Preparation is the key to success in any interview. In this post, we’ll explore crucial Furniture Touch-Up interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Furniture Touch-Up Interview

Q 1. What types of wood finishes are you familiar with (e.g., lacquer, polyurethane, shellac)?

I’m familiar with a wide range of wood finishes, each with its unique properties and requiring specific touch-up techniques. These include:

- Lacquer: A fast-drying, hard finish known for its durability and high gloss. It’s often used on high-end furniture but can be challenging to repair due to its hardness.

- Polyurethane: A popular choice for its durability and water resistance, offering both gloss and satin finishes. It’s relatively easy to touch up, especially in its water-based varieties.

- Shellac: A natural resin-based finish, creating a warm, amber tone. It’s a more delicate finish compared to lacquer or polyurethane and requires careful handling during touch-ups.

- Varnish: Similar to polyurethane in terms of durability, varnish offers a range of sheens from high gloss to matte. Repairing varnish often involves careful blending to avoid noticeable patches.

Understanding the specific finish is crucial for successful touch-ups, as using the wrong product can lead to an uneven or noticeable repair.

Q 2. Describe your experience with color matching techniques for furniture touch-ups.

Color matching is an art form in furniture touch-ups. It’s rarely a perfect match, but a skilled approach minimizes discrepancies. My process usually involves:

- Visual Assessment: Carefully examining the damaged area and the surrounding finish in different lighting conditions to identify the nuances of color and sheen.

- Sample Testing: If possible, I’ll test small amounts of stain or finish on an inconspicuous area to ensure a close match before applying it to the damaged area. This prevents larger mistakes.

- Mixing Techniques: I often need to mix different stains or tints to achieve the precise color needed. I start with a slightly lighter shade and gradually darken it until it blends seamlessly.

- Using Color Charts and Tools: While not always perfect, color charts and digital color-matching tools are invaluable in achieving close color approximations.

For example, I once had to repair a small chip on an antique cherry table. The cherry’s color had darkened with age, requiring me to mix several different stains to replicate the multi-tonal depth of the original finish.

Q 3. How do you prepare a wood surface for touch-up, including sanding and cleaning?

Proper surface preparation is paramount for a successful touch-up. This process generally involves:

- Cleaning: First, I thoroughly clean the surface with a tack cloth or a slightly damp cloth to remove dust, dirt, and any loose particles. This ensures better adhesion of the finish.

- Sanding: I gently sand the surrounding area of the damage to feather the edges of the imperfection. This creates a smooth transition between the old and new finish, minimizing the visibility of the repair. I use progressively finer grits of sandpaper (e.g., 180, 220, and 320), following the wood grain to avoid scratches.

- Vacuuming and Cleaning: After sanding, I meticulously remove all sanding dust with a vacuum cleaner and a tack cloth to ensure the surface is completely clean. Any remaining dust will interfere with the adhesion of the finish.

Careful sanding and cleaning are crucial. Rushing this step often results in a noticeable repair, no matter how well the finish is applied.

Q 4. What are the different methods for applying stain to furniture?

Several methods exist for applying stain, each with its advantages and disadvantages:

- Brush Application: This allows for good control and is ideal for smaller areas or intricate details. It requires a high-quality brush and careful technique to avoid brush strokes.

- Cloth Application: Applying stain with a clean cloth results in a more even and less textured finish. This is especially suitable for larger areas and helps avoid brush marks.

- Spray Application: A spray gun allows for a very even finish, especially for larger pieces. This method requires practice to avoid drips and runs, and appropriate ventilation.

- Rag Rubbing: Applying stain using a rag and wiping off excess results in a more antique or distressed look, excellent for certain styles.

The chosen method should depend on the size of the area being stained, the desired finish, and the skill level of the applicator.

Q 5. Explain your process for repairing minor scratches and dents in wood furniture.

Repairing minor scratches and dents involves a methodical approach:

- Clean the Area: Thoroughly clean the damaged area.

- Fill Dents: For dents, I use wood filler that closely matches the wood’s color. I apply it sparingly, let it dry completely, and sand it flush with the surrounding surface.

