Are you ready to stand out in your next interview? Understanding and preparing for Architectural Finishing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Architectural Finishing Interview

Q 1. Explain the process of preparing a surface for painting.

Preparing a surface for painting is crucial for a long-lasting, aesthetically pleasing finish. Think of it like preparing a canvas for a masterpiece – a poorly prepped surface will show through no matter how good the paint is. The process involves several key steps:

- Cleaning: Remove all loose dirt, dust, cobwebs, and any previous loose paint using a brush, scraper, or vacuum. For greasy surfaces, a degreaser might be necessary. Imagine trying to paint over a dusty window – the paint wouldn’t stick!

- Repairing: Fill any holes, cracks, or imperfections with spackle or patching compound. Allow it to dry completely and sand smooth for a seamless surface. This step is like patching holes in a wall before decorating; it prevents blemishes from showing through.

- Priming: Applying a primer seals the surface, improves adhesion, and provides a uniform base for the topcoat. Primers are especially important on porous surfaces like drywall or bare wood. This acts like a foundation for the paint, ensuring a smooth and even finish.

- Sanding: After the primer dries, lightly sand the surface to create a smooth finish, removing any imperfections or bumps. This is similar to smoothing a canvas before painting; a smooth surface allows for better paint application.

- Cleaning Again: After sanding, remove all dust particles using a tack cloth or vacuum. This ensures that the final coat adheres properly, without any particles interfering. Think of this as a final clean-up before the main event.

By following these steps meticulously, you ensure that the paint adheres properly, resulting in a professional and durable finish. Skipping any step, especially priming, will lead to paint peeling or an uneven appearance.

Q 2. Describe different types of paint finishes and their applications.

Paint finishes vary greatly in their sheen and durability, impacting both aesthetics and practicality. Choosing the right finish depends on the surface and intended use.

- Flat/Matte: This finish has minimal sheen, hiding surface imperfections well, but it’s less durable and harder to clean. It’s ideal for low-traffic areas like ceilings or formal living rooms where a subtle, sophisticated look is desired.

- Eggshell: Slightly more sheen than flat, eggshell offers better scrubbability and durability while still concealing minor flaws. It’s a popular choice for bedrooms and hallways.

- Satin: A moderate sheen offering good durability and washability. It’s frequently used in kitchens and bathrooms, areas prone to moisture and spills, providing easy cleaning.

- Semi-Gloss: Higher sheen than satin, providing excellent durability and washability. It’s a great choice for trim, doors, and window frames where frequent cleaning is needed. It also reflects more light, making it visually striking.

- Gloss: The highest sheen, providing maximum durability and washability. It’s generally used for trim in high-traffic areas or where a high-gloss finish is desired, but it shows imperfections more readily.

The choice ultimately depends on the desired look and the room’s functionality. For example, a high-gloss finish might be perfect for a kitchen but would be inappropriate for a bedroom where a more subdued finish is preferred.

Q 3. What are the key considerations for selecting appropriate wall coverings?

Selecting appropriate wall coverings depends on several factors, including aesthetics, durability, budget, and the room’s intended use. Think about the overall design and how the wall covering will complement it.

- Budget: Paint is generally the most economical option, while wallpaper or high-end textured wall coverings are more expensive.

- Durability: For high-traffic areas, washable and durable materials like vinyl wallpaper or certain types of paint are preferable. In areas with less wear and tear, delicate wallpapers can be used.

- Aesthetics: Consider the style and color of the room. A bold wallpaper might be suitable for an accent wall, while a more subtle paint color might be better for a larger surface area. Texture is another significant element.

- Maintenance: Some wall coverings are easier to clean and maintain than others. Consider the level of maintenance you’re willing to undertake.

- Room Function: A bathroom requires moisture-resistant wall coverings, while a bedroom might benefit from sound-dampening materials.

For instance, a busy family with young children might opt for washable vinyl wallpaper in the living room, while a quieter, more formal setting might call for a delicate, textured wall covering. Each decision should consider the practical and aesthetic elements.

Q 4. How do you ensure proper adhesion of wall coverings?

Proper adhesion of wall coverings is vital for a long-lasting and professional finish. The surface preparation is key; it’s like ensuring a strong foundation for a building. The steps include:

- Surface Preparation: Clean and smooth the wall as previously described for painting. Any imperfections will show through.

- Primer (if necessary): Certain wall coverings might require a primer, especially if applied to porous surfaces. The primer improves adhesion and provides an even base.

- Proper Application: Follow the manufacturer’s instructions carefully. This includes using the correct adhesive, applying it evenly, and allowing for proper drying time. Rushing this process compromises the final result.

- Seaming: Ensure that seams are properly aligned and pressed firmly to eliminate gaps or bubbles. This is like creating invisible joints between separate pieces.

