Preparation is the key to success in any interview. In this post, we’ll explore crucial Familiar with various types of dump truck equipment and controls interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Familiar with various types of dump truck equipment and controls Interview

Q 1. Describe the different types of dump trucks you are familiar with (e.g., end-dump, side-dump, bottom-dump).

Dump trucks are categorized based on how they discharge their load. The three primary types are end-dump, side-dump, and bottom-dump trucks. Each is suited to different applications.

- End-dump trucks: These are the most common type, lifting the body to discharge material from the rear. Think of the classic image of a dump truck; that’s an end-dump. They are efficient for general hauling and construction sites where access is relatively straightforward.

- Side-dump trucks: These trucks have a hinged side that opens to release the load. They’re ideal for situations where dumping at the rear is difficult or impossible, such as working along roadsides or narrow spaces. Their maneuverability is a key advantage.

- Bottom-dump trucks: These trucks have a mechanism that opens the bottom of the bed, allowing the material to flow out. These are often used to haul materials that are prone to bridging (forming an arch and not flowing freely), such as loose aggregates, or in applications where clean dumping is paramount. They are typically larger and more expensive.

Beyond these three main types, there are variations based on size (from small pickup-truck-sized models to massive haul trucks), drive type (2-wheel drive, 4-wheel drive, or all-wheel drive), and specific features tailored to specific applications (e.g., specialized bodies for hauling asphalt).

Q 2. Explain the operating procedures for a standard dump truck.

Operating a dump truck safely requires a methodical approach. Here’s a breakdown of the typical procedure:

- Pre-trip inspection: This is crucial for safety and should always be conducted before operating the truck (detailed below in question 3).

- Starting and maneuvering: Securely fasten your seatbelt, check your mirrors, and carefully start the engine. Observe all traffic laws when moving the truck.

- Loading: Position the truck correctly to receive the load, ensuring it is evenly distributed to maintain stability and avoid overloading.

- Transporting: Drive at safe speeds, respecting weight limits and road conditions, keeping an eye on the load throughout the journey. Consider the road surface and adjust your speed accordingly.

- Unloading: Choose a stable and safe location to unload. Ensure the area is clear of obstacles and personnel. Carefully raise the bed, releasing the load. Keep yourself clear of the falling material.

- Post-dump procedures: Lower the bed, secure it, and check for any material spills or damage.

Remember, the exact controls and procedures might slightly vary depending on the truck’s make and model, but the overall process remains consistent. Always refer to the manufacturer’s operation manual.

Q 3. How do you perform a pre-trip inspection on a dump truck?

A thorough pre-trip inspection is non-negotiable for safe dump truck operation. This involves a systematic check of various components:

- Visual Inspection: Check for any obvious damage to the body, tires, lights, and other external components.

- Tire Pressure: Inspect tire condition and pressure, ensuring they’re inflated correctly and free of damage.

- Fluid Levels: Verify the levels of engine oil, coolant, brake fluid, power steering fluid, and transmission fluid.

- Brakes: Test the service and parking brakes to ensure they function correctly.

- Lights and Signals: Check that all lights (headlights, taillights, brake lights, turn signals, hazard lights) and indicators are working as expected.

- Steering and Suspension: Check for free and correct movement in the steering wheel and check the suspension for any signs of damage or leakage.

- Dump Body Mechanism: Inspect the hoist and hydraulic system, checking for any leaks, damage, or unusual noises. Test the lifting and lowering mechanisms, ensuring smooth operation.

- Safety Equipment: Verify that all safety equipment, including seatbelts, mirrors, warning lights, and emergency equipment, is in good working order.

Proper documentation of findings is essential. Many companies use checklists to ensure all points are covered. Failure to perform a proper pre-trip inspection could result in serious accidents.

Q 4. What are the common safety hazards associated with operating a dump truck?

Operating a dump truck presents several inherent safety hazards:

- Rollover: Dump trucks are top-heavy, making them prone to rollovers, especially on uneven terrain or when turning sharply.

- Falling Objects: The risk of falling material from the bed during loading, transport, or unloading is significant. Both the driver and bystanders are at risk.

- Blind Spots: The large size of dump trucks creates significant blind spots, requiring careful observation and use of mirrors.

- Backover Accidents: Backing up with a dump truck can be hazardous due to reduced visibility. Special care must be exercised to avoid accidents, particularly near pedestrians or other vehicles.