- Fill Scratches: For scratches, a wood filler may not be necessary if they are superficial. A colored wax stick or scratch concealer might be sufficient.

- Sand Smoothly: Once the filler is dry, I carefully sand the area with progressively finer grits of sandpaper, blending the repair seamlessly.

- Apply Finish: After sanding, I apply a thin coat of finish matching the existing finish. I may use multiple thin coats to build up the finish, allowing each coat to dry completely before applying the next.

- Buff and Polish: Finally, I buff and polish the repaired area to achieve a smooth, even finish.

For example, a shallow scratch on a lacquered surface might only need careful sanding and a touch of matching lacquer, while a deeper dent in solid oak might require wood filler, sanding, and possibly several coats of stain and finish.

Q 6. How do you handle repairs on various wood types (e.g., oak, cherry, mahogany)?

Different wood types require slightly different approaches, mainly due to their varying densities and grain patterns:

- Oak: Known for its hardness, oak requires careful sanding to avoid scratches. The open grain structure may necessitate grain filling before staining.

- Cherry: A softer wood with a beautiful reddish-brown color. Cherry can be more easily damaged, and the repair must carefully match its rich tones.

- Mahogany: A luxurious, dense hardwood that takes stain beautifully. It requires precision during sanding and finishing to maintain its elegant appearance.

The key is understanding the wood’s properties. For example, a deep scratch in oak might need a more robust filler than a similar scratch in cherry.

Q 7. Describe your experience with working with different types of furniture finishes (e.g., gloss, satin, matte).

The sheen of the finish significantly impacts the appearance and the repair process:

- Gloss: Gloss finishes show imperfections more readily, demanding precise color matching and a very smooth finish. Repairing a gloss finish often involves several thin coats of finish and careful polishing.

- Satin: Satin finishes are more forgiving, allowing for slight imperfections to be less visible. They generally require less polishing than gloss finishes.

- Matte: Matte finishes hide imperfections well. Repairing matte finishes often focuses on color matching and textural blending rather than achieving a high-gloss sheen.

Consider the example of a dining table: a gloss finish will highlight any imperfections, requiring very precise touch-ups, whereas a matte finish on a rustic table allows for a less perfect repair to go relatively unnoticed.

Q 8. How do you ensure a seamless blend between the touch-up and the original finish?

Achieving a seamless blend in furniture touch-up is paramount. It’s all about mimicking the original finish as closely as possible. This involves several key steps. First, careful color matching is crucial. I use a variety of techniques, including comparing the damaged area to an inconspicuous part of the furniture, using color charts, and sometimes even mixing custom shades to get the perfect match. Next, I focus on achieving the correct sheen. If the original finish is matte, I avoid using a glossy touch-up paint. Similarly, I use techniques like wet-on-wet blending or applying several thin coats to avoid a noticeable difference in texture. Finally, I use fine-grit sandpaper to gently feather the edges of the repaired area into the surrounding finish, further minimizing any visible transition. For example, when touching up a cherry wood table with a shellac finish, I’d carefully select a shellac-based touch-up paint that matches the cherry’s tone and work in thin layers until the blend is seamless.

Q 9. What safety precautions do you take when working with solvents, paints, and other chemicals?

Safety is my top priority when working with solvents, paints, and other chemicals. I always work in a well-ventilated area, preferably outdoors or near an open window with a fan for proper air circulation. I wear appropriate personal protective equipment (PPE), including safety glasses or a face shield to protect my eyes, a respirator or dust mask to prevent inhaling harmful fumes or particles, and gloves to safeguard my skin from irritants. I meticulously follow the manufacturer’s instructions on the safety data sheets (SDS) for every product used, paying close attention to warnings and handling procedures. I also store chemicals properly, away from heat sources and in clearly labeled containers, ensuring that only authorized personnel have access to them. For example, when using lacquer thinner, I always wear a respirator, as the fumes can be quite strong and harmful if inhaled.

Q 10. What tools and equipment are essential for professional furniture touch-up?

