Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Automotive Finishing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Automotive Finishing Interview

Q 1. Describe your experience with different paint types (e.g., acrylic lacquer, urethane, waterborne).

My experience encompasses a wide range of automotive paint types, each with its unique properties and application techniques. Acrylic lacquer, for instance, is known for its fast drying time and high gloss, but it’s less durable than other options. I’ve used it extensively on smaller projects and restoration work where a quick turnaround is crucial. Urethane paints, on the other hand, are significantly more durable and resistant to chipping and fading, making them the standard for modern automotive finishes. They offer excellent UV protection and a hard, long-lasting finish. Finally, waterborne paints represent a more environmentally friendly choice, reducing VOC (Volatile Organic Compound) emissions. They require a different application technique and have a longer drying time compared to urethanes, but the environmental benefits are significant. I’ve successfully implemented waterborne systems in line with increasingly stringent environmental regulations, and I find them to deliver a high-quality finish with proper preparation and application.

The choice of paint type depends heavily on the project’s requirements; factors like budget, desired durability, environmental considerations, and the overall aesthetic goal influence this decision greatly. For instance, a classic car restoration might benefit from the quick drying and high gloss of acrylic lacquer, while a new production line would likely favour the durability and longevity of urethane or the environmental benefits of a waterborne system.

Q 2. Explain the process of color matching.

Color matching is a critical aspect of automotive finishing. It involves identifying the precise color formula for a damaged area to ensure a seamless blend with the existing paint. The process typically starts with a visual inspection of the existing paintwork, followed by using a spectrophotometer. This sophisticated instrument measures the color’s reflectance values, providing a digital representation of the color. This digital data is then fed into a paint mixing system, which precisely calculates the necessary amount of pigments and basecoats to achieve an accurate match. However, it’s not always a simple process. Factors like age, weathering, and previous repairs can affect the paint’s color, making achieving a perfect match challenging.

Experience plays a key role here. I’ve encountered scenarios where slight adjustments were needed after the initial mix, often due to the subtle variations in lighting conditions. The expertise comes in knowing how to make these adjustments by carefully analyzing the color deviation and making small corrections to the mix. In some cases, especially with rare or discontinued colors, manual mixing based on experience and knowledge of pigment interactions may be necessary. It’s a delicate art that combines technology with skilled judgment.

Q 3. What are the different surface preparation techniques you’re proficient in?

Surface preparation is paramount to achieving a durable and aesthetically pleasing finish. I’m proficient in several key techniques. This begins with cleaning the surface thoroughly to remove dirt, grease, and any contaminants. Then comes the sanding process, which might involve wet sanding with progressively finer grits to remove imperfections and ensure a smooth surface. Depending on the damage, I’ll use various techniques like block sanding for larger areas or hand sanding for intricate details. For significant damage, filling with body filler might be necessary, followed by careful shaping and sanding to create a smooth transition. Before priming, the surface must be thoroughly cleaned again, often with a tack cloth to eliminate any dust particles that could compromise adhesion. Finally, masking off the areas to be painted is essential for a clean and professional result.

For example, on a car with rust damage, the rusted areas would first be removed, then the metal surface cleaned and prepared for filling. After carefully applying body filler and sanding smooth, the entire area would undergo the whole sanding process described earlier.

Q 4. How do you ensure proper paint adhesion?

Ensuring proper paint adhesion relies on meticulous surface preparation, as described earlier. A clean, smooth, and properly primed surface is crucial. The primer acts as an intermediary layer between the substrate (the metal of the car body) and the topcoat, providing a better bonding surface. The type of primer used should be compatible with both the substrate and the topcoat. Furthermore, environmental conditions significantly impact adhesion. Temperature and humidity levels must be within the paint manufacturer’s specifications to ensure proper curing and bonding. Using the correct thinners and application techniques are also important, ensuring the paint isn’t applied too thickly and has enough time to flash off (to evaporate the solvent) between coats. Finally, proper curing time is essential; rushing the drying process could result in poor adhesion.

Think of it like sticking a sticker to a surface. If the surface is dirty or greasy, the sticker won’t stick well. The primer is like preparing the surface with adhesive, ensuring a strong bond.

Q 5. What are the common causes of paint defects and how do you troubleshoot them?

Common paint defects include orange peel (a bumpy surface), runs (excess paint creating uneven streaks), sags (paint dripping and accumulating), dust nibs (small dust particles embedded in the paint), and fisheyes (small crater-like imperfections). Troubleshooting these issues involves identifying the root cause. Orange peel can result from incorrect spray technique, incorrect air pressure, or an unsuitable nozzle size. Runs and sags are often caused by applying too much paint at once, insufficient flash time between coats, or too high of an air pressure. Dust nibs are a result of inadequate booth cleanliness, while fisheyes might indicate contamination of the paint surface.

My approach to troubleshooting involves systematically checking each step of the process. I start by reviewing the preparation, application, and curing conditions. If the problem persists, I’ll analyze the paint itself, looking for contamination or improper mixing. Experience enables me to quickly identify the likely source of the defect and apply the correct remedial action, which may include re-sanding, repainting specific areas, or adjusting the spray parameters. For example, orange peel might be addressed by using a lower air pressure and a more even spray pattern. Runs are typically fixed by sanding down the affected area and re-spraying carefully.

