Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Wax Finishing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Wax Finishing Interview

Q 1. What types of waxes are commonly used in finishing, and what are their properties?

Several types of waxes are used in wood finishing, each with unique properties influencing the final result. The most common are:

- Beeswax: A natural wax known for its durability, water resistance, and ability to create a warm, slightly amber sheen. It’s a popular choice for furniture and smaller projects.

- Carnauba wax: A harder, more durable wax derived from a Brazilian palm tree. It offers excellent hardness, gloss, and water resistance, making it ideal for high-traffic areas or pieces requiring a very polished finish. It’s often blended with other waxes to improve its workability.

- Paraffin wax: A refined petroleum wax; it’s relatively soft and inexpensive. Often used as a base or blended with other waxes to improve their application or modify their properties like hardness. It typically offers less water resistance than beeswax or carnauba.

- Shellac wax blends: Combining shellac and wax creates a finish with both the protective qualities of wax and the buildable nature of shellac, offering a good compromise between ease of application and durability.

The choice of wax depends on the desired finish, the type of wood, and the intended use of the finished piece. For instance, a high-gloss finish on a dining table might benefit from a carnauba-based blend, while beeswax might suffice for a less-used piece.

Q 2. Describe the process of applying a wax finish to a wooden surface.

Applying a wax finish is a relatively straightforward process, but requires meticulous attention to detail for optimal results. Here’s a step-by-step guide:

- Preparation: Ensure the wood is properly sanded and clean (see question 3 for details).

- Application: Apply a thin, even coat of wax using your chosen method (see question 4). Less is more; avoid heavy application.

- Buffing: Allow the wax to dry for the time specified by the manufacturer (usually 15-30 minutes). Then, using a soft cloth, buff the surface vigorously in circular motions until the surface is smooth and glossy. This process removes excess wax and helps achieve a deeper shine.

- Multiple Coats (Optional): For deeper color, increased durability, or a higher gloss, you may apply additional coats. Allow each coat to dry completely and buff before applying the next.

Remember that patience is key. Rushing the process can lead to uneven application or a dull finish.

Q 3. How do you prepare a surface for wax finishing?

Surface preparation is crucial for a successful wax finish. A poorly prepared surface will result in an uneven finish that doesn’t last. The process typically includes:

- Sanding: Begin with coarser grit sandpaper (e.g., 120-grit) to remove imperfections and then progressively move to finer grits (e.g., 220-grit and even 320-grit) for a smooth surface. Always sand in the direction of the wood grain to prevent scratches.

- Cleaning: After sanding, thoroughly remove all dust particles using a tack cloth or vacuum cleaner. Dust trapped under the wax will create an uneven and imperfect finish.

- De-greasing (Optional): If the wood is particularly oily or dirty, consider cleaning it with a suitable solvent (such as mineral spirits) to ensure the wax adheres properly. Always follow the solvent manufacturer’s safety instructions.

Proper preparation is like laying a strong foundation for a house – it ensures the final finish is beautiful and durable.

Q 4. What are the different methods of applying wax?

Several methods can be used to apply wax:

- Cloth Application: This is the most common method. A soft, lint-free cloth is used to rub the wax onto the surface in a thin layer.

- Brush Application: A soft-bristled brush can be used for more even application, particularly on larger surfaces or intricate designs. Avoid using stiff brushes as these can scratch the surface.

- Wax Applicator Pads: These are designed specifically for wax application and can provide a more even, controlled spread of wax.

The best method depends on personal preference and the project’s scale. I often use a combination – a brush for initial application, followed by a cloth for smoothing.

Q 5. How do you achieve a high-gloss finish using wax?

Achieving a high-gloss finish with wax requires several key steps:

- Use high-quality wax: Carnauba wax is renowned for its ability to create a high-gloss finish. Consider using a wax blend specifically formulated for high-gloss applications.

- Multiple thin coats: Applying multiple thin coats, rather than one thick coat, is crucial. This allows each layer to properly adhere and build gloss. Allow ample drying time between coats.