A comprehensive toolkit is essential for professional furniture touch-up. My kit includes a variety of high-quality brushes in different sizes (synthetic for water-based paints and natural bristle for oil-based), fine-grit sandpaper (ranging from 220 to 400 grit) for smoothing and blending, various wood fillers to address different types of damage, a palette knife for applying fillers and mixing paints, lint-free cloths for cleaning and wiping, a selection of quality touch-up paints and stains that match common wood species, and specialized tools like scraping tools and putty knives for deeper repairs. I also utilize a variety of specialized tools for high-gloss finishes. Having the right tools at my fingertips not only enables me to work more efficiently but also ensures a professional, high-quality finish.

Q 11. How do you handle unexpected challenges during a furniture touch-up project?

Unexpected challenges are part and parcel of furniture touch-up. My approach is systematic and involves thorough assessment. If I encounter a problem like a deeper gouge than initially thought, I don’t panic. Instead, I carefully assess the damage and adjust my strategy accordingly. This may involve using a different type of wood filler, employing a specialized repair technique, or adding additional coats of paint or stain to achieve the correct depth and color. For example, if a scratch reveals a different wood layer beneath, I would carefully match the color of that underlying layer and use blending techniques to create a natural-looking transition. Problem-solving involves not only technical skill but also creative thinking and resourcefulness.

Q 12. Explain your experience with repairing veneer damage.

Veneer repair requires a delicate touch and precise technique. My experience spans various methods. For minor chips or scratches, I use a veneer repair kit, carefully matching the color and grain to the existing veneer. For more significant damage, I might need to carefully lift the damaged piece and glue it back down, using clamps to ensure proper adhesion. If the piece is beyond repair, I may need to source a replacement piece of veneer that matches the original as closely as possible. Successful veneer repair hinges on careful color and grain matching, precise application of adhesive, and the use of clamps to secure the repair during the drying process. I’ve repaired everything from small chips on antique furniture to substantial sections on modern pieces.

Q 13. Describe your knowledge of different types of wood fillers and their application.

I am familiar with a wide range of wood fillers, each with its unique properties and applications. I use epoxy fillers for deep gouges and cracks because of their strong bonding properties. For minor scratches and imperfections, I prefer a wax-based filler, as it’s easy to apply and blend, especially on softer woods. For porous woods, I often utilize a paste filler, allowing for smoother application and better adhesion. The choice of filler depends on several factors, including the type and severity of damage, the type of wood, and the desired finish. Knowing which filler to use and how to apply it correctly is key to a successful repair. For instance, when working with an antique piece, I would likely favor a color-matched wax stick filler to maintain the antique’s character and integrity.

Q 14. What is your experience with repairing scratches on high-gloss surfaces?

Repairing scratches on high-gloss surfaces demands meticulous attention to detail. My approach involves a multi-step process. First, I clean the surface thoroughly to remove any dirt or debris. Then, I carefully fill the scratch using a high-quality filler designed for gloss finishes. I then use very fine-grit sandpaper (e.g., 6000 grit) to gently level the filled area, working carefully to avoid sanding through the finish. Next, I apply several thin coats of high-gloss lacquer or clear coat, allowing each coat to dry completely before applying the next. Finally, I may use a rubbing compound and polishing compound to achieve a mirror-like shine. This entire process necessitates patience and precision. A successful repair on a high-gloss surface is almost invisible, blending seamlessly with the surrounding area, often resembling a mirror finish.

Q 15. Have you worked with antique or high-value furniture pieces? Describe your approach.

Working with antique or high-value furniture requires a meticulous and conservative approach. My priority is always preservation, not just cosmetic repair. I begin with a thorough examination, carefully documenting the existing finish – its type, age, and any previous repairs. This helps me choose the most appropriate techniques and materials to ensure the integrity of the piece. I might use very fine sandpaper and specialized antique-restoration products, and in some cases, I might even opt to leave minor imperfections as they are, especially if they contribute to the piece’s character and value. For example, I recently restored a Victorian writing desk with inlaid mother-of-pearl. Any aggressive intervention would have risked damaging the delicate inlay, so I focused on gentle cleaning, careful color matching, and applying a minimal amount of shellac to stabilize the finish.

