection Process: I carefully select subcontractors based on their reputation, experience, insurance coverage, and past performance. References and safety records are thoroughly checked.

- Detailed Contracts: Contracts are meticulously drafted, specifying scopes of work, payment schedules, deadlines, insurance requirements, and dispute resolution mechanisms. This minimizes misunderstandings and potential conflicts.

- Regular Communication and Oversight: Ongoing communication is vital. Regular site visits, progress reports, and meetings ensure the subcontractor stays on track and meets quality standards. I actively address any issues promptly.

- Quality Control: Strict quality control measures are in place, including inspections at various stages of the subcontractor’s work. This assures the work meets the project specifications and my overall quality expectations.

- Example: On a recent project, we utilized a subcontractor for milling the existing road surface. Clear communication ensured that the milling depth was precisely as specified, avoiding costly delays and rework.

Q 17. How do you account for material pricing fluctuations in your asphalt bids?

Material price fluctuation is a major risk in asphalt bidding. We mitigate this by employing several strategies.

- Market Research: We continuously monitor market prices for asphalt, aggregate, and other materials using industry publications, market reports, and direct contact with suppliers. We build in a buffer to accommodate fluctuations.

- Price Escalation Clauses: We incorporate price escalation clauses into our bids, allowing for adjustments based on verifiable price changes that occur between bid submission and project commencement. These clauses usually specify a formula or method for calculating price adjustments.

- Material Price Locking: Where possible, we secure firm pricing from suppliers prior to bidding, locking in prices for a specific amount of material for a defined time period. This reduces uncertainty.

- Hedging Strategies: In certain cases, especially on large projects, we might explore hedging strategies to mitigate risk, though this often requires financial expertise beyond basic asphalt bidding.

- Example: During periods of high oil prices, we’ve successfully used price escalation clauses in our bids to protect against increased asphalt costs, thus ensuring project profitability despite these market shifts.

Q 18. What is your experience with using various estimating software (e.g., HCSS, Sage 300 CRE)?

I am proficient in using several estimating software packages, including HCSS HeavyBid and Sage 300 CRE. These tools significantly enhance accuracy and efficiency in asphalt bidding.

- HCSS HeavyBid: This software is exceptionally robust for heavy construction estimating. I utilize it extensively for creating detailed cost estimates, managing equipment costs, and tracking labor productivity. It allows for creating detailed breakdowns of costs for different aspects of a project.

- Sage 300 CRE: Sage 300 CRE provides comprehensive project management capabilities, including cost tracking and financial reporting. I often use this alongside HCSS HeavyBid to ensure seamless integration between estimating and project accounting.

- Data Management and Reporting: Both systems enable efficient management of bid data, allowing for easy comparison of bids, analysis of cost trends, and generation of comprehensive reports for clients and stakeholders.

- Integration with other tools: These systems often integrate with GPS tracking for equipment, enabling accurate cost allocation and monitoring of project progress.

- Example: Using HCSS HeavyBid, I was able to identify a potential cost savings by optimizing the sequence of operations, resulting in a more competitive bid without compromising project quality.

Q 19. How do you manage and mitigate project risks in asphalt bidding?

Risk management is crucial in asphalt bidding. We employ a proactive approach to identify, assess, and mitigate potential risks.

- Risk Identification: We start by conducting a thorough risk assessment, identifying potential problems like material price fluctuations (discussed earlier), inclement weather delays, labor shortages, unforeseen site conditions (e.g., underground utilities), and equipment malfunctions.

- Risk Analysis: Each identified risk is analyzed to determine its likelihood and potential impact on the project’s schedule and budget. This involves assigning probabilities and quantifying potential losses.

- Risk Mitigation Strategies: We then develop and implement mitigation strategies for each significant risk. For example, we can use contingency plans for weather delays, secure multiple equipment rental options to avoid equipment malfunctions, build buffer time into the schedule, and carefully review site surveys to minimize unforeseen conditions.