- Meticulous buffing: The most important step! Vigorous and consistent buffing is essential to remove excess wax and create a smooth, reflective surface. Use a clean, soft cloth and continue buffing until the surface is highly polished.

- Use a polishing compound (optional): For an extra layer of shine, a polishing compound can be used after the final wax coat. Apply sparingly and buff vigorously.

Think of it like polishing a gemstone – the more effort you put into it, the more radiant the result.

Q 6. How do you troubleshoot common problems encountered during wax finishing, such as uneven application or dust nibs?

Troubleshooting common wax finishing issues requires careful observation and systematic problem-solving:

- Uneven Application: This is often caused by applying wax too thickly or not buffing sufficiently. To remedy this, carefully remove excess wax with a clean cloth, then reapply a thin coat and buff thoroughly.

- Dust Nibs: These small bumps are caused by dust particles trapped under the wax. Preventing dust nibs starts with careful surface preparation, using a tack cloth or vacuum to remove dust before waxing. If dust nibs appear, gently remove them with very fine sandpaper before re-waxing.

- Lack of Gloss: Inadequate buffing or using a low-gloss wax can cause this. Buff the surface more vigorously and consider using a higher-gloss wax for subsequent coats.

- Water Spots: Ensure the surface is completely dry before applying wax. Water spots indicate insufficient drying time. Water-resistant waxes are a good prevention.

Experience and keen observation are key to addressing these challenges effectively. Often, the solution involves revisiting earlier steps in the process.

Q 7. Explain the importance of proper ventilation when working with wax finishes.

Proper ventilation is crucial when working with wax finishes because many waxes and associated products (like solvents used in cleaning) emit volatile organic compounds (VOCs). VOCs can be harmful if inhaled in sufficient quantities. They can cause respiratory irritation, headaches, and other health problems.

Always work in a well-ventilated area, ideally outdoors or in a space with adequate exhaust fans. If working indoors, open windows and doors to improve air circulation. Using respiratory protection like a dust mask is also a prudent practice when working with certain waxes or solvents.

Prioritizing safety ensures both your health and the quality of your work. Ignoring ventilation risks compromising your health and potentially impacting the integrity of the wax finish through premature drying or uneven application caused by poor air circulation.

Q 8. What safety precautions should be taken when working with waxes and solvents?

Safety is paramount when working with waxes and solvents. Waxes themselves are generally low-hazard, but solvents can be volatile and flammable, posing significant risks. Always work in a well-ventilated area, ideally with a respirator to avoid inhaling fumes. Solvents like mineral spirits or citrus solvents should never be used near open flames or sparks. Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a long-sleeved shirt to protect your skin from contact. Properly dispose of waste materials according to local regulations. Keep solvents away from ignition sources. In the case of a spill, immediately ventilate the area and follow your specific safety plan for hazardous material clean-up. Always refer to the Safety Data Sheet (SDS) for each product you use to understand its specific hazards and handling procedures. For example, when using turpentine, remember its strong smell and ensure sufficient ventilation; improperly using a flammable solvent near heat is a common cause of accidents. It’s crucial to remember that safety isn’t just about following rules; it’s about developing a mindful and cautious approach to every step of the process.

Q 9. How do you determine the correct amount of wax to apply?

Determining the correct amount of wax depends on several factors: the type of wood, the desired level of sheen, and the porosity of the wood. A common technique is to apply a thin, even coat using a lint-free cloth or a brush designed for wax application. Too much wax can lead to a sticky or gummy finish that takes longer to cure and may never fully harden, leaving a tacky feel. Too little, on the other hand, will leave the wood inadequately protected and may result in an uneven sheen. Think of it like painting a wall; you wouldn’t slap paint on in thick globs, you’d apply thin coats for even coverage. Start with a small amount and apply it carefully, buffing lightly after the wax has hazed slightly. If needed, add additional thin coats, allowing each to dry properly before buffing, until the desired effect is achieved. It is always better to apply multiple thin coats than one thick coat.

Q 10. What are the advantages and disadvantages of using wax as a finishing method compared to other methods (e.g., lacquer, varnish)?