- Overloading: Overloading a dump truck can compromise its stability, leading to rollovers or structural damage.

- Hydraulic System Failures: Malfunction of the hydraulic system controlling the dump body poses significant danger.

- Tire Blowouts: Driving with worn-out or improperly inflated tires increases the risk of blowouts.

Addressing these hazards requires rigorous training, adherence to safety procedures, and regular maintenance of the vehicle.

Q 5. Describe your experience with different types of dump truck bodies and their applications.

My experience encompasses various dump truck bodies, each suited to particular applications:

- Steel bodies: These are the most common, offering durability and strength, ideal for hauling heavy aggregates and construction debris. They can be prone to rust over time, requiring maintenance.

- Aluminum bodies: Lighter than steel, these bodies improve fuel efficiency, but they are more expensive and may not be as durable for extremely heavy loads.

- Specialized bodies: These bodies are designed for specific materials, like those with sealed compartments for hauling hazardous materials or those with multiple compartments for separating different loads.

For example, when working on a road construction project, a steel body would be appropriate for hauling crushed stone, but for a project involving sensitive materials, a specialized body might be necessary. Material compatibility and weight are always crucial considerations when selecting the right dump truck body.

Q 6. How do you handle challenging terrain while operating a dump truck?

Navigating challenging terrain with a dump truck demands careful planning and execution. Key considerations include:

- Speed control: Reduce speed significantly when encountering rough terrain, avoiding sudden acceleration or braking to maintain control.

- Tire pressure: Adjust tire pressure according to terrain conditions. Lower pressure improves traction on loose surfaces, while higher pressure is better for hard surfaces.

- Route planning: Plan the route carefully, choosing the most suitable path and avoiding steep inclines or obstacles.

- Load distribution: Ensure the load is properly distributed to maintain stability. An unevenly distributed load can easily lead to a rollover.

- Differential locks: Utilize differential locks on four-wheel or all-wheel-drive vehicles for improved traction in challenging conditions.

- Awareness of surroundings: Always be aware of your surroundings, being mindful of potential obstacles and hazards.

For instance, when hauling materials up a steep incline, a cautious approach is critical. This might involve using lower gears for increased engine braking, ensuring adequate tire grip, and avoiding sharp turns.

Q 7. What are the load limits and weight distribution considerations for a dump truck?

Load limits and weight distribution are paramount for safe dump truck operation. Exceeding these limits can lead to severe consequences, such as rollovers, structural damage, or even component failure.

Each dump truck has a Gross Vehicle Weight Rating (GVWR), which is the maximum allowable weight of the truck when fully loaded. This includes the weight of the truck itself, the load, and any additional equipment. The truck’s weight distribution also matters; an uneven load can destabilize the truck, especially during turning or on uneven terrain.

The load must be distributed evenly across the bed of the truck. This is particularly critical for side and end-dump trucks where uneven weight can cause instability. For bottom dump trucks, the concern is less about side-to-side instability and more about longitudinal weight distribution which can heavily impact braking and traction during transit.

Always check the GVWR and axle weight ratings of your specific truck before loading. Overloading is a serious safety concern, and the penalties for violating weight limits can be severe.

Q 8. Explain the importance of maintaining proper tire pressure in a dump truck.

Maintaining proper tire pressure in a dump truck is crucial for safety, fuel efficiency, and tire longevity. Under-inflation leads to excessive heat buildup, increased rolling resistance (reducing fuel economy), and premature tire wear, potentially causing a blowout. Over-inflation can lead to a harsh ride, reduced traction, and increased risk of tire failure. Think of it like this: your tires are the dump truck’s shoes – if they’re not the right fit, everything suffers.

Regularly checking tire pressure using a reliable gauge is essential. The correct pressure is specified on the sidewall of each tire and in the truck’s owner’s manual. Adjusting pressure to the recommended levels ensures optimal performance and safety. I always check tire pressure before each shift and after long hauls or driving on rough terrain. Ignoring this simple step can have significant consequences.

Q 9. How do you address a mechanical issue with a dump truck while on-site?