Q 6. Describe your experience with various spraying techniques (e.g., conventional, HVLP, electrostatic).

I’m experienced in various spraying techniques, each offering unique advantages. Conventional spraying utilizes a standard air compressor and spray gun, providing good control for experienced technicians. However, it has a relatively high overspray rate (paint lost in the air), making it less environmentally friendly. HVLP (High Volume Low Pressure) spraying reduces overspray significantly, improving efficiency and reducing material waste. It’s a better option for both environmental reasons and cost-effectiveness. Electrostatic spraying utilizes an electric charge to attract the paint particles to the surface, minimizing overspray further and increasing transfer efficiency. This technique is particularly useful for complex shapes or large production runs.

The choice of spraying technique depends on various factors like the project scale, budget, desired finish quality, and environmental considerations. In a small shop working on custom projects, conventional or HVLP might be preferred for its versatility. For large-scale automotive manufacturing, electrostatic spraying is often chosen due to its increased efficiency and reduced environmental impact.

Q 7. How do you maintain a paint booth and its equipment?

Maintaining a paint booth and its equipment is crucial for ensuring consistent quality and a safe working environment. Regular cleaning is paramount, both inside and outside the booth. This includes removing overspray, dust, and debris. The booth filters need regular checks and replacements to prevent contaminants from affecting the paint job. The ventilation system should be regularly inspected and maintained to ensure proper airflow and prevent build-up of hazardous fumes. Spray guns require regular cleaning and maintenance, including nozzle adjustments to ensure optimal spray pattern and prevent clogging. The air compressor needs periodic checks for leaks and filter changes, along with regular oil changes. Regular calibration of the paint mixing system is essential to ensure accuracy and consistency.

In addition to these maintenance tasks, a preventative maintenance schedule helps to avoid unexpected downtime and ensures long-term equipment life. This proactive approach is cost-effective in the long run and promotes a safer work environment for everyone involved.

Q 8. What safety precautions do you take while working with automotive paints and solvents?

Safety is paramount in automotive finishing. Working with paints and solvents exposes us to hazardous materials, so a rigorous safety protocol is essential. This begins with proper Personal Protective Equipment (PPE), including respirators (specifically designed for paint fumes), safety glasses, gloves (nitrile is preferred for its chemical resistance), and coveralls to prevent skin contact. We always work in well-ventilated areas, ideally with a dedicated spray booth equipped with exhaust systems to remove airborne particles and fumes. Before commencing any task, I thoroughly read the Safety Data Sheets (SDS) for each product to understand its specific hazards and handling instructions. Regular cleaning of the work area is crucial to prevent spills and accumulation of flammable materials. In case of spills, I follow the established cleanup procedures and utilize appropriate absorbent materials. Finally, proper disposal of waste materials, following all local and environmental regulations, is non-negotiable.

For instance, I recall a situation where a colleague accidentally spilled some thinner. Instead of panicking, we calmly followed the established spill response procedure: isolating the area, using absorbent pads to soak up the spill, and then properly disposing of the contaminated materials according to the SDS instructions. This prevented further hazards and potential environmental damage.

Q 9. Explain your experience with different sanding techniques and abrasives.

My experience with sanding techniques spans various applications within automotive finishing, from initial surface preparation to final polishing. I’m proficient in both wet and dry sanding techniques, utilizing different grits of sandpaper (from coarse to fine) depending on the stage of the process. Wet sanding, particularly with water and a suitable lubricant, minimizes dust and provides a smoother finish, especially useful in removing imperfections between coats of paint or clear coat. Dry sanding, on the other hand, is often used for initial surface preparation, removing blemishes, or when working with filler. The choice of abrasive is critical; I select the grit based on the surface condition and the desired level of smoothness. For example, a coarser grit (e.g., 80-grit) might be used for initial leveling, followed by progressively finer grits (e.g., 180, 320, 600, and even higher) to achieve a flawless surface for painting. I also have experience with using various sanding tools, from hand sanding blocks to orbital sanders and random orbital polishers, each suited to specific tasks and surface areas.

For instance, when preparing a car for repainting, I’d start with coarser grits to remove any existing paint imperfections and rust. Then, I gradually move to finer grits to achieve a smooth and even surface that’s ready for priming and painting. The transition between grits is crucial to ensure a seamless finish; skipping steps can lead to noticeable imperfections.

Q 10. How do you manage your time and workload effectively in a busy paint shop?

Managing time and workload in a busy paint shop requires a structured approach. I begin by prioritizing tasks based on urgency and deadline, often using a Kanban-style system (or a similar visual management tool) to track progress. This helps me visualize the workflow and identify potential bottlenecks. I break down large tasks into smaller, manageable units, making them less daunting and easier to track. Effective time management also includes anticipating potential delays – for instance, allowing extra time for paint to dry properly or for unexpected repairs. Open communication with my team is vital; if a task requires more time than initially anticipated, I inform my colleagues immediately to avoid impacting other projects. Furthermore, maintaining a clean and organized workspace significantly improves efficiency; a cluttered workspace slows down the process and increases the risk of mistakes.

One specific example is when we had a sudden influx of vehicles needing repairs before a major car show. By utilizing a Kanban board and effectively delegating tasks based on individual skills, we managed to complete all repairs on time and to the highest standard, delivering all the cars on time for the show. The key was clear communication and prioritizing tasks based on deadlines.