- Appropriate Tools: Use the right tools for the job. For example, using a smoothing tool or a seam roller to press out air bubbles and ensure a smooth finish.

Ignoring these steps will result in peeling, bubbling, or uneven application. Always test a small area before committing to the full application. This allows for adjustments in technique or material choice.

Q 5. What are the common problems encountered during drywall finishing?

Drywall finishing, while seemingly simple, presents several common challenges. These can range from minor aesthetic issues to significant structural problems.

- Tape Joints: Improper taping and mudding can lead to visible seams, cracks, or uneven surfaces.

- Nail Pops: Nails pushing through the drywall, creating small bumps or holes.

- Sanding Issues: Over-sanding can create thin spots, while insufficient sanding leaves an uneven surface.

- Mudding Issues: Applying too much mud at once leads to cracking and sagging. Too little leaves gaps.

- Texture Issues: Creating a consistent texture (e.g., orange peel) can be difficult, requiring practice and skill.

Addressing these issues requires careful attention to detail, proper techniques, and high-quality materials. For example, using the appropriate type of drywall tape and mud, and applying thin coats is critical.

Q 6. Describe your experience with different types of drywall mud and taping techniques.

My experience encompasses various drywall muds and taping techniques. The choice of mud depends on the specific application and desired outcome.

- All-Purpose Mud: A versatile option suitable for most applications, offering a good balance of workability and strength.

- Lightweight Mud: Easier to work with, reducing strain, but might require more coats for the same level of coverage.

- Setting-Type Mud: Sets quickly, ideal for large areas or when a fast turnaround is needed, but demands experience to manage the setting time.

Taping techniques include:

- Embedding Tape: Pressing the tape into wet mud, ensuring complete adhesion and preventing cracks.

- Coat Application: Applying thin, even coats of mud to cover the tape and create a smooth surface. Multiple coats are usually needed, allowing ample drying time between each.

- Sanding: Using progressively finer grits of sandpaper to achieve a perfectly smooth surface.

I’m proficient in various taping techniques like the ‘hot mud’ method where the mud is applied hot to improve its flow and coverage. The key is patience and attention to detail to achieve a flawless finish.

Q 7. How do you manage the timing of finishing work to avoid delays?

Managing the timing of finishing work requires careful planning and coordination with other trades. Delays can cascade through the entire project, impacting timelines and budgets. My approach involves:

- Detailed Scheduling: Creating a detailed schedule that outlines each stage of the finishing process, including drying times and potential delays. This involves accounting for the curing time of each material.

- Coordination with Other Trades: Close communication with other tradespeople, like plumbers and electricians, to ensure that their work is completed before the finishing stage begins. Waiting for them to finish saves valuable time.

- Contingency Planning: Building in buffer time to account for unforeseen delays or material shortages. This prevents major disruptions to the project timeline.

- Prioritization: Prioritizing tasks based on their dependency on other aspects, for example, priming needs to be done before painting. This helps avoid bottlenecks.

- Regular Monitoring: Regularly monitoring progress and identifying potential issues early on. This ensures that corrective actions can be taken promptly.

Effective communication and proactive planning are crucial for avoiding delays and ensuring a smooth, efficient finishing process. An example of this would be checking the weather forecast before scheduling exterior painting.

Q 8. Explain the importance of maintaining a clean and organized worksite.

Maintaining a clean and organized worksite is paramount in architectural finishing for several crucial reasons. It directly impacts safety, efficiency, and the final quality of the work. A cluttered site increases the risk of accidents – tripping hazards from tools and materials, for example. A clean site allows for easier access to tools and materials, streamlining the workflow and reducing project time. Finally, a clean environment ensures that the finished product isn’t marred by dust, debris, or accidental damage.

- Safety: A clear pathway minimizes tripping hazards, preventing injuries to workers and damage to materials.

- Efficiency: Easily accessible tools and materials reduce wasted time searching and increase productivity.

- Quality: A clean environment prevents dust and debris from contaminating the finished surfaces, ensuring a pristine final product.

For instance, on a recent project involving intricate plasterwork, maintaining a dust-free environment was critical. We used drop cloths, vacuum cleaners regularly, and enforced a strict ‘clean-as-you-go’ policy, ensuring the final finish was flawless and free from imperfections.

Q 9. How do you handle unexpected changes or challenges during a project?

Unexpected changes and challenges are inevitable in construction. My approach involves a proactive and adaptable strategy. First, I carefully assess the situation, identifying the root cause of the change and its potential impact on the project timeline and budget. Then, I communicate transparently with the client and the project team, explaining the issue and exploring potential solutions together. This collaborative approach fosters trust and allows for informed decision-making.

