Preparation is the key to success in any interview. In this post, we’ll explore crucial Pouncing Lathe Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Pouncing Lathe Operation Interview

Q 1. Explain the principle of operation of a pouncing lathe.

A pouncing lathe, unlike a typical wood lathe, is a specialized machine primarily used in the creation of decorative patterns, particularly in the upholstery and furniture industries. Its principle of operation revolves around transferring a design from a pattern (pounce pattern) onto a workpiece (e.g., fabric, leather, or wood veneer) using a pouncing wheel or bag. The pounce pattern is typically made of paper or card stock and contains the design. Powdered chalk or other marking substance is placed within the pouncing tool and then applied across the design, leaving an imprint on the material.

Think of it like using a specialized stamp. Instead of a fixed image, the pouncing tool allows for precise transfer of a more complex, detailed design onto the workpiece. The lathe’s rotation ensures even application and prevents smudging. The rotary motion enhances the consistency and accuracy of the transfer process.

Q 2. Describe the different types of pouncing lathes you are familiar with.

While the core principle remains consistent, pouncing lathes come in various forms based on size, power source, and features. I’ve worked with several types:

- Manual Pouncing Lathes: These are smaller, hand-cranked devices, ideal for smaller projects and intricate designs. They require more manual dexterity and effort but offer excellent control.

- Electric Pouncing Lathes: These utilize electric motors for rotation, increasing speed and efficiency, particularly useful for larger workpieces and larger batches of similar items. I’ve found that these are more common in larger upholstery workshops.

- Variable-Speed Electric Pouncing Lathes: These allow for adjustable rotational speed, providing versatility to match different material thicknesses and design complexities. This is crucial for achieving the optimal transfer without damaging the material.

The choice of lathe largely depends on the scale and nature of the project. For instance, I would opt for a variable-speed electric pouncing lathe for mass-producing upholstered chair backs with intricate patterns, while a manual lathe would suffice for a smaller project like marking a decorative design onto leather.

Q 3. What safety precautions are crucial when operating a pouncing lathe?

Safety is paramount when operating any machinery, and pouncing lathes are no exception. Here are some critical safety precautions:

- Eye Protection: Always wear safety goggles to protect your eyes from flying debris or chalk dust.

- Proper Attire: Avoid loose clothing or jewelry that could get caught in the rotating parts.

- Secure Workpiece: Ensure the workpiece is securely fastened to the lathe to prevent it from flying off during operation.

- Machine Guarding: Check for and use any provided machine guarding to protect your hands from the rotating components.

- Dust Control: Use a dust collection system or work in a well-ventilated area to minimize inhalation of chalk dust, which can be irritating.

- Training and Supervision: Always receive adequate training before operating a pouncing lathe, especially if it’s an electric model. If unsure, seek supervision from an experienced operator.

A thorough safety check before each use is critical, this is something I always make a priority to avoid accidents.

Q 4. How do you identify and address common malfunctions in a pouncing lathe?

Troubleshooting pouncing lathes often involves methodical diagnosis. Here’s how I approach it:

- No Rotation: Check power supply (for electric lathes), belt tension, and motor functionality. A simple belt adjustment might solve the issue. If it is a motor issue, you’ll need to know how to troubleshoot that separately.

- Uneven Rotation: This usually points towards a problem with the drive mechanism or imbalance in the workpiece. Inspect the belt alignment and ensure the workpiece is properly centered and balanced.

- Poor Pouncing Quality: Check the amount of pounce powder in the pouncing bag, the condition of the bag itself (replace if worn), and the pressure applied during the transfer. It could also mean the pattern needs adjustment.

- Excessive Vibration: This might be a sign of loose bearings or other components. Check for looseness and tightness and consult a technician if necessary.

Keeping a detailed maintenance log and performing regular inspections can significantly reduce the likelihood of malfunctions. Remember, prevention is better than cure. I always perform a routine check before each operation.

Q 5. Explain the process of setting up a pouncing lathe for a specific job.

Setting up a pouncing lathe for a specific job involves several steps:

- Select the Correct Lathe: Choose a lathe appropriate for the workpiece size, material, and complexity of the design.

- Prepare the Workpiece: Clean the workpiece thoroughly and ensure it’s properly sized and prepared for the transfer process (e.g., stretching fabric, prepping leather).