Addressing a mechanical issue on-site requires a methodical approach prioritizing safety. First, I ensure the truck is parked safely away from traffic and other hazards, activating hazard lights. Then, I conduct a preliminary assessment of the problem. For example, if it’s an engine issue, I’ll check oil levels and listen for unusual noises; if it’s a hydraulics problem, I’ll examine fluid levels and look for leaks. My experience has taught me that careful observation is key.

Next, I determine if the problem is minor enough for on-site repair or requires a tow. For minor issues like a flat tire, I’ll change the tire using the truck’s onboard equipment and appropriate safety precautions (wheel chocks, etc.). For major issues, I contact my supervisor or the designated mechanic, providing a clear description of the problem. Safety is my top priority; I’d rather err on the side of caution and call for help than risk further damage or injury.

Q 10. What are your procedures for securing a load on a dump truck?

Securing a load on a dump truck is non-negotiable for safety. My procedure always begins with a visual inspection of the load to ensure it’s evenly distributed and doesn’t exceed the truck’s weight capacity. I then use appropriate tie-down methods based on the type of load. For loose materials, a tarp secured with straps is often necessary. For palletized goods, I’ll use chains or straps that are properly rated for the weight and securely fastened to the designated anchor points on the truck bed.

Every strap or chain must be taut and secured to prevent shifting during transit. I double-check all fastenings before driving and regularly inspect the load throughout the journey to ensure everything remains secure. Proper load securing is not just about following regulations; it’s about preventing accidents and protecting others on the road.

Q 11. How do you ensure safe dumping procedures to prevent accidents?

Safe dumping procedures are critical to preventing accidents. Before dumping, I ensure the area is clear of obstructions and personnel. This means visually checking the surroundings and, if necessary, using a spotter to guide me. The truck must be positioned on stable, level ground; I never dump on uneven terrain or slopes. I always engage the parking brake before starting the dump process.

During dumping, I slowly and carefully operate the controls to avoid sudden movements. Once the material is dumped, I lower the bed slowly and safely, checking for any residual material before moving the vehicle. After each dump, I conduct a final visual inspection of the area to confirm the safe disposal of the load. It’s crucial to remember that dumping is a high-risk maneuver that demands patience and precision.

Q 12. Describe your experience with different types of dump truck transmissions (manual, automatic).

I have extensive experience with both manual and automatic dump truck transmissions. Manual transmissions offer greater control, particularly on challenging terrain, allowing for precise gear selection to manage engine speed and torque. However, they require more skill and are more physically demanding. Automatic transmissions are more convenient and less tiring, especially on long hauls, but they might not provide the same level of control on steep inclines or uneven surfaces.

My experience with both types allows me to adapt to different trucks and situations efficiently. For instance, in mountainous regions, a manual transmission is preferable for better hill control, while on flat, paved roads, an automatic transmission is more comfortable. Understanding the nuances of each type is key to safe and efficient operation.

Q 13. What are the legal regulations and requirements for operating a dump truck in your area?

Legal regulations for operating a dump truck vary by location but typically include having a valid commercial driver’s license (CDL) with the appropriate endorsements (e.g., for hauling specific materials). Regular vehicle inspections are mandated to ensure the truck is roadworthy and meets safety standards. Load limits must be strictly adhered to, and the truck must comply with weight and dimension regulations.

Furthermore, drivers are responsible for knowing and obeying all traffic laws, including speed limits and rules related to oversized loads. Regular training and safety certifications are usually required to maintain compliance. I stay up-to-date on all relevant legislation in my area, prioritizing both safety and legal compliance.

Q 14. How do you handle different weather conditions while operating a dump truck?

Operating a dump truck in various weather conditions requires careful adjustments and extra precautions. In rain or snow, reduced traction necessitates slower speeds and increased following distances. Tire chains might be necessary in snowy or icy conditions. Visibility is critical; I use headlights and wipers as needed and exercise extra caution during low visibility periods.

Strong winds can affect the stability of the vehicle, especially with a heavy load. I adjust my driving accordingly, reducing speed and avoiding sudden maneuvers. Extreme temperatures can impact tire pressure and engine performance. Therefore, I regularly monitor tire pressure and ensure the truck is properly maintained for the given conditions. Adaptability and awareness are essential for safe operation in unpredictable weather.

Q 15. Explain your experience with using GPS or other navigation systems in a dump truck.