Wax finishes offer several advantages over methods like lacquer or varnish. Wax provides a natural, warm look that enhances the wood grain. It’s also relatively easy to apply and repair; minor scratches or imperfections can be easily addressed with another application of wax. Wax is also environmentally friendly compared to many other finishes as it generally utilizes natural ingredients and produces less hazardous waste. However, wax finishes are less durable and offer less protection against water damage and wear and tear compared to lacquer or varnish. They are also not suitable for high-traffic areas or outdoor use, making them more suitable for furniture or smaller projects. Lacquer and varnish, while more durable, can yellow over time and are more difficult to repair. The choice depends on the application – for a delicate antique piece, wax might be preferred, while for a kitchen table, a more durable varnish would be a better choice.

Q 11. How do you maintain and clean your wax finishing tools?

Maintaining and cleaning your wax finishing tools is crucial for keeping them in good working order and preventing cross-contamination. Immediately after use, clean your brushes or applicators with a suitable solvent (e.g., mineral spirits for oil-based waxes, or soap and water for water-based waxes), ensuring you remove all wax residue. Store brushes in a clean, dry place. Cloth applicators can often be washed and reused, however, for sanitary reasons it is best to always use fresh lint-free cloths for each project. Never use the same cloth for different waxes or projects to prevent cross-contamination and potential unwanted reactions. If you are working with multiple types of wax, dedicate specific tools to each type to avoid mixing different formulations, as this can compromise the finish’s quality.

Q 12. Describe your experience with different types of wood and their suitability for wax finishing.

Different woods have varying porosities and grain structures, influencing how they accept wax finishes. Hardwoods like cherry or mahogany generally take wax well, producing a smooth, even finish. However, woods with open pores, such as oak, may require a pre-treatment like a wood conditioner before waxing to prevent uneven absorption. Softwoods like pine can be more challenging due to their softer nature and tendency to absorb more wax unevenly, requiring more careful application and potentially more coats. For instance, I found that working with figured maple, it is crucial to work in the direction of the grain. I’ve had excellent results with a combination of wax and linseed oil on oak, enhancing its grain dramatically. It’s always best to test your wax on a small, inconspicuous area of the wood before applying it to the entire piece to ensure you’re achieving the desired result.

Q 13. How do you achieve a consistent finish across multiple pieces?

Achieving a consistent finish across multiple pieces requires careful planning and execution. First, ensure all pieces are prepared uniformly – sanding to the same grit, and using the same wood conditioner if necessary. This minimizes variations in the wood’s surface. Maintain consistent environmental conditions during application, avoiding extremes in temperature and humidity. Use the same wax, applying it in the same manner and to the same thickness. Use a standardized approach, such as applying thin coats and buffing with a consistent pressure, to ensure even coverage. Practice on a test piece first to refine your technique, and make sure your tools are in good shape and clean. Consistency is key; repeat the same process for each piece to maintain quality and uniformity.

Q 14. What are the different levels of sheen achievable with wax?

The level of sheen achievable with wax can range from a matte or low-luster finish to a subtle, soft sheen, depending on the type of wax used and the buffing technique employed. A low-sheen wax will result in a more natural look, enhancing the wood grain without a high gloss, while a wax with a higher level of carnauba wax, or a more aggressive buffing technique, will increase the gloss. The amount of buffing directly correlates with the sheen. For example, using only a soft cloth buffing produces a low sheen, whereas using a machine buffer increases the sheen dramatically. By carefully controlling these variables, you can achieve a wide range of finishes, from a subtle glow to a more pronounced shine.

Q 15. How do you repair minor imperfections in a wax finish?

Minor imperfections in a wax finish, like small scratches or blemishes, can often be repaired without completely stripping and re-waxing the piece. The key is to use a minimal amount of wax and blend it seamlessly into the existing finish.

- Assess the damage: Determine the severity. A tiny scratch might only need a touch-up, while a larger imperfection may require more work.

- Prepare the area: Gently clean the affected area with a soft cloth and a mild cleaner to remove any dust or debris. Let it dry completely.

