Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Proficient in loading and unloading waste materials interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Proficient in loading and unloading waste materials Interview

Q 1. Describe your experience loading and unloading various types of waste materials.

My experience encompasses loading and unloading a wide variety of waste materials, from everyday household garbage to more specialized industrial waste. I’ve handled everything from bulky items like furniture and appliances to smaller items like packaging and food scraps. I am familiar with the different characteristics of these materials, understanding their weight, volume, and potential hazards. For example, I’ve successfully loaded and unloaded construction debris, carefully separating wood, metal, and concrete to facilitate efficient recycling and disposal. Similarly, I’ve managed the loading and unloading of medical waste, adhering strictly to all safety protocols and regulations to prevent contamination.

In one instance, I was responsible for unloading a truck containing a mix of municipal solid waste and bulky waste. My careful sorting ensured that recyclable materials such as cardboard and metal were separated from the general waste stream, maximizing recycling efficiency.

Q 2. What safety procedures do you follow when handling waste?

Safety is my paramount concern. My routine includes wearing appropriate personal protective equipment (PPE), including high-visibility vests, gloves, safety boots, and sometimes respirators depending on the waste type. Before starting any loading or unloading operation, I perform a thorough site inspection to identify potential hazards, such as uneven ground, sharp objects, or unstable loads. I always ensure that the loading area is clear and free from obstacles to prevent accidents.

I strictly adhere to weight limits for the vehicles and follow safe lifting techniques to avoid strains and injuries. I also communicate clearly with colleagues and drivers to ensure coordinated and safe operations. Furthermore, I am trained in emergency procedures and know how to react appropriately in case of accidents or spills.

Q 3. How do you identify and handle hazardous waste materials?

Identifying and handling hazardous waste is a critical aspect of my work. I’m trained to recognize hazardous waste through visual inspection and by checking accompanying documentation (manifest). This includes looking for warning labels, recognizing specific materials (e.g., chemicals, medical sharps, asbestos), and being aware of potential hazards based on the source of the waste.

Hazardous waste requires specialized handling. This might include segregation into separate containers, using appropriate PPE, and following specific protocols for loading, transport, and disposal. For instance, I have experience handling medical waste, which involves double bagging the waste, ensuring appropriate labeling, and using puncture-resistant containers. I always report any suspected hazardous waste to my supervisor immediately.

Q 4. Explain your experience with different types of waste collection vehicles.

My experience extends to a variety of waste collection vehicles, including roll-off containers, front-loading trucks, rear-loading trucks, and side-loading trucks. I’m familiar with the loading mechanisms and capacities of each type. For example, I know how to safely and efficiently load roll-off containers, ensuring the waste is evenly distributed to maintain balance and prevent tipping. Similarly, I’m adept at using the hydraulic mechanisms of rear-loading trucks for compacting waste before final disposal.

I also understand the importance of securing the load to prevent spillage during transport. This includes using appropriate straps, chains, and tarps where necessary. My knowledge extends to recognizing vehicle maintenance needs and reporting any potential problems, ensuring safe operation.

Q 5. How do you ensure efficient and safe loading and unloading procedures?

Efficient and safe loading and unloading procedures are crucial. I begin by carefully planning the workflow, considering the type and volume of waste, the vehicle’s capacity, and available space. I always prioritize safe lifting techniques, using mechanical aids where necessary to minimize physical strain. This includes using forklifts, pallet jacks, or other appropriate equipment when handling heavy or bulky items.

I follow a systematic approach to loading, ensuring that heavier items are placed at the bottom to maintain stability and preventing shifting during transport. I regularly check the vehicle’s load to ensure it’s securely packed and doesn’t exceed its weight limit. Communication is key; I coordinate with colleagues and drivers throughout the process.

Q 6. What is your experience with waste segregation and sorting?

Waste segregation and sorting are essential for efficient waste management and recycling. I have considerable experience in separating different types of waste, including recyclables (paper, plastic, glass, metal), organic waste (food scraps, yard waste), and hazardous waste. My sorting skills are critical for maximizing recycling rates and minimizing landfill waste.

I’m trained in identifying various materials and classifying them correctly. In one instance, I worked on a project sorting construction debris, which allowed for the separate recycling of wood, metal, and concrete. This skill reduces the environmental impact of waste disposal and improves efficiency.

Q 7. Describe your experience with operating waste compactors or other equipment.

I have experience operating waste compactors, which significantly reduce the volume of waste and improve efficiency in transportation and disposal. I understand the safety procedures associated with their operation, including ensuring proper maintenance and reporting any mechanical issues. I know how to operate them safely and effectively, compacting the waste without causing damage to the equipment or creating hazardous conditions.

My experience also includes operating other equipment such as forklifts and pallet jacks, when necessary for moving and positioning waste containers. I am always careful to follow all safety regulations when using this equipment and am fully licensed and trained in their operation.

Q 8. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is paramount for safety and efficiency. Think of it like a well-stocked kitchen – everything has its place, and knowing where things are saves time and prevents accidents. My approach involves several key steps:

- Designated areas: I always ensure that different types of waste have designated areas for storage before loading. This prevents mixing and potential hazards.

- Regular sweeping and clearing: After each unloading or loading, I sweep and clear the area to remove debris and spilled materials. This also reduces the risk of slips and falls.

- Proper storage of equipment: Tools and equipment are stored in designated locations to prevent them from becoming obstacles and ensure easy access when needed. For instance, I’d always put my wheel chocks away after use.

- Waste segregation: Sorting waste streams according to their type – recyclable, hazardous, etc. – is crucial. It’s like organizing a pantry; you wouldn’t mix your spices with your grains. This keeps the area tidy and aids efficient disposal.