- Contingency Planning: Contingency reserves are built into the bid to absorb unexpected costs or delays. This helps to ensure the project’s financial viability even with unforeseen challenges.

- Example: On a project in a location prone to heavy rainfall, we added a significant contingency to account for potential weather delays and incorporated a more aggressive schedule only after incorporating the risk of rainy days into our planning.

Q 20. How familiar are you with local and state regulations related to asphalt paving?

Staying compliant with local and state regulations is paramount. I possess a thorough understanding of asphalt paving regulations in [Insert relevant state/local area]. This includes everything from environmental permits and safety protocols to pavement design specifications.

- Permitting and Approvals: I am experienced in obtaining necessary permits and approvals from relevant authorities. This includes environmental permits, traffic control permits, and any other regulatory approvals required for the specific project location.

- Safety Regulations: I ensure strict adherence to all relevant safety regulations, including those concerning worker safety, equipment operation, and traffic control. We maintain detailed safety plans, provide necessary training, and conduct regular safety inspections.

- Pavement Design Standards: We design pavements in accordance with state and local specifications, ensuring that the asphalt mix design and pavement structure meet required strength and durability standards.

- Environmental Compliance: I am familiar with environmental regulations regarding asphalt production, handling, and disposal. We maintain proper documentation and ensure compliance with all relevant environmental protection rules.

- Example: Recently, I navigated complex permitting requirements related to a project near a sensitive wetland area, ensuring full regulatory compliance without delaying the project.

Q 21. Describe your experience with value engineering in asphalt projects.

Value engineering is essential for optimizing asphalt projects. It involves finding ways to reduce costs without compromising quality or performance.

- Material Optimization: We analyze material specifications to see if alternative materials can be used without sacrificing performance. This might involve exploring different asphalt mixes or aggregate sources that are cost-effective but still meet the required specifications.

- Construction Methodologies: We investigate different construction methods to identify more efficient approaches. This can include optimizing paving sequences or using specialized equipment that increases productivity.

- Design Modifications: Working collaboratively with the client and design team, we might suggest minor design adjustments to simplify construction or reduce material quantities without significantly impacting the project’s overall functionality.

- Lifecycle Cost Analysis: We consider the long-term lifecycle cost implications of various design options, identifying options that might have slightly higher upfront costs but lead to lower maintenance costs in the future.

- Example: On a recent project, value engineering efforts identified a more efficient paving sequence and the use of a more cost-effective aggregate blend, resulting in significant savings without jeopardizing the project’s quality or durability.

Q 22. How do you prepare for and participate in bid openings?

Preparing for and participating in bid openings requires meticulous planning and precision. It’s akin to preparing for a high-stakes sporting event – you wouldn’t show up unprepared!

- Pre-Bid Meeting Attendance: I always attend pre-bid meetings. This is crucial for clarifying ambiguities in the bid documents, understanding the owner’s expectations, and networking with other potential bidders.

- Thorough Plan Review: I meticulously review the project plans and specifications, identifying potential challenges and opportunities for cost savings or value engineering. This includes careful analysis of quantities, material requirements, and potential site constraints.

- Cost Estimation: I develop a detailed cost estimate, considering all direct and indirect costs, including labor, materials, equipment, permits, and contingencies. I use various estimation techniques, such as quantity takeoff, unit pricing, and parametric estimation, to ensure accuracy. Software like HCSS HeavyBid is invaluable here.

- Bid Preparation & Submission: I prepare the bid documents accurately, ensuring they are complete, legible, and submitted on time. This involves double-checking all calculations and ensuring compliance with all submission requirements. Late bids are almost always disqualified.

- Bid Opening Attendance (Optional but Recommended): While not always mandatory, attending the bid opening allows me to observe the competitive landscape and gain insights into the pricing strategies of other bidders. This helps inform future bidding strategies.

For example, on a recent project involving a large highway resurfacing, I identified a potential opportunity to optimize the paving process, reducing both time and material costs by carefully reviewing the plans and specifications and proposing an alternative approach. This ultimately led to a more competitive bid.