- Apply wax sparingly: Use a small amount of wax—a tiny dab on a cotton swab or the tip of an applicator—on the damaged area. Avoid using too much wax, which can create a noticeable build-up.

- Blend the wax: Use a soft cloth, gently buff the wax into the surrounding finish, working in small, circular motions. The goal is to create a seamless transition and eliminate any visible lines.

- Buff to a shine: Once the wax is fully blended, buff the area to a shine with a clean, soft cloth. This step helps remove excess wax and restore the original luster.

For example, I once repaired a small scratch on an antique table using this method. The result was almost invisible, preserving the beauty and integrity of the piece.

Career Expert Tips:

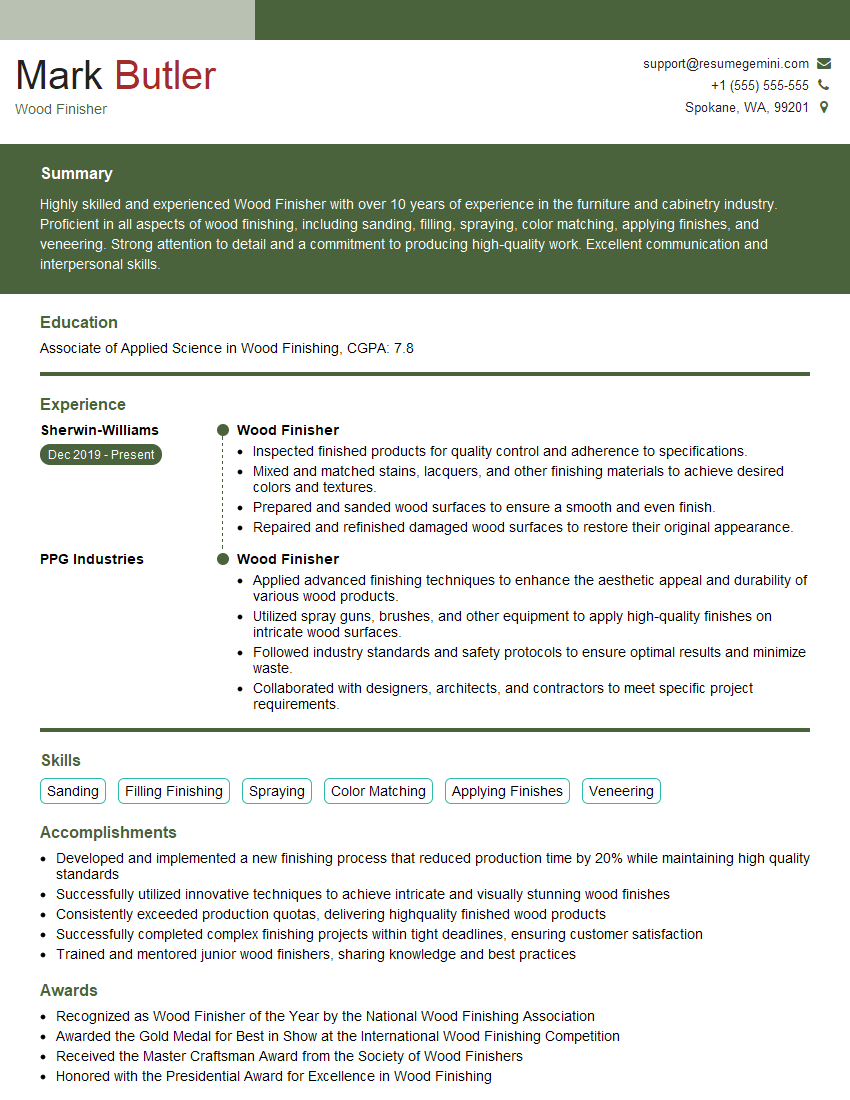

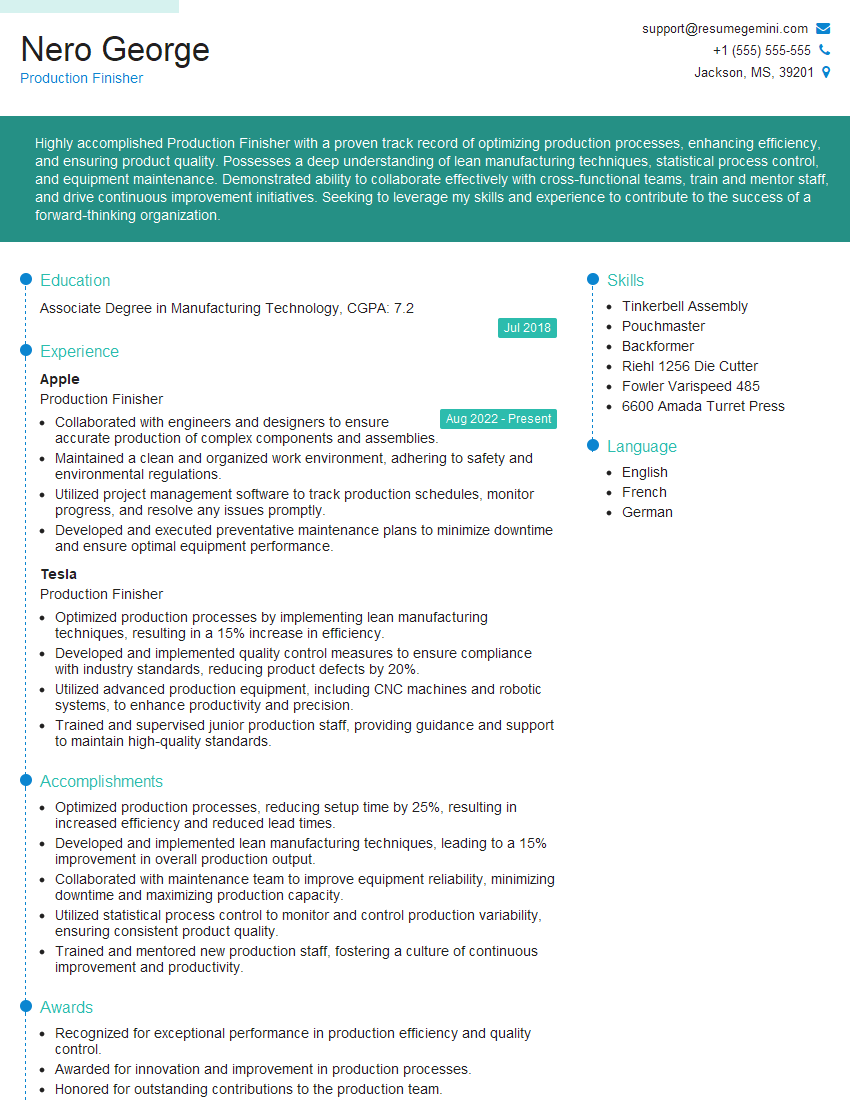

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you remove old wax finishes?

Removing old wax finishes requires patience and the right tools. The method depends on the type of wax and the surface being treated. Aggressive techniques can damage the underlying wood, so a gentle approach is usually best.

- Assess the finish: Determine the type of wax and its thickness. Multiple layers might require more effort to remove.

- Use a heat gun (carefully!): A low-heat setting can soften the wax, making it easier to scrape away. Always test in an inconspicuous area first to avoid damage. This step needs caution to avoid burning the wood or yourself.

- Mechanical removal: For stubborn wax, a plastic scraper or a putty knife can be used, working gently to avoid scratching the underlying surface. Remember to use light pressure and multiple passes.

- Chemical strippers (as a last resort): Chemical strippers specifically designed for wax removal are available, but they should be used with extreme caution and according to the manufacturer’s instructions. Proper ventilation is crucial.

- Clean thoroughly: After removing the wax, clean the surface with mineral spirits or a suitable cleaner to remove any residue. Allow it to dry fully before applying a new finish.

I’ve found that using a combination of a heat gun and a plastic scraper is the most effective method for most wax removal jobs, minimizing the risk of damage to the wood.