- Secure the Workpiece: Clamp or otherwise secure the workpiece firmly to the lathe chuck ensuring stability and preventing movement during rotation.

- Prepare the Pounce Pattern: Check the pounce pattern for accuracy and any potential issues. Make any adjustments necessary.

- Load the Pouncing Bag/Wheel: Fill the pouncing bag or wheel with the appropriate type and amount of pounce powder. Chalk is common but other materials may be used based on the material being worked on.

- Adjust the Lathe Speed: Select an appropriate rotational speed based on the material’s thickness and the design’s complexity.

- Test Run: Before starting full operation, it is best to conduct a test transfer on a scrap piece of material to check the settings and the transfer quality.

- Transfer the Pattern: Gently and steadily apply the pouncing bag/wheel to the pattern, ensuring even pressure and complete transfer of the design.

Each step requires precision, and meticulous attention to detail is paramount for achieving accurate results.

Q 6. Describe your experience with different types of materials used in pouncing lathe operations.

My experience includes working with various materials on the pouncing lathe:

- Fabric: Upholstery fabrics (cotton, linen, velvet, etc.) require careful consideration of tension and pounce powder selection to avoid damage. Too much pressure on a delicate fabric, for instance, could cause tearing or stretching.

- Leather: Leather presents its own challenges. The type of leather (e.g., full-grain, top-grain) influences the appropriate pouncing technique and powder selection to avoid marking or damaging the leather’s surface. I often adjust pressure and speed.

- Wood Veneer: Thin wood veneers require extra caution. The pouncing must be gentle to avoid tearing or damaging the delicate veneer. Often, I would use a lighter pounce powder.

Material selection has a direct impact on the choice of lathe speed, pouncing technique and the type of pounce powder used. Each material requires a tailored approach to ensure the best results and prevent damage.

Q 7. How do you ensure the accuracy and precision of your work on a pouncing lathe?

Ensuring accuracy and precision in pouncing lathe operation relies on several key factors:

- Precise Pattern Making: The accuracy of the final product begins with the precision of the pounce pattern itself. Creating accurate patterns is essential.

- Proper Lathe Setup: Careful attention to workpiece clamping, rotational speed adjustment, and pouncing bag/wheel selection significantly impacts accuracy.

- Consistent Technique: Maintaining consistent pressure and speed during the pouncing process prevents uneven powder application or smudging.

- Regular Maintenance: Ensuring the lathe is well-maintained, with regular checks on bearings, belts and other mechanisms prevents inaccuracies caused by mechanical malfunctions.

- Material Selection and Preparation: Carefully selecting and preparing the workpiece material is paramount for achieving the desired accuracy.

Through consistent practice and meticulous attention to detail in each step, I’ve honed my ability to produce highly accurate and consistent results on the pouncing lathe.

Q 8. What are the key performance indicators (KPIs) for a pouncing lathe operator?

Key Performance Indicators (KPIs) for a pouncing lathe operator center around production efficiency, product quality, and safety. Think of it like this: we want to make lots of good parts, safely and quickly.

- Units Produced per Hour/Shift: This measures the operator’s speed and efficiency. A higher number indicates better performance. For example, consistently producing 150 pieces per hour shows high productivity.

- Defect Rate: This KPI tracks the percentage of flawed parts produced. A low defect rate (ideally close to zero) shows high quality control. We might aim for a defect rate below 1%.

- Machine Uptime: This reflects the percentage of time the lathe is actively producing parts. Maximizing uptime minimizes downtime due to maintenance or breakdowns. A target of 95% uptime is excellent.

- Safety Record: This is paramount. Zero safety incidents is the ultimate goal. This includes proper use of PPE (Personal Protective Equipment) and adherence to safety protocols.

- Material Waste: Minimizing material waste demonstrates efficient material handling and operational precision. Tracking waste allows us to identify and correct areas of inefficiency.

Q 9. How do you maintain and perform routine maintenance on a pouncing lathe?

Routine maintenance on a pouncing lathe is crucial for its longevity and consistent performance. It’s like regular checkups for a car – preventing small problems from becoming major ones.

- Daily Inspection: Check for loose screws, worn belts, and any unusual noises or vibrations. This is your quick daily health check.

- Weekly Lubrication: Apply lubricant to moving parts according to the manufacturer’s recommendations. Proper lubrication reduces friction and extends the life of components.