GPS navigation systems are invaluable in dump truck operation, especially on large construction sites or when navigating unfamiliar routes. My experience includes using various GPS systems, both integrated into the truck’s infotainment system and standalone units. These systems help me efficiently plan routes, ensuring I reach designated dumping sites and material sources with minimal delays and fuel consumption. For example, on a recent project, the GPS guided me through a complex network of roads to avoid congested areas, saving approximately 30 minutes on a daily round trip. I’m also proficient in using GPS to track my location for dispatch, ensuring timely delivery and improving overall project management.

Beyond basic navigation, I utilize GPS features like tracking mileage, total operating hours, and even recording the route and time spent at each location. This detailed data is crucial for optimizing logistics and minimizing downtime. It’s like having a detailed logbook, always available at my fingertips.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage fuel efficiency while operating a dump truck?

Fuel efficiency is a critical aspect of dump truck operation, impacting both cost and environmental responsibility. My approach to maximizing fuel efficiency involves a combination of techniques. Firstly, I maintain a consistent speed, avoiding sudden acceleration or braking. Think of it like driving a car – smooth driving saves fuel. Secondly, I anticipate traffic and road conditions to minimize unnecessary idling. This is particularly important in stop-and-go situations common in construction. I also ensure the truck’s tires are properly inflated, as under-inflation significantly increases rolling resistance and fuel consumption.

Proper load management is another key element. Overloading a dump truck reduces fuel efficiency dramatically. I always adhere to weight limits and ensure the load is evenly distributed to optimize the truck’s performance. Finally, I regularly perform preventative maintenance checks, ensuring the engine and other mechanical components are operating at peak efficiency. This includes keeping an eye on the engine oil levels and air filters.

Q 17. What is your experience with hydraulic systems in dump trucks?

Hydraulic systems are fundamental to dump truck operation, powering the lifting and tilting of the truck bed. My experience with these systems includes routine checks for leaks, ensuring proper fluid levels, and understanding the basic operation of hydraulic components like pumps, cylinders, and valves. I’m familiar with the different types of hydraulic fluids used and their importance in system longevity. I can identify signs of malfunction, such as unusual noises, slow lifting/tilting, or fluid leaks. On one occasion, I noticed a slow leak in a hydraulic hose. By promptly reporting it, a costly breakdown was prevented, avoiding significant downtime and repair costs.

Beyond basic maintenance, I understand the importance of safe operation. I’m always cautious when working around the hydraulic system, aware of pinch points and potential dangers. I never attempt any repairs myself unless properly trained and authorized to do so, always prioritizing safety.

Q 18. How do you identify and report potential mechanical problems?

Identifying and reporting potential mechanical problems is a crucial responsibility. My approach involves proactive daily inspections focusing on key areas such as tires, brakes, lights, hydraulic systems, and engine compartment. I check for leaks, unusual noises, or any signs of wear and tear. I maintain a detailed logbook to record any observations, which is crucial for preventative maintenance and for tracing issues.

If I identify a potential problem, I immediately report it to my supervisor. I describe the issue clearly, mentioning the specific location and any related observations. For instance, if I hear unusual engine knocking, I will report it, noting the frequency and circumstances under which it occurs. This detailed approach ensures prompt attention and minimizes the risk of bigger issues later.

Q 19. Describe your experience with different types of dump truck braking systems.

Dump trucks utilize various braking systems to ensure safe operation, including service brakes, parking brakes, and engine brakes (Jake brakes). I’m experienced with both air brakes and hydraulic brakes, understanding the importance of regular inspections and maintenance for each. I know how to test the effectiveness of the brakes and to identify problems such as air leaks, low brake fluid levels, and brake pad wear. The service brakes are the primary braking system; I always ensure they are in top condition. The parking brake secures the truck when parked, and the engine brake assists in slowing down heavy loads, reducing wear on service brakes.

Understanding the nuances of these systems is crucial for safety. For instance, air brake systems require regular checks for air leaks to ensure sufficient braking pressure. Ignoring such a problem can lead to brake failure. This is not only dangerous, but it could also be very costly to repair.

Q 20. How do you communicate effectively with other workers on a construction site?

Effective communication on a construction site is vital for safety and efficiency. I use a variety of methods including hand signals, two-way radios, and direct communication to coordinate with other workers. Understanding and following established site protocols is crucial. For example, I use standardized hand signals to communicate with the spotter during loading and dumping operations, ensuring safe maneuvers and preventing accidents. I also utilize two-way radios to stay informed about changes in the work plan, traffic flow, or potential hazards.