Q 17. What are the environmental considerations related to wax finishing?

Environmental considerations in wax finishing are primarily focused on the ingredients used in the waxes and the disposal of waste materials.

- Wax composition: Opt for waxes with natural ingredients and minimal volatile organic compounds (VOCs), which contribute to air pollution. Many manufacturers now offer eco-friendly, low-VOC options.

- Waste disposal: Used rags and cleaning materials containing wax and solvents should be disposed of properly, following local regulations. Avoid pouring solvents down the drain, which can contaminate water systems.

- Sustainable sourcing: Consider the origin of the waxes used. Choose products from sustainable sources whenever possible.

- Ventilation: Ensure adequate ventilation when applying waxes, especially in enclosed spaces, to minimize exposure to any potential fumes.

It’s important to select products with certifications that verify their environmental friendliness and responsible manufacturing practices. My work always involves prioritizing environmentally sound choices.

Q 18. Explain your understanding of color blending and tinting with wax.

Color blending and tinting with wax allows for customization and achieving specific aesthetic effects. It involves skillfully mixing different colored waxes to create unique shades.

- Start with a base color: Choose a base wax color that’s close to your desired final color. This provides a foundation to build upon.

- Gradual addition: Add small amounts of tinting wax, carefully mixing until you achieve the desired shade. It is easier to add more color than to remove it.

- Test on a scrap piece: Always test your color blend on a piece of scrap wood before applying it to the main project to ensure the color matches your vision.

- Multiple layers: For deeper and richer colors, apply multiple thin layers of the tinted wax, allowing each layer to dry before applying the next. This builds depth and evenness.

- Transparency vs. opacity: Different waxes have varying degrees of transparency. Experiment to understand how this affects the final color.

I’ve created numerous custom colors using this technique, adapting my approach depending on the wood species and the desired outcome. For example, I once created a beautiful, custom-blended grey wax for a client’s dining table, perfectly matching their existing décor.

Q 19. How do you handle different types of wood grain?

Handling different types of wood grain requires understanding how the wood’s texture and porosity will influence the wax application and the final finish.

- Open-grained woods: Open-grained woods (like oak or ash) require filling the grain with a wood filler prior to waxing to create a smoother surface. Wax can settle into the open grain, creating an uneven appearance.

- Close-grained woods: Close-grained woods (like maple or cherry) are typically easier to wax, requiring less preparation. The wax usually adheres evenly.

- Porosity: Wood porosity affects how much wax the wood absorbs. More porous woods might require more wax applications to achieve the desired saturation.

- Direction of the grain: Always follow the direction of the wood grain when applying wax, to minimize the risk of streaking and to achieve a more natural look.

My experience has taught me that each wood species requires a unique approach. A technique that works beautifully for a close-grained cherry might result in an uneven finish on a piece of rustic oak.

Q 20. Describe your experience with using different wax application tools (e.g., brushes, rags, applicators).

Different application tools are suitable for various tasks and provide different outcomes in wax finishing. Each has its advantages and disadvantages.

- Brushes: Brushes (natural bristle brushes are often preferred) are great for covering large areas efficiently and working wax into the grain, especially for open-grained woods. However, brush strokes can be more visible.

- Rags: Cotton rags are excellent for blending and buffing, providing a more uniform and smooth finish. They are ideal for achieving a polished, streak-free look.

- Applicators: Foam applicators or lint-free cloths provide a good balance between coverage and control, especially for smaller projects or intricate details. They are easy to clean and use.

The choice of tool depends largely on the job at hand and personal preference. I often use a combination of brushes and rags for optimal results—using brushes for initial application and rags for blending and final buffing.

Q 21. How do you ensure the durability and longevity of a wax finish?

Ensuring the durability and longevity of a wax finish involves careful application, proper maintenance and understanding the limitations of wax.

- Multiple thin coats: Applying several thin coats of wax, allowing each to dry completely before applying the next, creates a more durable and protective layer than one thick coat.

- Proper drying time: Adequate drying time is essential. Rushing the process can lead to cracking or peeling.