- Monthly Cleaning: Remove dust and debris from the machine to prevent overheating and malfunction. A clean machine is a happy machine.

- Quarterly Inspection: More thorough check of belts, pulleys, and bearings. This is your more in-depth health check.

- Annual Maintenance: A comprehensive service by a qualified technician, including potential part replacements and adjustments. Think of this as your annual MOT (Ministry of Transport test).

Documentation is key. I meticulously record all maintenance activities, including dates, tasks performed, and any parts replaced. This helps track maintenance history and predict potential future issues.

Q 10. Describe your experience with troubleshooting and repairing pouncing lathe issues.

Troubleshooting pouncing lathes requires a systematic approach. I’ve dealt with a range of issues, from simple malfunctions to more complex problems.

For instance, I once experienced inconsistent tooling performance. After systematically checking each component – the tooling itself, its mounting, the machine’s speed and feed settings – I discovered a slight misalignment in the toolholder. A simple adjustment resolved the problem.

Another time, the machine experienced frequent shutdowns. Through careful diagnostics and checking the electrical system, I found a loose wire in the control panel causing intermittent power failures. This was promptly repaired.

My approach always involves:

- Safety First: Power down the machine before any troubleshooting.

- Visual Inspection: Look for obvious signs of problems such as loose connections, damaged parts, or unusual wear.

- Systematic Testing: Test individual components one by one to isolate the problem.

- Documentation: Keep thorough records of the troubleshooting process and the solution implemented.

Q 11. How do you handle unexpected issues or emergencies during pouncing lathe operation?

Handling unexpected issues demands quick thinking and a calm approach. Think of it like a firefighter – you need to assess the situation quickly and act decisively.

My priority is always safety. If a safety hazard is present, such as a fire or leaking fluid, I immediately shut down the machine and evacuate the area. I then follow established emergency procedures.

For less critical issues, I’ll assess the problem, attempt a quick fix if possible (while ensuring safety), and if I’m unable to resolve it quickly, I’ll contact maintenance or my supervisor for assistance. Clear communication is critical in these situations.

Having a pre-planned emergency procedure and good communication significantly aids my response to unexpected events.

Q 12. What are the different types of tooling used in pouncing lathe operations?

Tooling in pouncing lathe operations varies depending on the material being processed and the desired finish. It’s like having a toolbox with different tools for different jobs.

- Cutting Tools: These tools remove material from the workpiece. Examples include various types of lathe bits, designed for different cuts and materials. The choice depends on the material’s hardness and the desired surface finish.

- Forming Tools: Used to shape the workpiece. These might include specialized dies or punches depending on the application of the pouncing lathe.

- Finishing Tools: These create the final surface finish. Examples include polishing wheels or brushes.

- Holding Fixtures: These are crucial for securely holding the workpiece during the process. Chucks, faceplates, and specialized jigs are examples.

Q 13. Explain the process of changing tooling on a pouncing lathe.

Changing tooling on a pouncing lathe requires precision and care to avoid damage to the machine or the operator. It’s similar to changing the bits on a drill – the process needs to be precise.

- Power Down: Always ensure the lathe is completely powered down and disconnected before attempting to change tooling.

- Secure Tooling: Use the correct tools and procedures to securely remove the existing tooling. This often involves loosening clamps or bolts.

- Clean Mounting Surfaces: Clean any mounting surfaces to ensure a secure fit for the new tool.

- Install New Tooling: Carefully install the new tooling, ensuring it’s properly aligned and securely fastened.

- Safety Check: Before restarting the machine, visually inspect the tooling to ensure it’s correctly mounted and there are no loose parts.

- Test Run: Perform a test run at a low speed to check for any vibrations or misalignments before commencing full operation.

Q 14. How do you ensure the quality of the finished product produced on a pouncing lathe?

Ensuring the quality of the finished product involves meticulous attention to detail throughout the entire process. It’s like baking a cake – every step matters.

- Material Selection: Using high-quality raw materials is fundamental. Poor-quality materials will always result in a poor-quality product.

- Tooling Condition: Sharp, properly maintained tooling is essential for producing accurate, smooth parts. Dull tools produce inconsistent results.

- Process Control: Monitoring machine parameters (speed, feed rate, etc.) is crucial. Consistent parameters ensure consistent output.

- Regular Inspections: Periodically inspecting the workpiece during the operation helps identify and correct defects early on. Early detection prevents major rework.