Q 23. How do you maintain accurate records and documentation for asphalt bids?

Maintaining accurate records is paramount in asphalt bidding; it’s the foundation of accountability and successful project execution. Imagine trying to build a house without blueprints—chaotic and ultimately unsuccessful.

- Centralized System: I utilize a centralized digital system to store all bid-related documents, ensuring easy access and version control. This could be a cloud-based system or a dedicated project folder on a secure server.

- Detailed Documentation: Every step, from initial plan review to final bid submission, is meticulously documented. This includes copies of plans, specifications, cost estimates, material quotes, labor calculations, equipment rental agreements, and communication logs with all stakeholders.

- Version Control: All documents are version-controlled to prevent accidental overwriting or confusion. Changes are clearly marked and tracked.

- Regular Backups: Regular backups are implemented to safeguard against data loss.

- Audit Trail: A complete audit trail is maintained to track all actions taken during the bidding process. This proves invaluable during any potential disputes or inquiries.

For instance, I recently used a cloud-based system to organize all bidding documents for a large airport runway rehabilitation. This made sharing information with my team easy and facilitated real-time collaboration, saving valuable time and ensuring everyone worked from the most up-to-date information.

Q 24. Explain your experience with analyzing bid results and making adjustments.

Analyzing bid results and making adjustments is a continuous learning process; it’s about understanding why you won or lost and refining your approach for future success. Think of it as a post-game analysis in sports.

- Win/Loss Analysis: I thoroughly analyze both successful and unsuccessful bids, identifying factors contributing to each outcome. This includes examining pricing strategies, cost estimates, and the overall competitiveness of the bid.

- Market Research: I continuously monitor market conditions, material prices, and competitor activities to better understand the dynamics of the bidding environment.

- Cost Optimization: I analyze areas where costs can be reduced without compromising quality or safety. This involves negotiating better prices from suppliers, optimizing labor efficiency, and exploring alternative construction methods.

- Risk Assessment: I critically assess potential risks and develop strategies to mitigate them. This might involve incorporating contingencies into cost estimates or developing backup plans.

- Data-driven Decision Making: I rely on data-driven insights to make informed decisions regarding future bids, rather than relying solely on intuition or gut feeling.

For example, after losing a bid on a large municipal project, I analyzed the winning bid and discovered a significant difference in the labor costs. This led me to re-evaluate our labor costing methods and implement improvements to our internal processes.

Q 25. How do you prioritize different tasks and deadlines during the bidding process?

Prioritizing tasks and deadlines in asphalt bidding is crucial for success; it’s a juggling act of multiple moving parts, requiring careful coordination and time management. Think of it like conducting an orchestra – each instrument must play its part at the right time.

- Project Timeline: I create a detailed project timeline outlining all key tasks and deadlines, including plan review, cost estimation, bid preparation, and submission.

- Task Prioritization: Tasks are prioritized based on their urgency and importance, using methods like the Eisenhower Matrix (urgent/important). Critical tasks, such as cost estimating and bid preparation, receive top priority.

- Resource Allocation: Resources, including personnel and equipment, are allocated effectively to ensure timely completion of all tasks.

- Regular Monitoring: I regularly monitor progress against the timeline, identifying and addressing any potential delays proactively.

- Contingency Planning: I build contingency plans to handle unexpected delays or challenges.

For instance, on a fast-track project with a tight deadline, I prioritized the cost estimation and material procurement stages to avoid delays that could impact the overall bid submission timeline.

Q 26. How do you collaborate effectively with project teams and stakeholders?

Effective collaboration is the cornerstone of successful asphalt bidding; it involves seamless communication and coordinated efforts among various stakeholders. It’s like a team sport, where everyone plays a critical role in achieving a common goal.

- Regular Meetings: I conduct regular meetings with the project team to discuss progress, address challenges, and make informed decisions.