For example, during a recent project, we encountered unforeseen water damage behind a wall that required extensive repairs. Instead of panicking, I immediately documented the damage, consulted with the structural engineer, and worked with the client to determine the best course of action. We adjusted the schedule, secured additional materials, and managed to complete the repairs with minimal disruption to the overall project timeline.

Ultimately, my experience has taught me that flexibility and clear communication are key to successfully navigating unexpected hurdles. A problem-solving approach, rather than a reactive one, is critical in ensuring project success.

Q 10. Describe your experience with various types of flooring finishes.

My experience encompasses a wide range of flooring finishes, including hardwood, tile, carpet, and resilient flooring such as vinyl and luxury vinyl plank (LVP). Each material requires a unique approach to installation and finishing.

- Hardwood: I’m proficient in various hardwood finishing techniques, from traditional polyurethane finishes to more modern oil-based options. Understanding wood grain, moisture content, and proper sanding techniques is crucial for a durable and beautiful finish.

- Tile: I’m experienced in installing and grouting various types of tile, including ceramic, porcelain, and natural stone. Precise cutting and careful grout selection are vital for a seamless and watertight installation.

- Carpet: My expertise includes proper carpet stretching, trimming, and seaming techniques to ensure a smooth and wrinkle-free installation. Understanding different carpet fibers and their respective properties is key.

- Resilient Flooring: I’m familiar with the installation and finishing of vinyl and LVP flooring, including proper subfloor preparation and seam sealing to prevent moisture damage.

Understanding the properties of each material and its limitations is key to achieving a high-quality, long-lasting floor.

Q 11. What are the safety precautions associated with working with different finishing materials?

Safety is paramount in architectural finishing. Working with various finishing materials requires strict adherence to safety protocols to protect both myself and others on the job site. This includes:

- Respiratory Protection: Many finishing materials, such as paints, stains, and sealants, release volatile organic compounds (VOCs) that can be harmful if inhaled. Respiratory protection, such as respirators with appropriate cartridges, is essential.

- Eye Protection: Safety glasses or goggles are crucial to protect against splashes or airborne particles.

- Skin Protection: Gloves should always be worn to prevent skin irritation or allergic reactions from contact with finishing materials. Protective clothing might be needed for certain materials.

- Proper Ventilation: Adequate ventilation is necessary to remove VOCs and prevent the buildup of harmful fumes. This might involve using fans or opening windows.

- Material Safety Data Sheets (MSDS): Before working with any material, I always review the MSDS to understand its potential hazards and necessary safety precautions.

Ignoring these precautions can lead to serious health consequences. Prioritizing safety ensures a healthy and productive work environment.

Q 12. How do you ensure consistency in color and finish across large areas?

Maintaining color and finish consistency across large areas requires meticulous planning and execution. This involves:

- Using the same batch of materials: Ordering enough material from a single batch minimizes variations in color and shade.

- Thorough mixing: Ensuring the finishing materials are thoroughly mixed prevents inconsistencies in color and application.

- Consistent application techniques: Maintaining a uniform application technique, whether brushing, rolling, or spraying, helps achieve a consistent finish.

- Regular color checks: Periodically checking the color and finish throughout the application process ensures consistency and allows for quick correction of any variations.

- Using color charts and samples: Referring to color charts and samples throughout the process ensures that the final finish matches the desired color.

For large projects, I often use a calibrated paint mixing system to ensure precise color matching across batches. This level of precision is essential for creating a seamless and aesthetically pleasing finish.

Q 13. What are some common issues with wood finishing and how do you address them?

Common issues with wood finishing include:

- Uneven color: This can be caused by inconsistent application or variations in wood absorption. Careful sanding and multiple thin coats can solve this.

- Brush marks or roller marks: These are caused by improper application techniques. Using a high-quality brush, proper technique, and multiple thin coats can minimize these issues.

- Dust nibs: Small particles embedded in the finish. Thorough cleaning and dust control during sanding and finishing is key to prevention.

- Run or sags: Applying too much finish at once can cause runs. Applying thin, even coats is critical.

- Checking or cracking: This can be caused by using incompatible finishes or incorrect drying conditions. Selecting appropriate finishes and ensuring proper ventilation is essential.

Addressing these issues often requires careful attention to detail throughout the finishing process. If a problem arises, I usually focus on identifying its root cause before implementing a solution. This might involve sanding, re-coating, or even starting over in severe cases. A detailed understanding of wood properties and finishing materials is fundamental in addressing these challenges effectively.

Q 14. Explain your experience with different types of caulking and sealing techniques.

My experience with caulking and sealing encompasses various techniques and materials suited for different applications. I’m proficient in using different types of caulks, including silicone, acrylic latex, polyurethane, and butyl rubber. Each offers distinct properties and is chosen based on the specific application and material being sealed.

- Silicone Caulk: Excellent for bathrooms and kitchens due to its water resistance and flexibility. It requires proper surface preparation and careful tooling for a smooth finish.