My approach always prioritizes minimal intervention, selecting the least invasive method to achieve the desired result. Extensive photographic documentation is crucial, allowing me to track my progress and revert if necessary. The focus is always on preserving the history and authenticity of the piece.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify the type of finish on a piece of furniture?

Identifying the type of finish is crucial before any touch-up work. There are several ways to do this. Firstly, I carefully examine the surface for its sheen – high gloss, semi-gloss, satin, or matte. Then, I perform a simple test: I carefully rub a cotton swab dipped in denatured alcohol on an inconspicuous area. If the finish softens or transfers to the swab, it’s likely a lacquer or shellac. If it remains unchanged, it could be an oil-based varnish or polyurethane. I might also use a magnifying glass to observe the finish’s texture and any distinctive grain patterns. If I’m unsure, a small sample can be taken for further analysis (always with the client’s permission). Knowing if it’s a shellac, lacquer, varnish, or polyurethane finish guides my selection of compatible materials for repair and matching.

Q 17. Describe your experience with using spray guns for furniture finishing.

Spray guns offer a superior finish for larger surfaces and allow for smooth, even color application. My experience with spray guns includes the careful preparation of the surface (thorough cleaning, sanding, and priming), selection of the correct spray nozzle and pressure, and mastering the technique of even passes to avoid runs or drips. I’m familiar with using different types of spray equipment, from HVLP (High Volume Low Pressure) systems for finer work to airless sprayers for larger projects. For example, when refinishing a set of antique dining chairs, the spray gun allowed me to achieve a consistent and flawless finish across all the pieces much more efficiently than hand-brushing. Safety is paramount – I always work in a well-ventilated area, wear appropriate personal protective equipment, and dispose of materials responsibly.

Q 18. What methods do you use to clean up after a touch-up project?

Clean-up is a vital part of the process and impacts both the final result and the safety of the workspace. I start by immediately wiping down tools and equipment with the appropriate solvent, ensuring no paint is left to harden. I then carefully dispose of used rags in sealed containers to prevent spontaneous combustion. For overspray, I might use a tack cloth to remove dust and loose particles. All surfaces are thoroughly cleaned using appropriate cleaning solutions, being mindful of the type of finish used. For water-based paints, soap and water are sufficient; for oil-based paints, mineral spirits or a suitable alternative are used. Finally, the workspace is thoroughly cleaned, and all materials are disposed of according to local regulations.

Q 19. How do you ensure the longevity of your touch-up work?

The longevity of my touch-up work depends heavily on proper preparation and the selection of high-quality materials. This includes selecting the correct type of primer and topcoat compatible with the existing finish and using the appropriate application technique. For example, I use durable acrylic-urethane paints for their exceptional resistance to scratches and wear. I also ensure thorough surface preparation, taking the time to properly sand, clean, and prime the area before applying any paint or finish. I educate clients on proper care and maintenance of the repaired surface, advising on things such as avoiding harsh cleaning chemicals and using coasters to prevent watermarks. By combining quality materials and preparation with client education, I aim to achieve a touch-up that’s indistinguishable from the original finish and lasts for years.

Q 20. What is your experience with working with different types of paints (e.g., acrylic, oil-based)?

My experience encompasses a wide range of paints, including oil-based and water-based (acrylic) options. Oil-based paints offer a durable, hard finish, ideal for high-traffic areas. However, they have a strong odor and require solvents for cleanup, making them less environmentally friendly. Acrylic paints, on the other hand, are water-based, low-odor, and easier to clean up. They are less durable than oil-based paints but offer excellent color retention and are a good choice for delicate pieces. The choice of paint depends heavily on the piece, the existing finish, and client preferences. I always test any paint in an inconspicuous area before proceeding with the full repair to ensure proper color matching and adhesion. In many cases, I prefer modern acrylic-urethane paints for their combination of durability and easy application.

Q 21. Describe your process for dealing with chipped or peeling paint.