- Clear Communication: I maintain clear and open communication with all stakeholders, including project managers, estimators, subcontractors, and clients. I use various communication channels, including email, phone, and project management software.

- Shared Goals: I ensure that all team members understand and are committed to the project’s goals and objectives.

- Conflict Resolution: I actively participate in resolving any conflicts or disagreements that may arise during the bidding process.

- Feedback Mechanism: I establish a feedback mechanism to gather input and improve team performance.

In one instance, during a complex project, I facilitated collaborative meetings involving the project manager, estimators, and subcontractors to address concerns about material availability and scheduling. This proactive collaboration ensured we submitted a competitive and feasible bid.

Q 27. Describe your experience with the submittal process for asphalt projects.

The submittal process for asphalt projects is critical; it’s the final stage of the bidding process where accuracy and completeness are paramount. Think of it as submitting a meticulously crafted proposal—first impressions matter.

- Compliance: I ensure that all submitted documents comply with the project’s specifications and requirements, paying close attention to deadlines and formatting.

- Completeness: I carefully review all submitted documents to ensure they are complete and accurate, including all necessary permits, insurance certificates, and bonding information.

- Organization: I organize all documents logically and clearly, making them easy for reviewers to understand and evaluate.

- Electronic Submission: For many projects, electronic submission is preferred. I utilize secure online platforms or email secure attachments to adhere to this preference.

- Confirmation: I obtain confirmation of receipt from the project owner, verifying that the bid was successfully submitted.

For instance, for a recent state highway project, I ensured all submitted documents were digitally signed and timestamped for increased security and verification of submission timeline.

Q 28. How do you handle challenging situations or conflicts during the bidding phase?

Handling challenging situations or conflicts during the bidding phase requires diplomacy, problem-solving skills, and a proactive approach. It’s like navigating a complex negotiation—finding mutually beneficial solutions is crucial.

- Proactive Communication: I address any potential challenges or conflicts proactively through open communication with all stakeholders.

- Problem Solving: I utilize collaborative problem-solving techniques to find mutually acceptable solutions.

- Conflict Mediation: If conflicts arise, I mediate between involved parties to find a resolution.

- Escalation Protocol: I follow established escalation protocols to address situations that cannot be resolved at the project level.

- Documentation: I meticulously document all challenges, proposed solutions, and the resolutions achieved. This helps avoid future conflicts and provides a record for accountability.

One time, a dispute arose with a subcontractor over pricing. I successfully mediated the conflict by facilitating open dialogue and finding a compromise that satisfied both parties, ensuring the project continued on schedule without compromising overall bid competitiveness.

Key Topics to Learn for Asphalt Bidding Interview

- Estimating Costs: Understanding material costs, labor rates, equipment rental, and potential unforeseen expenses. This involves analyzing project specifications and accurately predicting resource needs.

- Project Planning & Scheduling: Developing realistic timelines, factoring in weather conditions, material delivery, and crew availability. This also includes understanding critical path analysis and risk mitigation strategies.

- Contract Negotiation & Legal Aspects: Familiarity with different contract types (lump sum, unit price, etc.), understanding payment schedules, and awareness of legal implications and risk management within the bidding process.

- Competitive Analysis & Pricing Strategies: Researching competitor bids, analyzing market trends, and developing competitive yet profitable pricing models. Understanding profit margins and break-even points is crucial.

- Technical Specifications & Compliance: Interpreting project blueprints, specifications, and ensuring adherence to local regulations and industry best practices. This includes understanding asphalt types and their applications.

- Risk Assessment & Mitigation: Identifying potential risks (e.g., weather delays, material shortages, labor disputes) and developing strategies to mitigate their impact on project timelines and budgets.

- Software Proficiency: Demonstrating competency with relevant software used for estimating, project management, and bidding (mention specific software if appropriate, but avoid branding).