- Acrylic Latex Caulk: Paintable and less expensive than silicone, suitable for interior applications where water resistance is not a primary concern. It’s often used for gaps around trim and baseboards.

- Polyurethane Caulk: High strength and durability, ideal for exterior applications and areas requiring a strong bond. It expands and contracts less than silicone making it ideal for expansion joints.

- Butyl Rubber Caulk: Excellent for sealing against moisture, often used in flashing and roofing applications.

Proper caulking technique involves applying the caulk smoothly and evenly into the gap, ensuring complete filling. Tooling the caulk with a wet finger or a specialized caulking tool creates a clean and professional finish. I always ensure proper adhesion by thoroughly cleaning the surfaces before applying the caulk. The choice of caulk is critical; a poorly chosen sealant can result in leaks or cosmetic issues.

Q 15. How do you manage material waste and disposal during a project?

Managing material waste is crucial for both environmental responsibility and project profitability. My approach involves a multi-pronged strategy starting with meticulous planning. This includes accurate material take-offs based on detailed shop drawings and specifications, factoring in potential waste and spoilage. I work closely with suppliers to ensure accurate ordering, often negotiating for smaller quantities to minimize excess stock. On-site, we implement a strict waste segregation system, separating materials like wood, metal, plastics, and demolition debris into designated bins. This allows for efficient recycling and responsible disposal, minimizing landfill waste. We continuously monitor material usage during the project, comparing actual consumption with initial estimates, and adjusting our ordering as needed to avoid overstocking. Regular site clean-ups are essential, preventing accidental damage or loss of usable materials. Finally, we maintain comprehensive waste disposal records to comply with all environmental regulations. For example, on a recent project involving marble tiling, we meticulously planned the cuts to minimize waste and donated the remaining scraps to a local art school.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of tile installation methods.

My experience with tile installation encompasses various methods, each tailored to the specific tile type and substrate. For instance, thin-set mortar is the most common method for ceramic and porcelain tiles on walls and floors, requiring careful mixing and application to ensure proper adhesion and a level surface. Large-format tiles, often heavier and requiring more precision, often benefit from a modified thin-set method or even a thicker-bed mortar system to manage variations in the substrate. For natural stone tiles, like marble or travertine, I prefer a richer, modified thin-set specifically designed for the material’s characteristics, sometimes augmented by additional support like backer boards to prevent cracking or settling. Specific techniques, such as using notched trowels of varying sizes to control mortar thickness, are essential for successful results. I’m also proficient in using different methods of grouting, from traditional cement-based grouts to more contemporary epoxy grouts, which are suited to wet areas due to their impermeability. The choice of method always depends on careful consideration of the tile material, substrate condition, and desired aesthetic finish.

Q 17. What are the challenges of working with intricate architectural details?

Intricate architectural details present unique challenges in architectural finishing. The complexity requires meticulous planning and execution, often demanding highly skilled craftsmanship. Precision is paramount; a slight error in measurement or installation can significantly impact the final result. Coordinating with other trades is crucial, ensuring that the finishing work aligns perfectly with existing structures or installations. For instance, working with ornate moldings requires precise measurements, often involving custom fabrication to achieve the desired effect. Another challenge is material selection, as some materials might not be suitable for highly detailed work due to their fragility or difficulty in manipulating them. On a recent project featuring hand-carved stone detailing, I had to source specialists in stone carving and ensure a seamless integration with the rest of the finishings, this required extensive planning, meetings, and a careful selection of materials appropriate for the intricate nature of the design.

Q 18. How do you manage client expectations regarding finishes?

Managing client expectations regarding finishes is a crucial aspect of my work. I achieve this through clear and proactive communication. This starts with an initial consultation where I thoroughly discuss various finish options, their pros and cons, and associated costs. I present samples, and create mood boards collaboratively with the client to visualize the end result. I emphasize the importance of realistic expectations concerning lead times, cost variations, and the limitations of materials. Throughout the project, I provide regular updates, sharing photos and videos of progress. I encourage open communication to address any concerns promptly. Addressing potential issues and challenges proactively prevents misunderstandings and maintains a positive client relationship. For example, if there is a delay in material delivery, I would proactively inform the client, explaining the reason and offering alternative solutions to minimize the impact. This proactive communication builds trust and reinforces a positive working relationship.

Q 19. How do you measure and calculate the quantities of finishing materials needed?

Accurate material quantification is essential to avoid waste and ensure project completion within budget. I rely on a combination of techniques, starting with detailed shop drawings and architectural plans. I use these plans to meticulously measure areas and calculate the required quantities of materials, considering factors such as waste, breakage, and overage for complex designs. I also use digital tools and software like AutoCAD, Revit, and specialized estimating software. These applications allow for precise calculations of surface areas, volumes, and material quantities. For example, when calculating the amount of paint needed, I factor in the coverage rate of the paint, the number of coats required, and an additional percentage for waste and touch-ups. For intricate designs or unusual materials, I often build physical mock-ups or sample areas to determine material requirements before large-scale ordering, ensuring minimal waste and maximum efficiency.