Q 11. Describe your experience with mixing and tinting paints.

Mixing and tinting paints requires precision and a keen eye for color. I’m experienced in using both computerized color matching systems and traditional methods. Computerized systems use spectrophotometers to scan the desired color and then generate a formula for mixing the correct proportions of base coats, pigments, and clear coats. This approach is highly accurate and efficient, especially for complex colors. Traditional methods involve using color charts and mixing paints manually, requiring a good understanding of color theory and extensive experience to achieve the desired shade. This involves careful measurement and thorough mixing to ensure a consistent and uniform color throughout the paint. Regardless of the method, meticulous attention to detail is essential; even slight variations in ratios can lead to noticeable color discrepancies. Regular calibration of equipment is vital for maintaining accuracy in color matching.

I remember a particularly challenging job where we had to match a very rare and unusual color. Using the computerized system combined with manual adjustments, we were able to achieve a near-perfect match, demonstrating the importance of combining technology with expertise in achieving high-quality results.

Q 12. What is your experience with using different types of masking materials and techniques?

Masking is crucial for achieving sharp lines and protecting areas that should not be painted. I have extensive experience with various masking materials and techniques. This includes using masking tape (different widths and adhesives for various surfaces), masking paper, plastic sheeting, and specialized masking films. The choice of material depends on the complexity of the masking job and the surface being protected. Proper application is key; the tape or film must adhere securely to prevent paint bleed-through, but it should also be easy to remove without leaving residue. I’m skilled in using different application techniques, from simple straight lines to complex curves and intricate detailing. The use of specialized tools, such as masking knives and smoothing tools, enhances precision and speed. Poor masking can lead to significant rework, so meticulous attention to detail is paramount.

For instance, when painting a car with multiple colors and stripes, precise masking is critical for sharp lines. We use different widths of masking tape and carefully apply it to ensure the paint remains within the designated areas. Any gaps or imperfections can lead to bleed-through, ruining the final finish.

Q 13. How do you ensure the quality of your work meets industry standards?

Ensuring the quality of my work adheres to industry standards involves a multi-step process. First, I meticulously prepare the surface, ensuring it’s clean, free of defects, and properly primed. Next, I apply the paint according to manufacturer specifications, paying close attention to proper application techniques (gun pressure, distance, overlap, etc.). Throughout the process, I regularly inspect my work for imperfections – such as runs, sags, orange peel, or dust nibs – addressing them immediately to prevent compounding the issues. After the paint has dried, I perform quality control checks, including visual inspections under various lighting conditions. In some cases, using measuring instruments to evaluate the thickness of paint coats is necessary. Finally, detailed documentation of the entire process, including materials used and procedures followed, is part of maintaining quality control.

We use a checklist to ensure every step in the process is completed correctly. This allows for early detection of errors and minimizes rework, ensuring that the final product meets the highest quality standards.

Q 14. Describe your understanding of VOC regulations.

Volatile Organic Compounds (VOCs) are organic chemicals that readily evaporate at room temperature and contribute to air pollution. Regulations regarding VOC emissions in automotive paints are stringent and designed to protect both the environment and the health of workers. These regulations typically specify limits on the amount of VOCs allowed in paint formulations. Paints that meet these requirements are labeled as low-VOC or compliant paints. As a professional in automotive finishing, I’m aware of and comply with all applicable VOC regulations. This includes using approved low-VOC paints and solvents, ensuring proper ventilation during the painting process, and following proper disposal procedures for waste materials. Regular training on VOC regulations is crucial to stay updated on changes and best practices. In some cases, specific permits or licenses might be required for handling certain paints and solvents.

For instance, we recently transitioned to a new line of low-VOC paints that still provide excellent results but have significantly reduced our environmental impact. This highlights the ongoing effort in the industry to balance performance with environmental responsibility.

Q 15. How do you handle challenging or complex repair jobs?

Tackling complex repair jobs requires a methodical approach. It starts with a thorough assessment – identifying the damage extent, the underlying cause (e.g., accident damage, rust, previous poor repair), and the vehicle’s specific paint code. I use a systematic process:

- Detailed Inspection: This involves meticulously examining the area, assessing the depth and type of damage. For instance, a deep scratch might need more filler than a minor scuff.

- Preparation: Proper preparation is key. This includes sanding (using appropriate grits to avoid burn-through), cleaning the surface thoroughly (removing any contaminants that could affect adhesion), and masking off adjacent areas to protect the undamaged paint.

- Repair Techniques: The repair technique will depend on the damage. Small dents may be addressed with filler and careful sanding, while larger areas might require panel replacement or dent pulling. I’m proficient in various repair techniques, including metal finishing, plastic repair, and color matching.

- Color Matching: Achieving a perfect color match is crucial. I utilize computerized color systems (discussed later) to accurately formulate the paint mix, and I might use blending techniques to seamlessly integrate the repair into the existing paintwork.

- Application: Paint application involves multiple thin coats, allowing each to flash off before applying the next for even coverage and optimal durability. Proper spray gun technique and air pressure are crucial.

- Finishing and Inspection: After painting, I inspect the repair under various lighting conditions to identify any imperfections such as orange peel, runs, or dust nibs, rectifying them using wet sanding and polishing. This ensures a flawless finish.