- Spill response kit readily available: I always have a kit with absorbent materials nearby to tackle any spills quickly, preventing them from becoming major cleanup operations. Think of it as having a fire extinguisher – you hope you don’t need it, but it’s essential to have it readily accessible.

Following these steps ensures a safe and productive work environment, reducing the risk of accidents and improving overall efficiency.

Q 9. What are your strategies for handling unexpected waste situations?

Unexpected waste situations can range from overflowing bins to unexpected hazardous materials. My approach is based on quick assessment, safe handling, and clear communication:

- Assessment: First, I assess the situation to determine the nature and extent of the problem. Is it a minor spill or a major blockage? What type of waste is involved?

- Safe handling: I prioritize safety. If I encounter hazardous materials, I follow the appropriate safety protocols and contact my supervisor or relevant authorities. For example, if I find a leaking container of unknown chemicals, I’d immediately cordon off the area and contact emergency services.

- Communication: I communicate clearly with my supervisor and colleagues to coordinate efforts. If I need extra help or specialized equipment, I report the situation immediately. Clear communication prevents delays and potential risks.

- Documentation: I always document the unexpected event, noting the time, location, type of waste, and actions taken. This is crucial for future reference and incident reporting.

Using this structured approach allows for a calm and efficient response to unforeseen circumstances, ensuring the safety of myself and others.

Q 10. How do you prioritize different tasks when loading and unloading waste?

Prioritizing tasks during loading and unloading involves understanding the urgency and safety implications of each. My approach utilizes a combination of factors:

- Safety first: Tasks that pose a safety risk, such as handling hazardous materials or working in unstable conditions, always take precedence. This is non-negotiable.

- Urgency: Tasks with tight deadlines, such as loading a truck before a scheduled departure, are prioritized over less time-sensitive tasks.

- Efficiency: I aim to optimize the process by loading similar waste streams together, reducing the time and effort required. Think of it like packing a suitcase – you group similar items together to maximize space and efficiency.

- Regulations: Compliance with regulations regarding waste disposal and handling is a top priority. This ensures legal compliance and safety.

By combining these considerations, I can effectively manage multiple tasks and maintain a smooth and efficient workflow.

Q 11. Explain your knowledge of relevant health and safety regulations.

My understanding of health and safety regulations is comprehensive and regularly updated. I am familiar with:

- OSHA (Occupational Safety and Health Administration) guidelines: These regulations cover various aspects of waste handling, including personal protective equipment (PPE), safe lifting techniques, and hazard communication.

- Waste disposal regulations: I am aware of local, state, and federal regulations pertaining to the disposal of different types of waste, ensuring compliance in every aspect of my work.

- Emergency procedures: I am trained in emergency response protocols, including spill response, fire safety, and first aid. I am always prepared to handle any situation that might arise.

- Manual handling regulations: I understand the guidelines for safe lifting and movement of heavy objects to prevent injuries. I know how to use lifting aids where appropriate to make sure my work is done safely.

Staying informed about these regulations is essential for ensuring a safe and compliant work environment. I regularly review updates and participate in safety training to maintain my knowledge and skills.

Q 12. How do you handle challenging weather conditions during waste collection?

Challenging weather conditions can significantly impact waste collection. My strategies for handling these situations include:

- Assessing the risk: Before starting work, I evaluate the weather conditions and assess any potential risks. High winds, heavy rain, or icy conditions could make the work more dangerous.

- Appropriate clothing and equipment: I always wear appropriate PPE, including high-visibility clothing, waterproof gear, and sturdy footwear, to protect myself from the elements.

- Slow and steady approach: I work more slowly and carefully in adverse weather, prioritizing safety over speed. This might include taking more frequent breaks to avoid fatigue.

- Communication: I communicate with my supervisor about the weather conditions and any potential delays or safety concerns. It’s always better to be safe and proactive.

- Extra caution when handling heavy loads: I ensure extra stability and take extra precautions to avoid slips and falls in inclement weather conditions.

Safety is paramount. If conditions become dangerously unsafe, I would not hesitate to stop work and notify my supervisor immediately.

Q 13. Describe your experience with manual handling techniques for waste materials.

Proper manual handling techniques are crucial for preventing injuries. My experience includes:

- Assessment of the load: Before lifting, I assess the weight, size, and shape of the waste material to determine the safest lifting method.

- Proper lifting technique: I use my legs, not my back, to lift, keeping the load close to my body. This reduces strain on my back and minimizes risk of injury.

- Teamwork: For heavy or awkward loads, I always work with a colleague to ensure the load is handled safely and efficiently.

- Use of lifting aids: Where appropriate, I use lifting aids such as hand trucks, dollies, or hoists to reduce strain and improve efficiency.

- Awareness of my physical limitations: I’m aware of my physical limitations, and I don’t hesitate to ask for help if a load is too heavy or awkward to handle safely on my own. It’s better to ask for help than risk injury.

Consistent application of these techniques ensures efficient and safe handling of waste materials, minimizing the risk of injury.

Q 14. How do you ensure the proper disposal of different waste streams?

Ensuring proper disposal of different waste streams requires a detailed understanding of waste classifications and regulations. My process involves:

- Segregation: I carefully segregate waste materials according to their type: recyclable materials (paper, plastic, glass, metal), hazardous waste (batteries, chemicals, sharps), organic waste (food scraps, yard waste), and general waste. Each stream has specific handling and disposal requirements.

- Labeling and containment: Hazardous waste is carefully labeled and contained to prevent spills or cross-contamination. This is vital for safety and environmental protection.