- Final Inspection: A thorough inspection of the finished product ensures it meets specified dimensions, tolerances, and surface finish requirements.

Utilizing measuring tools like calipers and micrometers, and adhering to strict quality control standards are essential in ensuring only the highest-quality products leave the pouncing lathe.

Q 15. Describe your experience with using different types of lubricants and coolants in pouncing lathe operations.

Selecting the right lubricant and coolant is crucial for efficient and safe pouncing lathe operation. The choice depends heavily on the material being machined and the specific operation. For instance, when working with softer metals like aluminum, a water-soluble coolant is often preferred to prevent excessive heat buildup and improve surface finish. This type of coolant offers excellent cooling and lubricity, reducing friction and preventing tool wear. However, for harder materials such as hardened steel, a heavier-duty, oil-based lubricant might be necessary to provide adequate lubrication and prevent tool chipping.

My experience includes working with various coolants, from synthetic coolants designed for specific alloys to traditional mineral oil-based lubricants for demanding applications. I always carefully consult the material’s specifications and the manufacturer’s recommendations to ensure optimal results and prevent damage to the workpiece or the machine. For example, using a water-soluble coolant on a porous material could lead to absorption and staining. Conversely, using a mineral oil on a material prone to corrosion could be detrimental. Proper disposal of spent coolants is also a key part of my process, ensuring environmental compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret blueprints and technical drawings related to pouncing lathe operations?

Interpreting blueprints and technical drawings is fundamental to accurate pouncing lathe operation. I approach it systematically, starting with a comprehensive review of the overall design, noting dimensions, tolerances, material specifications, and surface finishes. I pay close attention to details like the specific lathe setup instructions and any special notes or annotations that may be included. I use a combination of digital tools and traditional measurement techniques to ensure precise replication of the design. For example, I might use a digital caliper to verify dimensions against the blueprint, ensuring the workpiece conforms to the specified tolerances. I’m proficient in reading various types of technical drawings, including orthographic projections, isometric views, and detailed sectional drawings, translating these 2D representations into a 3D understanding for effective machining.

Q 17. Explain your understanding of the relationship between speed, feed, and depth of cut in pouncing lathe operations.

The relationship between speed, feed, and depth of cut is a critical aspect of pouncing lathe operation. It’s a delicate balance that directly impacts surface finish, tool life, and the overall efficiency of the process. Speed refers to the rotational speed of the workpiece; feed relates to the rate at which the tool advances into the workpiece; and depth of cut defines how much material is removed with each pass.

Increasing speed generally improves material removal rate, but it can also lead to excessive heat generation and reduced tool life. Similarly, a higher feed rate increases productivity but risks a rougher surface finish and potential tool damage. A deeper depth of cut means more material removal per pass, increasing productivity but potentially increasing stress on both the tool and the machine. Finding the optimal combination requires experience and careful consideration of factors such as material hardness, tool geometry, and desired surface finish. Think of it like baking a cake; you need the right temperature (speed), the right amount of ingredients (feed), and the right pan size (depth of cut) to achieve a perfect result.

Q 18. Describe your experience with using measuring instruments to check the accuracy of your work.

Accuracy is paramount in pouncing lathe operations. I routinely use a variety of measuring instruments to ensure the precision of my work. These include dial calipers for precise measurements of dimensions, micrometers for even finer tolerances, and height gauges for vertical measurements. I also use surface roughness gauges to verify surface finish requirements. Regular calibration of these instruments is essential to maintain accuracy.

For example, after machining a component, I might use a dial caliper to measure its diameter, comparing the result to the blueprint specifications. If any discrepancies exist, I’ll investigate the root cause and make any necessary adjustments before proceeding. My meticulous approach ensures that the final product meets the required quality standards.

Q 19. How do you maintain a clean and organized work area around a pouncing lathe?

Maintaining a clean and organized work area is vital for safety and efficiency. Around the pouncing lathe, I follow a strict system of organization. All tools are neatly stored in designated locations, and cutting fluids are handled and disposed of according to safety regulations. Workpieces are kept separate from finished parts, reducing the risk of accidental damage or misidentification. Regular cleanup removes chips and debris, preventing accidents and ensuring the machine’s smooth operation. This organized workspace contributes not only to efficiency but also to a safer work environment for myself and my colleagues.