Dealing with chipped or peeling paint requires a methodical approach. First, I carefully remove all loose and flaking paint using a scraper or sandpaper (carefully, to avoid damaging the underlying wood). Then, I assess the depth and extent of the damage. For small chips, I might use wood filler to repair the damage and sand it smooth before painting. For larger areas, I may need to remove more paint and apply multiple layers of primer to ensure a proper adhesion. The paint I choose for repair must match the existing finish as closely as possible, often requiring mixing to achieve an exact shade. In some instances, color matching might even involve creating a custom shade for a perfectly seamless blend. Finally, I apply several thin coats of finish, allowing each coat to dry thoroughly before applying the next to achieve a durable and seamless repair.

Q 22. How do you maintain the quality and consistency of your touch-up work?

Maintaining consistent, high-quality touch-up work relies on a meticulous approach. It starts with careful preparation. I always begin by thoroughly cleaning the damaged area to remove any dirt, grease, or loose paint. This ensures the new paint adheres properly. Then, I select the appropriate paint, matching color and finish as closely as possible. I use professional-grade paints designed for furniture restoration, known for their durability and color accuracy. To ensure consistency, I use small test patches in an inconspicuous area to fine-tune the color match before starting the main touch-up. My process includes multiple thin coats rather than one thick coat, allowing each layer to dry completely before applying the next, preventing drips and ensuring even coverage. Finally, I use fine-grit sandpaper (if needed) to smooth any imperfections between coats before finishing with a protective clear coat to increase longevity.

Imagine painting a miniature: You wouldn’t slap on a thick coat of paint, would you? The same principle applies to furniture touch-ups. Patience and precision are key to a seamless finish.

Q 23. How do you handle client communication and expectations regarding touch-up work?

Client communication is paramount. Before starting any project, I have a detailed consultation to understand their expectations, the type of damage, and the desired outcome. This often involves photos of the furniture piece and a discussion about the level of detail and the desired finish. I clearly explain the process, including potential challenges and the estimated timeframe. I maintain open communication throughout the project, providing updates and addressing any concerns the client may have. Transparency is key – if I encounter unexpected problems, I immediately inform the client and discuss possible solutions. Finally, I always follow up after the project is complete to ensure client satisfaction. I strive to exceed expectations, turning what might be a stressful situation into a positive experience.

For example, I once had a client who was initially concerned about the color match on an antique chair. After a thorough explanation and a successful test patch, their anxiety disappeared and they were thrilled with the final result. It’s all about building trust and confidence.

Q 24. What are the common problems you encounter during furniture touch-ups, and how do you solve them?

Common problems include poor color matching, uneven application, and filling deep scratches or gouges. Poor color matching can often be solved by using a color matching system or carefully blending multiple shades. Uneven application usually stems from applying too much paint at once; the solution is to apply multiple thin coats, allowing each to dry properly. For deep scratches or gouges, I use wood filler to create a smooth surface before painting. Sometimes, the underlying wood needs repair before any paint is applied. I always assess the damage carefully before determining the best solution. Another challenge is working with different types of finishes; each requires a slightly different approach and matching finish.

Think of it like a painter dealing with a cracked wall. You wouldn’t just slap on paint; you’d repair the crack before painting for a lasting solution. It’s the same with furniture touch-ups.

Q 25. What are your strengths and weaknesses when it comes to furniture touch-up?

My strengths include a keen eye for detail, color matching expertise, and patience in achieving a seamless finish. I am meticulous in my work, paying close attention to even the smallest imperfections. I’m also adept at problem-solving and finding creative solutions to complex touch-up challenges. A weakness, if I were to be critical, would be the time it takes to perfectly match colors, especially in older or unusual finishes. Finding exact matches for vintage pieces can be challenging, but I always strive for the best possible outcome, even if it takes additional time and effort.

While speed isn’t always my primary focus, my attention to detail guarantees superior results which my clients consistently appreciate.

Q 26. Describe your experience with using different types of brushes and applicators.

My experience with various brushes and applicators is extensive. I use a variety of tools depending on the project’s needs and the type of finish. For delicate work, like touching up small scratches, I use fine-tipped artist’s brushes. For larger areas, I might use a small foam brush or a specialized furniture touch-up brush that offers excellent control. For applying fillers, I might use a putty knife or a flexible spatula. I also have experience with spray applicators for even, consistent coats on larger surfaces, but I always prefer brushes for a more refined and detailed finish for most furniture pieces. The selection of the right tool is crucial for achieving a professional finish.