- Appropriate disposal methods: Different waste streams require different disposal methods. For example, recyclable materials are sent to recycling facilities, hazardous waste requires specialized handling and disposal in accordance with relevant regulations, and organic waste might be composted.

- Documentation: I carefully maintain records of all waste streams processed, including weight, type, and disposal location. This documentation is crucial for compliance audits and environmental reporting.

- Compliance with regulations: I adhere strictly to all relevant local, state, and federal regulations concerning waste disposal, ensuring environmentally responsible practices.

This meticulous approach guarantees that all waste streams are managed correctly and disposed of in an environmentally sound and safe manner.

Q 15. What is your experience with record keeping and documentation related to waste handling?

Accurate record-keeping is paramount in waste handling. It ensures compliance with regulations, allows for efficient tracking of waste streams, and aids in identifying potential problems. My experience includes meticulous documentation using both manual and digital systems. This involves creating and maintaining detailed logs of waste type, quantity, disposal method, and the date and time of each transaction. I’m proficient in using various software platforms designed for waste management tracking, including those that generate reports for analysis and auditing purposes. For example, I’ve successfully implemented a system where we transitioned from handwritten logs to a digital database, resulting in a 20% reduction in errors and a significant improvement in reporting speed. This allowed us to easily demonstrate compliance during a recent environmental audit.

- Maintaining detailed waste manifests.

- Using barcodes or RFID tags for waste tracking.

- Generating and archiving reports for regulatory compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with your team during waste handling operations?

Effective communication is crucial for safe and efficient waste handling. I utilize a multi-pronged approach. Before any operation, I conduct thorough briefings, ensuring everyone understands their roles, safety procedures, and the specific waste characteristics. During operations, I use clear and concise verbal instructions, coupled with hand signals where necessary, especially when operating heavy machinery near team members. For instance, I’ve successfully coordinated the unloading of a particularly hazardous material by clearly communicating the necessary precautions, including the proper PPE and lifting techniques, to my team. After each operation, we conduct debriefings to address any issues, identify areas for improvement, and celebrate successful completions. Open communication, active listening, and respectful feedback are key to fostering a collaborative and safe working environment.

Q 17. Describe your problem-solving skills in relation to waste handling challenges.

Problem-solving in waste handling often involves quick thinking and resourcefulness. For example, during a recent incident where a container was unexpectedly overloaded, I immediately assessed the situation, identifying the contributing factors (incorrect waste segregation, inaccurate weight estimations). I then developed a solution by redistributing the waste into smaller containers and implemented corrective actions to prevent future occurrences. These actions included additional training for the team on waste sorting and stricter weight checks. Another time, we faced a blockage in our compacting system. By systematically checking each component and utilizing my knowledge of the system’s mechanics, I quickly identified the cause – a jammed hydraulic system – and implemented the solution by carefully clearing the obstruction. My approach involves analyzing the situation, identifying the root cause, generating solutions, implementing them, and conducting post-incident reviews to prevent similar issues.

Q 18. How do you stay updated on changes in waste management regulations and best practices?

Staying updated on waste management regulations and best practices is critical. I achieve this by actively participating in industry conferences and workshops, subscribing to relevant professional journals and online resources, and completing continuing education courses. Specifically, I regularly review updates on local, state, and federal regulations related to waste disposal, hazardous materials handling, and environmental protection. I also actively seek information on advancements in waste reduction technologies and best practices to find new ways to streamline operations and boost efficiency. Being proactive in my learning ensures I’m always equipped to handle any changes and implement the most appropriate methods for efficient and compliant waste management.

Q 19. What are your experience with different types of waste containers and equipment?

My experience encompasses a wide variety of waste containers and equipment, including roll-off containers, dumpsters, compactors, balers, and specialized containers for hazardous waste. I’m familiar with the different sizes, capacities, and materials of these containers and understand their appropriate applications. I’m also proficient in operating various loading and unloading equipment, such as forklifts, front-end loaders, and specialized waste handling vehicles. I understand the safety protocols and operating procedures specific to each type of equipment and have hands-on experience in safely operating them within various environments. For example, I’ve successfully managed the loading and unloading of hazardous materials using specialized containers and equipment, ensuring proper segregation and preventing cross-contamination. This includes documenting the entire process with utmost precision to adhere to all safety and legal standards.

Q 20. How do you prioritize safety when working with heavy equipment?

Safety is my top priority when operating heavy equipment. I always perform pre-operational checks to ensure the equipment is in optimal working condition. This includes inspecting hydraulics, brakes, lights, and any other relevant safety features. Before commencing any task, I secure the work area, ensuring it’s free from obstructions and that all personnel are a safe distance away. I adhere strictly to all safety regulations and procedures, wearing appropriate personal protective equipment (PPE) including safety glasses, gloves, and steel-toe boots. I’m also trained in the use of various safety devices, including load restraints and fall protection equipment. Communication is key; I always maintain clear communication with my team members, using hand signals and verbal cues, especially when operating equipment in close proximity to others. For example, I successfully implemented a system using colored cones and designated personnel to create a secure buffer zone during loading and unloading operations, preventing accidental collisions and minimizing the risk of injury.

Q 21. Describe your experience with lifting and carrying heavy objects.

I have extensive experience lifting and carrying heavy objects, acquired through years of hands-on work in waste handling. I understand the principles of proper lifting techniques, using my legs to lift and keeping the object close to my body. I always assess the weight of an object before attempting to lift it, and if it’s too heavy, I seek assistance or use appropriate mechanical aids like forklifts or pallet jacks. I avoid twisting or bending awkwardly and maintain a firm grip on the object to prevent drops or injuries. I’m aware of the potential risks associated with manual handling and am trained in risk assessment procedures to ensure safe lifting practices. My experience allows me to judge weight and select the safest and most efficient method of handling any load. I am also proficient in using lifting equipment and am aware of the importance of load balancing and strain prevention when using these aids.