Q 20. Describe your experience with working in a team environment in a pouncing lathe operation setting.

Teamwork is essential in a pouncing lathe operation setting. I’ve consistently worked collaboratively with machinists, engineers, and quality control personnel. Effective communication is key – keeping team members informed about progress, challenges, and any potential issues is vital for efficient workflow. We frequently discuss optimal machining strategies, troubleshoot problems, and share best practices. For example, if a particular component proves challenging to machine, I’ll collaborate with the engineering team to explore alternative designs or machining approaches. This collaborative spirit fosters a supportive and productive work environment, ensuring everyone contributes to meeting project objectives.

Q 21. How do you manage your time effectively while operating a pouncing lathe?

Effective time management during pouncing lathe operation requires planning and prioritization. I typically start by carefully reviewing job orders, noting deadlines and required specifications. This allows me to estimate the time needed for each task and prioritize accordingly, focusing on the most critical tasks first. I also utilize lean manufacturing principles to identify and eliminate waste, streamlining processes for maximum efficiency. Throughout the operation, I track my progress against the planned schedule, making adjustments as necessary. This proactive approach, coupled with a commitment to efficient workflows, allows me to consistently meet deadlines while maintaining high quality standards.

Q 22. How do you prioritize tasks while operating a pouncing lathe?

Prioritizing tasks on a pouncing lathe hinges on understanding the job order, material properties, and deadlines. I typically employ a system that combines urgency and importance.

- Urgent and Important: These are tasks with immediate deadlines and potential for significant impact if delayed, like fulfilling a rush order for a critical component. These take precedence.

- Important but Not Urgent: These tasks are crucial for long-term production efficiency or quality control, such as preventative maintenance on the lathe itself. I schedule these strategically to avoid last-minute rushes.

- Urgent but Not Important: These might be small, immediate requests that don’t significantly affect the overall workflow. I prioritize these based on their impact on the schedule of more important tasks.

- Neither Urgent nor Important: These tasks are often administrative or less critical. I delegate these whenever possible or schedule them during periods of lower production workload.

For instance, if I have a tight deadline for a complex pouncing job and a routine cleaning scheduled, I’ll complete the complex job first. The cleaning, while important for maintenance, can be postponed slightly if absolutely necessary.

Q 23. Describe your experience with using CNC controls on a pouncing lathe (if applicable).

While traditional pouncing lathes are largely manual, I’ve had extensive experience with CNC-controlled auxiliary equipment in conjunction with pouncing lathe operations. This includes CNC-controlled polishing machines and CNC-driven material handling systems. My experience specifically involves programming and operating CNC units to perform precise tasks like pre-pouncing shaping, post-pouncing finishing, and accurate material cutting and feeding.

For example, I’ve used CNC milling machines to create precise jigs for holding components during the pouncing process, ensuring consistent results and reducing manual setup time. I’m proficient in interpreting G-code and adapting programs to accommodate varying material properties and pounced surface requirements.

Q 24. How do you handle quality control issues arising during pouncing lathe operations?

Quality control on a pouncing lathe is crucial. My approach involves proactive measures throughout the process, along with reactive adjustments based on identified issues.

- Pre-Pouncing Checks: I inspect the raw material for defects, ensuring it meets the required specifications. This includes checking for consistent thickness, texture, and freedom from flaws.

- In-Process Monitoring: During pouncing, I continuously monitor the lathe’s performance and the evolving surface of the workpiece, making adjustments to speed, pressure, and tool position as needed. I utilize precision measuring instruments to ensure the pounced surface is within acceptable tolerances.

- Post-Pouncing Inspection: After pouncing, a thorough examination of the finished product is carried out using optical and tactile methods to detect any imperfections. This may involve magnification to assess surface quality. Documentation of these inspections is crucial.

- Corrective Actions: If defects are found, I investigate their root cause – whether it’s material flaws, improper lathe settings, or operator error. Corrective actions are then implemented, which might involve adjustments to the pouncing process or rejecting substandard material. I maintain detailed records of any quality control issues encountered and corrective actions taken.

For instance, if I notice a consistent pattern of surface imperfections, I would review my setup, machine calibration, and material properties to identify the cause, and adjust accordingly.

Q 25. Describe your problem-solving skills related to pouncing lathe operation.