It’s like having a toolbox filled with different sized screwdrivers – you wouldn’t use a Phillips head for a flat-head screw, would you? Each tool serves a specific purpose in achieving the desired result.

Q 27. How do you estimate the time and materials needed for a furniture touch-up project?

Estimating time and materials requires a thorough assessment of the project. I begin by carefully examining the furniture piece, identifying the extent of the damage and the type of repair required. This includes considering the size of the area needing touch-up, the complexity of the repair (simple scratch versus deep gouge), and the number of coats of paint or finish needed. For materials, I factor in the cost of paint, wood filler, sandpaper, brushes, and any other necessary supplies. The time estimate considers the preparation, application, drying time, and any additional steps, such as sanding or clear coating. I always add a buffer to account for unexpected challenges. I provide clients with a detailed estimate before starting the work.

I find that visually breaking down the project into smaller, manageable steps helps determine the overall time and material needs. This creates a clear plan for efficient execution.

Key Topics to Learn for Furniture Touch-Up Interview

- Surface Preparation: Understanding different wood types, cleaning methods, sanding techniques, and filler application for optimal results.

- Color Matching & Mixing: Practical experience in accurately matching existing finishes and mixing paints or stains to achieve seamless repairs. This includes understanding color theory and its application to furniture restoration.

- Repair Techniques: Mastering various repair methods for scratches, dents, chips, and other common furniture damage, including the use of appropriate tools and materials.

- Finishing Techniques: Knowledge of different finishing methods such as staining, sealing, lacquering, and waxing, and their appropriate application based on the furniture’s material and desired outcome.

- Understanding Furniture Styles & Finishes: Recognizing different furniture styles (e.g., antique, modern, mid-century) and their common finishing characteristics. This allows for accurate and historically appropriate repairs.

- Health & Safety: Familiarity with safe handling of chemicals, proper ventilation, and personal protective equipment (PPE) usage during the touch-up process.

- Troubleshooting & Problem Solving: Developing the ability to identify and resolve common issues encountered during furniture touch-up, such as uneven finishes, color mismatches, or unexpected reactions between materials.

- Estimating & Quoting: Understanding how to assess the scope of a furniture touch-up project and provide accurate time and cost estimates to clients.