Q 22. How do you adapt to different work environments and types of waste?

Adaptability is crucial in waste handling. Different sites present unique challenges – varying waste types, equipment, and safety protocols. My approach involves careful observation and quick learning. Before starting any task, I thoroughly assess the situation: the type of waste (hazardous, recyclable, general), the loading/unloading methods, and the specific safety requirements of the site. For example, handling medical waste requires meticulous attention to biohazard protocols and specialized containers, whereas construction debris requires different machinery and safety measures. I’m comfortable using various equipment, from forklifts and roll-off containers to smaller hand tools, adapting my technique to match the task. I actively seek guidance if needed and am always eager to adopt new best practices to ensure efficiency and safety.

Q 23. What are your experience with waste recycling and reduction strategies?

I have extensive experience in waste recycling and reduction. This involves more than just sorting; it’s about understanding the waste stream and implementing strategies to minimize waste generation from the source. In my previous role, we implemented a color-coded system for waste sorting, drastically improving recycling rates. We also introduced a composting program for organic waste, diverting a significant portion of waste from landfills. Furthermore, I actively participate in training sessions on improved sorting techniques and the latest advancements in waste management technology. Understanding different recycling processes—for example, the differences between single-stream and dual-stream recycling—helps me optimize my sorting and ensure materials are properly recycled. Reducing waste isn’t just environmentally responsible; it’s also economically beneficial as it reduces disposal costs.

Q 24. How do you ensure compliance with company and regulatory guidelines?

Compliance is paramount. I meticulously follow all company policies and regulatory guidelines, including OSHA (Occupational Safety and Health Administration) standards and any specific environmental regulations for handling hazardous materials. I’m familiar with relevant documentation, such as waste manifests and safety data sheets (SDS), and I ensure all waste is properly labeled and tracked throughout the entire process. I also actively participate in regular safety training and updates to stay informed on any changes in regulations or best practices. For instance, if I notice any discrepancy in waste labeling or handling, I immediately report it to my supervisor. Maintaining accurate records and adhering to protocols safeguards the environment and ensures legal compliance.

Q 25. What steps do you take to prevent accidents during waste handling?

Preventing accidents is my top priority. This starts with a thorough pre-task assessment, including a check of all equipment for functionality and safety features. I always wear the appropriate personal protective equipment (PPE), including gloves, safety boots, high-visibility clothing, and any other specialized gear required for the specific task. I follow strict lifting techniques to prevent strain injuries and maintain a safe working distance from moving machinery. I also communicate clearly with co-workers to coordinate movements and avoid collisions. Furthermore, I’m always vigilant about my surroundings, watching for potential hazards like spills, uneven ground, or exposed wires. Regularly inspecting the work area and reporting any unsafe conditions is critical for accident prevention.

Q 26. Describe a time you had to solve a problem related to efficient waste handling.

At a previous job, we faced a significant backlog in waste processing due to a faulty compactor. Instead of simply waiting for repairs, I analyzed the problem systematically. First, I identified the bottleneck (the broken compactor) and its impact on the entire workflow. Then, I proposed a temporary solution: we reorganized the storage area to optimize space and manually compacted smaller batches of waste, prioritizing hazardous materials. I also coordinated with the maintenance team to expedite repairs. This temporary solution minimized delays, preventing further disruptions to the overall waste management process and demonstrating my proactive problem-solving skills. The experience highlighted the importance of thinking critically under pressure and finding practical solutions.

Q 27. How do you ensure the security of waste materials during transportation?

Securing waste materials during transportation is crucial, especially for hazardous materials. This involves using properly sealed containers, ensuring adequate labeling with hazard warnings, and utilizing secure transport vehicles. I ensure that all materials are loaded and secured correctly to prevent spillage or shifting during transit. Depending on the material and regulations, this might include using specialized containers, such as those designed for hazardous materials or those equipped with GPS tracking for monitoring. Documentation is also critical. Accurate manifests and delivery receipts track the waste’s journey, ensuring accountability and tracing in case of any incidents. Security procedures vary depending on the type of waste, but my focus is always on preventing unauthorized access, spillage, and damage during transport.

Q 28. What are your salary expectations for this role?

My salary expectations are in line with the market rate for this role, considering my experience and skills. I’m open to discussing this further based on the complete compensation package, including benefits.

Key Topics to Learn for Proficient in loading and unloading waste materials Interview

- Safe Waste Handling Practices: Understanding and adhering to all relevant safety regulations and procedures for handling various types of waste materials, including hazardous waste (if applicable). This includes proper use of personal protective equipment (PPE).

- Equipment Operation and Maintenance: Demonstrating knowledge of operating loading and unloading equipment such as forklifts, conveyor belts, and other machinery used in waste management. This includes basic troubleshooting and preventative maintenance procedures.

- Waste Classification and Sorting: Understanding different types of waste materials and their proper segregation for recycling, disposal, or treatment. This includes identifying hazardous waste and following appropriate protocols.

- Efficient Loading and Unloading Techniques: Mastering techniques for maximizing efficiency and minimizing damage to materials and equipment during the loading and unloading process. This includes understanding load balancing and securing techniques.

- Environmental Regulations and Compliance: Familiarity with environmental regulations and best practices related to waste management and disposal. Understanding the impact of improper waste handling on the environment.

- Record Keeping and Documentation: Understanding the importance of accurate record-keeping related to waste quantities, types, and disposal methods. This includes completing necessary paperwork and maintaining accurate logs.