I always maintain clear and respectful communication, making sure my messages are concise and easy to understand. When receiving instructions, I confirm my understanding to prevent misunderstandings. This approach helps maintain a collaborative and safe work environment.

Q 21. Explain your understanding of load shifting and its potential dangers.

Load shifting is a dangerous situation where the material being carried shifts within the truck bed during transit, potentially causing instability and even rollovers. This is particularly dangerous on uneven terrain or during sharp turns. I’m well-versed in preventing load shifting through proper loading techniques. This includes ensuring the load is evenly distributed, taking into account the center of gravity. I also avoid overloading the truck and maintain a safe speed when driving.

Several factors contribute to load shifting, including uneven loads, excessive speed, and sudden braking or turning. To minimize risk, I always inspect the load before driving, checking for any signs of instability. If I suspect a potential issue, I address it immediately – this might involve redistributing the load or securing it further with tarps or other restraints. I understand that preventing load shifting is critical to ensuring the safety of myself and those around me.

Q 22. How do you handle emergencies or accidents while operating a dump truck?

My first priority in any emergency or accident involving a dump truck is safety – for myself, other drivers, pedestrians, and the environment. I follow a structured approach:

- Assess the Situation: Immediately assess the extent of the damage, injuries, and potential hazards (like leaking fuel or unstable cargo). If anyone is injured, call emergency services (911) immediately.

- Secure the Area: Use warning devices like hazard lights, flares, or cones to alert others to the danger and prevent further incidents. If possible, shut down the truck and engage the parking brake.

- Report the Incident: Report the accident to my supervisor and the relevant authorities as soon as it’s safe to do so. Document all details, including times, locations, and witness information.

- Follow Company Protocol: Adhere strictly to the company’s emergency response procedures, which might include specific steps for handling spills, securing hazardous materials, or contacting insurance.

- Cooperate with Investigations: Fully cooperate with any investigations conducted by authorities or insurance companies.

For example, once I had a tire blowout on a busy highway. I immediately activated my hazard lights, carefully steered the truck to the side of the road, and placed warning triangles. I called my dispatcher and the highway patrol before exiting the vehicle. This systematic approach ensured everyone’s safety and minimized any further complications.

Q 23. What is your experience with maintaining proper documentation for your work?

Maintaining proper documentation is crucial for accountability and efficient operations. My experience includes:

- Pre-trip Inspections: I meticulously document all pre-trip inspections, noting any existing damage or mechanical issues. This typically involves completing a standardized checklist and signing it.

- Delivery Receipts: I always obtain and carefully maintain signed delivery receipts for every load, ensuring accurate records of material delivery and quantities.

- Maintenance Records: I record all maintenance performed on the truck, including repairs, parts replaced, and dates. This information is essential for tracking the vehicle’s condition and anticipating future maintenance needs.

- Hours of Service Logs: I accurately maintain my hours of service logs in accordance with regulations, ensuring compliance with driving time limits and rest periods.

- Incident Reports: As mentioned previously, all accidents or incidents are thoroughly documented in detailed reports, including photos if appropriate.

Accurate and complete documentation provides a clear trail of events, facilitates insurance claims, protects the company from liability, and aids in continuous improvement of safety protocols.

Q 24. Describe your experience with using onboard computer systems in modern dump trucks.

Modern dump trucks are increasingly equipped with sophisticated onboard computer systems that monitor various operational parameters. My experience includes using systems that:

- Track GPS Location and Route: These systems provide real-time location data, optimize routes, and help track fuel consumption.

- Monitor Engine Performance: They display key engine data such as RPM, fuel efficiency, and potential malfunction codes, which aids in preventative maintenance.

- Manage Maintenance Schedules: Onboard computers often automate reminders for scheduled maintenance tasks, reducing the risk of breakdowns.

- Provide Driver Feedback: Some systems offer performance feedback to drivers on aspects such as fuel efficiency and driving behavior.

- Record Operational Data: Comprehensive data logs about vehicle operation, loads carried, and driver behavior are automatically stored, improving operational efficiency and safety analysis.

For example, I recently used an onboard computer to identify a potential issue with my engine’s fuel injection system. An error code prompted a preventative maintenance action, preventing a more significant breakdown later.