Problem-solving on a pouncing lathe requires a methodical approach and a strong understanding of the underlying mechanics. My strategy typically involves:

- Problem Definition: Clearly identifying the issue, whether it’s a performance problem, a quality defect, or a machine malfunction. Is the pounced surface uneven? Is the machine vibrating excessively? Is the material tearing?

- Data Gathering: Collecting relevant data – production logs, machine readings, visual inspections – to understand the context of the problem.

- Hypothesis Generation: Developing potential explanations for the problem. Is it a tool issue? A machine setting problem? Material-related?

- Testing and Validation: Systematically testing each hypothesis to determine its validity. This might involve making incremental adjustments to the machine settings, replacing tooling, or adjusting the material.

- Solution Implementation: Once a solution is validated, implementing it while carefully documenting the steps taken.

- Monitoring and Prevention: After implementing the solution, I monitor the situation to ensure the problem doesn’t recur. I also put measures in place to prevent similar issues in the future, including improved training and preventive maintenance routines.

For instance, if the pounced surface is consistently too shallow, I might systematically check the pressure settings, the tool condition, and the material’s hardness to find the root cause and implement the appropriate solution.

Q 26. Explain your understanding of health and safety regulations related to pouncing lathe operations.

Health and safety regulations are paramount in pouncing lathe operations. My understanding covers a broad range of areas, including:

- Personal Protective Equipment (PPE): Consistent use of safety glasses, hearing protection, and appropriate clothing to prevent injury from flying debris, noise, and potential contact with moving parts.

- Machine Guarding: Ensuring all machine guards are in place and functioning correctly to prevent accidental contact with moving parts.

- Emergency Stop Procedures: Knowing the location and operation of emergency stop buttons and following established procedures in case of equipment failure or accidents.

- Lockout/Tagout Procedures: Following proper lockout/tagout procedures before performing any maintenance or repairs on the lathe to prevent accidental start-ups.

- Ergonomics: Maintaining proper posture and work practices to prevent musculoskeletal injuries.

- Material Handling Safety: Using proper lifting techniques and equipment to prevent injuries from handling heavy materials.

- Housekeeping: Maintaining a clean and organized work area to prevent accidents caused by tripping hazards or cluttered surroundings.

I am also familiar with relevant OSHA or equivalent workplace safety regulations and actively participate in safety training programs.

Q 27. How do you contribute to a safe and efficient work environment in a pouncing lathe operation?

Contributing to a safe and efficient work environment involves a multifaceted approach:

- Proactive Safety Checks: Regularly inspecting the lathe and its surroundings for potential hazards, addressing issues promptly and reporting them to supervisors.

- Following Safety Procedures: Adhering strictly to all safety guidelines and regulations, setting a positive example for colleagues.

- Teamwork and Communication: Communicating effectively with colleagues about any safety concerns or potential hazards. Working collaboratively to maintain a safe environment.

- Maintaining Cleanliness: Keeping the work area clean, organized, and free of obstructions to prevent accidents.

- Participating in Safety Training: Actively participating in safety training programs to stay up-to-date on best practices and new regulations.

- Reporting Accidents and Near Misses: Immediately reporting any accidents or near misses to supervisors to facilitate investigation and corrective actions.

For example, I’ve proactively identified and reported a worn-out safety guard on the lathe before it posed a significant risk, preventing a potential accident.

Q 28. Describe your experience with different types of pouncing lathe applications.

My experience with pouncing lathe applications encompasses a wide range of materials and products:

- Metal Pouncing: Working with various metals, including steel, aluminum, and brass, to create textured surfaces for decorative or functional purposes.

- Wood Pouncing: Using pouncing lathes to create unique patterns and textures on wood components, enhancing their aesthetic appeal.

- Plastic Pouncing: Applying pouncing techniques to plastics to achieve specific surface finishes or textures, often for customized components.

- Composite Pouncing: Working with composite materials to create unique surface patterns and designs in applications ranging from aerospace to automotive industries.

Each material requires a specific approach, including adjustments to the lathe’s speed, pressure, and tooling selection. My experience includes adapting the pouncing process to the unique requirements of each material to achieve optimal results.

Key Topics to Learn for Pouncing Lathe Operation Interview

- Machine Operation & Safety: Understanding the mechanics of the pouncing lathe, including its various components and functions. Safe operating procedures and emergency protocols are crucial.