For example, I once repaired extensive damage to a classic car’s fender, involving significant rust repair and precise color matching using a vintage paint formula, resulting in an award-winning restoration.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with different types of clear coats.

Clear coats are the protective top layer of an automotive finish, providing UV protection, gloss, and durability. I have extensive experience with various types:

- Acrylic Lacquers: These are fast-drying and easy to apply but less durable and more susceptible to UV damage compared to other types. I use them sparingly, usually for restoration projects where the original paint specified this type.

- Acrylic Urethanes: These are the most common clear coats in today’s automotive refinishing. They offer excellent durability, gloss retention, and UV resistance, along with good chemical resistance and flexibility. They provide a superior finish compared to lacquer.

- Urethane 2K Clear Coats: These are 2-part (two-component) systems that require mixing a hardener with the clear coat. They cure to a significantly more durable finish and are highly resistant to scratches and chemicals. I prefer these for most modern vehicles as they provide the best long-term protection.

- Waterborne Clear Coats: These environmentally friendly clear coats use water as a solvent instead of harsh organic solvents. They provide a good finish and are increasingly popular in the industry due to their lower environmental impact. However, application techniques require attention to detail.

The choice of clear coat depends on the specific needs of the vehicle and the desired outcome. For a show car, a high-quality, premium 2K urethane clear coat would be the ideal choice. For a daily driver, a high-quality standard acrylic urethane offers a good balance between durability and cost-effectiveness.

Q 17. What is your understanding of different types of primers?

Primers are crucial for paint adhesion and corrosion protection. They prepare the surface for the subsequent layers of paint. Different types cater to various needs:

- Epoxy Primers: These offer excellent corrosion protection and adhesion, particularly on bare metal. They are typically used as a first coat, providing a barrier against rust and ensuring good adhesion of subsequent coats. They require proper surface preparation before application.

- 2K Urethane Primers: These provide superior adhesion and durability, often used on previously painted surfaces or areas requiring exceptional protection. They require careful mixing ratios and proper curing time.

- High-Build Primers: These primers are designed to fill in small imperfections and level the surface before the topcoat application. These primers are thicker than standard primers and used to smooth out small imperfections.

- Self-etching Primers: These primers chemically etch the surface they are applied to, creating better mechanical adhesion, particularly useful for aluminum and galvanized metal, where regular primers may not adhere well.

Choosing the right primer depends on the substrate and the repair requirements. For instance, bare metal requires an epoxy primer for corrosion protection, while repairing a minor scratch on an already painted surface might only need a 2K urethane primer.

Q 18. How do you identify and address paint imperfections after application?

Identifying and addressing paint imperfections is a critical part of the finishing process. I use a multi-stage approach:

- Visual Inspection: I carefully inspect the painted surface under different lighting conditions (natural light, halogen lamps) to highlight any imperfections like orange peel (uneven texture), runs (drips of paint), dust nibs (small bits of dust embedded in the paint), and fisheyes (small craters in the paint). I often use a bright, focused light at a low angle to highlight these imperfections.

- Wet Sanding: To remove minor imperfections, I carefully wet sand the paint using progressively finer grits of sandpaper, always keeping the surface wet to prevent clogging and burning. This requires patience and precision to avoid sanding through the paint.

- Polishing and Buffing: After sanding, I polish and buff the surface using various compounds and polishing pads to restore the gloss and remove any sanding marks. The selection of compound depends on the severity of imperfections. I start with a more aggressive compound and progress to finer ones to achieve a mirror-like finish.

- Final Inspection: After polishing, I thoroughly inspect the surface again for any remaining imperfections. Any remaining flaws could be addressed with additional polishing, touch-ups, or even re-spraying.

For instance, to address orange peel, I would begin with wet sanding using P1500 grit, followed by progressively finer grits (e.g., P2000, P3000). Then, I would polish and buff the surface to achieve the desired shine.

Q 19. Describe your experience working with computerized color systems.

Computerized color systems are essential for accurate color matching in automotive refinishing. My experience includes using systems from major manufacturers like PPG, BASF, and Axalta. These systems utilize spectrophotometers – devices that measure the reflectance of light off the paint surface. The spectrophotometer data is then used by the system’s software to formulate the precise paint mixture needed to match the original color.

The process typically involves:

- Scanning the Paint: The spectrophotometer is carefully placed against the original paint to obtain a color reading. This needs to be done on a clean, undamaged area of the vehicle.

- Formula Generation: The system’s software then analyzes the data and generates a formula for the required paint, including the base coat and clear coat. It also provides information on required pigments and mixing ratios.

- Paint Mixing: The formula is used to mix the paint accurately using computerized mixing equipment, ensuring consistent and repeatable results.

- Verification: Before applying the paint, I might make a small test spray to verify the color match. This allows for minor adjustments if necessary before applying it to the entire panel.

These systems dramatically improve color matching accuracy, reducing the need for guesswork and trial-and-error, leading to a more professional finish and minimizing the risk of color mismatch.

Q 20. What is your understanding of the different stages of the automotive painting process?

The automotive painting process typically involves several key stages:

- Preparation: This crucial step involves thoroughly cleaning the surface to be painted, removing any rust, repairing dents and scratches using filler, sanding to create a smooth surface, and masking off adjacent areas to protect them from overspray. Preparation accounts for up to 80% of the overall quality of the final finish.