Q 25. What are your strategies for preventing equipment damage?

Preventing equipment damage is a top priority, and I employ several strategies:

- Pre-Trip Inspections: Thorough pre-trip inspections are paramount. Identifying and addressing small problems early can prevent larger, more costly repairs.

- Proper Loading and Unloading: I ensure proper weight distribution and secure loads to avoid damage to the truck’s chassis or the cargo itself. Overloading is strictly avoided.

- Careful Operation: I operate the truck smoothly, avoiding sudden braking, acceleration, or sharp turns. This minimizes stress on the truck’s components.

- Regular Maintenance: I follow the manufacturer’s maintenance schedule and promptly report any maintenance needs. This helps catch issues before they become major problems.

- Safe Driving Practices: Following traffic laws, keeping a safe following distance, and being aware of the surroundings prevent accidents that can cause significant damage.

- Environmental Awareness: I am mindful of potential hazards such as low-hanging branches or uneven terrain, adapting my driving accordingly.

For example, noticing a slightly loose connection during a pre-trip inspection prevented a more serious electrical issue later on. Consistent preventative maintenance ensures the truck remains reliable and less prone to breakdowns.

Q 26. How do you prioritize safety while working under pressure?

Prioritizing safety under pressure requires discipline and a structured approach. I use the following techniques:

- Time Management: Effective planning and time management help reduce rush and stress. I plan my routes efficiently to meet deadlines without compromising safety.

- Focus and Mindfulness: I stay focused on the task at hand, avoiding distractions such as cell phones or excessive multitasking while operating heavy machinery.

- Breaks and Rest: I take regular breaks to rest and avoid fatigue, which significantly impairs judgment and reaction time. I adhere strictly to regulations regarding hours of service.

- Awareness of Limitations: I am aware of my own physical and mental limitations. If I feel tired or stressed, I take a break before continuing. Safety is never compromised to meet deadlines.

- Communication: I communicate effectively with dispatchers, supervisors, and other drivers to ensure everyone is aware of my situation and potential hazards.

Even under tight deadlines, I always prioritize safety first. A minor delay is far less significant than an accident.

Q 27. Describe a time you had to troubleshoot a dump truck problem.

I once encountered a situation where my dump truck’s hydraulic system malfunctioned. The bed wouldn’t lift or lower. My troubleshooting process involved:

- Safety First: I immediately secured the vehicle in a safe location, turning off the engine and engaging the parking brake.

- Visual Inspection: I performed a thorough visual inspection of all hydraulic lines and components for any obvious leaks, damage, or loose connections.

- Check Fluid Levels: I checked the hydraulic fluid level and condition. Low fluid or contaminated fluid could indicate a leak or system failure.

- Check Fuses and Breakers: I checked all relevant fuses and circuit breakers related to the hydraulic system.

- Consult Manual: I referred to the truck’s service manual to diagnose the potential causes of the malfunction and locate relevant trouble codes (if equipped).

- Contacting Support: As I couldn’t identify the problem, I contacted the maintenance crew for assistance. They identified a faulty hydraulic pump and promptly replaced it.

This systematic approach, beginning with safety and progressing to methodical troubleshooting, efficiently resolved the problem with minimal downtime.

Q 28. Explain your understanding of different types of dump truck suspensions.

Dump trucks employ different types of suspensions to handle the stresses of carrying heavy loads and traversing various terrains. The main types include:

- Leaf Spring Suspension: This is a relatively simple and robust system using multiple steel leaves stacked together. It provides good load capacity but can be harsh on rough roads. Think of it like a very heavy-duty leaf spring on a car, only much larger and stronger.

- Air Suspension: Air bags replace the leaf springs, providing a smoother ride and better load distribution. This is particularly beneficial when carrying delicate materials or operating on challenging terrain. Air pressure can be adjusted to accommodate varying loads.

- Multi-leaf Spring Suspension: This is a more advanced variation of the leaf spring suspension and usually employs more springs than a standard leaf spring suspension, leading to an improvement in ride comfort.

- Hydraulic Suspension: This advanced system utilizes hydraulic cylinders and fluid to control suspension characteristics, offering superior ride quality, load distribution, and ground clearance adjustments. It is commonly used in heavy-duty dump trucks operating in challenging environments.