- Problem-Solving and Troubleshooting: Ability to identify and resolve problems that may arise during the loading and unloading process, such as equipment malfunctions or unexpected waste characteristics. This includes effective communication and reporting procedures.

Next Steps

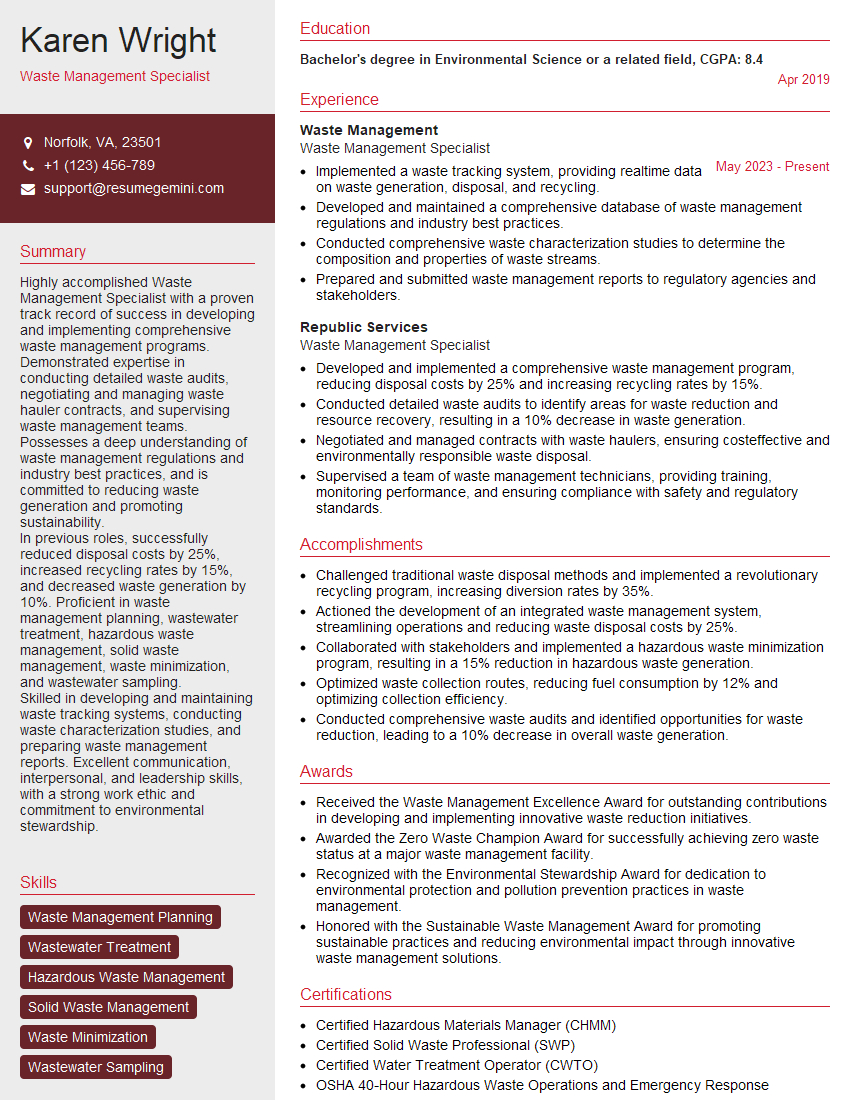