- Regular maintenance: Dusting and periodic cleaning with a soft cloth help maintain the finish and prevent damage. Re-waxing every few years or as needed will rejuvenate the finish and restore its luster.

- Protection from liquids: Wax finishes are not impervious to liquids. Use coasters or placemats to protect surfaces from spills.

- Avoid harsh chemicals: Harsh chemicals and abrasive cleaners can damage the wax finish. Use mild cleaners when necessary.

A well-maintained wax finish can last for many years, providing a beautiful and protective layer for the underlying wood. It’s all about careful attention to detail during application and consistent upkeep.

Q 22. Describe your experience with quality control in wax finishing.

Quality control in wax finishing is paramount for achieving a durable and aesthetically pleasing result. My approach involves a multi-stage process, beginning with meticulous inspection of the raw materials. This includes checking the wax for impurities, verifying its melting point and viscosity, and assessing its color and consistency. During the application process, I carefully monitor the evenness of the coating, looking for any streaks, drips, or areas of insufficient coverage. Post-application, I check for proper curing, examining for any signs of cracking, chipping, or uneven gloss. Finally, I perform a durability test, simulating real-world wear and tear to assess the finish’s resistance to scratches and abrasion. For example, on a high-end furniture piece, I might use a specialized gloss meter to ensure consistent shine across the entire surface. Any deviation from the pre-defined quality standards triggers corrective actions, from re-application of the wax to adjusting the application technique or even replacing faulty materials.

Q 23. Explain your process for troubleshooting a poorly applied wax finish.

Troubleshooting a poorly applied wax finish requires a systematic approach. First, I identify the specific problem: is it uneven application, insufficient shine, cracking, or something else? Then, I investigate the possible causes. Uneven application might indicate improper stirring of the wax, inconsistent application pressure, or an unsuitable applicator. Lack of shine could result from insufficient wax application or the use of an inappropriate wax type for the substrate. Cracking could be due to rapid drying, incompatible waxes, or inadequate surface preparation. Once the root cause is identified, I can implement corrective measures. This may involve removing the faulty finish using a suitable solvent (chosen carefully to avoid damaging the underlying material), re-preparing the surface, and re-applying the wax using the correct technique. For example, if the problem is caused by dust particles trapped under the wax, I would carefully clean the surface before reapplication. If the wax is not curing properly, I might investigate temperature and humidity conditions.

Q 24. What types of solvents are used in wax finishing, and what are their properties?

Several solvents are used in wax finishing, each with distinct properties. Mineral spirits are commonly used to thin waxes, clean application tools, and remove excess wax. They are relatively inexpensive and readily available but have a strong odor and are flammable. White spirit is a similar solvent, often preferred for its slightly milder odor. For more delicate surfaces or specific wax types, specialized solvents might be required. For example, citrus-based solvents are becoming increasingly popular as they are generally considered safer and have a more pleasant aroma. The choice of solvent depends on factors like the type of wax, the substrate material, and the desired level of cleaning or thinning. It is crucial to always consult the wax manufacturer’s recommendations regarding appropriate solvents and safety precautions.

Q 25. How do you select the appropriate wax for a specific project?

Selecting the appropriate wax for a specific project depends on several factors. The type of wood or material being finished is paramount. Hard waxes offer superior durability and protection against scratches, making them ideal for high-traffic furniture or floors. Soft waxes provide a more delicate, subtle finish, often preferred for delicate antique pieces or certain types of wood. The desired sheen is another crucial factor. Some waxes produce a high-gloss finish, while others result in a matte or satin finish. The project’s environmental conditions also need consideration. Waxes with UV inhibitors are essential for outdoor projects to prevent fading. Furthermore, the application method – brush, rag, or spray – can influence wax selection. I always carefully consider these factors and often perform small-scale test applications on scrap material to ensure the selected wax performs as expected and complements the substrate.

Q 26. Explain the importance of proper surface preparation before applying wax.