The choice of suspension depends on factors such as the truck’s load capacity, operating conditions, and desired ride comfort. For example, a construction site might favour a robust leaf spring system for durability, while a long-haul operation may opt for air suspension for driver comfort and reduced wear and tear.

Key Topics to Learn for Dump Truck Equipment and Controls Interviews

- Types of Dump Trucks: Understanding the differences between various dump truck types (e.g., end-dump, side-dump, bottom-dump) and their applications in different industries and terrains. Consider their weight capacities and operational limitations.

- Dump Truck Controls and Mechanisms: Detailed knowledge of the operation of various controls, including steering, braking, transmission (manual and automatic), hoisting systems (hydraulic, pneumatic), and safety features. Be prepared to discuss the sequence of operations for loading, transporting, and dumping.

- Hydraulic Systems: Understanding basic hydraulic principles as they relate to dump truck operation. This includes recognizing potential hydraulic system failures and troubleshooting basic problems. Familiarize yourself with common hydraulic components and their functions.

- Safety Procedures and Regulations: Thorough knowledge of relevant safety protocols, pre-trip inspections, load securement techniques, and compliance with local and national regulations concerning dump truck operation. Be ready to discuss accident prevention strategies.

- Maintenance and Troubleshooting: Basic understanding of routine maintenance procedures, common points of failure, and the ability to identify and describe potential mechanical issues. This includes preventative maintenance schedules and recognizing signs of wear and tear.

- Load Capacity and Weight Distribution: Understanding the importance of proper load distribution and weight limitations to prevent accidents and damage to the vehicle or surrounding environment. Be able to calculate safe load limits based on provided information.

- Operating in Various Conditions: Discuss experience (or theoretical understanding) of operating dump trucks in diverse conditions, such as inclement weather, rough terrain, and confined spaces. Highlight your ability to adapt to changing circumstances.