Next Steps

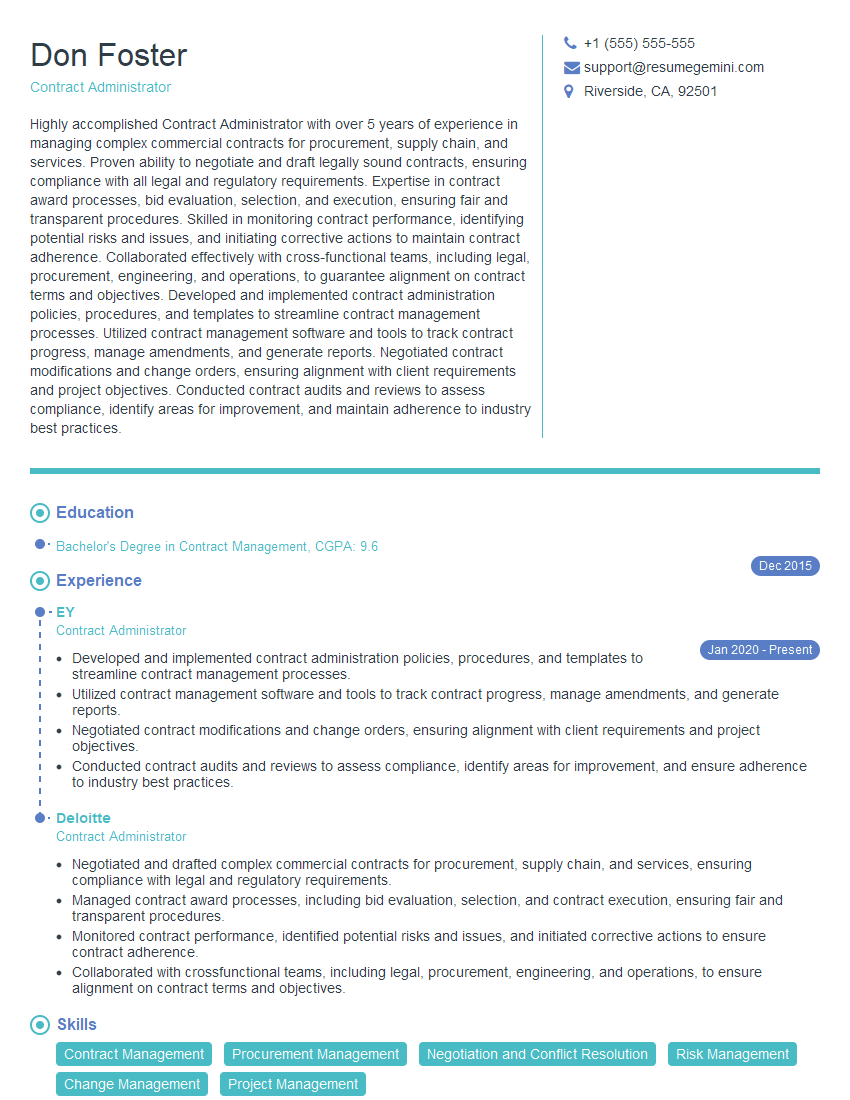

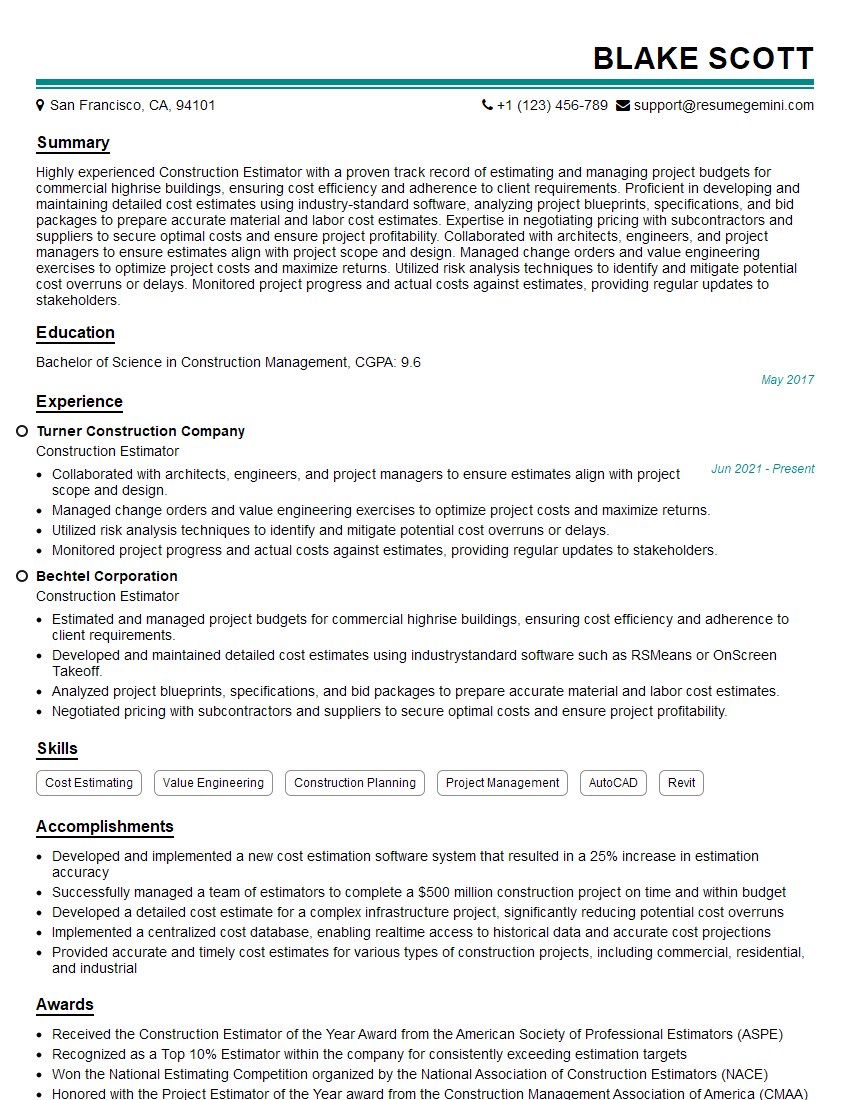

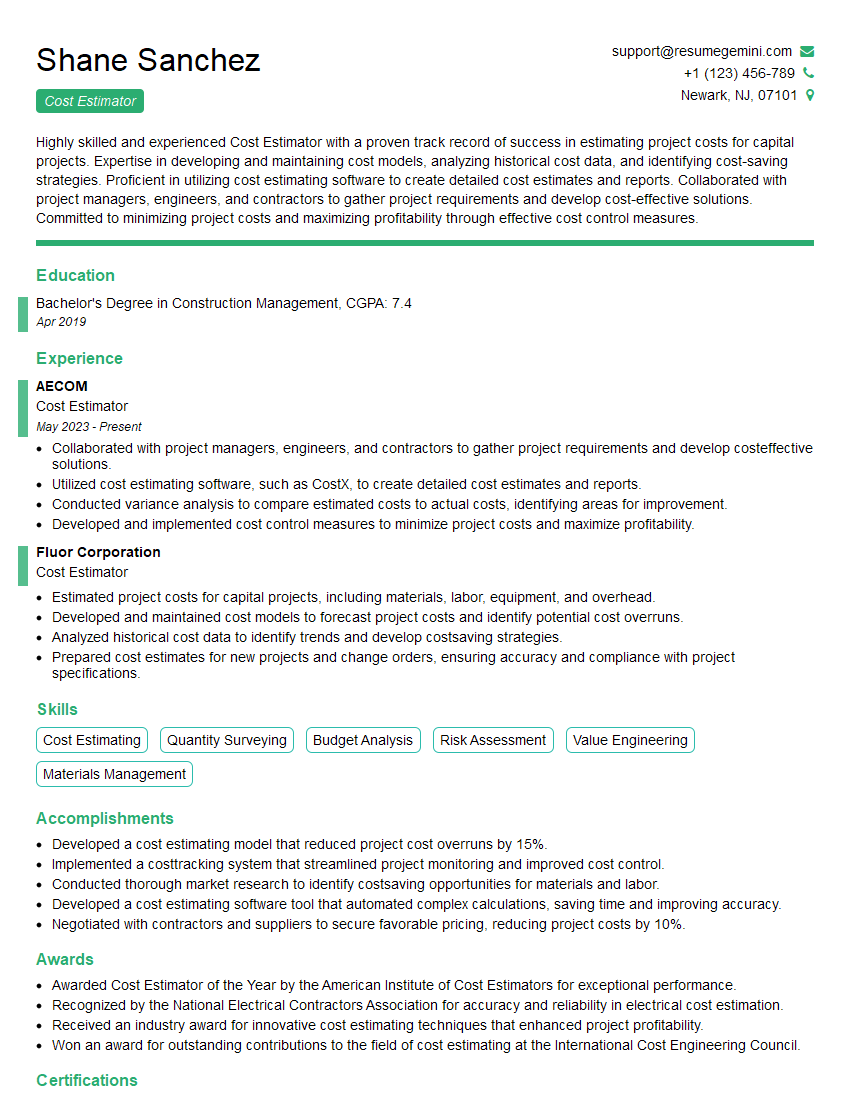

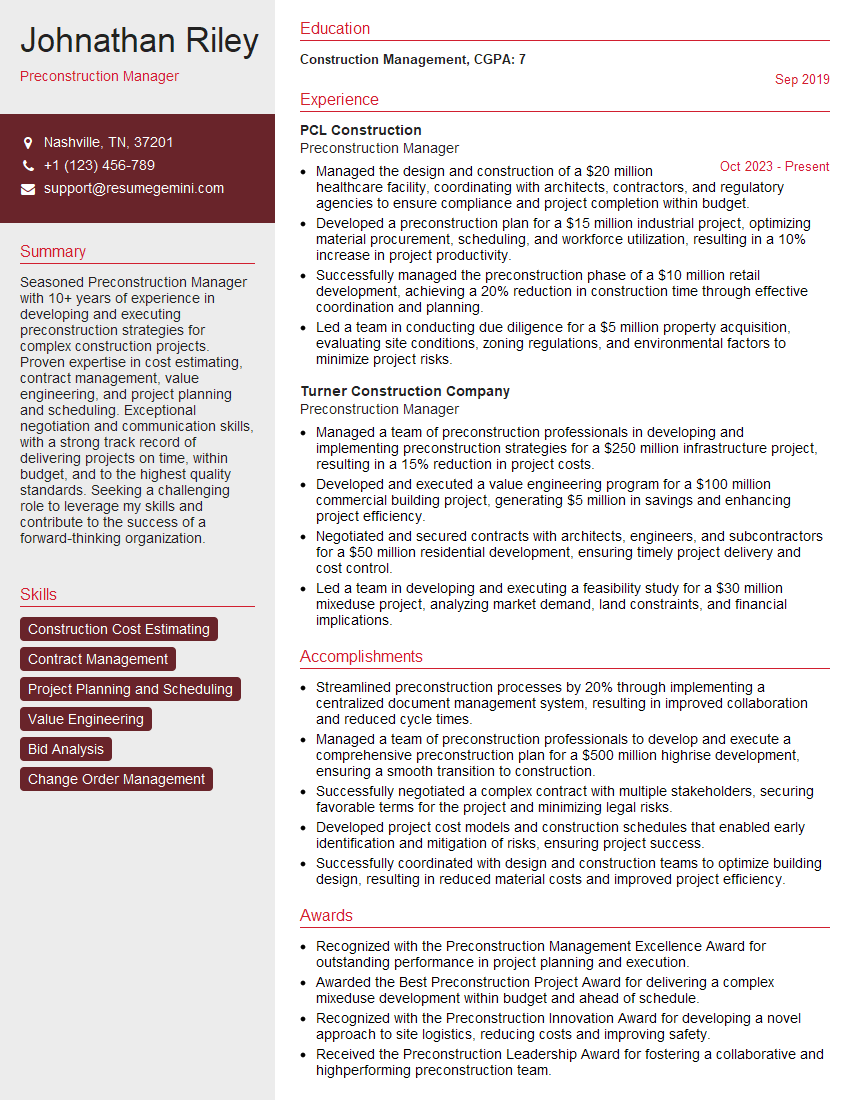