- Priming: Application of a suitable primer to enhance adhesion, provide corrosion protection, and create a uniform surface for the subsequent layers. The type of primer is chosen based on the substrate and the type of topcoat being used. Proper drying time is essential.

- Base Coat Application: Applying the base coat in multiple thin coats, allowing each to flash off before applying the next. This ensures an even coat, avoiding runs or sags. The use of a spray gun with proper air pressure is crucial for good atomization of the paint and preventing excessive paint buildup.

- Clear Coat Application: Applying several coats of clear coat to provide UV protection, durability, gloss, and depth of shine. Clear coat requires similar careful application techniques to the base coat.

- Finishing: This stage involves wet sanding and polishing to remove imperfections, such as orange peel, runs, or dust nibs and restoring the surface to a smooth and glossy finish. This is followed by a thorough cleaning to ensure the removal of any sanding residue.

Each stage requires meticulous attention to detail to ensure the best possible finish. Skipping steps or rushing the process can result in a poor quality finish.

Q 21. How do you maintain a clean and organized work area?

Maintaining a clean and organized workspace is paramount for efficiency and safety in automotive refinishing. My approach involves:

- 5S Methodology: I utilize the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize my workspace. This involves regularly sorting through tools and materials, organizing them logically, keeping the area clean and free of debris, standardizing procedures, and maintaining this organization over time.

- Proper Tool Storage: All tools and equipment are stored in designated places, preventing clutter and ensuring easy access when needed. This includes proper storage for spray guns, air hoses, sanding equipment, and mixing cups.

- Regular Cleaning: I regularly clean the workspace, removing paint overspray, dust, and debris. I use appropriate cleaning agents and equipment (e.g., pressure washers, vacuums) for different types of spills and debris.

- Waste Management: Proper disposal of hazardous waste (e.g., solvents, paint thinners) is crucial. I follow all safety regulations and guidelines for handling and disposing of hazardous materials.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including respirators, gloves, and eye protection, to protect myself from harmful chemicals and airborne particles.

A clean and organized workspace not only improves efficiency but also reduces the risk of accidents and improves the overall quality of the work. A cluttered workspace leads to mistakes and delays. Keeping it clean is a daily habit.

Q 22. How do you handle customer inquiries and concerns regarding paint work?

Handling customer inquiries regarding paint work requires a calm, professional, and solution-oriented approach. I begin by actively listening to understand their concerns completely, asking clarifying questions to ensure I grasp the specifics of the issue. This could range from minor imperfections to more significant damage. I then visually assess the work to identify the root cause of the problem. This might involve checking for defects in the application process, environmental factors affecting the curing, or even material issues. Depending on the nature of the complaint, I would explain the process of rectifying the situation, outlining the steps involved, the timeframe for completion, and the associated costs if any repairs or re-works are necessary. Transparency and open communication are key throughout this process. For example, if a customer complains about orange peel texture in the finish, I would explain the causes (e.g., incorrect spray gun distance, air pressure, or paint viscosity) and how I’d address it (e.g., wet-sanding and polishing). I would aim to exceed their expectations with a swift and effective solution, ensuring the customer leaves feeling satisfied and valued. Finally, I would document the entire interaction, including the complaint, the corrective actions taken, and the resolution, for future reference.

Q 23. Describe your experience with different types of body fillers.

My experience encompasses a wide range of body fillers, each suited to specific repair needs. I’m proficient with polyester fillers, which offer excellent strength and are ideal for larger repairs and filling deep scratches. I’m also experienced with epoxy fillers, preferred for their superior adhesion, especially on substrates like aluminum or galvanized steel. These are excellent for smaller repairs requiring precise filling and shaping. Furthermore, I have expertise in using lightweight fillers, frequently employed to minimize added weight and maintain vehicle integrity. The choice of filler depends critically on the type of damage and the underlying material. For instance, when dealing with rust repair, I would likely use a filler designed for corrosion-resistant properties. I understand the importance of applying fillers correctly, including proper mixing ratios, application techniques, and ensuring adequate curing time. Improper application can lead to cracking, shrinking, and poor adhesion, which would compromise the final finish. I always meticulously prepare the surface before filler application, ensuring the area is clean, dry, and free from any contaminants. This includes thorough cleaning, sanding, and priming to achieve optimal adhesion.

Q 24. What are your strengths and weaknesses as an automotive finisher?

My strengths lie in my meticulous attention to detail, my ability to consistently produce high-quality finishes, and my problem-solving skills. I’m adept at identifying and resolving issues efficiently and effectively, even under pressure. I am a quick learner and easily adapt to new technologies and techniques. For example, I recently mastered the application of a new water-based clear coat, reducing the shop’s VOC emissions while maintaining the exceptional shine and durability of the finish. However, my weakness lies in my occasional perfectionism, which can sometimes lead to me spending more time on a project than strictly necessary. I actively manage this by setting realistic deadlines and prioritizing tasks to avoid delays while still maintaining high standards of quality. I’m committed to continuous improvement and constantly seek feedback to refine my work process.

Q 25. How do you stay current with industry trends and technologies?