Next Steps

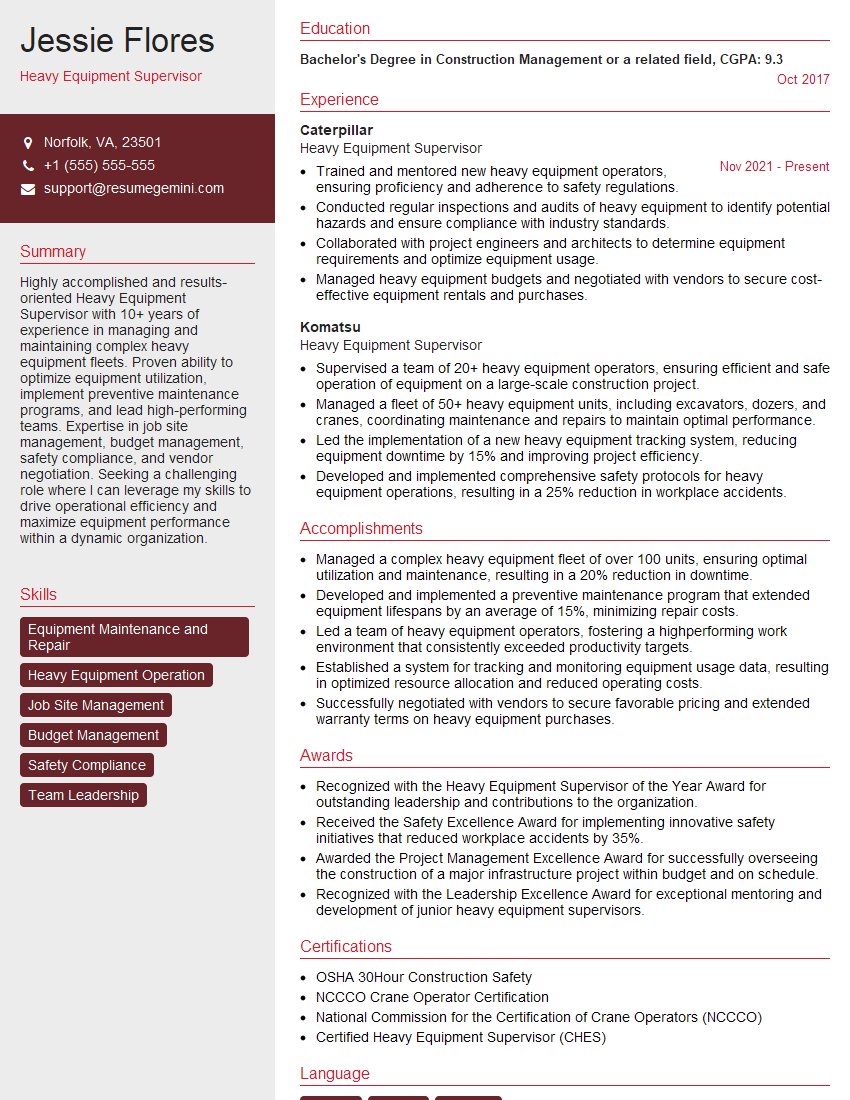

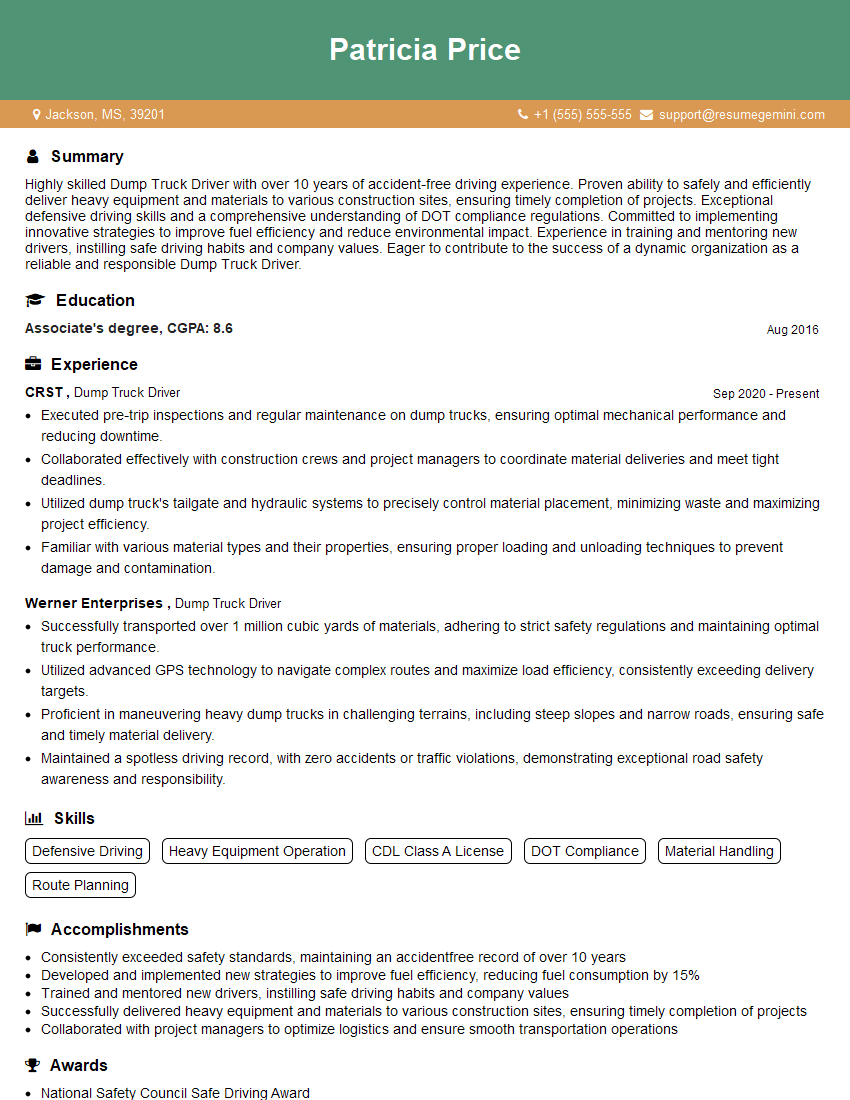

Mastering the operation and maintenance of dump truck equipment is crucial for career advancement in the construction, mining, and transportation industries. It demonstrates a commitment to safety and efficiency, which are highly valued by employers. Creating a strong, ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience with dump truck equipment and controls. Examples of resumes optimized for this field are available to help guide your creation process. Invest time in perfecting your resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Live Rent Free!

https://bit.ly/LiveRentFREE

Interesting Article, I liked the depth of knowledge you’ve shared.

Helpful, thanks for sharing.

Hi, I represent a social media marketing agency and liked your blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?