- Material Handling & Selection: Proper techniques for loading, unloading, and handling materials specific to pouncing lathe operations. Knowledge of different material properties and their impact on the process.

- Quality Control & Inspection: Techniques for inspecting finished products for defects and ensuring they meet required specifications. Understanding quality control metrics and procedures.

- Troubleshooting & Maintenance: Identifying common issues and malfunctions, performing basic maintenance tasks, and knowing when to seek assistance from supervisors or maintenance personnel.

- Precision & Accuracy: Understanding the importance of precision in pouncing lathe operations and the techniques used to achieve high accuracy in the finished product.

- Production Efficiency & Optimization: Strategies for maximizing output while maintaining quality and adhering to safety regulations. Understanding production targets and workflow optimization.

- Understanding Process Parameters: Knowledge of the various settings and parameters that affect the pouncing lathe’s operation, such as speed, feed rate, and depth of cut. Knowing how to adjust these parameters to achieve desired results.

Next Steps

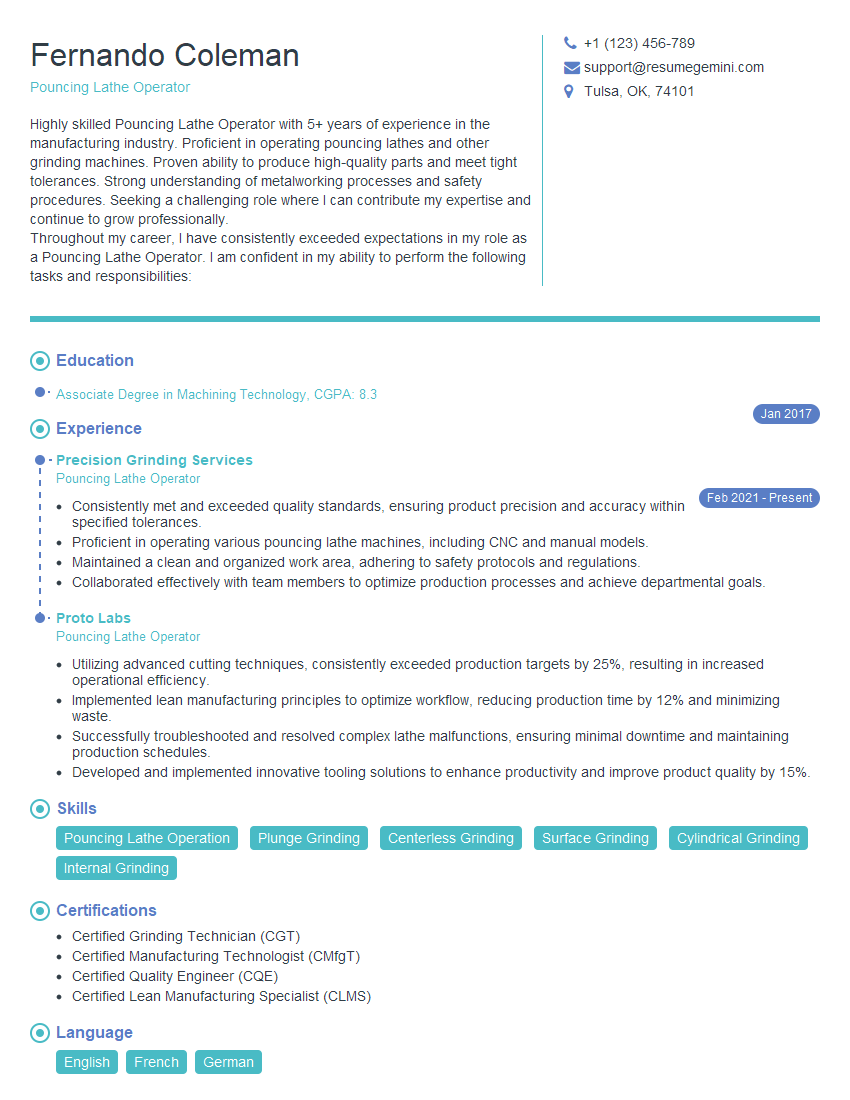

Mastering Pouncing Lathe Operation opens doors to rewarding careers in manufacturing and precision engineering, offering opportunities for advancement and specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, highlighting your skills and experience in pouncing lathe operation. Examples of resumes tailored to this specific field are available, providing valuable guidance and inspiration for crafting your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?