Next Steps

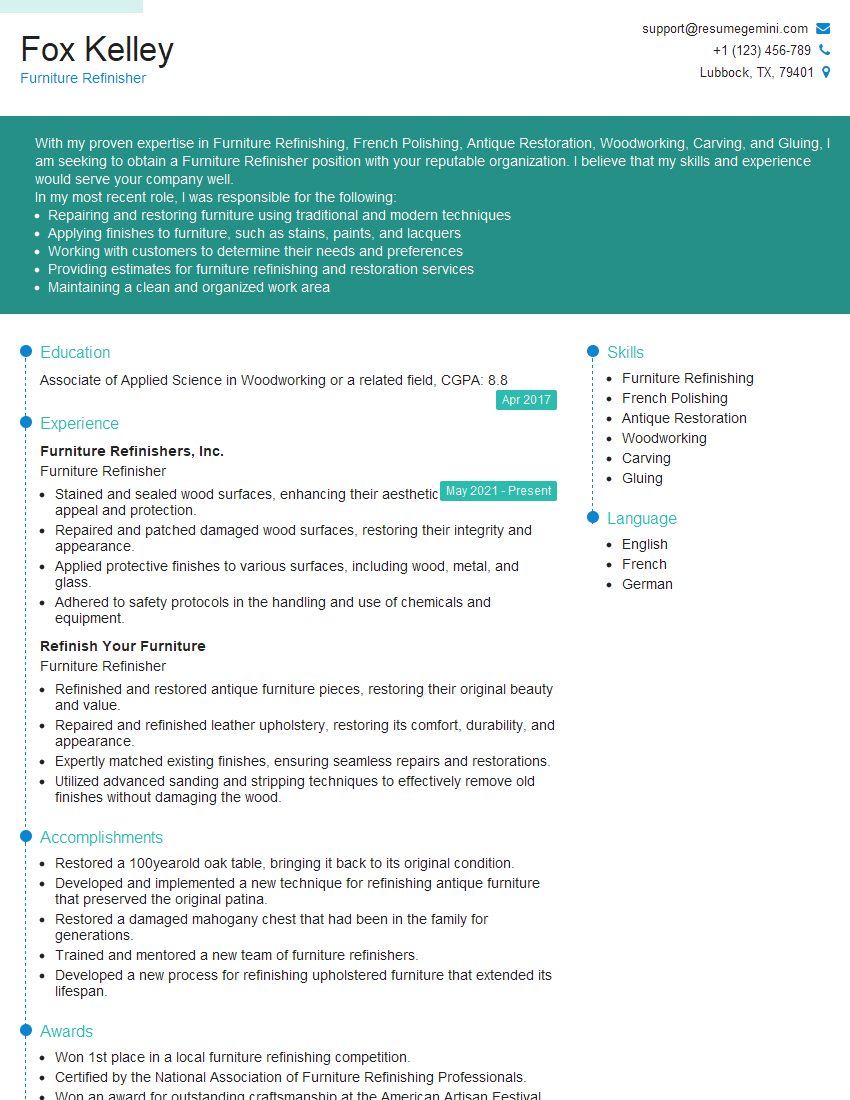

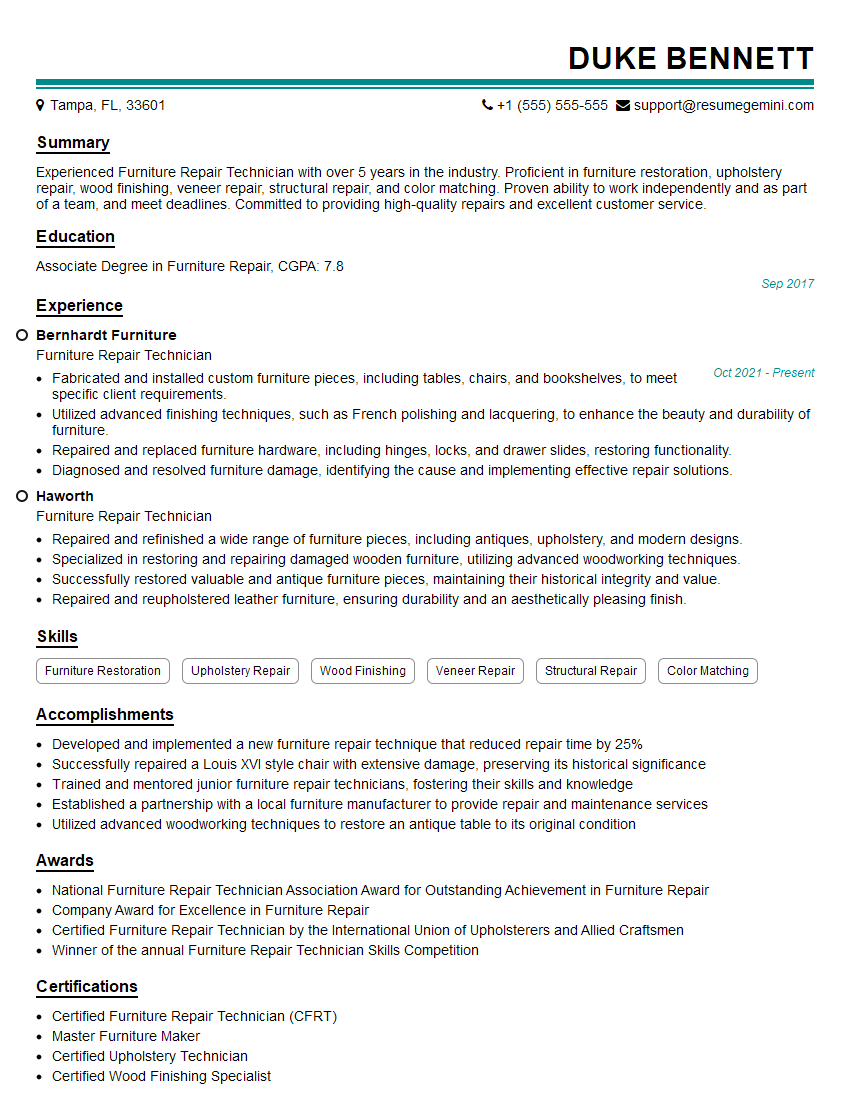

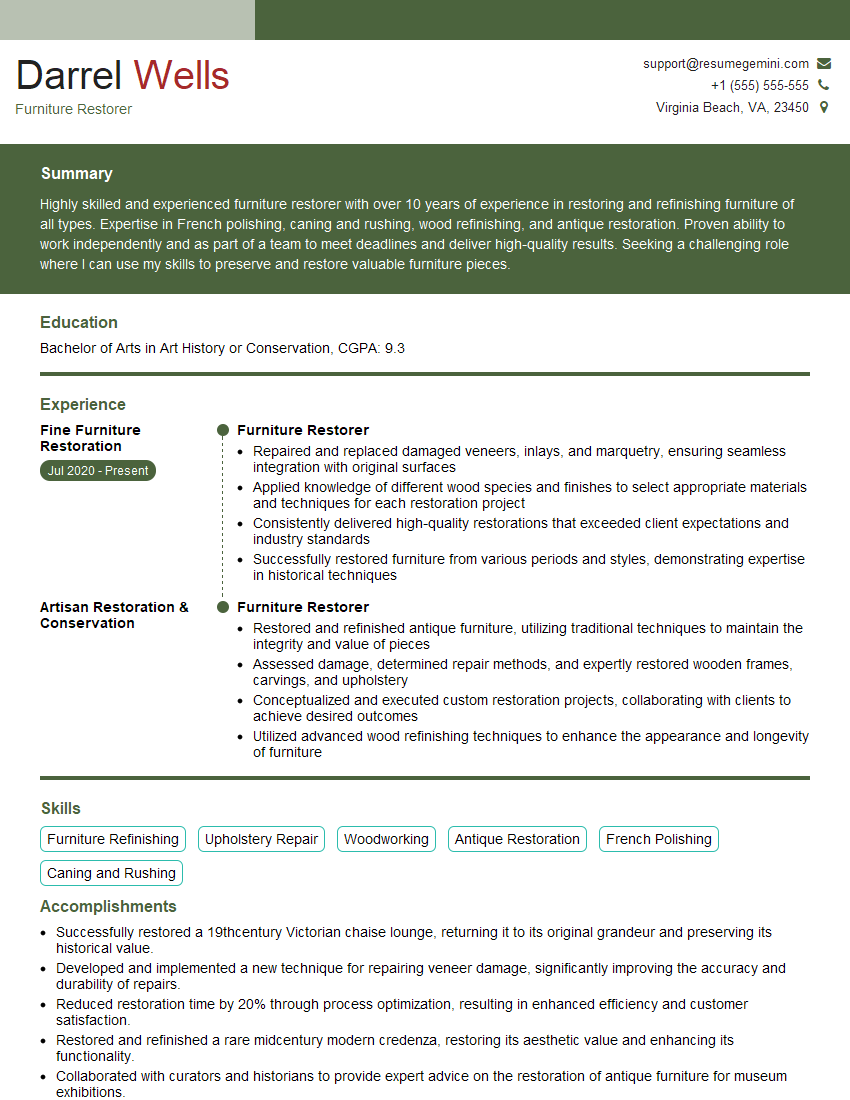

Mastering furniture touch-up techniques significantly enhances your value in the competitive job market. It demonstrates a valuable skillset and attention to detail highly sought after in various industries. To maximize your job prospects, focus on creating an ATS-friendly resume that clearly highlights your skills and experience. We strongly recommend using ResumeGemini to build a professional and impactful resume tailored to showcase your abilities in furniture touch-up. ResumeGemini provides tools and examples to help you create a winning resume. Examples of resumes tailored to Furniture Touch-Up are available.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?