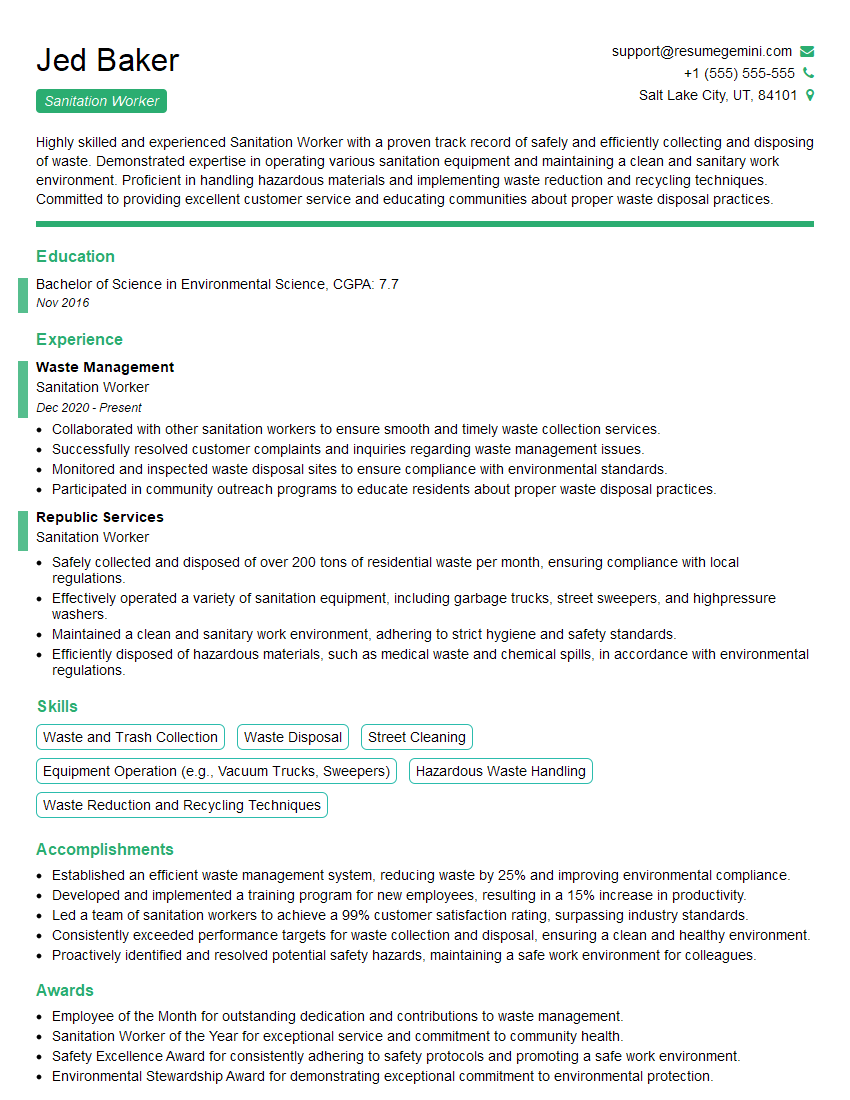

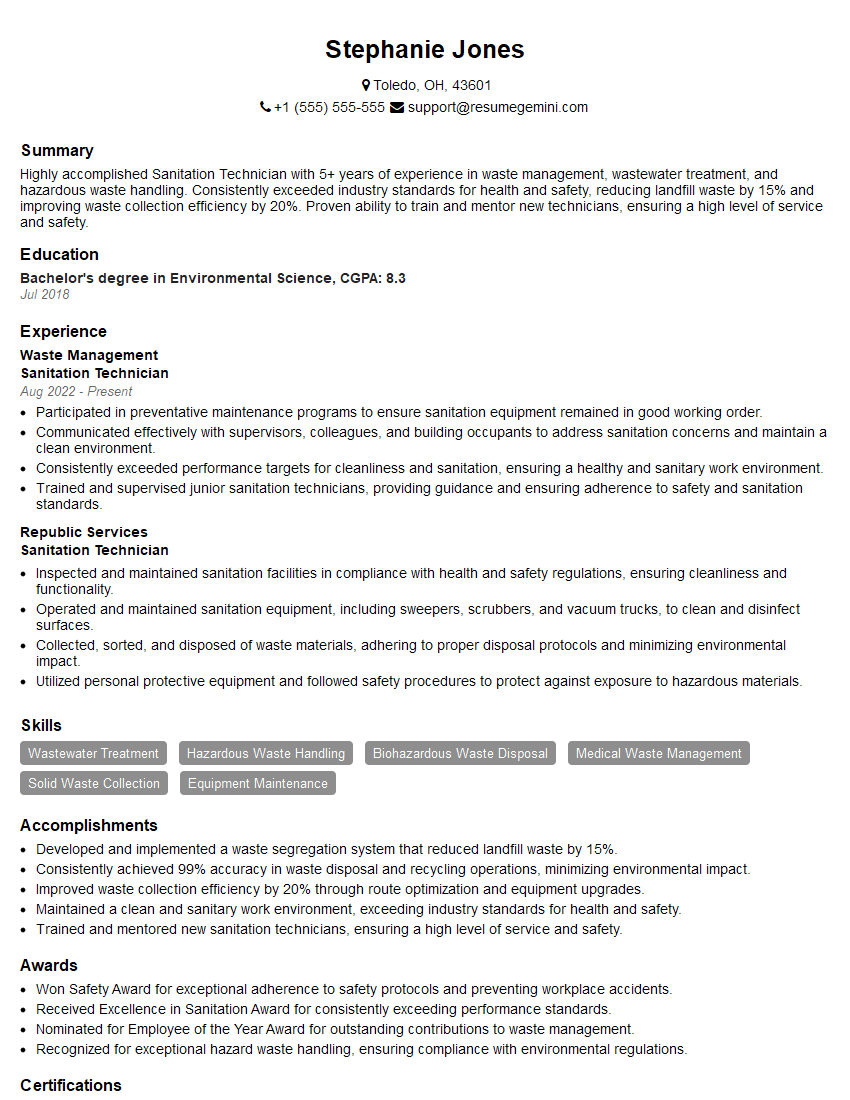

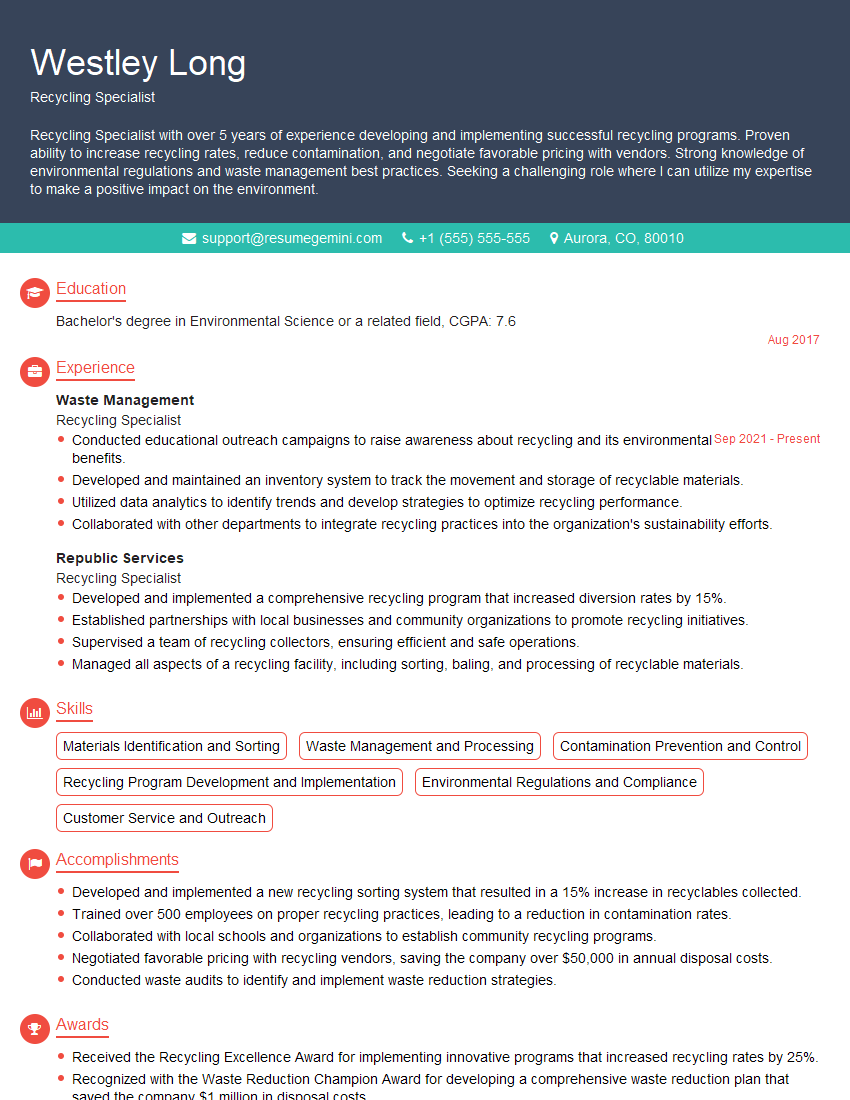

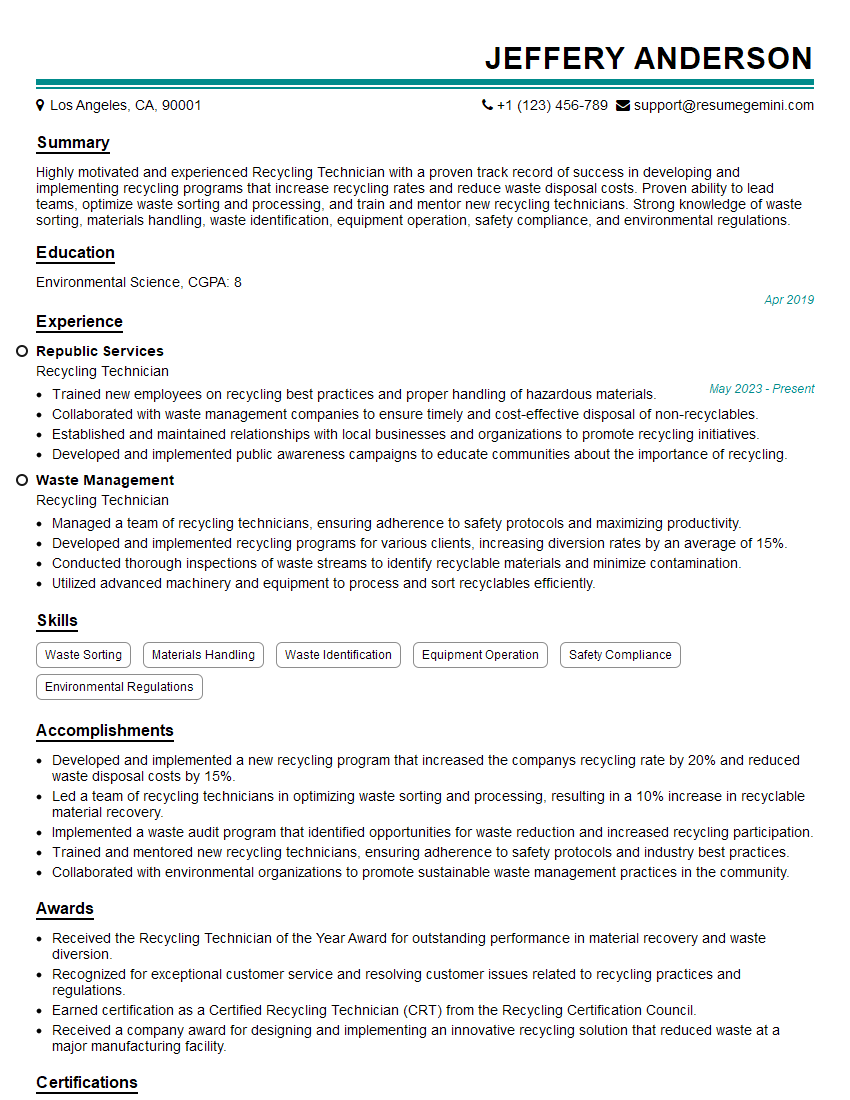

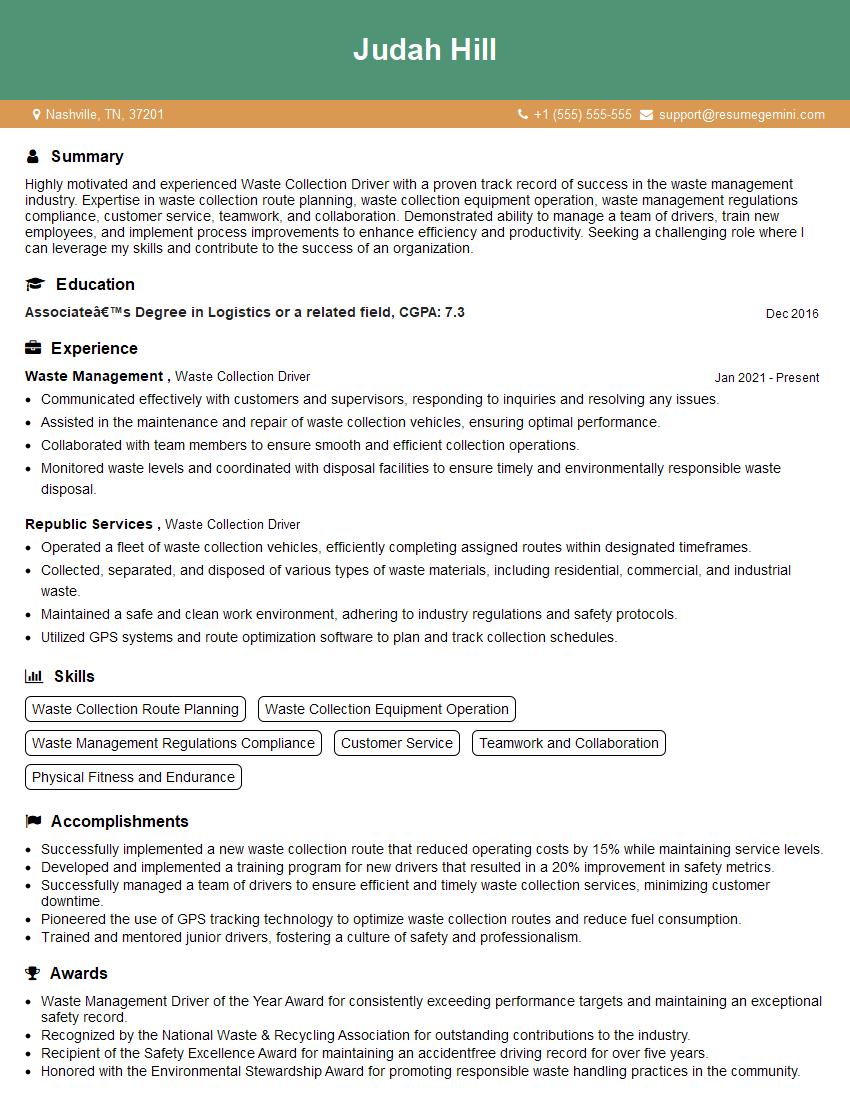

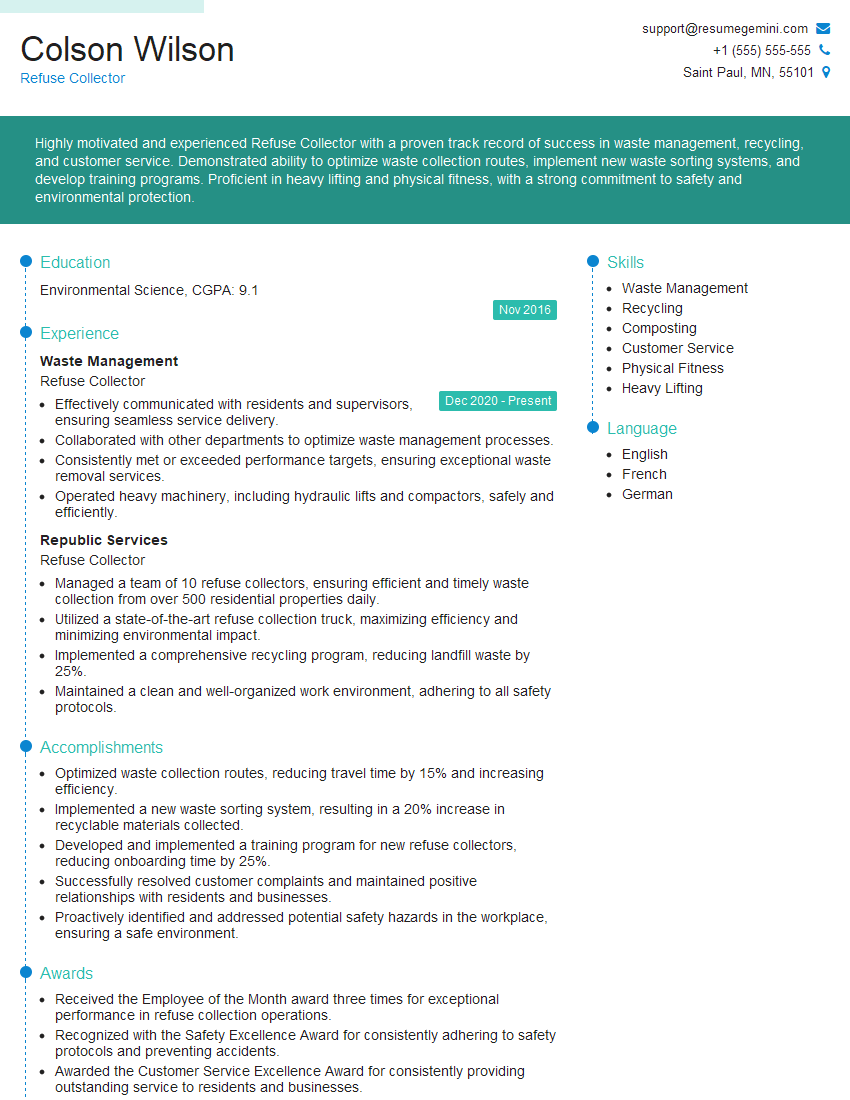

Mastering proficiency in loading and unloading waste materials significantly enhances your employability within the waste management and recycling industries, opening doors to a variety of roles and career advancement opportunities. A strong resume is crucial for showcasing your skills and experience to potential employers. Crafting an ATS-friendly resume is essential for getting your application noticed. To help you create a compelling and effective resume, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform to build professional resumes and offers examples of resumes tailored to roles such as “Proficient in loading and unloading waste materials,” helping you stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?