Q 20. Describe your experience with creating custom finishes or effects.

Creating custom finishes is a rewarding aspect of my work, allowing for unique and personalized results. I’ve had extensive experience in developing custom finishes, ranging from Venetian plaster techniques to unique metallic effects. For Venetian plaster, I’ve worked with various pigments and techniques to achieve diverse textures and patinas, tailoring the finish to the client’s specific vision. I’ve also developed custom metallic finishes using various techniques, including metallic paints, leafing, and patination, to create shimmering or antique effects. The process typically begins with detailed discussions with the client to understand their desired aesthetic and any functional requirements. I then experiment with different materials and techniques, creating samples to showcase the possibilities. This iterative process ensures that the final finish matches the client’s vision and meets all project requirements. For example, on a recent project, I developed a custom metallic finish for a bar counter using a combination of copper leaf and dark patina to achieve a unique, antique-bronze look.

Q 21. What software or tools do you use to aid in your work?

Several software and tools are invaluable in my work. AutoCAD and Revit are used for detailed design and drafting, allowing for precise measurements and visualizations. Specialized estimating software streamlines material quantification and cost analysis. Project management software, like Asana or Monday.com, helps track progress, manage tasks, and coordinate schedules. I also use digital color matching tools and software to ensure consistency and precision when applying color schemes, particularly useful with custom finishes or when matching existing materials. On-site, I use laser measuring tools for accurate measurements, ensuring the perfect alignment of tiles and other finishing materials. Furthermore, digital imaging and photography are vital for documentation, creating progress reports, and effectively communicating with clients.

Q 22. How do you ensure the quality of your work meets project specifications?

Ensuring the quality of my work aligns perfectly with project specifications is paramount. My approach is multifaceted and begins even before the first coat of paint or application of plaster. It involves a rigorous process encompassing several key stages:

- Thorough Review of Specifications: I meticulously review all architectural drawings, specifications, and material selections to understand the exact requirements. This includes noting color palettes, finish types, texture specifications, and any unique detailing.

- Material Selection and Verification: I verify that all materials ordered are as specified. This includes checking samples against the approved specifications and ensuring they meet quality standards. I also account for potential variations in material batches to minimize discrepancies.

- Precise Application Techniques: I strictly adhere to the manufacturer’s instructions for all materials used and employ best-practice techniques for each finish. This ensures the desired aesthetic and durability are achieved. For example, using proper surface preparation methods is crucial for preventing peeling or cracking in paintwork.

- Regular Quality Checks: Throughout the process, I conduct regular quality checks at various stages, often employing visual inspections and employing tools like moisture meters or thickness gauges depending on the material. This proactive approach allows for early detection and correction of any issues.

- Documentation and Reporting: Maintaining thorough documentation, including photographs and detailed notes, is essential. This provides a record of the work done and helps identify any deviations from the specifications or unforeseen issues that may arise.

- Final Inspection and Client Sign-Off: Finally, a complete inspection with the client and project manager takes place. This ensures all parties are satisfied with the final result before project completion.

For example, on a recent project involving a high-end residential renovation, I meticulously checked the paint color against the designer’s samples multiple times. This prevented a costly mistake by detecting a slight color difference between the initially received paint and the approved sample. My proactive quality control measures saved both time and resources.

Q 23. Explain your experience with different types of ceiling finishes.

My experience with ceiling finishes spans a wide range of materials and techniques. I’m proficient in:

- Gypsum Board Ceilings: From simple flat ceilings to complex, multi-level designs, including the application of joint compound, taping, sanding, and priming before final finishes.

- Suspended Ceilings: Working with various types of suspended ceiling systems, including metal grids with acoustical tiles, mineral fiber tiles, and even fabric-wrapped panels. I’m experienced with proper grid installation, tile alignment, and integration with lighting fixtures.

- Plaster Ceilings: I’m skilled in applying various plaster types, from traditional lime plaster to modern gypsum-based plasters, achieving smooth, textured, or decorative finishes. This includes understanding the need for proper curing and finishing techniques.

- Drywall Ceilings with Specialty Finishes: This encompasses applying textured finishes like knockdown, skip trowel, or orange peel, achieving specific aesthetic effects. I also have experience with specialty paints and coatings for enhanced durability or aesthetic qualities.

- Wood and Metal Panel Ceilings: Installing and finishing various types of wood and metal panel ceilings, ensuring seamless integration and attention to detail in panel alignment and finishing.