Staying current in this dynamic field is crucial. I achieve this through a multi-faceted approach. I regularly attend industry conferences and workshops, where I network with professionals and learn about the latest advancements in materials, techniques, and technologies. I also subscribe to relevant trade publications and online resources, keeping me abreast of new product releases and best practices. I participate in online forums and communities to engage in discussions and share knowledge with other automotive finishers. Moreover, I proactively seek out training opportunities from manufacturers of paints, coatings, and equipment to enhance my skills and stay informed about the latest advancements in their products. This continuous learning ensures I remain at the forefront of innovation and can adopt the best practices in my work.

Q 26. Describe your experience with using a spray gun.

I have extensive experience using various types of spray guns, from conventional gravity-feed guns to HVLP (High Volume Low Pressure) and airless spray systems. My proficiency encompasses adjusting spray gun settings such as air pressure, fluid viscosity, and fan pattern to achieve optimal atomization and paint distribution. I understand the importance of proper gun cleaning and maintenance to prevent clogging and ensure consistent performance. I am comfortable working with a variety of materials, including basecoats, clear coats, primers, and sealers. I am well-versed in techniques like wet-on-wet and flash-off application, adjusting my technique based on material requirements and environmental conditions. My ability to achieve smooth, uniform finishes with minimal overspray demonstrates my mastery of this crucial skill. For instance, my experience using HVLP spray guns has enabled me to significantly reduce material waste and improve the overall quality of my work while minimizing environmental impact.

Q 27. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and are in line with the industry standard for an automotive finisher with my level of expertise. I am open to discussing a competitive salary package that reflects my contributions to the company’s success.

Q 28. Do you have any questions for me?

Yes, I do have a few questions. I’d like to learn more about the company’s commitment to ongoing training and professional development. Also, I’m interested in understanding the company culture and the team dynamics within the automotive finishing department. Finally, I would like to know more about the types of projects and vehicles I would be working on.

Key Topics to Learn for Automotive Finishing Interview

- Paint Application Techniques: Understanding various spray methods (conventional, HVLP, electrostatic), their applications, and the factors influencing paint quality (e.g., air pressure, nozzle size, paint viscosity).

- Paint Chemistry and Properties: Knowledge of different paint types (e.g., acrylic lacquer, urethane, waterborne), their chemical composition, drying processes, and how these properties affect the final finish.

- Surface Preparation: Mastering techniques like cleaning, sanding, masking, and priming to ensure a smooth, defect-free surface for optimal paint adhesion and appearance. This includes understanding different materials and their preparation requirements.

- Quality Control and Inspection: Familiarizing yourself with methods for identifying and addressing defects like orange peel, runs, sags, and fisheyes, and implementing quality control measures throughout the finishing process. Understanding quality standards and metrics is crucial.

- Health and Safety Regulations: Demonstrate awareness of safety procedures related to handling paints, solvents, and other materials. Knowledge of relevant OSHA or industry-specific safety guidelines is essential.

- Troubleshooting and Problem Solving: Ability to diagnose and resolve common finishing problems efficiently and effectively. This requires a practical understanding of the entire process and its potential points of failure.

- Environmental Considerations: Understanding sustainable finishing practices, waste management, and compliance with environmental regulations related to paint and solvent disposal.

- Advanced Finishing Techniques: Explore specialized techniques like clear coat application, metallic paint application, and color matching. Understanding the nuances of these techniques will showcase advanced knowledge.