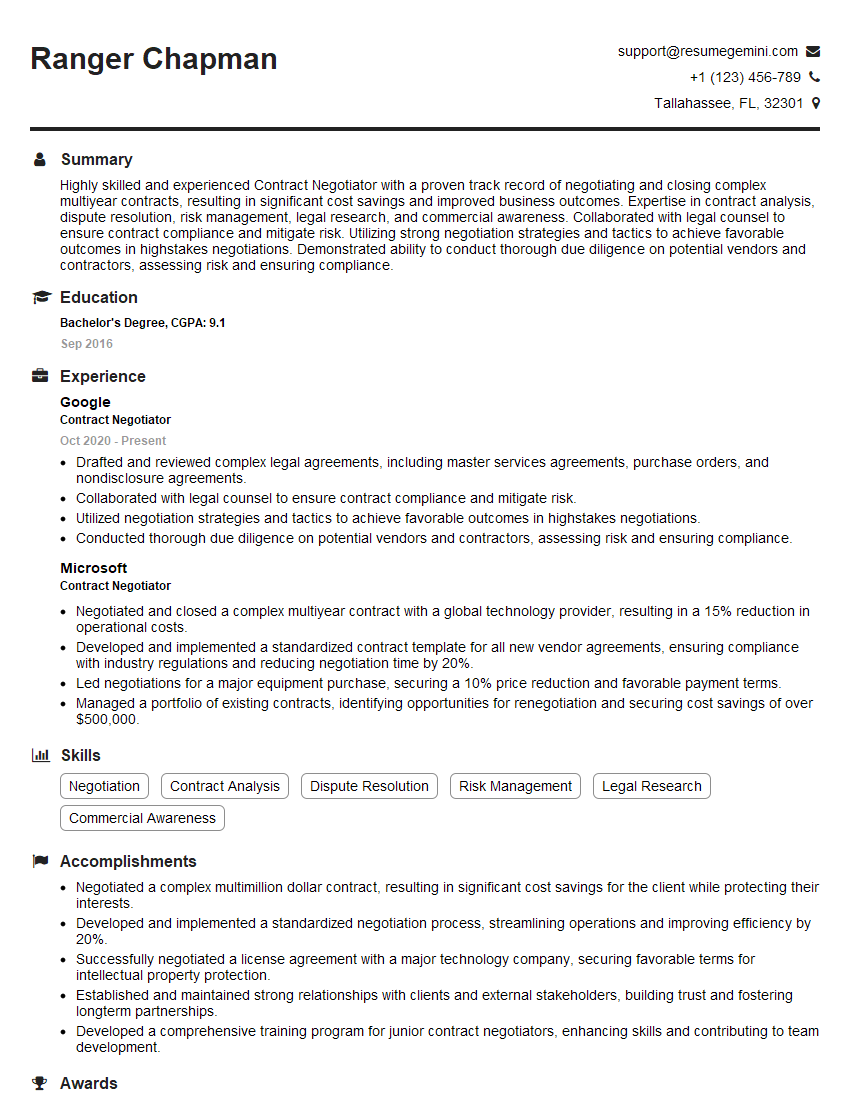

Mastering asphalt bidding opens doors to rewarding career opportunities with increased earning potential and leadership roles within the construction industry. Your expertise in accurate estimations, strategic planning, and shrewd negotiation will be highly valued. To significantly enhance your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of asphalt bidding roles. Examples of resumes crafted for this field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?