I consider the environmental conditions of the space and the client’s design intent when selecting the appropriate ceiling finish. For instance, in a high-humidity environment, I would recommend a moisture-resistant drywall or a specific type of plaster designed to withstand such conditions to prevent problems like mold growth.

Q 24. Describe your troubleshooting skills related to finishing problems.

Troubleshooting is a crucial aspect of architectural finishing. My approach involves a systematic process:

- Careful Observation and Identification: I start by thoroughly inspecting the affected area, identifying the nature and extent of the problem. This includes documenting the problem with pictures and notes.

- Root Cause Analysis: I then work to determine the root cause of the problem. This might involve investigating factors like improper surface preparation, defective materials, incorrect application techniques, or even environmental factors.

- Testing and Experimentation (when appropriate): Sometimes, I might conduct small-scale tests to determine the best course of action. For example, I might test different primers on a small section of a wall before applying it to the entire surface.

- Solution Implementation and Verification: Once I’ve identified the cause and chosen a solution, I meticulously implement it and verify that the fix is effective. I document this repair thoroughly.

- Preventive Measures: After resolving the immediate problem, I analyze what caused it in order to avoid similar issues in the future. This might involve recommending changes to the project process or specifying alternative materials.

For example, if I encounter paint peeling, I’d systematically investigate whether the problem stems from poor surface preparation (e.g., insufficient cleaning), moisture problems, incompatible paint types, or underlying structural issues. I might use a moisture meter to determine if moisture is a factor and then recommend repairs to address any underlying issues before repainting.

Q 25. How do you stay updated with the latest trends and techniques in architectural finishing?

Staying current in architectural finishing requires continuous learning. My strategies include:

- Industry Publications and Websites: I regularly read trade magazines and visit websites dedicated to architectural finishing. This allows me to stay updated on new materials, techniques, and industry trends.

- Trade Shows and Conferences: Attending industry events allows for hands-on experiences and networking opportunities. I learn about the latest products and engage with manufacturers and other professionals.

- Continuing Education Courses: I actively participate in workshops and training sessions offered by manufacturers and industry organizations to enhance my skills and knowledge.

- Professional Organizations: Membership in relevant professional organizations provides access to educational resources and keeps me connected with other professionals in the field. This allows for peer-to-peer learning and sharing of best practices.

- Online Resources and Tutorials: I utilize online resources like videos and webinars to explore new techniques and expand my knowledge base.

This commitment to ongoing learning ensures I remain at the forefront of innovative approaches and materials.

Q 26. What is your experience with sustainable and eco-friendly finishing materials?

I have significant experience with sustainable and eco-friendly finishing materials. My familiarity includes:

- Low-VOC Paints and Coatings: These paints emit significantly fewer volatile organic compounds (VOCs), improving indoor air quality. I understand the nuances of application and performance compared to traditional paints.

- Recycled and Reclaimed Materials: I’m experienced in using recycled materials, such as reclaimed wood for paneling or repurposed materials for unique decorative elements.

- Plant-Based Finishes: I’ve worked with plant-based oils and waxes for wood finishing, which offer a natural and sustainable alternative to synthetic finishes.

- Natural and Organic Pigments: I have experience utilizing natural pigments derived from minerals or plants to create environmentally friendly color schemes for various finishes.

- Bamboo and Other Sustainable Materials: Incorporating bamboo, cork, and other sustainable materials as appropriate elements in finishing work to minimize environmental impact.

Choosing sustainable materials not only reduces the environmental footprint of a project but also contributes to a healthier indoor environment for the occupants. For example, in one project, I specified and used low-VOC paints in a school, prioritizing the health and well-being of students and staff.

Q 27. Describe a time you had to adapt your approach to meet a project’s unique requirements.

On a recent project involving the restoration of a historic building, I had to adapt my approach significantly. The project required the use of traditional lime plaster, a material I had limited experience with compared to modern gypsum plasters. To address this, I:

- Researched Traditional Techniques: I dedicated time to researching historic lime plastering techniques, studying books, articles, and online resources. This involved understanding the unique properties of lime plaster and the specific techniques for its application.

- Consulted with Experts: I consulted with experienced lime plasterers to gain hands-on insights and practical advice. Learning from their experience was invaluable.

- Trial Runs and Adjustments: I conducted small-scale trial runs to perfect my technique before applying the lime plaster on a larger scale. This allowed me to experiment and adapt my approach based on the actual conditions and material behavior.

- Close Collaboration: I worked closely with the project architect and the historical preservation consultant to ensure that my approach adhered to the project’s requirements and preserved the building’s historical integrity.

The result was a successful restoration project that preserved the building’s historic character while achieving a high standard of finish. This experience highlighted the importance of adaptability and continuous learning in architectural finishing.