Next Steps

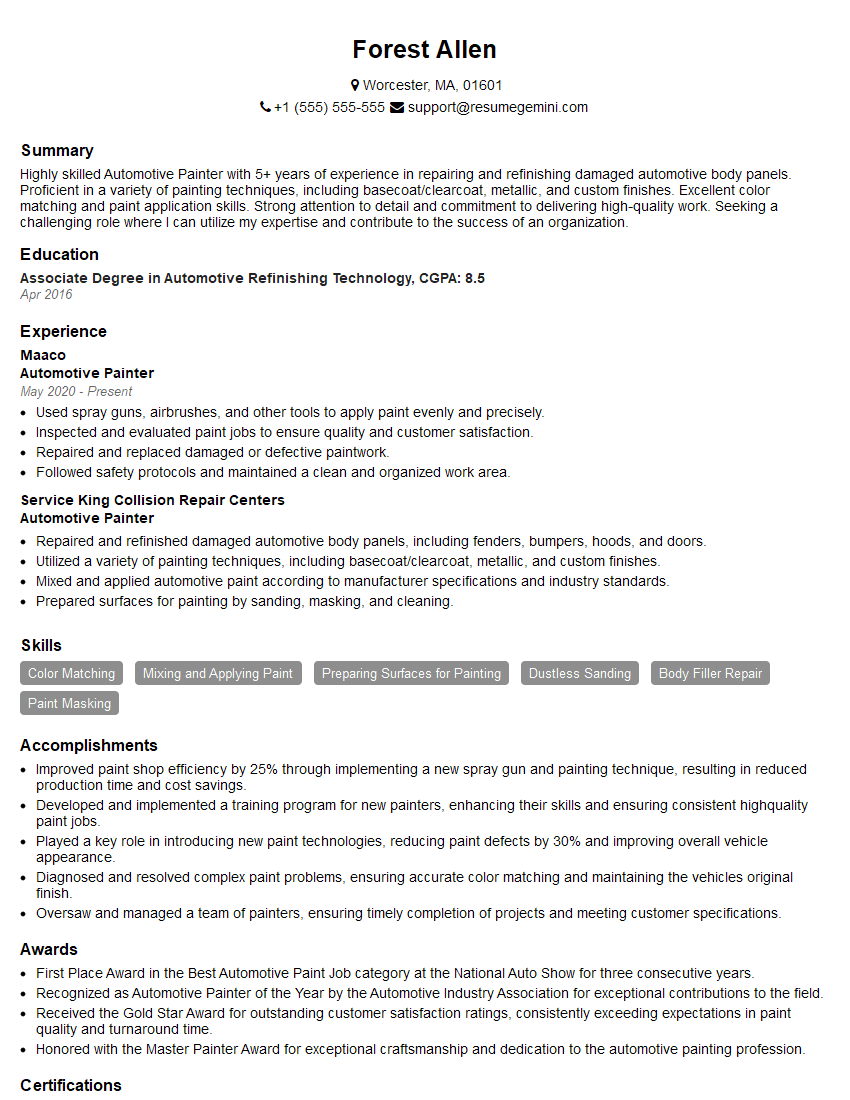

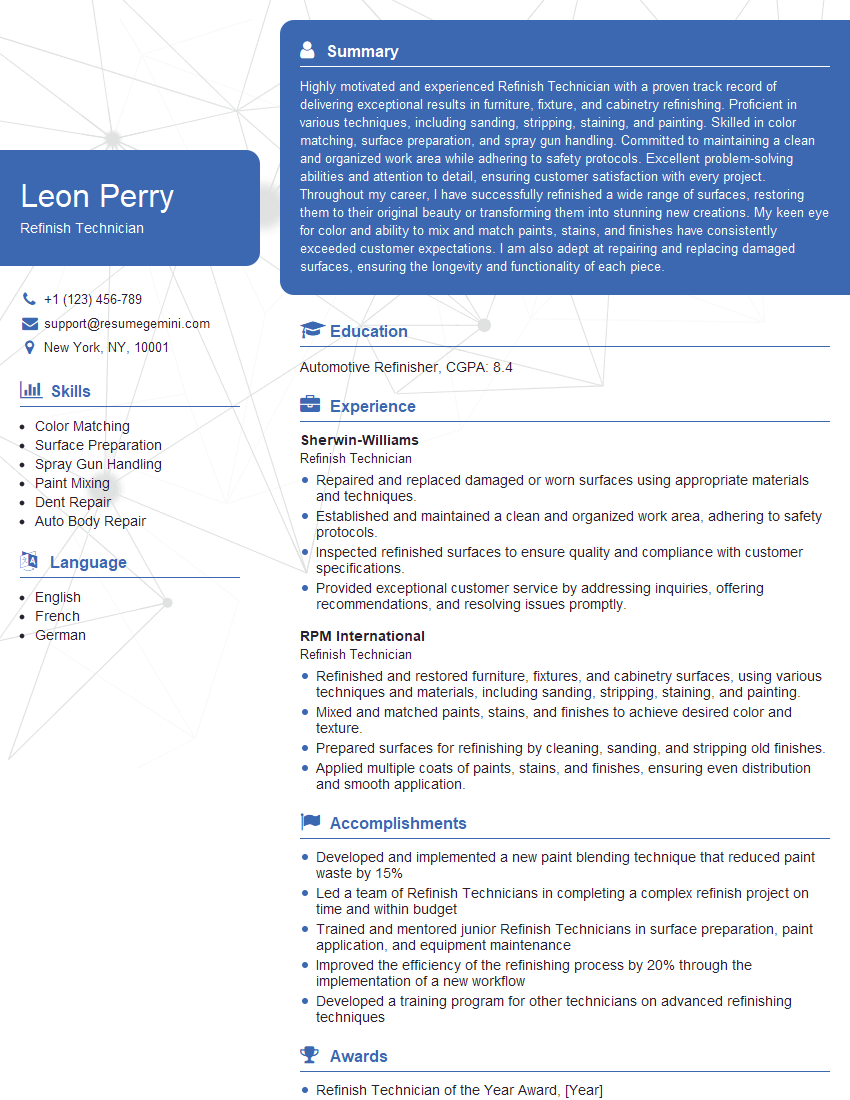

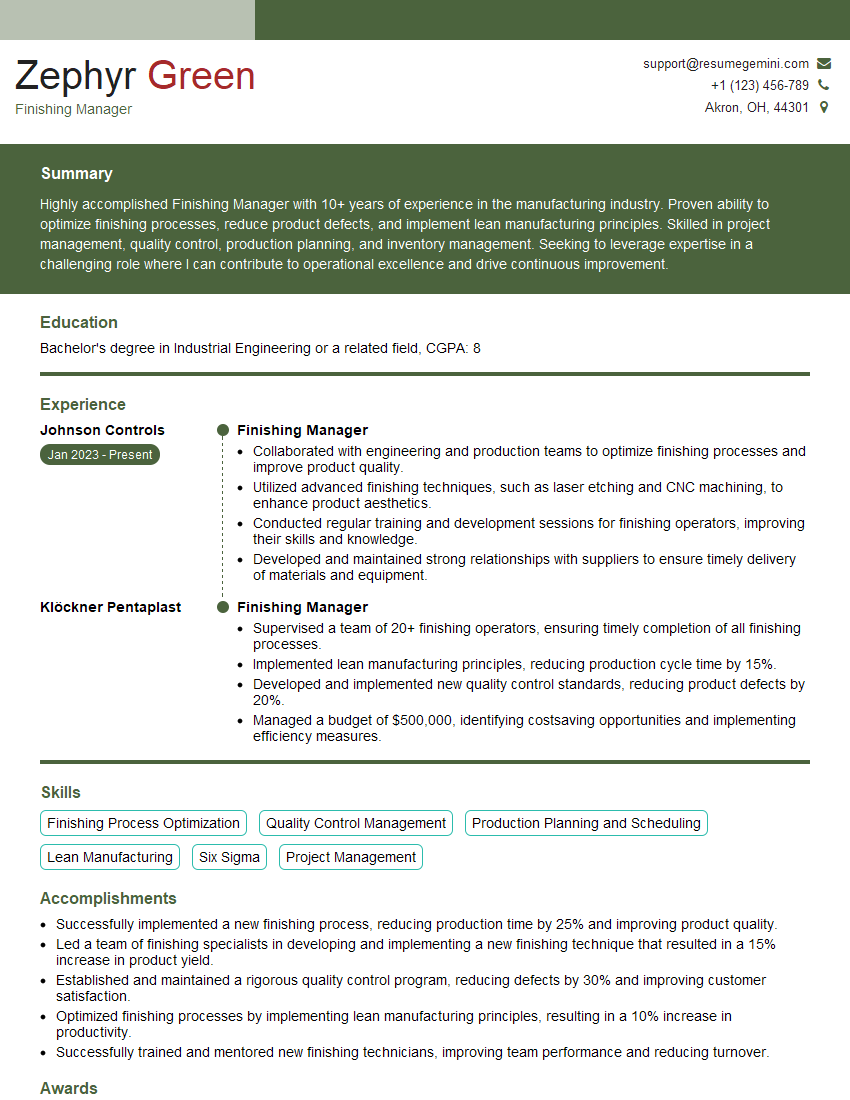

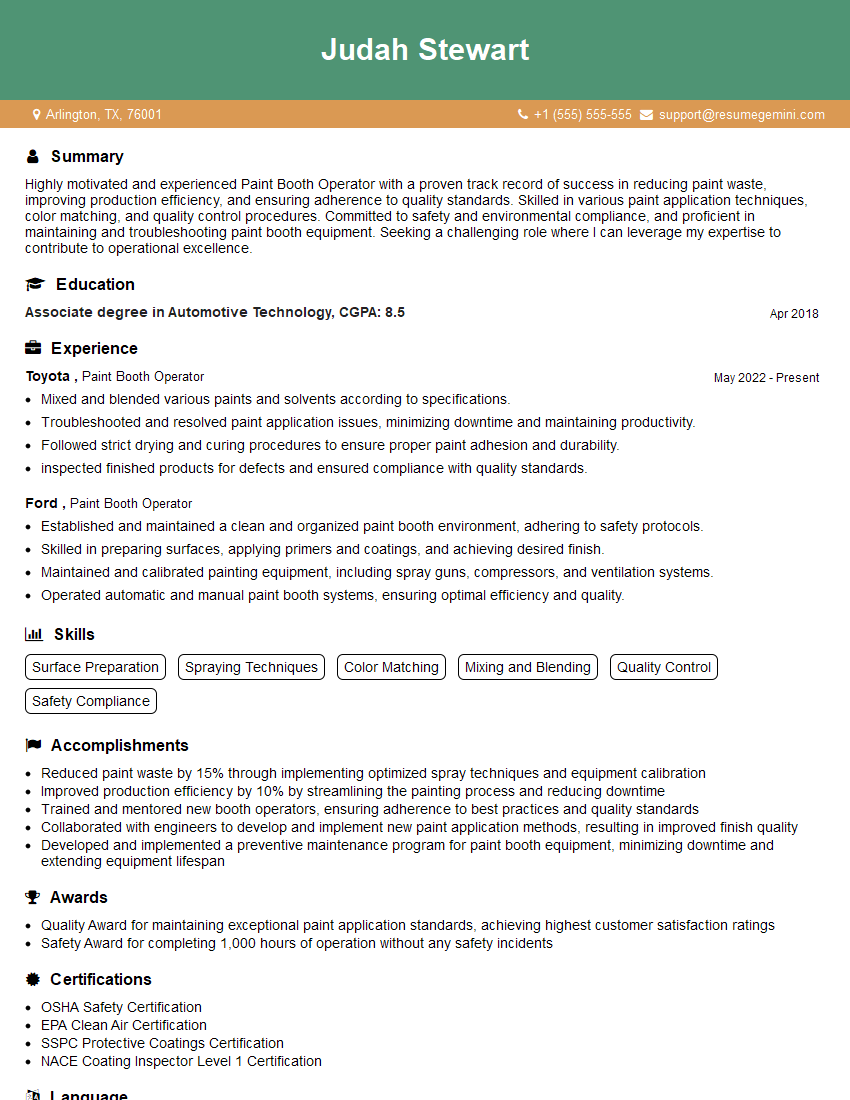

Mastering Automotive Finishing opens doors to rewarding careers with excellent growth potential. Advancement opportunities range from skilled technician to supervisor and beyond, depending on experience and expertise. To significantly improve your job prospects, creating a strong, ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional, impactful resume tailored to the Automotive Finishing industry. Examples of resumes specifically designed for Automotive Finishing roles are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Amazing blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?