Proper surface preparation is crucial for a successful wax finish. It significantly impacts adhesion, durability, and the overall appearance of the final finish. The process typically involves cleaning the surface to remove dust, dirt, grease, and any other contaminants that might prevent proper wax bonding. This might include using a tack cloth, vacuuming, or even cleaning with a suitable solvent. Next, sanding might be necessary to smooth out imperfections and create a uniform surface for even wax application. The grit of the sandpaper is selected based on the condition of the surface; coarser grits are used for rough surfaces, and finer grits create a smoother finish. Following sanding, it’s important to remove sanding dust thoroughly before applying the wax. This ensures the wax adheres properly, preventing chipping or peeling and ensuring a professional, uniform finish. A poorly prepared surface can lead to an uneven, blotchy, or prematurely failing finish, making this step incredibly important.

Q 27. Describe your experience working with different types of finishing equipment.

My experience encompasses a variety of finishing equipment. I’m proficient with hand-application techniques using brushes and rags, which offer precise control, particularly for intricate details and smaller projects. I’m also experienced with spray application systems, ideal for larger surfaces and achieving a consistent, even finish. These systems often involve airless sprayers or HVLP (High Volume Low Pressure) sprayers, requiring careful adjustment of the spray pattern and pressure to prevent overspray or runs. Furthermore, I have experience using specialized tools like wax applicators, which improve efficiency and consistency. The selection of equipment depends on project scale, the surface’s geometry, and the desired finish quality. Safety protocols are paramount when operating any equipment, and regular maintenance is crucial for optimal performance and longevity.

Q 28. What are your strategies for improving efficiency in the wax finishing process?

Improving efficiency in wax finishing involves streamlining the entire process. This begins with optimizing surface preparation, employing techniques like efficient sanding methods and dust collection systems. Batch processing, where multiple items receive the same finish simultaneously, is crucial for larger projects. Selecting the appropriate application method—spraying for large, uniform areas and hand-application for detailed work—maximizes efficiency. Proper organization of materials and tools reduces downtime. Finally, continuous monitoring of the process, tracking application times and material usage, helps identify areas for improvement. For example, implementing a standardized workflow, with clear steps and timelines for each stage, can greatly reduce errors and improve overall efficiency. Regular training and upskilling ensure the team remains proficient and can adapt to new techniques and equipment. Investing in time-saving tools, such as specialized applicators or improved ventilation systems, can also enhance efficiency significantly.

Key Topics to Learn for Wax Finishing Interview

- Wax Types and Properties: Understanding the characteristics of different waxes (e.g., paraffin, microcrystalline, beeswax) and their suitability for various applications.

- Application Techniques: Mastering various application methods like dipping, spraying, brushing, and flow coating, and understanding their impact on final finish.

- Finishing Processes: Familiarizing yourself with pre-wax treatments (cleaning, sanding), wax application techniques, and post-wax treatments (buffing, polishing).

- Quality Control and Inspection: Knowing how to assess the quality of the wax finish, identify defects (e.g., orange peel, runs, drips), and implement corrective measures.

- Equipment and Maintenance: Understanding the operation and maintenance of wax finishing equipment (e.g., spray booths, dipping tanks, buffing machines).

- Safety Procedures and Regulations: Familiarity with relevant safety protocols, handling of hazardous materials, and adherence to industry regulations.

- Troubleshooting and Problem Solving: Developing the ability to diagnose and resolve common issues encountered during the wax finishing process.

- Cost Optimization and Efficiency: Understanding techniques to minimize waste, improve efficiency, and reduce overall costs associated with wax finishing.

- Environmental Considerations: Awareness of environmentally friendly waxes and sustainable practices in wax finishing.

Next Steps

Mastering wax finishing opens doors to exciting career opportunities in diverse industries. A strong understanding of this specialized skillset is highly valued, leading to increased earning potential and career advancement. To maximize your chances of landing your dream role, creating an ATS-friendly resume is crucial. An effectively designed resume highlights your skills and experience, ensuring it’s easily searchable by applicant tracking systems. We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to Wax Finishing to help you showcase your expertise effectively. Take the next step in your career journey and craft a compelling resume that reflects your capabilities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Amazing blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?