Q 28. How do you handle conflicts or disagreements with other tradespeople on a project?

Conflict resolution is a crucial skill on any construction project. My approach emphasizes open communication and collaboration:

- Proactive Communication: I maintain open and clear communication with all tradespeople involved in the project, ensuring that everyone is aware of their responsibilities and potential conflicts. Regular meetings and updates are crucial.

- Respectful Dialogue: When disagreements arise, I address them directly but respectfully, focusing on finding solutions rather than assigning blame. I encourage everyone to express their concerns and perspectives.

- Seeking Common Ground: I look for common ground and areas of agreement to build consensus. This often involves compromise and finding solutions that satisfy all parties involved.

- Escalation Protocol: If the conflict cannot be resolved through direct communication, I utilize the established project escalation protocol, involving the project manager or superintendent as needed to mediate.

- Documentation: I maintain clear and concise documentation of all communication and decisions related to conflicts, protecting all parties involved.

My goal is to resolve disputes professionally and efficiently, always prioritizing the successful completion of the project and maintaining positive working relationships. A calm and professional approach allows for finding workable solutions that address the root causes of conflicts.

Key Topics to Learn for Architectural Finishing Interview

- Surface Preparation: Understanding different surface types (plaster, drywall, concrete), appropriate primers, and methods for achieving a smooth, even finish. Practical application: Explaining your experience selecting and applying primers for various substrates to ensure optimal paint adhesion.

- Paint Application Techniques: Mastering various paint application methods (brushing, rolling, spraying) and their suitability for different surfaces and finishes. Practical application: Describing a project where you had to choose the best painting technique to achieve a specific aesthetic or functional outcome, and the rationale behind your choice.

- Finishes and Coatings: Knowledge of various paint types (latex, oil-based, epoxy), their properties, and applications. Understanding specialty coatings like stains, varnishes, and sealants. Practical application: Explaining the differences between various finishes (e.g., matte, satin, gloss) and their appropriateness for different architectural elements.

- Color Theory and Specification: Understanding color mixing, matching, and the impact of lighting on color perception. Experience with color specification systems (e.g., Pantone). Practical application: Describing a situation where you had to match an existing color or create a custom color blend to meet a client’s requirements.

- Health and Safety Regulations: Familiarity with relevant safety regulations, including proper handling of materials, personal protective equipment (PPE), and waste disposal. Practical application: Demonstrating awareness of safety protocols related to working at heights, using solvents, and handling hazardous materials.

- Project Management and Cost Estimation: Understanding project timelines, budgeting, material procurement, and client communication. Practical application: Explaining your experience managing materials and labor costs on previous projects, and any challenges you overcame.

Next Steps

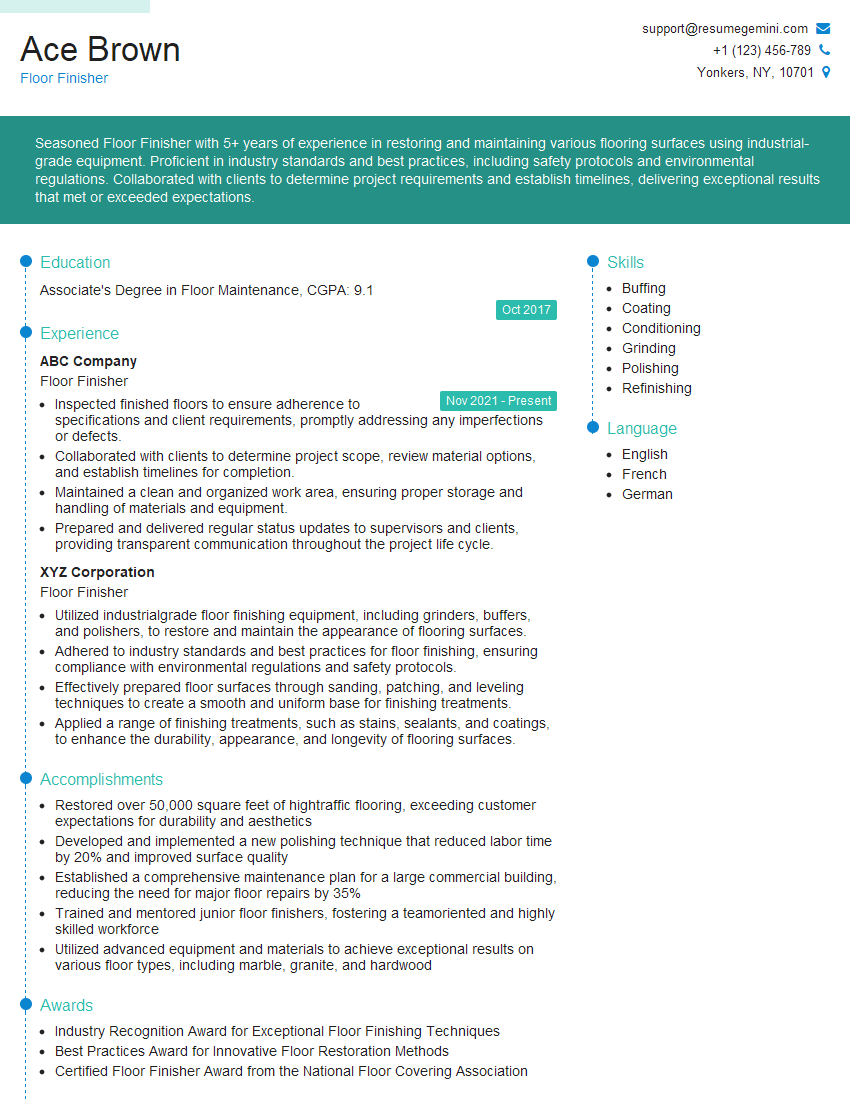

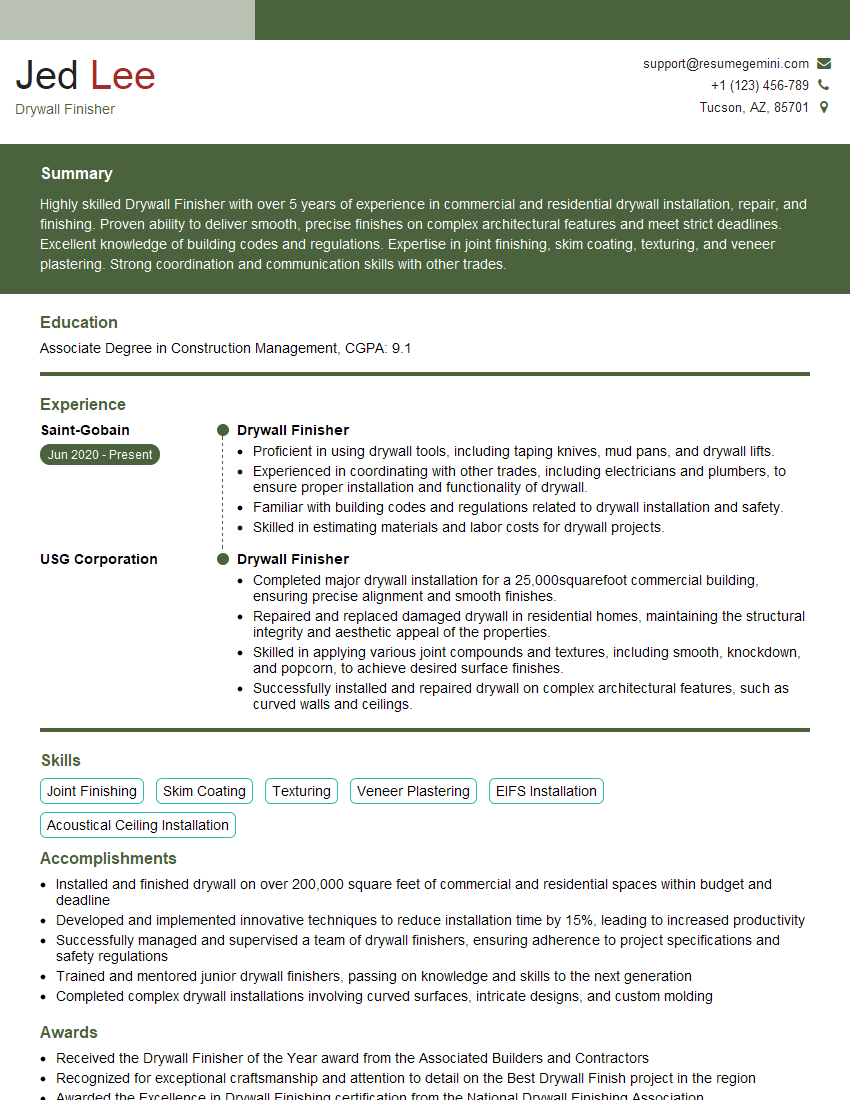

Mastering architectural finishing techniques significantly enhances your career prospects, opening doors to specialized roles and higher earning potential. An ATS-friendly resume is crucial for getting your application noticed by recruiters. To build a compelling resume that highlights your skills and experience in architectural finishing, we strongly recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to the architectural finishing field, enabling you to craft a professional document that showcases your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

These apartments are so amazing, posting them online would break the algorithm.

https://bit.ly/Lovely2BedsApartmentHudsonYards

Reach out at [email protected] and let’s get started!

Take a look at this stunning 2-bedroom apartment perfectly situated NYC’s coveted Hudson Yards!

https://bit.ly/Lovely2BedsApartmentHudsonYards

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?